Glaze for extra-high voltage porcelain insulator, and production method thereof

A technology of a porcelain insulator and a manufacturing method, which is applied in the field of electric porcelain insulators, can solve the problems such as insufficient performance of glaze machine, electricity and heat, difficulty in ensuring long-term reliable operation of a power grid, unfavorable and uniform distribution, etc., so as to improve the glaze surface. Quality and mechanical properties, effects of improving suspension and fluidity, increasing mechanical strength and insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

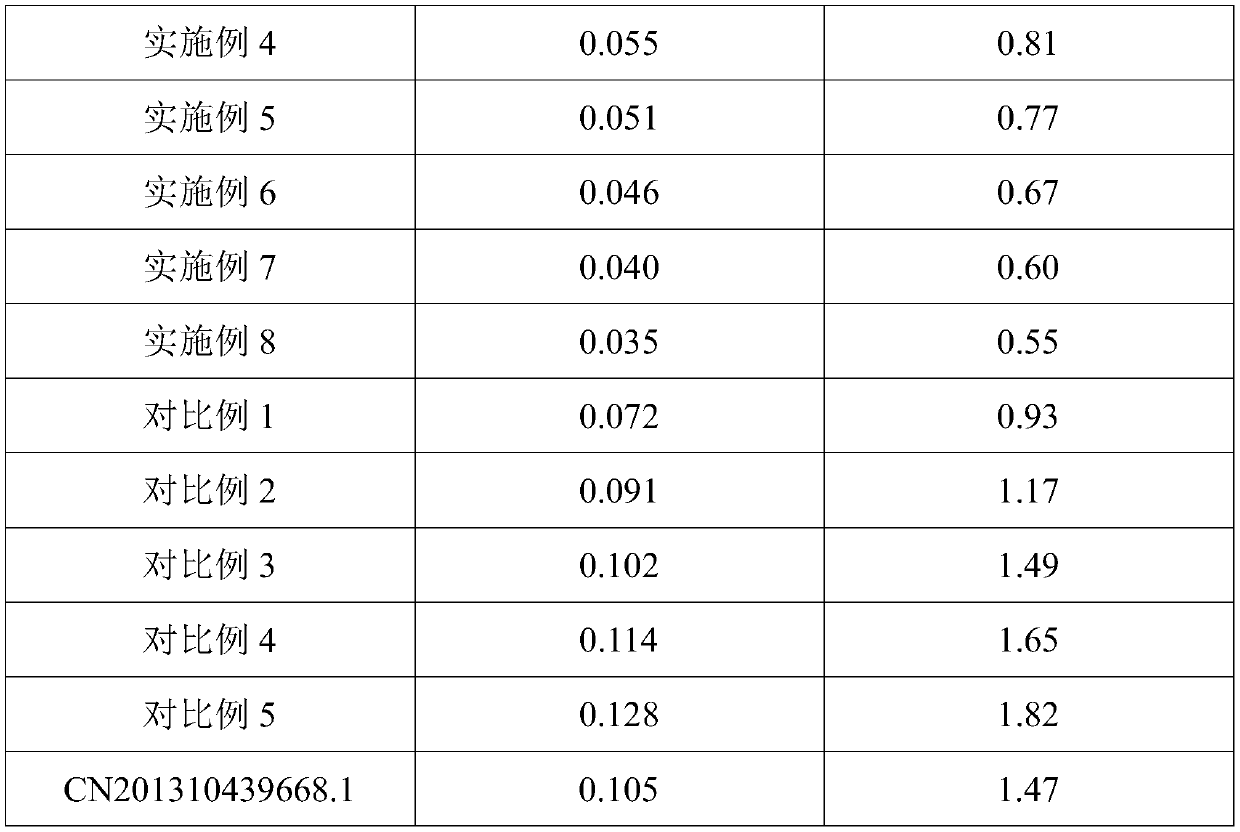

Embodiment 1

[0046] Glaze formula: 20 parts of quartz, 18 parts of illite, 15 parts of half mountain clay, 10 parts of zirconium silicate powder, 4 parts of white corundum powder, 1 part of nano silicon dioxide, 3 parts of wollastonite, 1 part of barium carbonate, left 7 parts of dolomite, 7 parts of manganese oxide, 1 part of iron oxide, 1 part of chromium oxide, 3 parts of antimony oxide, 2 parts of sepiolite powder, and 8 parts of bentonite. Wherein, the particle diameter of the nano silicon dioxide is 20-100 nm, and the particle diameter of the sepiolite powder is 200-500 nm.

[0047] The preparation method of the glaze for UHV porcelain insulators of the present invention comprises the following steps:

[0048] S1. Prepare a N,N-dimethylformamide solution of trimethylolpropane with a mass concentration of 10%, add sepiolite powder to it, and mix evenly to obtain a mixed solution;

[0049] Add nano-silica, dispersant EFKA SL 3034, defoamer Deform 6800 and wetting agent GSK-582 into de...

Embodiment 2

[0056] Glaze formula: 33 parts of quartz, 10 parts of illite, 10 parts of semi-mountain clay, 15 parts of zirconium silicate powder, 6 parts of white corundum powder, 5 parts of nano silicon dioxide, 6 parts of wollastonite, 2 parts of barium carbonate, left 10 parts of dolomite, 5 parts of manganese oxide, 1 part of iron oxide, 2 parts of chromium oxide, 5 parts of antimony oxide, 8 parts of sepiolite powder, 6 parts of organic modified bentonite. Wherein, the particle diameter of the nano silicon dioxide is 20-100 nm, and the particle diameter of the sepiolite powder is 300-500 nm.

[0057] The preparation method of the glaze for UHV porcelain insulators of the present invention comprises the following steps:

[0058] S1. Prepare a N,N-dimethylformamide solution of trimethylolpropane with a mass concentration of 20%, add sepiolite powder to it, and mix evenly to obtain a mixed solution;

[0059] Add nano-silica, dispersant Dow Corning 51, defoamer Efka SL 2038 and wetting a...

Embodiment 3

[0066] Glaze formula: 25 parts of quartz, 15 parts of illite, 12 parts of half mountain clay, 12 parts of zirconium silicate powder, 5.5 parts of white corundum powder, 4 parts of nano silicon dioxide, 5 parts of wollastonite, 2 parts of barium carbonate, left 10 parts of dolomite, 5.5 parts of manganese oxide, 1.5 parts of iron oxide, 1.5 parts of chromium oxide, 4 parts of antimony oxide, 7 parts of sepiolite powder, and 7 parts of organically modified bentonite. Wherein, the particle diameter of the nano silicon dioxide is 50-100 nm, and the particle diameter of the sepiolite powder is 200-500 nm.

[0067] The preparation method of the glaze for UHV porcelain insulators of the present invention comprises the following steps:

[0068] S1. Prepare a N,N-dimethylformamide solution of trimethylolpropane with a mass concentration of 15%, add sepiolite powder to it, and mix evenly to obtain a mixed solution;

[0069] Add nano-silica, dispersant Dow Corning 51, defoamer Dow Corni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com