Manufacturing method of soft-light glazed ceramic chip

A manufacturing method and technology of soft glaze, applied in the direction of manufacturing tools, glass manufacturing equipment, glass furnace equipment, etc., can solve the problems of difficult control of firing temperature, increase of polishing cost, and increase of polishing process, so as to increase hardness and improve bonding Performance, effect of increasing opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

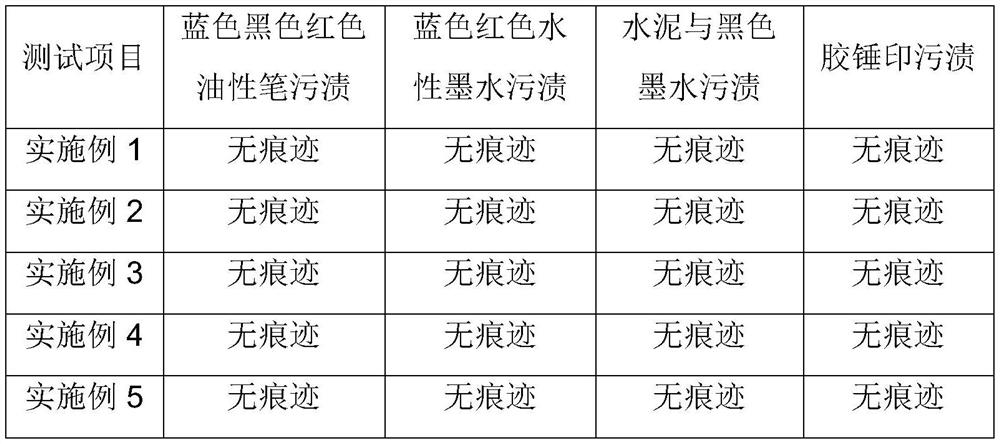

Examples

Embodiment 1

[0030] Preparation of Soft Glazed Porcelain:

[0031] a. According to the weight percentage of frit raw materials: calcite: 12%, barium carbonate 15%, potassium feldspar 36%, zinc oxide 6%, kaolin 15%, calcium borate 4%, soda ash 2%, quartz sand 10% weighed raw material. After the raw materials are mixed, they are put into the frit furnace to be calcined and melted at 1540°C, and then flow out of the frit furnace and quenched into frit particles for later use.

[0032] The chemical composition of the frit is: SiO2 50.9%, Al 2 o 3 11.4%, MgO 0.35%, CaO 8.9%, Na 2 O is 1.5%, K 2 O is 4.5%, BaO is 13.45%, ZnO is 6.5%, B 2 o 3 2.2%, TiO 2 0.1%, Fe 2 o 3 0.2%.

[0033] b. Weigh 71% of frit, 15% of zirconium silicate, 5% of calcined kaolin, 8% of air-knife clay, 0.4% of methyl cellulose, and 0.6% of sodium tripolyphosphate according to the raw materials of soft glaze, and the water content is dry 39% of the weight of the material, ball milled for 8 to 12 hours to obtain a...

Embodiment 2

[0039] Preparation of Soft Glazed Porcelain:

[0040] a. According to the weight percentage of frit raw materials: calcite: 10%, barium carbonate 18%, potassium feldspar 36%, zinc oxide 5%, kaolin 15%, calcium borate 4%, soda ash 2%, quartz sand 10% weighed raw material. After the raw materials are mixed, they are put into the frit furnace to be calcined and melted at 1600°C, and then flow out of the frit furnace and quenched into frit particles for later use.

[0041] The chemical composition of the frit is: SiO 2 50.55%, Al 2 o 3 11.5%, MgO 0.35%, CaO 7.0%, Na 2 O is 1.5%, K 2 O is 4.5%, BaO is 16%, ZnO is 6.0%, B 2 o 3 2.3%, TiO 2 0.1%, Fe 2 o 3 0.2%.

[0042] b. Weigh 89.4% of frit, 2% of zirconium silicate, 4% of calcined kaolin, 4% of air-knife clay, 0.4% of methyl cellulose, and 0.2% of sodium tripolyphosphate according to the raw materials of soft glaze, and the water content is dry 39% of the weight of the material, ball milled for 8 to 12 hours to obtain ...

Embodiment 3

[0048] Preparation of Soft Glazed Porcelain:

[0049] a. According to the weight percentage of frit raw materials: calcite: 14%, barium carbonate 12%, potassium feldspar 40%, zinc oxide 7%, kaolin 12%, calcium borate 4%, soda ash 1%, quartz sand 10% weighed raw material. After the raw materials are mixed, they are put into the frit furnace to be calcined and melted at 1500°C, and then flow out of the frit furnace and quenched into frit particles for later use.

[0050] The chemical composition of the frit is: SiO 2 52.25%, Al 2 o 3 10%, MgO 0.35%, CaO 10.5%, Na 2 O is 1.0%, K 2 O is 5.0%, BaO is 10.5%, ZnO is 7.7%, B 2 o 3 2.3%, TiO 2 0.1%, Fe 2 o 3 0.3%.

[0051] b. Weigh 79.45% of frit, 12% of zirconium silicate, 8% of air-knife soil, 0.2% of methyl cellulose, and 0.35% of sodium tripolyphosphate according to the raw materials of soft glaze, and the water content is 39% of the weight of dry material , ball milled for 8 to 12 hours to obtain the glaze slurry, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com