Dyeing method for anti-cutting fabric

A dyeing method and anti-cutting technology, applied in the field of fabrics in the textile industry, can solve problems such as unstable effect, and achieve the effects of increasing adhesion, reducing costs, and reducing consumption of pigments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] A dyeing method for cut-resistant fabrics, comprising the following steps: gray fabric pretreatment → primary drying → corona treatment → scratch printing paint color paste → secondary drying → baking → finished product; wherein:

[0028] The specifications of the gray cloth are as follows: the ultra-high molecular weight polyethylene woven fabric is adopted, and the grammage is 235g / m 2 , a width of 235cm, and a thickness of 0.58mm.

[0029] The gray cloth pre-treatment:

[0030] The process flow is as follows: return water → add treatment solution at 70°C → scouring at 95°C for 40 minutes → cloth output → washing at 70 °C → normal temperature water washing → cloth output;

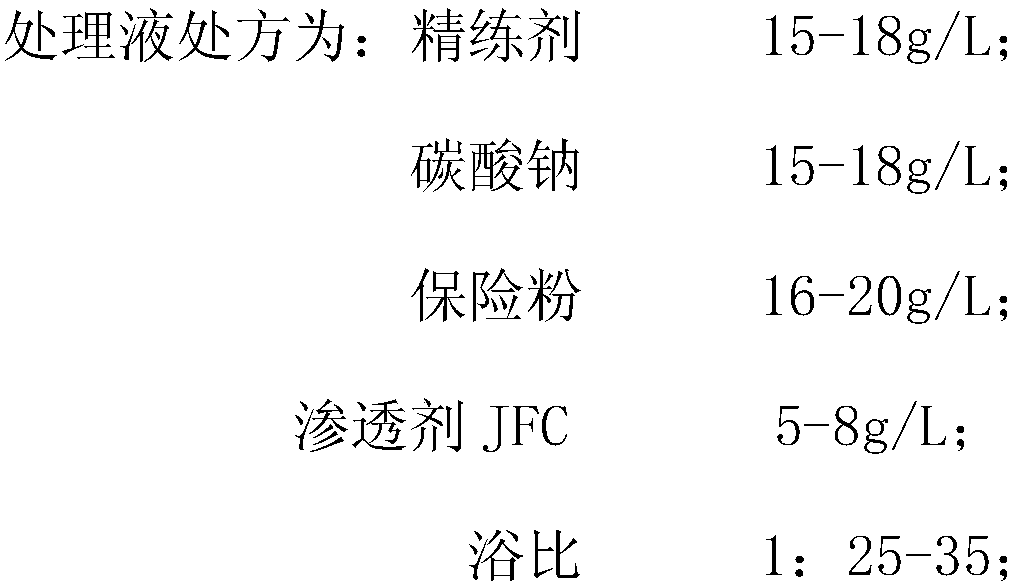

[0031]

[0032] The primary drying: the drying temperature of the setting machine is 110° C., and the drying time is 2 minutes.

[0033] The corona treatment:

[0034] Voltage 5000V / m 2 ;

[0035] Output power 2kW;

[0036] Frequency 10kHz;

[0037] The scraping paint color paste:

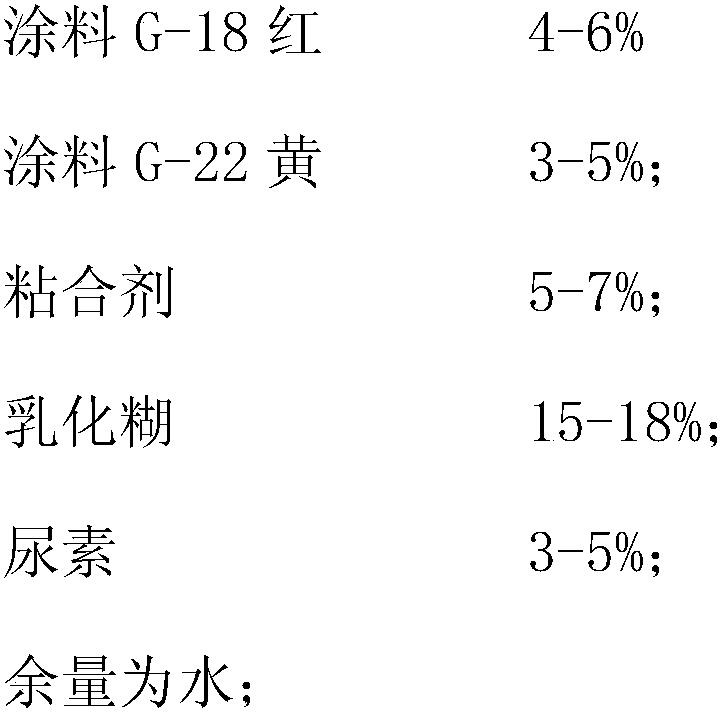

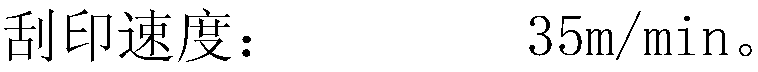

[003...

specific Embodiment 2

[0043] A dyeing method for cut-resistant fabrics, comprising the following steps: gray fabric pretreatment → primary drying → corona treatment → scratch printing paint color paste → secondary drying → baking → finished product; wherein:

[0044] The specifications of the gray cloth are as follows: use ultra-high molecular weight polyethylene woven fabric, the grammage is 255g / m 2 , a width of 240cm, and a thickness of 0.62mm.

[0045] The gray cloth pre-treatment:

[0046] The process flow is as follows: return water → add treatment solution at 75°C → scouring at 102°C for 50 minutes → cloth output → washing at 80 °C → normal temperature water washing → cloth output;

[0047]

[0048] The primary drying: the drying temperature of the setting machine is 120° C., and the drying time is 3 minutes.

[0049] The corona treatment:

[0050] Voltage 15000V / m 2 ;

[0051] Output power 70kW;

[0052] Frequency 25kHz;

[0053] Described scratch printing paint color paste:

[0...

specific Embodiment 3

[0058] A dyeing method for cut-resistant fabrics, comprising the following steps: gray fabric pretreatment → primary drying → corona treatment → scratch printing paint color paste → secondary drying → baking → finished product; wherein:

[0059] The specifications of the gray cloth are as follows: the ultra-high molecular weight polyethylene woven fabric is adopted, and the grammage is 240g / m 2 , a width of 237cm, and a thickness of 0.6mm.

[0060] The gray cloth pre-treatment:

[0061] The process flow is as follows: return water → add treatment solution at 73°C → scouring at 99°C for 47 minutes → cloth output → washing at 72 °C → normal temperature water washing → cloth output;

[0062]

[0063]

[0064] The first drying: the drying temperature of the setting machine is 110-120° C., and the drying time is 2-3 minutes.

[0065] The corona treatment:

[0066] Voltage 8000V / m 2 ;

[0067] Output power 40kW;

[0068] Frequency 18kHz;

[0069] Described scratch print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com