Patents

Literature

136results about How to "High parcel rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

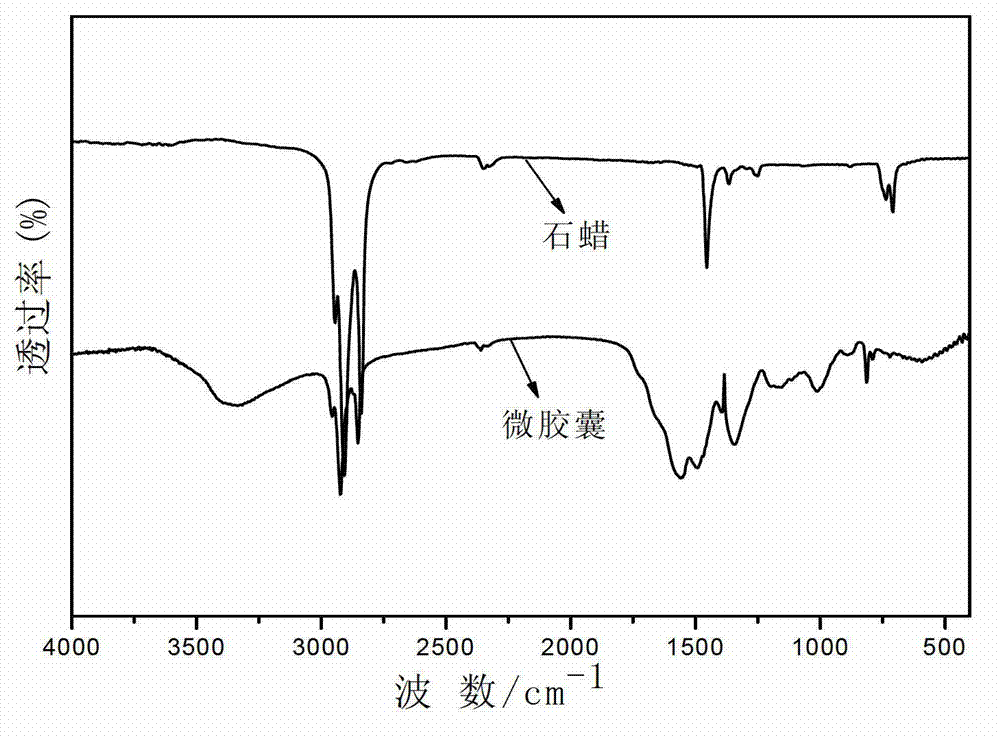

Paraffin wax phase change energy storage material and preparation method thereof

InactiveCN102127395ALow priceImprove surface propertiesSolid waste managementHeat storage plantsParaffin waxFilm coating

The invention provides a paraffin wax phase change energy storage material and a preparation method thereof. The paraffin wax phase change energy storage material comprises 48 to 56.7 percent of paraffin wax, 14.2 to 32 percent of high-density polyethylene, 4 to 5.7 percent of sodium dodecyl benzene sulfonate serving as a surfactant, 10.4 to 15.6 percent of sodium alginate serving as a film forming material and 5.6 to 7.8 percent of anhydrous calcium chloride serving as a crosslinking agent. The method for preparing paraffin wax phase change energy storage material comprises the following steps: preparing a microcapsule phase change material by using paraffin wax as a core material and high-density polyethylene as supporting material and by using a melting method; and preparing millimetercapsule phase change material by using a thin film coating technique. In the invention, the technical problems of low paraffin wax mixing amount, low storage performance, leakage, low stability and the like of the conventional microcapsule phase change material are solved.

Owner:SOUTHEAST UNIV

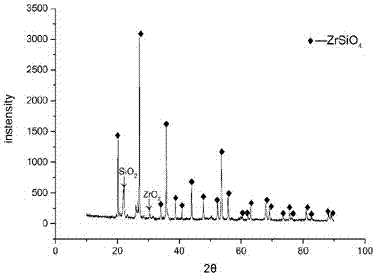

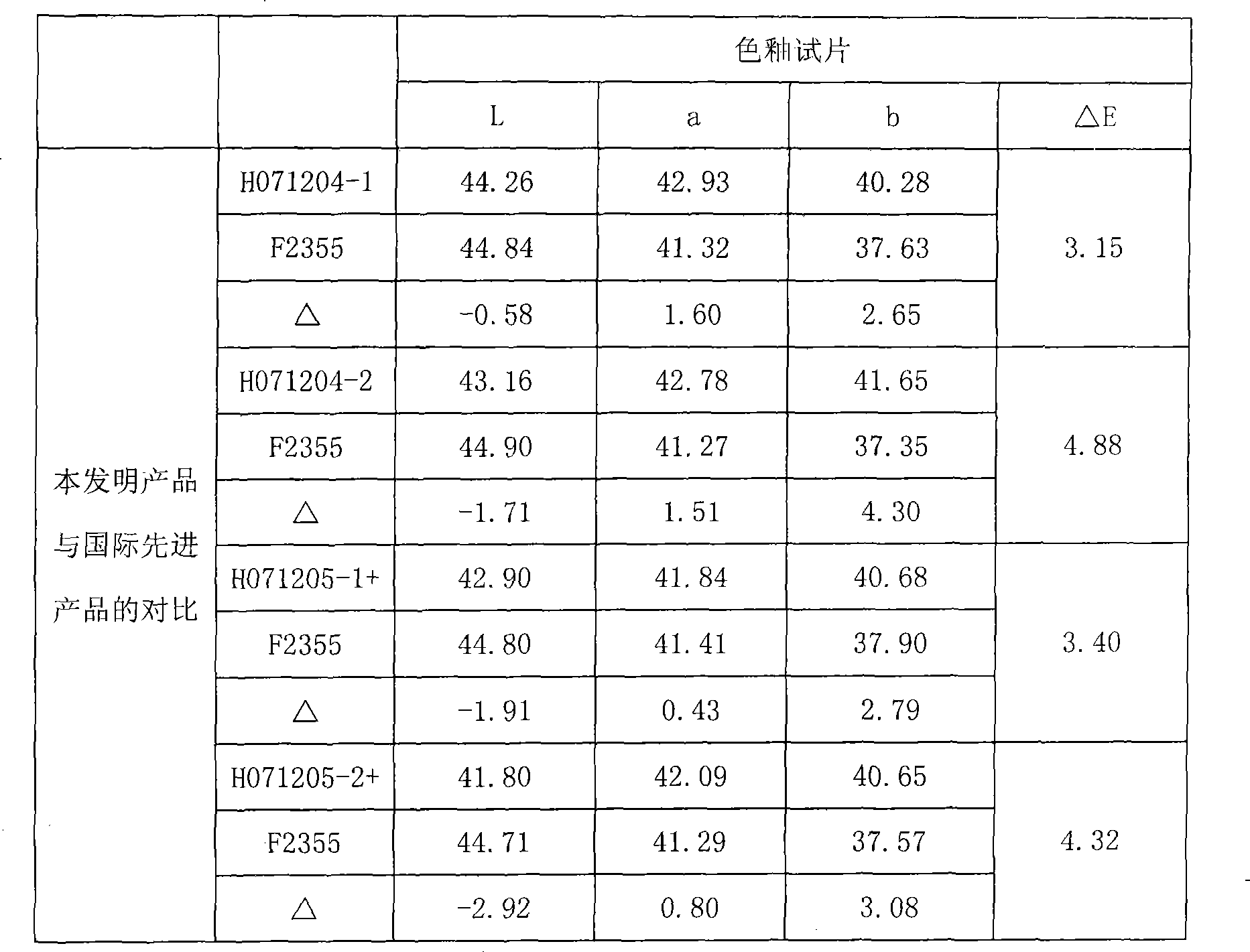

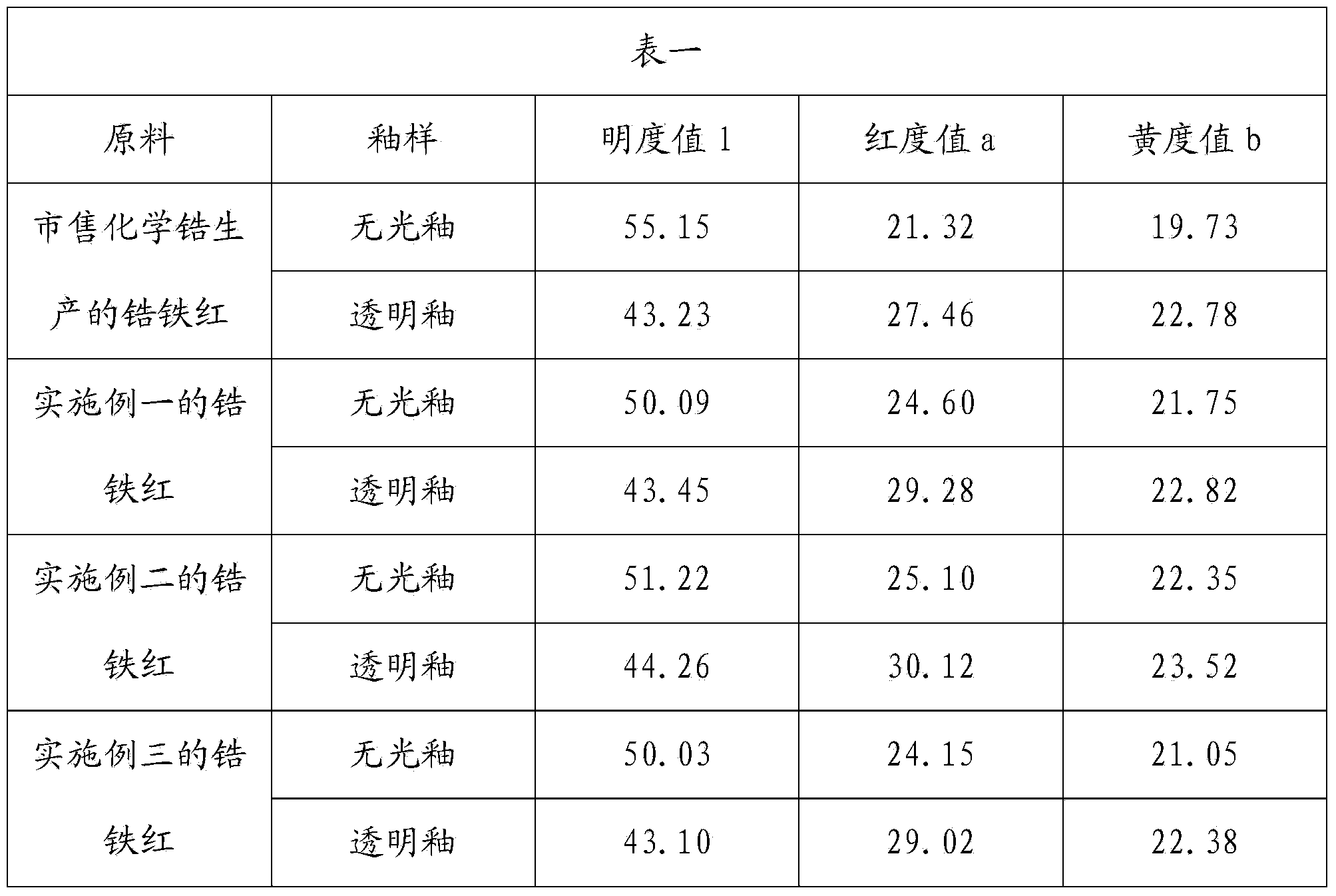

Zirconium silicate coated ceramic pigment and method for making same

InactiveCN101182236ALower crystallization activation energyAccelerate the crystallization rateThermal treatmentAccelerant

The invention provides a zirconium silicate enwrapped ceramic pigment which comprises a color body and also comprises a shell body of metal oxide which is compounded by the zirconium silicate, and the shell body enwraps the color body compactly and completely. The invention also provides a preparation method of the zirconium silicate enwrapped ceramic pigment. Because accelerant is introduced into the preparation process, the method has the advantages that the loss of the color body is little; the enwrapping layer of the pigment is compact; the enwrapping rate is high; no thermal treatment of high temperature is required during the preparation process etc.

Owner:GUANGDONG DONGPENG CERAMIC CO LTD

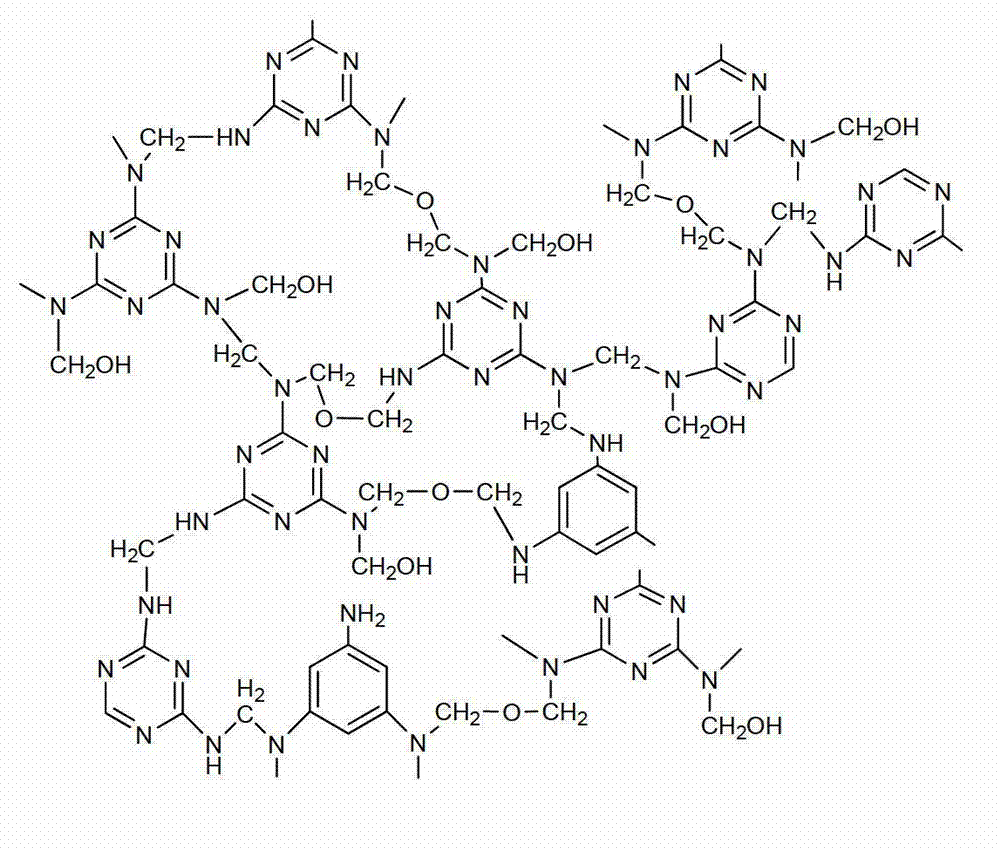

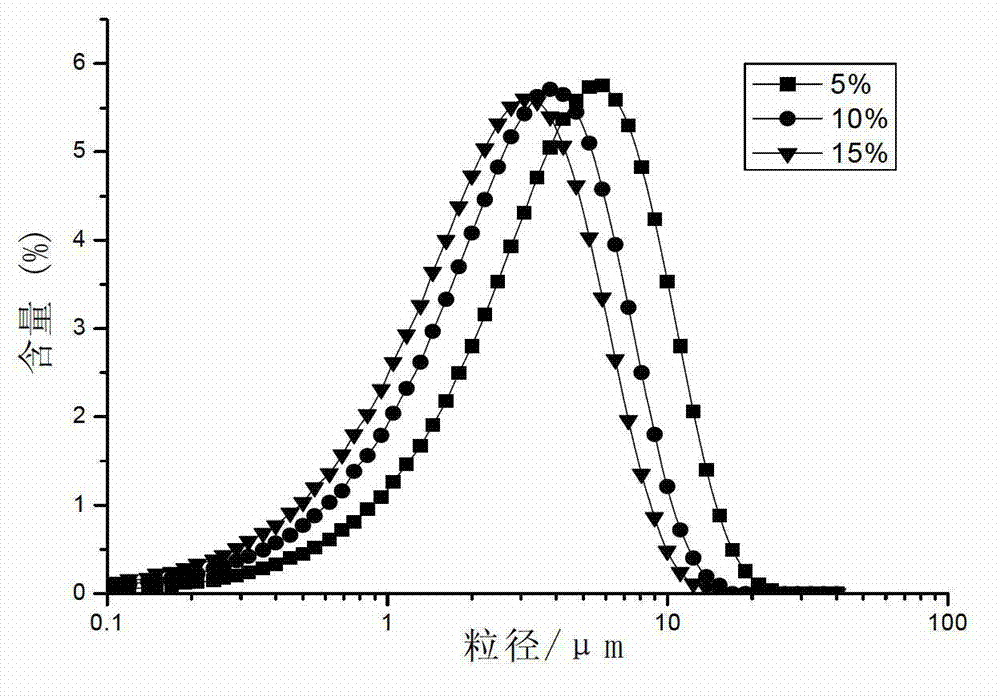

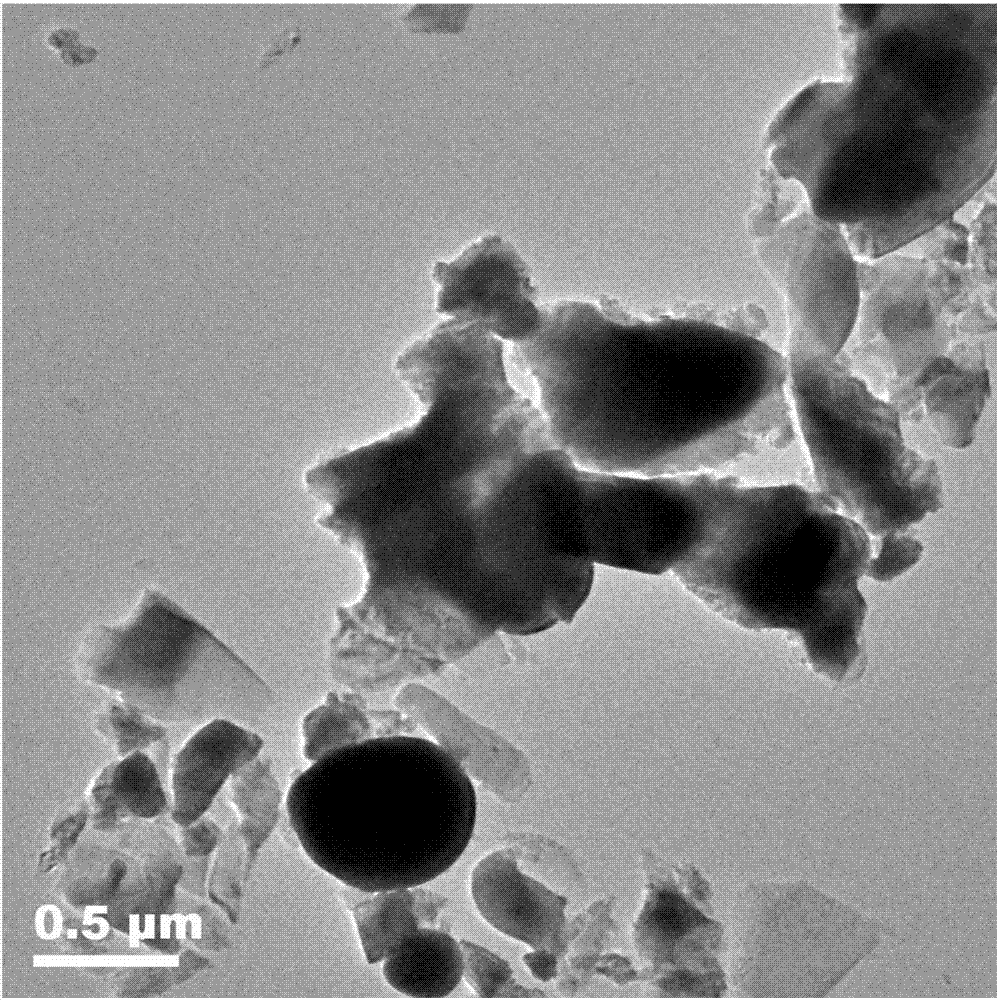

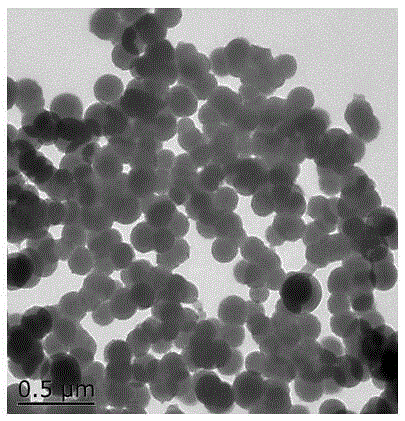

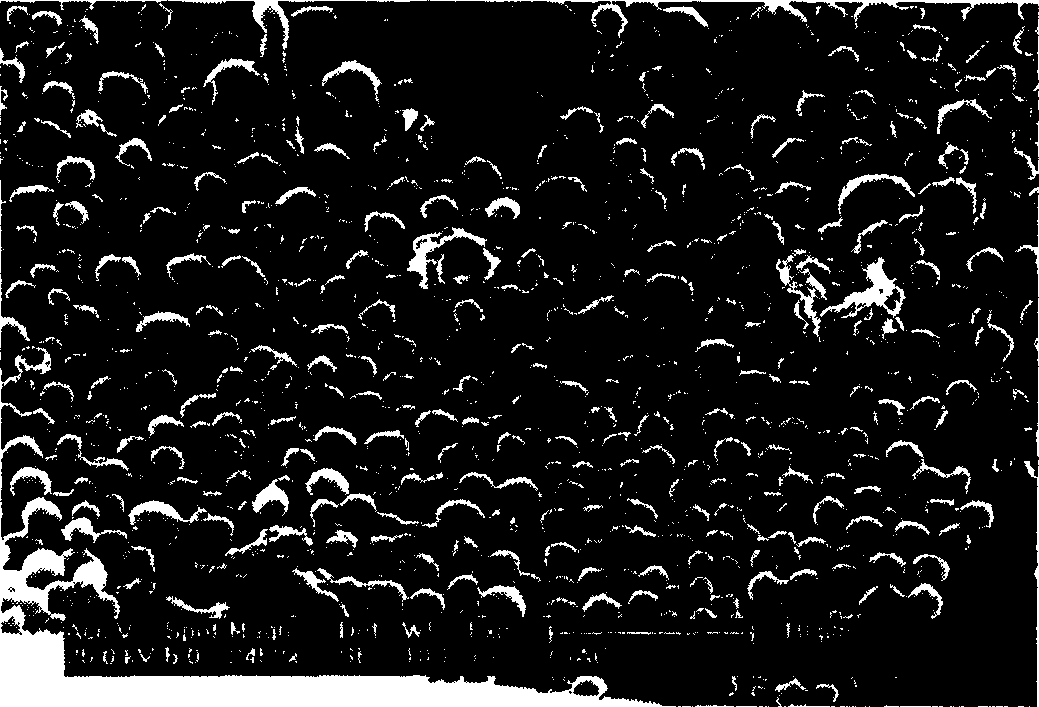

Method for preparing microcapsule phase change material by using composite emulsifier

InactiveCN103170289AUniform particle size distributionOvercome the problem of air bubbles during stirringHeat-exchange elementsMicroballoon preparationParaffin waxIn situ polymerization

The invention discloses a method for preparing a microcapsule phase change material by using a composite emulsifier, which is used for preparing a microcapsule phase change material by using an in-situ polymerization method with paraffin as the core material and melamine-formaldehyde resin as the wall material. According to the method, firstly an oil-in-water (o / w) latex is prepared under the certain rotation speed with tween-20 and span-80 as the composite emulsifier, then melamine-formaldehyde prepolymer solution is added into the latex, the prepolymer gradually swells and deposits on the surface of the core material, a solid capsule shell is finally formed due to continuous cross linking and polymerization, and the encapsulated-completely phase change material microcapsule is obtained. The microcapsule phase change material prepared according to the method has the particle size of 3-4 mum, and has regular surface morphology, high encapsulation rate and good permeability resistance, and the method is simple and applied to the fields of building energy storage, textile and clothing, military affairs and the like.

Owner:DALIAN UNIV

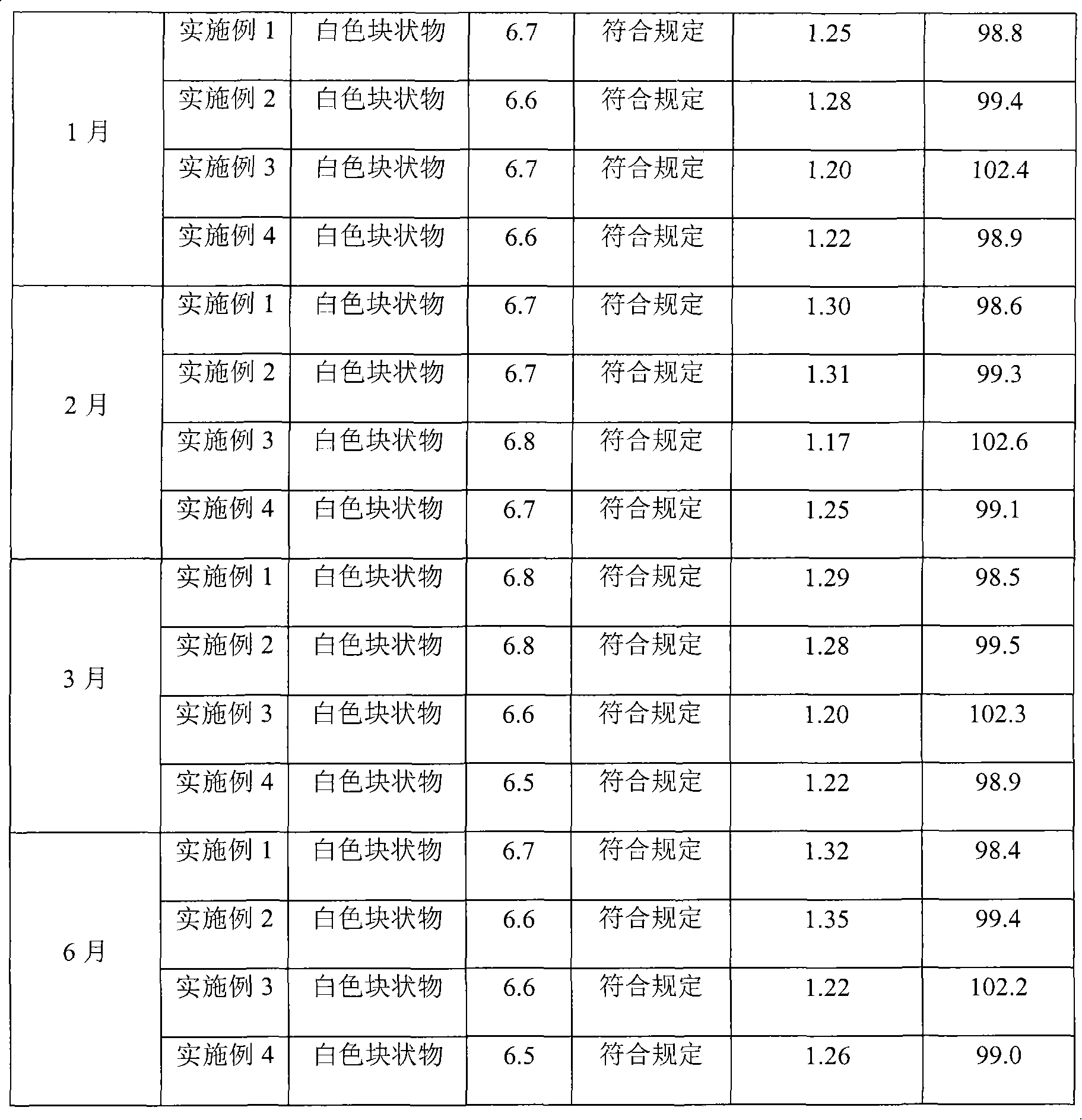

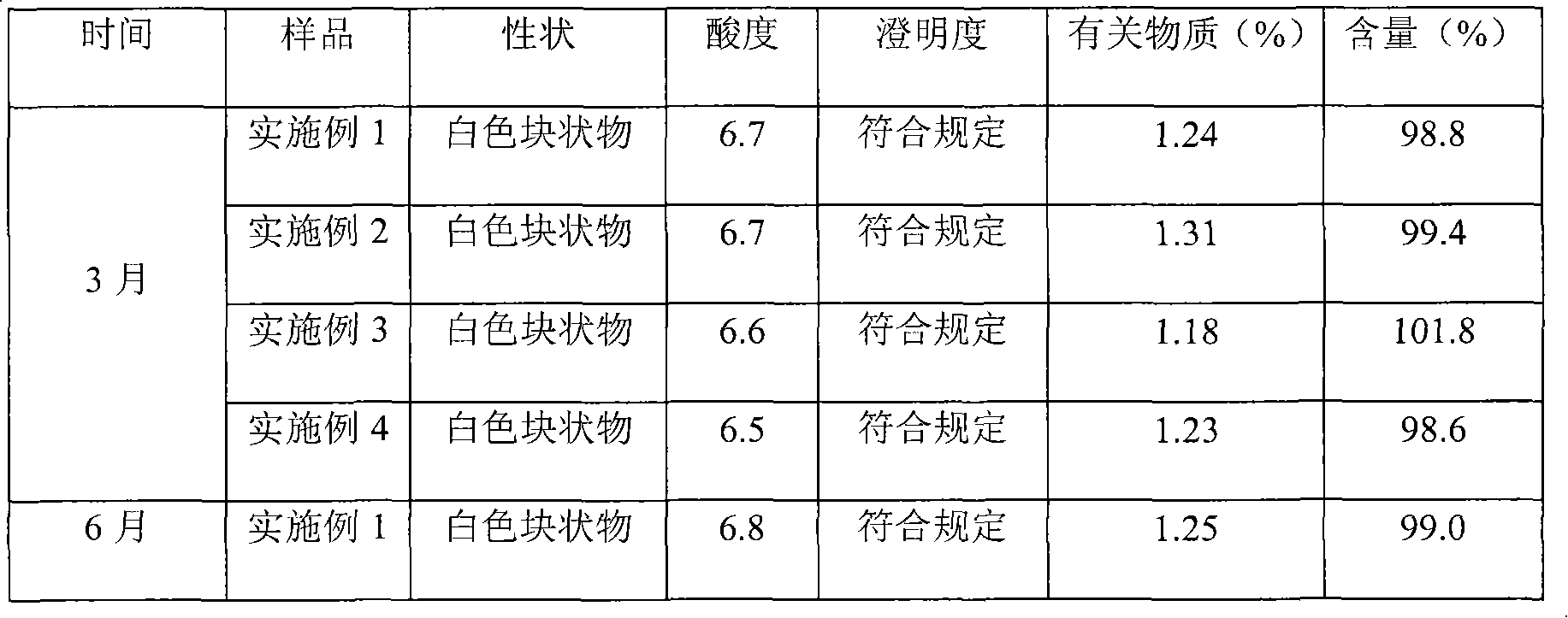

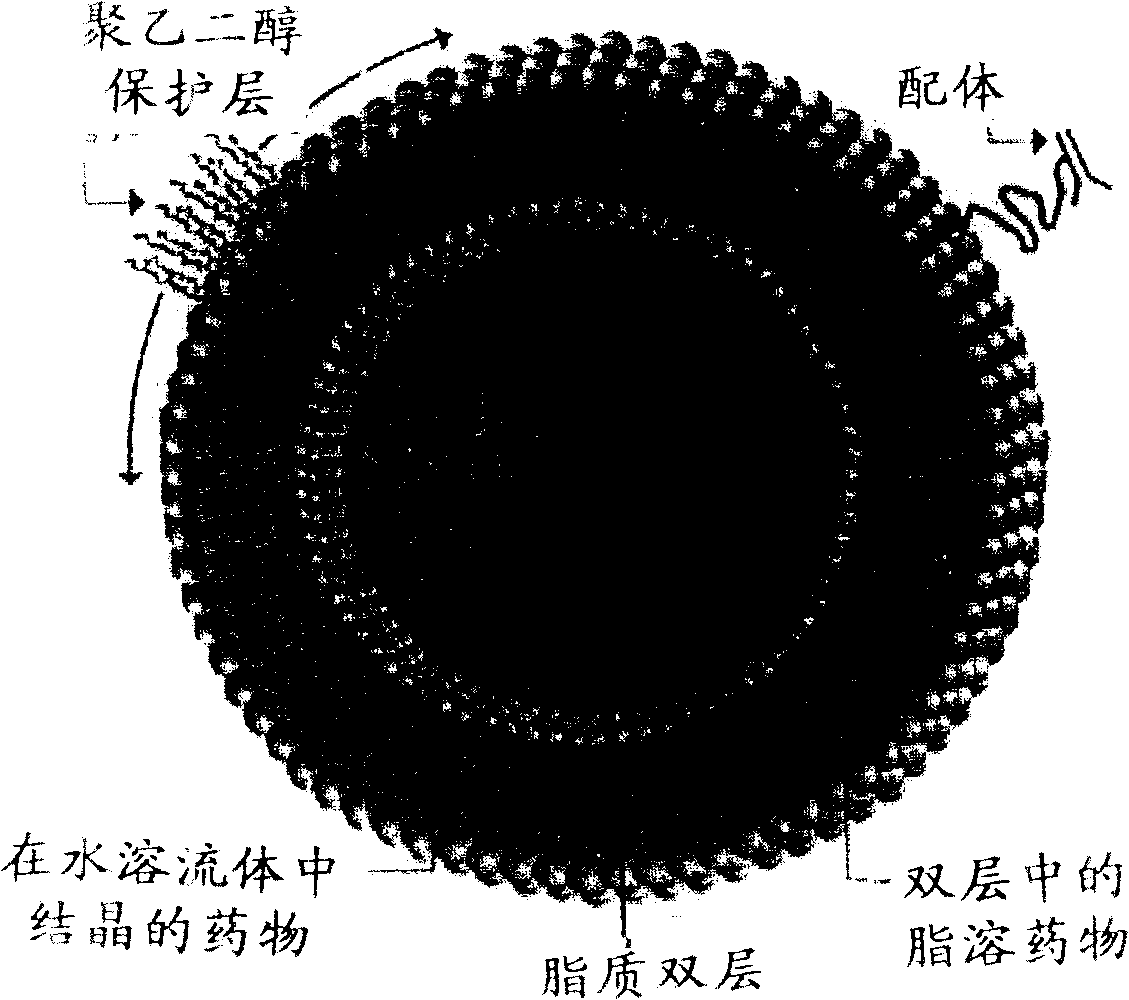

Aztreonam liposomes freeze-dry preparations and method of preparing the same

InactiveCN101249074AImprove stabilitySolve the problem of quality stabilityAntibacterial agentsOrganic active ingredientsFreeze-dryingAztreonam

The invention discloses a freeze-dried preparation of aztreonam liposomes, wherein aztreonam is encapsulated in antioxidant-containing liposomes made of neutral phospholipids, negative charge phospholipids and cholesterol. The freeze-dried preparation has stable quality. Additionally, the aztreonam is encapsulated to minimize toxicity and adverse effects without affecting drug effectiveness.

Owner:HAINAN LINGKANG PHARMA CO LTD

Preparation method of zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as zirconium source and product prepared by preparation method

ActiveCN106928752AIncrease color depthHigh parcel rateInorganic pigment treatmentHydrogenZirconium(IV) silicate

The invention discloses a preparation method of a zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as a zirconium source. The preparation method comprises the following steps: firstly, after dispersing powder of a coloring agent, uniformly stirring the coloring agent and an ammonium zirconium carbonate solution to form a stable suspension solution; reacting to form sedimentation on surfaces of coloring agent particles, so as to obtain a zirconium oxide inclusion; adding the zirconium oxide inclusion into a silicon source solution and uniformly mixing; adjusting the pH (Potential of Hydrogen) value to obtain sediment; drying the sediment to obtain a ceramic pigment precursor; calcining the ceramic pigment precursor and removing the uncovered coloring agent so as to obtain the zirconium silicate covered ceramic pigment powder. Furthermore, the invention further discloses a product prepared by the preparation method. By adopting the preparation method disclosed by the invention, damages to the ceramic pigment can be avoided and the covered pigment with high covering ratio and a core-shell structure is formed; the problem that the high covering ratio of the zirconium silicate covered ceramic pigment is incompatible with a low ratio of the coloring agent to the pigment is effectively solved, so that the color-causing depth of the covered pigment is effectively improved and the adding amount in a utilization process is reduced.

Owner:JINGDEZHEN CERAMIC UNIV

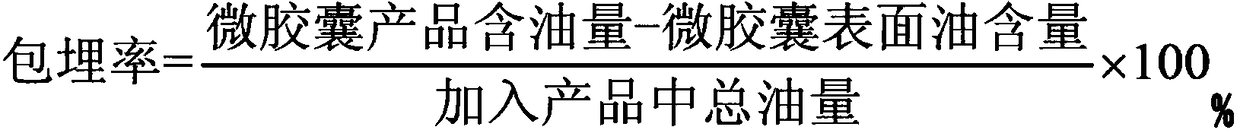

Linseed oil microcapsules and preparation method thereof

InactiveCN108450954AImprove qualityHigh purityFood ingredient as antioxidantFood homogenisationSolubilityLinseed oil

The invention discloses linseed oil microcapsules and a preparation method thereof. The preparation method comprises the following steps of (1) performing hydrolyzing and extracting by an enzyme method to obtain linseed oil; (2) preparing an aqueous phase; (3) preparing an oil phase; (4) performing high-speed cutting emulsifying on a mixture of the aqueous phase and the oil phase by a cutter; (5)performing homogenizing on obtained emulsion by a high pressure homogenizer; and (6) performing spray drying on the obtained emulsion to obtain linseed oil microcapsule granules. The linseed oil microcapsules are high in solubility, good in emulsibility, high in stability, good in film-forming properties and high in packing rate. The linseed oil microcapsules have good mouth feel and flavor, and are safe and reliable in quality; and besides, the preparation technology is simple, mass production is convenient, and the loading quantity of the obtained linseed oil microcapsule granule linseed oilcan achieve 42%, and the microcapsule entrapping rate is 90% or above.

Owner:广州利众生物科技有限公司

Method for synthesizing polypyrrole microcapsules

The invention relates to the technical field of polypyrrole synthesis and polypyrrole microcapsule synthesis, in particular to a method for synthesizing polypyrrole microcapsules. The method includes the steps that benzoyl peroxide, lauryl sodium sulfate and polyethylene glycol 2000 are mixed with deionized water, then a small amount of butanol and a small amount of ethyl alcohol are added, after stirring is carried out, peracetic acid is used for adjusting the mixed system to be strongly acidic, pyrrole monomers are added and stirred for reacting to obtain a black solid, and the black solid is washed with cyclohexane and absolute ethyl alcohol and dried in a vacuum mode to obtain the polypyrrole microcapsules. The method is low in cost and energy consumption and high in use ratio, and a wrapped core material can be released in oily solvent to serve as initiator of emulsion polymerization.

Owner:YANGZHOU UNIV

Biological degradable macromolecule microspheres of carrying insulin and preparation method

InactiveCN1562356AHigh parcel rateEvenly distributedPowder deliveryPeptide/protein ingredientsDrugOrganic solvent

A diodegradable high-molecular microsphere carrying insulin is prepared through preparing the nanoparticles of insulin, preparing the mixed solution of different two polymers, and dual-layer coating of said insulin nanoparticles.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Glass solidifying body for halide radioactive waste and preparation method thereof

ActiveCN105741897AHigh parcel rateReduce volumeRadioactive decontaminationALUMINUM PHOSPHATERadioactive waste

The invention relates to a preparation method of a glass solidifying body for halide radioactive waste.The method comprises the steps that 1, 55%-75% by weight of phosphorous compound, 15%-30% by weight of aluminiferous compound, 10%-30% by weight of sodium carbonate, 0-20% by weight of ferruginous compound and 0-30% by weight of leady compound are mixed, and powdered glass is formed; 2, 10%-30% by weight of the halide radioactive waste and 70%-90% by weight of the powdered glass are mixed, and the glass solidifying body is formed.The invention further provides the glass solidifying body for the halide radioactive waste.The glass solidifying body is used for solidifying the halide radioactive waste rich in fluorides, chlorides and the like through a sodium and aluminum phosphate system, therefore, the wrapping rate of the glass solidifying body to the halide radioactive waste is greatly increased, and the volume of the waste solidifying body is reduced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Preparation method and application of active zirconium dioxide

The invention discloses a preparation method of active zirconium dioxide. The preparation method comprises the steps of firstly mixing zircon sand with a carbon reducing agent and then performing electric smelting calcining to obtain desiliconized zirconium; adding alkali and performing alkali fusion calcining to obtain sodium zirconate; hydrolyzing sodium zirconate and adding acid for neutralizing to form zirconium hydroxide and sodium salt; then adding sodium hydroxide and controlling the pH value to be 8-9; and finally washing to remove sodium salt and drying materials to obtain active zirconium dioxide. The active zirconium oxide prepared by adopting the preparation method contains zirconium dioxide of tetragonal crystal phase, has high activity and is suitable for manufacturing ferrozirconium pigment; in addition, side products generated in the preparation process does not pollute the environment and thus the environment-friendly and pollution-free effects are achieved; silicon is converted into silicon dioxide to be recycled after being subjected to electric smelting calcining; after the preparation is completed, all sodium is converted into sodium chloride or sodium sulfate to be recycled.

Owner:SHENGQUAN FUJIAN GLAZE MAKING CO LTD

Method for preparing micro-spheres using modified ploylactic acid material as shell material

InactiveCN1935127ASmall particle sizeParticle size controllableBiocidePharmaceutical non-active ingredientsMicrosphereWater soluble

The present invention relates to a microphere preparation method using modified polylactic acid material as capsule material. Said preparation method includes the following steps: firstly, the capsule core material can be dissolved or dispersed in the water, the modified polylactic acid material is dissolved in the solvent which can be mixed with water-phase; then the aqueous solution of capsule core material is added into the solution of modified polylactic acid material or the solution of modified polylactic acid material is added into the aqueous solution of capsule core material or said two solutions are simultaneously added into the solvent capable of dissolving polylactic acid material or their mixed solution is added into the solvent capable of dissolving modified polylactic acid material, then they are stirred so as to obtain microsphere solution, filtered to obtain microspheres.

Owner:CHONGQING UNIV

Encapsulated sustained-release acid for oil-water well reconstruction and preparation method thereof

ActiveCN102533244AUniform particle sizeHigh true sphericityDrilling compositionAcrylic resinControl manner

The invention discloses an encapsulated sustained-release acid for oil-water well reconstruction and a preparation method thereof. The encapsulated sustained-release acid comprises a capsule core and a sustained-release supporting layer coated on the outer layer of the capsule core, wherein the capsule core is a soluble or meltable solid acid, the sustained-release supporting layer comprises a sustained-release wall material and a supporting wall material, the sustained-release wall material is an organic fatty acid or a derivative thereof, the supporting wall material is acrylic resin or a derivative thereof, and the solid acid is solid hydrochloric acid powder or citrate. The encapsulated sustained-release acid is a spherical granule with the particle size of 0.15-0.25 mm. The encapsulated sustained-release acid also comprises an adhesive spray-coated on the capsule core, wherein the adhesive is water-soluble vegetable gum or a derivative thereof, and is specifically guar gum, hydroxypropyl guar gum or carboxymethyl hydroxypropyl guar gum. According to the invention, the control mode of the acid radical ion consumption is simple and accurate; the preparation process is simple; and the encapsulated sustained-release acid is reliable in performance, safe for transportation and carrying, and convenient for use, and can be used for reducing the probability of underground tool acid corrosion and operation personnel damage in the application.

Owner:PETROCHINA CO LTD

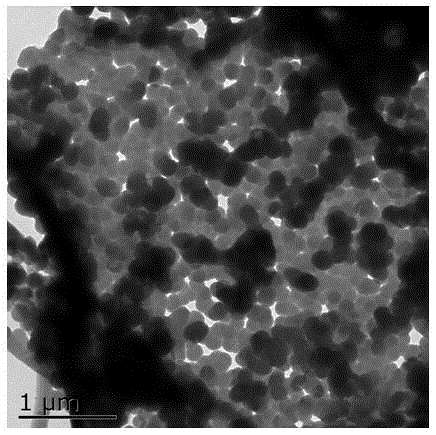

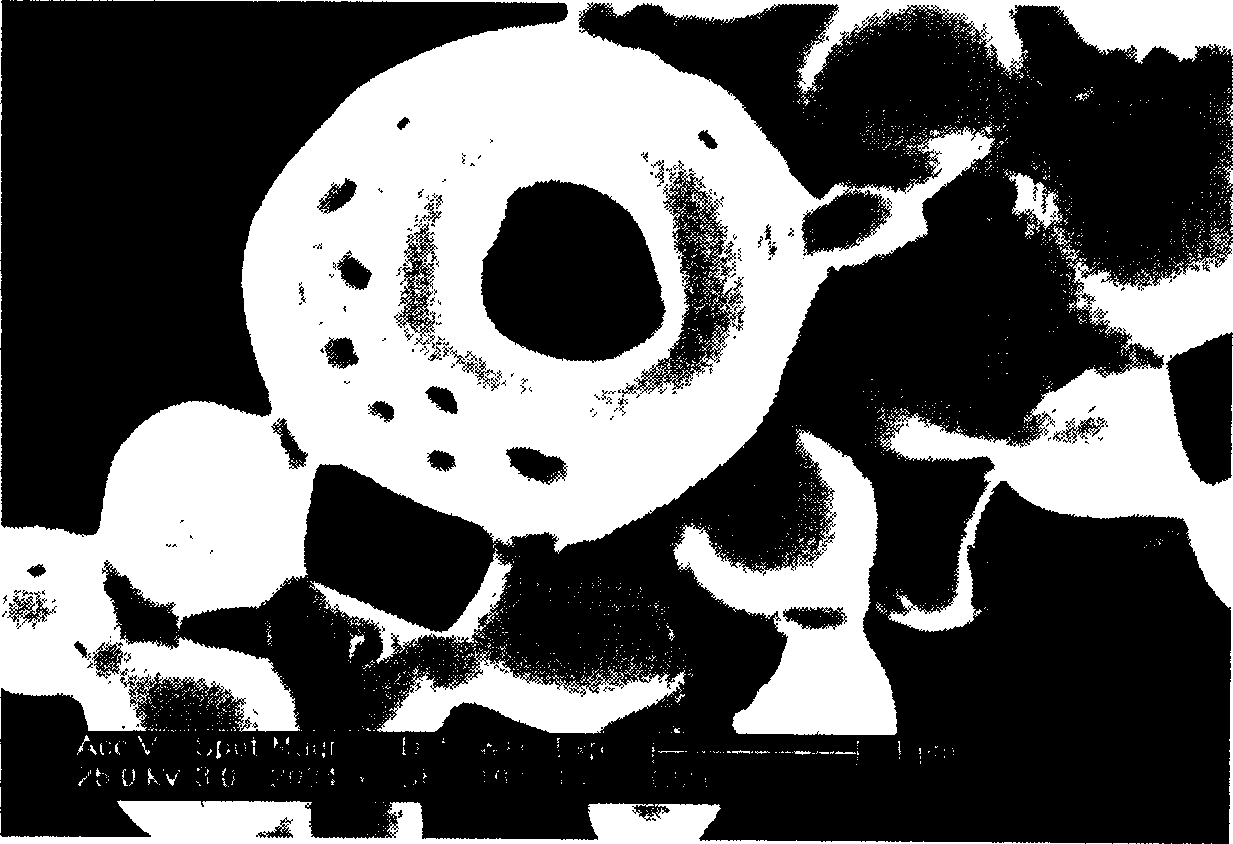

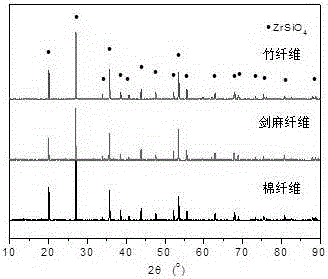

Method for preparing zirconium silicate coated carbon nanosphere ceramic black pigment

The invention discloses a method for preparing a zirconium silicate coated carbon nanosphere ceramic black pigment. The method is characterized in that carbon nanospheres prepared from a biomass raw material by a hydrothermal method replace a traditional carbon source, the hydrophilicity is improved by use of rich oxygen-containing functional groups on the surfaces of the carbon nanospheres and the negative potential state, and the dispersity of the carbon source is enhanced; the thickness of wrappers of the carbon nanospheres and the electrostatic adsorption capability are adjusted and controlled to enable a zirconium silicate precursor to tightly wrap the carbon nanospheres; and under the action of a mineralizer, the ceramic black pigment in which zirconium silicate wraps the carbon nanospheres is prepared after high-temperature calcination. In the experiment process, through optimization and control of such conditions as the addition of glucose, the hydrothermal temperature, the hydrothermal time, the silicon-zirconium ratio, the stirring time of the precursor, type and consumption selection of the mineralizer and a firing system, the synthesized black pigment is pure in color, uniform in particle size and stable in performance, can be used in various high-temperature ceramic glazes, and has a high economical value.

Owner:JINGDEZHEN CERAMIC INSTITUTE

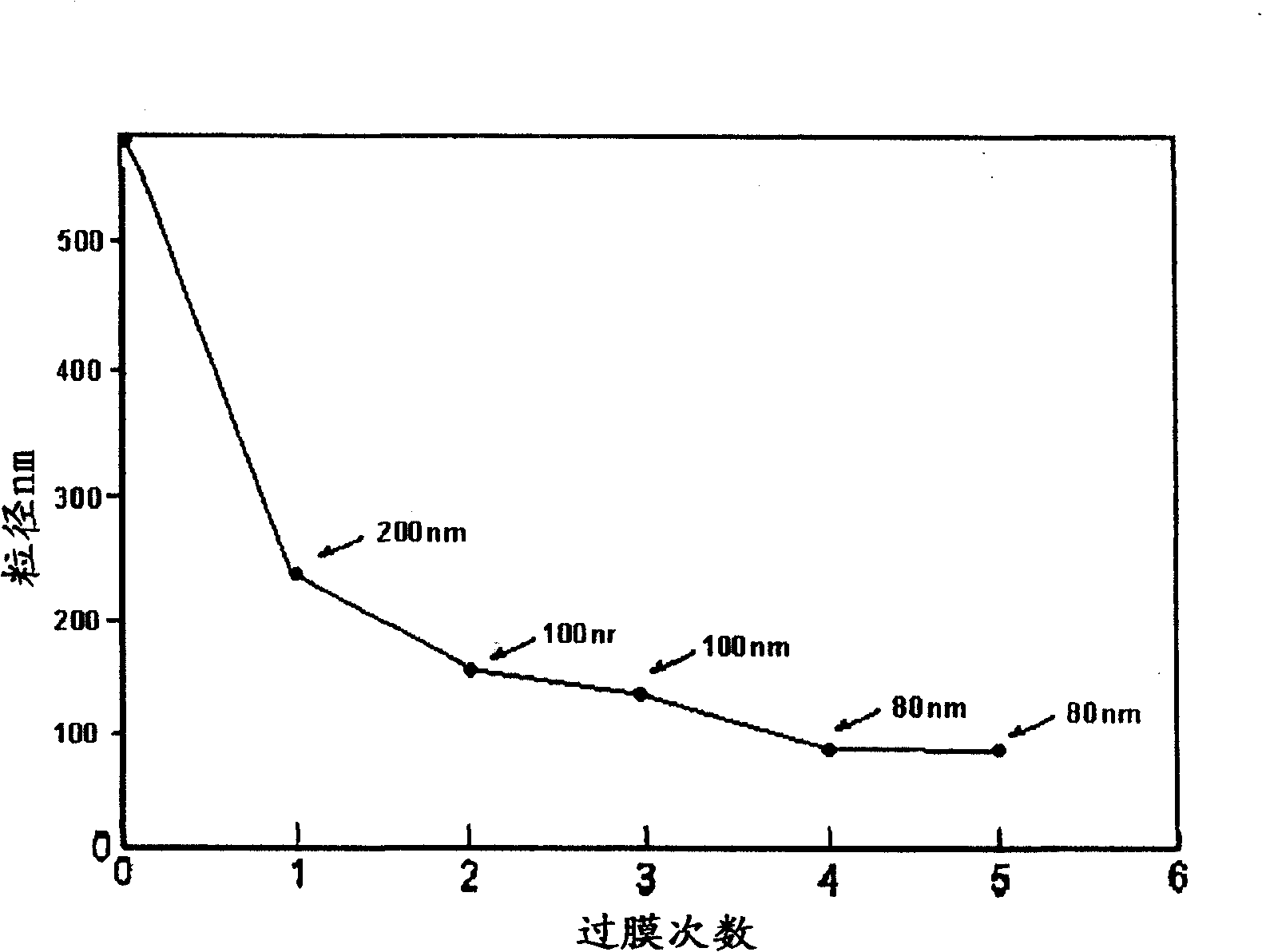

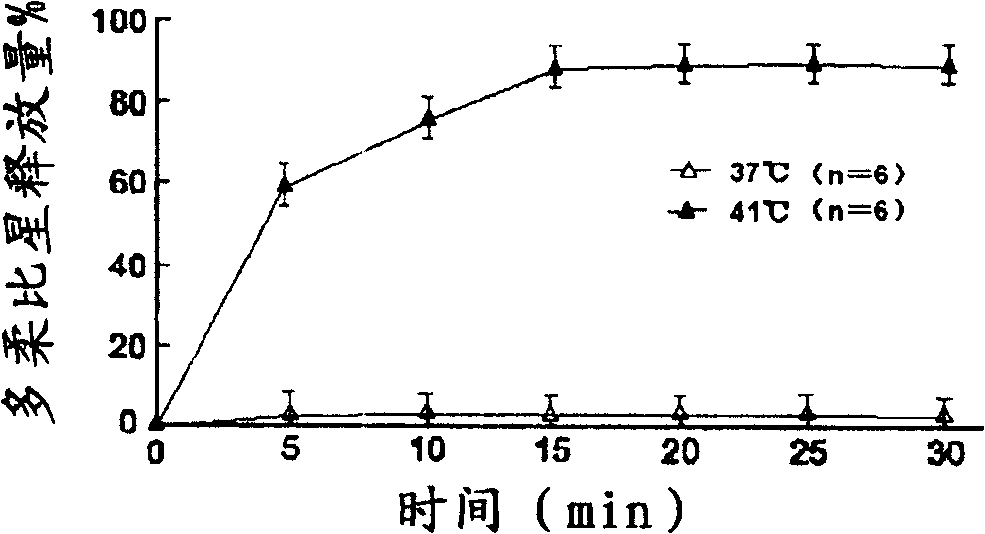

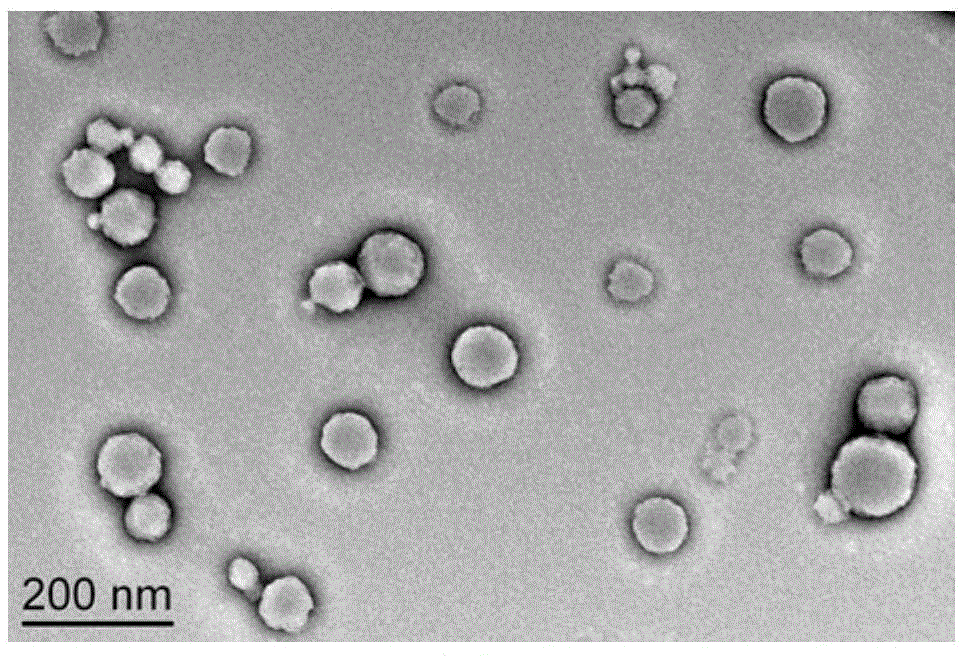

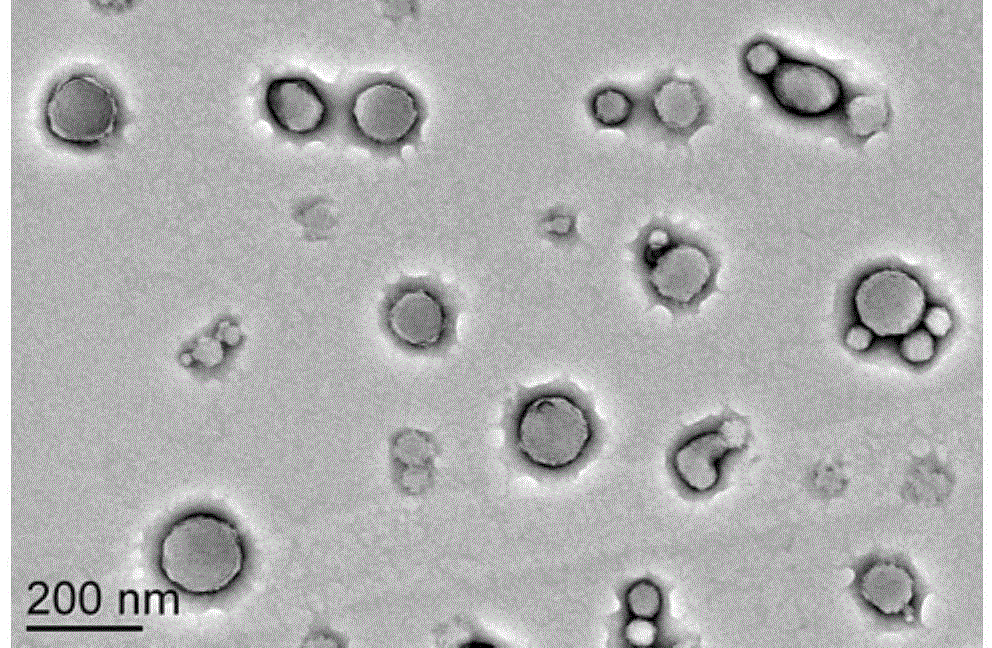

Biological endophilic ligand numerator mediated target liposome, preparation and uses thereof

InactiveCN101317820AImprove stabilityHigh parcel rateOrganic active ingredientsPowder deliverySolubilityTolerability

The invention discloses a targeted liposome mediated by the ligand molecule with biological affinity, and a preparation as well as the application thereof. The targeted liposome of antitumor drug prepared by the invention has little toxicity, good tolerance for patients and enhanced water-solubility and stability. And the invention also discloses the processing technique of the preparation. Freeze-dry liposome consists of natural or synthetic phospholipid, charged phospholipid, target material, antitumor drugs, buffer solution and freeze-drying protective agent. The processing technique comprises the procedures of the preparation of phospholipid membrane of the antitumor drug, the homogenization of the liposome, the addition of the freeze-drying protective agent, volume metering, sterilizing, split charging, freeze-drying and storage, etc. The liposome is kept under room temperature for 12 months with good stability. The entrapment rate of the liposome is over 90 percent. The granule diameter of the liposome is within 50 to 300mm. The liposome has little toxic and side effects and simple technique, thus facilitating the commercial process of the liposome.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

Microwave sintering method of coated superfine sulphide selenide cadmium red pigment for ceramic glaze

A microwave sintering method of a coated superfine sulphide selenide cadmium red pigment for ceramic glaze is characterized in that sulphide selenide cadmium powder [CdSexS[1-x]-SiO2] coated with silica is used; 0.2-0.8 per mill by weight of sodium hexametaphosphate or OP-10 dispersant or sodium dodecyl benzene sulfonate is added before sintering; the microwave sintering mode is adopted, wherein the microwave frequency is 250MHz-250GHz, the microwave sintering temperature is 800-1500 DEG C, the sintering time is 0-10hr; and the pigment is discharged from the furnace after temperature preservation. Compared with the prior art, the method has the following advantages: the aggregation phenomenon of the coated pigment can be effectively prevented in the sintering process and the manufacturingcost is low.

Owner:佛山市中国地质大学研究院

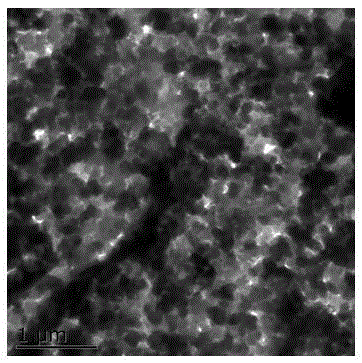

Method for preparing black pigment by wrapping carbon black with zirconium silicate

The invention discloses a method for preparing a black pigment by wrapping carbon black with zirconium silicate. The black pigment with high wrapping rate is synthesized at the temperature of 1000-1100 DEG C by using high pigment carbon black or high wear-resistant carbon black or acetylene carbon black as raw materials and using a non-hydrolytic sol-gel technology. The synthesis method is simple in process, high in synthesis speed and low in synthesis temperature; and the prepared black pigment is pure in color, stable in performance, high in service temperature being up to 1300 DEG C, capable of being widely applied to high-temperature glaze materials of various ceramic products and higher in economic values.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Microwave sintering method of coated superfine sulphide selenide cadmium red pigment for ceramic glaze

Owner:佛山市中国地质大学研究院

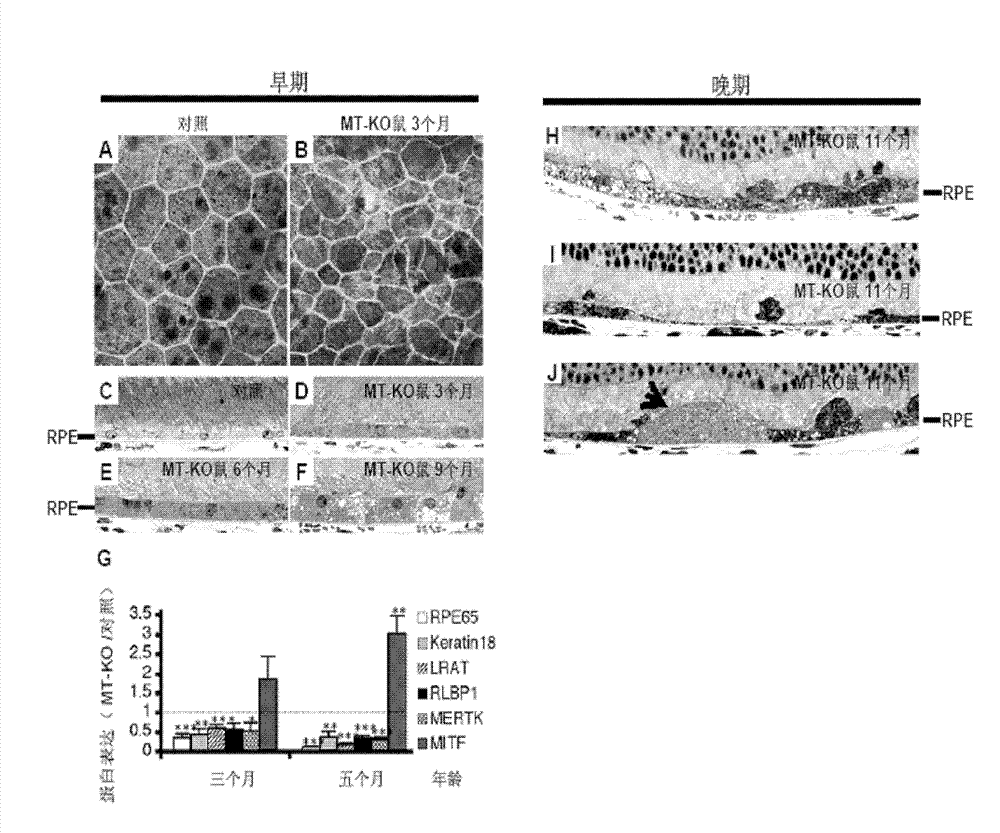

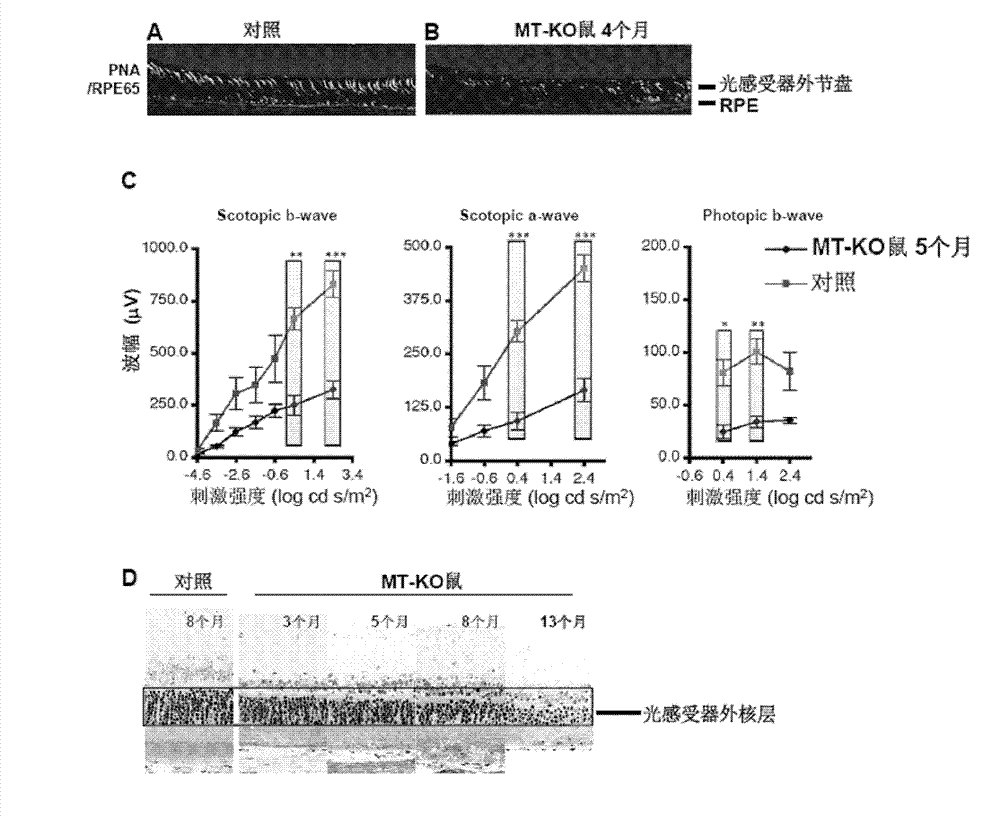

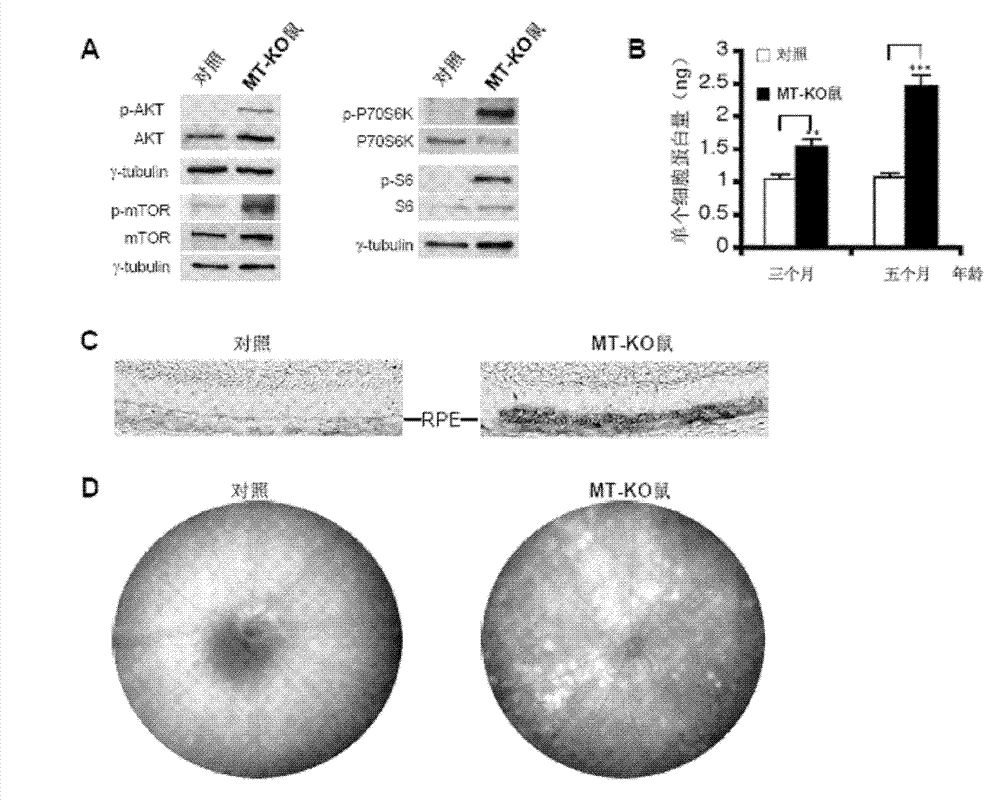

Rapamycin microemulsion injection for eyes and preparation method and application thereof

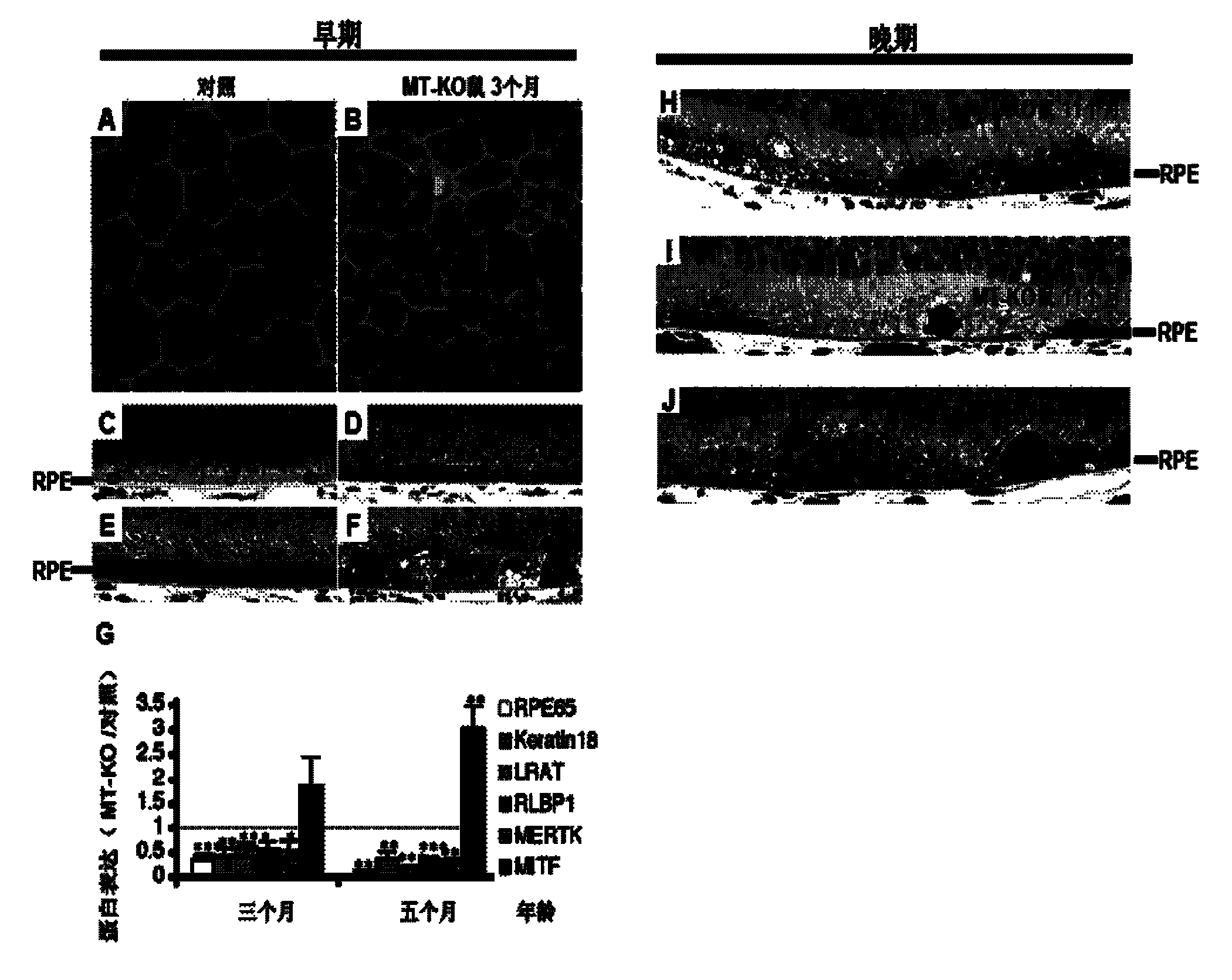

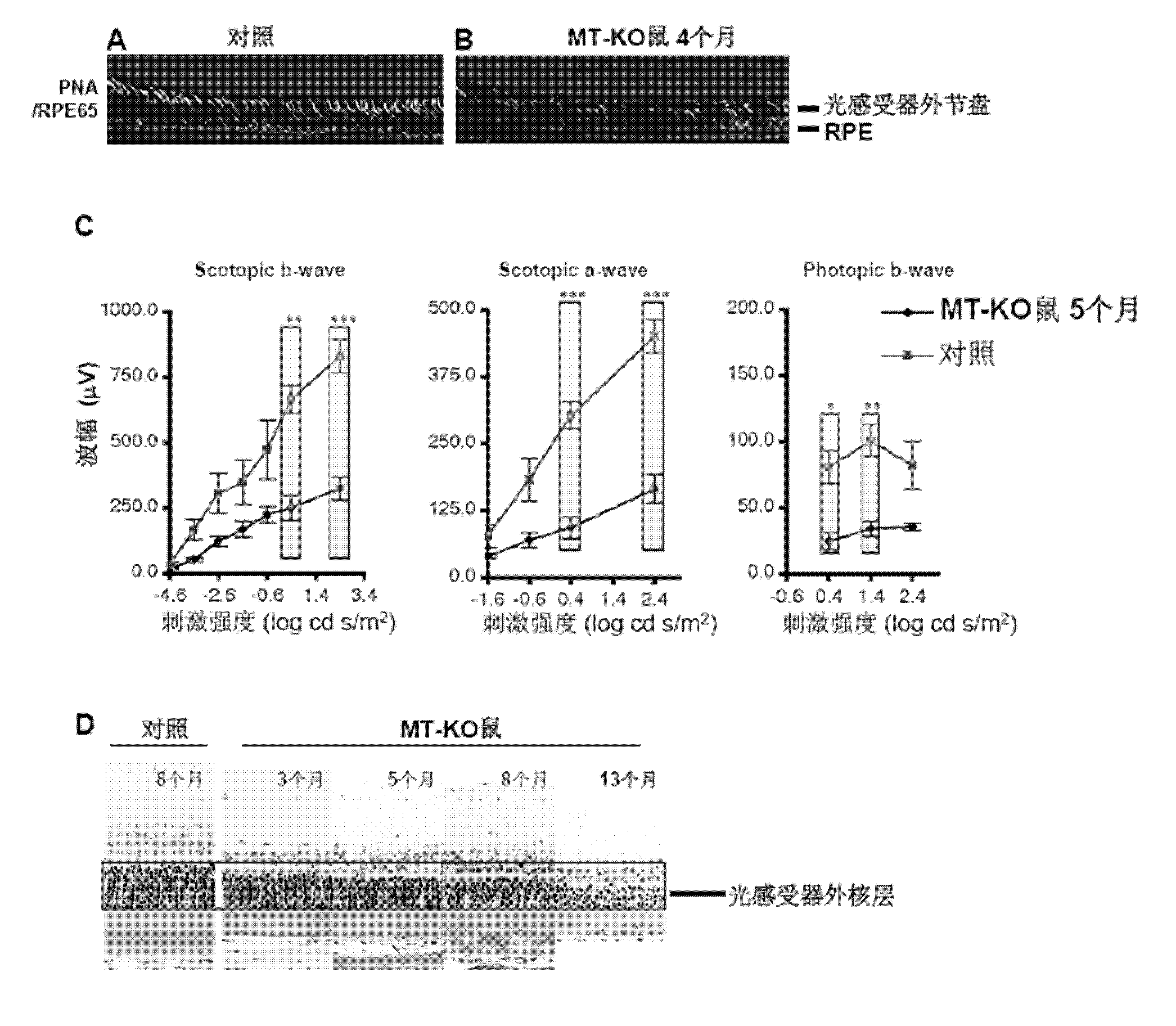

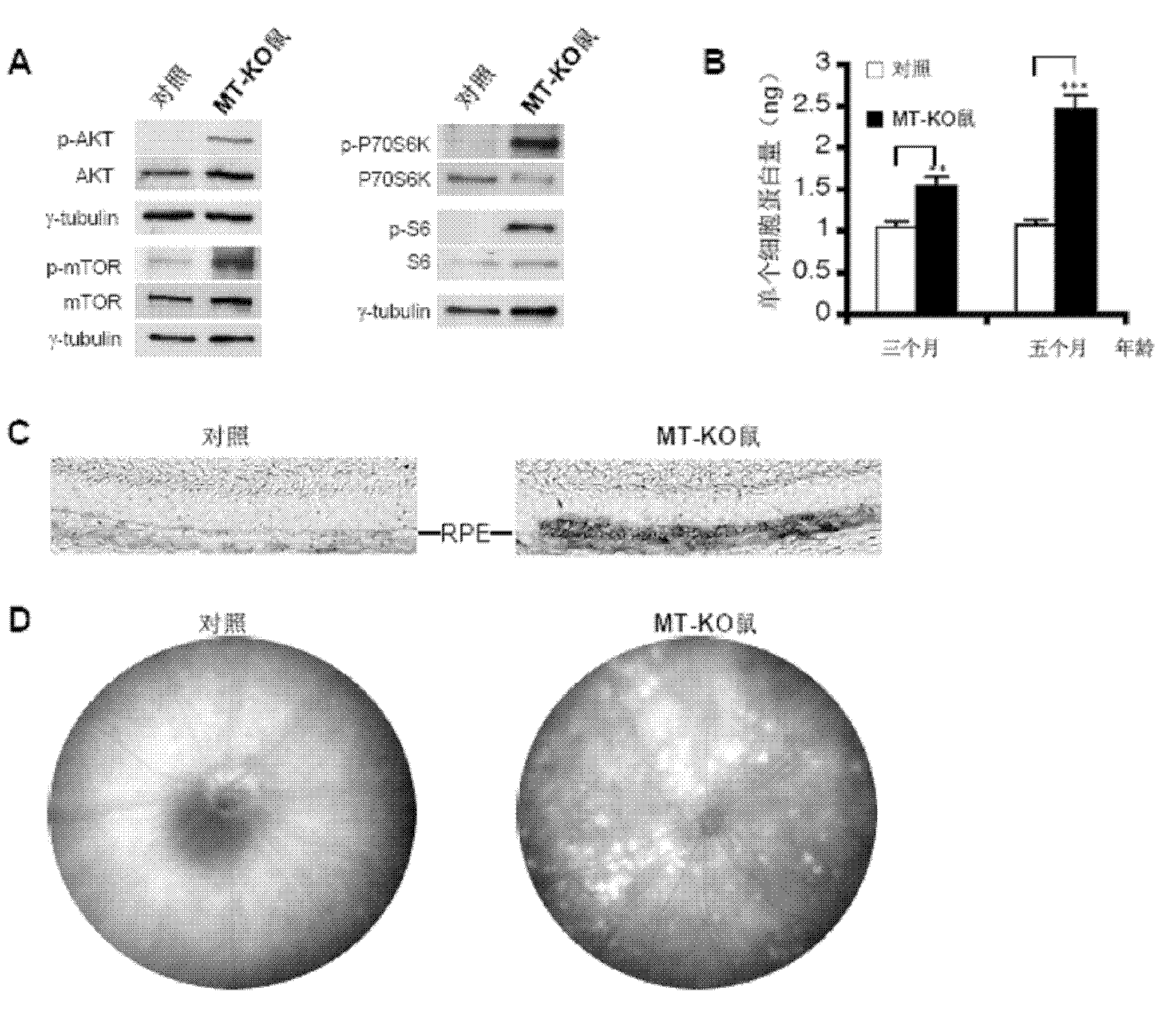

InactiveCN102008437AHigh parcel rateLow costOrganic active ingredientsSenses disorderSide effectDegenerative disease

The invention discloses rapamycin microemulsion injection for eyes and a preparation method and application thereof. In the injection, rapamycin is taken as an active ingredient and is added with a pharmaceutically acceptable carrier, and each 1,000ml of preparation contains 0.05 to 20g of rapamycin. The microemulsion injection for eyes has low cost and high stability, does not have obvious irritation and toxic or side effect on the eyes, can be used for treating retinal degenerative diseases, and particularly has obvious effect of treating age-related macular degeneration disease. The treatment effect of the injection is provided on the basis of breakthrough and discovery of a pathogenic mechanism, and the rapamycin microemulsion injection has profound significance for treating the diseases.

Owner:赵晨

Process for producing ferrozirconium red material

InactiveCN101429053AImprove high temperature resistanceSmall particle sizePigmenting treatmentSodium metasilicateAcid washing

The invention discloses a method for preparing ferrozirconium red stain, which is characterized by comprising the following steps in turn: (1) liquid-phase reaction, which is to perform liquid-phase reaction on zirconium oxychloride, ferrous sulfate and sodium metasilicate pentahydrate in water; (2) separation and drying, which is to separate and dry solid-liquid suspended substances generated by liquid-phase reaction; (3) precalcination, which is to crush dried substances and calcine the crushed substance for 2 to 3 hours at a temperature of between 750 and 850 DEG C; (4) mixing, which is to mix products of precalcination uniformly with lithium fluoride, sodium fluorosilicate and sodium fluoride; (5) calcination, which is to calcine the mixture in the four step for 2 to 5 hours at a temperature of between 900 and 1,000 DEG C; and (6) post processing, which is to treat sintered solid substances by grinding, acid washing, water scrubbing, drying and sieving. The method for combination of liquid-phase reaction and solid-phase reaction improves the encapsulation rate of high-temperature solid-phase reaction, and synthesizes ferrozirconium red stain products which have beautiful chromogenic colors and strong chromogenic force and are stable at high temperature.

Owner:广东万兴无机颜料股份有限公司

Tylosin tartrate premix composition and preparation method of tylosin tartrate sustained-released pellets

InactiveCN106309409AAchieve full encapsulation rateHigh parcel rateAntibacterial agentsOrganic active ingredientsSolid componentAdhesive

The invention relates to a tylosin tartrate premix composition and a preparation method of tylosin tartrate sustained-released pellets, aiming at solving the problems in the prior art that the encapsulation efficiency of tylosin tartrate is low, the light-shielding property and the palatability are poor, the releasing efficiency of the tylosin tartrate cannot be effectively controlled and industrial production is not easy to realize and the like. The preparation method comprises: firstly crushing a solid component and sieving; mixing the tylosin tartrate and a filling agent; adding an adhesive and covering an enteric coating layer and a sustained-released layer on the tylosin tartrate through a granulator. According to the tylosin tartrate premix composition and the preparation method of the tylosin tartrate sustained-released pellets, provided by the invention, whole encapsulation is realized and the palatability is good; the releasing efficiency of the tylosin tartrate can be effectively controlled and the industrial production can be realized.

Owner:乐山市佰尔特生物工程合伙企业(有限合伙)

Ferrozirconium red material

The present invention discloses a ferrozirconium red material, which is prepared from the following raw materials: silicon dioxide, an iron compound, a mineralizer, a rare earth fluoride, and zirconium dioxide. According to the present invention, the ferrozirconium red material prepared according to the formula has the following characteristics that: the wrapping rate is high, and ion is wrapped into the zirconium silicate crystal lattice in the ferric ion form so as to achieve stable color generation; and the active zirconium dioxide is adopted, and the rare earth fluoride is introduced, such that the prepared ferrozirconium red material has a good coloration effect.

Owner:SHENGQUAN FUJIAN GLAZE MAKING CO LTD

Nanometer platinum polymer, and preparation method and application thereof

ActiveCN107198789AGood biocompatibilityGood antibacterial effectAbsorbent padsBandagesWound dressingMedical product

The invention discloses a nanometer platinum polymer, and a preparation method and application thereof. The nanometer platinum polymer is prepared from the following raw materials of nanometer platinum, chitosan oligosaccharide, poly gamma-glutamic acid, propanediol and cross linking agents EDC / NHS. The nanometer platinum polymer obtained through preparation can be applied to medical products, in particular to the wound dressing aspect. Compared with the prior art, the obtained nanometer platinum polymer medicine has good biocompatibility and antibacterial activity; the nanometer platinum is preferably selected to be used as the medicine; propanediol is used as a lubricating agent; the medicine coating rate is higher; high degradability is realized; the swelling behavior performance is good; the raw materials are cheap and can be easily obtained; the production process is simple.

Owner:广州博士派生物科技有限公司

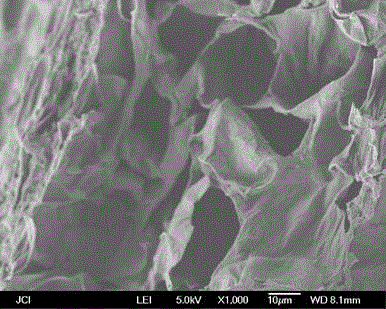

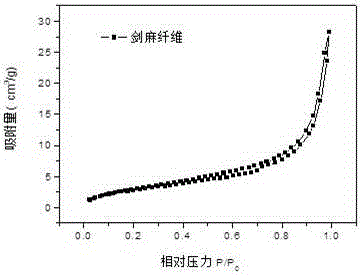

Method for preparing high-color-developing zirconium-silicate-coated carbon black pigment by taking plant fiber as carbon source

The invention discloses a method for preparing a high-color-developing zirconium-silicate-coated carbon black pigment by taking plant fiber as a carbon source. Good dispersing can be formed in zirconium silicate sol through the porous structure and spatial distribution of the plant fiber, and the high-color-developing zirconium-silicate-coated carbon black pigment which is coated compactly is obtained through hot treatment in a high-temperature inert atmosphere. The coated black pigment has the advantages of being pure in color and luster, easy to prepare, wide in raw materials, low in price, easy to obtain, green and environmentally friendly, can be applied to coloring in glazes or blanks of ceramic products and is suitable for industrialized production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

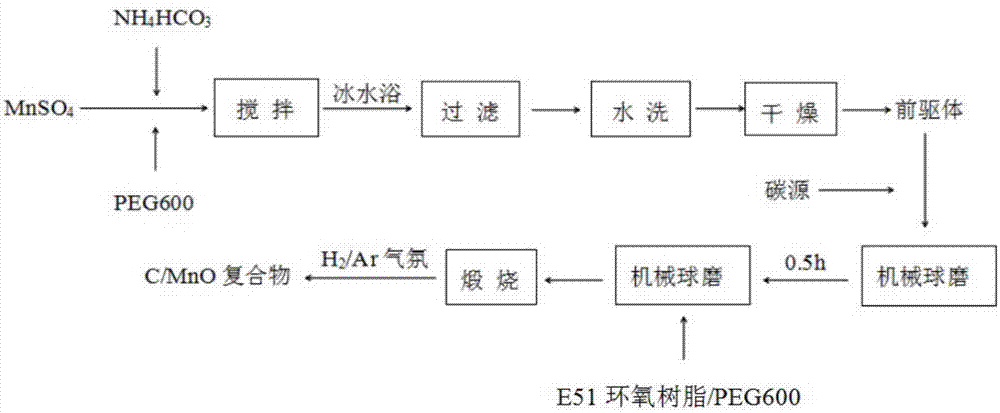

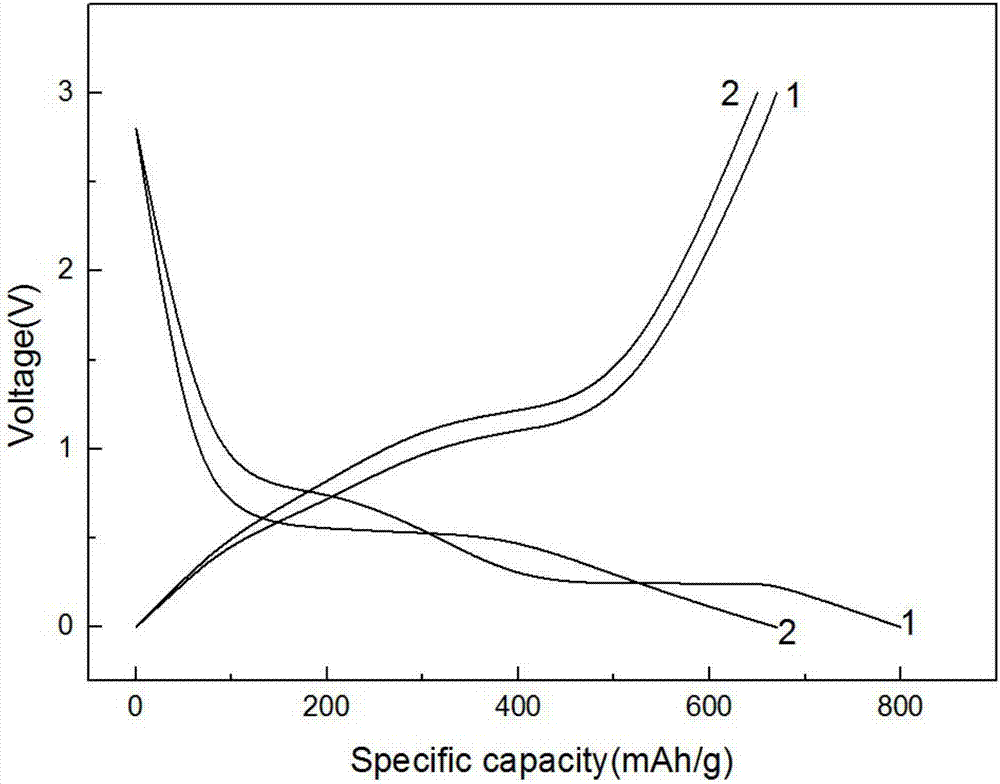

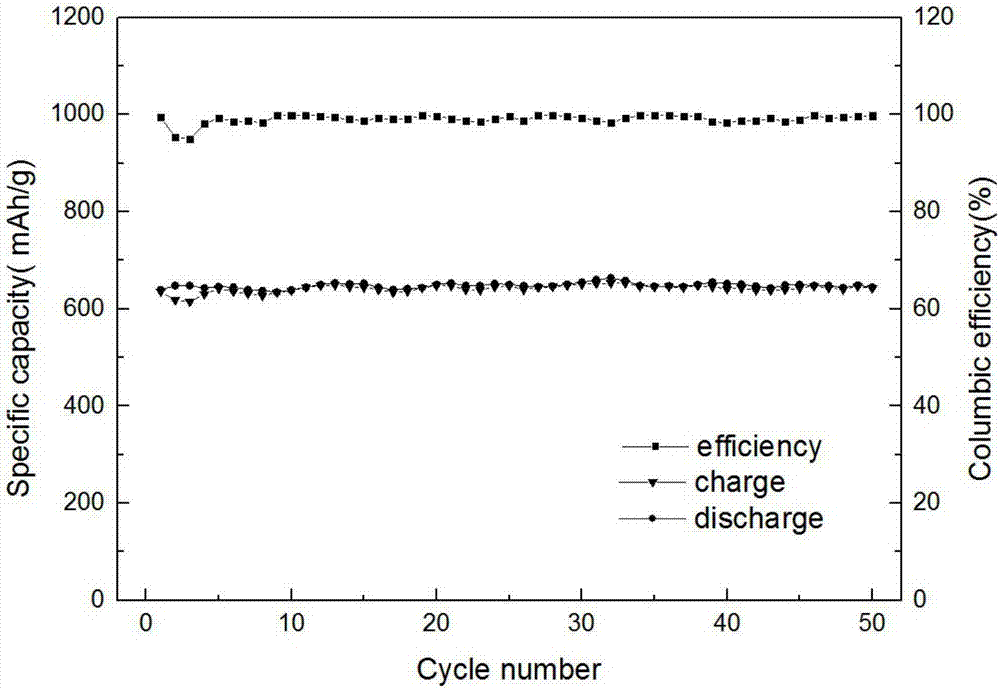

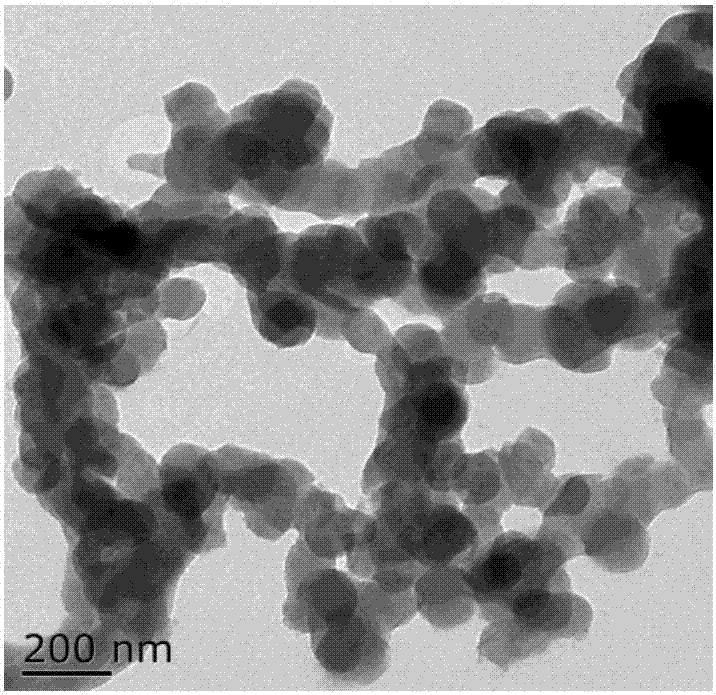

Preparation method of C/MnO composite electrode material

InactiveCN107546374AImprove uniformityGood dispersionHybrid capacitor electrodesCell electrodesEpoxyComposite electrode

The invention discloses a preparation method of a C / MnO composite electrode material, and belongs to the technical field of composite materials. The preparation method comprises the following steps: configuring an MnSO4 solution with the concentration of 0.25 mol / L and an NH4HCO3 solution with the concentration of 0.25 mol / L respectively, mixing the MnSO4 solution and the NH4HCO3 solution in the volume ratio of 1: (0.15 to 1), then adding PEG600 into the solution, and controlling the pH of the solution to be 6 to 7; putting the mixed liquor into an ice-water bath for stirring for 1.5 to 2 h, filtering the solution after the reaction is ended, washing the precipitate with deionized water, and then drying to obtain a precursor; mixing a carbon source and the precursor in a mass ratio of 1: (25 to 50), then carrying out mechanical ball-milling for 0.5 h, adding E51 epoxy resin / PEG 600, continuously carrying out ball-milling for 1 to 2 h, and then taking out a ball-milling product; puttingthe ball-milling product into H2 / Ar mixed gas for calcinations, carrying out natural furnace cooling after the reaction is ended, and finally obtaining the C / MnO composite material. The C / MnO composite material prepared in the invention is stable in performance and high in specific capacity; the method is simple in technology, mild in reaction conditions, low in cost and high in production efficiency, and is applicable for industrial production.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

Controllable slow-release phase transfer catalyst microcapsules and preparation method of controllable slow-release phase transfer catalyst microcapsules

InactiveCN106883324AGood dispersionReduce viscosityMicroballoon preparationMicrocapsule preparationBenzoyl peroxidePolyethylene glycol

The invention relates to controllable slow-release phase transfer catalyst microcapsules and a preparation method of the controllable slow-release phase transfer catalyst microcapsules. The method comprises the following steps: sufficiently stirring sodium dodecyl sulfate, polyethylene glycol 6000, a phase transfer catalyst, a strong oxidant, an auxiliary surfactant, ethanol, a pH (Potential of Hydrogen) value regulator and a pyrrole monomer into de-ionized water solution under a room-temperature condition; centrifuging and drying to obtain the phase transfer catalyst microcapsules. Reaction is carried out on the de-ionized water so that an oil-soluble core material is easily subjected to phase transfer catalyst microencapsulation; a preparation process of the controllable slow-release phase transfer catalyst microcapsules is not only limited in the de-ionized water, and the phase transfer catalyst microcapsules with a water-soluble core material can also be prepared in an oily solvent system; a core material phase transfer catalyst is not limited to 2,2'-azobis(2-methylpropionitrile) and can be any one of ammonium persulfate, benzoyl peroxide, tert-butyl hydroperoxide, tert-butyl peroxybenzoate and diisopropyl peroxydicarbonate.

Owner:YANGZHOU POLYTECHNIC INST

Encapsulated sustained-release acid for oil-water well reconstruction and preparation method thereof

ActiveCN102533244BUniform particle sizeHigh true sphericityDrilling compositionAcrylic resinAdhesive

The invention discloses an encapsulated sustained-release acid for oil-water well reconstruction and a preparation method thereof. The encapsulated sustained-release acid comprises a capsule core and a sustained-release supporting layer coated on the outer layer of the capsule core, wherein the capsule core is a soluble or meltable solid acid, the sustained-release supporting layer comprises a sustained-release wall material and a supporting wall material, the sustained-release wall material is an organic fatty acid or a derivative thereof, the supporting wall material is acrylic resin or a derivative thereof, and the solid acid is solid hydrochloric acid powder or citrate. The encapsulated sustained-release acid is a spherical granule with the particle size of 0.15-0.25 mm. The encapsulated sustained-release acid also comprises an adhesive spray-coated on the capsule core, wherein the adhesive is water-soluble vegetable gum or a derivative thereof, and is specifically guar gum, hydroxypropyl guar gum or carboxymethyl hydroxypropyl guar gum. According to the invention, the control mode of the acid radical ion consumption is simple and accurate; the preparation process is simple; and the encapsulated sustained-release acid is reliable in performance, safe for transportation and carrying, and convenient for use, and can be used for reducing the probability of underground tool acid corrosion and operation personnel damage in the application.

Owner:PETROCHINA CO LTD

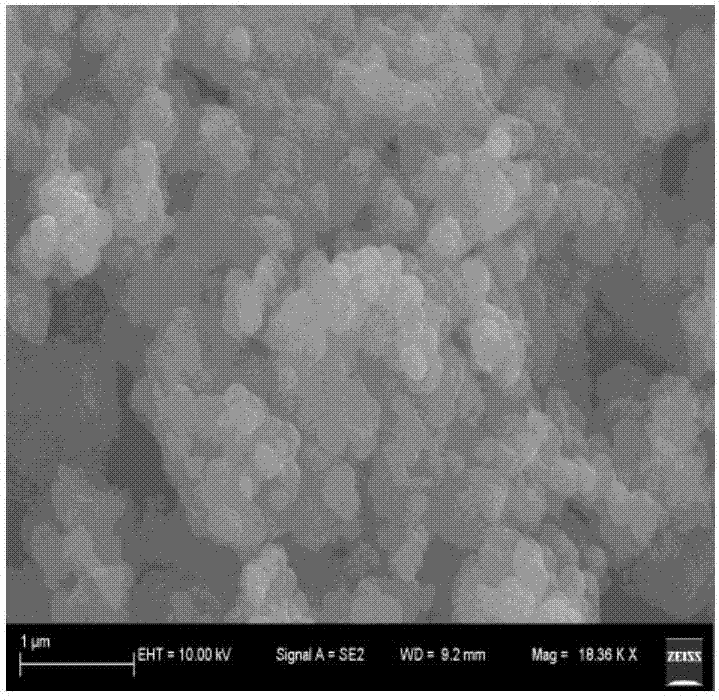

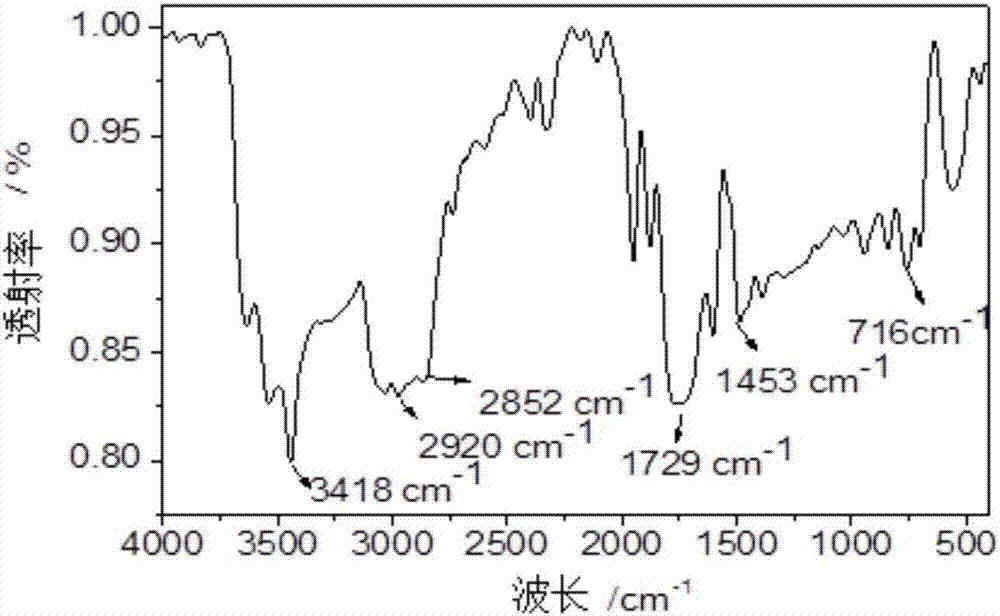

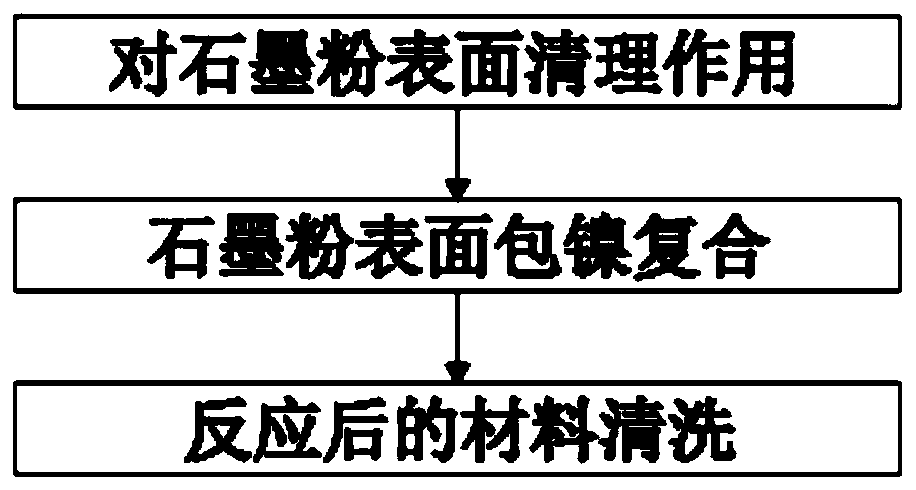

Preparation method of high-coating-rate nickel-coated graphite composite powder material

InactiveCN111408713AHigh parcel rateSimple preparation processMagnetic/electric field screeningTransportation and packagingNickel coatingGraphite composite

The invention belongs to the technical field of preparation of nickel-coated graphite composite powder, and particularly relates to a preparation method of a high-coating-rate nickel-coated graphite composite powder material. The preparation method of the high-coating-rate nickel-coated graphite composite powder material comprises the following specific preparation steps that S1, the surface of graphite powder is cleaned, the graphite powder is stored after being subjected to oil cleaning treatment, sensitization treatment and activation treatment; S2, graphite powder surface nickel-coated composite is carried out, specifically, the graphite powder treated in the step S1 is taken out and fully mixed with a plating solution, the plating solution comprises main salt, a reducing agent and a complexing agent; and S3, material cleaning after reaction is carried out, specifically, the nickel-coated graphite powder composite material obtained after reaction in the step S2 is taken out, the nickel-coated graphite powder composite material is washed with distilled water, and then the cleaned nickel-coated graphite powder composite material is dried. According to the scheme, the preparationprocess is simple, the nickel coating rate is high, and the product quality is improved; and the prepared excess materials are convenient to treat, and the pollution to the environment is small.

Owner:苏州逸峰新材料科技有限公司

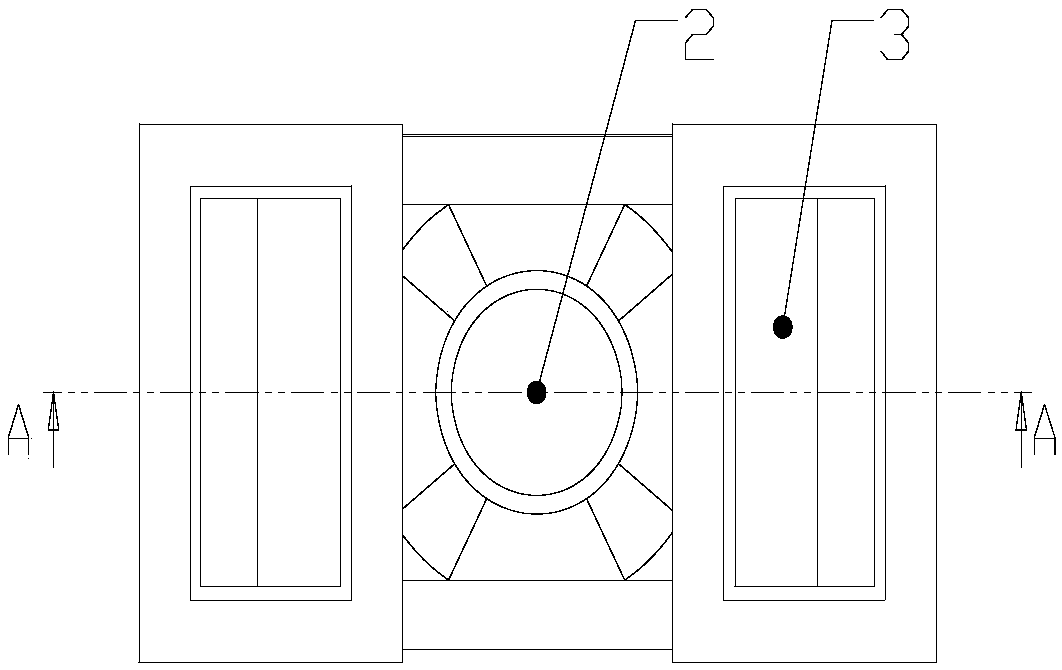

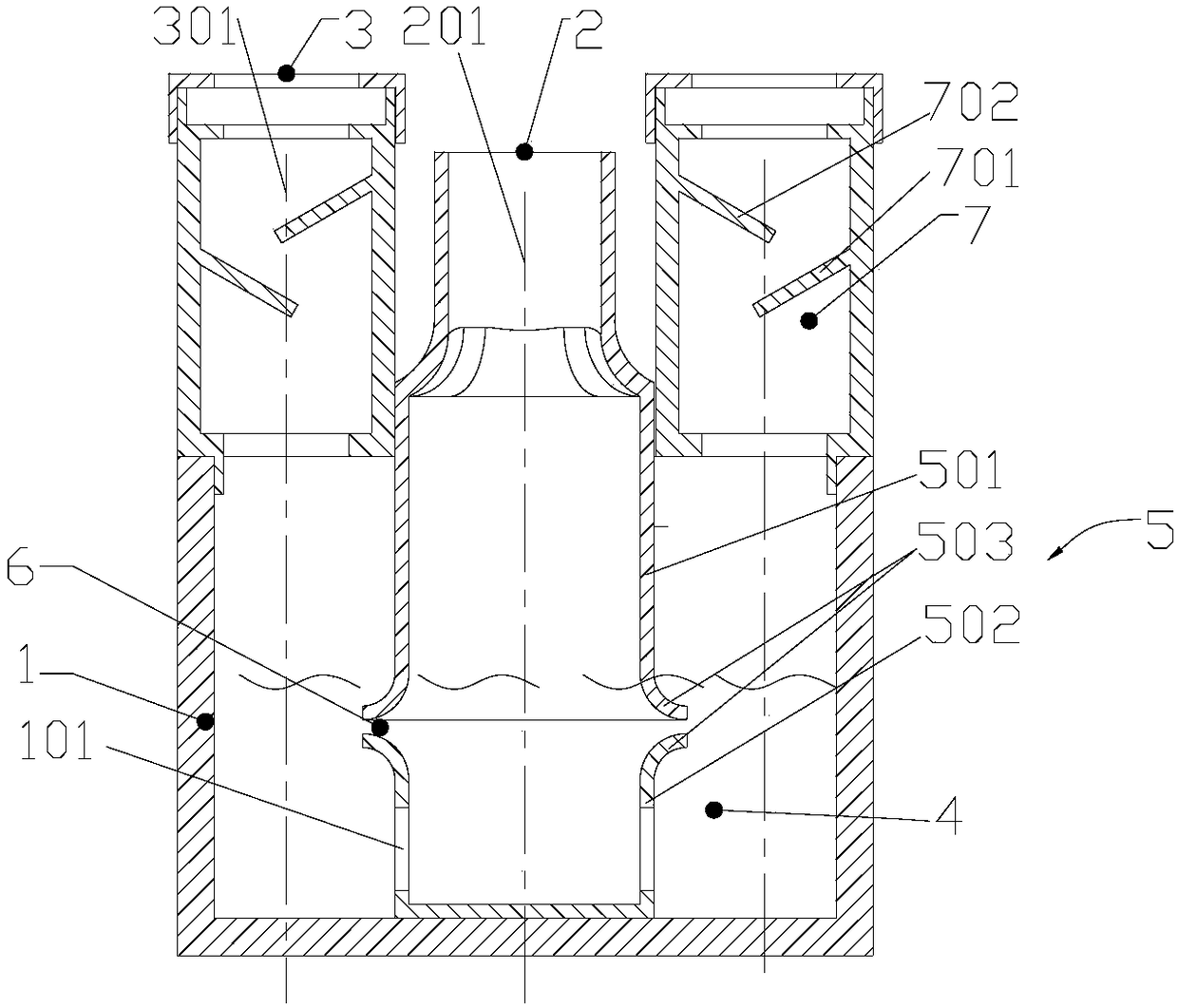

Air purifier

InactiveCN109078419AImprove filtration and purification efficiencyIncrease collision speedGas treatmentUsing liquid separation agentInlet channelAir purifiers

The invention relates to the field of air purification, and discloses an air purifier. A water tank is formed in the bottom of the cavity of the air purifier, a barrier wall which downwards extends into the water tank is formed between an air inlet and an air outlet, thus, an air inlet channel is formed between the air inlet and the water tank, an air outlet channel is formed between the water tank and the air outlet, the barrier wall is provided with a jet flow seam which is positioned below the liquid level of the water tank, and the jet flow seam is shrinking flow channel from the air inletchannel to the air outlet channel. The jet flow seam is in the design of the shrinking flow channel, air flows into the shrinking flow channel from the air inlet channel, the sectional dimension of aflowing path is suddenly reduced, and air flow is accelerated for the first time; and when air flows through the jet flow seam, the sectional dimension is further reduced, the air flow is acceleratedagain, after the air flow is accelerated twice, water-air mixing adequacy is also increased, and the air filtering and purifying efficiency is improved.

Owner:MIDEA GRP CO LTD

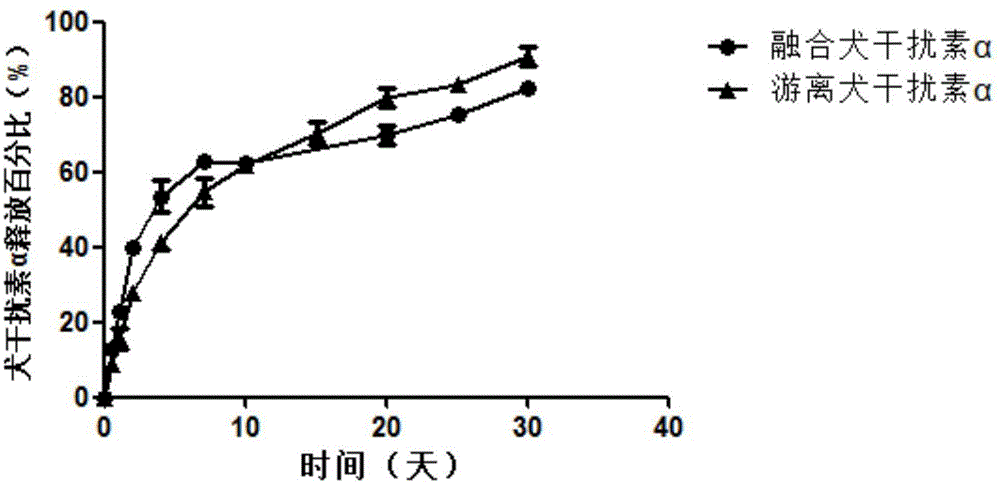

Canine interferon alpha particle compound as well as preparation method and application thereof

ActiveCN104587450ADegradableGood biocompatibilityPeptide/protein ingredientsAntiviralsSide effectAntiviral drug

The invention discloses a canine interferon alpha particle compound CaIFN alpha-NPa and a preparation method thereof. The compound comprises a gamma-polyglutamic acid-phenylalanine shell and canine interferon alpha wrapped in the shell and is formed by assembling the gamma-polyglutamic acid-phenylalanine shell and the canine interferon alpha through a self-polymerization process. The invention also discloses application of the canine interferon alpha particle compound in the preparation of canine antiviral drugs and an antiviral composition. The canine interferon alpha particle compound is high in wrapping rate, free of toxic and side effects and good in biocompatibility, can be used for retarding enzymatic degradation to realize the drug effect slow-release effect, is simple and easy to operate, low in cost and suitable for large-scale production, and has favorable application prospect.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com