Patents

Literature

106results about How to "Increase high temperature viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

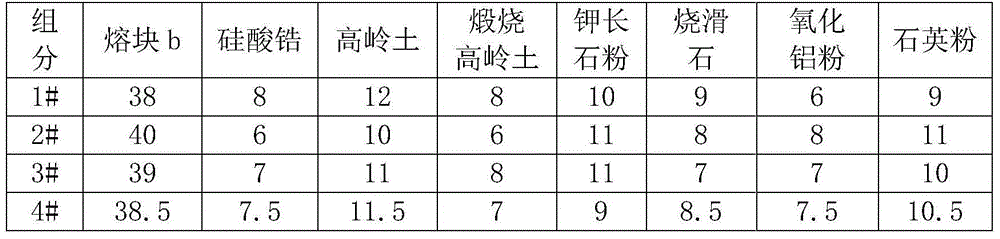

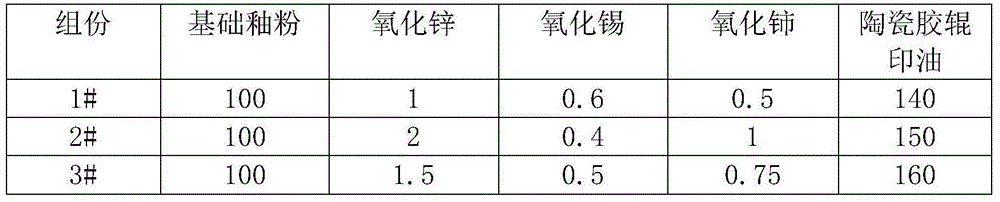

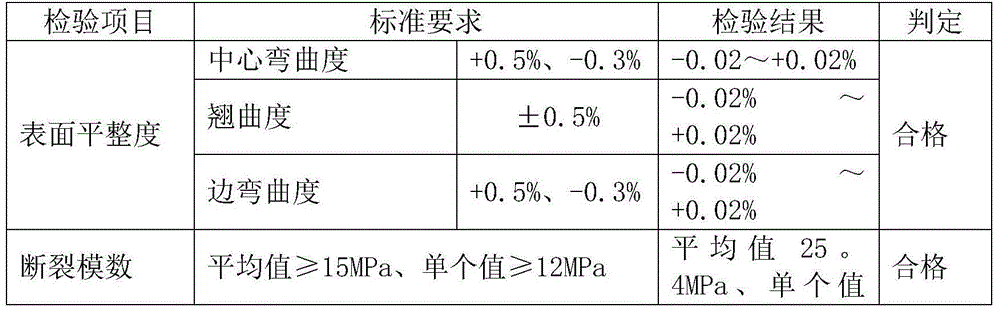

Glaze and preparation of embossment phantom glazed brick

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Method for preparing polished crystal tile

The invention discloses a method for preparing a polished crystal tile, comprising the following steps of: accumulating a mixture of low-temperature clinkers and high-temperature clinkers on a printed tile surface baked at high temperature; baking; and polishing. The polished crystal tile prepared with the preparation process has high high-temperature viscosity and stable glass network structure, the baked clinker has certain height and has stereoscopic impression and artistic feeling. The action of the skeleton of the high-temperature clinker is favorable to the discharge of bubbles, and the obtained enamel layer has few bubbles, high transparency and high enamel quality. By regulating the proportion of the low-temperature clinkers and the high-temperature clinkers, the preparation method is suitable for different baking temperatures, is convenient and flexible and is suitable for different products.

Owner:广东道氏陶瓷材料有限公司

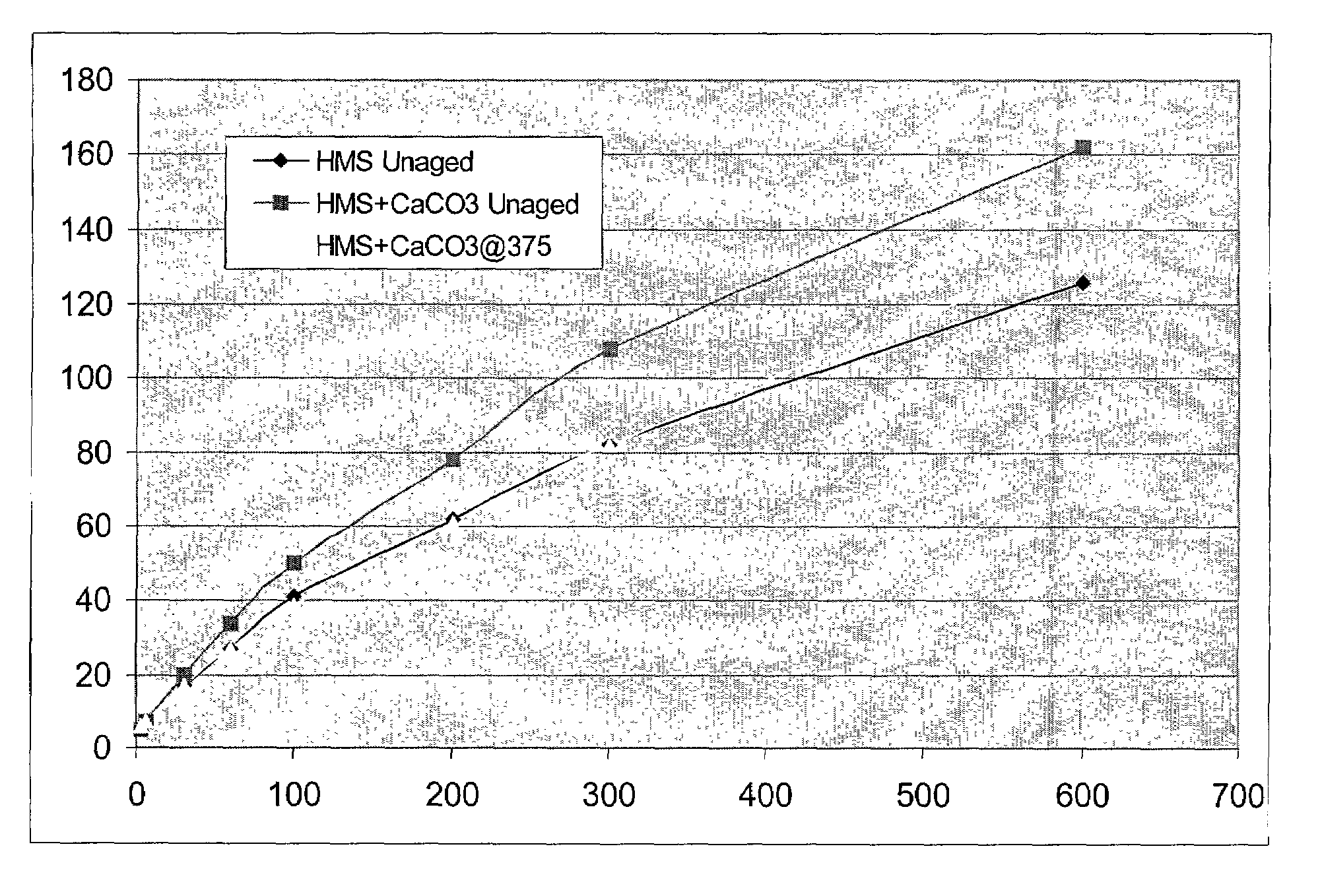

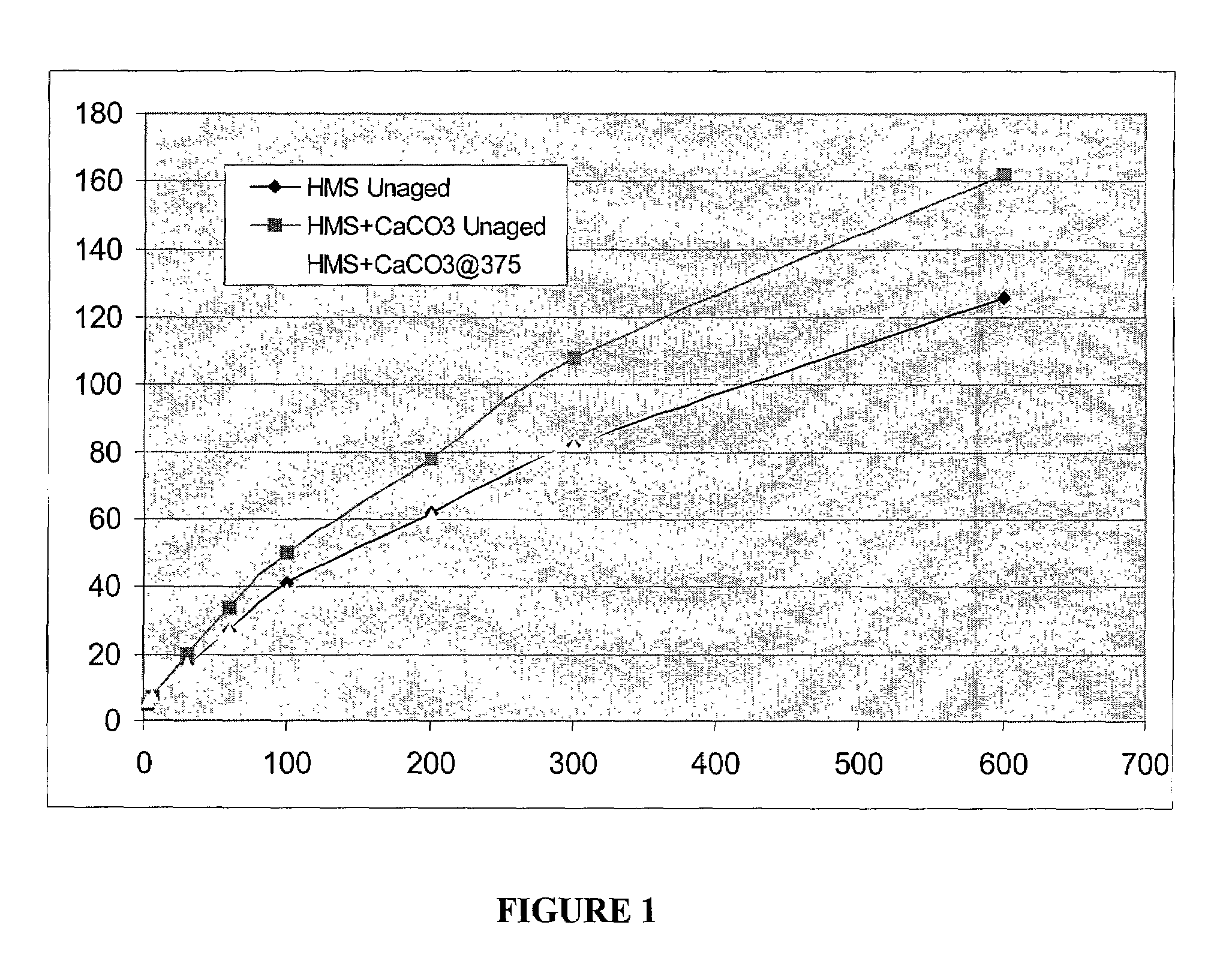

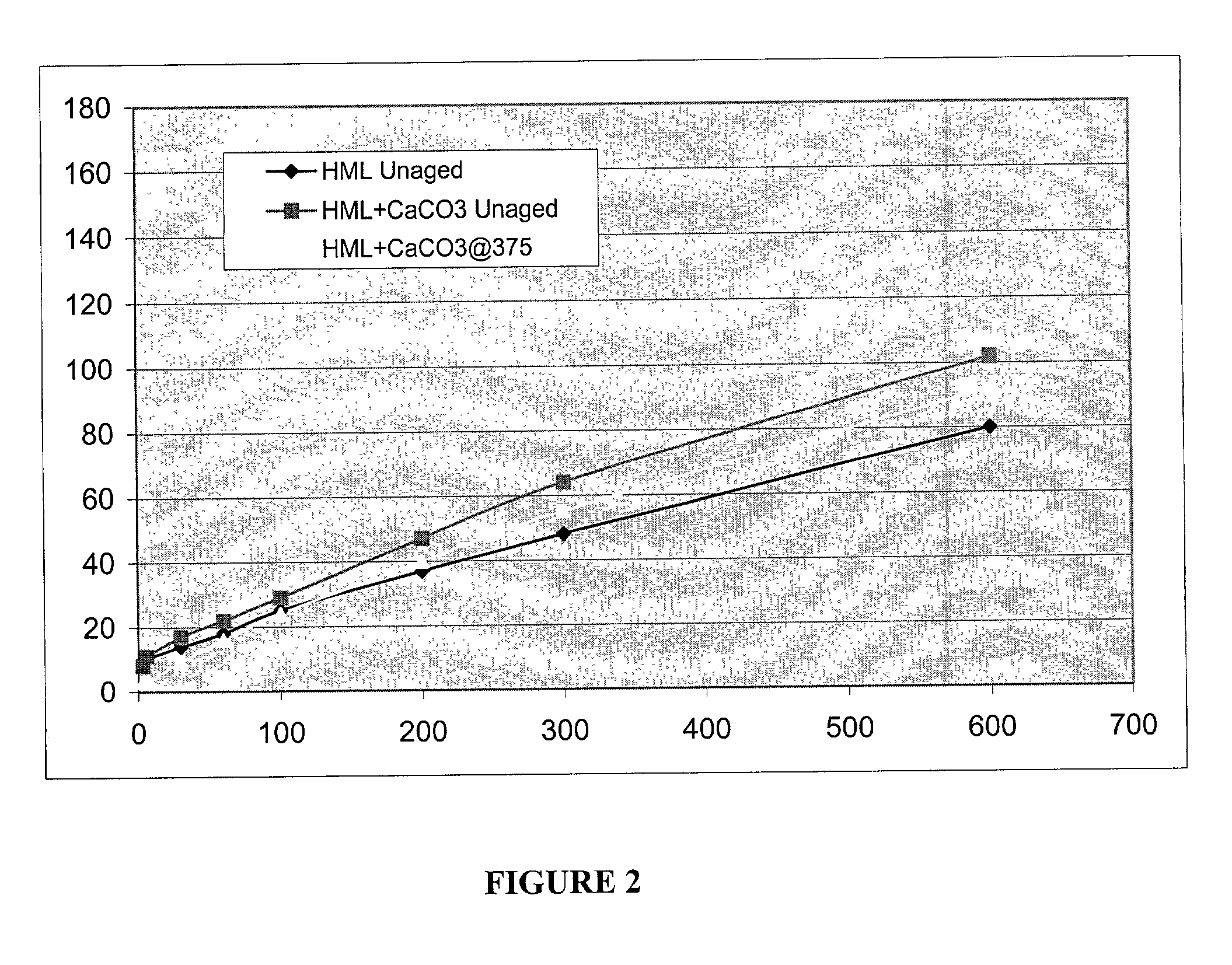

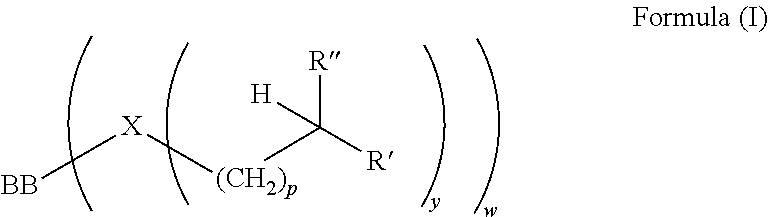

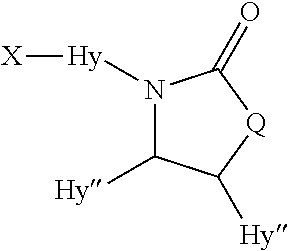

Hydrophobe associative polymers and compositions and methods employing them

Water soluble associative polymers and compositions comprising them together with alkali metal salts of carboxylic acid are disclosed. Methods comprise introducing into a wellbore a fluid comprising such associative polymers and alkali metal salts of carboxylic acid, e.g., cesium formate. Disclosed water soluble associative polymers have functionality including at least sulfonate groups, carboxylate groups and hydrophobes associative with one another in a saturated aqueous solution of an alkali metal salt of a carboxylic acid. Water soluble associative polymers are formed as the polymerization reaction product of reactants comprising an AMPS reactant, an alpha, beta-unsaturated carbonyl reactant and a hydrophobe reactant selected from acrylic esters, methacrylic esters and a mixture of any of them, having a —COOR moiety wherein R is a hydrophobe which, as hydrophobe moieties of the resultant associative polymer, are associative with one another in a saturated aqueous solution of an alkali metal salt of a carboxylic acid.

Owner:CABOT CORP

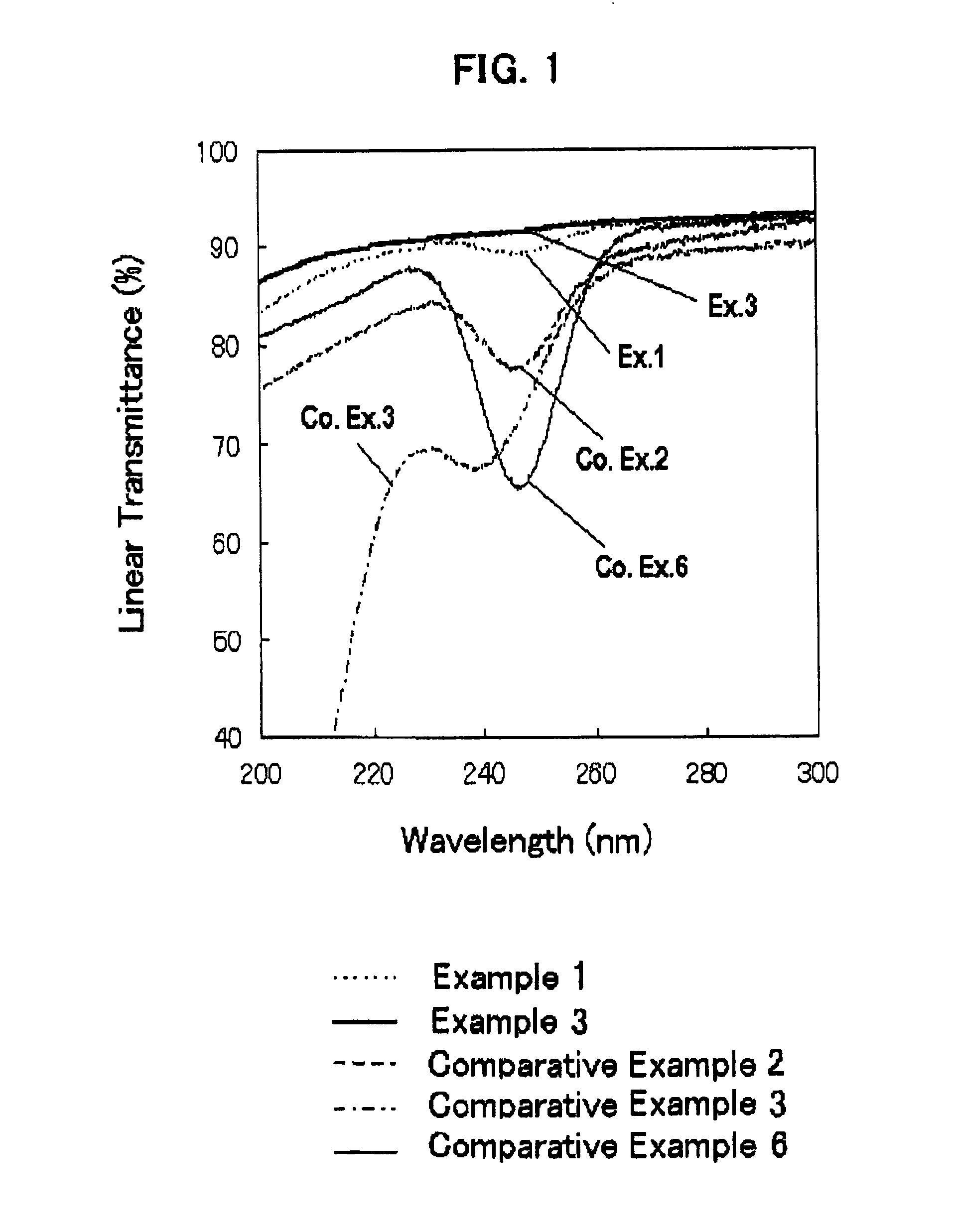

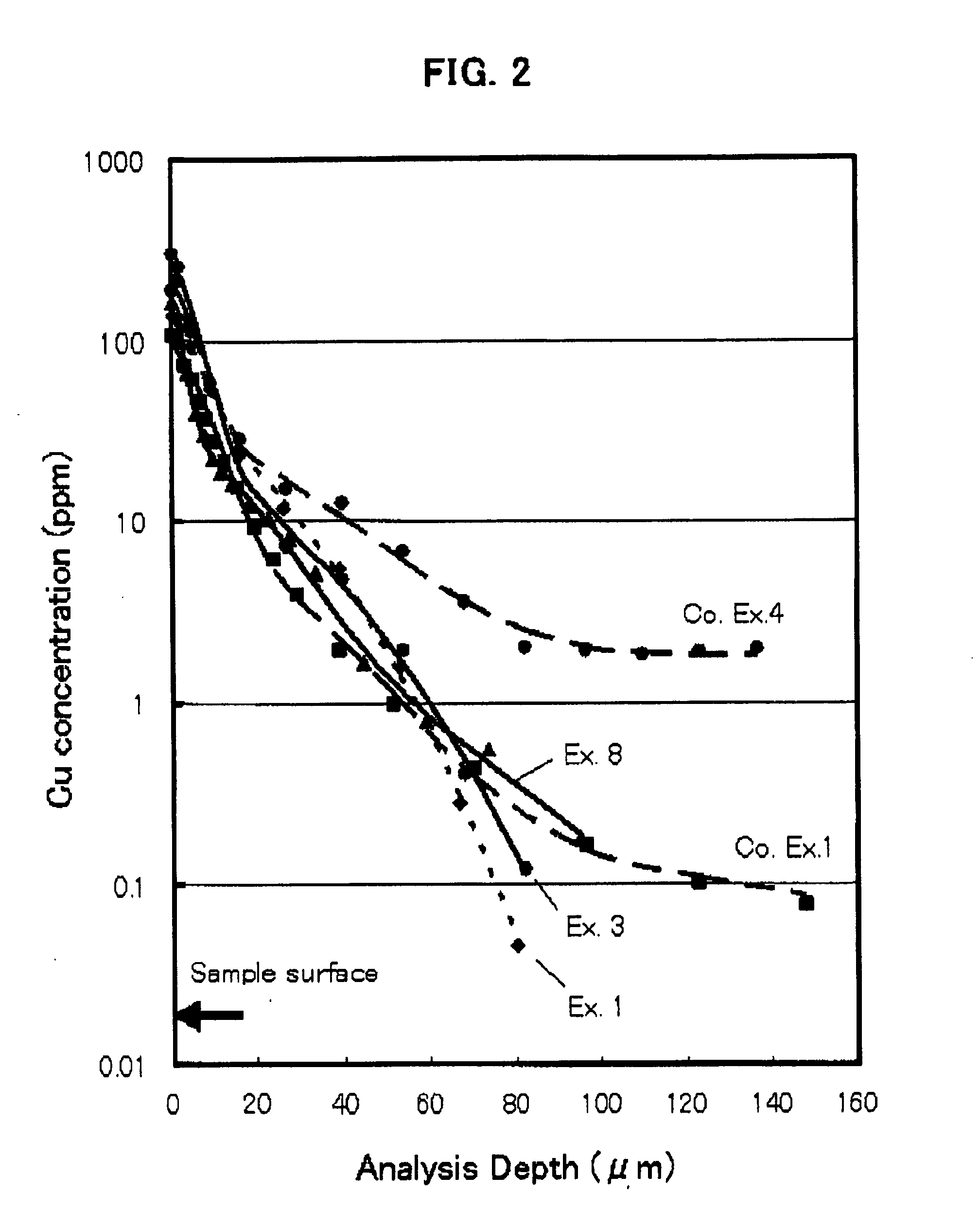

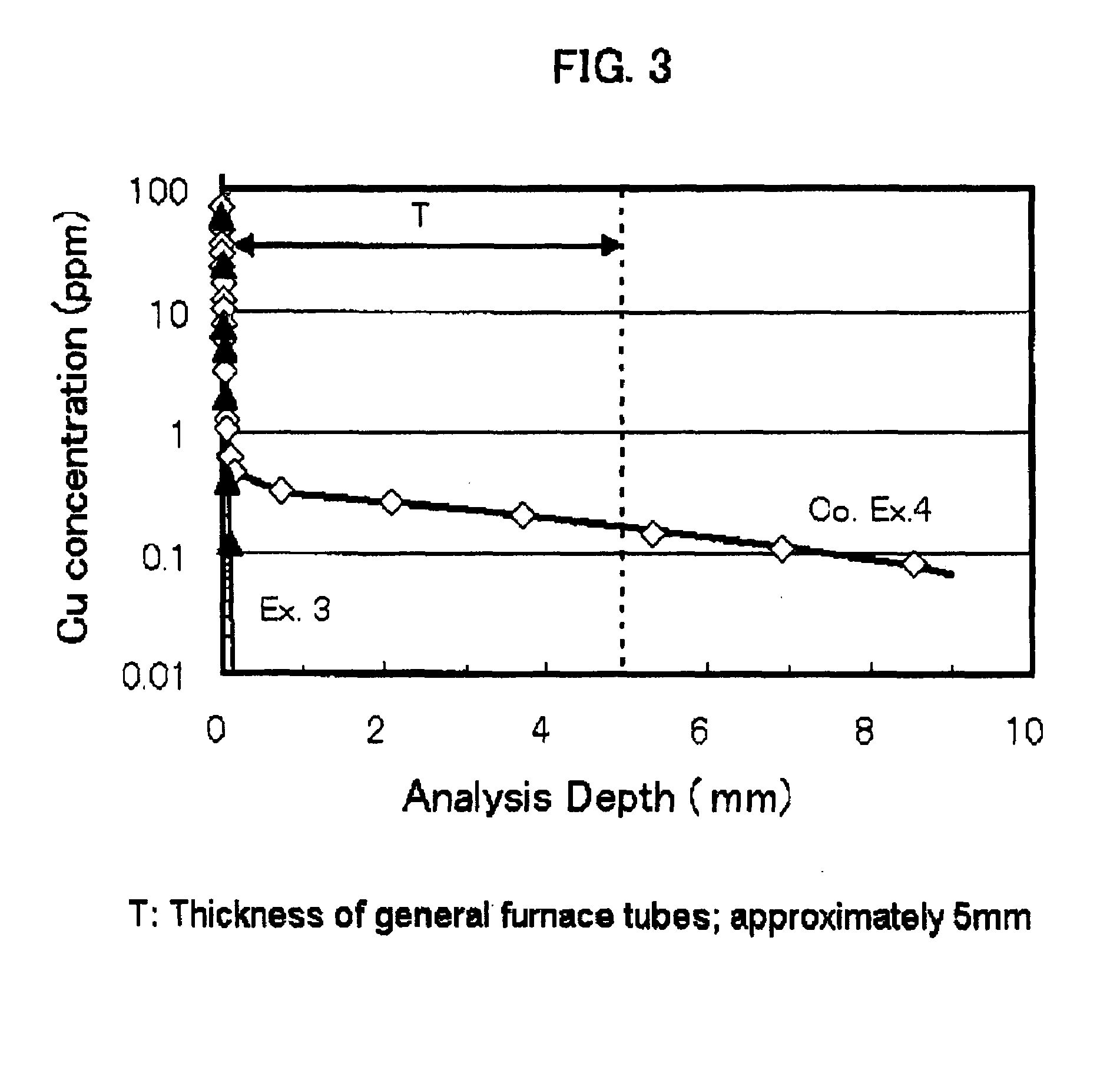

Fused silica glass and process for producing the same

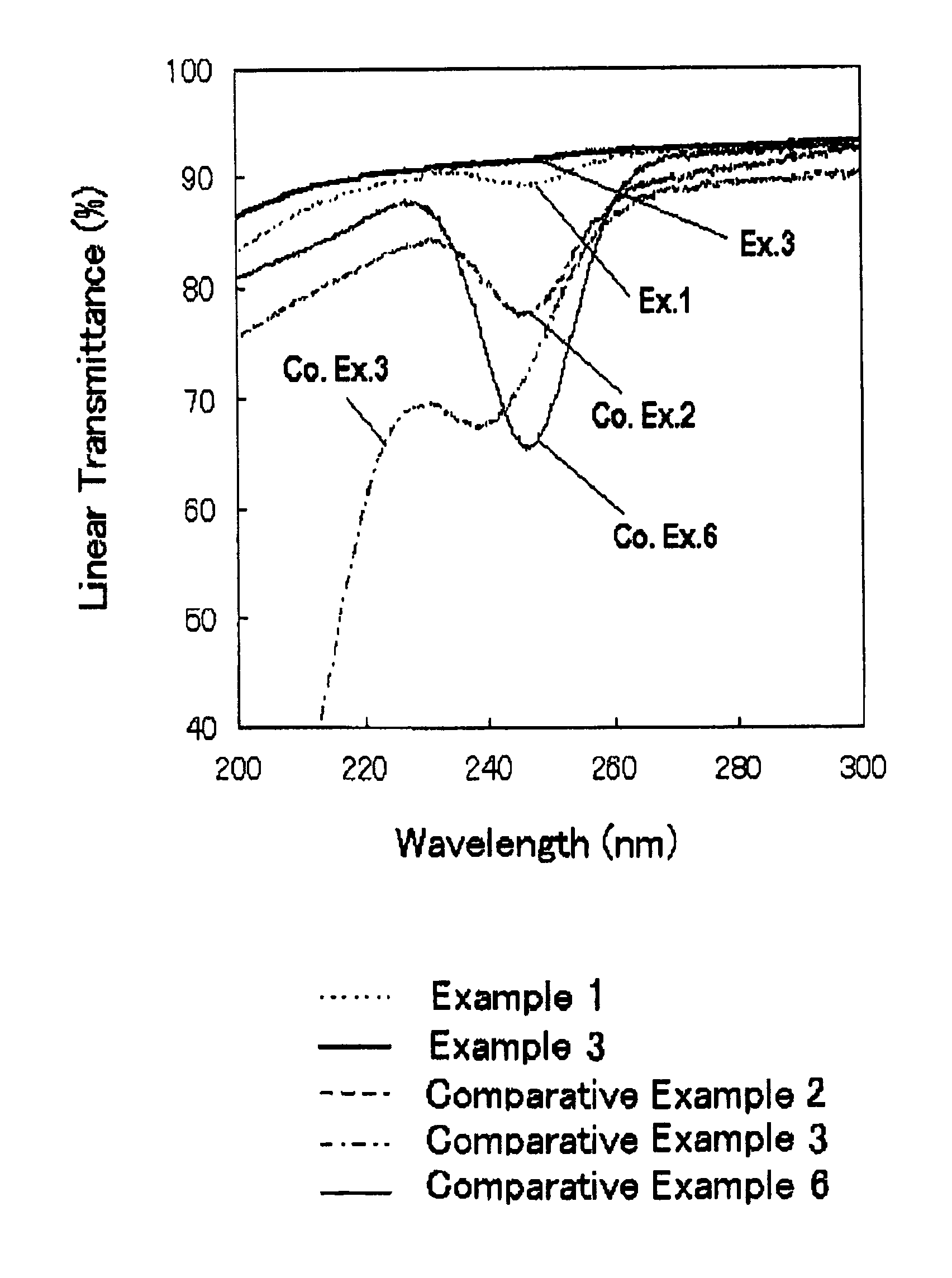

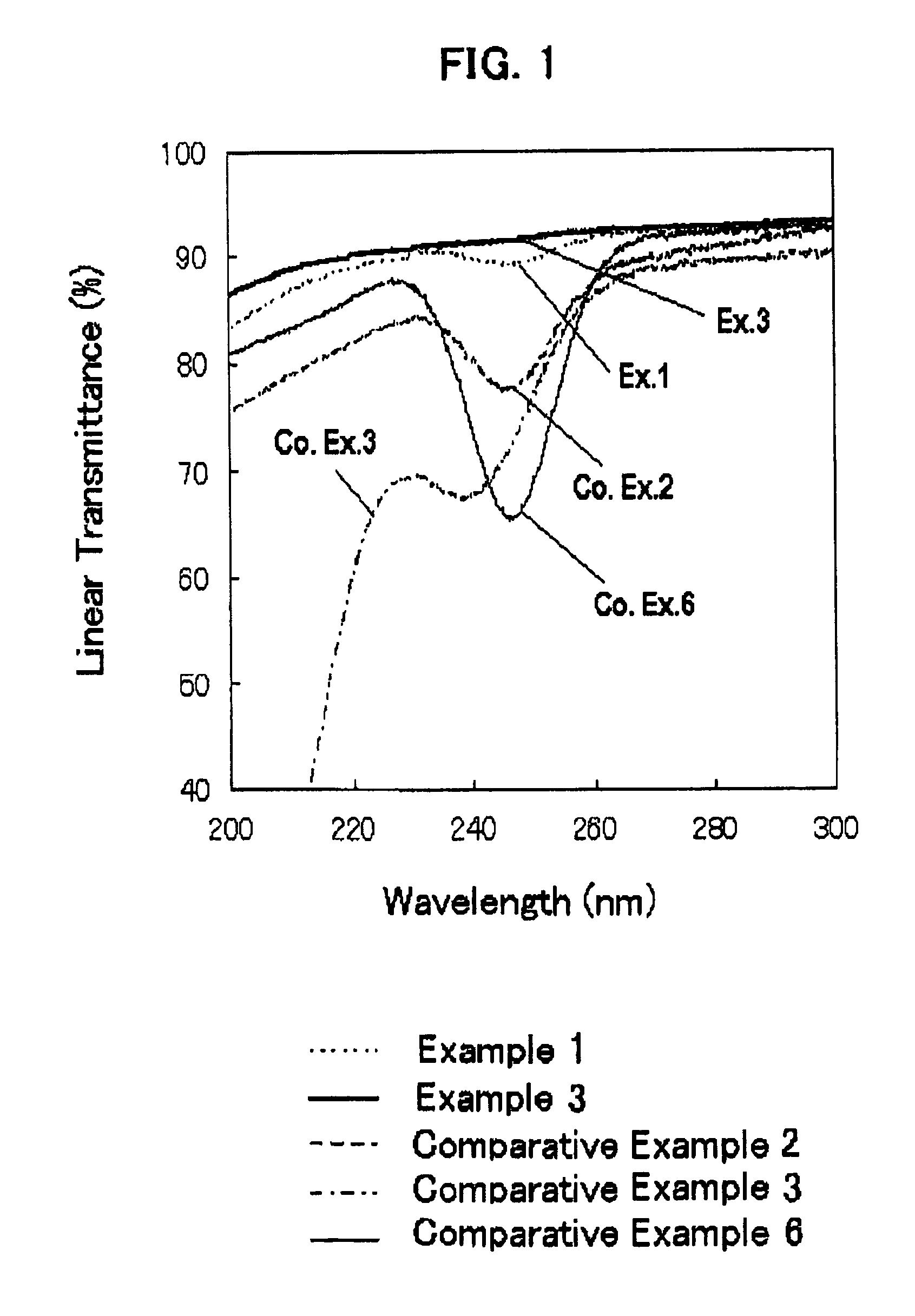

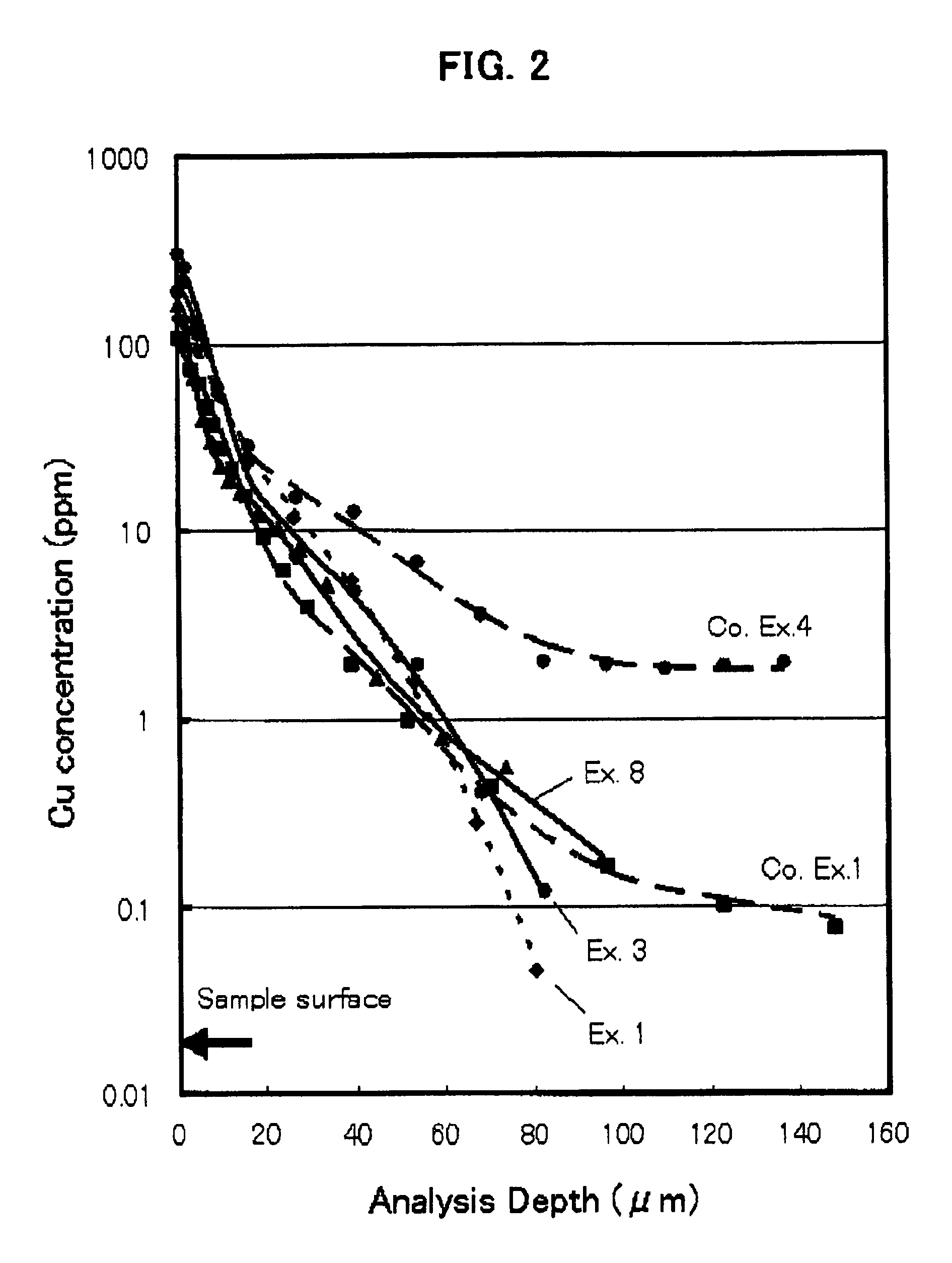

ActiveUS20100041538A1High transparencyReduce the probability of spreadingGlass shaping apparatusGlass tempering apparatusMetal impuritiesUltraviolet

Fused silica glass having an internal transmittance of UV with 245 nm wavelength, being at least 95% at 10 mm thickness, a OH content of not larger than 5 ppm, and a content of Li, Na, K, Mg, Ca and Cu each being smaller than 0.1 ppm. Preferably the glass has a viscosity coefficient at 1215° C. of at least 1011.5 Pa·s; and a Cu ion diffusion coefficient of not larger than 1×10−10 cm2 / sec in a depth range of greater than 20 μm up to 100 μm, from the surface, when leaving to stand at 1050° C. in air for 24 hours. The glass is made by crystobalitizing powdery silica raw material; then, fusing the crystobalitized silica material in a non-reducing atmosphere. The glass exhibits a high transmittance of ultraviolet, visible and infrared rays, has high purity and heat resistance, and exhibits a reduced diffusion rate of metal impurities, therefore, it is suitable for various optical goods, semiconductor-production apparatus members, and liquid crystal display production apparatus members.

Owner:TOSOH CORP +1

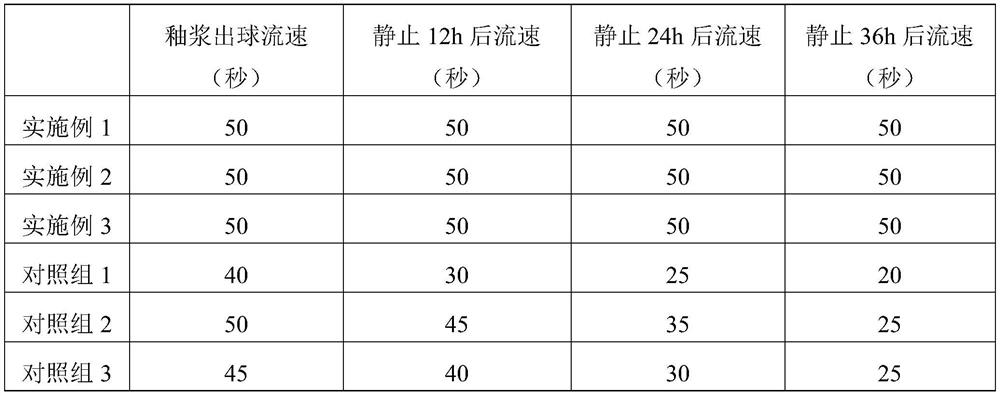

Preparation method of enamel coating

InactiveCN107513747AIncrease high temperature viscosityImprove thermal stabilityElectrophoretic coatingsPorosityElectrophoresis

The invention discloses a preparation method of an enamel coating. The method comprises the following steps that 1, a metal matrix is pretreated, wherein the metal matrix is subject to heat preservation for 20-40 min at the temperature ranging from 950 DEG C to 980 DEG C and then decarburized, the decarburized metal matrix is placed into an acid solution for acid pickling and taken out till a clean metal surface is obtained, clean water is used for repeated washing to remove surface residual acid liquor, and finally the metal matrix is placed at the temperature ranging 200 DEG C to 300 DEG C, rapidly dried and placed to a dry pollution-free place for standby application; 2, ceramic glaze powder is prepared; 3, ceramic slurry is prepared, and 4, enamelling and firing are carried out. According to the preparation method, the production process is simplified, the production efficiency is improved, an electrophoresis method is adopted for forming a uniform low-porosity porcelain enamel premade coating, the coating is uniform and compact in texture, oxide particles are small, grains are refined, the macro surface of the coating is flat, smooth and glossy, and cracking and block disengagement phenomena are effectively reduced.

Owner:GUIZHOU XINGREN COUNTY RONGKAI HARDWARE ENAMEL PROD

Star polymer viscosity index improver for oil compositions

InactiveCN1291223AIncrease high temperature viscosityHigh Shear Rate (HTHSR) ViscosityAdditivesPolymer scienceButadiene Dioxide

The present invention includes star polymers which can be used as viscosity index improvers in oil compositions formulated for high performance engines. The star polymers have tetrablock copolymer arms of hydrogenated polyisoprene-polybutadiene-polyisoprene with a block of polystyrene and which provide excellent low temperature performance in lubricating oils, exhibit good thickening efficiency, and are finishable as polymer crumb.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Novel preform body for bone porcelain and preparation process of preform body

InactiveCN107032762AImprove performanceImprove thermal shock resistanceCeramic materials productionClaywaresLithiumGranularity

The invention provides a novel preform body for bone porcelain and a preparation process of the preform body. The novel preform body for bone porcelain comprises the following components in percentage by weight: 50-55% of bone meal, 24-28% of kaolin, 9-11% of quartz, 8-10% of feldspar, 0.38-0.52% of lithium chinastone, 0.8-1.6% of zircon sand and 0.4-0.8% of nano-aluminum oxide. The preparation process comprises the following steps: mixing various ground materials with proper granularity to prepare the preform body, and calcining once again before the bone meal is mixed. The preform body prepared in the invention is good in thermal shock resistance, high in strength, uniform in structure, compact in toughness and excellent in overall performance.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

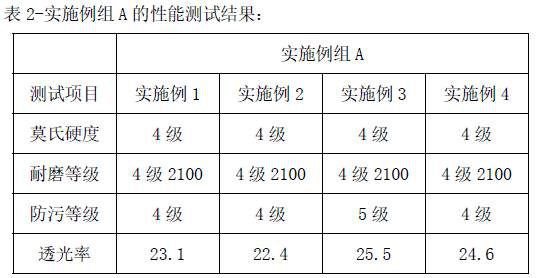

Wear-resistant glaze for glazed bricks, and preparation method thereof

The invention discloses a wear-resistant glaze for glazed bricks, and a preparation method thereof. The wear-resistant glaze is prepared from raw glaze powder, No.1 frit powder and No.2 frit powder, wherein the raw glaze powder comprises, by weight, 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 8-15% of nepheline, 5-10% of zinc oxide, 3-6% of barium sulfate and 6-12% of strontium carbonate. The raw materials of the No.1 frit powder comprise zircon sand and barium sulfate, and raw materials of the No.2 frit powder comprise kaolin, calcined talc, fluorite and barium sulfate. The glaze disclosed by the invention contains barium sulfate, so that the color development condition can be improved, the problem of color difference of red and yellow ceramic ink-jet inks during firing of a product is avoided, and the transparency of the wear-resistant glaze is improved under the condition that the hardness and the wear resistance are notinfluenced.

Owner:佛山市东鹏陶瓷发展有限公司 +1

Glass protection lubricant powder used for titanium alloy die forging forming and paint

InactiveCN105132103AWide temperature rangeNo flowCoatingsLubricant compositionCelluloseWater soluble

The invention belongs to the technical field of paint, and relates to glass protection lubricant powder used for titanium alloy die forging forming and paint. The glass protection lubricant powder comprises silicon dioxide (SiO2), sodium oxide (Na2O), calcium oxide (CaO) and boric oxide (B2O3). Brush coating is conducted through suspension prepared from heat-resistant type water-soluble cellulose and water, wherein the grain size of glass powder is 200 meshes or below. The use temperature range of the glass protection lubricant is wide and is between 700 DEG C and 1000 DEG C, melting begins at the temperature of 700 DEG C, and no flowing happens at the temperature of 1000 DEG C. the forging process temperature of titanium alloy is 945+ / -15 DEG C. The high temperature viscosity change range of the glass protection lubricant is narrow, and melting coverage can be achieved within the short time of 8 minutes or less. The flowing and protection deficiency phenomena do not happen within the heat preservation time of 8 hours. In addition, the high-temperature contact angle of the prepared glass protection lubricant on the surface of TC4 titanium alloy is small, the temperature is 40 degrees lower than the temperature of 945+ / -15 DEG C, and in other words, the titanium alloy surface wettability is good. The friction coefficient measured through a circular ring test is lower than 0.01.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

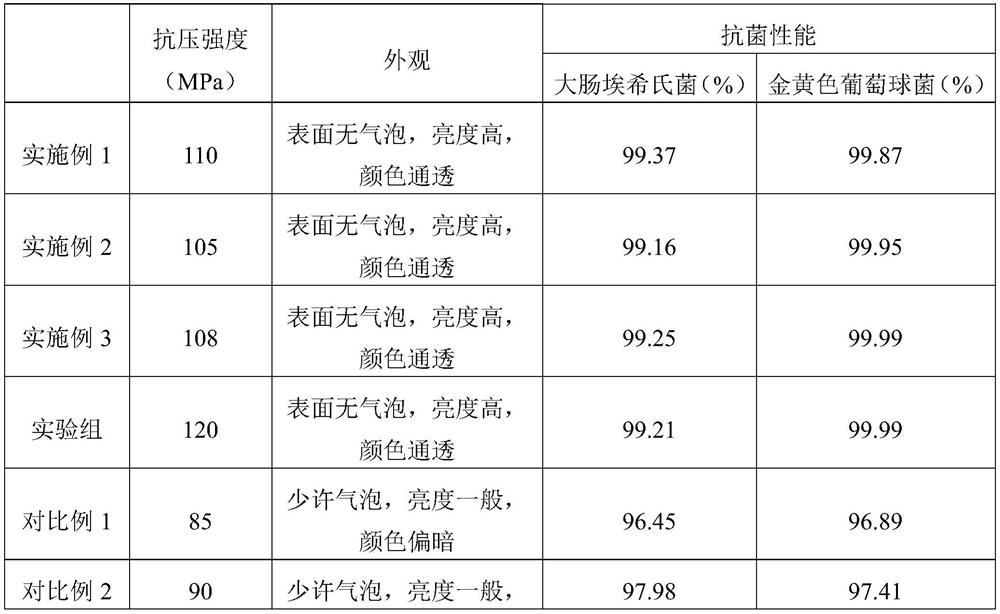

Antibacterial glaze, antibacterial brick and preparation method of antibacterial brick

PendingCN112239372ALow melting pointIncrease high temperature viscosityClaywaresKaolin clayAnti bacteria

The invention discloses an antibacterial glaze, an antibacterial brick and a preparation method of the antibacterial brick. The antibacterial glaze comprises the following raw materials in parts by weight: 25-35 parts of albite, 10-15 parts of potassium feldspar, 5-7 parts of kaolin, 5-15 parts of quartz, 3-5 parts of aluminum oxide, 5-10 parts of talc, 5-7 parts of zinc oxide, 10-20 parts of dolomite, 5-15 parts of wollastonite, 7-12 parts of strontium carbonate, 3-5 parts of barium carbonate and 4-6 parts of nano antibacterial powder. The antibacterial glaze is prepared through crushing, uniform mixing and ball milling, and then the surface of a green body layer is coated with the antibacterial glaze, so the antibacterial brick disclosed by the invention is prepared. The antibacterial effect of the antibacterial glaze reaches 99%, the firing temperature range is wide during ceramic tile preparation, and a prepared ceramic tile glaze layer is high in mechanical strength, almost free of bubbles, good in layering sense and capable of being suitable for a low-water-absorption green body and a high-water-absorption green body at the same time.

Owner:FOSHAN TAOYING NEW MATERIAL CO LTD

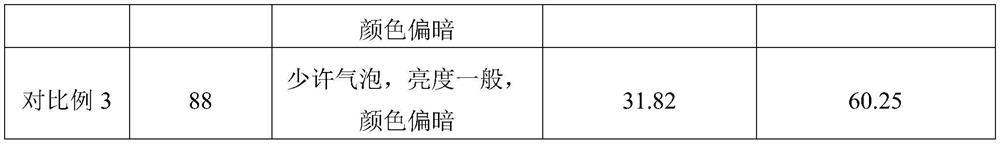

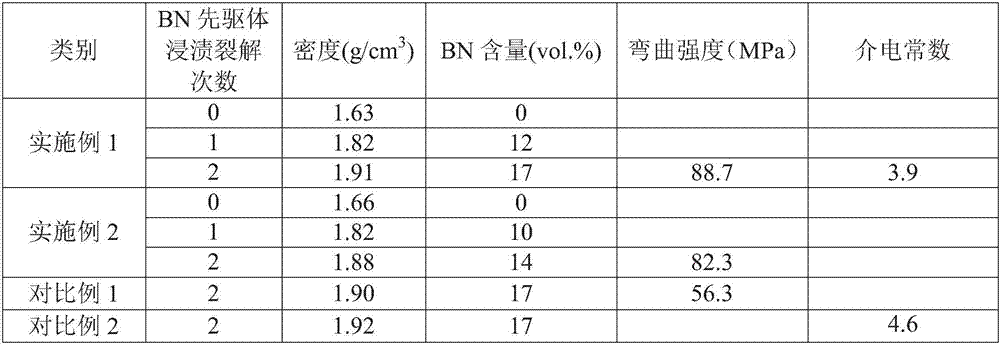

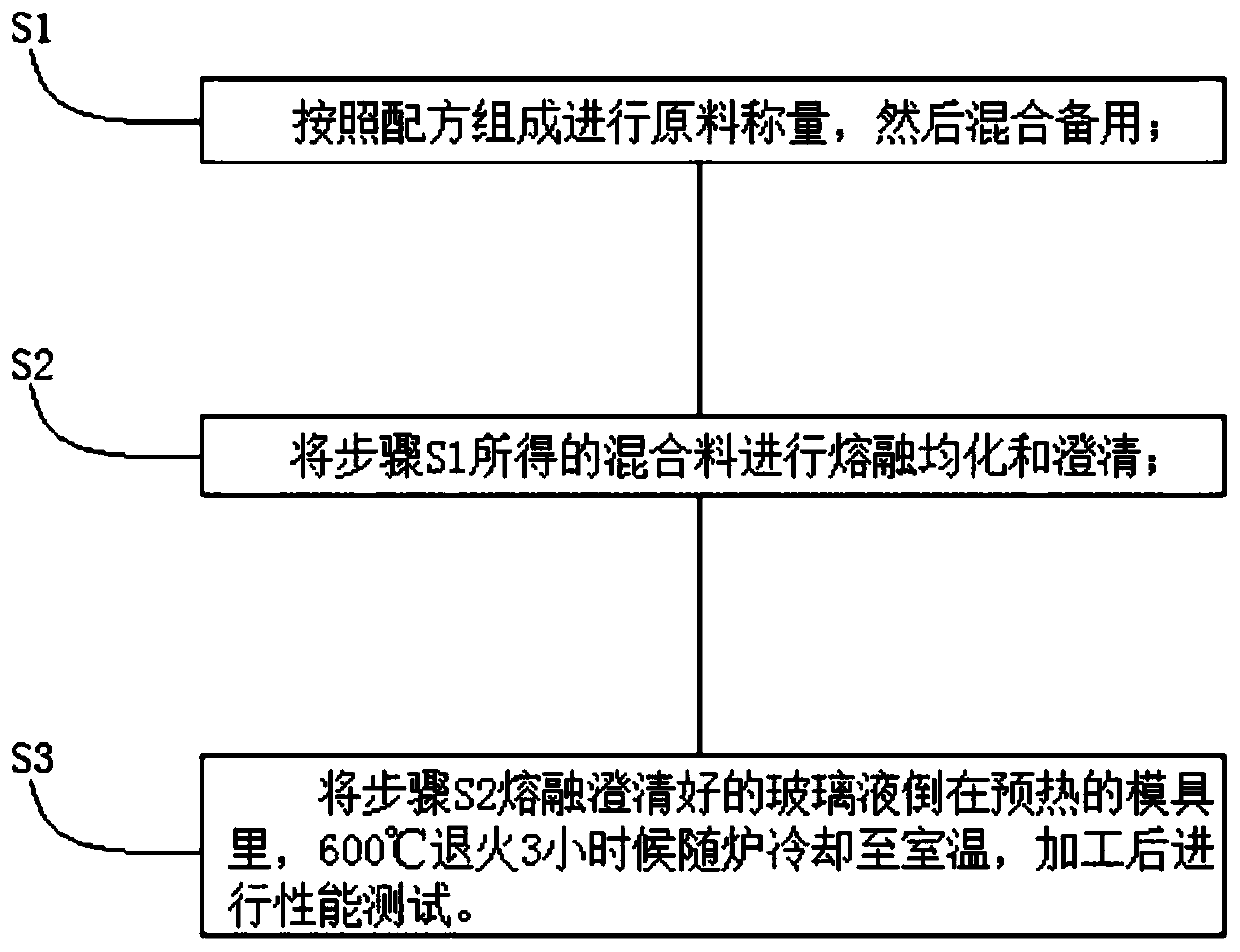

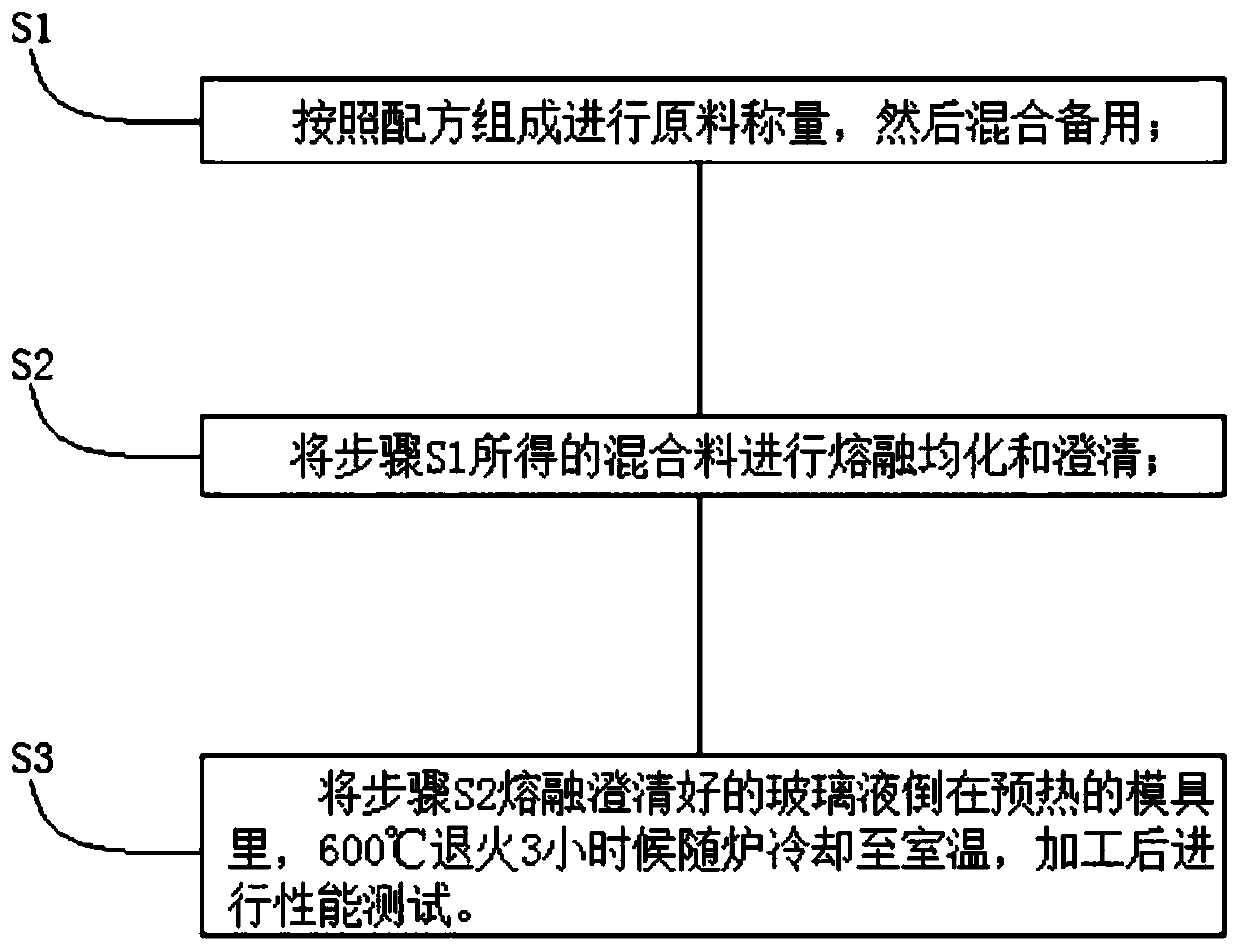

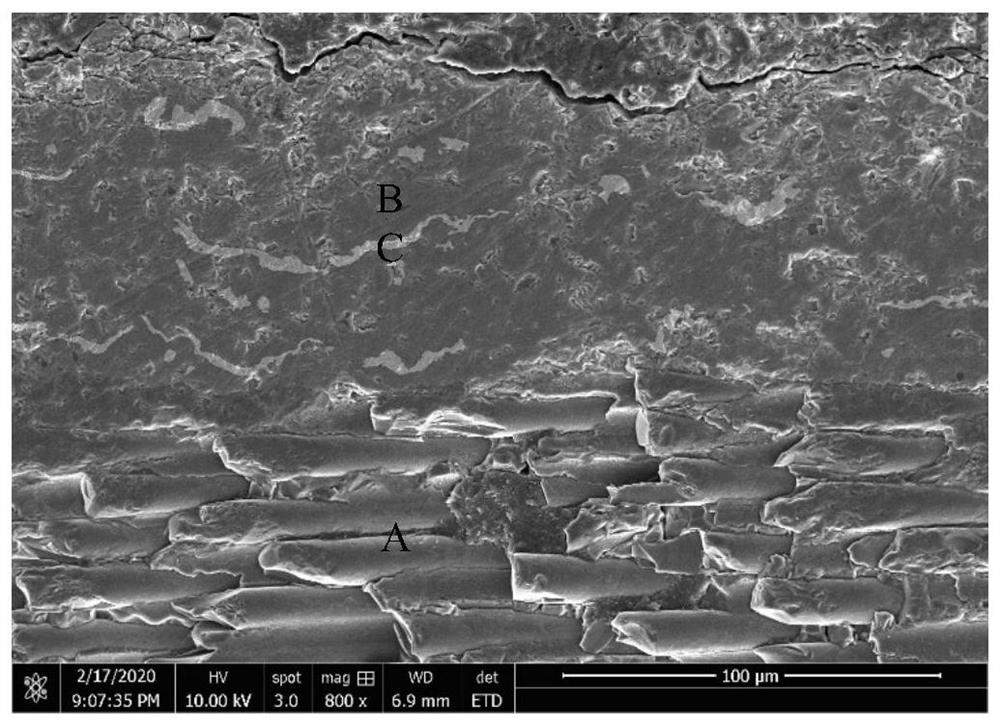

Silicon nitride fiber-enhanced silicon dioxide and boron nitride ceramic matrix composite and preparing method and application thereof

The invention discloses a silicon nitride fiber-enhanced silicon dioxide and boron nitride ceramic matrix composite and a preparing method and application thereof. The silicon nitride fiber-enhanced silicon dioxide and boron nitride ceramic matrix composite is prepared from a Si3N4 fiber prefabricated member, a SiO2 ceramic matrix and a BN ceramic matrix, wherein gaps of the Si3N4 fiber prefabricated member are filled with the SiO2 ceramic matrix and the BN ceramic matrix. The preparing method comprises the steps that firstly, the Si3N4 fiber prefabricated member is subjected to super glue heat treatment; secondly, a Si3N4f / SiO2 composite midbody is prepared; thirdly, a Si3N4f / SiO2-BN composite midbody is prepared; fourthly, decarbonization treatment is carried out. The composite has the advantages of being high in density, good in temperature resistance and high in carrying capacity, having a high dielectric property and the like, and the composite has high application value in the high-temperature wave-transmitting material field; the preparing method is simple in process, relatively low in cost and suitable for industrialized production.

Owner:NAT UNIV OF DEFENSE TECH

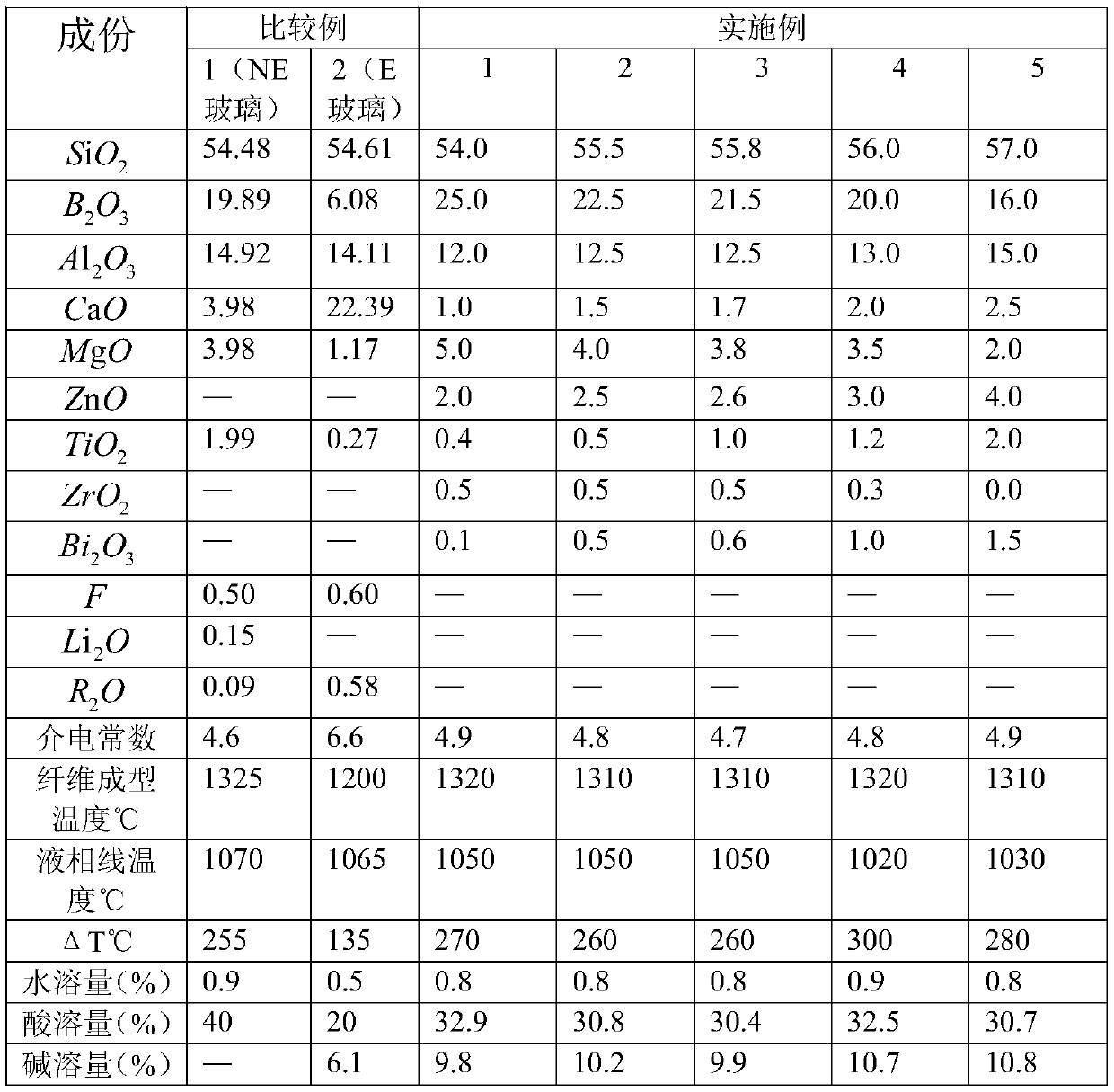

Low dielectric glass fiber component and production method thereof

The present invention relates to the field of electronic information base plate materials, particularly to a low dielectric glass fiber component, which comprises, by mass, 54.0-57.0% of SiO2, 12.0-15.0% of Al2O3, 16.0-25.0% of B2O3, 1.0-2.5% of CaO, 2.0-5.0% of MgO, 2.0-4.0% of ZnO, 0.4-2.0% of TiO2, 0-0.5% of ZrO2, and 0.1-1.5% of Bi2O3. According to the present invention, the total amount of ROis controlled at lower than 10% by controlling the composition of SiO2, Al2O3 and B2O3 oxides within a certain range and mainly using the mixed alkaline earth effect, and the water resistance, the acid resistance and the alkali resistance of glass can be improved through the composite adding of a small amount of ZrO2 and TiO2; and by introducing a small amount of Bi2O3 into the composition, the high-temperature viscosity of the glass melt is reduced, such that the effects of melting temperature reducing, energy saving and emission reducing in glass production can be achieved while the dielectric properties of the glass are not damaged.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH +1

Lubricating Composition Containing Viscosity Modifier Combination

InactiveUS20120329694A1Oxidative stability be improveReduce operationThickenersAdditivesOperating temperatureChemistry

The present invention relates to a lubricating composition containing (a) an oil of lubricating viscosity, (b) a star polymer and (c) a substantially linear polymer with a weight average molecular weight of 45,000 or less. The invention further provides a method of lubricating a mechanical device, typically a manual transmission with the lubricating composition. The invention further provides for the use of the lubricating composition to provide a number of benefits including lower operating temperatures and fuel economy

Owner:THE LUBRIZOL CORP

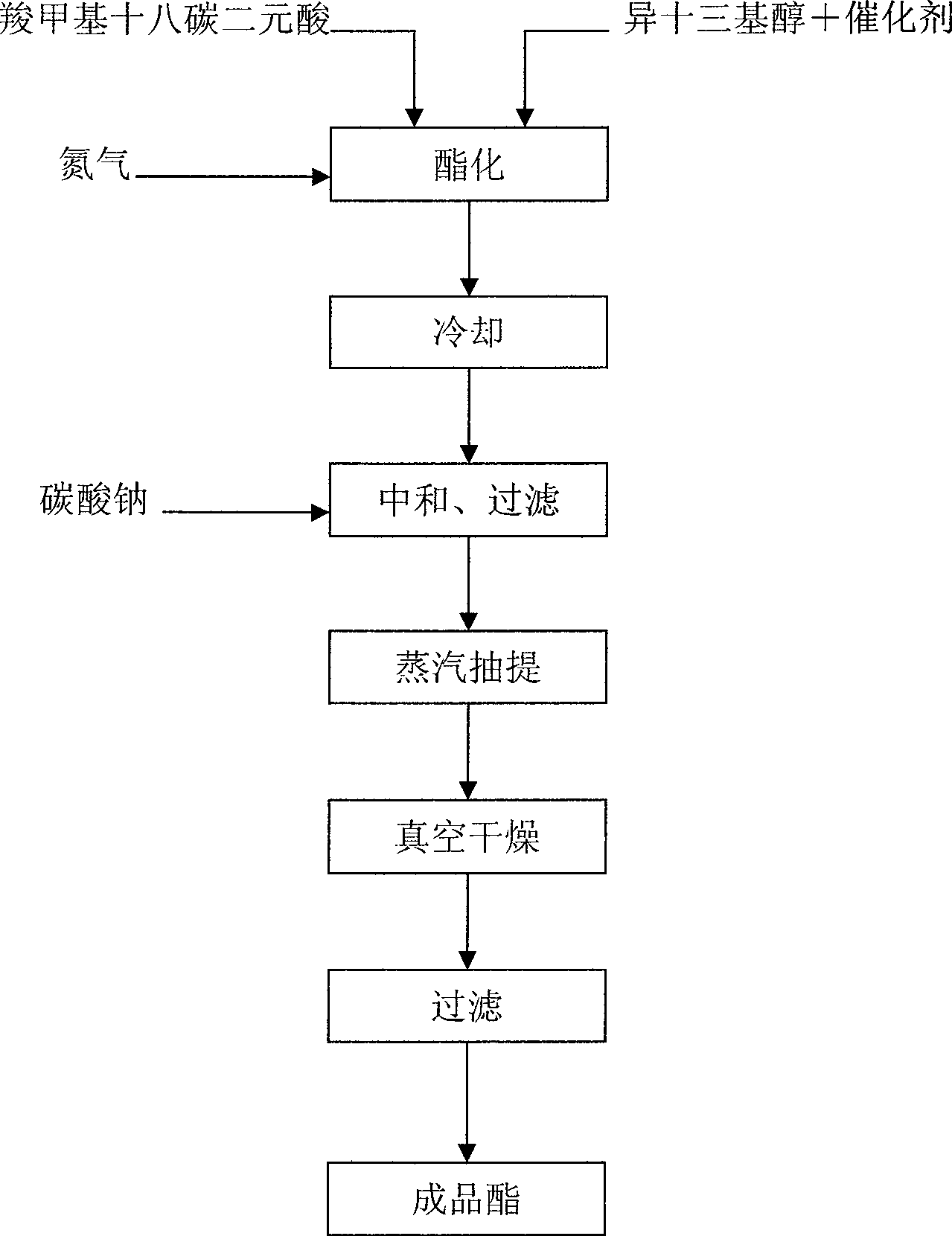

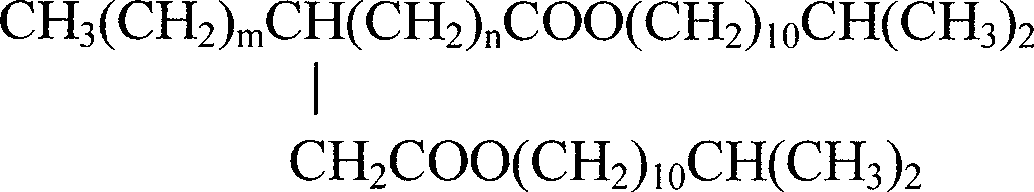

High viscosity dibasic acid esters oil and method of producing the same

InactiveCN101368124AHigh molecular weightIncrease high temperature viscosityBase-materialsHeteropoly acidRare earth

The invention relates to high viscosity diester oil and a preparation method thereof. The chemical composition of the diester oil is iso-tridecanol carboxymerhyl octadecatrienal dioic acid ester, the chemical formula is shown in the lower right formula, and the preparation method comprises the following steps: carboxymerhyl octadecatrienal dicarboxylic acid and iso-tridecanol prepared by using methyl oleate are adopted as raw materials, under 180 to 240 DEG C and the atmospheric pressure, rare earth solid multiphase acid (heteropoly acid and La-Ce) is adopted as catalyst, and the iso-tridecanol carboxymerhyl octadecatrienal dioic acid ester is prepared under vacuum condition. The preparation method has the advantages that the iso-tridecanol carboxymerhyl octadecatrienal dioic acid ester prepared has high relative molecular weight; the high temperature viscosity of oil product is high; the other properties are corresponded to other diester; and high viscosity lubricating oil can be prepared. When the rare earth solid multiphase acid catalyst is adopted in a technological process, the reaction time is short; the conversion rate can reach 100 percent; neutralization and water washing is not required; the rare earth solid multiphase acid catalyst can be recovered and reused, and the heat energy can be recycled in the process.

Owner:俏东方生物燃料集团有限公司

Process for making high temperature color glaze for porcelain

The invention provides a process for making high temperature color glaze for porcelain by employing fused block protection method, which comprises, preparing base fused blocks by means of conventional methods, assembling base fused blocks with base glaze with metal coloring agent by a finite proportion, charging at least one addition agent having lower fusible point and stronger oxidizing property than the chromophoric metal in the base glaze, so as to protect the chromophoric metal from being oxidized and sublimated.

Owner:HUNAN HUALIAN CHINA IND

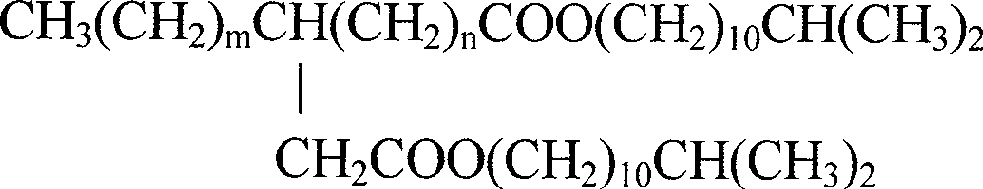

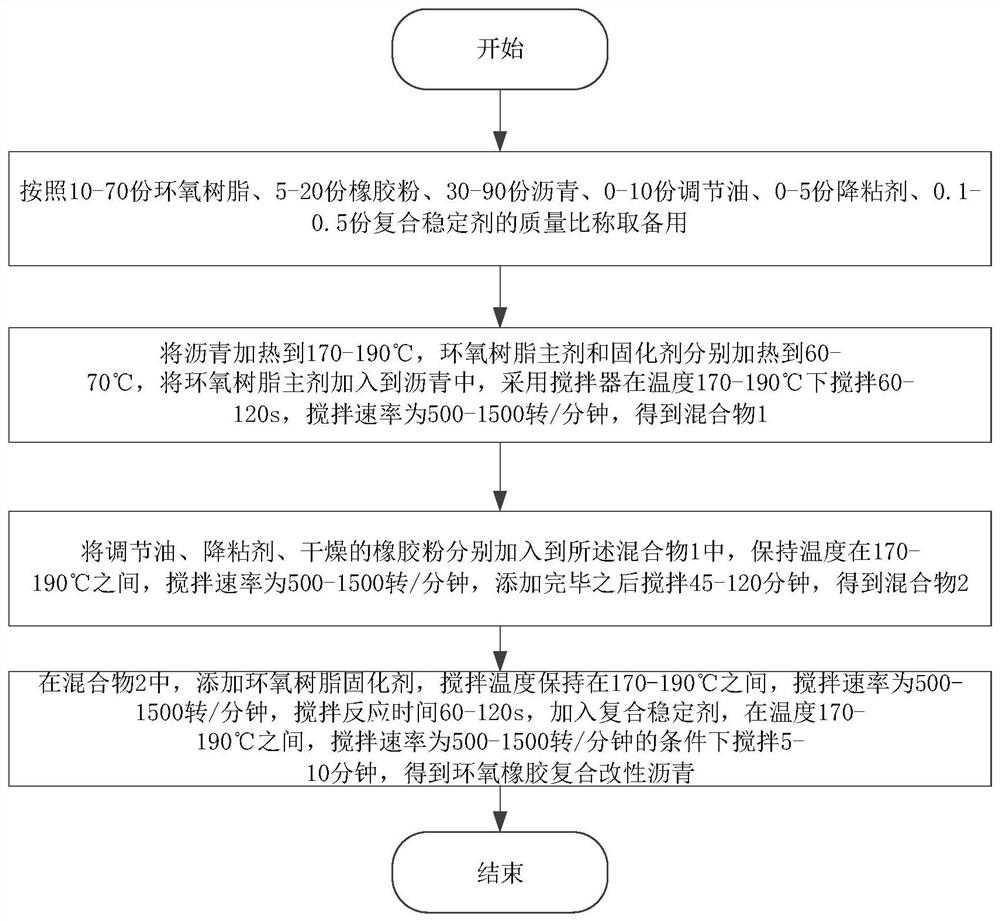

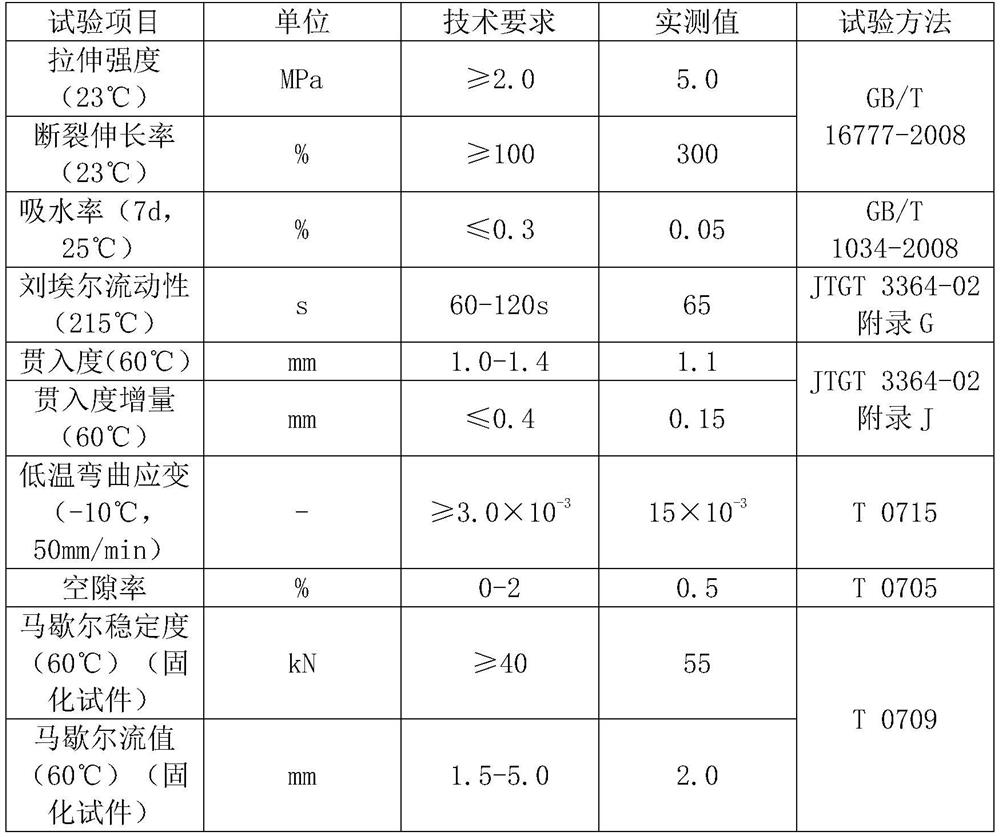

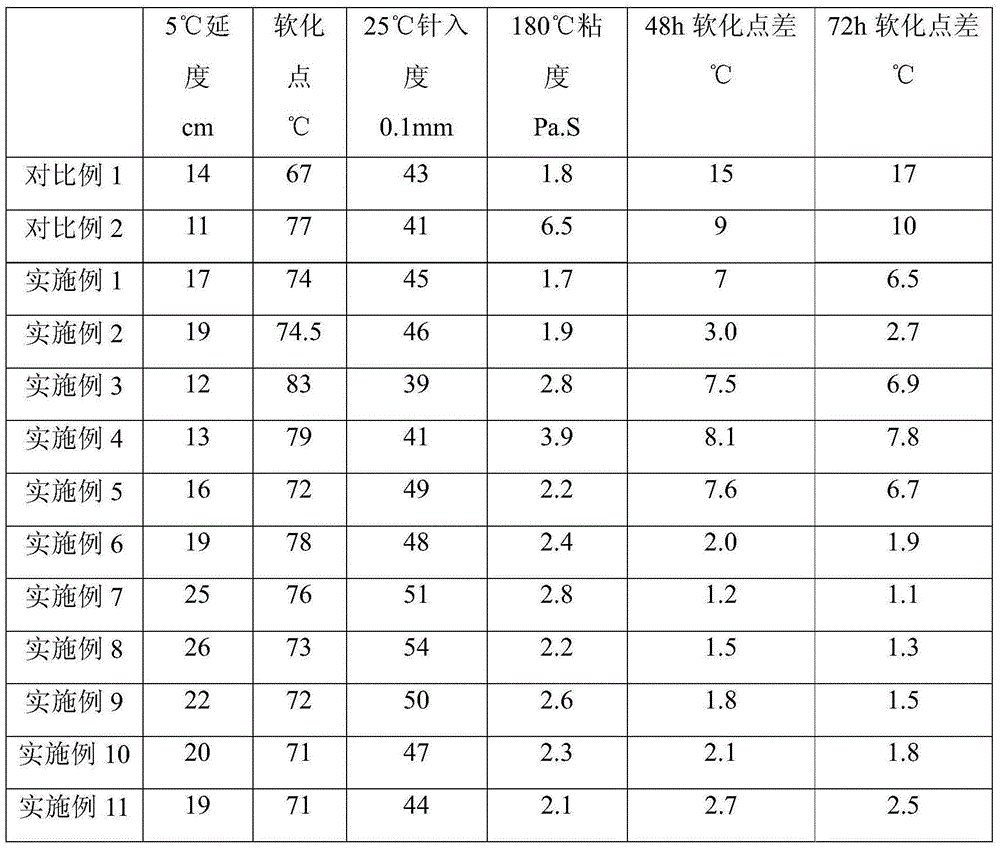

Epoxy rubber composite modified asphalt and preparation method thereof

The invention provides epoxy rubber composite modified asphalt and a preparation method thereof. The epoxy rubber composite modified asphalt comprises the following components in parts by weight: 10-70 parts of epoxy resin, 5-20 parts of rubber powder, 30-90 parts of asphalt, 0-10 parts of regulating oil, 1-5 parts of a viscosity reducer and 0.1-0.5 part of a composite stabilizer. The epoxy rubber composite modified asphalt has the remarkable technical characteristics of being adjustable in rigidity, low in viscosity in the construction process, high in viscosity and elasticity under the service condition, good in high-temperature stability, high in durability, energy-saving and environment-friendly.

Owner:JIANGYIN TAIFU ASPHALTUM

High-refractive index and low-dispersion heavy lanthanum flint optical glass

The invention relates to a high-refractive index and low-dispersion heavy lanthanum flint optical glass which is prepared from the following components in percentage by mass of oxides: 9.25-13.37 percent of B2O3, 5.48-7.34 percent of SiO2, 43.60-51.63 percent of La2O3, 3.53-9.12 percent of Y2O3, 4.18-10.23 percent of Gd2O3, 3.47-6.52 percent of Nb2O5, 3.47-6.62 percent of ZrO2, 0.81-1.50 percent of WO3, 3.96-6.95 percent of TiO2, 3.28-6.79 percent of ZnO and 0.61-1.52 percent of Al2O3; and in the composition, the following conditions are also met: B / Si is larger than 1.33 and smaller than 2.54 (by mass percentage), a sum of the mass percentages of La2O3, Y2O3 and Gd2O3 is 58.61-60.32 percent, and a sum of the mass percentages of WO3 and TiO2 is 4.85-8.34 percent. The optical glass does not contain Ta2O3 with high cost to facilitate reduction of the cost of the glass, does not contain alkali metals, alkaline-earth metals and toxic components including Pb, As and Cd either, has the refractive index nd being 1.883-1.915 and an abbe number vd being 35.65-38.32, is excellent in crystallization resistance and is suitable for batch production.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

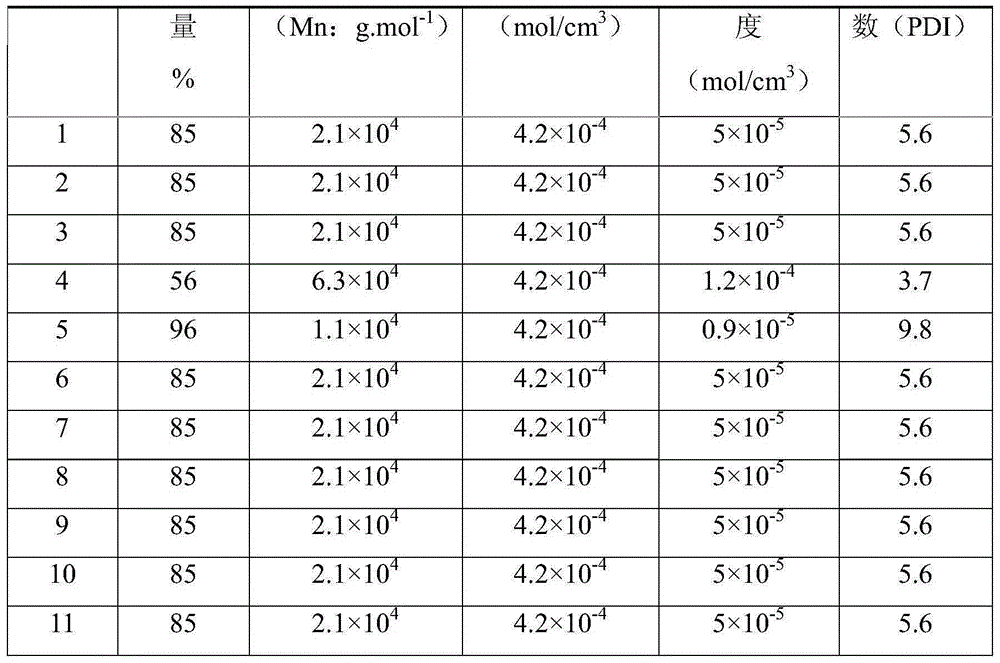

Composite-waste-rubber-powder-particle modified asphalt mixture capable of being stored stably and preparation method thereof

ActiveCN104693820AControl "Secondary Pollution"Stable storageBuilding insulationsCross-linkPolymer science

The invention relates to a composite-waste-rubber-powder-particle modified asphalt mixture capable of being stored stably and a preparation method thereof. The preparation method comprises the steps of firstly carrying out deep-desulfurization degradation on low-mesh rubber powder so as to prepare high-desulfurization-degree reclaimed rubber, then, mixing high-mesh rubber powder, the high-desulfurization-degree reclaimed rubber and a small amount of cross-linking agent according to a certain ratio so as to prepare composite waste-rubber-powder particles, then, mixing the composite waste-rubber-powder particles and matrix asphalt, so as to prepare modified asphalt, and mixing the modified asphalt and aggregate, thereby preparing the modified asphalt mixture. According to the composite waste-rubber-powder particles, linear macromolecules in the high-desulfurization-degree reclaimed rubber are uniformly attached to the surface of the rubber powder, and meanwhile, a linear macromolecule-cross-linked structured core-shell structure is formed by using the micro-crosslinking action of the cross-linking agent. Due to the structure, a large number of linear molecules can intermesh in asphalt, and then, a stable rubber powder-asphalt mesh structure is formed, so that the aim of preparing the stably-stored rubber powder modified asphalt mixture is achieved.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

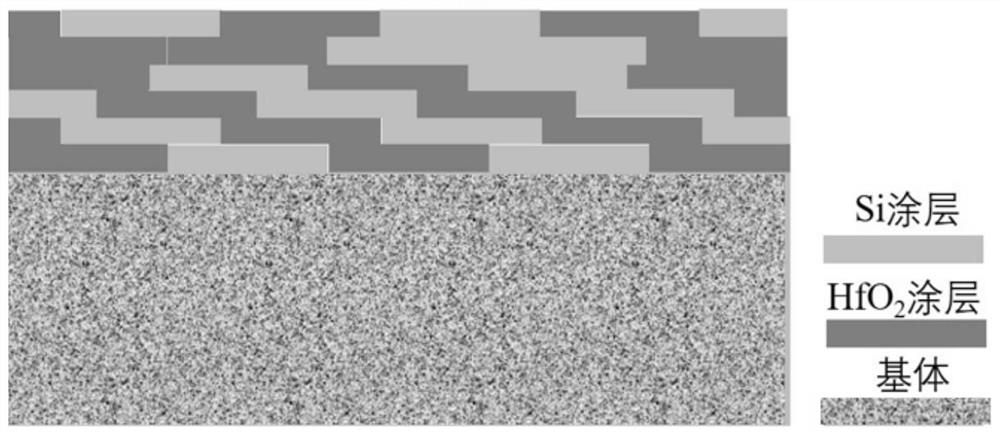

Silicon-based composite coating, preparation method and application thereof and aero-engine

PendingCN112279682AImprove high temperature viscosityGood heat resistanceSilicon basedCeramic matrix composite

The invention provides a silicon-based composite coating, a preparation method and application thereof and an aero-engine, and belongs to the technical field of materials. The preparation method comprises the steps that atmospheric plasma spraying is adopted for spraying a Si-HfO2 composite coating on the surface of a ceramic matrix composite, and a double-pipe independent simultaneous powder feeding mode is adopted for atmospheric plasma spraying so that a Si raw material and an HfO2 raw material can be independently fed to a flame flow center at the same time. The method is simple and convenient to operate, a compact and uniform Si-HfO2 silicon-based composite coating can be obtained, and the service temperature of a silicon-based bonding layer in the silicon-based composite coating is increased. The prepared silicon-based composite coating has better temperature resistance and can meet the design requirements of aero-engines in the future. The silicon-based composite coating can beused for processing an aero-engine, so that the aero-engine has good heat resistance.

Owner:GUANGDONG INST OF NEW MATERIALS

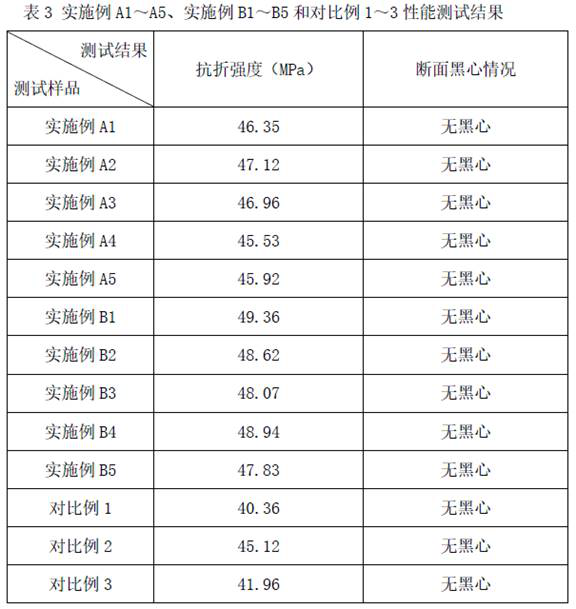

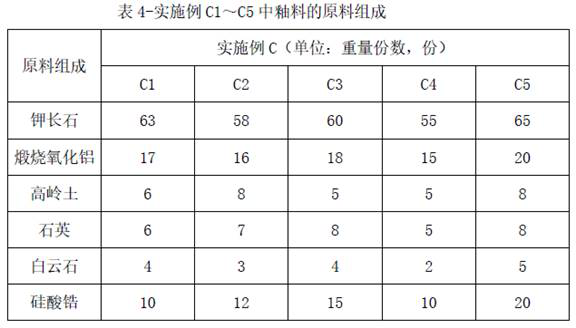

Preparation method of fast-fired ceramic tile and product of fast-fired ceramic tile

The invention discloses a preparation method of a fast-fired ceramic tile and a product thereof. The preparation method of the fast-fired ceramic tile comprises the following steps: A, uniformly mixing green body raw materials, then carrying out ball-milling pulping and drying granulation to prepare green body powder, and carrying out compression molding on the green body powder to obtain a green body, wherein the green body raw materials comprise the following chemical components in percentage by mass: 4.1 to 4.5% of K2O, 1.3 to 1.7% of Na2O and 1.4 to 1.7% of MgO; and B, applying glaze on the surface of the green body; wherein the raw materials of the glaze comprise potassium feldspar, calcined alumina, kaolin, quartz, dolomite and zirconium silicate. According to the preparation method of the fast-fired ceramic tile, fast firing in a short kiln can be achieved, the production speed of the ceramic tile is effectively increased, the productivity of a production line is improved, energy saving is facilitated, and the fast-fired ceramic tile prepared through the preparation method of the fast-fired ceramic tile is high in strength and good in quality.

Owner:FOSHAN DONGPENG CERAMIC +3

Fused silica glass and process for producing the same

ActiveUS8211817B2High purityIncrease high temperature viscosityGlass shaping apparatusGlass tempering apparatusUltravioletMetal impurities

Fused silica glass having an internal transmittance of UV with 245 nm wavelength, being at least 95% at 10 mm thickness, a OH content of not larger than 5 ppm, and a content of Li, Na, K, Mg, Ca and Cu each being smaller than 0.1 ppm. Preferably the glass has a viscosity coefficient at 1215° C. of at least 1011.5 Pa·s; and a Cu ion diffusion coefficient of not larger than 1×10−10 cm2 / sec in a depth range of greater than 20 μm up to 100 μm, from the surface, when leaving to stand at 1050° C. in air for 24 hours. The glass is made by cristobalitizing powdery silica raw material; then, fusing the cristobalitized silica material in a non-reducing atmosphere. The glass exhibits a high transmittance of ultraviolet, visible and infrared rays, has high purity and heat resistance, and exhibits a reduced diffusion rate of metal impurities, therefore, it is suitable for various optical goods, semiconductor-production apparatus members, and liquid crystal display production apparatus members.

Owner:TOSOH CORP +1

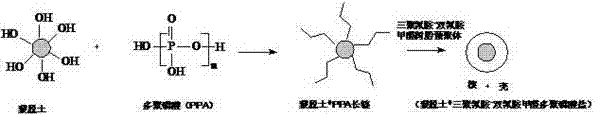

Composite flame retardant, flame-retardant asphalt and preparation method of flame-retardant asphalt

The invention discloses a composite flame retardant, flame-retardant asphalt and a preparation method of the flame-retardant asphalt. The composite flame retardant comprises montmorillonite and melamine-dicyandiamide formaldehyde resin polyphosphate, wherein the melamine-dicyandiamide formaldehyde resin polyphosphate coats on the surface of the montmorillonite and is inserted between layers of the montmorillonite. According to the composite flame retardant, the dispersibility and the homogeneity of montmorillonite particles in asphalt can be improved, the filling amount of the flame retardant is reduced, and the properties, such as the water resistance, the anti-crack property, the rut resistance, the low temperature resistance, the thermo-oxidative aging resistance and the photo-oxidative aging resistance are improved at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

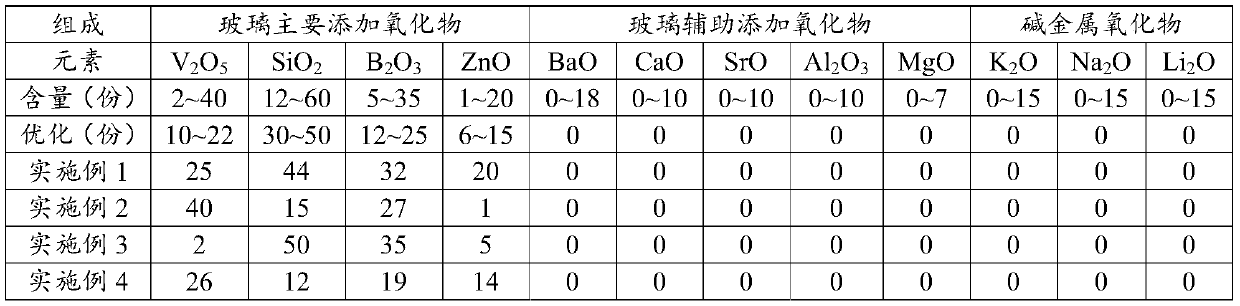

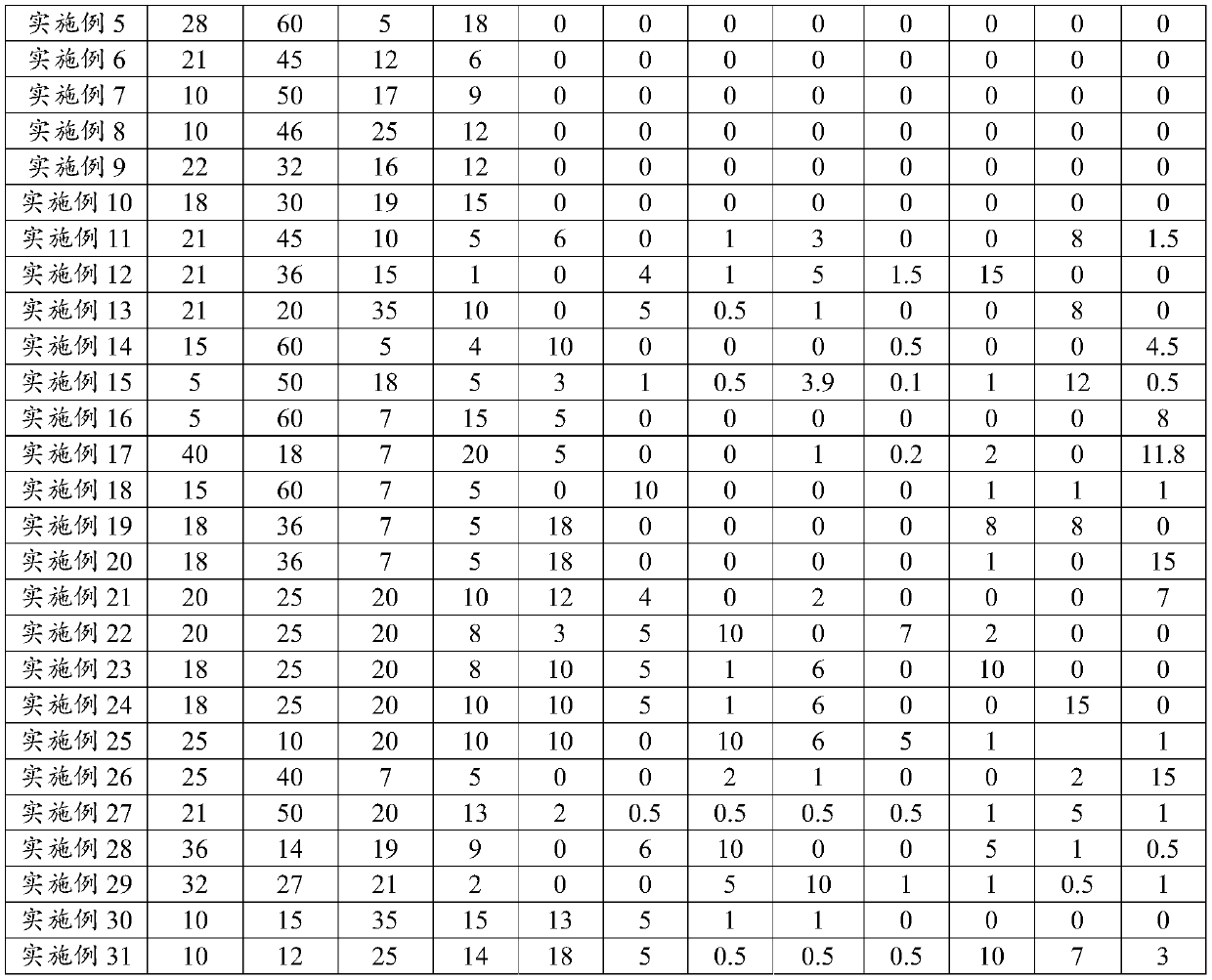

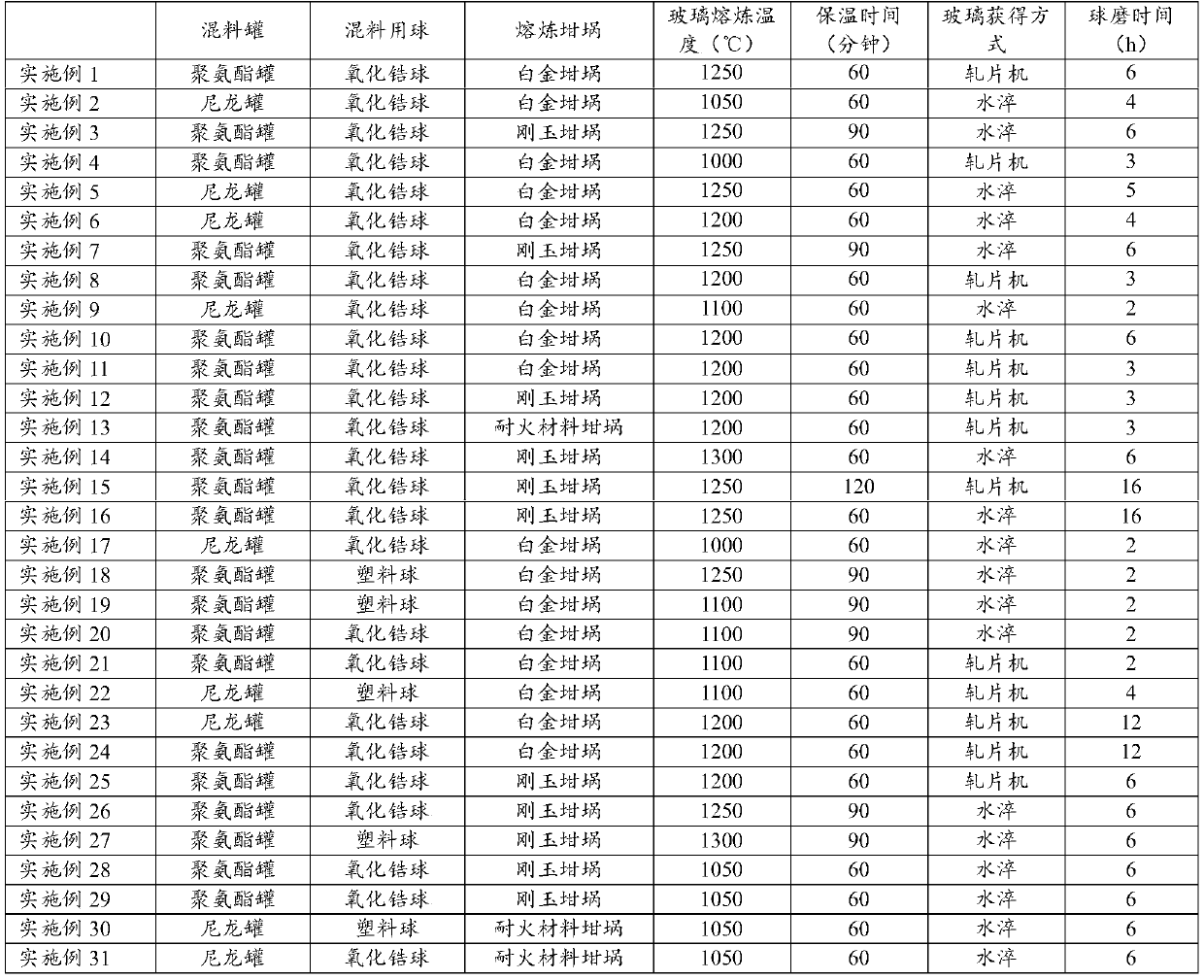

Glass powder for copper conductive paste, preparation method and application thereof

InactiveCN110423013AStrong adhesionImprove compatibilityFixed capacitor dielectricStacked capacitorsVitrificationConductive paste

The invention discloses glass powder for copper conductive paste, which comprises the following components in parts by weight: 2-40 parts of vanadium pentoxide, 12-60 parts of silicon dioxide, 5-35 parts of boron oxide and 1-20 parts of zinc oxide. The glass powder is crystallized glass, can obtain high high-temperature viscosity, can prevent glass transition defects, and reduces interference on welding wetting and welding adhesion. The glass powder is used for preparing the conductive copper paste, and the copper paste is used for preparing MLCC end electrodes. The glass powder shows strong adhesive force with a BaTiO3 ceramic matrix, ensures good compatibility between end electrodes and base metal internal electrodes, and meets all requirements of MLCC on copper end electrode paste glasspowder. Meanwhile, the invention also provides a preparation method and application of the glass powder for the copper conductive paste.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Preparation method of fine sand antiskid ceramic rock plate and prepared fine sand antiskid ceramic rock plate

The invention relates to a preparation method of a fine sand antiskid ceramic rock plate. The preparation method comprises the steps of (1) grinding and polishing a formed planar green body; (2) keeping constant temperature and heat, and controlling the surface temperature of the green body to be 80-90 DEG C; (3) applying ground coat with a wide high-temperature high-viscosity firing range; (4) conducting ink-jet printing decoration, specifically, jet-printing the pattern on the surface of the ground coat layer through a digital ink jet machine to form rich colors; (5) spraying protective glaze, wherein the glazing specific gravity of the protective glaze is 1.15-1.20, and the glazing amount is 30-35g / m<2>; and (6), firing, wherein the firing temperature is 1180-1200 DEG C, and the firingtime is 120 minutes.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +1

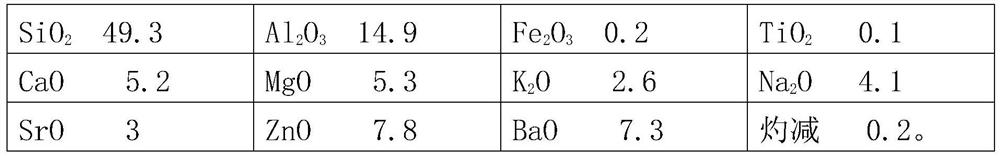

Special HME fiber glass for wind turbine blades

InactiveCN101792267AImprove acid resistanceIncrease high temperature viscosityMachines/enginesWind energy generationElectricityGlass fiber

The invention relates to special HME fiber glass for wind turbine blades, which is mainly prepared by mixing SiO2, Al2O3, Fe2O3, CaO, MgO, NaO2 and K2O according to the proportion; and the special HME fiber glass is characterized in that the following components are added in the components by weight percent: 0.3-2.5% of TiO2, 0.1-0.6% of LiO2, 0-0.8% of WO3, and 0.1-0.6% of CeO2. The special HME fiber glass takes the SiO2, the Al2O3, the CaO and the like as the main components, further adds four important auxiliary components of the TiO2, the LiO2, the WO3 and the CeO2, and mainly uses the TiO2 for replacing B2O3 and F2 which are conventional in alkali-free glass fiber, thereby realizing the environment-friendly property; the WO3 is used selectively, so as to improve the elastic modulus and the acid resistance of the special HME fiber glass for the wind turbine blades while ensuring the cost; particularly, the SiO2 is selected to be more than 58%, so as to improve the high-temperature viscosity of the glass. In short, the special HME fiber glass for the wind turbine blades produced by using the components has the advantages of high elastic modulus, high requirement on product rigidness, good acid resistance and good insulation performance.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Optical glass for precision molding, prefabricated glass, optical element and optical instrument

ActiveUS20150225282A1Improve accuracyLow production costGlass pressing apparatusOptical elementsDevitrificationResource saving

The invention provides a low-cost high-precision molding optical glass, with density below 4.54 g / cm3, refractive index ranging from 1.85 to 1.95, Abbe number ranging from 25 to 35 and transition temperature lower than 610° C. Expensive Ta2O5 is not added in the invention, so the production cost is saved, and resource saving is realized; the combination of B2O3 and La2O3 effectively improves the devitrification resistance and the chemical stability of glass; the combination of WO3 and TiO2 allows the staining degree of the optical glass to be excellent; and the combination of Gd2O3 and La2O3 effectively improves the devitrification resistance of the glass.

Owner:CDGM OPTICAL GLASS

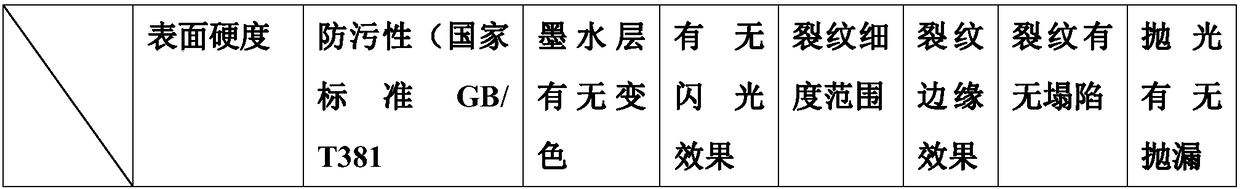

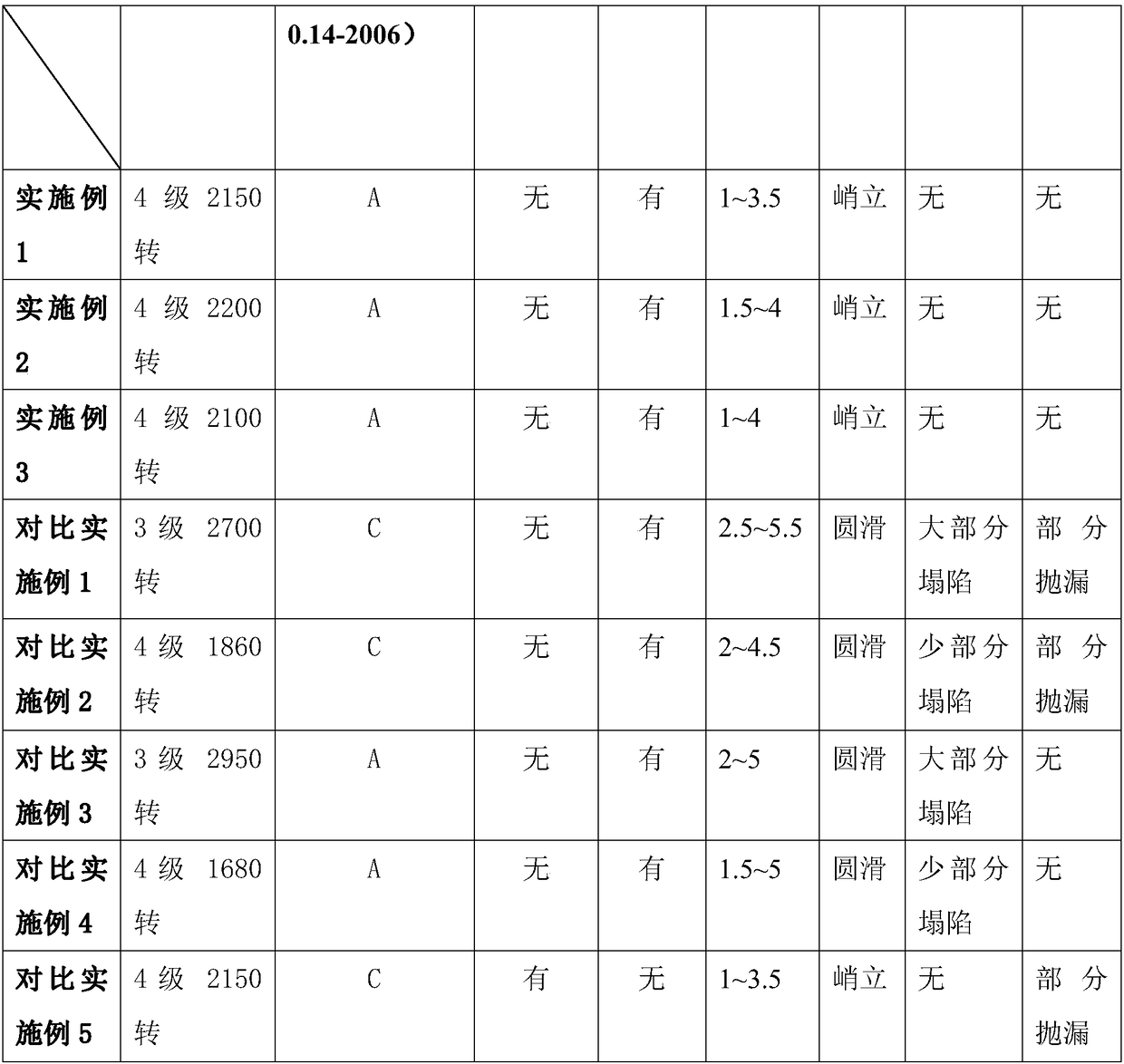

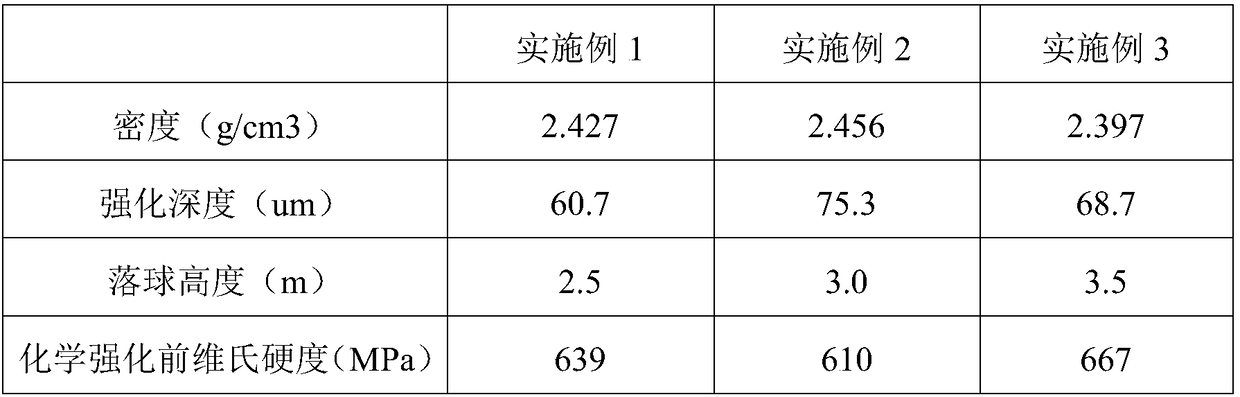

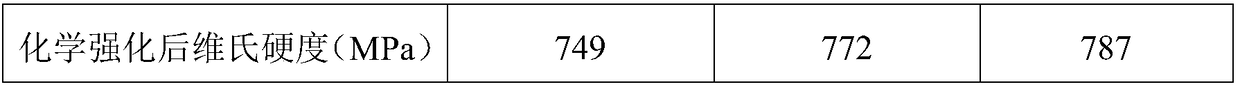

Glazed tile with crack effect and preparation technology thereof

ActiveCN108623331AProtect against discolorationRealistic and delicate without discolorationBrickSilicon dioxide

The invention discloses a glazed tile with a crack effect and a preparation technology thereof. The preparation technology comprises the steps: (1) spraying clean water on the surface of a green brickof a ceramic tile and applying high-temperature cover glaze to form a high-temperature cover glaze layer, wherein the high-temperature cover glaze contains silicon dioxide with the weight percentagelarger than 55%, a proportion of a silicon-aluminum ratio is 2.3 to 2.5, and the glazing amount is a 110+ / -2g / 330*660 measurement disk; (2) jet printing decoration ink on the cover glaze layer to forma decoration pattern layer; (3) jet printing bright protection ink on the decoration pattern layer and then jet printing engraving ink, wherein the ink jet amounts are both larger than 30 / m<2>; (4) spraying polish glaze on the surface of the green brick, wherein the polish glaze contains superfine aluminum oxide with the mass percent as 1.5 to 3%, and the glaze spraying amount is a 135+ / -g / 330*660 measurement disk; (5) drying the green brick before the green brick is put into a kiln and performing high-temperature sintering, polishing and edging treatment to obtain the glazed tile with the crack effect. Thickness and transition of the crack lines of the glazed tile prepared by the glazed tile preparation technology disclosed by the invention are easier to regulate, a line effect is more obvious and vivid, and good antifouling performance is further achieved.

Owner:FOSHAN OCEANO CERAMICS +1

Building material mildew-resistant additive

The invention relates to a building material mildew-resistant additive. The building material mildew-resistant additive comprises, by weight, 25 to 55 parts of quicklime, 20 to 35 parts of zirconium dioxide, 2 to 15 parts of fumaric acid diester, 10 to 30 parts of mint and 5 to 17 parts of xanthan gum. The building material mildew-resistant additive has a low production cost and lasting mildew-resistant and antibacterial effects and does not produce the side-effect on a human body.

Owner:申思

High temperature resistant tempered glass and preparation method thereof

ActiveCN108529876AIncrease high temperature viscosityGood chemical resistanceCoatingsGlass tempering apparatusStress relaxationTemperature resistance

The invention relates to the field of glass materials, and discloses high temperature resistant tempered glass and a preparation method thereof. The tempered glass comprises, by weight, 50-55 parts ofquartz sand, 10-20 parts of alumina, 10-13 parts of sodium carbonate, 4-6 parts of mirabilite, 10-15 parts of dolomite, 3-5 parts of feldspar, 1-2 parts of ceraphite, 3-5 parts of limestone, 1-3 parts of cosolvent, 0.2-0.5 part of cerium oxide composite clarifying agent, 1-2 parts of coloring agent, 10-15 parts of cullet, 1-3 parts of titanium oxide, 1-2 parts of antimony oxide, 0.5-1 part of yttrium oxide and 15-20 parts of high temperature resistant component. According to the tempered glass, components in the glass composition have a synergistic effect, so that the stress relaxation of theobtained glass is effectively improved, and the tempered glass has the advantages of enhanced compressive stress, deep strengthening depth, high impact strength, high temperature resistance and the like.

Owner:云南阳光利生玻璃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com