Organic-inorganic hybrid high-silicon-content acrylic ester emulsion and preparation method thereof

An acrylate and acrylate technology, applied in the fields of hybrid nano-coatings, high-performance high-silicon content acrylate emulsions and their preparation, can solve problems such as low silicon content in silicone-acrylic emulsions, achieve easy-to-obtain prices and reduce production costs , The effect of stable and easy control of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

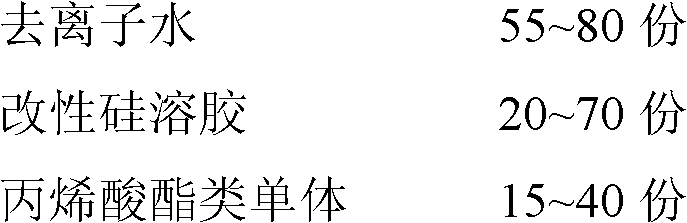

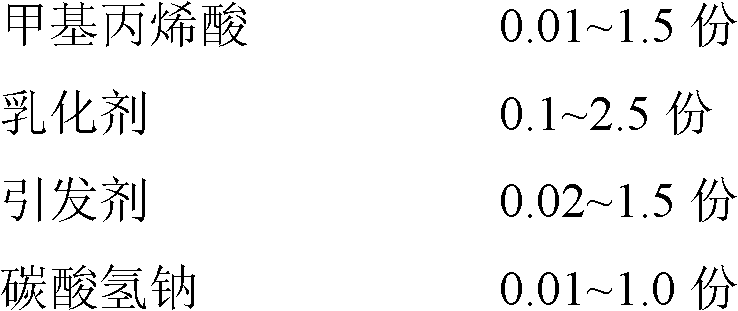

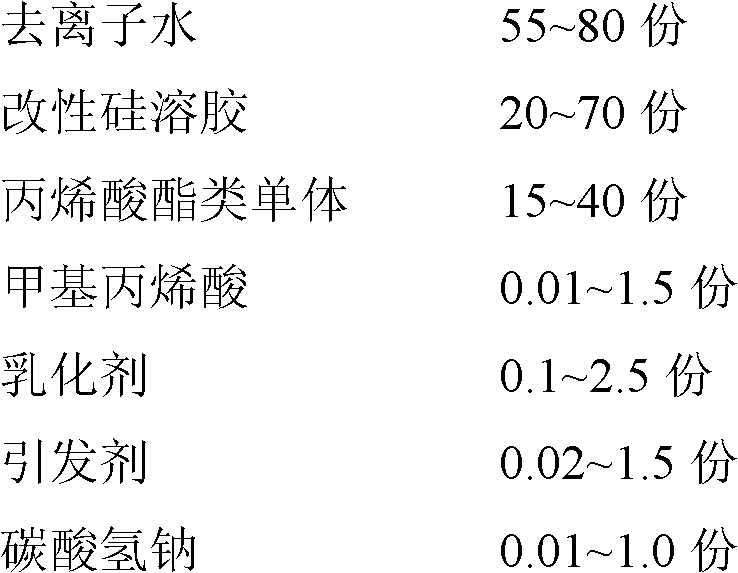

Method used

Image

Examples

Embodiment 1

[0039] Add 15g of isopropanol and 0.84g of γ-(methacryloyloxy)propyltrimethoxysilane to 35g of silica sol, stir and react at 50°C for 8h to obtain modified silica sol.

[0040] Add 3g of deionized water, 0.1g of DNS-86 and OP-10 (the mass ratio of anionic emulsifier to nonionic emulsifier is 1:1) into the jar, after dissolving evenly, add it dropwise at a constant speed within 10min 2g mixed monomer methyl methacrylate and butyl acrylate (mass ratio is 1: 1), after the dropwise addition is completed, stir with a magnetic stirrer at a speed of 2000rpm for 15min, and then stir at a speed of 500rpm for 5min to obtain a pre-emulsified nucleosomes.

[0041] Add 5g of deionized water, 0.3g of DNS-86 and OP-10 (the mass ratio of anionic emulsifier and nonionic emulsifier is 1:1) into the jar, after dissolving evenly, add it dropwise at a constant speed within 20min 10g of mixed monomers methyl methacrylate and butyl acrylate (mass ratio is 1:1), and 0.15g of methacrylic acid, after ...

Embodiment 2

[0044] Add 15 g of ethanol and 1.05 g of vinyltriethoxysilane to 35 g of silica sol, and stir and react at 40° C. for 6 h to obtain modified silica sol.

[0045] Add 3g of deionized water, 0.2g of PEO-10 and T-80 (the mass ratio of anionic emulsifier to nonionic emulsifier is 2:1) into the jar, after dissolving evenly, add it dropwise at a constant speed within 5min 4g mixed monomer methyl methacrylate and butyl acrylate (mass ratio is 1: 1), after the dropwise addition is completed, stir with a magnetic stirrer at a speed of 1000rpm for 30min, and then stir at a speed of 800rpm for 5min to obtain a pre-emulsified nucleosomes.

[0046] Add 13g of deionized water, 0.9g of PEO-10 and T-80 (the mass ratio of anionic emulsifier to nonionic emulsifier is 2:1) into the jar, dissolve evenly, and drop it at a constant speed within 25min Add 23g of mixed monomers methyl methacrylate and butyl acrylate (mass ratio is 1:1), and all 0.7g of methacrylic acid in the formula, after the ...

Embodiment 3

[0049] Add 15g of isopropanol and 1.05g of γ-glycidoxypropyltrimethoxysilane to 35g of silica sol, and stir and react at 20°C for 12h to obtain modified silica sol.

[0050] Add 5g of deionized water, 0.35g of PEO-10 and T-80 (the mass ratio of anionic emulsifier to nonionic emulsifier is 1:1) into the jar, dissolve evenly, and drop it at a constant speed within 10min Add 7g of mixed monomers methyl methacrylate and butyl acrylate (mass ratio is 1: 1), after the dropwise addition is completed, stir with a magnetic stirrer at a speed of 1500rpm for 15min, and then stir at a speed of 500rpm for 5min to prepare the prepared Emulsified nucleomonomers.

[0051] Add 10g of deionized water, 0.7g of PEO-10 and T-80 (the mass ratio of anionic emulsifier to nonionic emulsifier is 1:1) into the jar, dissolve evenly, and drop it at a constant speed within 20min Add 20g of mixed monomer methyl methacrylate and butyl acrylate (mass ratio is 1:1), and all 0.3g of methacrylic acid in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com