Preparation method of fine sand antiskid ceramic rock plate and prepared fine sand antiskid ceramic rock plate

An anti-slip and ceramic technology, applied in the field of ceramics, can solve the problems of large fluctuations in glaze gloss, difficult to be welcomed by consumers, and large texture differences, and achieve the effects of improving stain resistance and anti-slip function, stable quality of anti-slip effect, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The preparation method of fine-sand non-slip ceramic rock plate comprises the following steps:

[0043] (1) Grinding and polishing the formed flat body;

[0044] ⑵Constant temperature and heat preservation, control the surface temperature of the green body to 85±2℃;

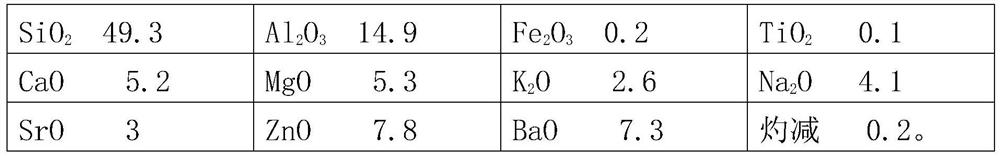

[0045] (3) Apply high-temperature, high-viscosity bottom glaze with a wide firing range; the bottom glaze adopts high-pressure spray glaze method, pressure 13±0.5MP, 4 spray guns, nozzle diameter of spray gun nozzle is 0.31mm, sprayed glaze slurry atomized particle size is 0.2± 0.05mm; step (3) the bottom glaze contains binder, the binder is added directly before spraying the glaze, stirred evenly and sieved for use, the binder is sodium carboxymethyl cellulose hydrate or ceramic glue , wherein the ratio of sodium carboxymethyl cellulose hydrate is material: water = 1:15, adding a binder to the bottom glaze can make the glaze maintain good water retention performance on the one hand, and on the other hand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com