Polyester fabric dyeing technology

A technology of polyester fabric and process, applied in the field of polyester fabric dyeing process, can solve the problems such as the dyeing effect needs to be improved, the procedure is complicated, and the environmental protection needs to be improved, so as to achieve the effect of saving caustic soda consumption, simplifying the processing process and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

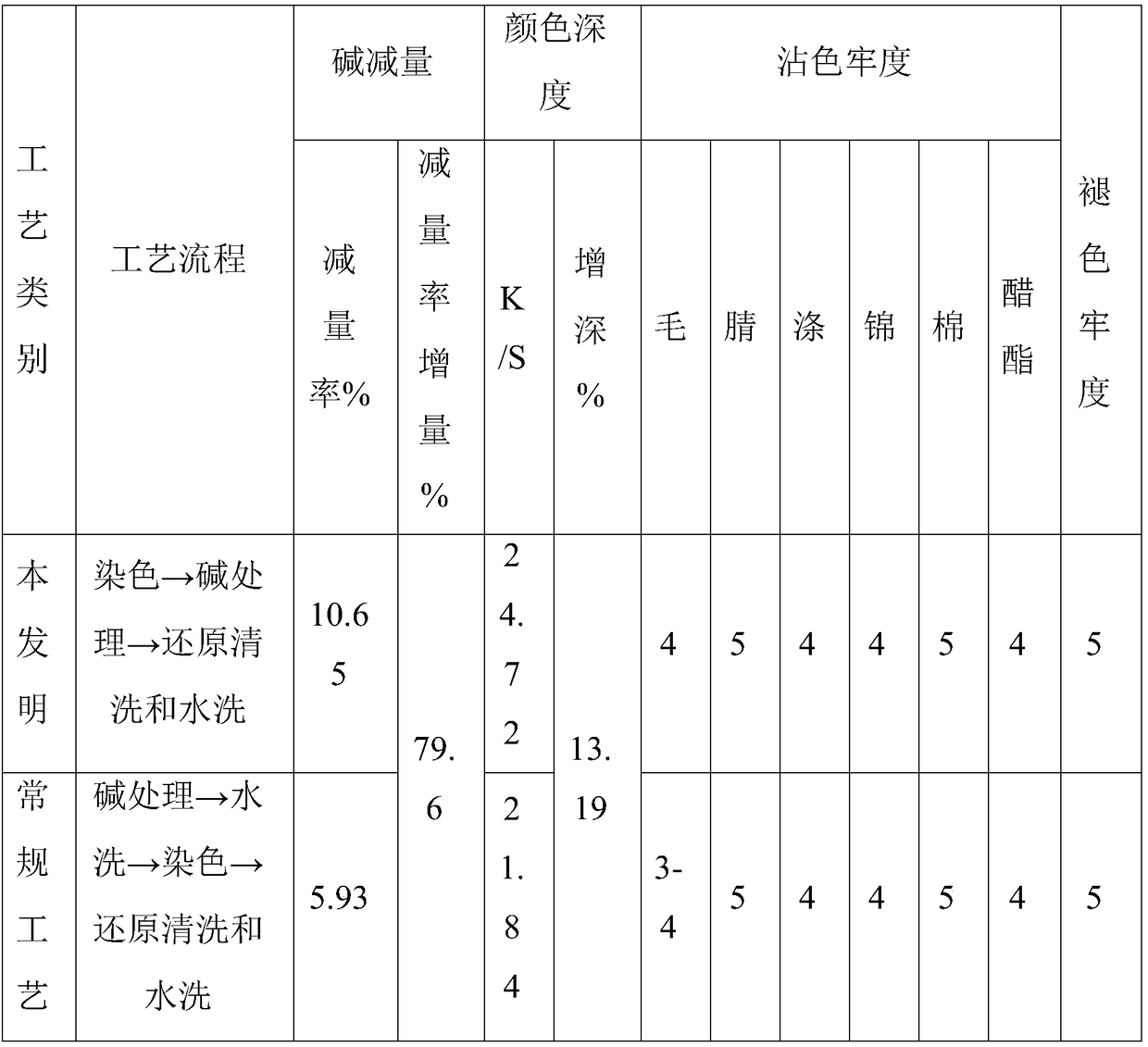

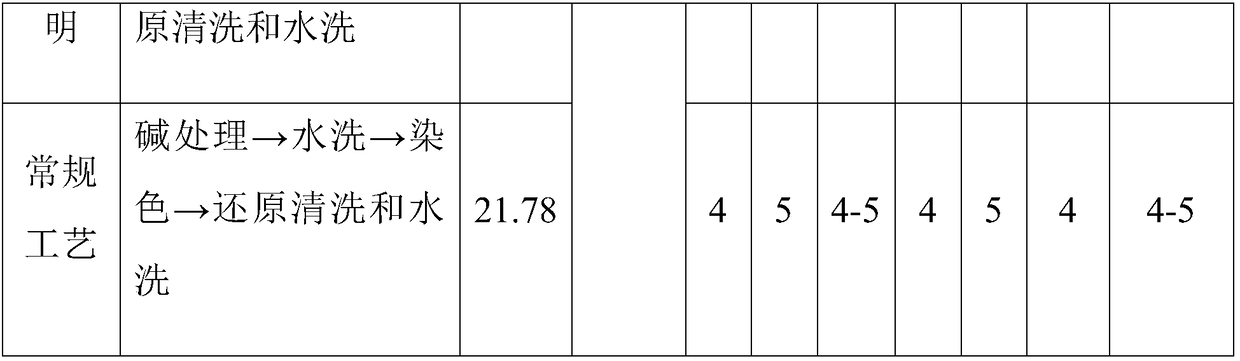

Examples

Embodiment 1

[0048] Disperse Scarlet HA-G Dyed Polyester Knitted Fabric

[0049] Polyester fabric dyeing process provided by the invention, the steps are as follows:

[0050](1) High-temperature and high-pressure dyeing of polyester knitted fabrics: the amount of dyestuff is 2% of the weight of the fabric, and the leveling agent is 2g / L (NICCASUNSOLT 7000Z, Zhejiang Rihua Chemical Co., Ltd.); prepared according to the weight ratio of dye liquor and fabric at 20:1 For the dyeing solution, heat up to 90°C at 2°C / min on the high-temperature and high-pressure dyeing machine, and keep warm for 15 minutes; then raise the temperature to 120°C at a heating rate of 2°C / min, and keep warm for 45 minutes; after dyeing, cool down at a cooling rate of 4°C / min To below 80 ℃, discharge the dye liquor.

[0051] (2) Alkali reduction of dyed polyester knitted fabric: inject 5g / L caustic soda solution into the dyeing vat, the weight ratio of caustic soda solution to fabric is 20:1, raise the temperature to ...

Embodiment 2

[0063] Disperse Scarlet HA-G Dyed Polyester Knitted Fabric

[0064] Polyester fabric dyeing process provided by the invention, the steps are as follows:

[0065] (1) High temperature and high pressure dyeing of polyester knitted fabric: the amount of dyestuff is 2% of the weight of the fabric, and the leveling agent is 1g / L NICCASUNSOLT 7000Z (Zhejiang Rihua Chemical Co., Ltd.); at room temperature, the weight ratio of dyeing liquor to fabric is 20:1 Prepare the dyeing solution, raise the temperature to 100°C at 1°C / min on the high-temperature and high-pressure dyeing machine, and keep warm for 20 minutes; then raise the temperature to 130°C at a heating rate of 1°C / min, and keep warm for 60 minutes; after dyeing, cool down at a rate of 4°C / min Cool down to below 80°C and discharge the dye liquor.

[0066] (2) Alkali treatment of dyed polyester knitted fabric: inject alkaline solution into the dyeing vat, the weight ratio of alkaline solution to fabric is 20:1, and the alkali...

Embodiment 3

[0079] Disperse Scarlet HA-G Dyed Polyester Knitted Fabric

[0080] Polyester fabric dyeing process provided by the invention, the steps are as follows:

[0081] (1) High-temperature and high-pressure dyeing of polyester knitted fabrics: the amount of dyestuff is 0.1% of the weight of the fabric, and the leveling agent is 0.5g / LNICCA SUNSOLT 7000Z (Zhejiang Rihua Chemical Co., Ltd.); at room temperature, the weight ratio of the dye liquor to the fabric is 20: 1 Prepare the dyeing solution, raise the temperature to 70°C at 0.5°C / min on the high-temperature and high-pressure dyeing machine, and keep it warm for 20 minutes; then raise the temperature to 130°C at a heating rate of 1°C / min, and keep it warm for 60 minutes; after dyeing, cool down at 0.5°C / min The temperature is lowered to below 80°C, and the dye liquor is discharged.

[0082] (2) Alkali treatment of dyed polyester knitted fabric: inject alkaline solution into the dyeing vat, the weight ratio of alkaline solution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com