Patents

Literature

131 results about "Melilite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melilite refers to a mineral of the melilite group. Minerals of the group are solid solutions of several endmembers, the most important of which are gehlenite and åkermanite. A generalized formula for common melilite is (Ca,Na)₂(Al,Mg,Fe²⁺)[(Al,Si)SiO₇]. Discovered in 1793 near Rome, it has a yellowish, greenish-brown color. The name derives from the Greek words meli (μέλι) "honey" and lithos (λίθους) "stone".

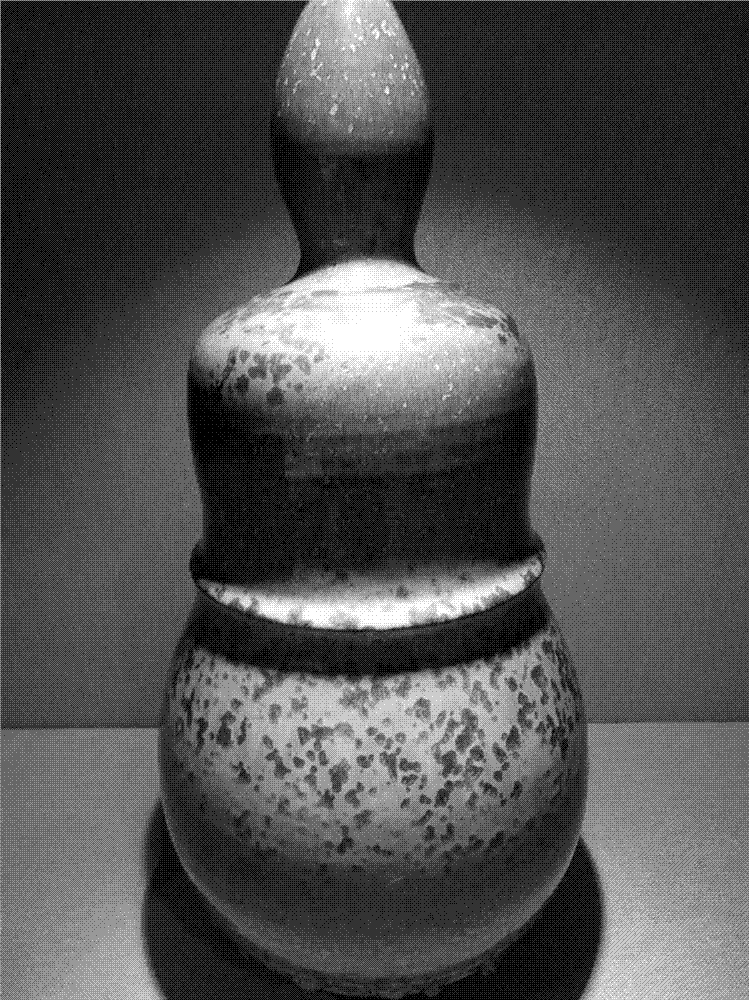

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Method for making archaistic semimatte thin glaze for Ru porcelain

The invention discloses a method for making an archaistic semimatte thin glaze for a Ru porcelain, which comprises the following steps: respectively taking 4-10% of kaoline, 55-65% of melilite, 18-22% of calcite, 4-6% of white feldspar, 6-10% of black feldspar and 1-3% of plant ash as raw materials for making the glaze; calcining the kaoline for 4-6 hours at a temperature of 880-920 DEG C for future use; mixing the melilite, the calcite, the white feldspar, the black feldspar and the plant ash with the calcined kaoline, adding water to the obtained mixture to carry out wet grinding on the obtained mixture, and removing natant iron to obtain a glaze material; selecting the kaoline as a blank material, adding the water and a water reducing agent to the blank material to carry out the wet grinding on the kaoline, and then, making slurry into a blank, and sintering the blank to obtain a biscuit; adding the water to the glaze material to adjust the concentration of the glaze material, immersing the biscuit in the glaze, and finishing the biscuit; putting the biscuit in a kiln, ventilating the kiln, increasing a temperature to 1050 DEG C, and then, reducing an inlet air amount, so that a fuel in the kiln is combusted incompletely in an anaerobic condition, and gradually increasing the temperature to 1135 DEG C; and preserving heat for 10 minutes, and then, decreasing the temperatureto 900 DEG C, stopping a fire, and cooling the obtained product, thereby completing the making.

Owner:刘冬青

Manufacture of ceramic tiles from industrial waste

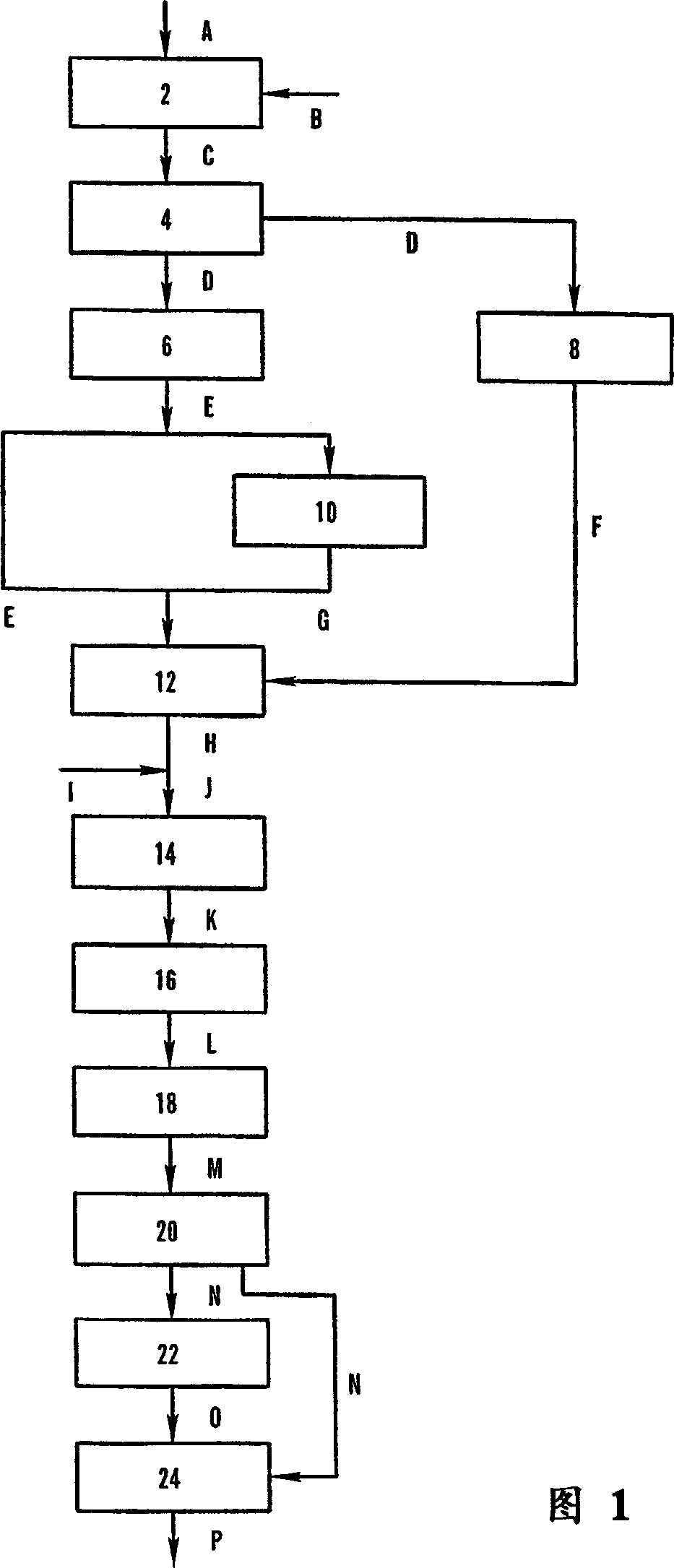

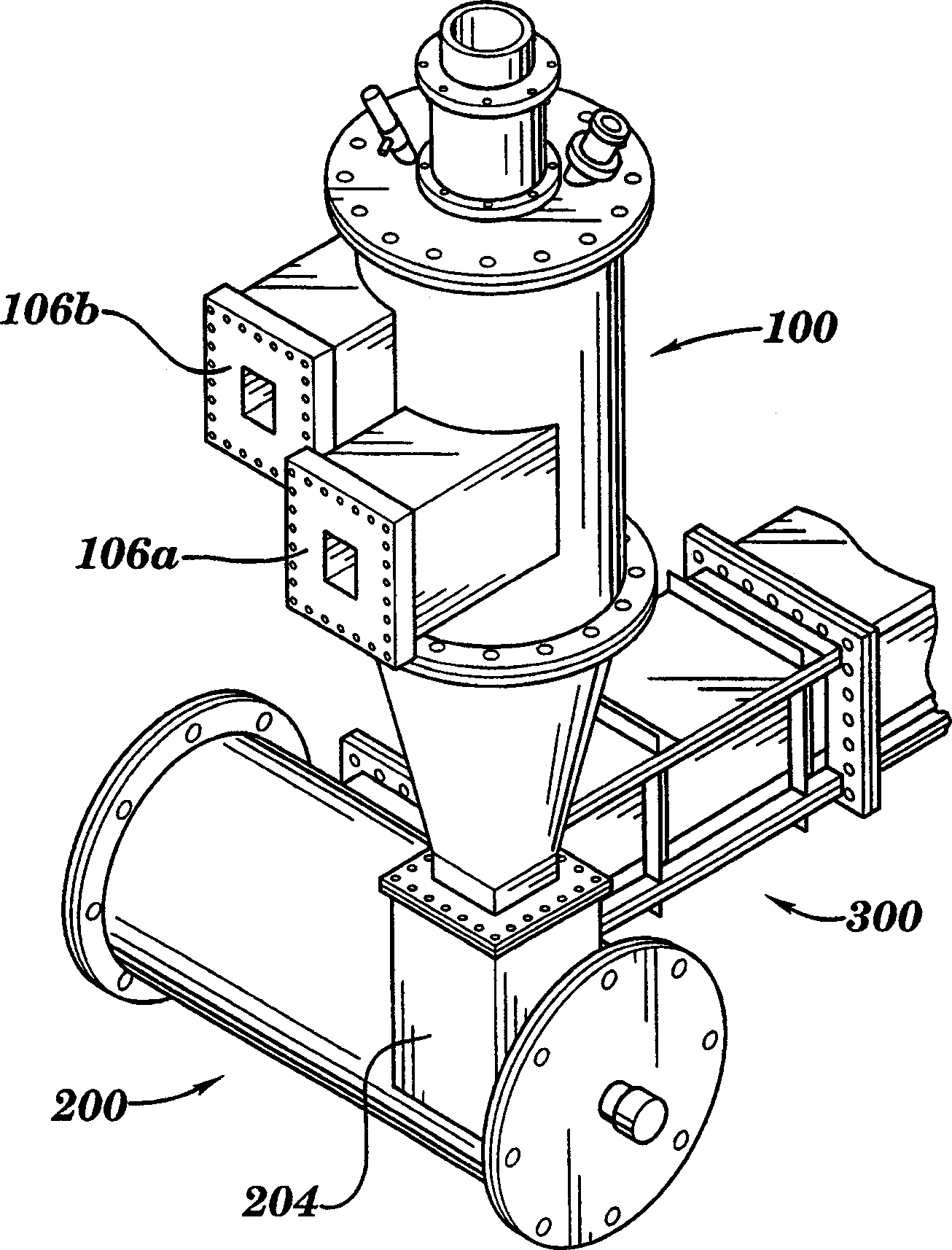

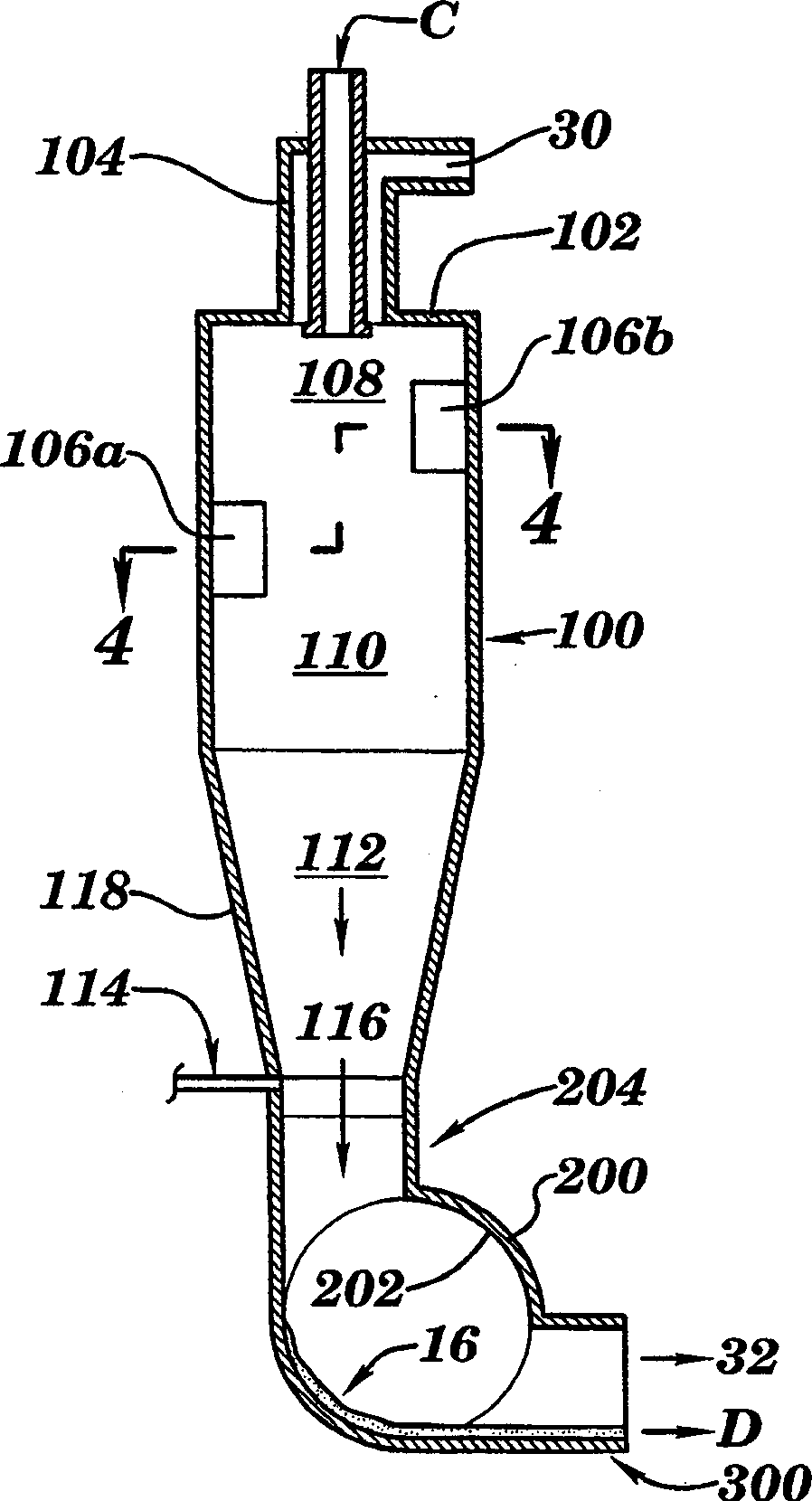

The present inveniton relates to a process of forming ceramic tiles having the appearance of tiles produced from clays. The process includes melting a material to form a glass melt, treating the glass melt to produce a solid glass product, grinding the solid glass product to produce glass particles having a particle size of less than 200 microns, mixing the glass particles with a first additive to form a glass power mixture having a composition of 55 to 99 wt.% glass particles and 45-1 wt.% first additive, forming the glass powder mixture into tiles by dry pressing, where the tiles have a primary crystalline phase selected from the group consisting of nepheline, diopside, anorthite, wollastonite, melilite, merwinite, spinel, akermanite, gehlenite, crystalline phases based on iron substitutions in the crystalline phase, and mitures thereof. The process includes a devitrifying step where the solid glass product is devitrified prior tothe grinding step or the glass particles in the tile are devitrified after the forming step.

Owner:沃特克有限公司 +1

Manufacture craft for pale yellowish green colored glaze of Ru porcelain

A manufacture craft for pale yellowish green colored glaze of Ru porcelain includes the steps of utilizing kaolin, melilite, black feldspar, white feldspar, quartz, calcite, potassium feldspar and zinc oxide as glaze raw materials, performing wet grinding with water after the green body raw materials are crushed and adjusting the moisture content of slurry into 58-60%; placing a wiped biscuit into glaze slurry for dipping; and placing the dipped biscuit into a furnace for firing in an oxidizing atmosphere and then for firing in a reduction atmosphere after the furnace temperature rises to 1058 DEG C, holding at the temperature of 1058 DEG C prior to that the temperature rises to 1245 DEG C, and holding for half an hour prior to firing off for cooling, so that the pale yellowish green colored glaze is prepared. In the technical scheme, all raw material components are firmly bonded, the body color of Ru porcelain teaware fired by the preparation method is pale yellowish green, and the Ru porcelain teaware is attractive in appearance.

Owner:姚瑞平

Copper-red glaze for Jun porcelain and preparation method of copper-red glaze

InactiveCN107586022AIncrease the amount of participationCommon technology improvementCalciteCopper oxide

The invention discloses copper-red glaze for Jun porcelain. The copper-red glaze is prepared from raw materials in parts by weight as follows: 26-34 parts of melilite, 6-10 parts of white feldspar, 10-14 parts of kaolin, 6-10 parts of talc, 22-26 parts of quartz, 10-14 parts of calcite, 0.9-1.1 parts of copper oxide, 1-3 parts of zinc oxide, 1.1-1.3 parts of silicon carbide and 1-3 parts of wood ash. The preparation method of the copper-red glaze for the Jun porcelain comprises steps as follows: (1) the raw materials are crushed, mixed and put in a ball mill for ball milling, water is added, so that the mass concentration of the glaze reaches 52%-53%, wet grinding is performed for 15-16 h, slurry obtained through wet grinding is sieved by a 200-300-mesh sieve, and glaze slurry is obtained;(2) glazing is performed in a glaze dipping manner, wherein the glazing thickness is 0.8-1.2 mm; (3) firing at the temperature of 1,260-1,300 DEG C is performed.

Owner:禹州市大龙山钧瓷文化有限公司

Lujun glaze

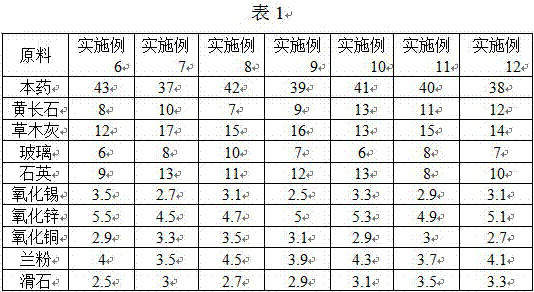

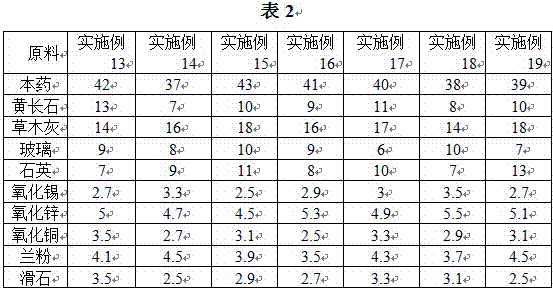

Lujun glaze is prepared from the following raw materials in parts by weight: 37 to 43 parts of original medicine, 7 to 13 parts of melilite, 12 to 18 parts of plant ash, 6 to 10 parts of glass, 7 to 13 parts of quartz, 2.5 to 3.5 parts of stannic oxide, 4.5 to 5.5 parts of zinc oxide, 2.5 to 3.5 parts of copper oxide, 3.5 to 4.5 parts of blue powder and 2.5 to 3.5 parts of talc. Compared with the prior art, the Lujun glaze has the advantages that the glaze is not liable to loss and can be controlled through scientific and reasonable raw material proportion and a control firing process; meanwhile, big kiln firing can be realized; the fired Lujun glaze has rich glaze colors and little floating light, the glaze surface is natural and not dull, gold spots occur on the surface, and the rate of the finished products can reach 60 percent or higher.

Owner:禹州市神器钧窑有限公司

Agate glaze for Ru porcelain, preparation method and application thereof of agate glaze in Ru porcelain

The invention belongs to the technical field of ceramics, and particularly discloses an agate glaze for Ru porcelain, a preparation method and an application thereof in Ru porcelain. By metering by volume percent, the agate glaze for Ru porcelain is prepared from the following components in parts by weight: 5 to 11 parts of kaolin, 4 to 8 parts of wind cave soil, 2 to 8 parts of half-slope soil, 3to 7 parts of Tang ditch soil, 10 to 20 parts of black stone, 8 to 16 parts of quartz, 1 to 3 parts of bovine bone, 0.5 to 3.0 parts of agate, 5 to 15 parts of calcite, 10 to 26 parts of melilite and2 to 8 parts of talc. According to the agate glaze for the Ru porcelain, through scientific and reasonable blending, the obtained glaze color is jade-like, bright, soft, mild, bright and smooth, theglaze is fat-piled, quiet and elegant, the color is moist, the internal quality, the appearance quality and the mechanical strength resistance of the Ru porcelain are improved, and the firing rate ofa product is greatly increased.

Owner:张斌洋

Starry sky glaze material, starry sky glaze Jun porcelain and preparation method thereof

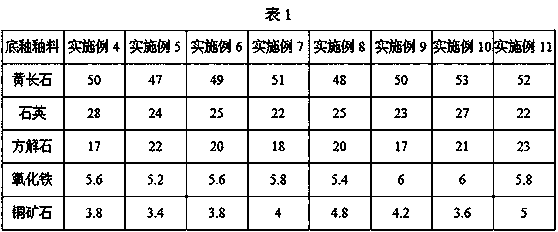

The invention discloses a starry sky glaze material. The glaze material includes a bottom glaze material and a face glaze material; the bottom glaze material consists of, by weight, 3-6 parts of kaolin, 30-40 parts of melilite, 20-24 parts of calcite, 4-6 parts of steatite, 14-18 parts of quartz, 3-5 parts of iron ore, 2-4 parts of zinc oxide, 1-2 parts of aluminum oxide, and 2-3 parts of apatite;and the face glaze material consists of, by weight, 45-55 parts of the melilite, 16-18 parts of the calcite, 10-14 parts of the quartz, 4-6 parts of copper ore, 2-4 parts of cobalt oxide, 3-5 parts of zirconium silicate, and 2-3 parts of spodumene. The prepared starry sky glaze Jun porcelain is lustrous in color, high in glossiness, exquisite and bright and high in mechanical strength, and the appearance of the Jun porcelain is the same as starry sky; and the starry sky glaze Jun porcelain is low in manufacturing cost, easy in firing, low in product scrap rate and small in energy consumption.

Owner:大宋官窑股份有限公司

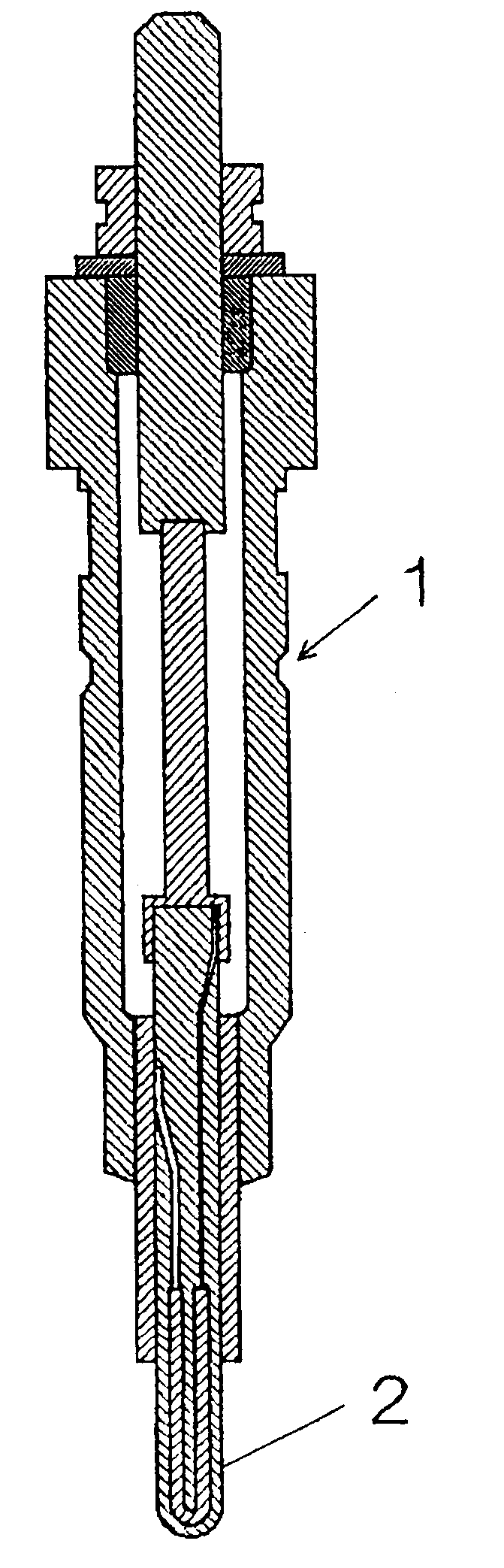

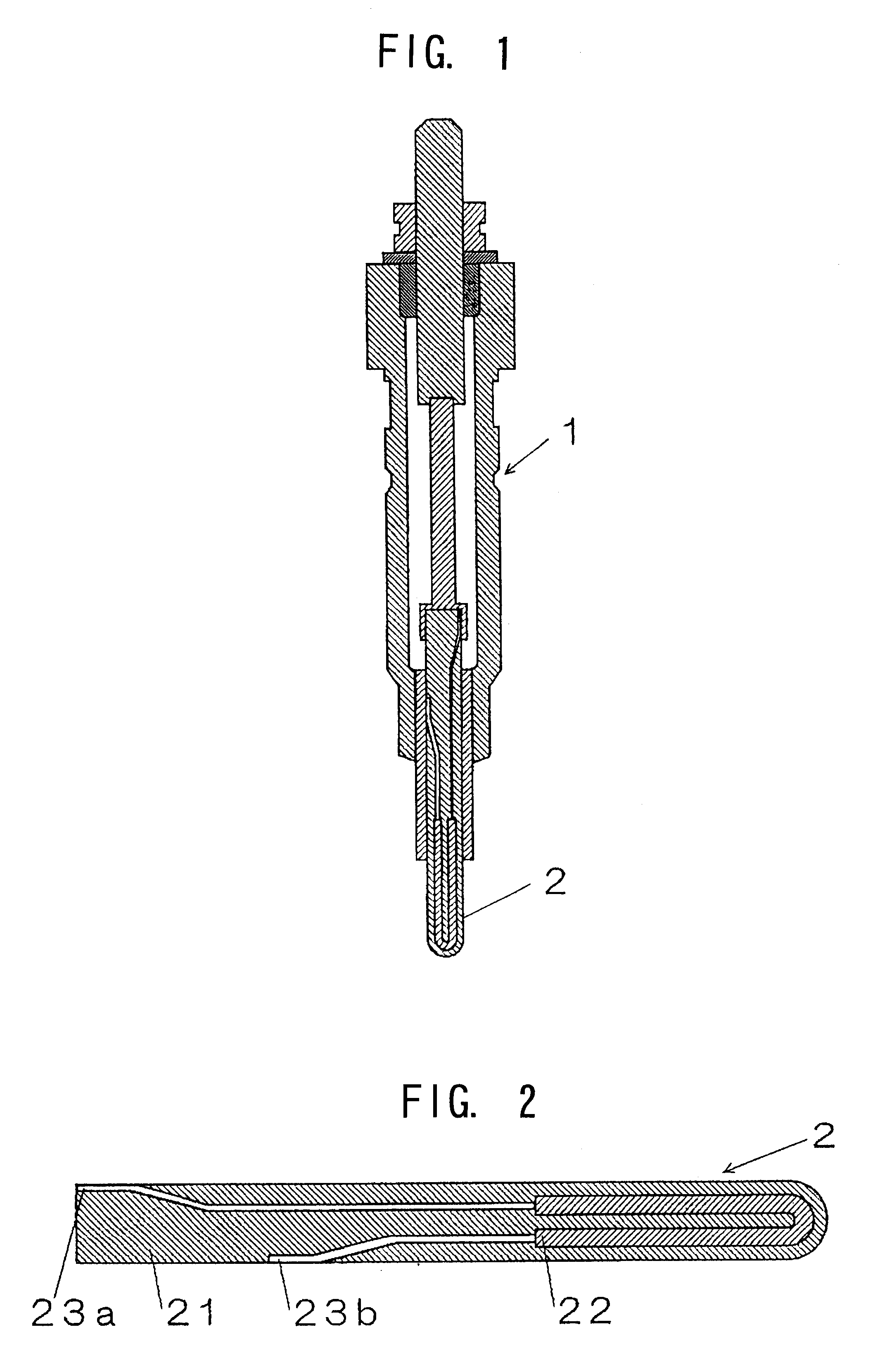

Heating resistor, heating resistor for use in ceramic heater, and ceramic heater using the same

InactiveUS6274853B1High mechanical strengthSolve the lack of durabilityIncandescent ignitionOhmic-resistance heating detailsRare-earth elementGrain boundary

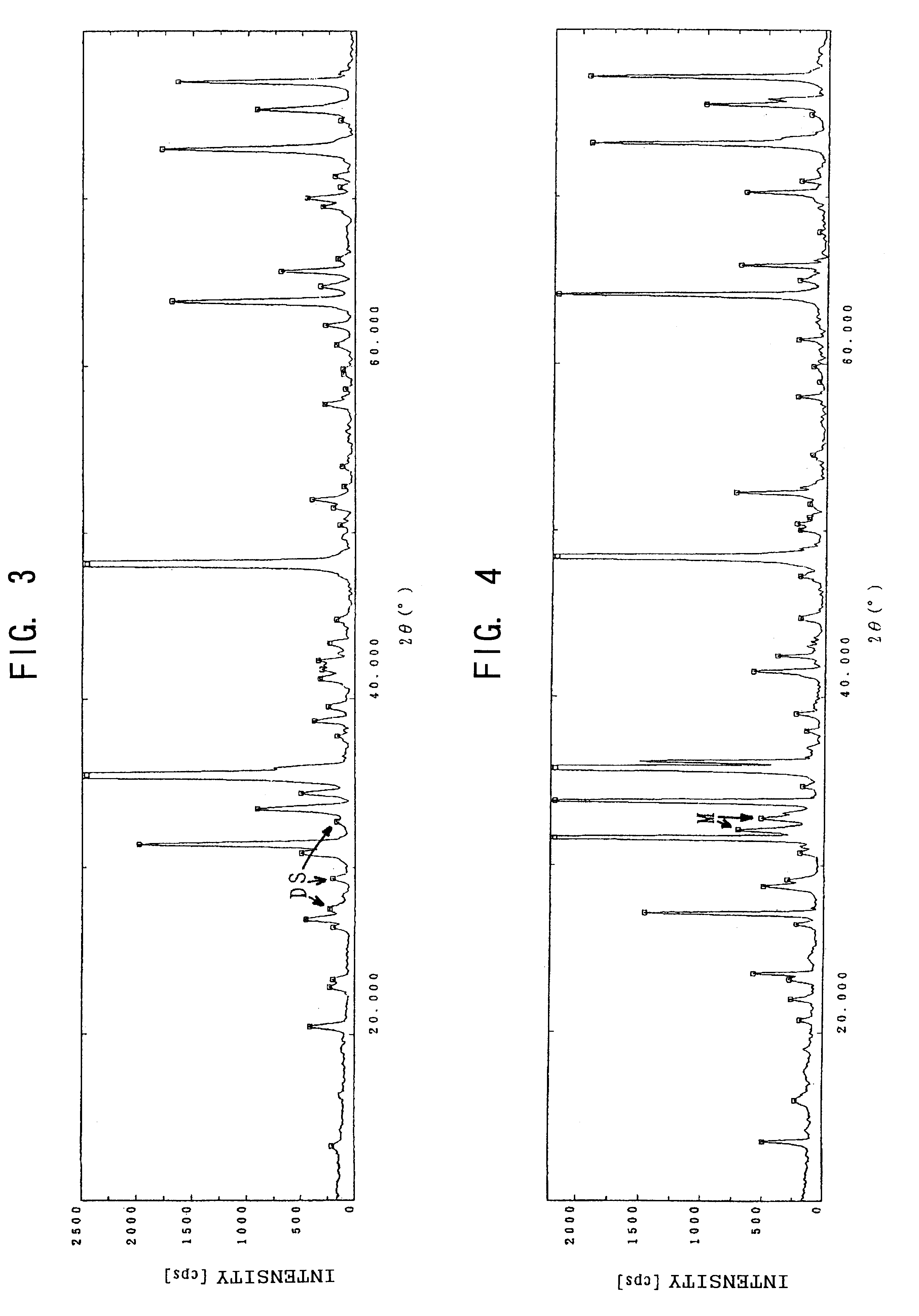

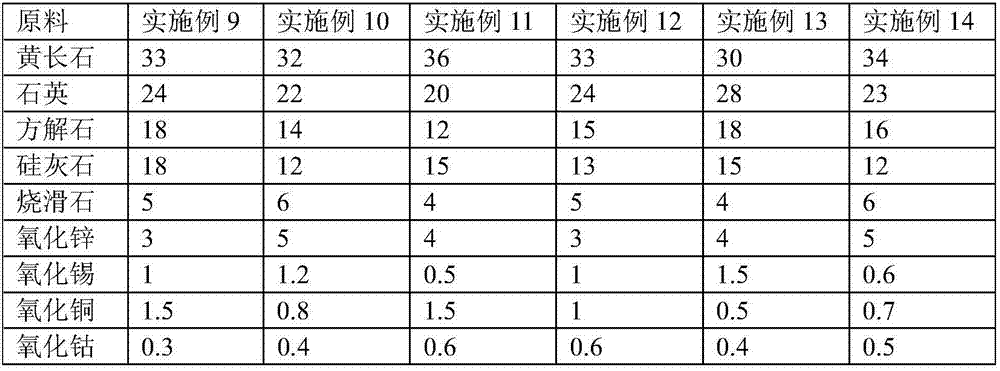

A heating resistor containing RE2O3 (where RE represents a rare earth element) in a predetermined amount. The mole ratio of residual oxygen to RE2O3, the amount of residual oxygen being expressed on an SiO2 basis and being obtained by subtracting the amount of oxygen contained in RE2O3 from the total amount of oxygen, falls within a predetermined range. A crystal phase of disilicate or melilite serves as a predominant phase of grain boundaries. The heating resistor contains a conductive component, such as WC or TiN, which contains one or more elements selected from among Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W. The heating resistor is embedded in a substrate, yielding a ceramic heater.

Owner:NGK SPARK PLUG CO LTD

High-hardness Jun porcelain sapphire glaze and preparation method thereof

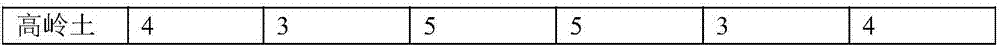

The invention discloses a high-hardness Jun porcelain sapphire glaze, which is characterized by being prepared from the following materials in parts by weight: 30 to 36 parts of melilite, 20 to 28 parts of quartz, 12 to 18 parts of calcite, 12 to 18 parts of wollastonite, 4 to 6 parts of calcined talc, 3 to 5 parts of zinc oxide, 0.5 to 1.5 parts of tin oxide, 0.5 to 1.5 parts of copper oxide, 0.3to 0.7 part of cobalt oxide and 3 to 5 parts of kaolin. A preparation method of the high-hardness Jun porcelain sapphire glaze includes the following steps: (1) after being crushed, the materials aremixed, put into a ball mill and milled, water is added, so that the mass concentration of the glaze material reaches 53 to 54 percent, wet milling is conducted for 7 to 8 hours, and wet-milled slurrypasses through a 250- to 320-mesh sieve, so that glaze slurry is obtained; (2) a green body is dipped in the glaze once or twice; (3) firing is carried out, wherein firing temperature is 1200 DEG C to 1240 DEG C.

Owner:禹州市锦丰源瓷业有限公司

Jun red glaze

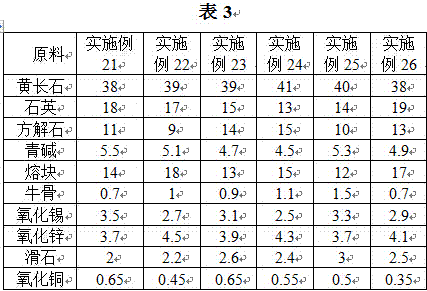

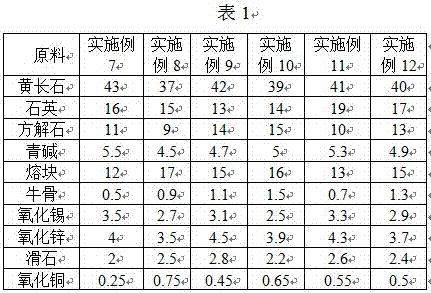

Jun red glaze is prepared from the following raw materials in parts by weight: 37 to 43 parts of melilite, 13 to 19 parts of quartz, 10 to 16 parts of calcite, 4.5 to 5.5 parts of sodium metasilicate, 12 to 18 parts of frit, 0.5 to 1.5 parts of bovine-derived power, 2.5 to 3.5 parts of stannic oxide, 3.5 to 4.5 parts of zinc oxide, 2 to 3 parts of talc, and 0.25 to 0.75 part of copper oxide. Compared with the prior art, through scientific and reasonable raw material matching and control on the firing process, the prepared jun red glaze is bright in color, good in glossiness, and moderate in flowability, and has fine cracks, the glazing colors are rich, on the basis of jun red, the colors including yellow, blue, purple and the like exist, the color transition is clear, distinct and natural, the rate of finished products is high, reaching 75% or above, the blank of no colorful graze exists in jun red glaze is filled, and a new variety is provided for jun red glaze.

Owner:禹州市神器钧窑有限公司

Green glaze and glazing process

The invention provides green glaze and a glazing process. The green glaze comprises following raw materials in parts by weight: 10 to 14 parts of quartz; 20-30 parts of melilite, 5-9 parts of modifiedtalcum, 6-8 parts of modified zinc oxide, 16-20 parts of kaolin, 5-7 parts of animal bone ash, 4-6 parts of plant ash, 11-15 parts of magnesian clay, 6-9 parts of copper ores, 12-14 parts of calcite,2-5 parts of glass powder, 1-3 parts of chromium oxide and 4-7 parts of iron ores. The prepared glazed porcelain is high in glossiness, smooth in surface and wide in market prospect.

Owner:福建省盛荣生态花卉研究院有限责任公司

High-hardness Jun porcelain copper red glaze and preparation method thereof

The invention discloses a high-hardness Jun porcelain copper red glaze, which is prepared from the following raw materials in parts by weight: 22-30 parts of feldspar, 6-10 parts of white feldspar, 6-10 parts of kaolin, and 8 parts of wollastonite ‑12 parts, talc 8‑12 parts, quartz 20‑24 parts, calcite 10‑14 parts, copper oxide 0.9‑1.1 parts, zinc oxide 1‑3 parts, silicon carbide 1.1‑1.3 parts. The preparation method of the high-hardness Jun porcelain copper red glaze includes the following steps: (1) crush the above-mentioned raw materials and put them into a ball mill for ball milling, add water to make the mass concentration of the glaze reach 54-55%, and wet mill for 14-55%. After 16 hours, the wet-grinded slurry is passed through a 200‑300 mesh sieve to obtain a glaze slurry; (2) Glaze is glazed by dipping, and the thickness of the glaze is 1mm~1.3mm; (3) Firing, the firing temperature is 1280‑1320°C .

Owner:禹州市大龙山钧瓷文化有限公司

Antique looking green glaze

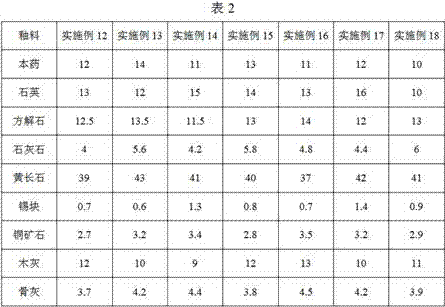

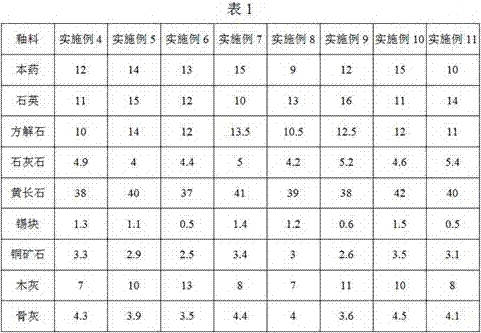

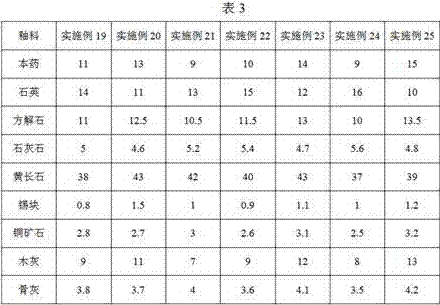

The invention provides antique looking green glaze which is prepared from the following raw materials in parts by weight: 9-15 parts of local natural feldspar from Yuzhou, He'nan, China, 10-16 parts of quartz, 10-14 parts of calcite, 4-6 parts of limestone, 37-43 parts of melilite, 0.5-1.5 parts of block bin, 2.5-3.5 parts of copper ore, 7-13 parts of wood ash and 3.5-4.5 parts of bone ash. Compared with the prior art, according to the antique looking green glaze, no chemical substance is added into the formula, and multiple color developing substances contained in the ore are adopted for developing color, so that the color development is more natural; moreover, through scientific and reasonable proportioning of the raw materials and control on the firing technology, the prepared antique looking green glaze has a jade texture, a strong opacifying property and high yield of 95% or more.

Owner:禹州市锦丰源瓷业有限公司

Ru porcelain retro glaze and production method thereof

InactiveCN108483918AThe enamel is warm and moist like jadeImprove the status quo of strong glass textureClaywaresPotassiumCalcite

The invention provides Ru porcelain retro glaze and a production method thereof. The Ru porcelain retro glaze comprises the following components as raw materials in percent by weight: 18.8% of potassium feldspar, 5% of calcite, 12% of plant ash, 13.5% of melilite, 12% of black stone, 2% of bone ash, 5.7% of golden soil, 14% of dolomite, 3% of talc, 11% of agate and 3% of kaolin. The green glaze produced by the invention is as gentle as jade, dignified and restrained in texture, and improves the current situation of a strong glass texture of a modern Ru porcelain glaze layer; through a unique glaze formula, by a retro firing method, the glazed surface shows a crystallization effect, the Ru porcelain is as gentle as jade, dignified and restrained, and a retro effect is achieved; the green glaze restores the true color of the Ru porcelain blueish green glaze and is different from the current situation of the bluish color of the existing Ru porcelain glaze in the market, and the retro effect is achieved.

Owner:刘冬青

Rainbow glaze and preparing method thereof

The invention provides rainbow glaze and a preparing method thereof. The rainbow glaze comprises bottom glaze and surface glaze. The bottom glaze is prepared from, by weight, 47-53 parts of melilite,22-28 parts of quartz, 17-23 parts of calcite, 5-7 parts of ferric oxide and 3-5 parts of copper ore. The surface glaze is prepared from, by weight, 43-49 parts of white feldspar, 11-17 parts of quartz, 10-14 parts of calcite, 5-7 parts of titanium oxide, 6-10 parts of zinc oxide, 8-12 parts of talc, 1.5-2.5 parts of tin oxide and 1.5-2.5 parts of Suzhou soil. Compared with the prior art, by scientifically and reasonably matching the raw materials and controlling the sintering process, the rainbow glaze which has seven colors of red orange yellow green cyan blue and purple, is natural and smooth in transition among color rings and is stable in color generation can be sintered on a blank.

Owner:禹州市土魂钧瓷有限公司

Emerald green glaze

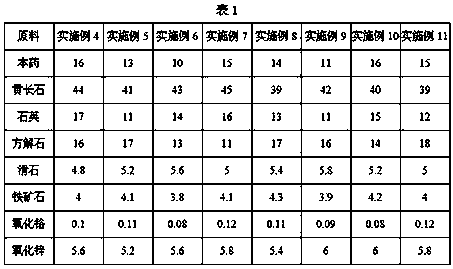

The invention provides emerald green glaze which is prepared from, by weight, 10-16 parts of primary medicines, 39-45 parts of melilite, 11-17 parts of quartz, 13-19 parts of calcite, 4-6 parts of talcum, 3.5-4.3 parts of iron ores, 0.08-0.12 part of chromium oxide and 5-7 parts of zinc oxide. Compared with the prior art, the emerald green glaze has the advantages that iron and chromium serve as coloring agents and are fired in reducing atmosphere to form the emerald green glaze, and the emerald green glaze with pure natural colors, strong jade texture and opalescence and high yield can be prepared by firing without removing iron in raw materials.

Owner:禹州市土魂钧瓷有限公司

Golden-spot blue glaze

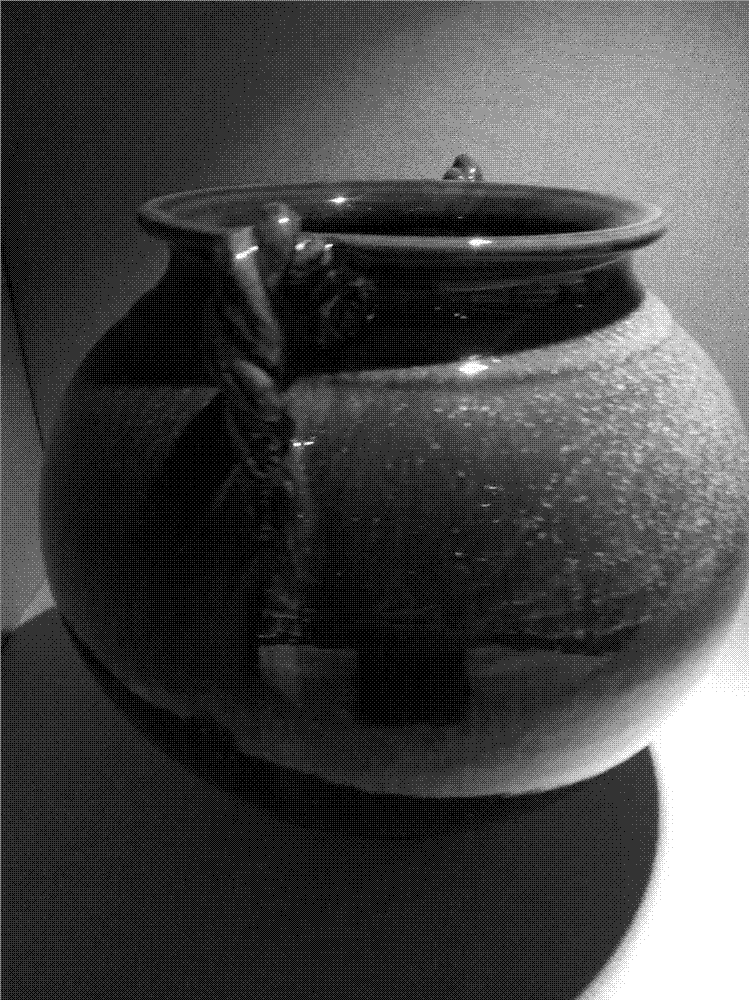

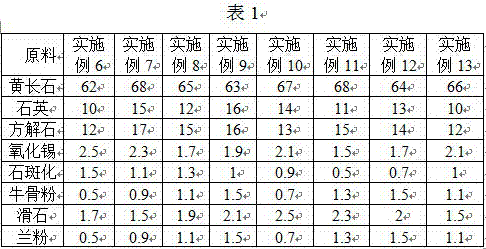

Golden-spot blue glaze is prepared from the following raw materials in parts by weight: 62 to 68 parts of melilite, 10 to 16 parts of quartz, 12 to 18 parts of calcite, 1.5 to 2.5 parts of stannic oxide, 0.5 to 1.5 parts of banhuashi (a kind of lean iron ore), 0.5 to 1.5 parts of bovine-derived power, 1.5 to 2.5 parts of talc and 0.5 to 1.5 parts of blue powder. Compared with the prior art, through scientific and reasonable raw material ratio and control on firing technique, the blue glaze with golden spots is prepared, the blank that the blue glaze has no golden spots is filled, and a new variety is provided for blue glaze jun porcelain; in addition, the golden-spot blue glaze prepared according to the invention is gorgeous, bright and smooth, the glaze surface has no pores and glaze missing, the firing temperature is convenient to control, and the rate of finished products is high, reaching 90% or above.

Owner:禹州市神器钧窑有限公司

Furnace Jun glaze and preparation method thereof

The invention provides furnace Jun glaze and a preparation method thereof. The furnace Jun glaze is prepared from, by weight, 42-48 parts of melilite, 7-13 parts of calcite, 7-13 parts of quartz, 4-6parts of copper ore, 0.5-1.5 parts of tin oxide, 4-6 parts of zinc oxide, 0.5-1.5 parts of Suzhou clay, 6-10 parts of plant ash and 12-18 parts of frit. Compared with the prior art, the furnace Jun glaze and the preparation method thereof have advantages that by a scientific and reasonable material ratio and control of a calcining process, the produced furnace Jun glaze is in seven colors including red, orange, yellow, green, indigo, blue and purple, rich in furnace transmutation, colorful and natural instead of rigid in glaze surface and has gold spots, red spots, black spots and green spots.

Owner:禹州市土魂钧瓷有限公司

Ceramic glaze with self-cleaning function

The invention relates to a ceramic glaze with a self-cleaning function. The ceramic glaze is prepared from melilite, white glass, boric acid powder, calcite, knar clay, glaze paste, green glass, tin crystal material, and copper barium silicate. The ceramic glaze with the self-cleaning function is good in water resistance and weather resistance, can resist the bacteria continuously for a long time,can also decompose volatile organic matters, and is high in self-cleaning capacity; the ceramic glaze is suitable for sanitary ceramics of construction, can also be applied to the surface of a product such as concrete boards, plastic boards, gypsum boards, paint, plastics, textiles and the like, and is wide in application range and good in popularization value; and the ceramic glaze is simple inpreparation process, stable in performance and low in preparation cost.

Owner:NANNING SHENGRUN TECH

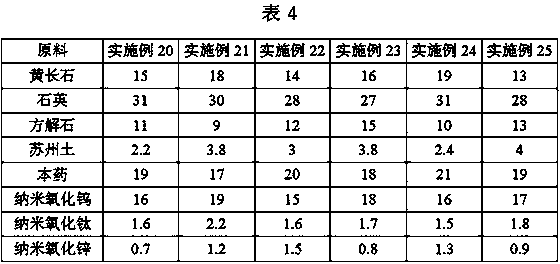

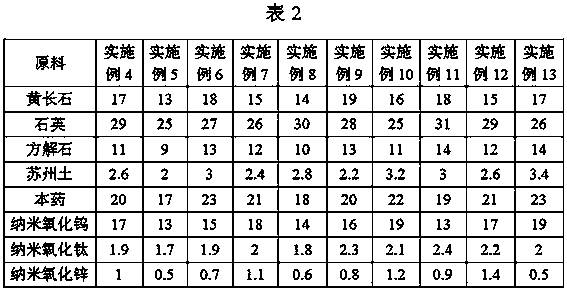

Photochromic Jun glaze and preparation method thereof

The invention provides photochromic Jun glaze and a preparation method thereof. The photochromic Jun glaze is prepared from raw materials in parts by weight as follows: 13-19 parts of melilite, 25-31parts of quartz, 9-15 parts of calcite, 2-4 parts of Suzhou clay, 17-23 parts of glarizonae, 13-19 parts of nano-tungsten oxide, 1.5-2.5 parts of nano-titanium oxide and 0.5-1.5 parts of nano-zinc oxide. The photochromic Jun glaze has the photochromic function, fewer air holes are formed in the glaze surface, the phenomenon of sagging is eliminated, the jade texture is great, and rate of finishedproducts is high.

Owner:张丹丹

Copper-red glaze and preparation method thereof

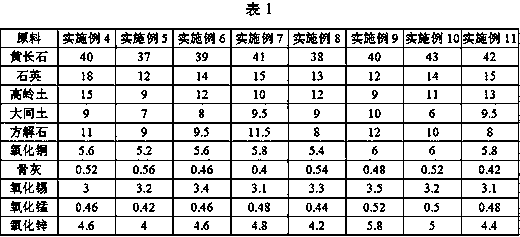

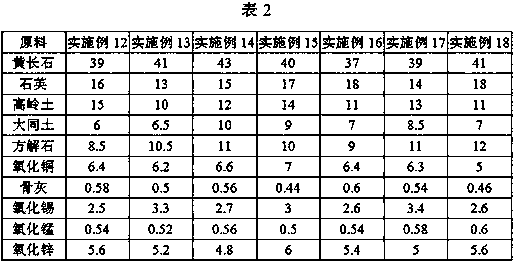

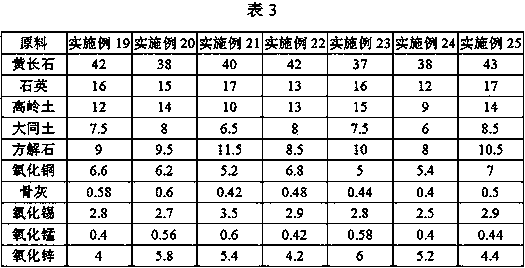

The invention provides copper-red glaze. The copper-red glaze is prepared from the following raw materials in parts by weight: 37 to 43 parts of melilite, 12 to 18 parts of quartz, 9 to 15 parts of kaolin, 6 to 10 parts of Datong soil, 8 to 12 parts of calcite, 5 to 7 parts of copper oxide, 0.4 to 0.6 part of bone ash, 2.5 to 3.5 parts of tin oxide, 0.4 to 0.6 part of manganese oxide and 4 to 6 parts of zinc oxide. According to the copper-red glaze and a preparation method thereof, the copper-red glaze, which has a deep, stable, thick and bright color, a strong jade texture and good glossiness, can be fired through strictly controlling a sintering atmosphere and the content of each raw material in a glaze material.

Owner:禹州市土魂钧瓷有限公司

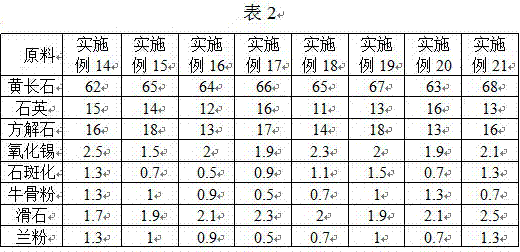

Ru-porcelain ru red glaze and preparation method therefor

The invention discloses a ru-porcelain ru red glaze and a preparation method therefor. The ru-porcelain ru red glaze is prepared from the following glaze raw materials in part by weight: 15 to 16 parts of white feldspar, 26 to 28 parts of melilite, 12 to 15 parts of calcite, 8 to 10 parts of quartz stone, 29 to 31 parts of potassium feldspar, 0.3 to 0.7 part of plant ash, 1.0 to 1.5 parts of bone meal and 0.5 to 1.0 part of talcum powder. According to the ru-porcelain ru red glaze and the preparation method therefor disclosed by the invention, the potassium feldspar containing a great deal of iron element is used in a formula, so that the iron element serves as a color developing agent to present red, namely a ru red glaze color referred to in the invention, in the firing process of the oxidizing atmosphere of a biscuit in the early stage; and the ru red glaze color is the color of an intermediate temperate transmutation glaze, the types of ru porcelain glaze colors are increased, and fired ru porcelain is bright in glaze color, moist and soft in glaze surface, pure like jade and attractive in appearance and practical.

Owner:姚瑞平

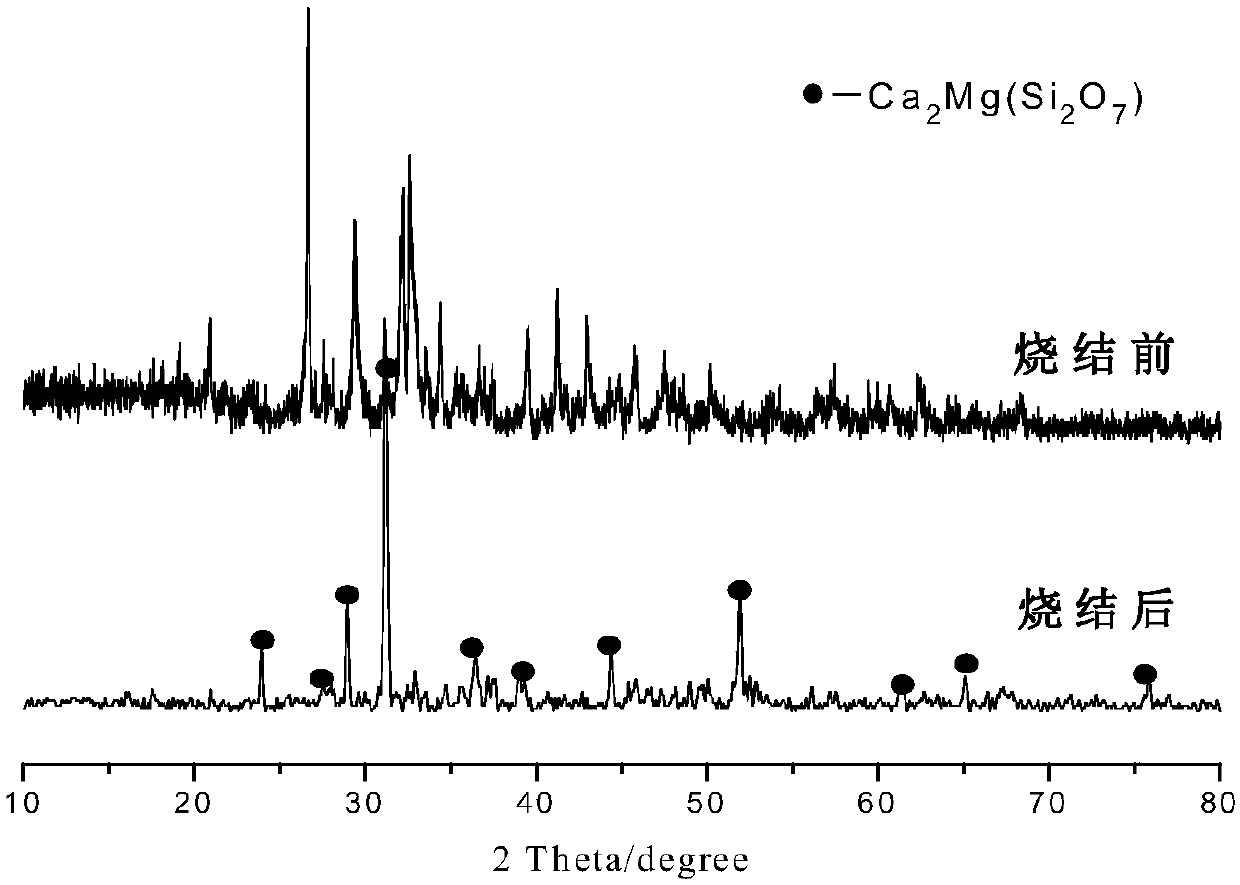

Method for preparing melilite phase-containing porous material by using magnesium residue, fly ash and carbide slag

ActiveCN107628819ARaise the ratioReduce complexityCeramic materials productionCeramicwareLand resourcesSlag

In the prior art, magnesium residue, fly ash, carbide slag and other industrial solid waste have high emission, occupying a large amount of land resources, and easily form dust so as to cause air andwater pollution. According to the present invention, a melilite phase-containing porous material is prepared through high temperature sintering by doping magnesium residue, fly ash and carbide slag, such that the waste can be treated with the waste, the prepared porous material can be used in the fields of sound insulation, thermal insulation, filtration and the like, and the industrial solid waste reutilization field is expanded.

Owner:BEIFANG UNIV OF NATITIES

Jun porcelain reddish black glaze

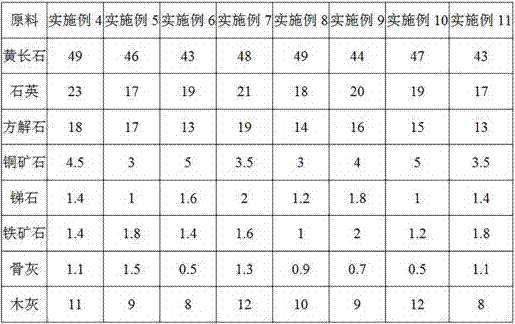

The invention provides a celadon glaze for Jun porcelain, which is prepared from the following raw materials in parts by weight: 43-49 parts of melamine feldspar, 17-23 parts of quartz, 13-19 parts of calcite, 3-5 parts of copper ore, antimonite 1‑2 parts, 1‑2 parts of iron ore, 0.5‑1.5 parts of bone ashes, 8‑12 parts of wood ash. Compared with the prior art, the present invention does not add any chemical substances in the formula, uses various color-forming substances contained in the ore to develop color, making the color more natural, and through scientific and reasonable raw material ratio and controlled firing process , the prepared Jun porcelain celadon glazed jade has strong texture and opacity, and the yield is high, which can reach more than 95%.

Owner:禹州市大龙山钧瓷文化有限公司

Method for high-temperature firing of underglaze color crackle ceramic

The invention discloses a method for high-temperature firing of underglaze color crackle ceramic. The method comprises steps as follows: 92-95 parts of zirconia, 1-3 parts of silicon oxide, 1-2 parts of feldspar, 0.5-1.5 parts of kaolin, 1.5-2.5 parts of zirconium silicate and 0.5-5 parts of a fluorine-containing additive are weighed out for ball milling and then mixed with an inorganic nano-particle dispersion liquid, and a ceramic clay body is prepared; 30-35 parts of feldspar powder, 5-10 parts of calcium magnesium powder, 3-8 parts of melilite, 5-10 parts of calcite, 3-8 parts of dolomite, 5-10 parts of kaolin, 20-25 parts of silicon oxide, 5-10 parts of zinc oxide, 3-6 parts of calcium carbonate, 3-6 parts of a heat-resistant agent and 5-15 parts of water are weighed out for ball milling, and then transparent feldspar glaze slurry is prepared; the obtained ceramic clay body is placed in the slurry for soaking and placed in a kiln for firing after being dried. The prepared finished product has the concave-and-convex stereoscopic crackle effect and the good shock resistance and heat stability.

Owner:PINGDINGSHAN UNIVERSITY

Firework display pattern glaze and preparation method thereof

The invention provides firework display pattern glaze and a preparation method thereof. The firework display pattern glaze is prepared from the following raw materials in parts by weight: 30-40 partsof melilite, 12-15 parts of chesterlite, 8-10 parts of calcite, 7-8 parts of quartz, 20-30 parts of frits, 5-8 parts of copper ores, 6-10 parts of zinc oxide and 1-4 parts of copper oxide. According to the firework display pattern glaze and the preparation method thereof, through the regulation and the control of the content of the frits in the glaze and the atmosphere in the firing process, and in combination with the other glaze materials, the fired firework display pattern glaze is high in fluidity, a glaze surface can show high-density spots in the firework state in the flowing process, and no defects such as glaze flowing, smoking and cracking exist.

Owner:禹州市土魂钧瓷有限公司

Fancy glaze and preparing method thereof

The invention relates to a fancy glaze and a preparing method thereof. The fancy glaze comprises 45% of melilite, 10% of white feldspar, 12% of calcite, 9% of quartz, 15% of frit, 1.5% of zinc oxide, 7% of copper ore and 0.5% of blue powder. The preparing method of the fancy glaze includes the following steps that the raw materials are added into a crusher and crushed, the crushed raw materials are sieved through a 150-mesh sieve to obtain mixed powder, and then mixed powder is put into a glaze pool to be ready for use; the blue powder and the copper ore are added into traditional raw materials, and under the matching effect of other chemical raw materials and natural raw materials and the high-temperature melting effect, the unique artistic effect of flowering-shape variation is generated, a fired finished product is in a flowering shape, and the quite good social benefits and the quite good economic benefits are achieved.

Owner:高根长

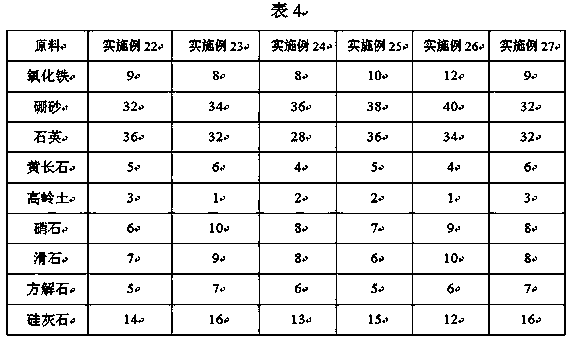

Jun porcelain iron sand gold glaze and preparation method thereof

The invention discloses jun porcelain iron sand gold glaze. The jun porcelain iron sand gold glaze is prepared from, by weight, 8-12 parts of ferric oxide, 32-40 parts of borax, 28-36 parts of quartz,4-6 parts of melilite, 1-3 parts of kaolin, 6-10 parts of kaolin, 6-10 parts of talc, 5-7 parts of calcite and 12-16 parts of wollastonite. The invention also provides a formula and a preparation method of the jun porcelain iron sand gold glaze. The stable sand gold glaze can be fired by adopting reasonable proportion and the preparation method. The firing temperature range of the sand gold glazeis wide, crystal patterns are obvious and are evenly distributed, no sagging phenomenon is produced, the jun porcelain iron sand gold glaze has high glossiness, smooth glaze surface, few cracks and strong replicability, the rate of finished products is 78% or above, the manufacturing cost can be reduced, and the glaze has active economic benefit.

Owner:张丹丹

Jun porcelain black diamond glaze and preparation method thereof

The invention discloses Jun porcelain black diamond glaze. The Jun porcelain black diamond glaze is prepared from the following raw materials in parts by weight: 23-35 parts of melilite, 26-30 parts of quartz, 4-8 parts of alkali stone, 4-5 parts of talc, 15-18 parts of spotted stone, 14-20 parts of calcite, 6-10 parts of zirconite and 8-12 parts of wollastonite. A preparation method of the Jun porcelain black diamond glaze comprises the following steps: (1) crushing the raw materials, carrying out mixing and ball milling, adding water until the mass concentration of glaze reaches 55%-56%, carrying out wet grinding for 8-10 hours, and sieving the wet-ground slurry by virtue of a 200-300-mesh sieve, so as to obtain glaze slurry; (2) dipping a blank into glaze for 2-3 times; (3) sintering at1280-1320 DEG C. By virtue of the reasonable ratio and the preparation method, the stable black diamond glaze can be prepared by sintering, is high in glossiness and strong in replicability and has positive economic benefits, the glaze surface is smooth, cracks are few, and the rate of finished products is 80% or above.

Owner:禹州市土魂钧瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com