Preparation method of zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as zirconium source and product prepared by preparation method

A technology of ammonium zirconium carbonate and ceramic pigments, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., and can solve the problems of alkali resistance and acid resistance, reducing the proportion of colorants in color materials, light color of color materials, etc. , to achieve high wrapping rate and improve the effect of color depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

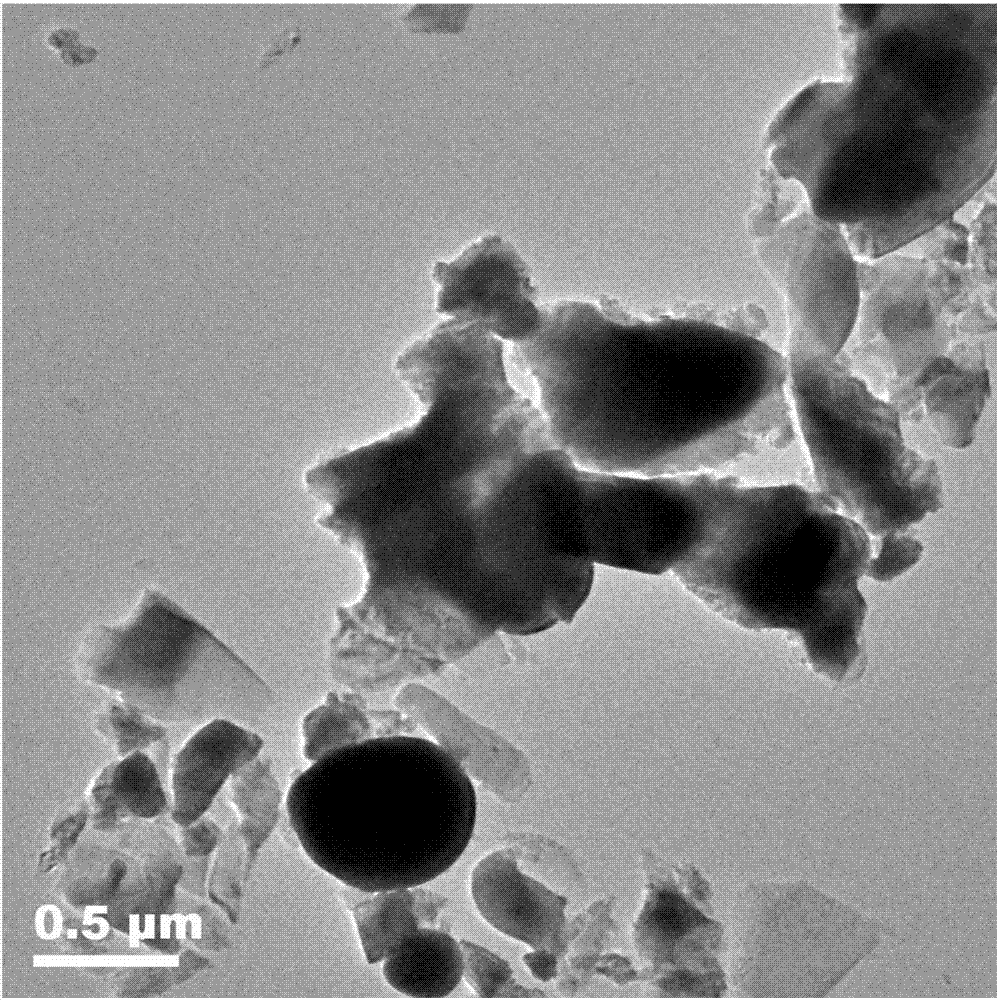

Image

Examples

Embodiment 1

[0023] In this embodiment, a method for preparing zirconium silicate wrapped ceramic pigments using ammonium zirconium carbonate as a source of zirconium, the steps are as follows:

[0024] (1) 10g carbon black, 0.5g 10wt% PEG-200 solution and 200mL water were vigorously stirred to form a stable suspension, and then added to 200mL concentration of zirconium ammonium carbonate solution of 25wt% (containing 19wt% ZrO in the solution after conversion) 2 ), stirred evenly and placed in a 55°C oven for 4 hours to form a zirconia-coated powder suspension; after being completely dried in a 150°C oven, crush it with a crusher to obtain a zirconia-coated carbon black powder;

[0025] (2) Add the above 10g of zirconia-wrapped carbon black powder to 20g of silica sol with a concentration of 30wt%, mix evenly, adjust the pH value to 9 with dilute ammonia water, form a gel, and heat to 150°C to dry to obtain a ceramic colorant Precursor;

Embodiment 2

[0029] In this embodiment, a method for preparing zirconium silicate wrapped ceramic pigments using ammonium zirconium carbonate as a zirconium source differs from Example 1 in that:

[0030] In step (1), ammonium zirconium carbonate solution contains 20wt% ZrO 2 ; The formed zirconia-encapsulated powder suspension is not dried or pulverized.

[0031] In step (2), the zirconia-coated powder suspension formed in step (1) is added to 100 g of silica sol with a concentration of 30 wt % and mixed evenly.

[0032] The encapsulation rate of the zirconium silicate wrapped carbon black material powder prepared in this embodiment is 85%, the mass ratio of carbon black in the finished color material product in the finished color material is 10.8%, and the chromaticity is: L*=23.81, a* = -0.51, b* = -0.13.

Embodiment 3

[0034] In this embodiment, a method for preparing zirconium silicate wrapped ceramic pigments using ammonium zirconium carbonate as a source of zirconium, the steps are as follows:

[0035] (1) 10g cadmium sulfoselenide (commercially available unwrapped cadmium selenide red material), 0.5g PEG-200 solution, 50g water and 50g ammonium zirconium carbonate solution (containing 20wt% ZrO 2 ), stirred rapidly to form a stable suspension, placed in a 55°C oven for 8 hours to form a zirconia-coated powder suspension; after being completely dried in a 150°C oven, crushed with a crusher to obtain zirconia-coated cadmium selenide sulfur powder body;

[0036] (2) Add 20 g of silica sol with a concentration of 30 wt % to the above-mentioned zirconia-wrapped cadmium selenide powder and mix evenly, adjust the pH value to 9 with dilute ammonia water, form a gel, and microwave-dry to obtain a ceramic pigment precursor;

[0037] (3) Add lithium fluoride in an amount of 3wt% to the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com