Manufacture of ceramic tiles from industrial waste

A technology of bricks and tiles, ceramics, applied in applications, household appliances, other household appliances, etc., can solve the problems of unsuitable and insufficient organic materials and metallurgical pollutants, ceramic materials, economic rationality, etc., to achieve low cost, High value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

[0095] Glass frits are prepared from fly ash from coal-fired boilers, which are then processed into glass suitable for the production of brick bodies. The glass undergoes a devitrification process before it is ground into granular material and mixed with additives to form a powder for pressing tiles. The tiles are pressed and fired using standard industrial tile presses and roller kilns. The resulting tile body has machinability and final properties desired by the commercial tile industry.

[0096] The fly ash composition of the coal-fired boilers is given in Table 5.

[0097] Oxide

weight%

SiO 2

51.8

al 2 o 3

25.6

MgO

0.80

CaO

1.74

Na 2 o

0.40

K 2 o

2.68

Fe 2 o 3

10.3

C

6.18

[0098] Based on this analysis, a flux needs to be added to the fly ash to lower its melting temperature below 1500°C, and the fly ash is mixed ...

Embodiment 2

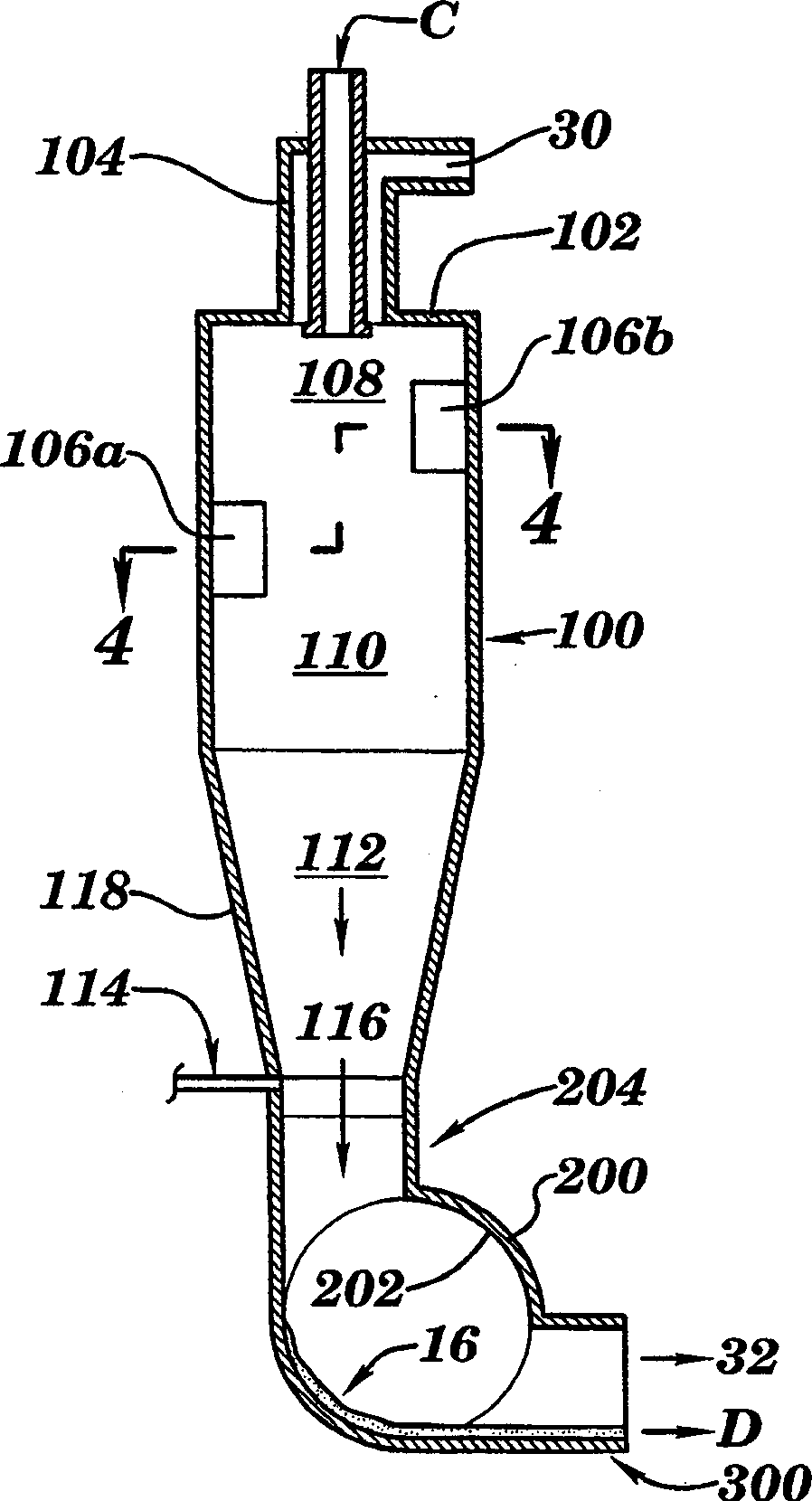

[0109] The glass is prepared from ashes from municipal waste incinerators ("MSW"), which are then processed into glass suitable for the production of adobe tiles. The glass used in this example was not devitrified before the tile was formed. Press bricks and tiles and fire with conventional bricks and tiles industrial equipment. The resulting tile body has machinability and final properties desired by the commercial tile industry.

[0110] The composition of the MSW ashes used in the vitrification process is given in Table 7.

[0111] Oxide

weight%

SiO 2

35.0

Al 2 o 3

9.68

MgO

5.25

CaO

18.8

Na 2 o

3.67

K 2 o

1.55

Fe 2 o 3

6.41

[0112] In order to make glasses from the composition, no glass-forming additives are required. The MSW ashes were melted in a cyclone-type glass melting furnace. The oxidizing atmosphere of this glass furnace i...

Embodiment 3

[0123] Glass was prepared from spent electrolyzers reduced by aluminum to produce dense ceramic bodies. The glass used in this example was not subjected to a devitrification process prior to tile formation. Samples are prepared on a test scale. The glass in the press body appeared to be completely devitrified during firing without deformation of the green body. The resulting ceramic body has properties required for use in the brick and tile industry.

[0124] Aluminum reduction spent pots ("SPL") consisted of a mixture of graphite blocks and refractory materials. Refractory bricks mainly include SiO 2 、Al 2 o 3 and CaO. In addition to carbon, graphite blocks also contain residual cryolite (Na 3 AlF 6 ), cyanides and metal aluminates. Typical oxide compositions for graphite block and refractory brick mixes are given in Table 9.

[0125] Oxide

weight%

SiO 2

16.5

Al 2 o 3

22.8

CaO

2.57

Na 2 o

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of rupture | aaaaa | aaaaa |

| Modulus of rupture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com