Patents

Literature

308 results about "Zirconium(IV) silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium silicate, also zirconium orthosilicate, ZrSiO₄, is a chemical compound, a silicate of zirconium. It occurs in nature as zircon, a silicate mineral. Powdered zirconium silicate is also known as zircon flour.

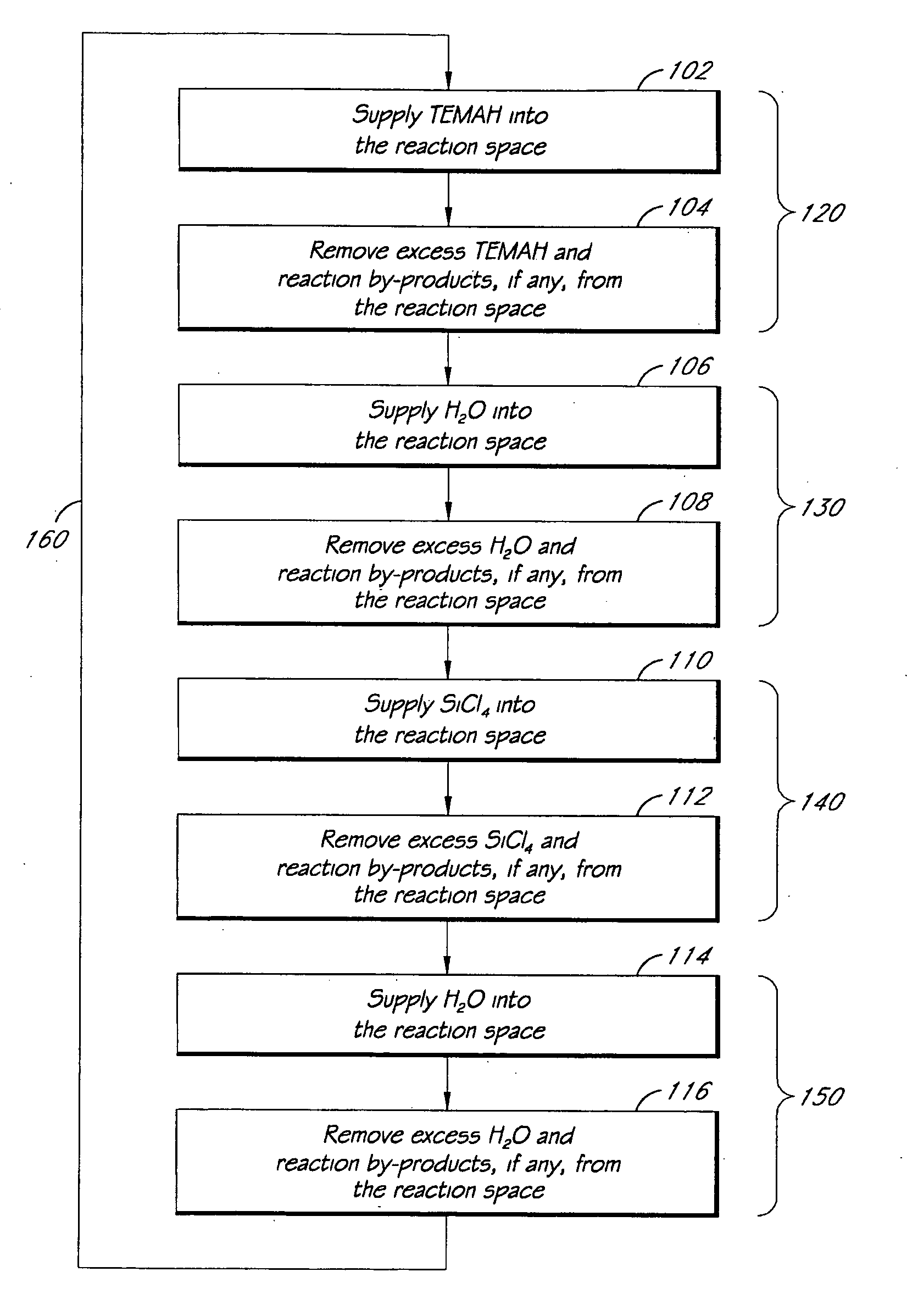

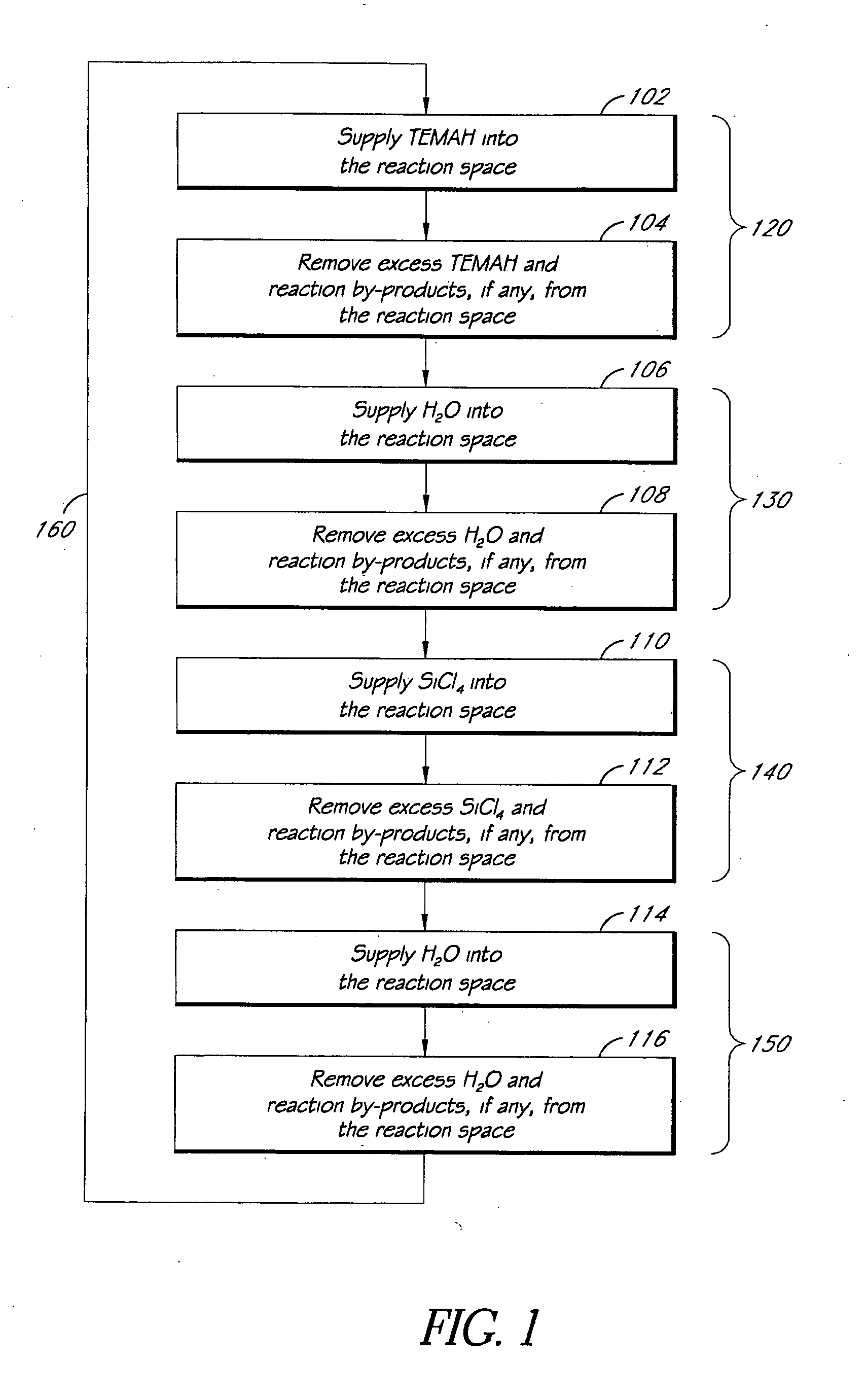

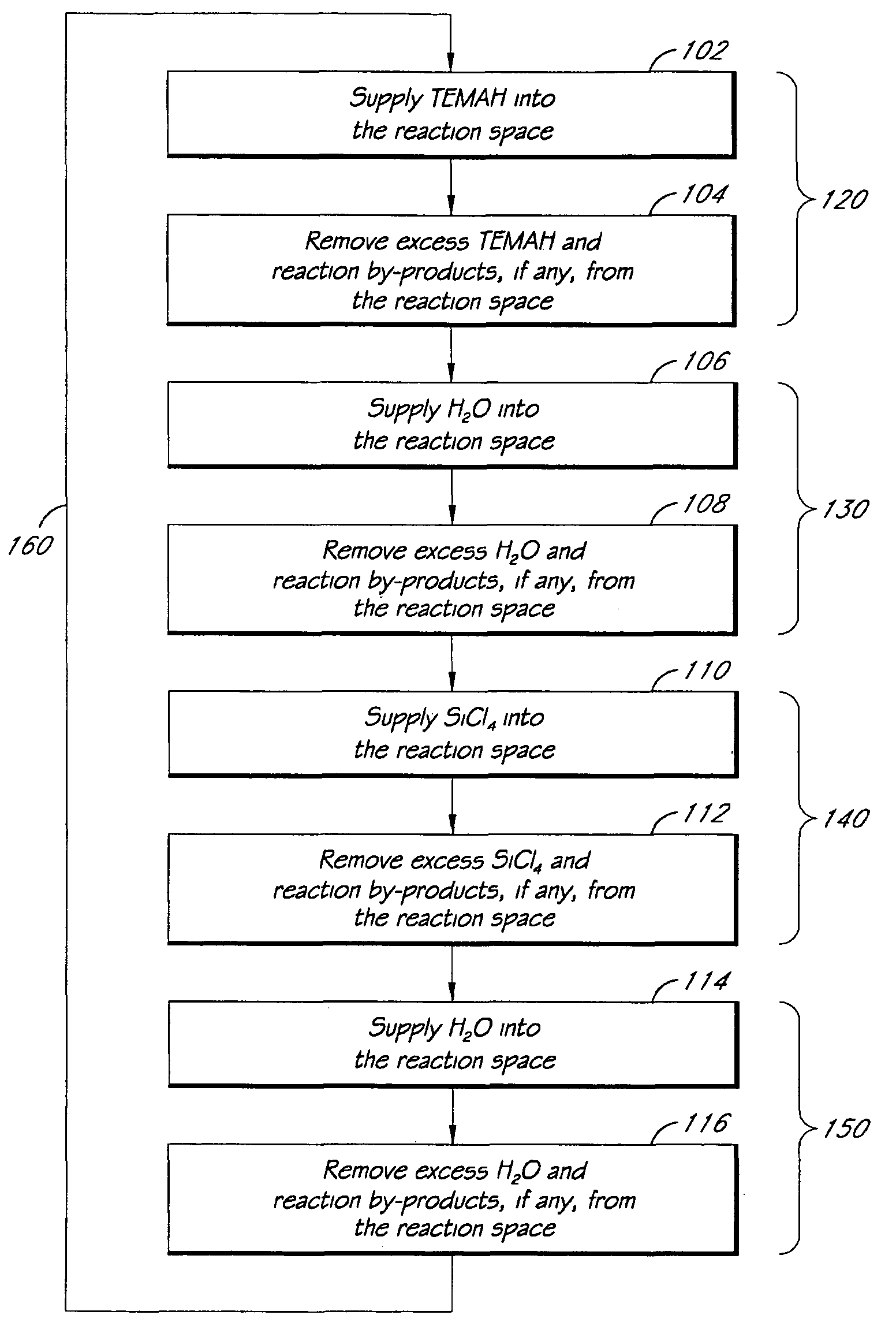

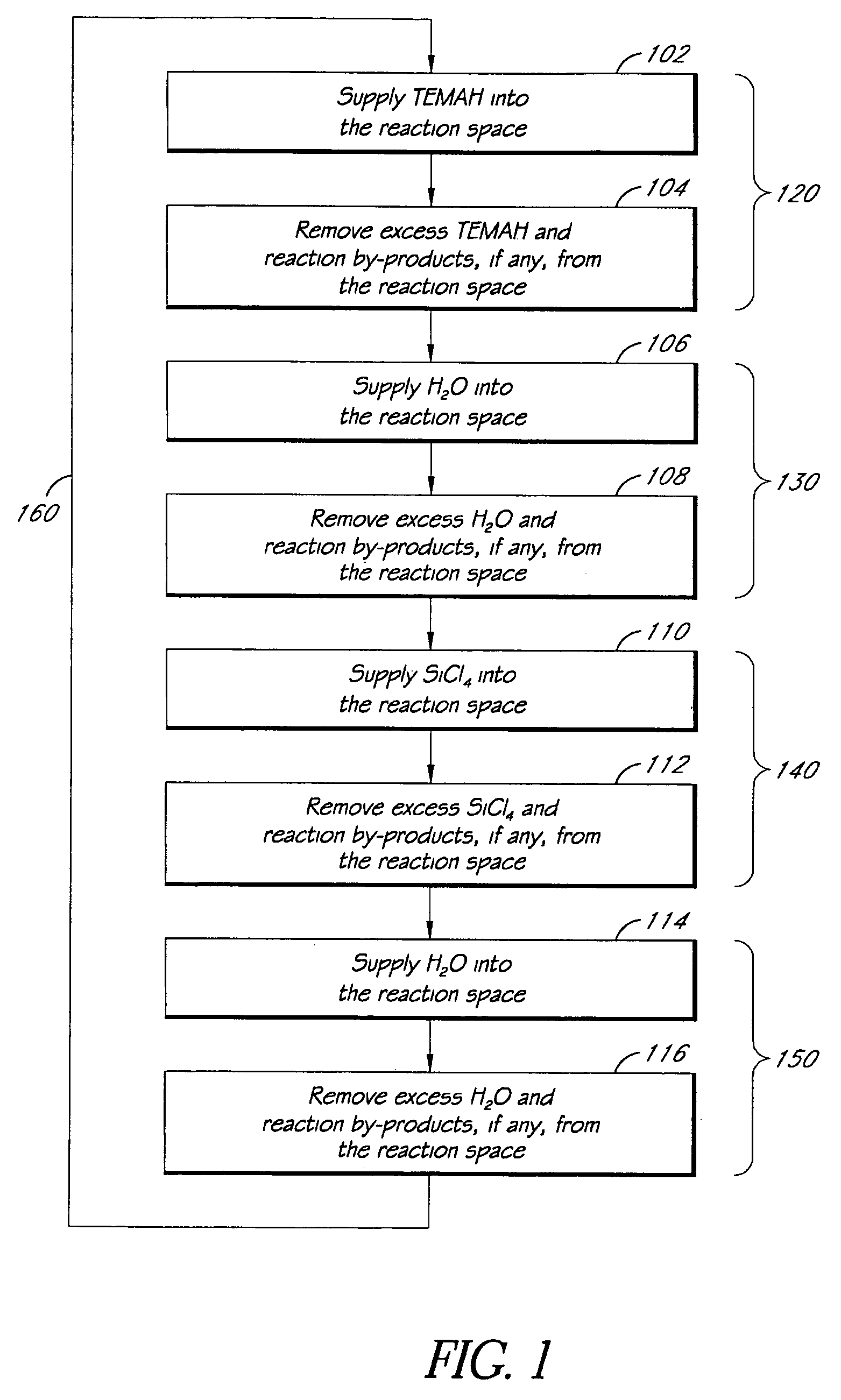

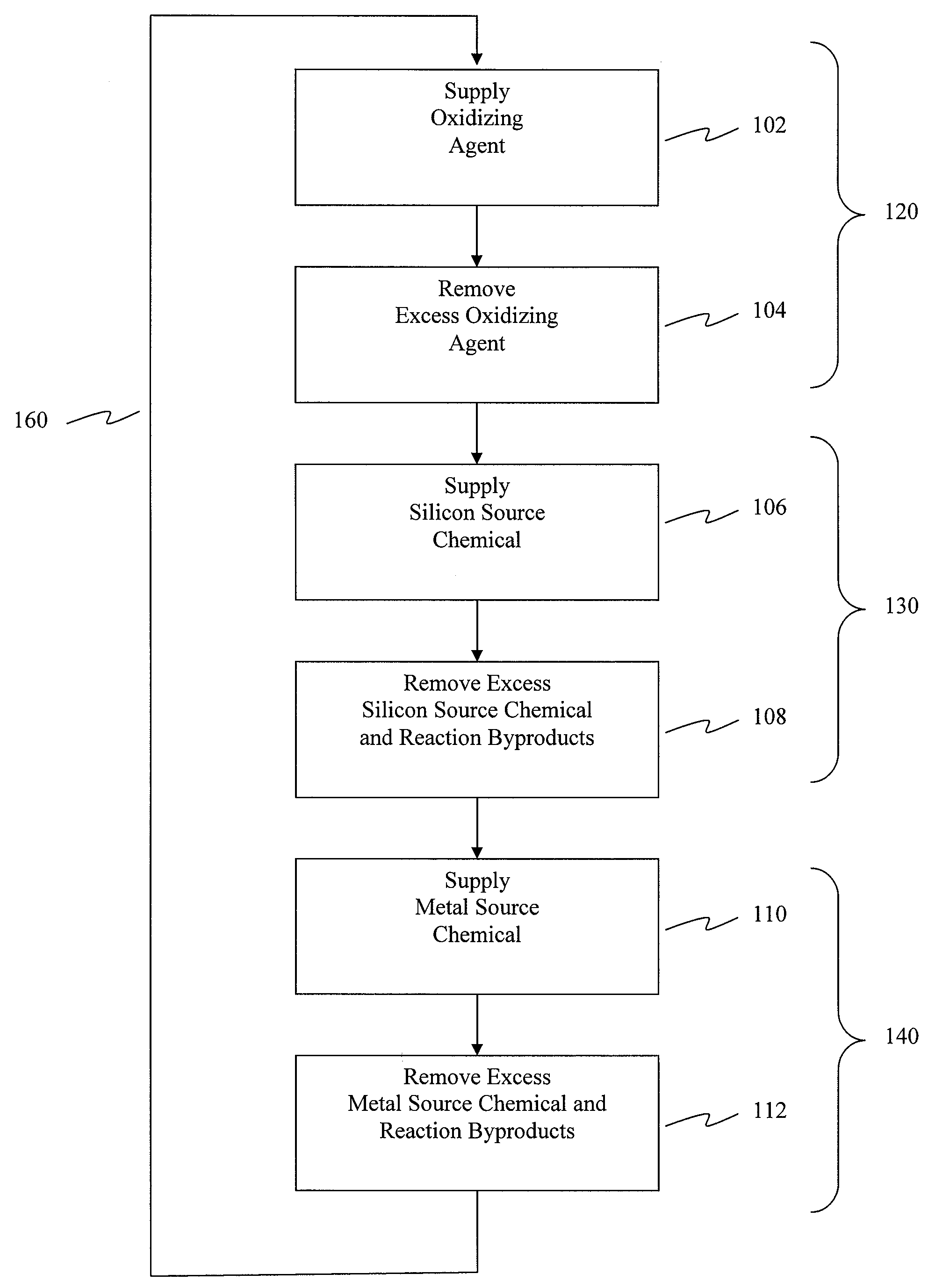

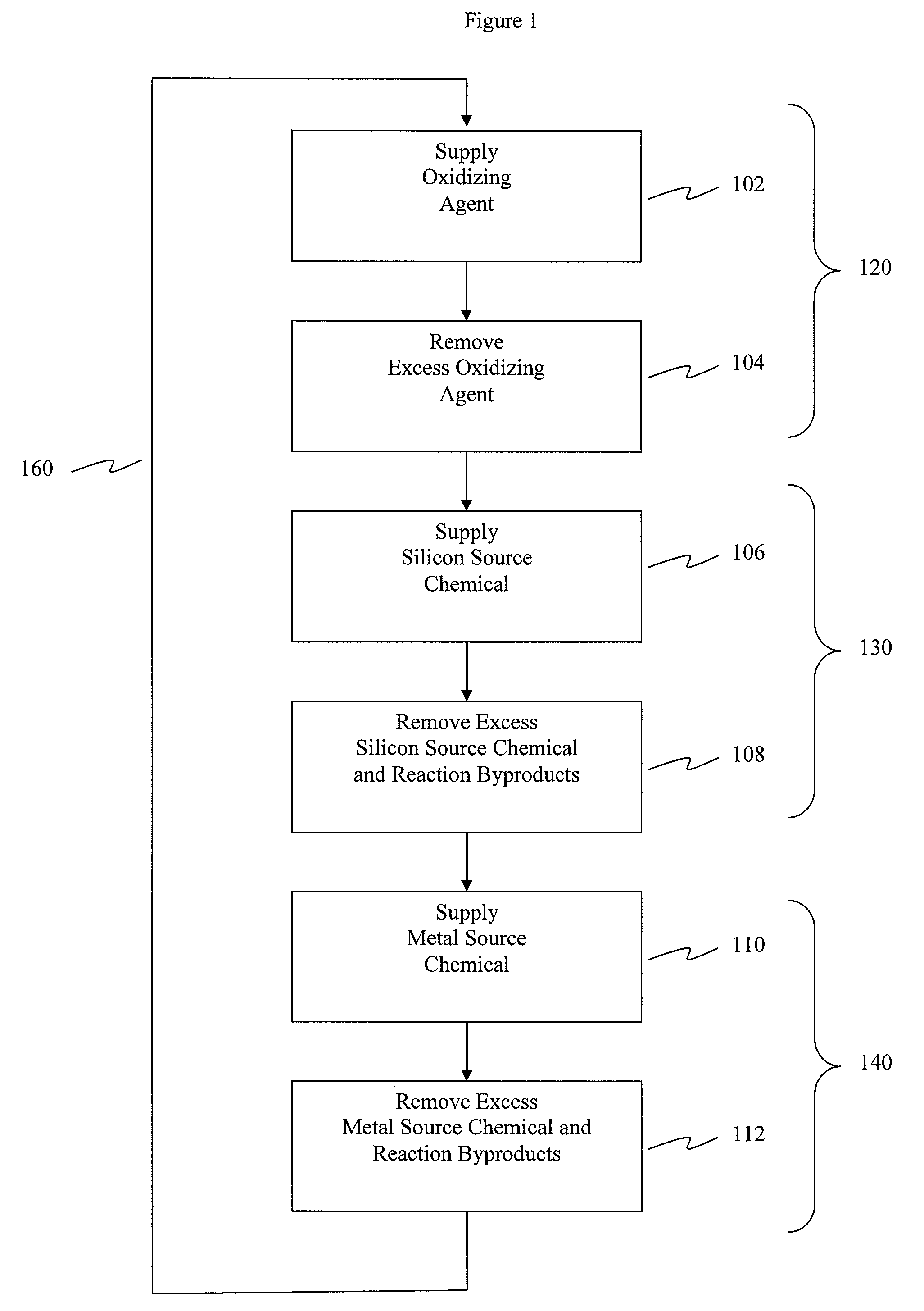

ALD of metal silicate films

ActiveUS20080020593A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHafnium

Methods for forming metal silicate films are provided. The methods comprise contacting a substrate with alternating and sequential vapor phase pulses of a metal source chemical, a silicon source chemical and an oxidizing agent. In preferred embodiments, an alkyl amide metal compound and a silicon halide compound are used. Methods according to preferred embodiments can be used to form hafnium silicate and zirconium silicate films with substantially uniform film coverages on substrate surfaces comprising high aspect ratio features (e.g., vias and / or trenches).

Owner:ASM IP HLDG BV

ALD of metal silicate films

ActiveUS7795160B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHafnium

Owner:ASM IP HLDG BV

Ald of metal silicate films

ActiveUS20080085610A1Semiconductor/solid-state device manufacturingSilicon compoundsGas phaseHafnium

Methods for forming metal silicate films are provided. The methods comprise contacting a substrate with alternating and sequential vapor phase pulses of a silicon source chemical, metal source chemical, and an oxidizing agent, wherein the metal source chemical is the next reactant provided after the silicon source chemical. Methods according to some embodiments can be used to form silicon-rich hafnium silicate and zirconium silicate films with substantially uniform film coverages on substrate surface.

Owner:ASM IP HLDG BV

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

Granular double-layer reaction glaze and preparation method

The invention belongs to the technical field of ceramic glazes and particularly relates to a granular double-layer reaction glaze and a preparation method. The granular double-layer reaction glaze comprises the following ingredients in parts by weight: a ground glaze: 30-40 parts of soda feldspar, 5-15 parts of quartz, 5-15 parts of wollastonite, 2-6 parts of calcined alumina, 25-35 parts of kaolin and 15-25 parts of toner; and an overglaze: 35-45 parts of high-boron clinker, 15-25 parts of quartz, 5-10 parts of wollastonite, 5-15 parts of spodumene, 10-20 parts of calcined zinc oxide, 5-15 parts of kaolin, 5-10 parts of calcined talcum, 5-10 parts of titanium dioxide powder and 5-15 parts of zirconium silicate. The granular double-layer reaction glaze is short in firing time and has relatively high thermal shock resistance and glazed surface hardness.

Owner:HUNAN HUALIAN CHINA IND

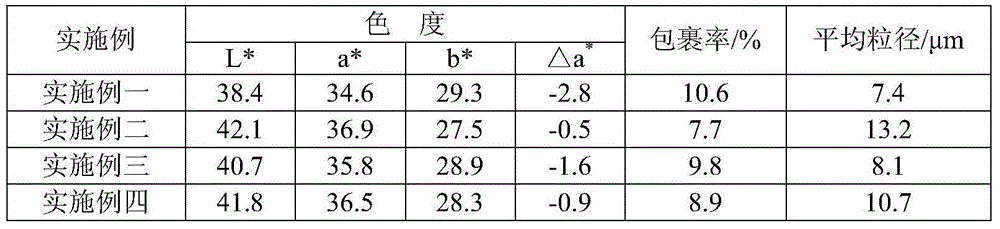

Preparation method of zirconium-silicate-coated cerium sulfide scarlet pigment and product prepared by same

The invention discloses a preparation method of a zirconium-silicate-coated cerium sulfide scarlet pigment, which comprises the following steps: introducing a cerium sulfide suspension into a zirconium source-silicon source mixed solution, and reacting the zirconium source and silicon source under hydrothermal conditions, thereby forming a precursor coating zirconium silicate on the surface of the color development body; and carrying out heat treatment on the precoated pigment in an non-oxidizing atmosphere to obtain the compact-coating high-coating-rate zirconium-silicate-coated cerium sulfide scarlet pigment. The method has the advantages of simple technique and low energy consumption; and the prepared pigment product has high stability, is applicable to the field of production of scarlet medium / low-temperature ceramics, and is suitable for industrial production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Wear-resistant glaze for preparing sanitary ceramics and method for preparing sanitary ceramics

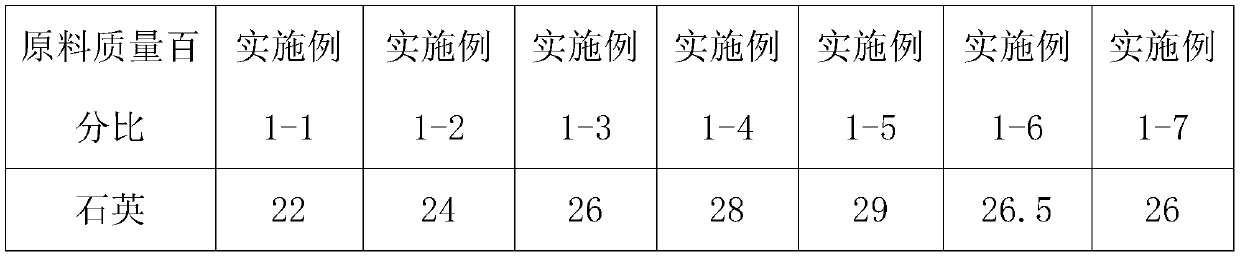

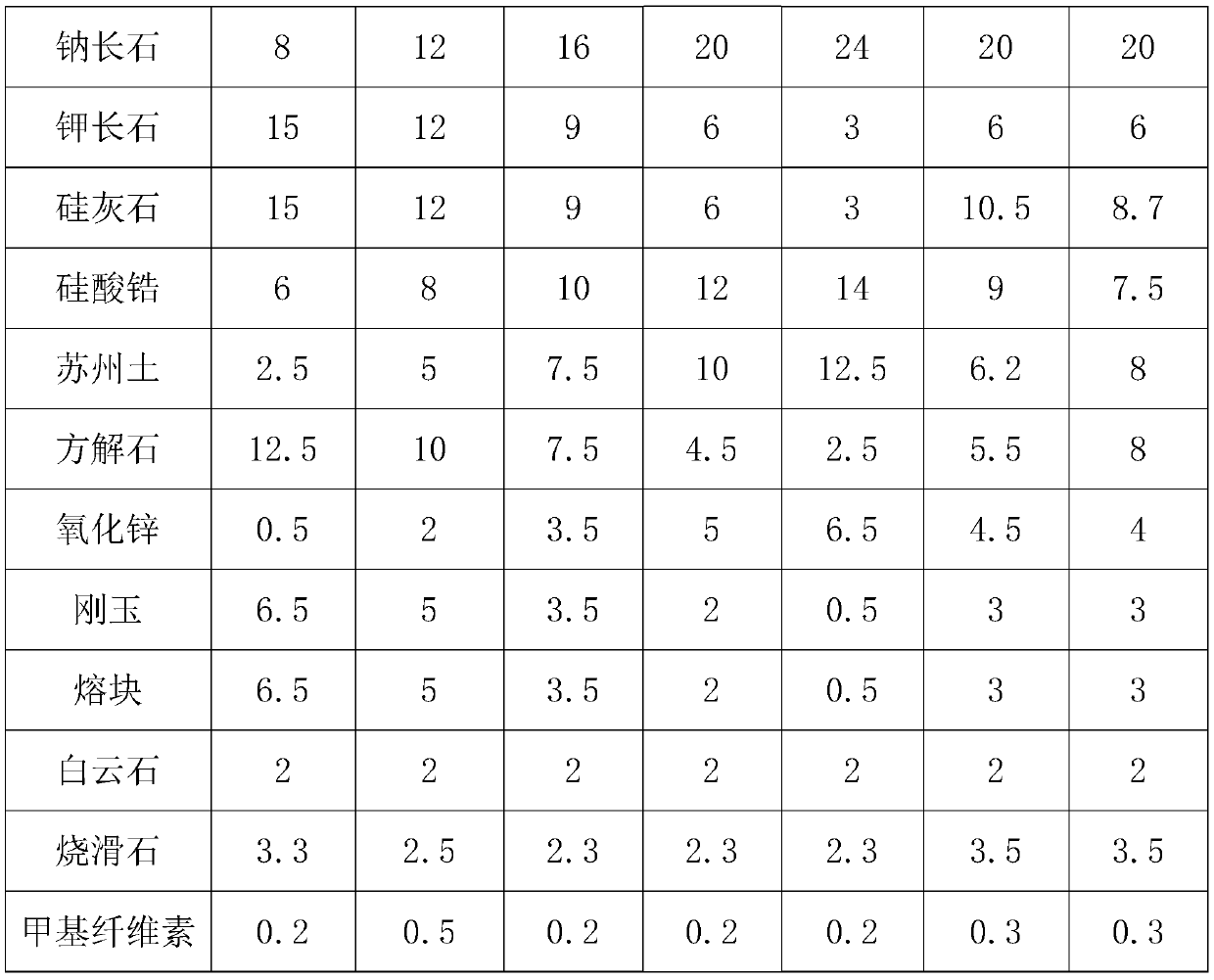

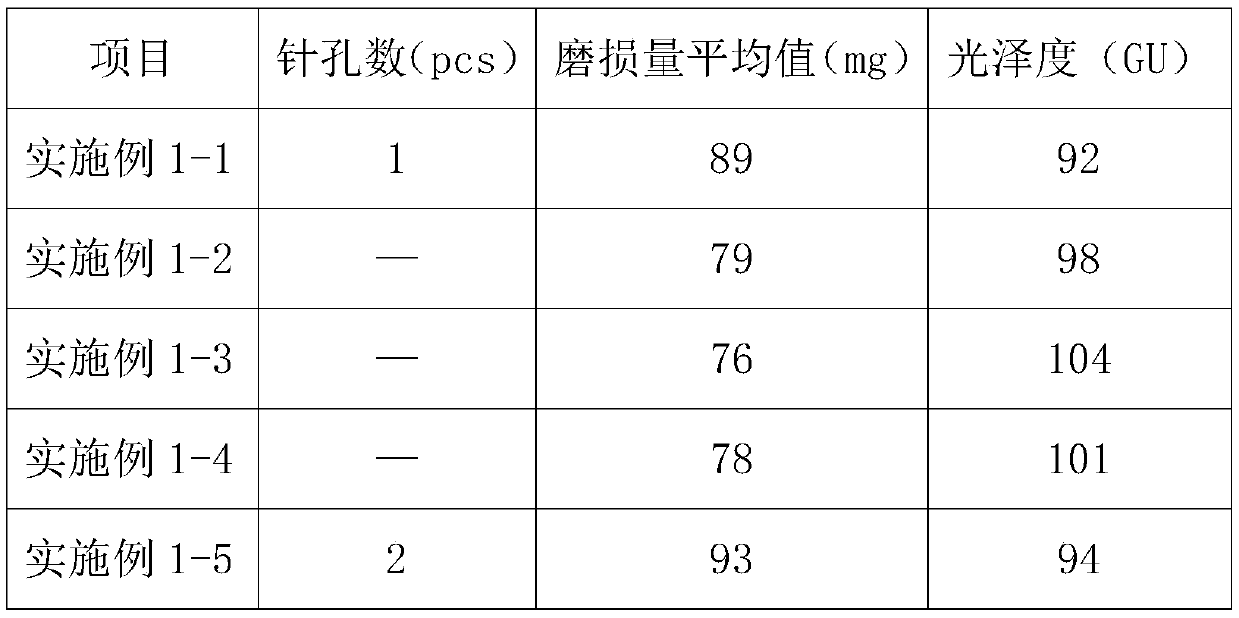

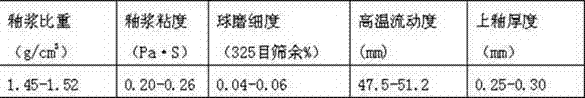

The invention discloses a wear-resistant glaze for preparing sanitary ceramics, which comprises the following components in percentage by mass: 24-28% of Quartz, 20-32% of feldspar, 6-13% of wollastonite, 8-12% of zirconium silicate, 5-10% of Suzhou soil, 5-10% of calcite, 2-5% of zinc oxide, 2-5% of corundum, 2-5% of clinker, 2-5% of dolomite, 2-5% of calcined talc and 0.2-0.5% of methyl cellulose. According to the wear-resistant glaze for preparing sanitary ceramics provided by the technical scheme, the usage amount of the feldspar and the wollastonite is adjusted to improve the Al / Si ratioof formula components, and the addition ratio of the raw materials of the zinc oxide, calcined talc and zirconium silicate for improving wear resistance is increased, so that the glaze wear amount ofthe sanitary ceramics is reduced as a whole, and the glossiness is improved. Furthermore, the preparation method for preparing the sanitary ceramics by using the wear-resistant glaze for preparing sanitary ceramics is proposed, so that the surface of the prepared sanitary ceramics is smooth and fine, the average wear amount of the glaze surface is reduced to 70-80 mg, the wear resistance is high,the service life is long, and the glossiness is as high as 95-105 GU.

Owner:FOSHAN DONGPENG CERAMIC +3

Low-temperature sintered zirconium silicate grinding ball and preparation method thereof

The invention relates to a low-temperature sintered zirconium silicate grinding ball and a preparation method thereof, relating to a grinding medium. The raw materials of the ball are as follows: zirconium silicate as the substrate material; and a combination of alumina, silicon oxide, zirconia, yttrium oxide, calcium carbonate, magnesium carbonate, potassium carbonate and sodium carbonate as a sintering aid. The raw materials are prepared according to an appropriate mass ratio, and go through ball milling using a ball mill, and high speed grinding by a vertical sand mill then drying to obtain raw material powder for the preparation of the zirconium silicate grinding ball at low temperature. The material powder is shaped to be biscuit balls for sintering to obtain compact, wear-resistant and high-strength zirconium silicon substrate grinding balls.

Owner:江苏金石研磨有限公司

High-strength electroceramics ash glaze formulation and preparation method thereof

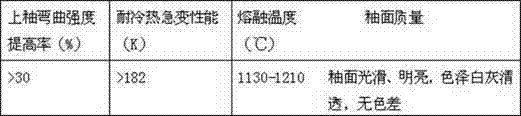

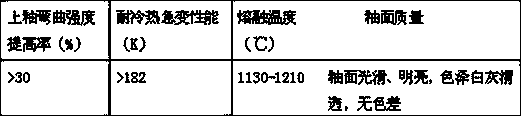

The invention relates to a high-strength electrotechnical porcelain ash glaze formulation which comprises white glaze base materials and coloring materials with mass of 15 to 35% of that of the white glaze base materials, wherein the white glaze base material comprises the following components in parts by weight: 23 to 27 parts of potassium feldspar, 25 to 29 parts of quartz, 8 to 15 parts of Xinhui powder, 4 to 9 parts of washed kaolin, 5 to 8 parts of Xingzi kaolin, 8 to 15 parts of talc, 4 to 7 parts of limestone, 3 to 8 parts of Zuoyun earth, 2 to 6 parts of zirconium silicate, and 5 to 15 parts of alumina. The preparation method comprises the following steps of: roasting three colorant raw materials at a high temperature firstly; grinding finely; and then milling in a wet way along with white glaze based on the ratio until the size fineness reaches to 325 meshes; and finally sieving to residue of 4 to 6%. The electrotechnical porcelain ash glaze prepared based on the formulation is suitable for various porcelain blank bodies, and can be coated to form a good intermediate layer which can be combined with the porcelain body well, thus, the mechanical performance of the porcelain can be greatly improved, and the bending strength of the porcelain can be increased by more than 30%; and meanwhile, the glazed surface of a porcelain component is smooth, the color is white gray and clear, and the surface has no defect, and the market demand can be met.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

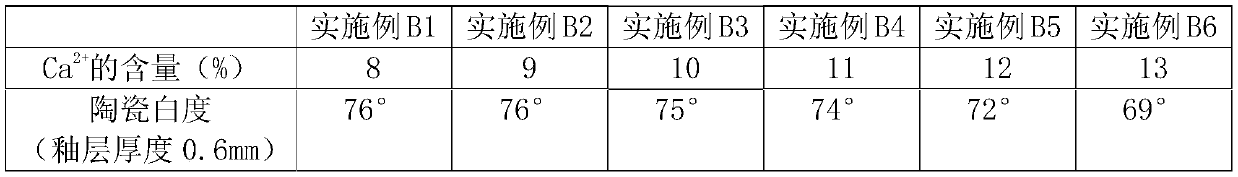

Preparation method of composite opaque glaze

The invention provides a preparation method of composite opaque glaze. The preparation method of the composite opaque glaze comprises the following steps of: (1) weighing the following materials in percentage by weight: 25 to 33 percent of feldspar, 17 to 25 percent of quartz, 6 to 15 percent of aedelforsite, 3 to 8 percent of zirconium silicate, 12 to 17 percent of Suzhou soil, 4 to 10 percent of calcined ZnO and 1 to 4 percent of CeO2, mixing and grinding the materials uniformly, and sieving to obtain glaze powder; and (2) uniformly mixing and grinding the glaze powder prepared in the step (1), water and ball-milling stones according to the ratio of 1:(0.9-1):(0.6-0.8) to prepare the composite opaque glaze. The composite opaque glaze is low in cost and has high whiteness, good opacifying effect and high brightness, the whole glaze surface is in good condition, and the composite opaque glaze can be prepared into various light glaze, wherein the composite opaque glaze is prepared from the glaze powder, the water and the ball-milling stones according to the ratio; and the diameter values of different ball-milling stones can correspondingly influence the grinding fineness of the materials. Glossy glaze surfaces with a high-whiteness opacifying effect can be respectively obtained by uniformly applying composite opaque glaze with the thickness of 0.3 to 1mm to the surface of a green body, drying and sintering at 1,150 and 1,250 DEG C for 1 hour.

Owner:美艺陶(福建)高新建材有限公司

Preparation method of zirconium silicate wrapped ceramic pigment

The invention discloses a preparation method of zirconium silicate wrapped ceramic pigment. In the method, after preparation of a raw material solution and preparation of a precursor suspension, the precursor suspension is dried so as to obtain the precursor powder, and consequentially, the wrapped ceramic pigment is obtained through roasting. In the method, by optimization of formula and control on pigment granularity, the whiteness of the ZrSiO4 wrapping layer is reduced effectively, and the color generation effect of the ceramic pigment is improved; by the obtained high-density wrapping layer, the effective wrapping efficiency and stability of the ceramic pigment are improved, and thus, the color source is protected effectively.

Owner:广西恒特新材料科技有限责任公司

Preparation method of zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as zirconium source and product prepared by preparation method

ActiveCN106928752AIncrease color depthHigh parcel rateInorganic pigment treatmentHydrogenZirconium(IV) silicate

The invention discloses a preparation method of a zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as a zirconium source. The preparation method comprises the following steps: firstly, after dispersing powder of a coloring agent, uniformly stirring the coloring agent and an ammonium zirconium carbonate solution to form a stable suspension solution; reacting to form sedimentation on surfaces of coloring agent particles, so as to obtain a zirconium oxide inclusion; adding the zirconium oxide inclusion into a silicon source solution and uniformly mixing; adjusting the pH (Potential of Hydrogen) value to obtain sediment; drying the sediment to obtain a ceramic pigment precursor; calcining the ceramic pigment precursor and removing the uncovered coloring agent so as to obtain the zirconium silicate covered ceramic pigment powder. Furthermore, the invention further discloses a product prepared by the preparation method. By adopting the preparation method disclosed by the invention, damages to the ceramic pigment can be avoided and the covered pigment with high covering ratio and a core-shell structure is formed; the problem that the high covering ratio of the zirconium silicate covered ceramic pigment is incompatible with a low ratio of the coloring agent to the pigment is effectively solved, so that the color-causing depth of the covered pigment is effectively improved and the adding amount in a utilization process is reduced.

Owner:JINGDEZHEN CERAMIC UNIV

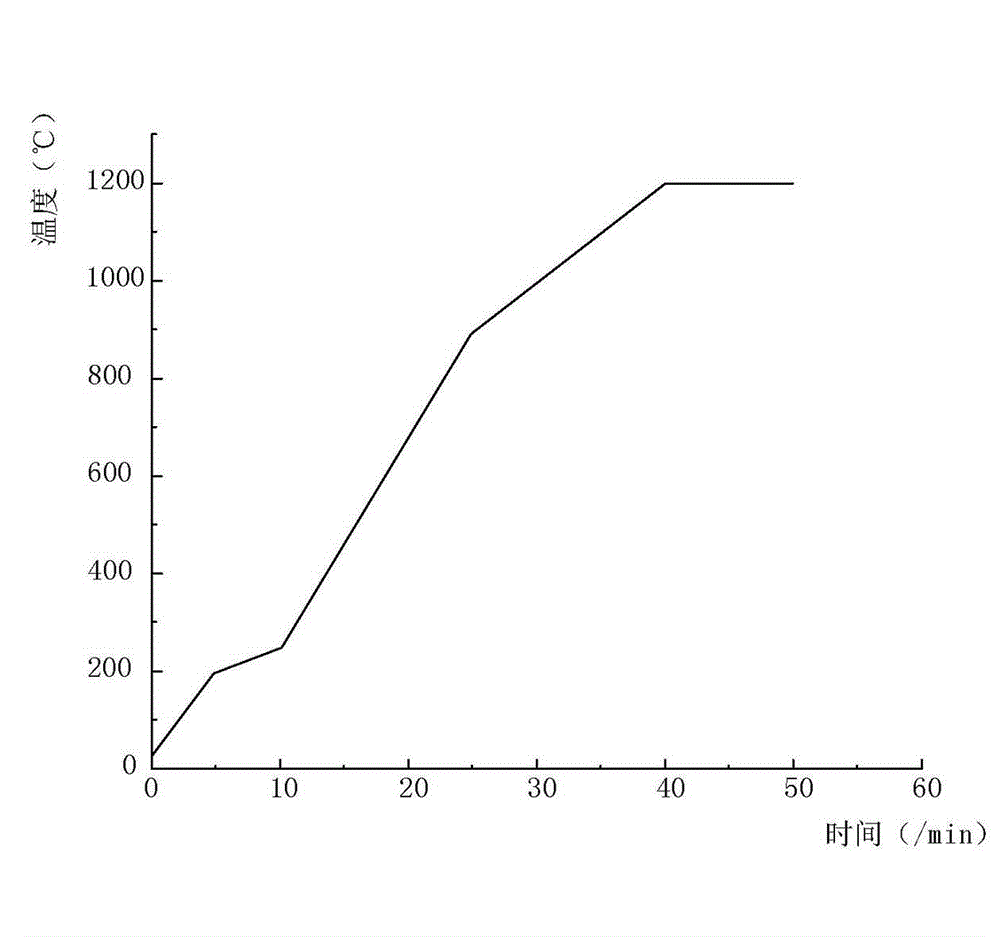

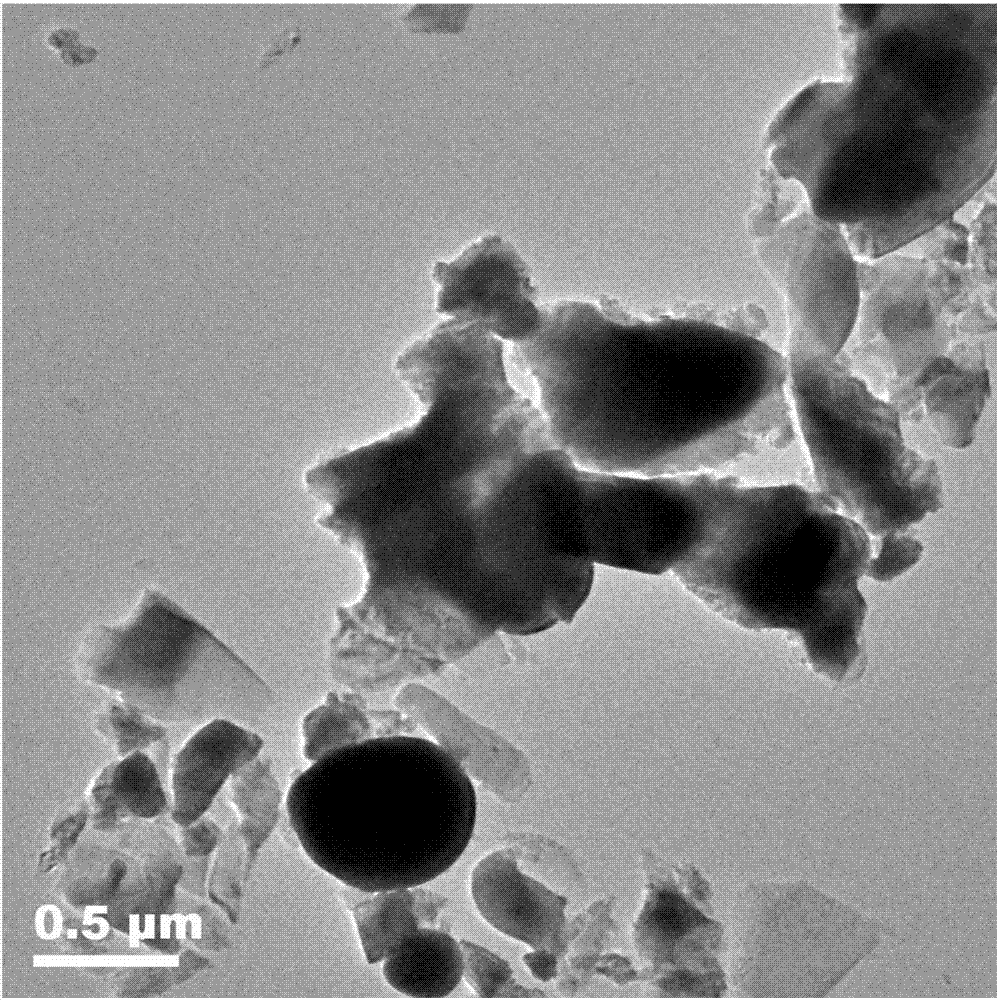

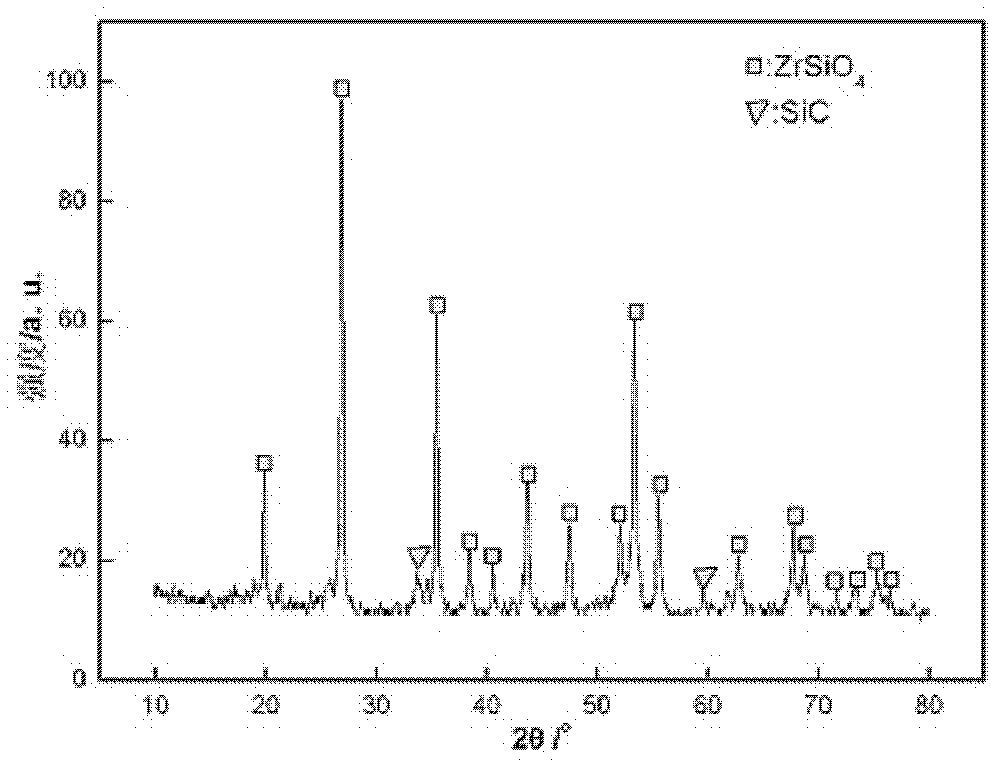

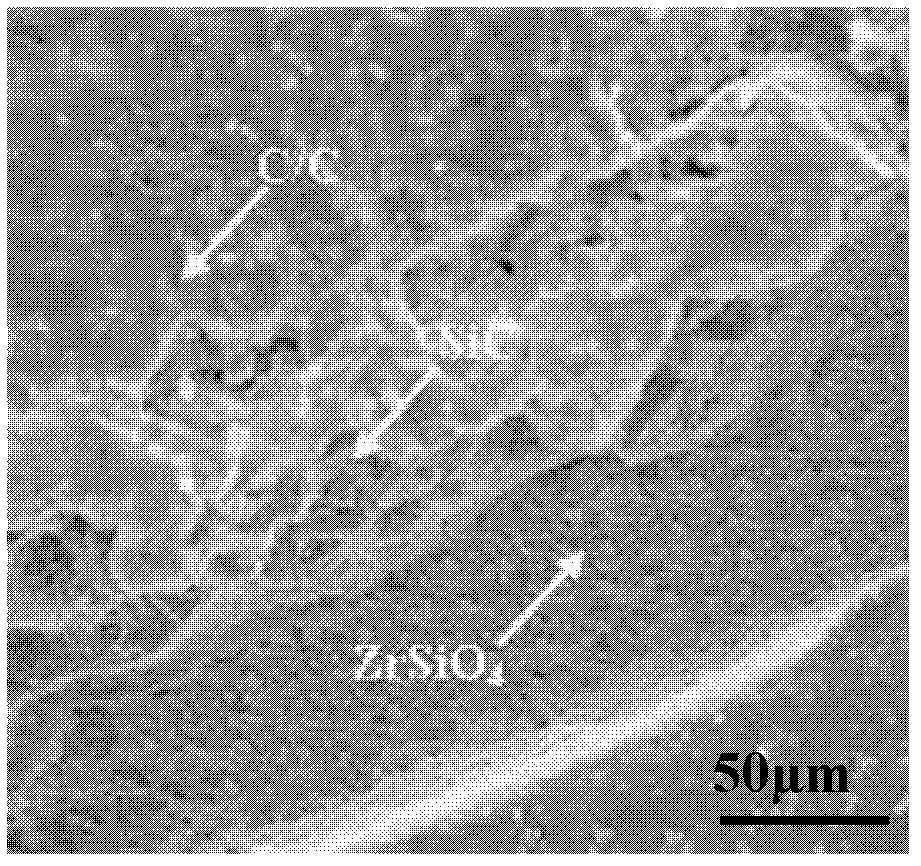

Method for preparing carbon/carbon composite zirconium silicate/silicon carbide antioxidant coating

The invention relates to a method for preparing a carbon / carbon composite zirconium silicate / silicon carbide antioxidant coating, which comprises the following steps: uniformly mixing silicon powder with graphite powder, thereby obtaining the powder A; uniformly mixing Al2O3 powder, Ta2O5 powder, WO3 powder and B2O3 powder, thereby obtaining powder B; mixing the powder A with the powder B, thereby obtaining the embedding powder C; placing a carbon / carbon sample into a graphite crucible, and adding the embedding powder C; sintering in a vertical vacuum furnace by taking argon as an protective atmosphere, thereby obtaining a carbon / carbon composite; adding zirconium silicate and iodine into isopropanol, thereby obtaining a suspension solution; placing the suspension solution into a water-heating kettle; selecting a graphite base as the anode of the water-heating kettle and the carbon / carbon composite with a silicon carbide transition layer as the cathode; sealing the water-heating kettle, placing the water-heating kettle into a microwave generator, and performing water-heating electrophoresis and electric-heating deposition; and after finishing the deposition, taking out the sample,and drying, thereby obtaining the carbon / carbon composite zirconium silicate / silicon carbide antioxidant coating. The reaction is once finished in the water-heating kettle, no post-heating treatment is required, the processing equipment is simple, the obtained zirconium silicate coating is compact and uniform, the reaction period is short and the cost is low.

Owner:青岛百顿特种陶瓷技术有限公司

Low-temperature matte reaction glaze and production method thereof

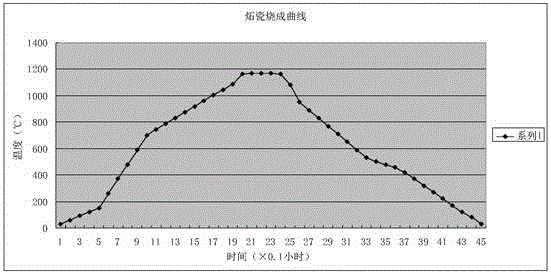

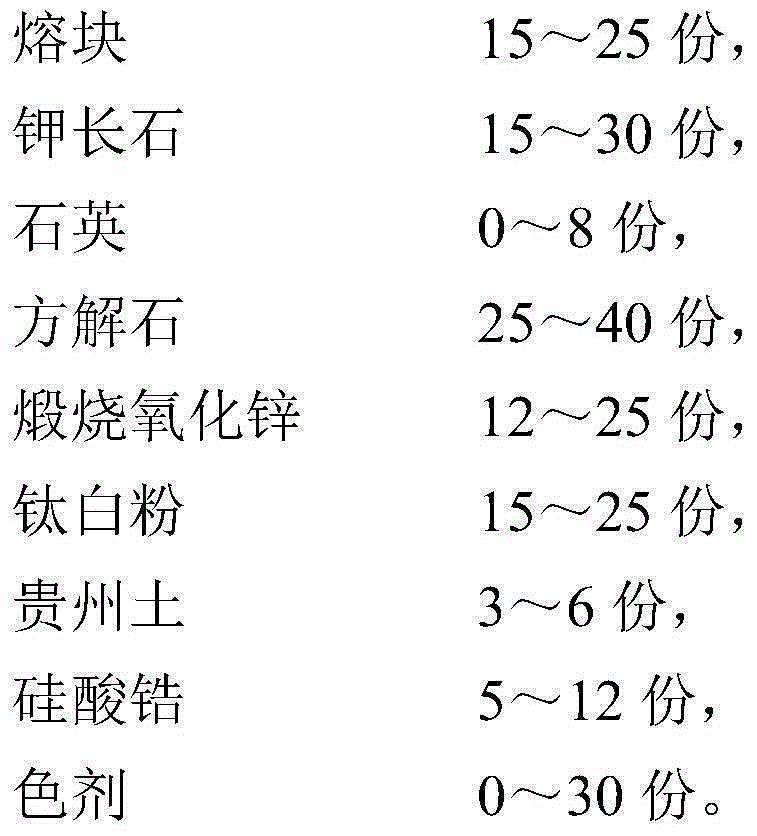

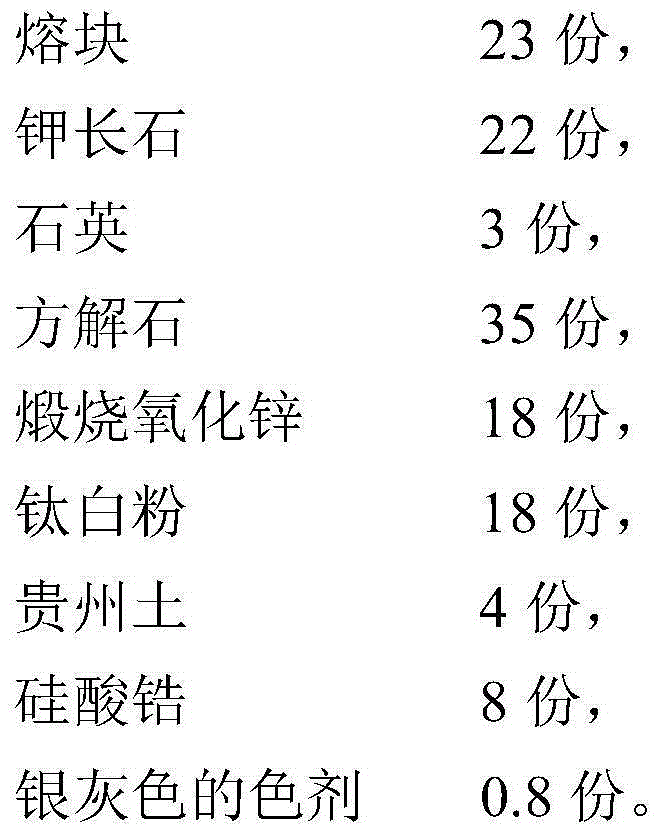

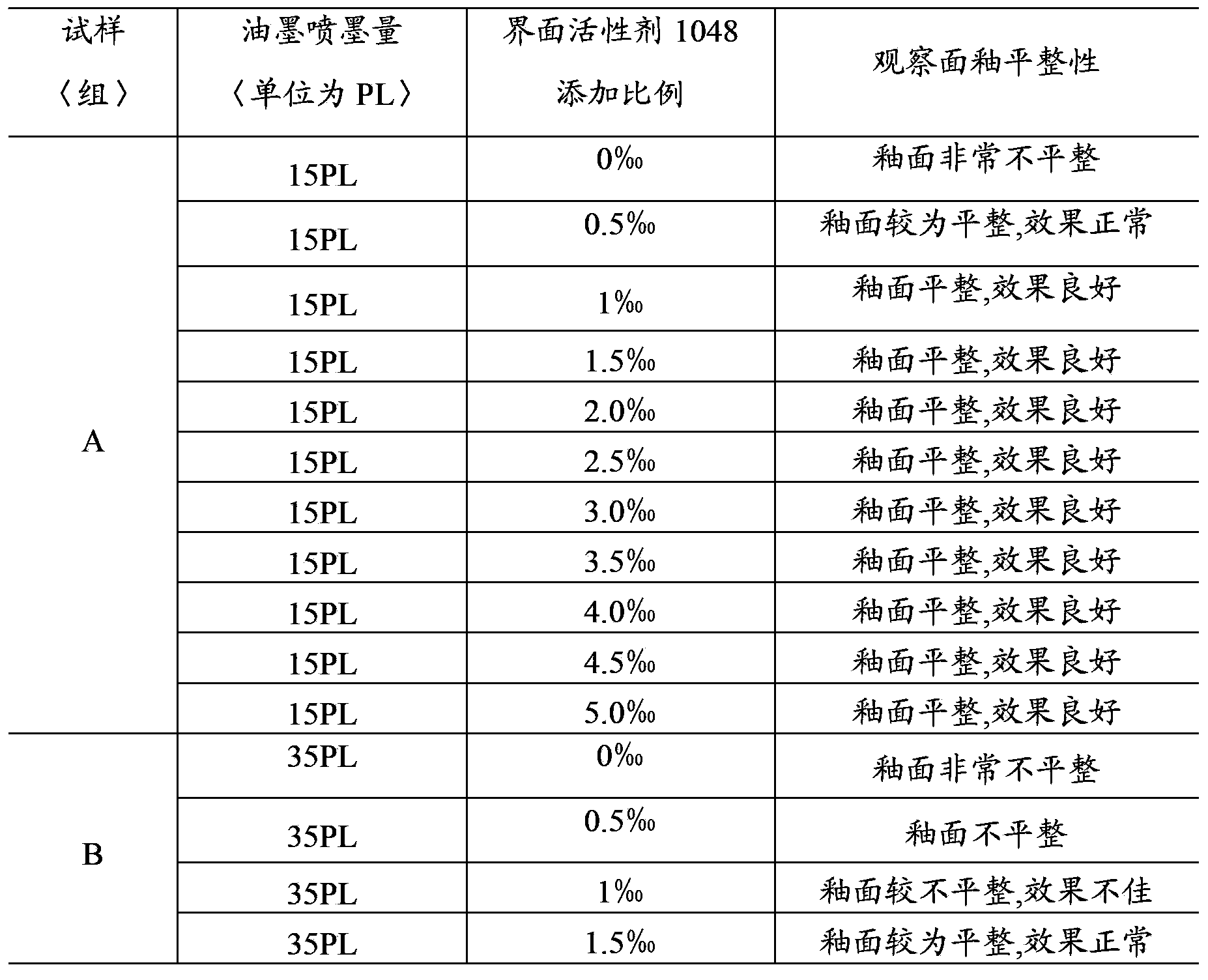

The invention discloses a low-temperature matte reaction glaze and a production method thereof. The glaze is prepared from following raw materials, by weight, 5-25 parts of frit, 15-30 parts of potassium feldspar, 0-8 parts of quartz, 25-40 parts of calcite, 12-25 parts of calcined zinc oxide, 15-25 parts of titanium dioxide, 3-6 parts of kaolin from Guizhou, 5-12 parts of zirconium silicate and 0-30 parts of toners. According to the low-temperature matted reaction glaze and production method thereof, the calcite and the titanium dioxide are used to achieve a low-temperature sub-reaction effect, then the zirconium silicate is used for stabilizing the glaze, thereby ensuring the effects of the glaze, namely, the effects of the low-temperature oxidizing flame matted reaction glaze (transmutation glaze). A single-layer reaction glaze (transmutation glaze) stoneware product prepared from the glaze is suitable for large-scale production conditions at present and can be produced stably. Meanwhile, physical and chemical conditions, such as thermal-stability, dissolving of lead and cadmium, glaze surface hardness and the like, of the stoneware product meet the national household stoneware standard.

Owner:HUNAN HUALIAN CHINA IND

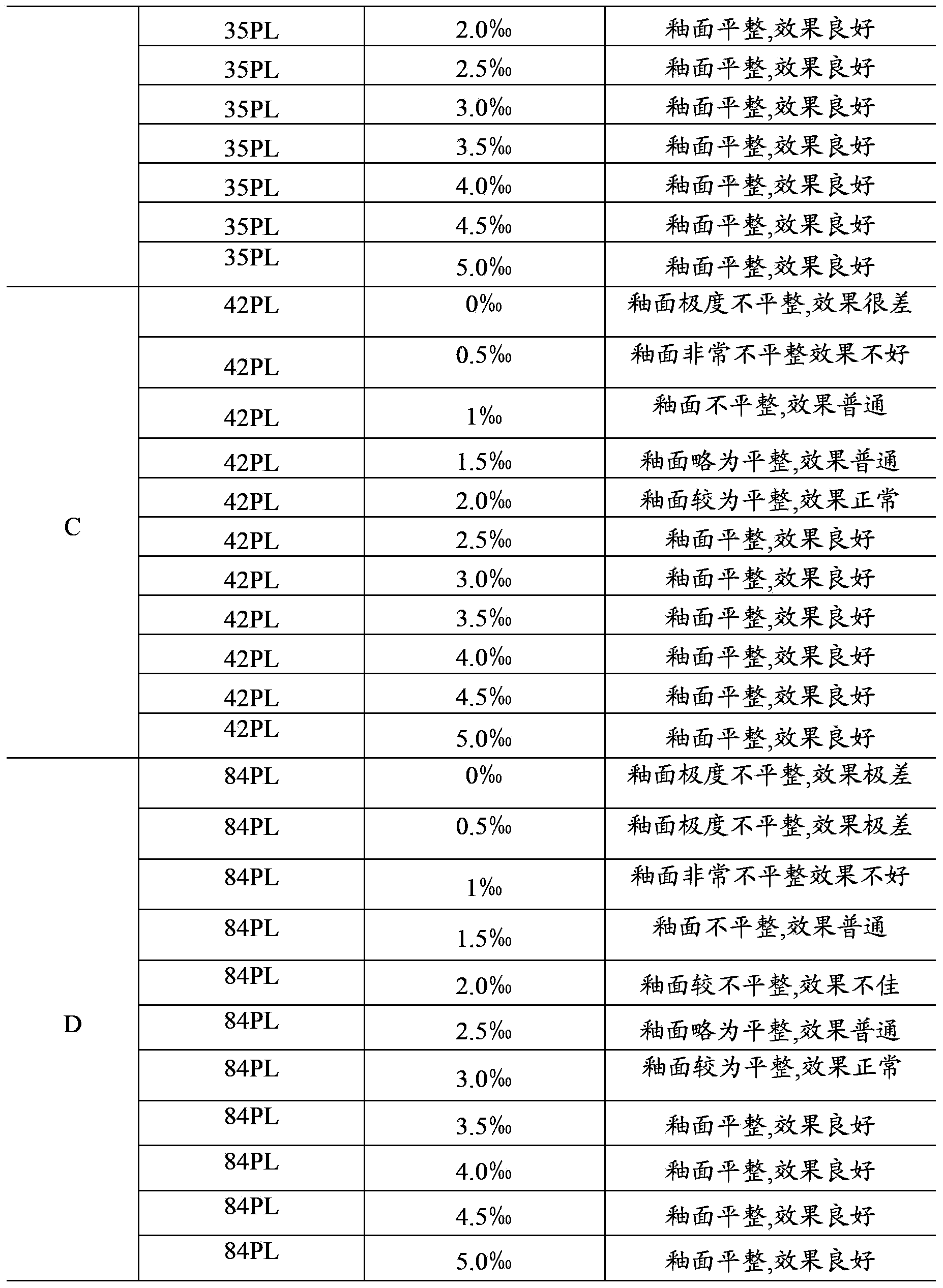

Novel printing glaze material and production method thereof

The invention provides a novel printing glaze material and a production method thereof. The novel printing glaze material consistent with standards is produced by putting the following components into a ball mill for grinding, wherein the components are as follows in percentage by weight: 32% to 42% of albite, 8% to 12% of nepheline orthoclase, 3% to 5% of wollastonite, 3% to 5% of kaolin, 1.5% to 2.5% of ball clay, 3% to 5% of quartz, 3% to 5% of aluminium oxide, 5% to 8% of corundum, 7% to 9% of calcium carbonate, 4% to 7% of zinc oxide, 1% to 2% of talc, 3% to 5% of dolomite, 1% to 2% of barium carbonate, 4% to 8% of clinker, and 6% to 15% of zirconium silicate. The produced novel printing glaze material has the advantages that color development of the ink is better, a problem of color system variation does not exist, the definition of ink figures and the flatness of glaze surfaces can be guaranteed, and a defect of printing ink gloss variation is overcome through controlling a molten softening point.

Owner:CARLOBBIA GLAZE KUNSHAN

Ceramic rock plate prepared from wollastonite tailings through ultralow-temperature fast firing and manufacturing method of ceramic rock plate

InactiveCN114163213AHigh whitenessReduce intensityCeramic materials productionClaywaresWollastonitePotassium feldspar

The invention discloses a ceramic rock plate prepared from wollastonite tailings through ultralow-temperature fast firing and a manufacturing method, the ceramic rock plate comprises a green body, and the green body comprises the following raw material components in parts by weight: 25-45 parts of wollastonite tailings, 10-50 parts of clay, 5-15 parts of potassium feldspar and albite, 10-20 parts of quartz, 0-5 parts of zirconium silicate, 2-10 parts of a mineralizing agent, 0-1.0 part of a dispergator and 0-1.0 part of a reinforcing agent. According to the invention, the wollastonite tailings are introduced into the formula of the ceramic rock plate blank, so that an ultralow-temperature fast firing process with the firing temperature of 1000-1100 DEG C and the firing period of 35-50 minutes can be realized, and the firing temperature and the firing time are greatly reduced; the high-proportion wollastonite tailings are introduced into the formula of the ceramic rock plate blank, so that the whiteness of the blank can be improved and reaches 50 degrees or above, and the ceramic rock plate blank can be well applied to development and production of various rock plate products; in addition, the wollastonite tailings are introduced to replace a large amount of expensive mud and sand raw materials, so that the production cost of the ceramic rock plate product is reduced.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +1

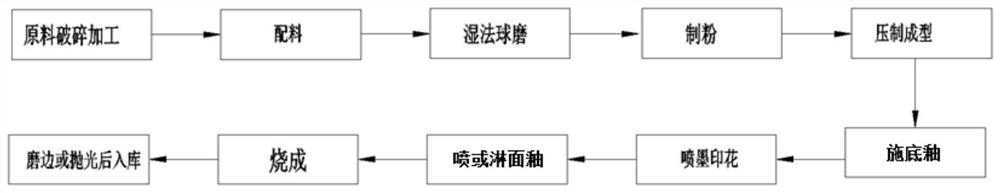

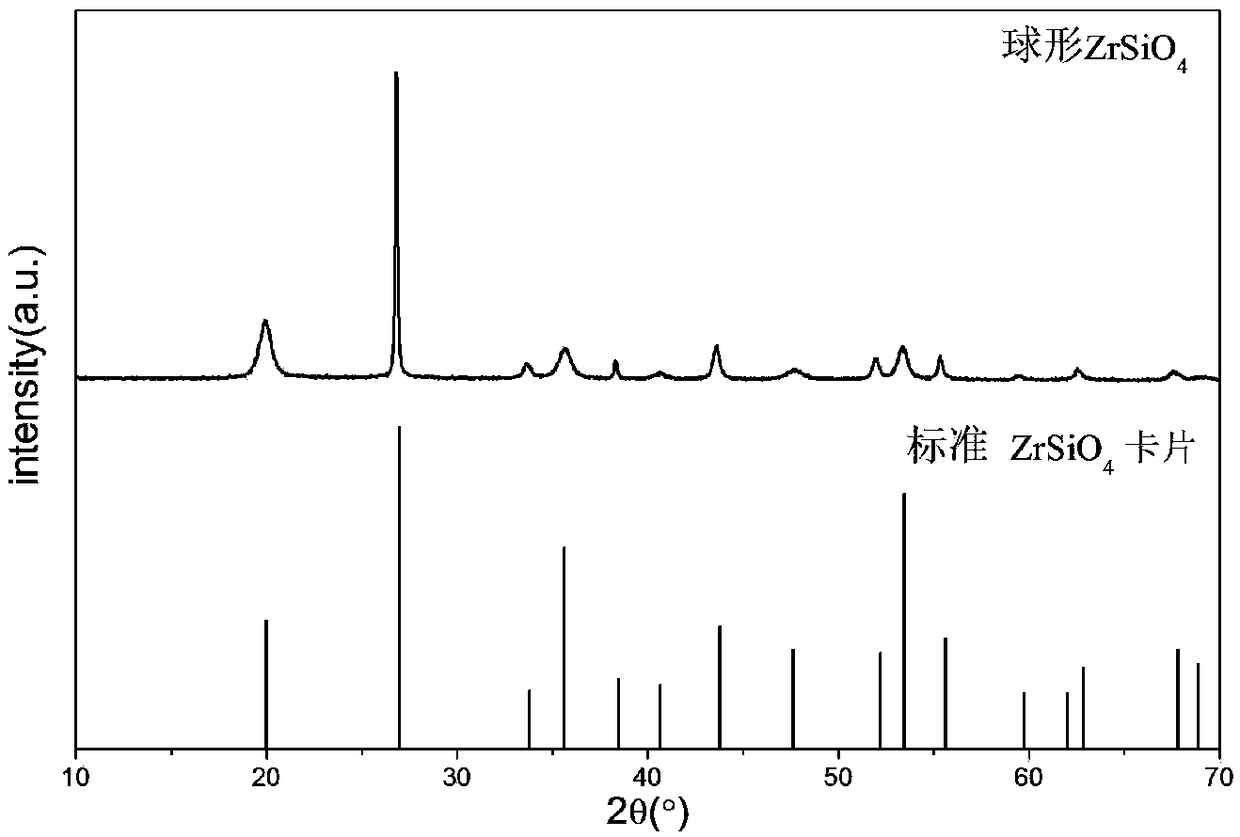

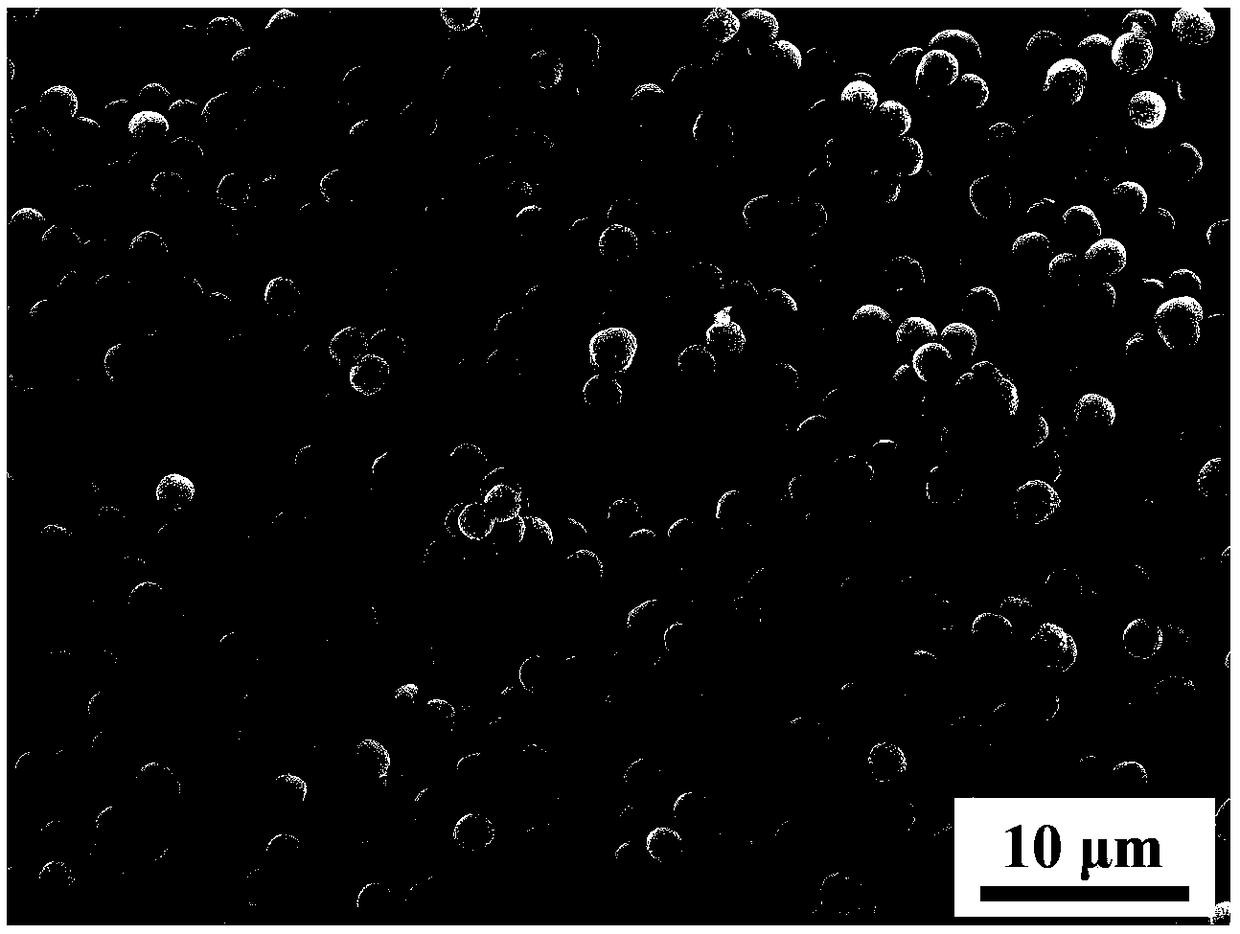

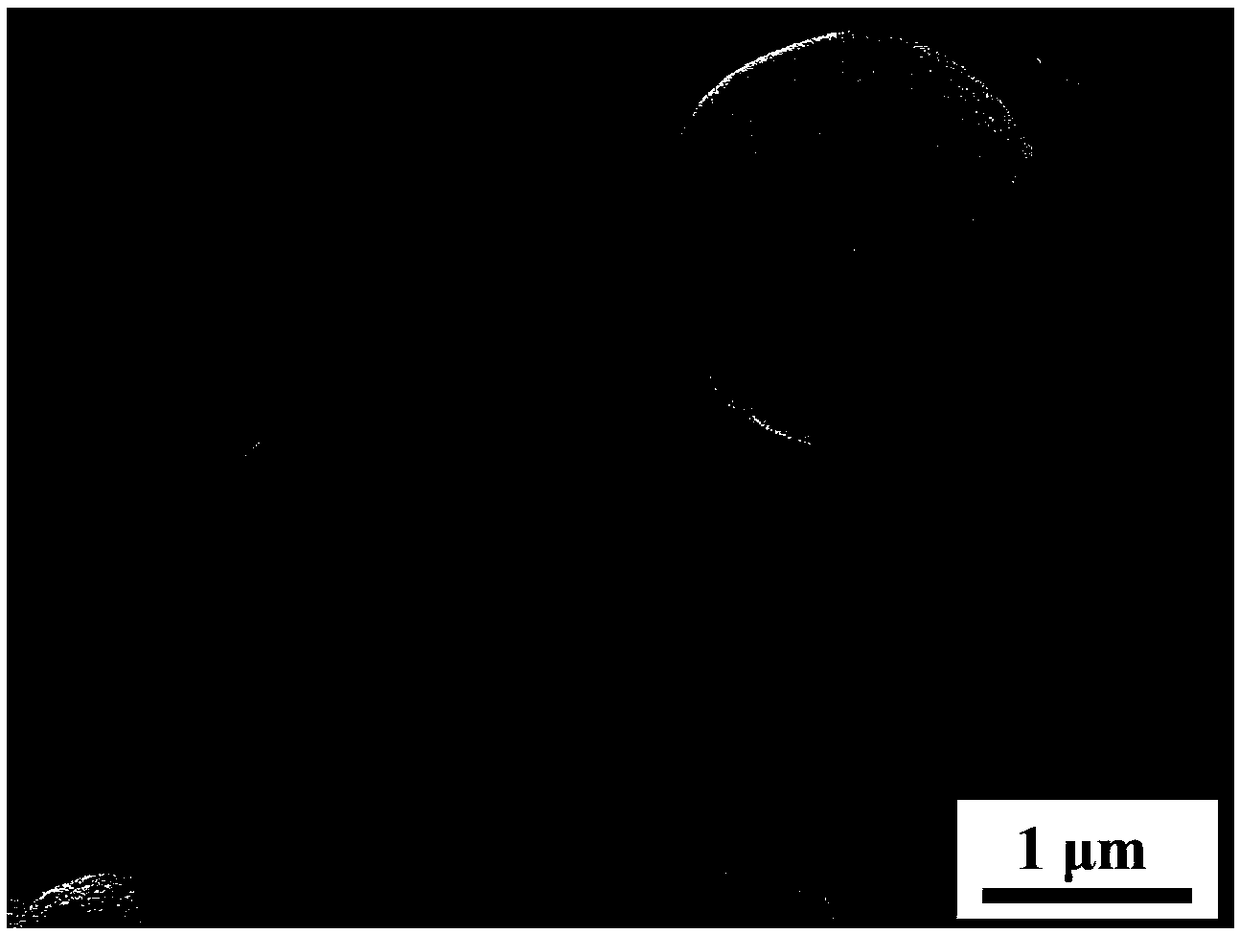

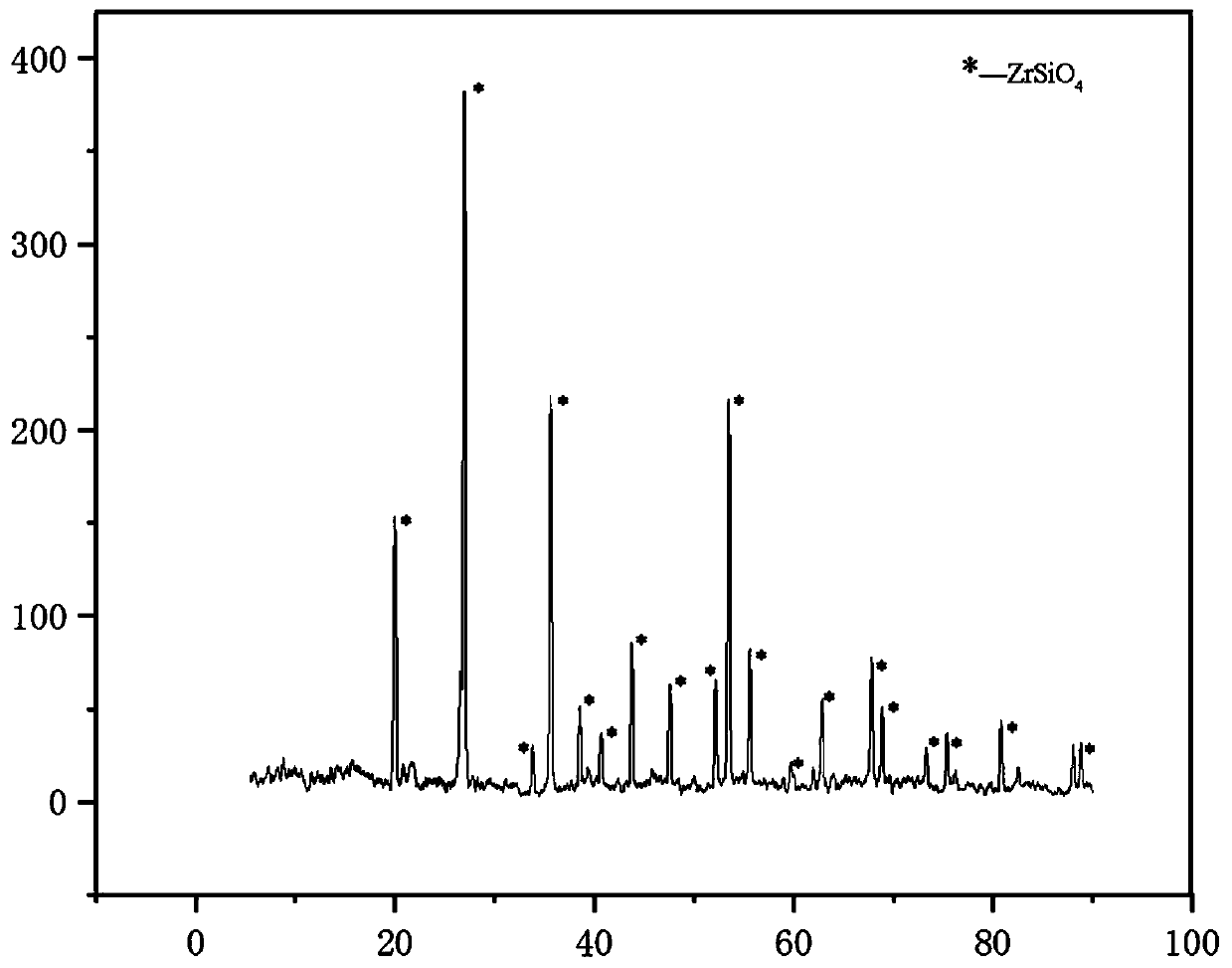

Zirconium silicate powder and preparation method and application thereof

The invention provides a preparation method of zirconium silicate powder, and relates to the technical field of high-performance powder materials. The preparation method of the zirconium silicate powder comprises the following steps that 1, a zirconium source, acid and water are mixed to obtain a zirconium source solution; 2, a silicon source and a solvent are mixed to obtain a silicon source solution; 3, the zirconium source solution obtained in the step 1 and the silicon source solution obtained in the step 2 are subjected to mixing and prehydrolysis in sequence to obtain a precursor solution; 4, the precursor solution obtained in the step 3, a mineralizer and a surfactant are mixed for solvothermal reaction to obtain the zirconium silicate powder; the sequence of the step 1 and the step2 is not limited. The zirconium silicate powder prepared by adopting the method is 0.2-2.0-micron spheres.

Owner:HUBEI UNIV +1

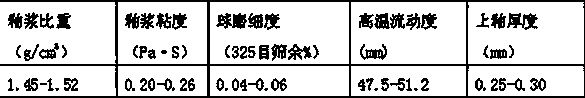

Low-zirconium white glaze for sanitary ceramic and preparation process of low-zirconium white glaze

The invention discloses a low-zirconium white glaze for a sanitary ceramic. The low-zirconium white glaze comprises the following raw materials in percentage by mass: 6.5-7.5% of zirconium silicate, 24-27% of quartz, 5-7% of kaolin, 2.5-3.5% of aluminum oxide, 12-18% of potassium feldspar, 9-15% of albite, 6-8.5% of calcite, 9-13% of wollastonite, 2-5% of dolomite, 2-3.5% of sintered talc, 2-3.5%of zinc oxide and 1.5-4% of frit. The low-zirconium white glaze is prepared by using a preparation process through operation of steps (1)-(3). Under a condition of a low zirconium silicate content, high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity of the low-zirconium white glaze can be still maintained, and the low-zirconium white glaze has the effects of high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity.

Owner:FOSHAN DONGPENG CERAMIC +3

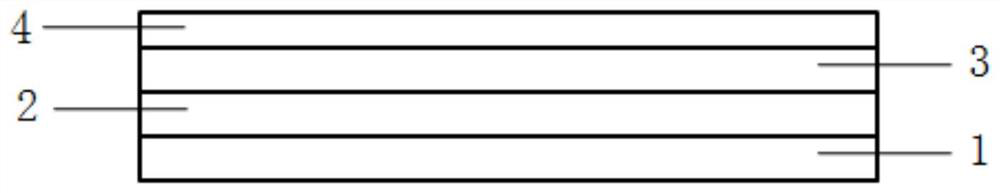

Rock plate with fine skin feeling and preparation method thereof

The invention discloses a rock plate with fine skin feeling and a preparation method thereof. The rock plate sequentially comprises a green body layer, a ground coat layer and a matt layer from bottom to top, and the matt layer is formed by spraying matt glaze and sintering at 1180-1200 DEG C; the spraying amount of the matte glaze is 400-900 g / m < 2 >; the matte glaze is prepared by mixing the following raw materials in parts by weight: 30-40 parts of albite, 20-30 parts of transparent frit, 12-20 parts of matte frit, 6-10 parts of zirconium silicate, 5-8 parts of modified graphene, 4-8 parts of titanium dioxide, 2-5 parts of calcium oxide, 1-4 parts of zirconium dioxide, 1-2 parts of zinc oxide and 0.2-1 part of sodium tripolyphosphate. The rock plate with the fine skin feeling is smooth and fine in glaze surface, good in matte effect and good in wear resistance.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

High-strength electric-porcelain ash glaze formula and its preparation method

The invention relates to a high-strength electrotechnical porcelain ash glaze formulation which comprises white glaze base materials and coloring materials with mass of 15 to 35% of that of the white glaze base materials, wherein the white glaze base material comprises the following components in parts by weight: 23 to 27 parts of potassium feldspar, 25 to 29 parts of quartz, 8 to 15 parts of Xinhui powder, 4 to 9 parts of washed kaolin, 5 to 8 parts of Xingzi kaolin, 8 to 15 parts of talc, 4 to 7 parts of limestone, 3 to 8 parts of Zuoyun earth, 2 to 6 parts of zirconium silicate, and 5 to 15 parts of alumina. The preparation method comprises the following steps of: roasting three colorant raw materials at a high temperature firstly; grinding finely; and then milling in a wet way along with white glaze based on the ratio until the size fineness reaches to 325 meshes; and finally sieving to residue of 4 to 6%. The electrotechnical porcelain ash glaze prepared based on the formulation is suitable for various porcelain blank bodies, and can be coated to form a good intermediate layer which can be combined with the porcelain body well, thus, the mechanical performance of the porcelain can be greatly improved, and the bending strength of the porcelain can be increased by more than 30%; and meanwhile, the glazed surface of a porcelain component is smooth, the color is white gray and clear, and the surface has no defect, and the market demand can be met.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

High-strength steatite porcelain

The invention relates to a high-strength steatite porcelain. The high-strength steatite porcelain comprises talcum as a primary raw material, and also contains kaolin, zinc oxide, barium carbonate and zirconium silicate, and concretely comprises 40-50wt% of calcined talcum powder, 30-40wt% of uncalcined talcum powder, 1-4wt% of zinc oxide, 3-8wt% of barium carbonate and 0.1-1wt% of zirconium silicate. A production technology of the high-strength steatite porcelain comprises the steps of raw material burdening, wet ball milling, spray drying, dry-pressing molding and sintering, the firing temperature of the steatite porcelain obtained in the invention is 1300DEG C, the firing temperature range is 35DEG C, and the static rupture strength is 258MPa, and the steatite porcelain has the characteristics of good rupture strength and ageing resistance, and widened firing temperature.

Owner:HUNAN MEICHENG CERAMIC TECH

Emulsion whitening agent for ceramic and preparation method thereof

InactiveCN103880475AReduce radioactive contaminationUnchanged structureAluminum Hydroxide HydrateAluminium hydroxide

The invention relates to the field of a ceramic product, and particularly relates to an emulsion whitening agent for ceramic and a preparation method thereof. The emulsion whitening agent for the ceramic consists of the following raw materials in parts by weight: 60-98 parts of zirconium silicate and 2-40 parts of a dopant mixture. The preparation method comprises the steps of wet-mixing active aluminum oxide or / and aluminum hydroxide hydrate as well as active silica powder or / and metasilicic acid and sodium carbonate according to the parts in weight so as to form the dopant mixture; wet-mixing zirconium silicate and the dopant mixture according to the parts in weight, grinding to 325 meshes, drying and then adding into a kiln, roasting under a micro-pressure of 0-0.2 Mpa, cooling and then wet-grinding, drying and packaging. The emulsion whitening agent for the ceramic provided by the invention is used for replacing the existing generally-used zirconium silicate so as to lower the cost of a ceramic enterprise, save limited zircon sand resources and reduce radioactive pollution of the ceramic.

Owner:JIANGSU MIRAFUL NANO MATERIAL CO LTD

Manufacturing method of soft-light glazed ceramic chip

ActiveCN111875415AHigh hardnessImprove stabilityGlass furnace apparatusCeramic glazeZirconium(IV) silicate

The invention provides a manufacturing method and a preparation method of a soft-light glazed ceramic chip, which comprises the following steps: spraying ground glaze on a biscuit, spraying soft-lightoverglaze, printing patterns, firing the ceramic, trimming the ceramic and finishing a finished product; by selecting the raw materials of the glaze, adjusting the frit content and selecting and optimizing the frit formula, the firing process is easy to control, the production cost is low, and the product quality is good. The frit accounts for 71-90% of the soft-light surface glaze, so that the possibility of dirt absorption caused by pinholes of the glaze is reduced, and the uniformity of the glaze is guaranteed. Zirconium silicate is stable in chemical performance and has the effects of whitening, improving opacification of the glaze, improving the bonding performance of the blank glaze and improving the hardness of the ceramic glaze in the glaze. The calcined kaolin acts in the glaze to increase the content of aluminum oxide, and the aluminum oxide can improve the stability and sintering strength of the glaze. The glossiness of the soft-light surface glaze is 15-35 degrees after the soft-light surface glaze is sintered, the glaze surface is smooth and moderate in brightness, and the requirements of consumers are met.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

Matte glaze applied to sanitary ceramics, sanitary ceramics applying matte glaze and preparation method

The invention discloses a matte glaze applied to sanitary ceramics, the sanitary ceramics applying the matte glaze and a preparation method, and relates to the technical field of sanitary ceramics. The matte glaze applied to sanitary ceramics comprises the following raw materials by weight: 25-27 parts of potassium feldspar, 17-20 parts of quartz, 1-3 parts of zinc oxide, 8-12 parts of dolomite, 5-8 parts of wollastonite, 5-8 parts of kaolin, 6-8 parts of aluminum oxide, 7-9 parts of zirconium silicate, 1-4 parts of frit, 6-9 parts of barium carbonate, 5-9 parts of calcined talc and 0.5-1.5 parts of lithium carbonate. A certain quantity of lithium carbonate is introduced to achieve fluxing, the melting temperature of the raw materials is reduced, mutual fusion of the raw materials is facilitated, the viscosity of the frit is improved through lithium carbonate, the viscosity of the matte glaze is reduced, the flowing property of the matte glaze at high temperature is improved, flowing of crystals separated out of the matte glaze is facilitated, the crystals are arranged more uniformly and orderly, the glaze surface flatness is conveniently controlled, and the sanitary ceramic firingefficiency is improved.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +1

Nickel-based ceramic cylinder sleeve and powder metallurgy preparation method thereof

The invention discloses a nickel-based ceramic cylinder sleeve and a powder metallurgy preparation method thereof. The nickel-based ceramic cylinder sleeve is composed of, by weight, 23-45 parts of nickel powder, 12-25 parts of silicon carbide, 6-11 parts of silicon nitride, 8-17 parts of silicon dioxide, 6-13 parts of titanium powder, 5-12 parts of zirconium silicate, 4-11 parts of zirconia, 7-19 parts of dispersing agents and 24-39 parts of water. Compared with the prior art, the nickel-based ceramic cylinder sleeve and the powder metallurgy preparation method thereof have the advantages that (1) the nickel-based ceramic cylinder sleeve is uniform in texture, high in toughness and high in corrosion resistance; (2) the powder metallurgy preparation method of the nickel-based ceramic cylinder sleeve is simple in process and small in energy consumption.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Method for preparing moon white glaze craft porcelain from porcelain clay

The invention discloses a method for preparing moon white glaze craft porcelain from porcelain clay. The moon white glaze craft porcelain comprises a green body and moon white glaze, the moon white glaze comprises the following raw materials: quartzite, dolomite, white corundum, clam meal, porcelain clay, chlorite, aluminum oxide, zinc oxide, zirconium silicate and low-temperature frit; the clam meal, zirconium silicate, chlorite, white corundum and zinc oxide are added into a glaze and matched with other chemical raw materials and natural raw materials, so that the fired craft porcelain is white and transparent in glaze surface, uniform, clean and thick in glaze layer and smooth in glaze surface, and a unique moon white glaze effect is achieved.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Glaze for extra-high voltage porcelain insulator, and production method thereof

The invention provides a formula and a preparation method of a glaze for an extra-high voltage porcelain insulator, wherein the raw materials of the formula comprise, by weight, 20-33 parts of quartz,10-18 parts of illite, 10-15 parts of semi-mountain clay, 10-15 parts of zirconium silicate micro powder, 4-7 parts of white corundum micro powder, 1-5 parts of nanometer silicon dioxide, 3-6 parts of wollastonite, 1-2 parts of barium carbonate, 7-12 parts of Zuoyun soil, 5-7 parts of manganese oxide, 1-2 parts of iron oxide, 1-2 parts of chromium oxide, 3-5 parts of antimony oxide, 2-8 parts ofsepiolite powder and 2-8 parts of bentonite. The preparation method comprises: preparing nanometer silicon dioxide composite modified sepiolite powder, preparing a solid solution, carrying out wet ball milling, and adjusting the specific gravity of glaze slurry. According to the invention, with the glaze obtained by the formula and the method, the insulator has excellent stain resistance and excellent voltage sharing performance, further has substantially improved mechanical performance and substantially improved electrical performance, and is suitable for extra-high voltage direct current power transmission systems.

Owner:江西高强电瓷集团有限公司

Opacified glaze with no zircon sand

The invention discloses opacified glaze with no zircon sand, which comprises the following components in parts by weight: 5-10 parts of zirconium silicate, 5-15 parts of zinc oxide, 5-10 parts of boric acid, 10-20 parts of potash feldspar, 2-5 parts of potassium nitrate, 4-10 parts of dolomite, 8-15 parts of calcite, 6-15 parts of kaolin, and 30-40 parts of quartz. The opacified glaze with no zircon sand replaces zircon sand with zirconium silicate, therefore, the harm to the health of human body is reduced, and the production cost is reduced at the same time.

Owner:谢健城

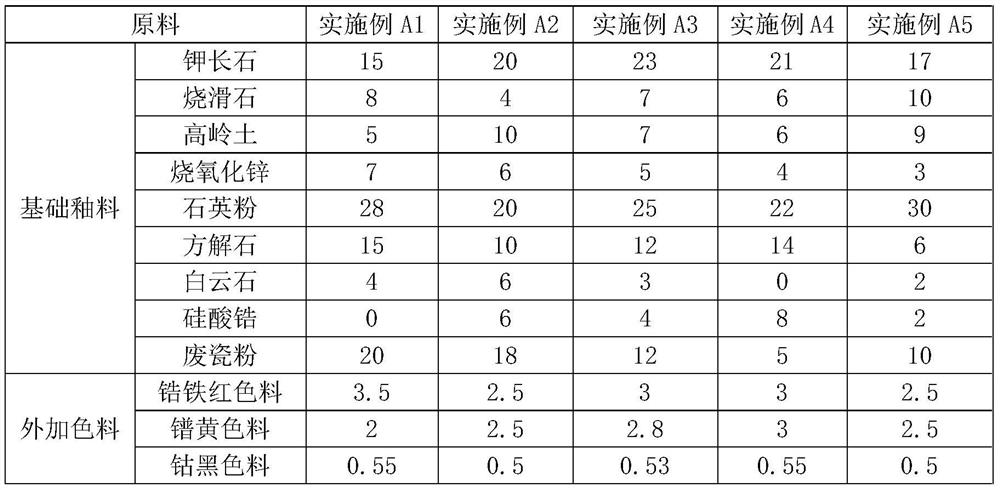

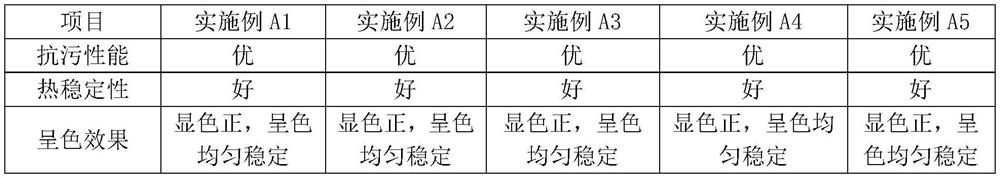

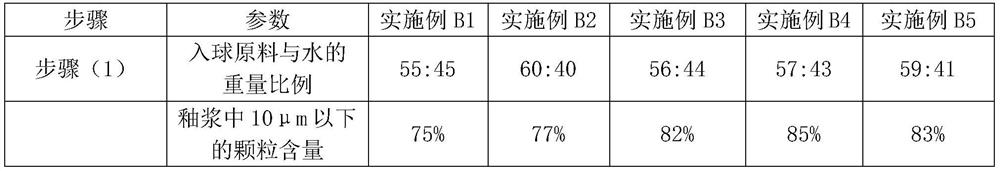

Waste porcelain powder doped matt color glaze, ceramic product and preparation method

The invention discloses a waste ceramic powder doped matt color glaze, a ceramic product, a preparation method of the ceramic product and a glaze. The formula of the basic glaze comprises the following raw materials in parts by weight: 15-30 parts of potassium feldspar, 4-10 parts of calcined talc, 5-10 parts of kaolin, 3-7 parts of calcined zinc oxide, 20-30 parts of quartz powder, 6-16 parts ofcalcite, 0-6 parts of dolomite, 0-8 parts of zirconium silicate and 5-20 parts of waste porcelain powder. The glaze surface of a ceramic product fired by adopting the glaze material is a matt glaze surface, and the color is normal, uniform and stable.

Owner:FOSHAN DONGPENG SANITARY WARE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com