Patents

Literature

32results about How to "Increase collision speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

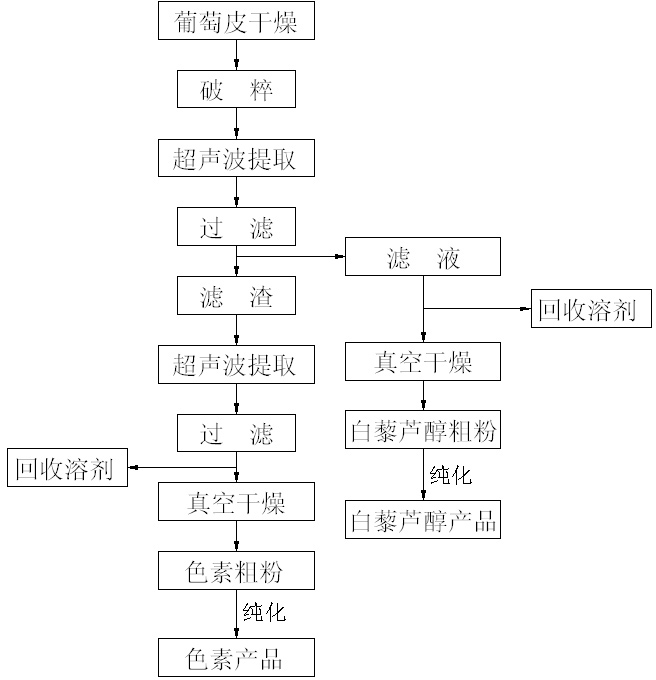

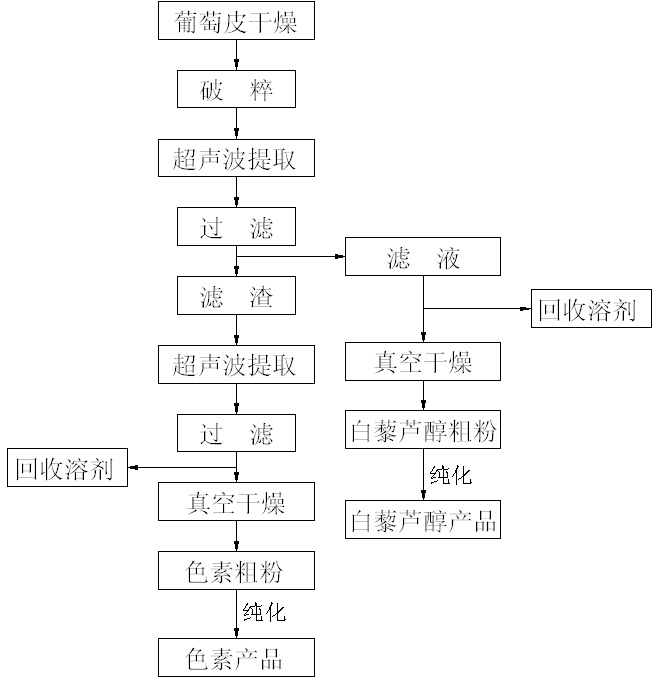

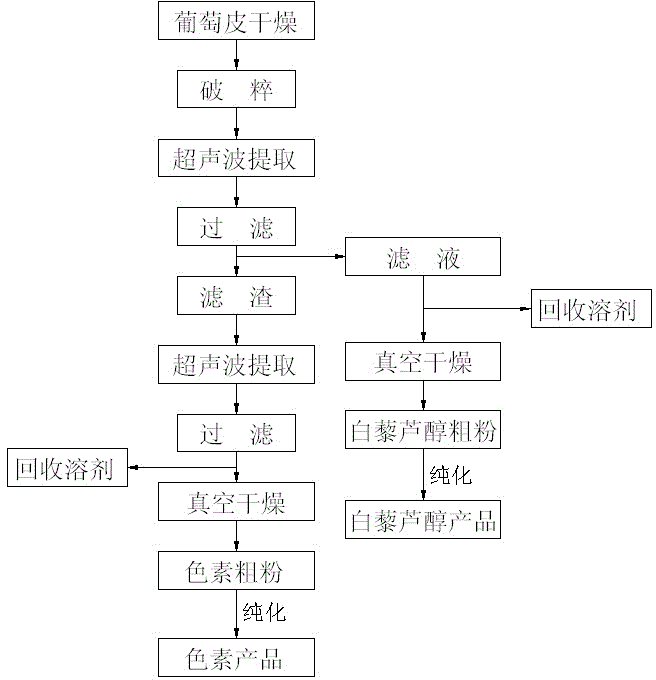

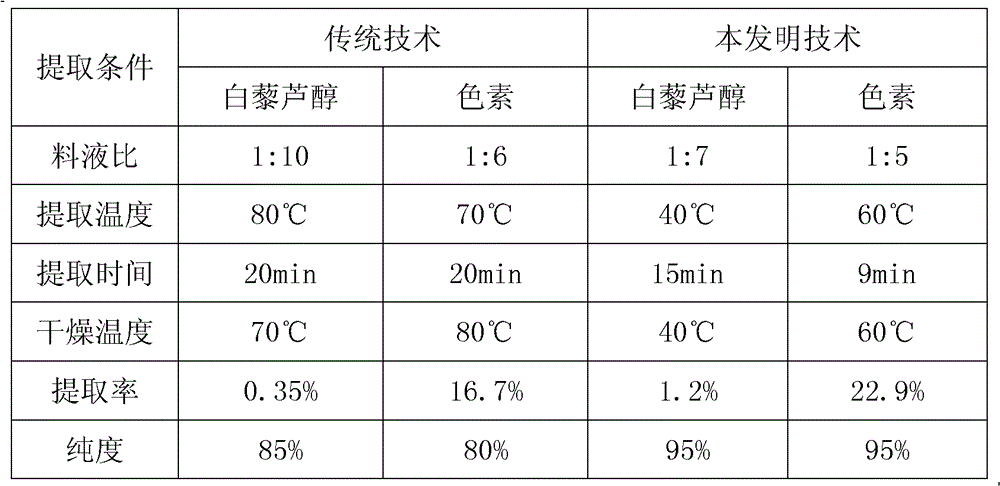

Technique for extracting resveratrol and pigment from grape skin

ActiveCN102491880AReduce dosageIncrease collision speedOrganic chemistryOrganic compound preparationSolventChemistry

The invention relates to a technique for extracting effective ingredients from a natural product, particularly a technique for extracting resveratrol and pigment from grape skin, which comprises the following steps: drying the grape skin, pulverizing, extracting resveratrol by ultrasonic waves, extracting pigment by ultrasonic waves, and purifying to obtain the resveratrol product and the pigment product. In the technical scheme provided by the invention, double solvents and ultrasonic extraction are integrated; the technical scheme provided by the invention has the advantages of high extraction efficiency, low extraction cost and low energy consumption by using the ultrasonic extraction technique according to the principle that the resveratrol and pigment in the grape skin have different solubilities in solvents with different polarities; the solvents used in the extraction process can be utilized cyclically, so that the solvent consumption is low, and the environmental influence is low, thereby avoiding destroying the bioactivities of the resveratrol and the pigment in the extraction process; and thus, the invention is suitable for extracting bioactive substances.

Owner:GANSU SHOULUSHAN PHARMA CO LTD

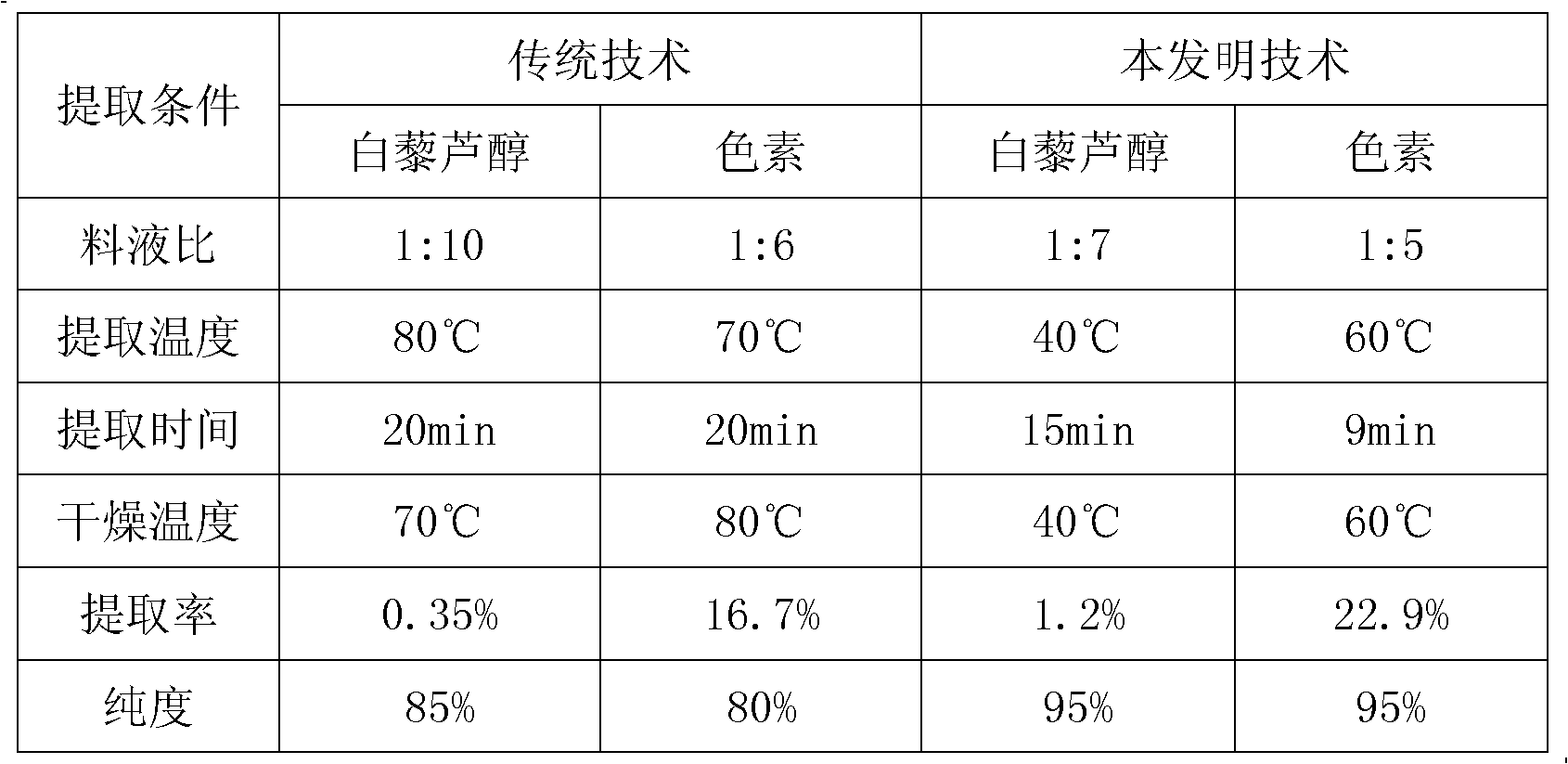

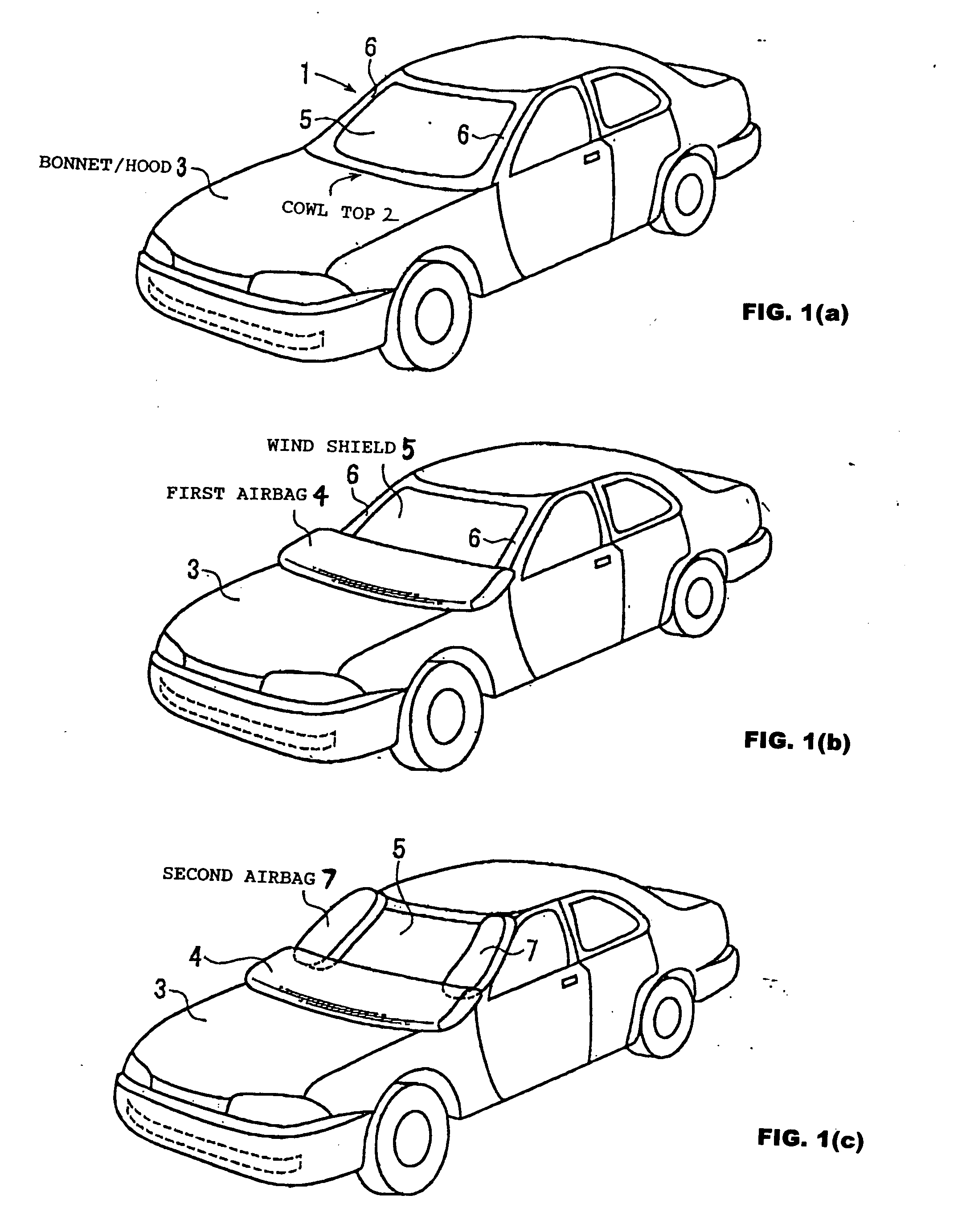

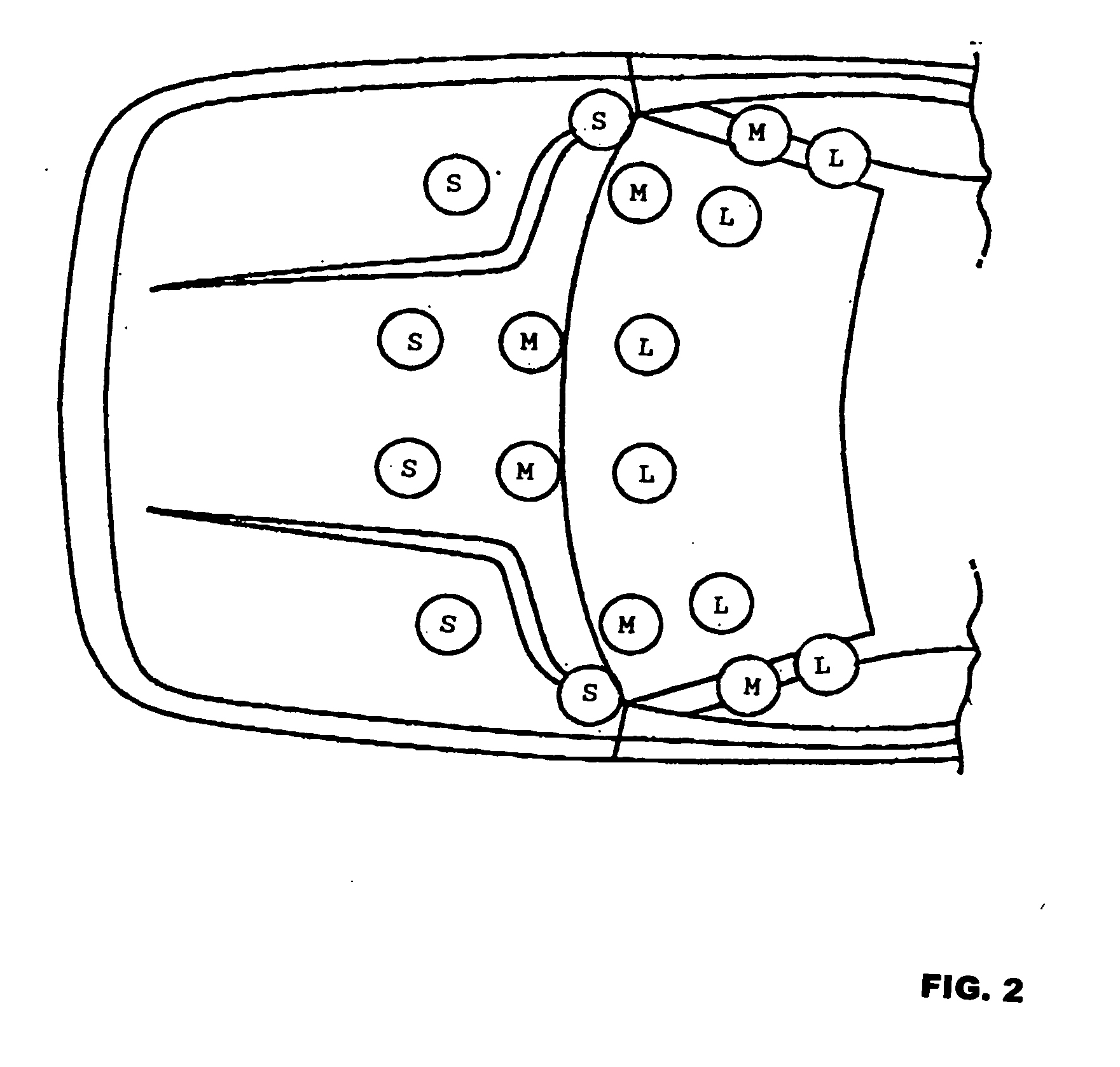

Protecting device for a pedestrian or the like

InactiveUS20050098372A1Increase collision speedShort durationPedestrian/occupant safety arrangementAutomatic initiationsAirbagMotorized vehicle

A protecting device is provided for pedestrians that accounts for various conditions of the collision (physical constitution of the pedestrian, the position of collision, the speed of the motor vehicle at the time of collision, etc.). In one form, a first airbag unit for inflating a first airbag to cover a portion of the cowl top upon collision with the pedestrian is provided at the rear part of the bonnet / hood, or in the cowl top. Second airbag units having second airbags for covering A-pillars are provided within the respective A-pillars. When collision with a pedestrian is detected, the first airbag is inflated so as to cover the portion in the vicinity of the cowl top. The second airbags inflate 5 to 30 mSec behind the ignition of a gas generator of the first airbag unit, and cover the A-pillars substantially entirely.

Owner:TAKATA CORPORATION

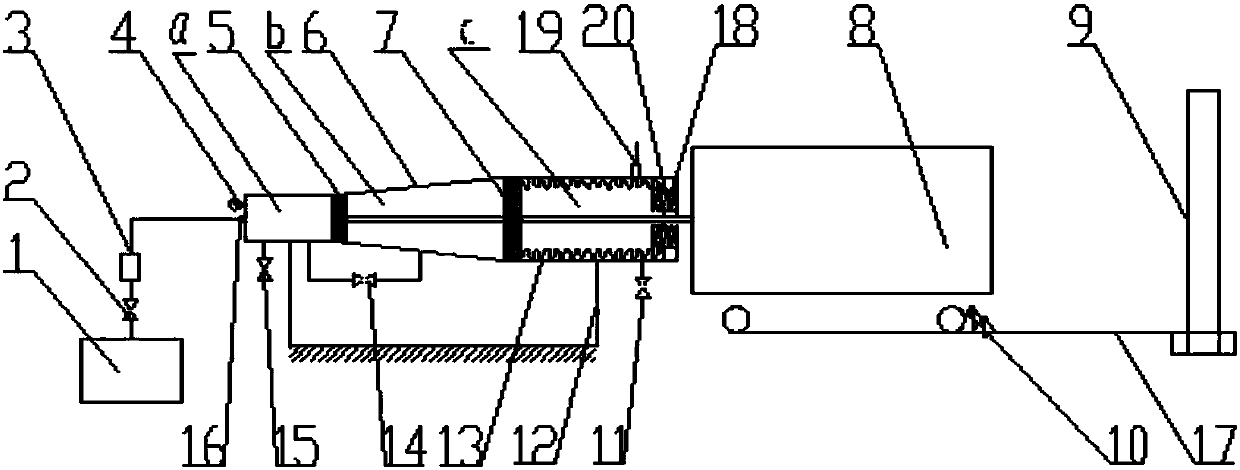

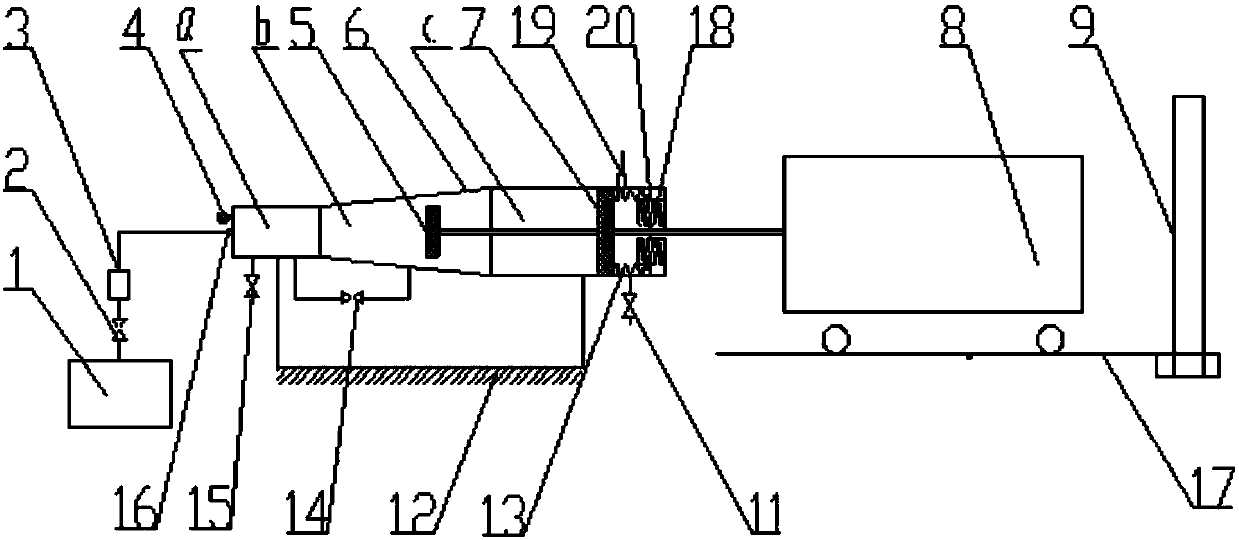

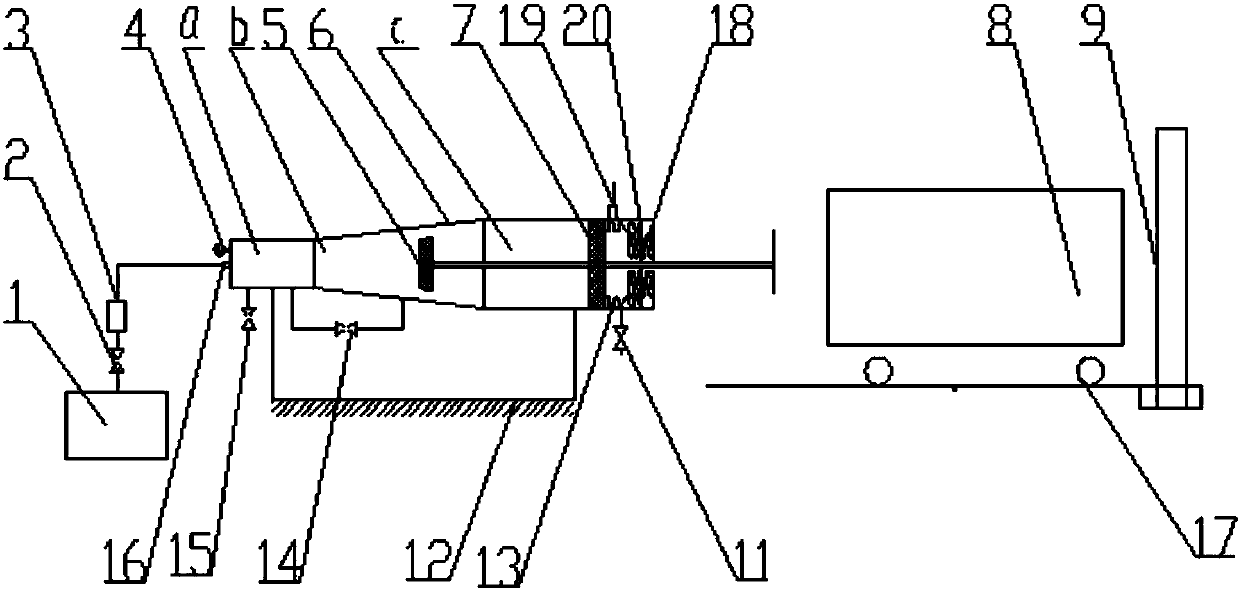

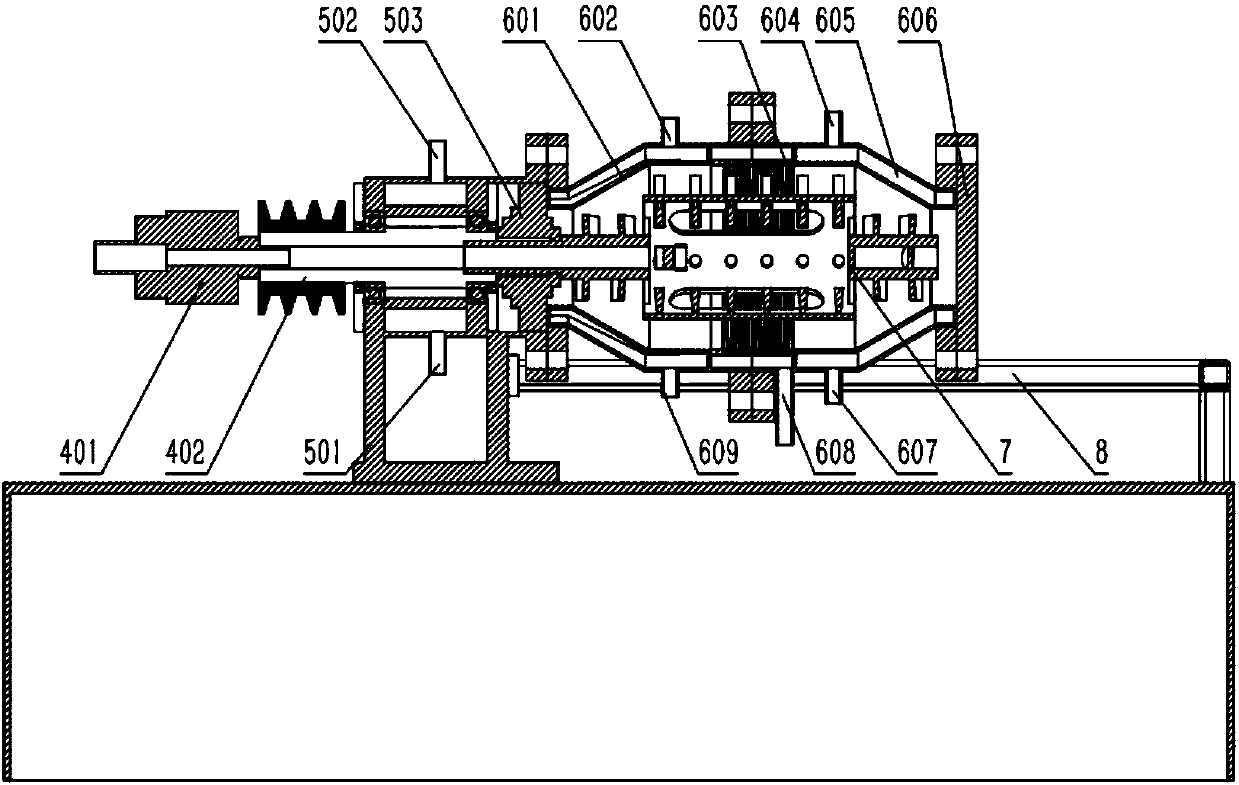

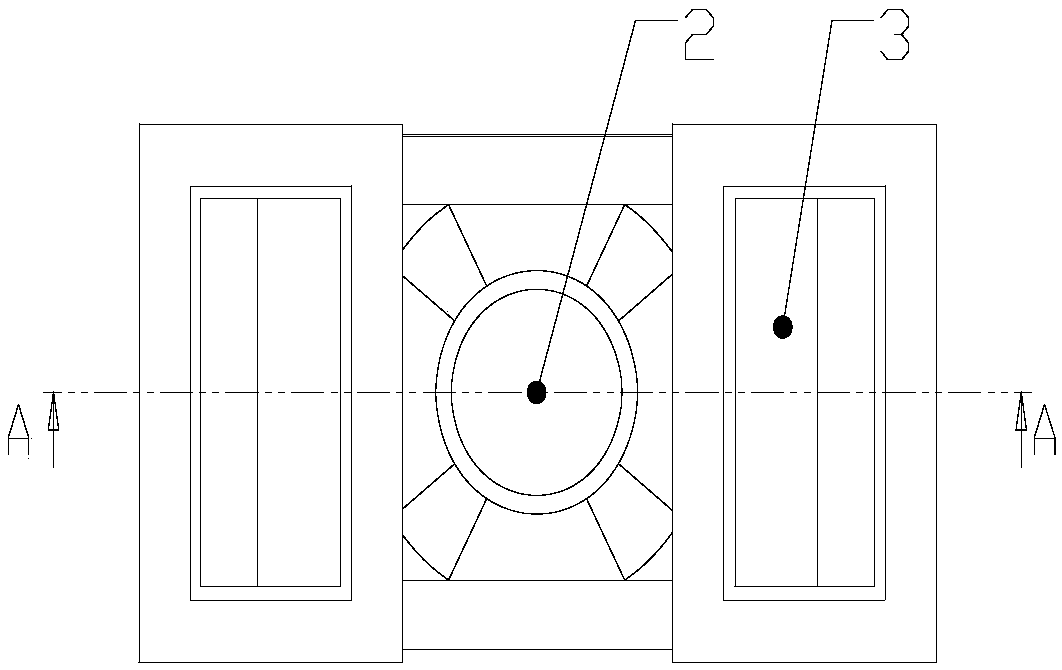

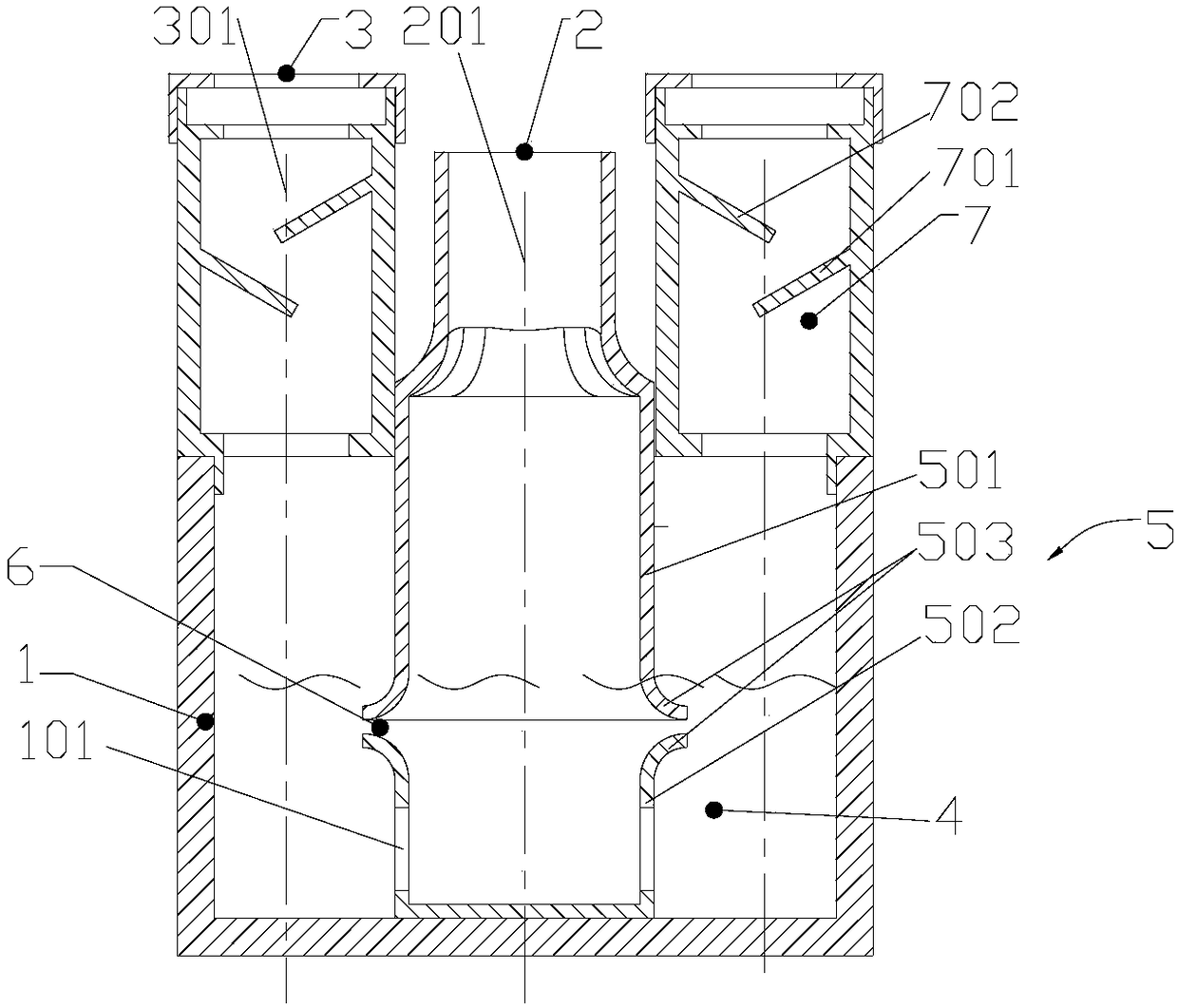

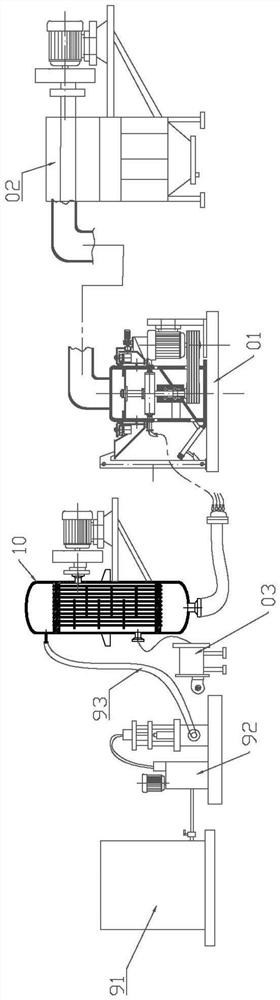

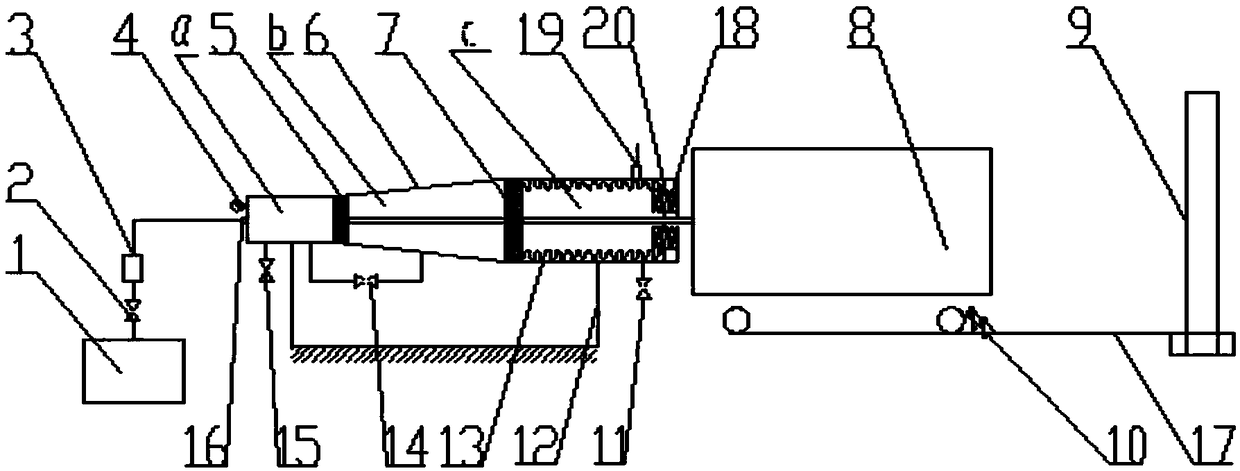

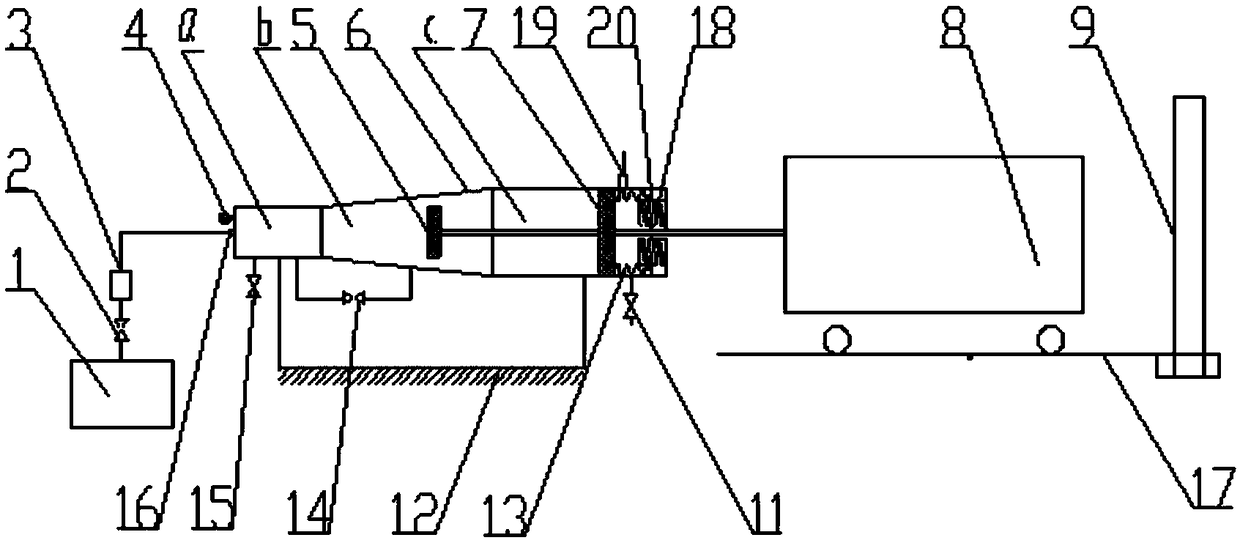

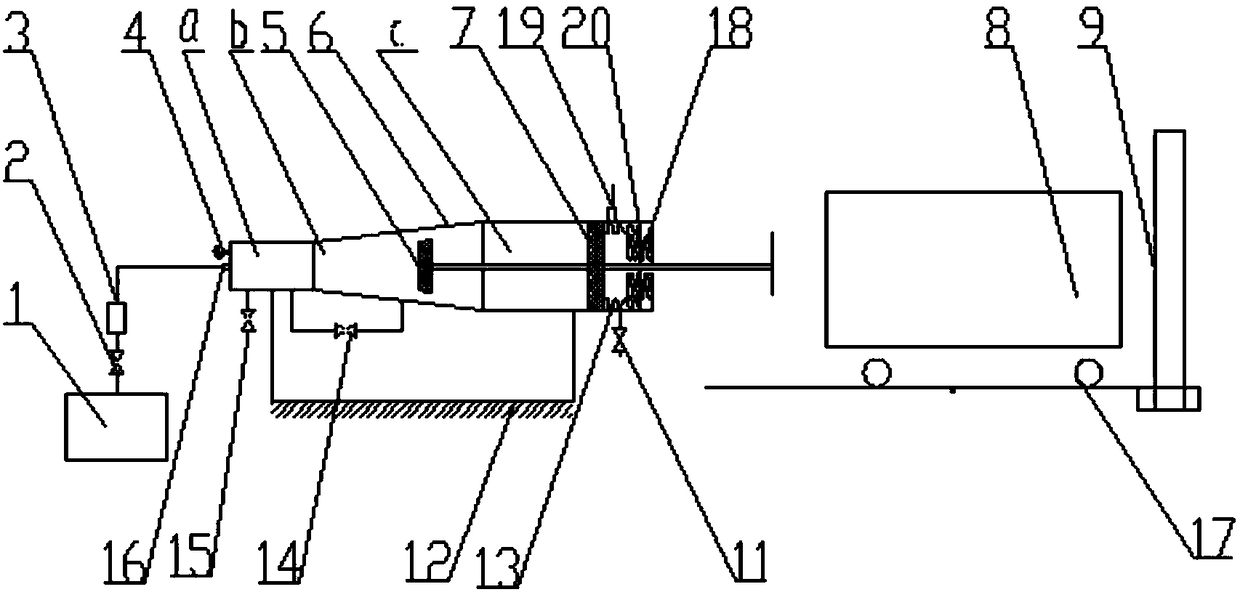

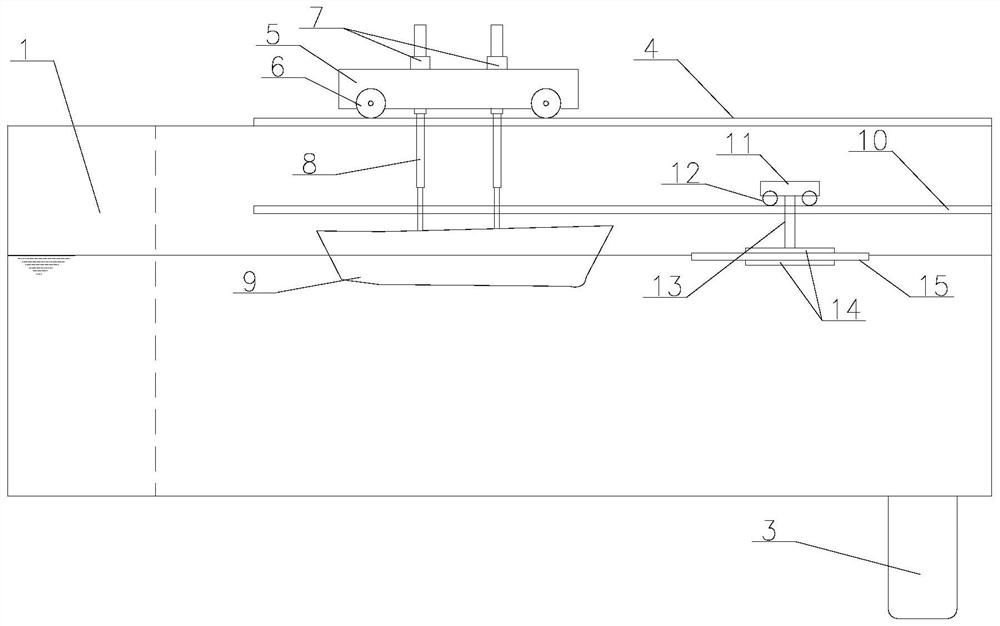

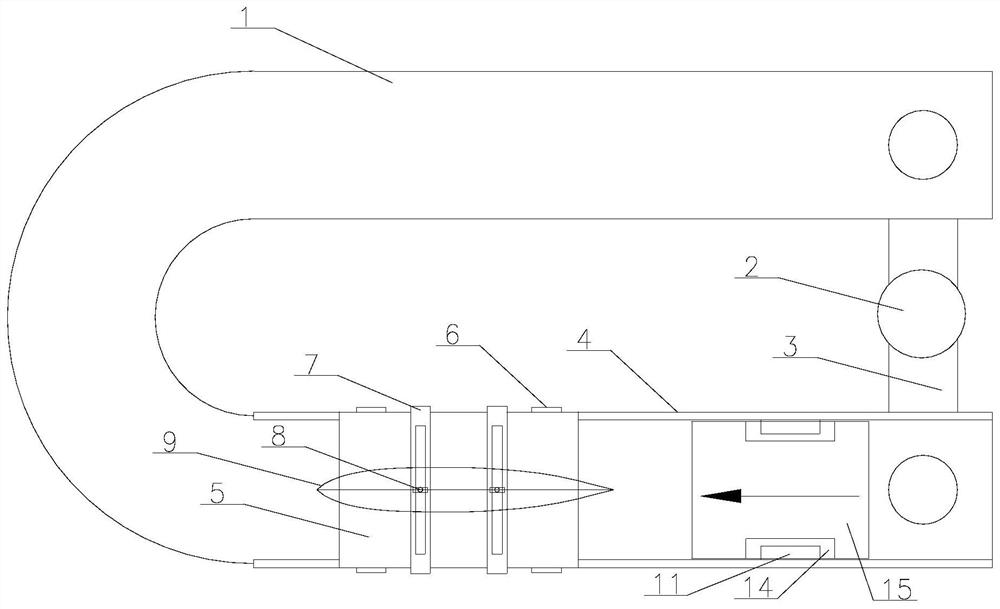

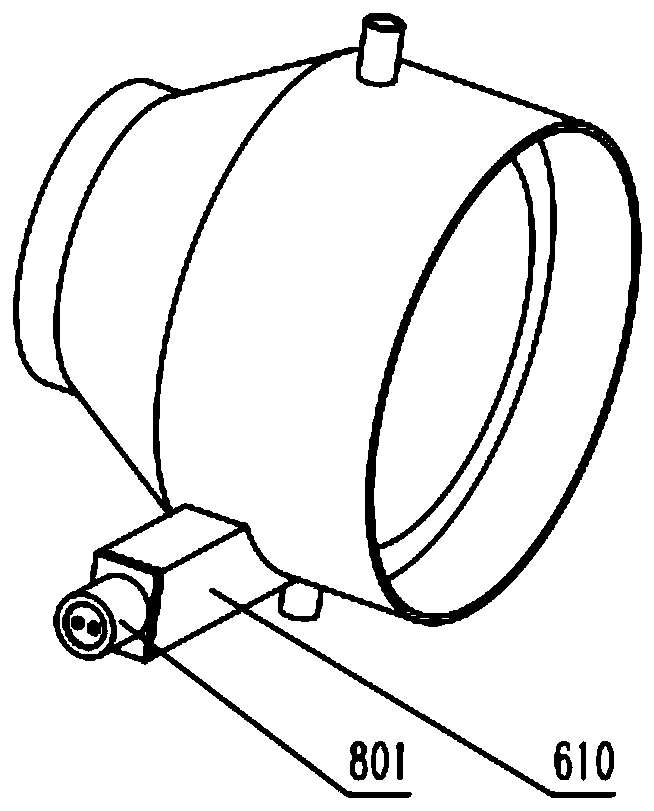

High-pressure gas ejection collision device

The invention provides a high-pressure gas ejection collision device, and belongs to the technical field of rail vehicle collision tests. The high-pressure gas ejection collision device comprises an air compressor, a collision vehicle body and a rigid wall at the front end of a rail, and is characterized in that an air cylinder is fixed with the ground foundation, an output pipeline of the air compressor is connected with a gas one-way valve and a gas dryer in series and is connected with the tail end of a back cavity a of the air cylinder through an inlet pipe joint, the air cylinder is provided with the back cavity a, a middle cavity b and an ejection cavity c, the cavities are internally provided with a duplex piston and a piston connecting rod, the bottom of the back cavity a is provided with an emergency release valve, a gas flow control valve is arranged between the back cavity a and the middle cavity b, the upper part of the ejection cavity c is provided with a release valve, and the lower part is provided with a water flow control valve; and the ejection cavity c is internally provided with a high-strength cloth bag, two ends of the cloth bag form closed spaces respectivelywith a high-pressure ejection piston and a right-end plate, and the right end of the ejection cavity c is provided with three uniformly distributed buffer springs. The high-pressure gas ejection collision device is mainly applied to rail vehicle collision tests.

Owner:SOUTHWEST JIAOTONG UNIV

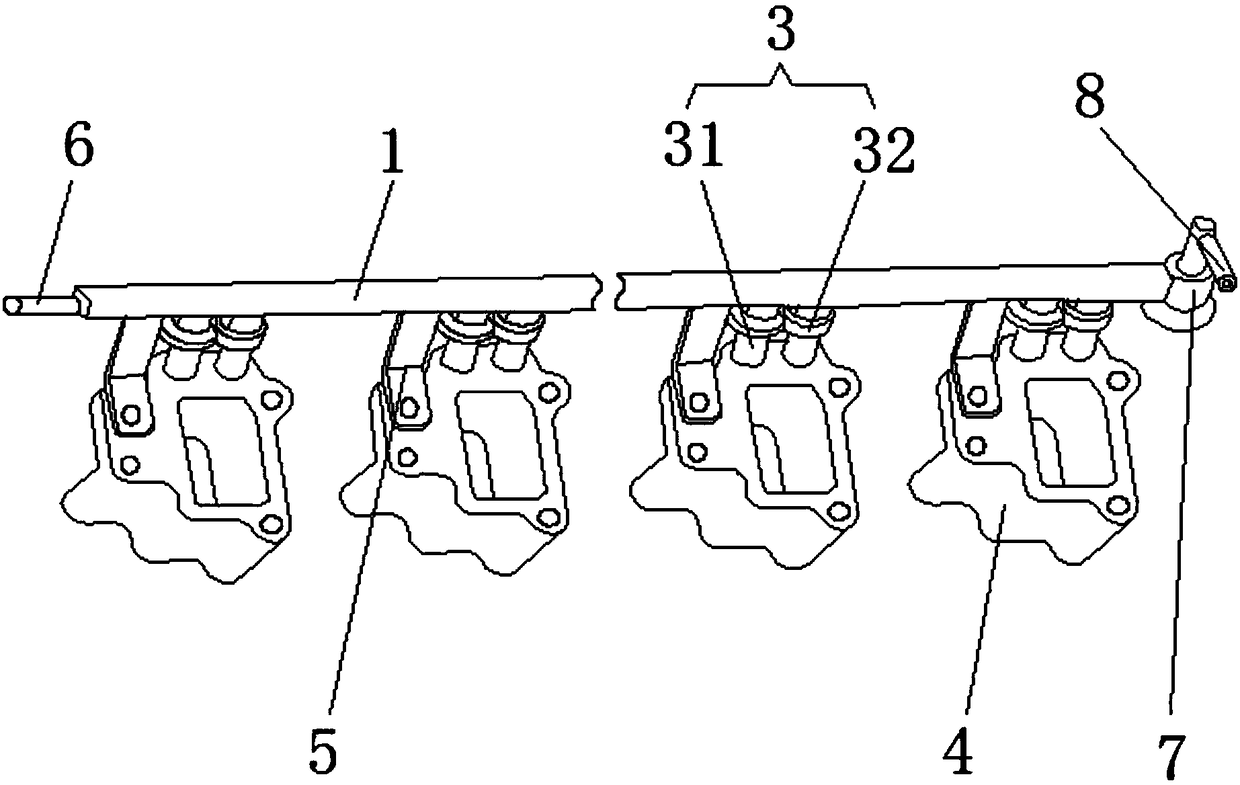

Combined thin-walled beam power absorbing method in trolley collision test

InactiveCN101776524AReduce peakPeak adjustableVehicle testingShock testingWave shapeTest requirements

The invention relates to a combined thin-walled beam power absorbing method in a trolley collision test and belongs to the field of automobile passive safety. A standard thin-walled square steel pipe is adopted; a combination mode of the length and the thickness of the thin-walled square steel pipe is regulated to form an energy absorber in the trolley collision test; and the energy absorber solves the problems of high cost, single waveform, complex operation and poor repeatability and the like existing in the conventional trolley energy absorber. In the combination mode, the action time of each group of the thin-walled square pipe is controlled by controlling the length of each group of the thin-walled square pipe, so that a peak and a valley between the groups are mutually supplemented and a smooth deceleration waveform is obtained. The combination mode of the thin-walled square pipe can be determined according to the trolley quality and the deceleration curve; the average length of the thin-walled square pipe can be determined according to a collision speed; a mounting block is arranged on the trolley, so that the thin-walled square pipe and the trolley are connected in a close fit mode; and prestrain is applied to the front end of the thin-walled square pipe, and the front end of the thin-walled square pipe is rigidly collided with a fixing wall barrier without a buffer block directly, so that the deceleration waveform meets the test requirements. The method provides a practical solution for a large amount of safety performance collision tests and biological tests of auto parts.

Owner:INST OF FIELD OPERATION SURGERY NO 3 MILITARY MEDICL UNIV PLA

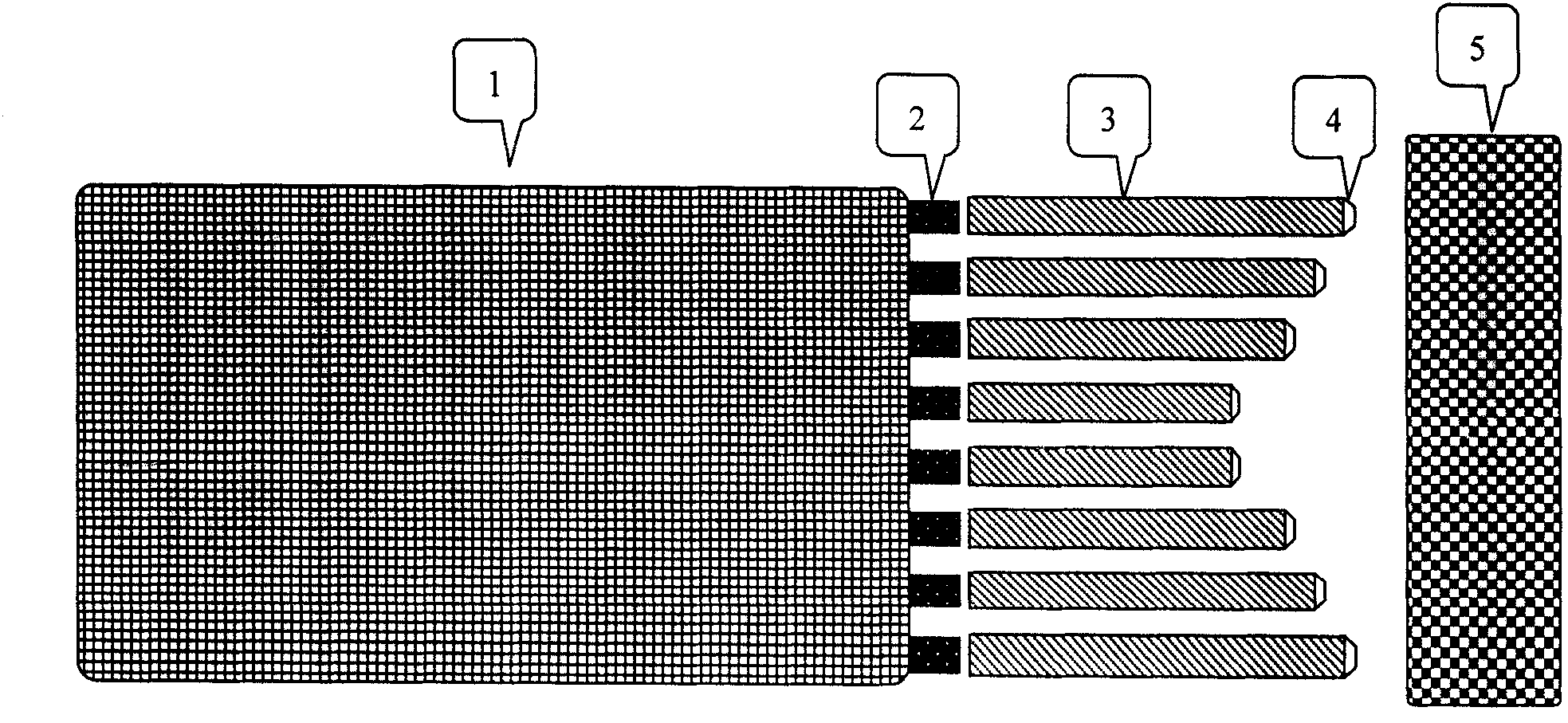

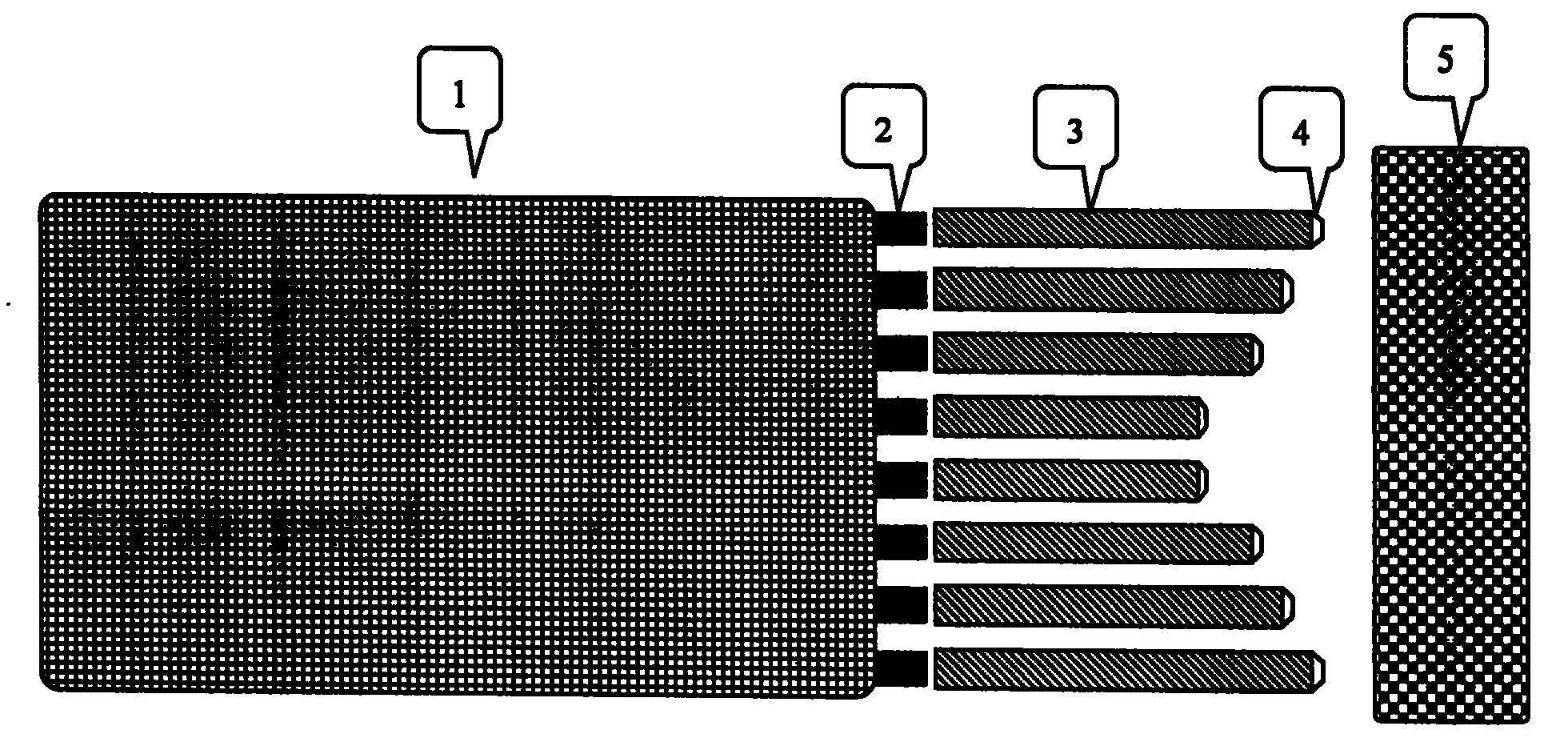

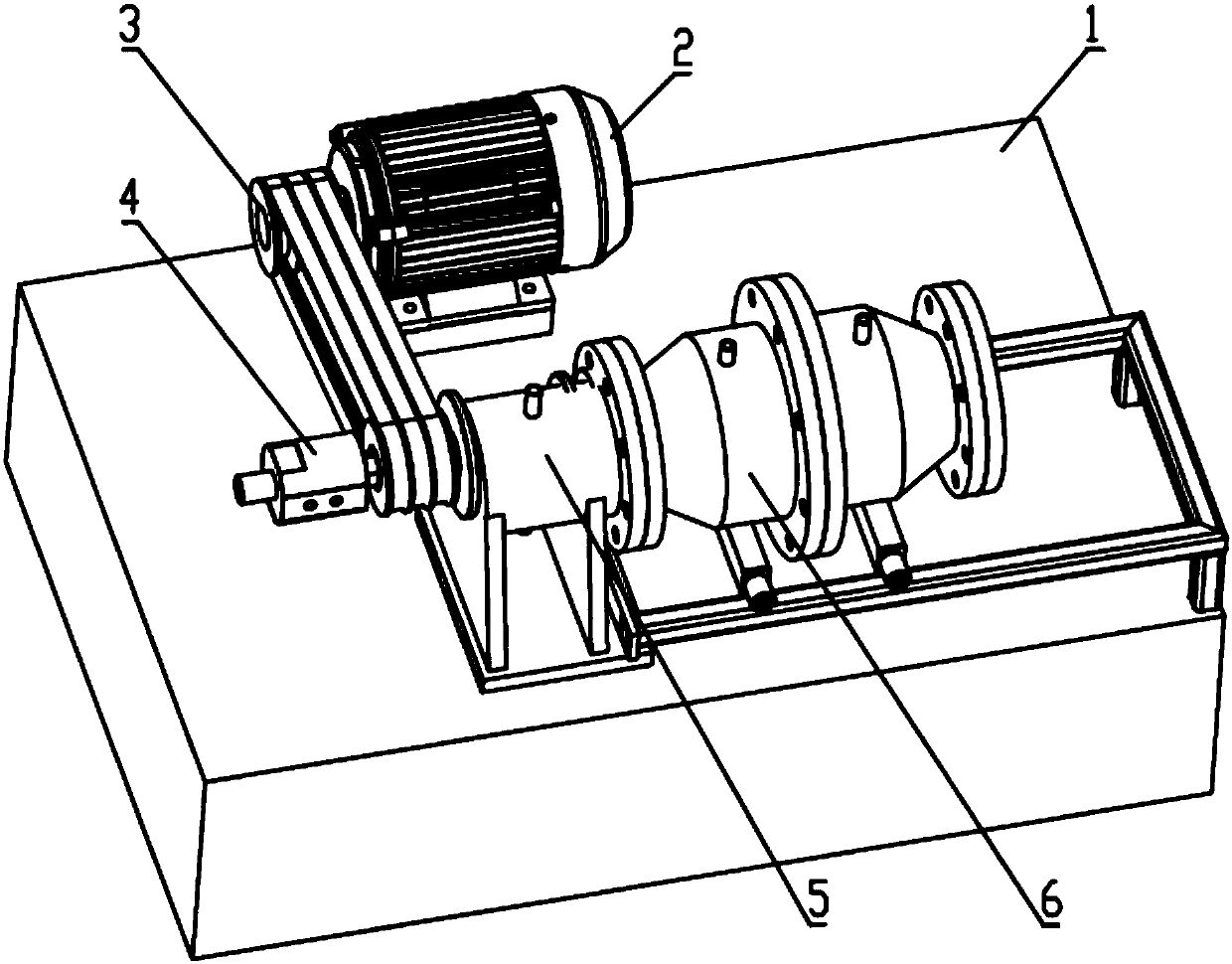

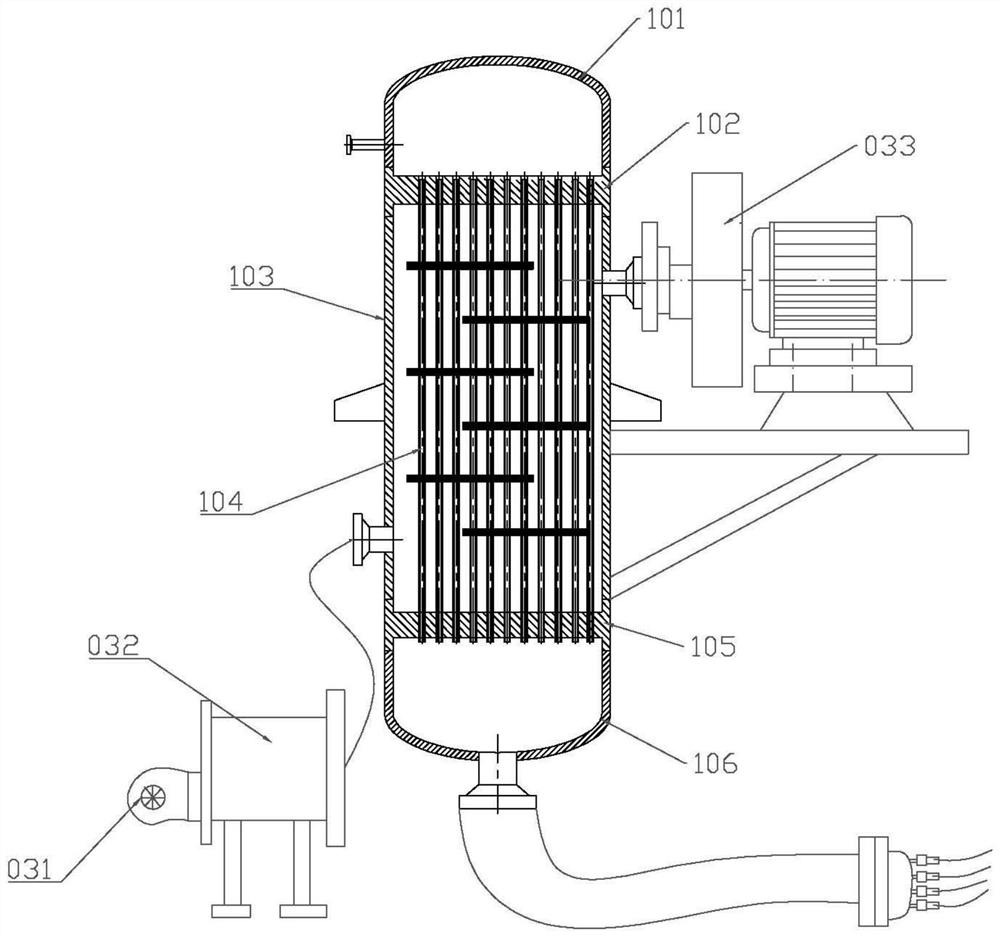

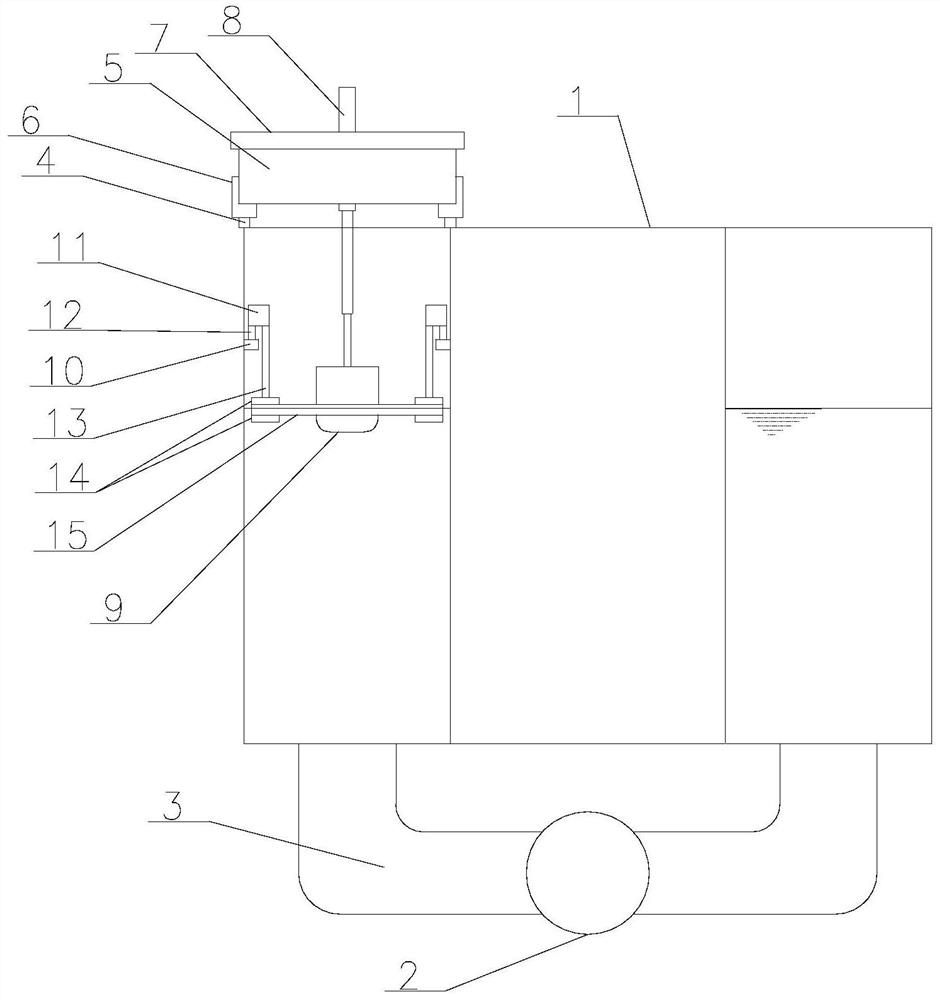

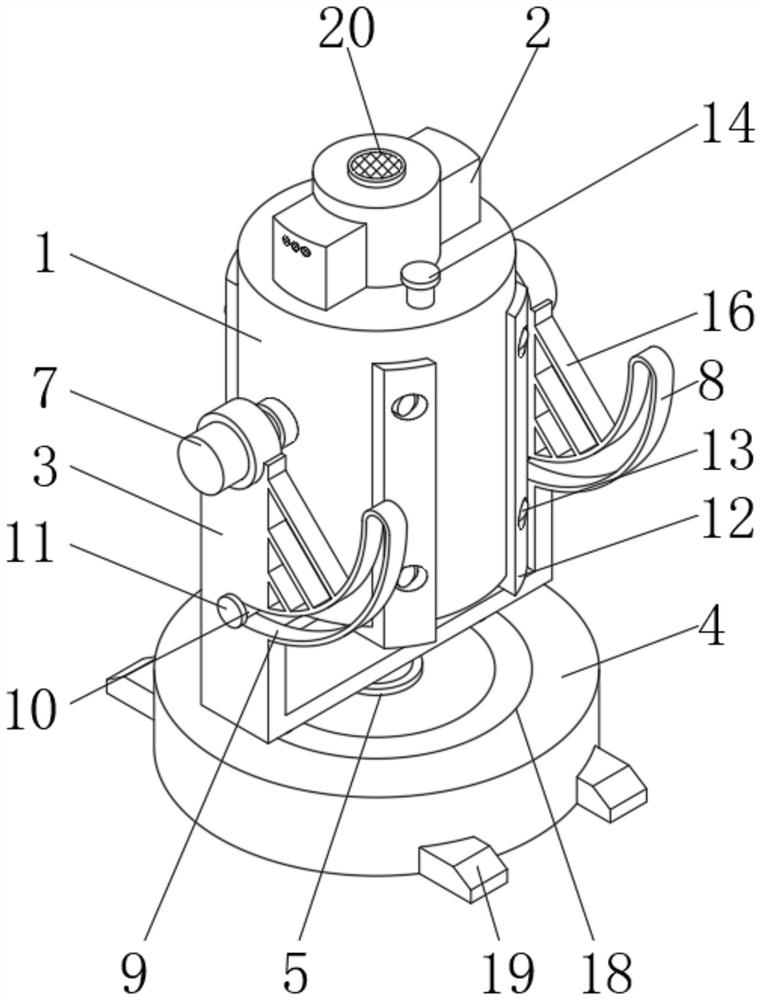

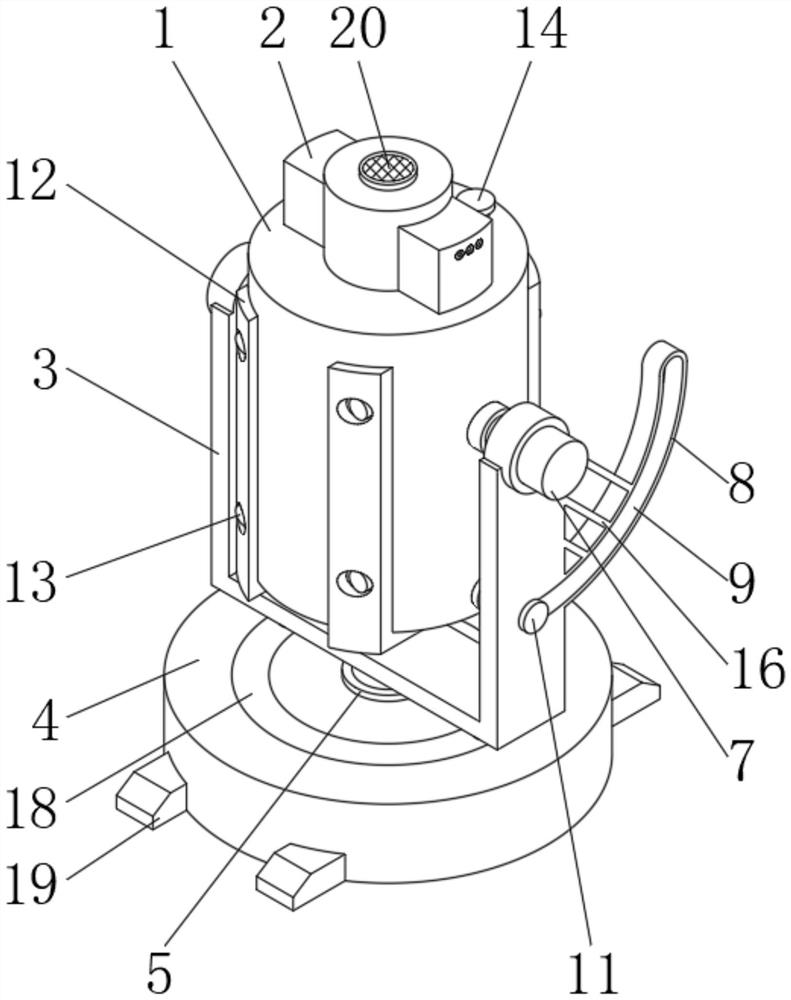

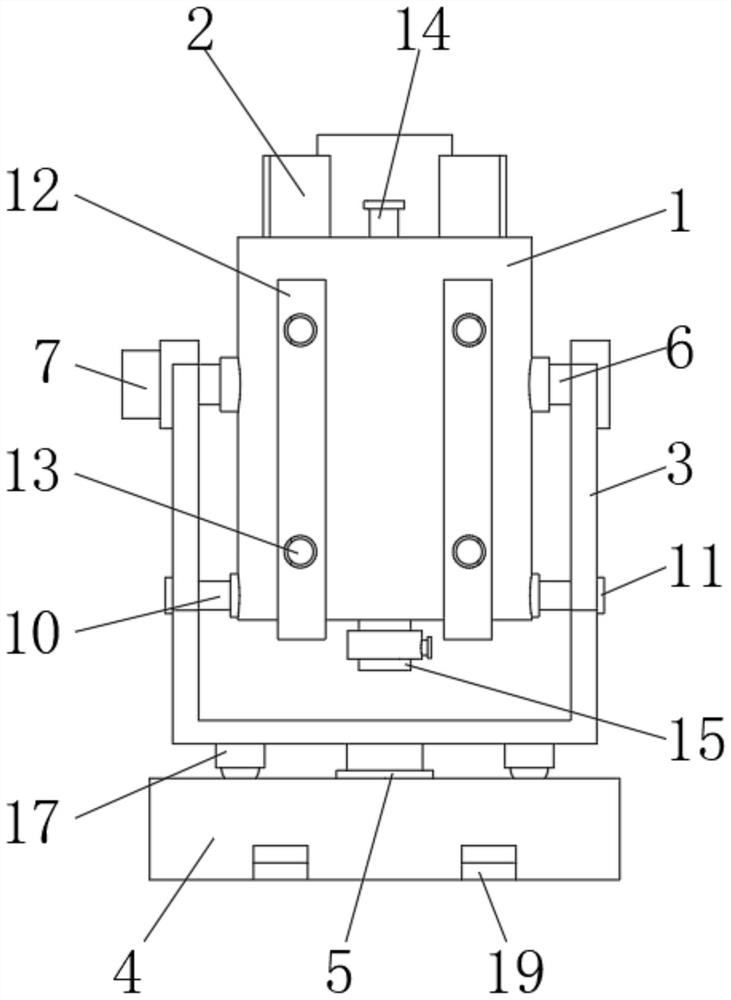

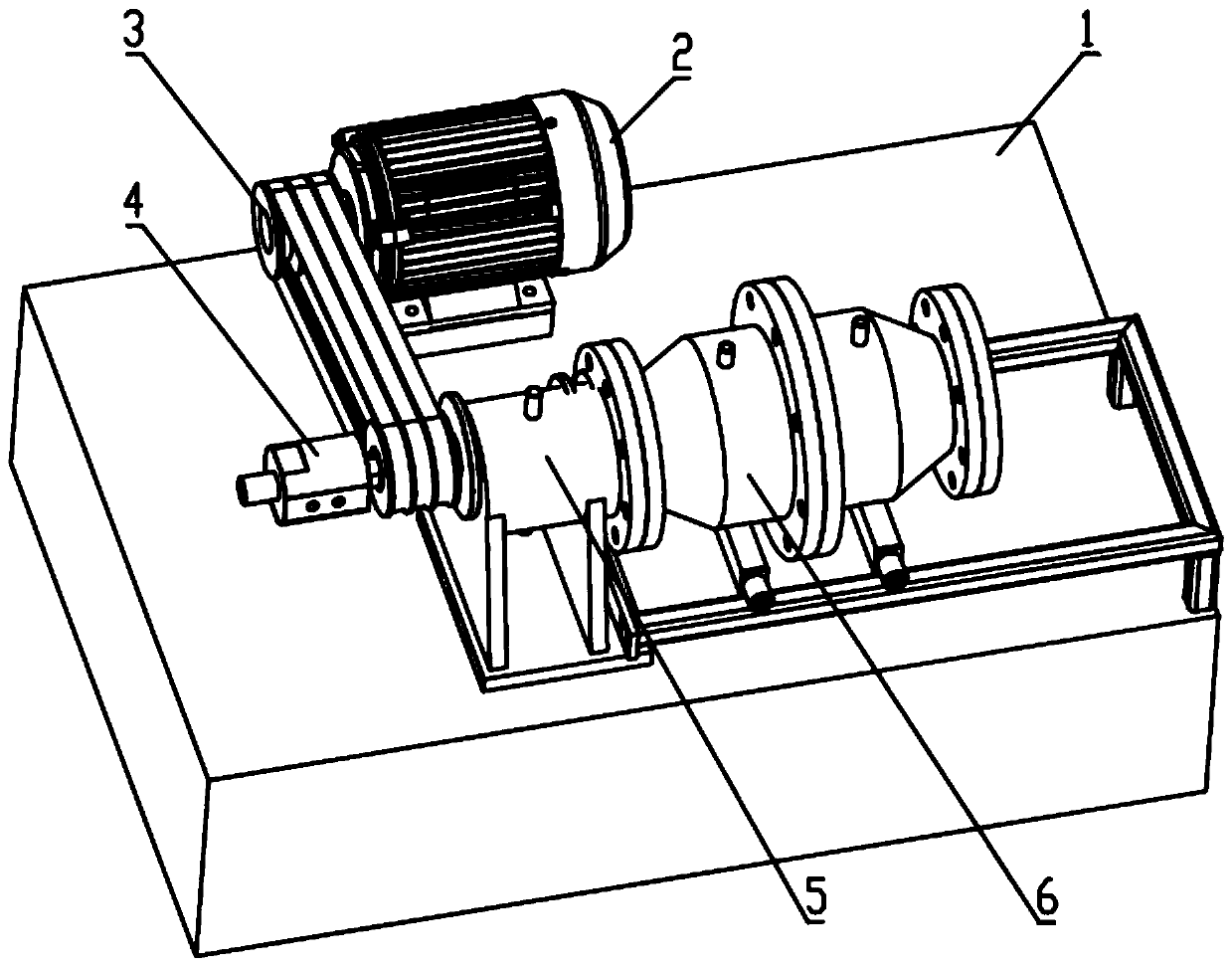

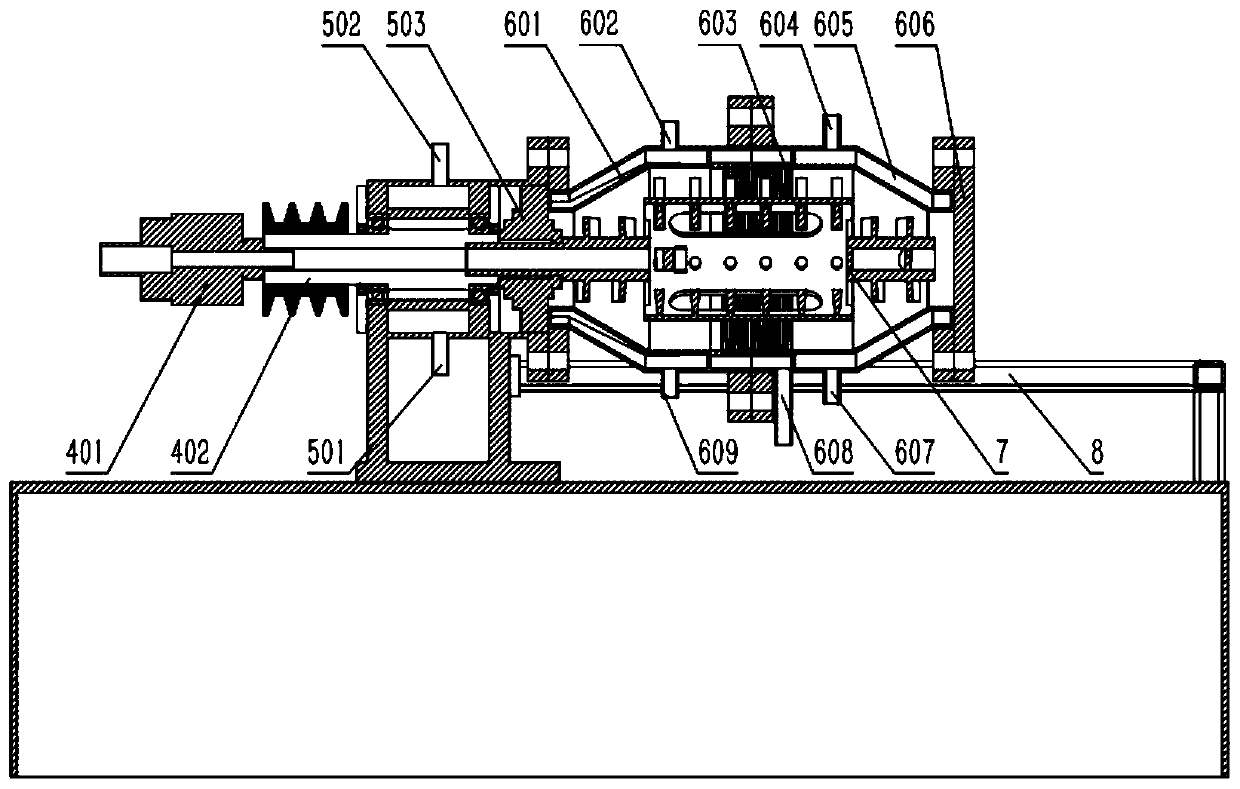

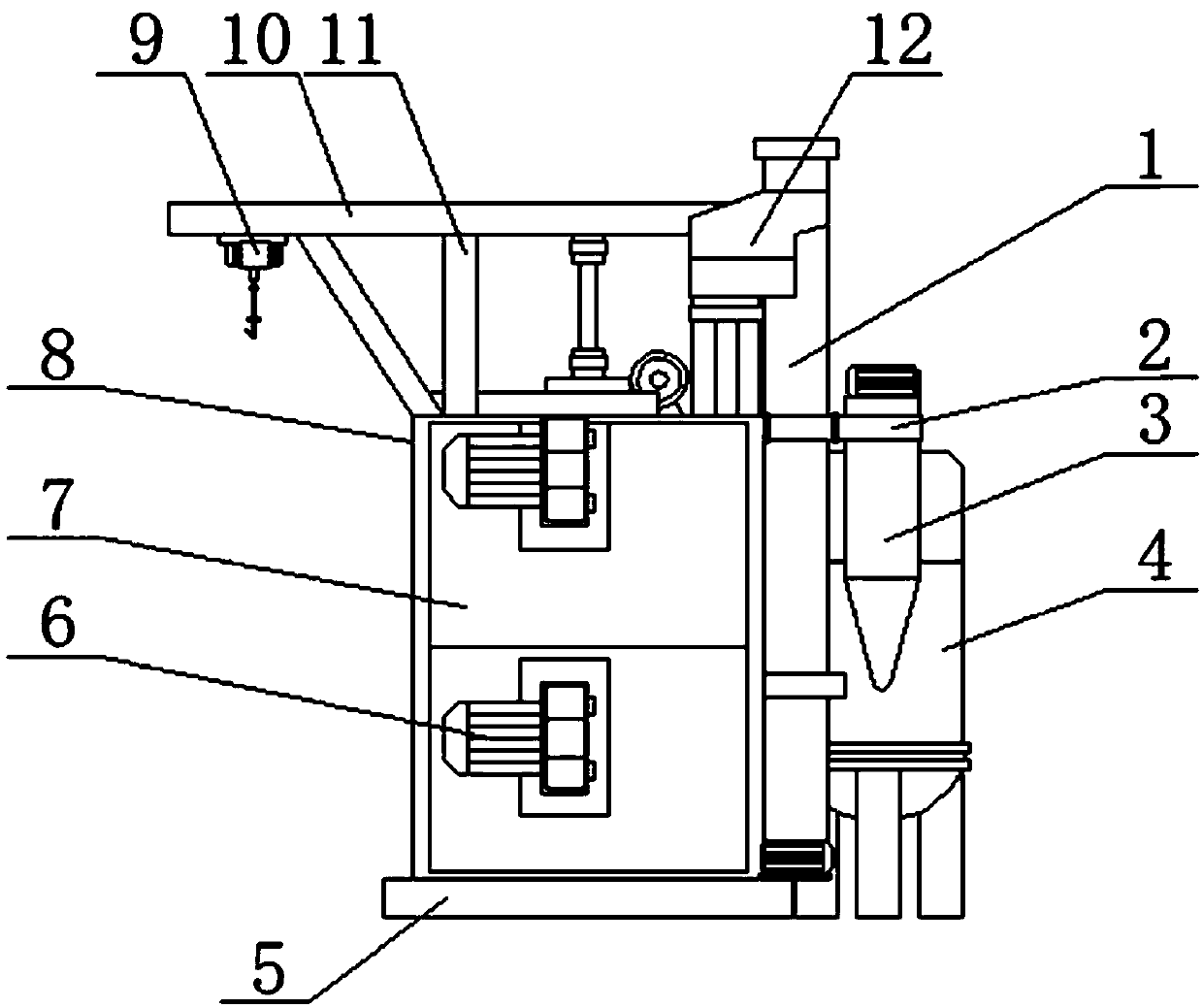

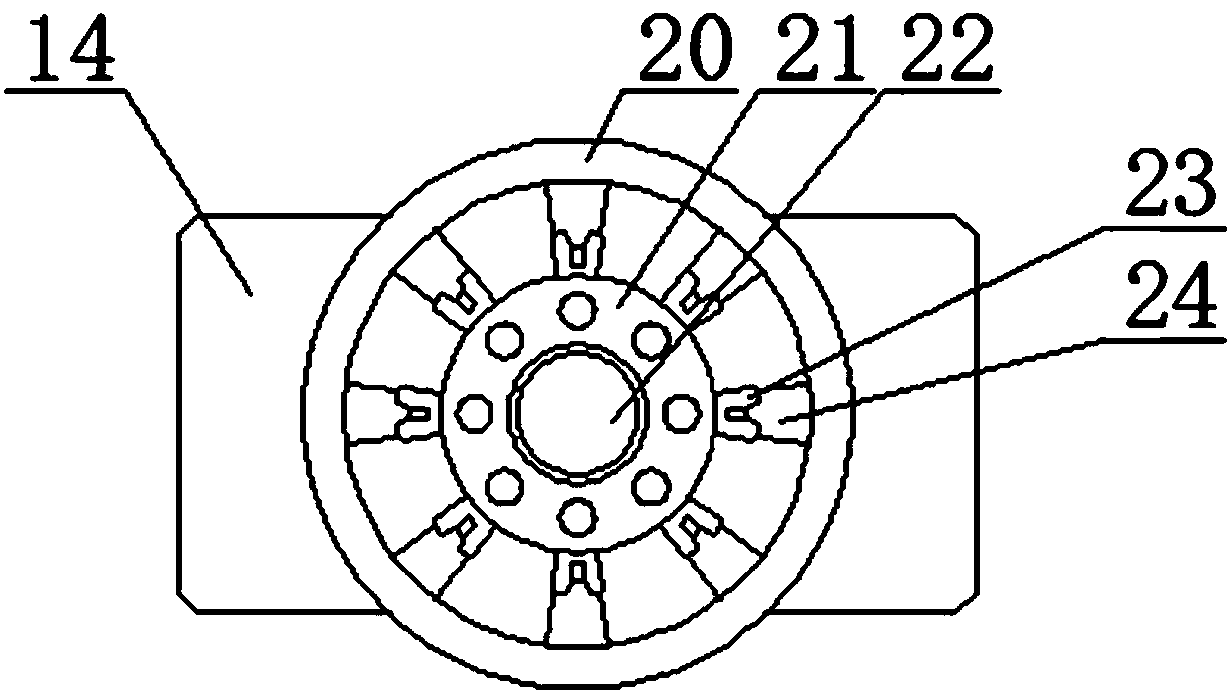

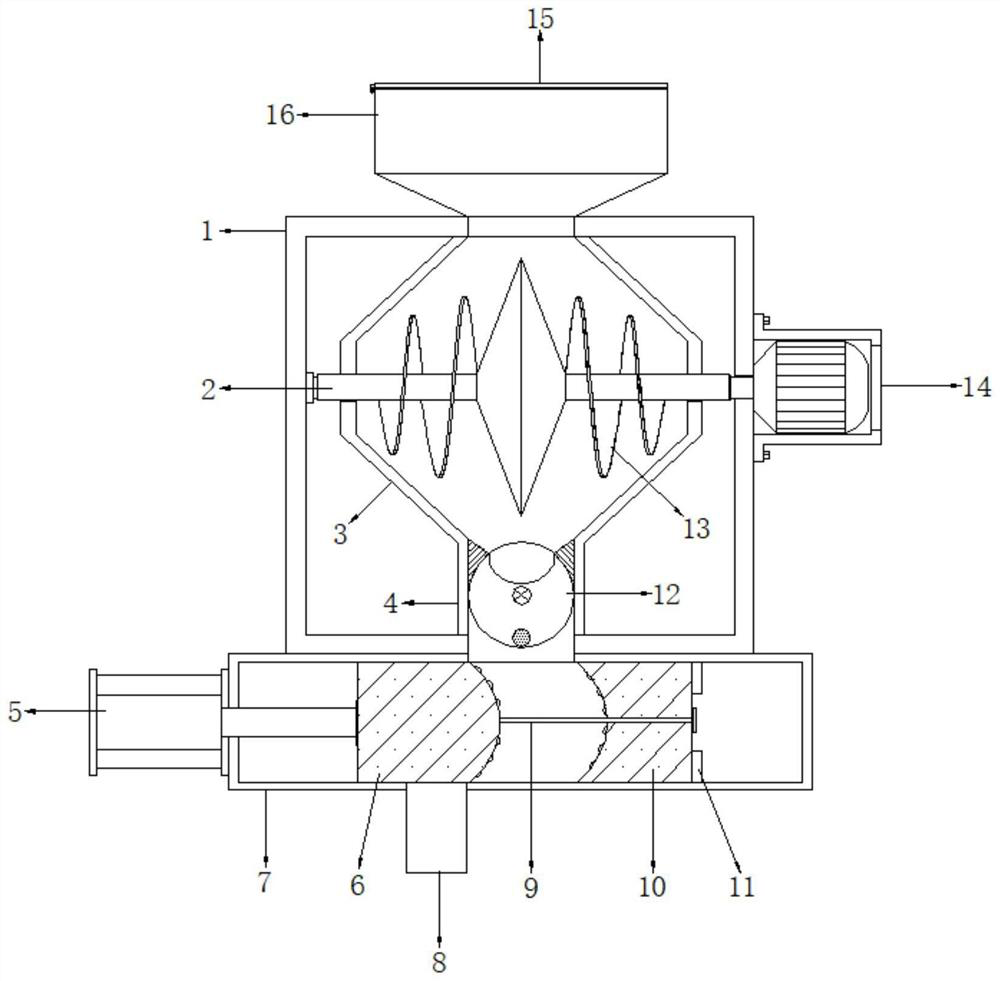

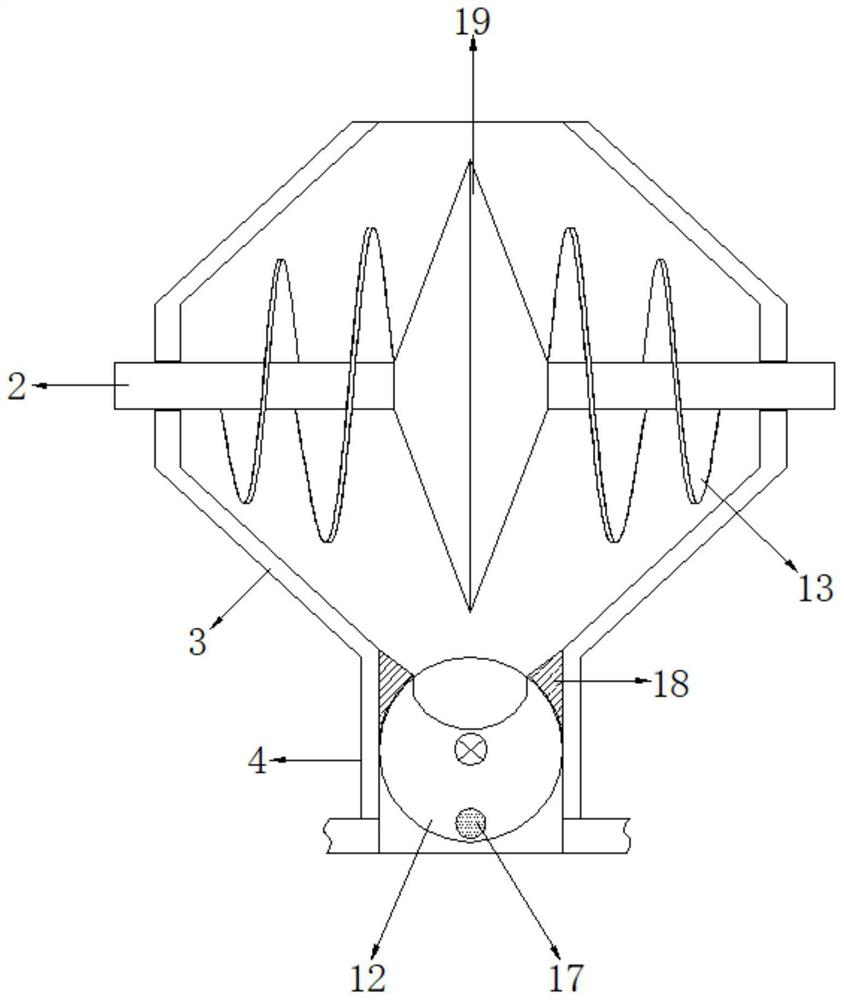

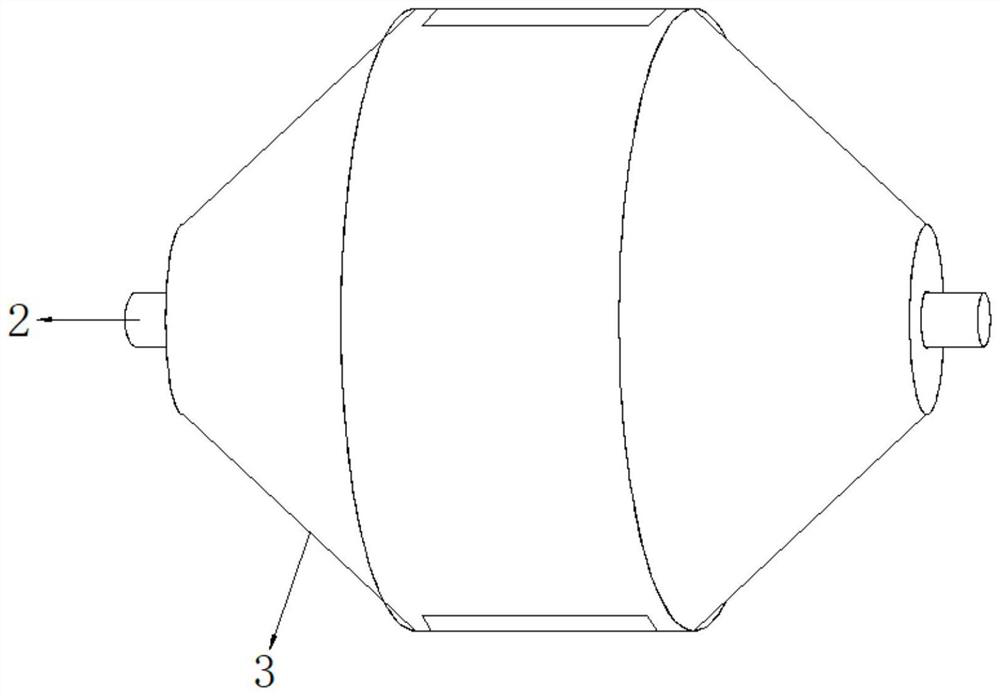

Rod pin type bifrustum-shaped sand mill device

ActiveCN107626395ACompact structureReasonable structureGrain treatmentsSurface mountingElectric machinery

The invention relates to a rod pin type bifrustum-shaped sand mill device. The rod pin type bifrustum-shaped sand mill device comprises a rack, wherein a motor is arranged on the upper surface of therack; the output end of the motor is connected with a spindle component through a driving component; one end of the spindle component is supported by a bearing base component; a sand mill barrel bodycomponent is arranged at the outer end of the bearing base component through a sealing device; a stirrer connected with the spindle component is arranged inside the sand mill barrel body; rollers arearranged on two sides of the sand mill barrel body component; a guide rail bracket for the rollers to run is arranged on the upper surface of the rack. The rod pin type bifrustum-shaped sand mill device disclosed by the invention has the advantages of compact and reasonable structure and convenience in operation; a barrel body with a conical structure is adopted, and the inner part of the barrel body is matched with the pin rod type stirrer for grinding materials, so that good milling effect and high working efficiency are realized.

Owner:WUXI HOPE LIGHT IND EQUIP TECH

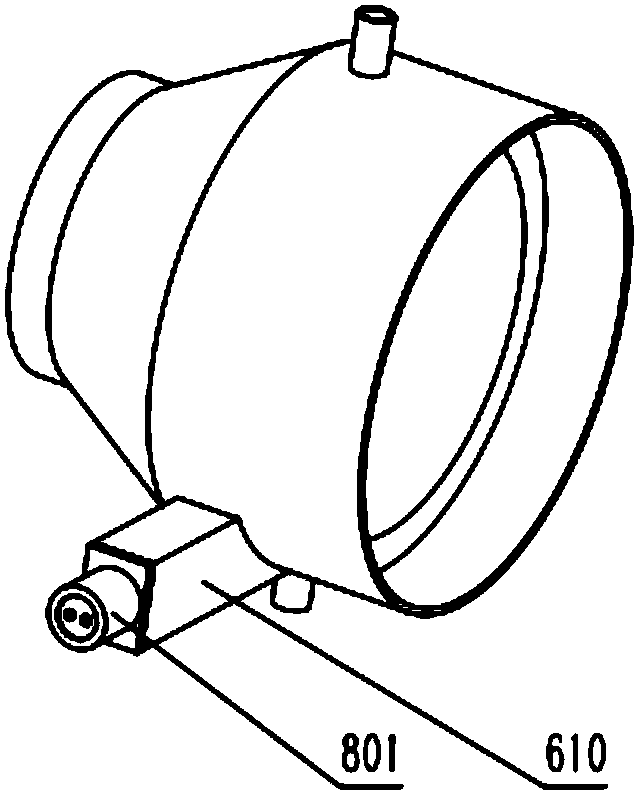

Nozzle structure for multi-point injection of heavy methanol engine

InactiveCN108457785ACompact structureReasonable designFuel injection apparatusMachines/enginesCombustionCommon rail

The invention discloses a nozzle structure for multi-point injection of a heavy methanol engine. The nozzle structure comprises a common rail tube, wherein groups of nozzle assemblies equal to air cylinders of the engine in quantity are arranged on the common rail tube; each of the nozzle assemblies comprises at least two nozzles communicating the common rail tube to the air cylinder of the engine, and each of the nozzles is obliquely arranged toward the side wall of the air cylinder of the engine. The invention provides the nozzle structure for multi-point injection of the heavy methanol engine compact in structure and reasonable in design. By changing the quantity and injection directions of the nozzles, the demand, on single nozzle flow, of the engine is reduced, the control precision and the combustion efficiency of a methanol injection flow are improved, and the energy consumption is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

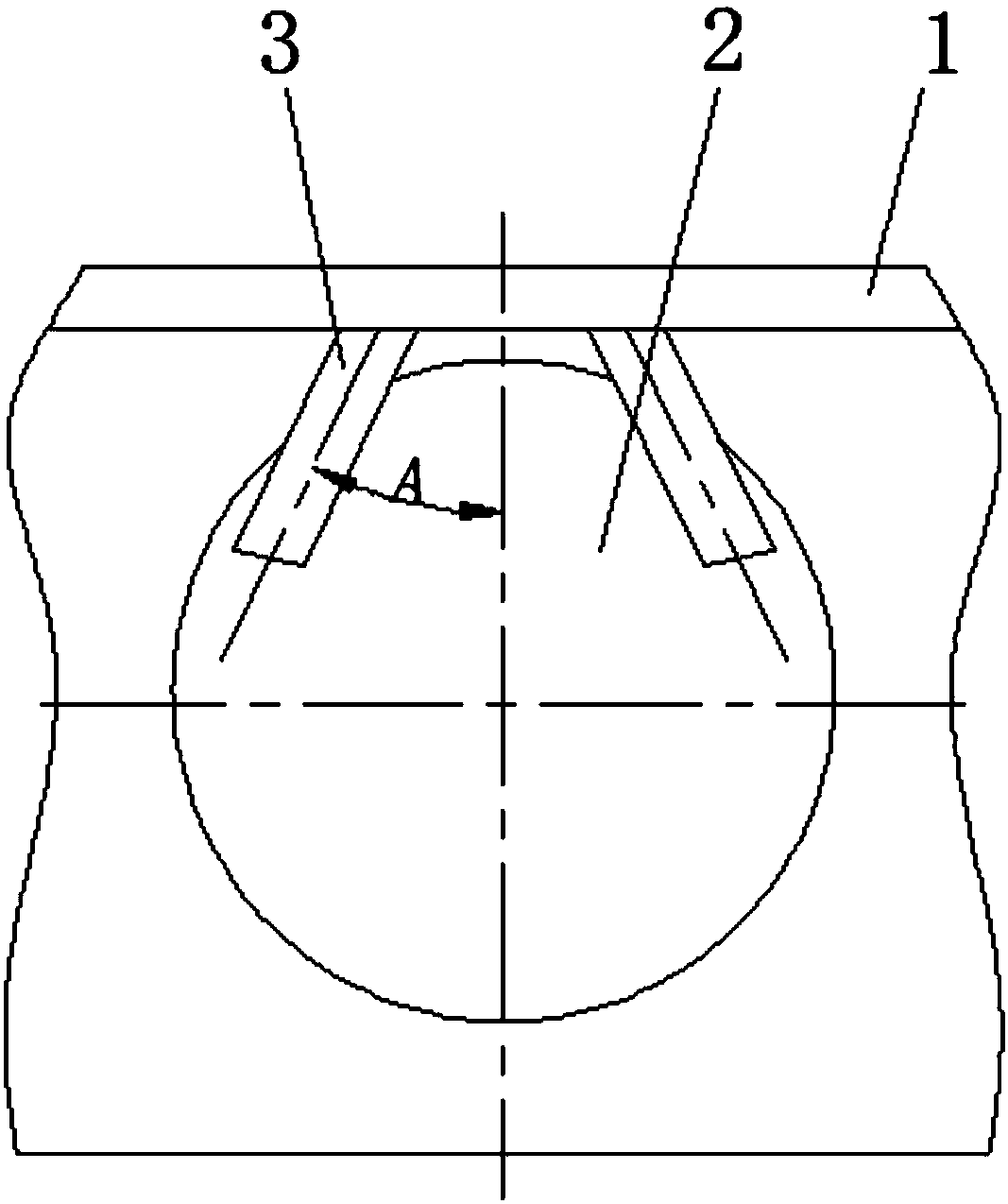

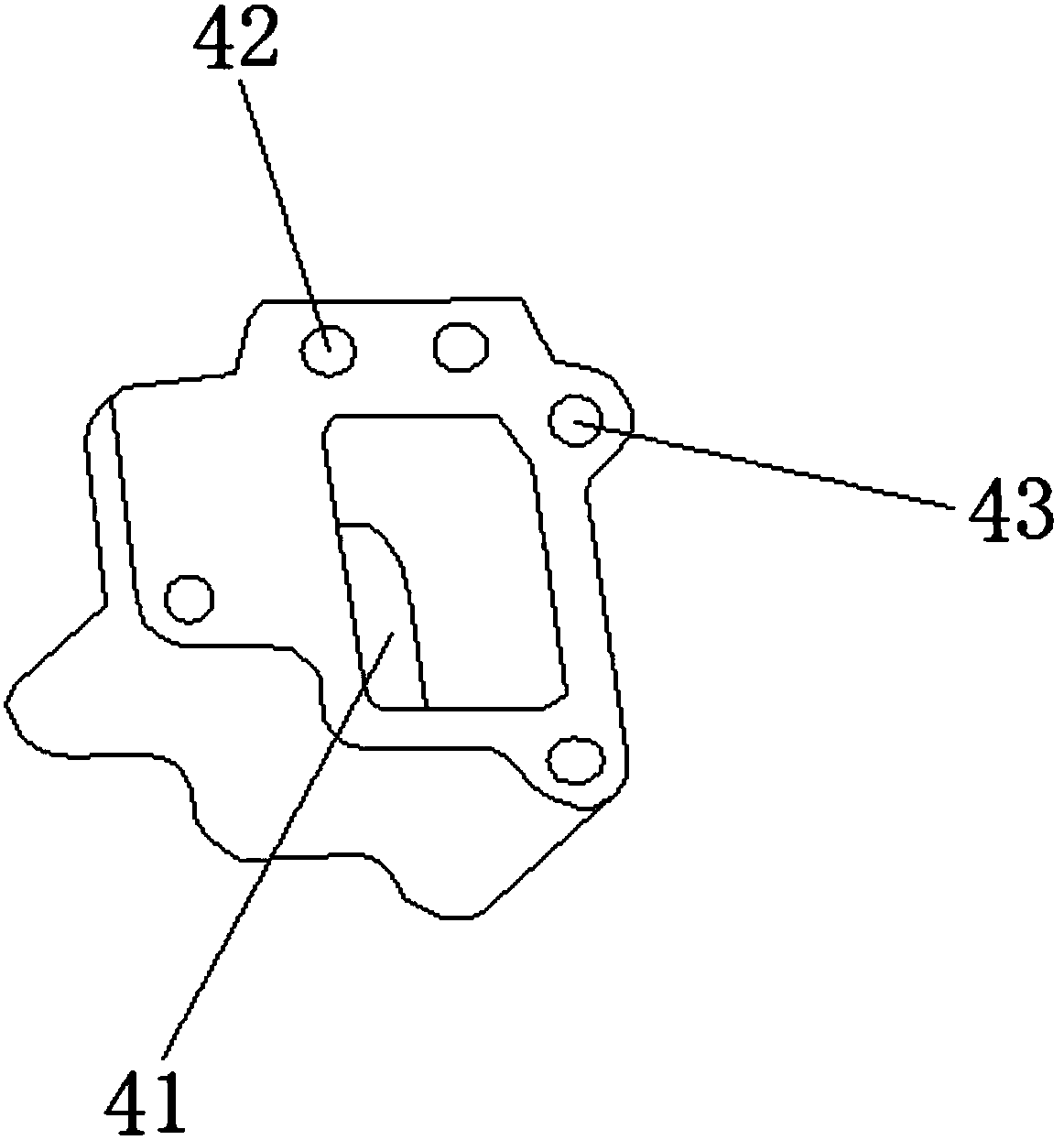

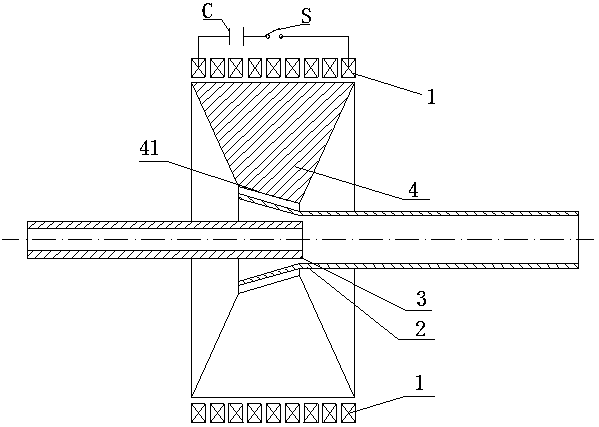

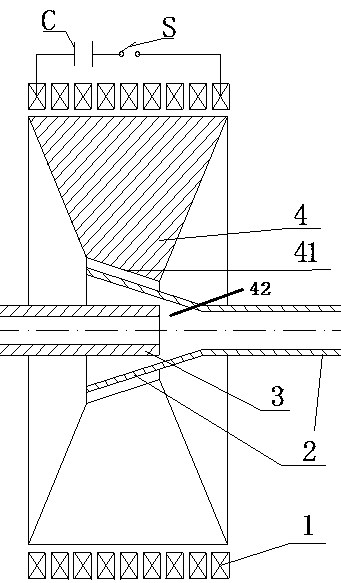

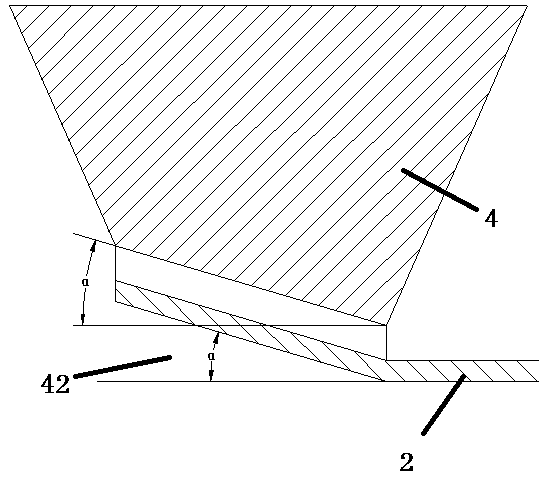

Dissimilar metal pipe overlap joint and welding method thereof

InactiveCN110802338AImprove match rateIncrease connection areaMetal working apparatusWelding apparatusPipe fittingLap joint

The invention puts forward a dissimilar metal pipe overlap joint. The dissimilar metal pipe overlap joint is applied to alignment of two pipes during magnetic pulse welding of the metal pipes and positioning of pipe fittings at welding equipment. The overlap joint comprises an outer pipe and an inner pipe; the welding end of the outer pipe and the welding end of the inner pipe are arranged in theworking zone of a field shaper of the welding equipment; the working zone of the field shaper adopts the conical surface structure; the welding end of the outer pipe is a trumpet-shaped flaring opening with the outer wall parallel with the conical surface of the working zone; the welding end of the inner pipe is inserted in the flaring opening and is adjacent to the small end of the flaring opening; and the pipe diameter of the welding end of the inner pipe is larger than or equal to the hole diameter of the small end of the flaring opening. When magnetic pulse welding is performed, the flaring opening generates the induction eddy due to the magnetic field of the field shaper; the magnetic field of the induction eddy repels the magnetic field, in the working zone, of the field shaper, so that the flaring opening collides with the welding end of the inner pipe at the high speed under the action of the repulsion force, and magnetic pulse welding is completed. According to the dissimilarmetal pipe overlap joint, the collision angle is favorably formed during magnetic pulse welding operation, the collision speed is increased, and the area of a metallurgical connection zone of the overlap joint is enlarged.

Owner:FUZHOU UNIV

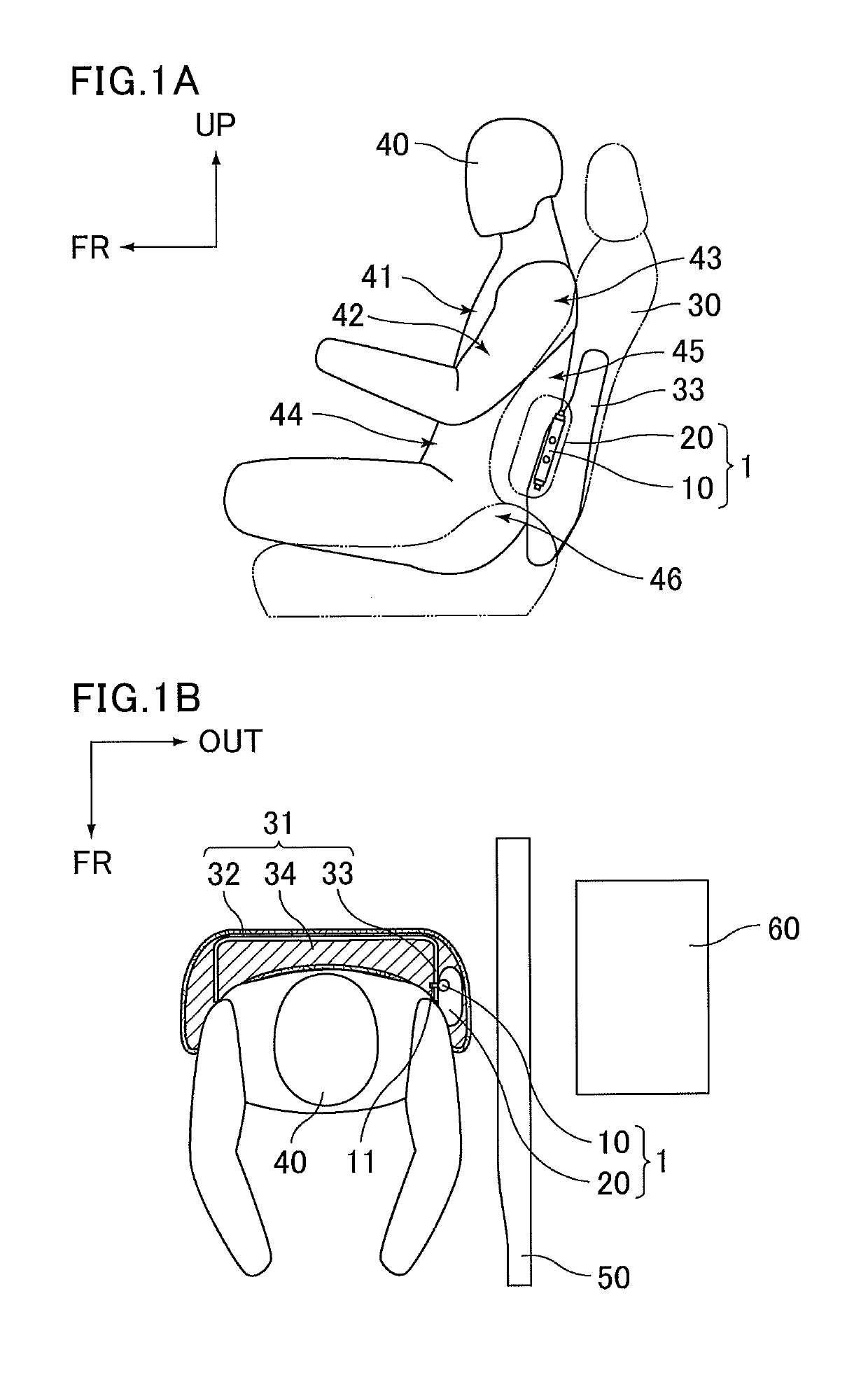

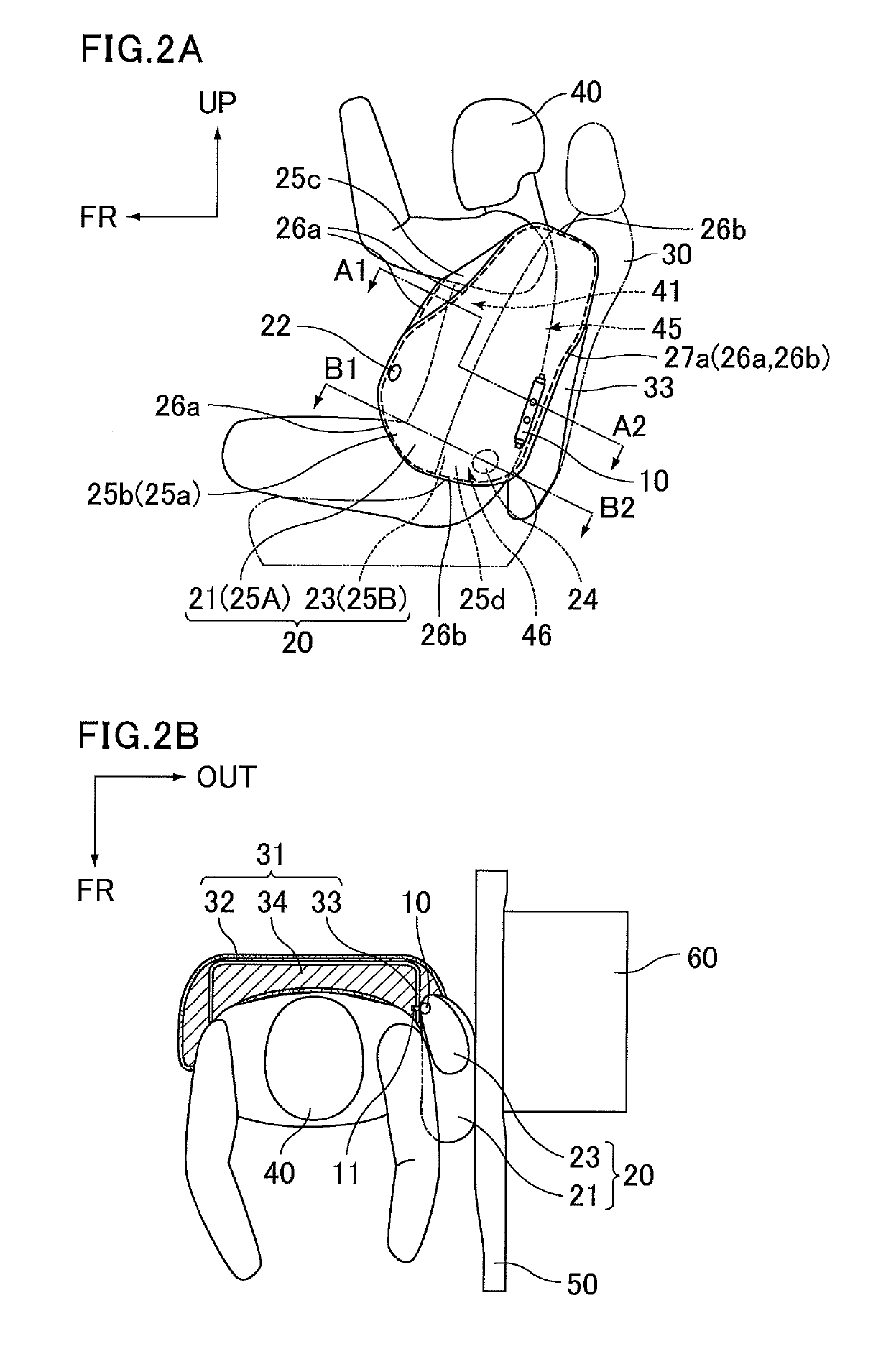

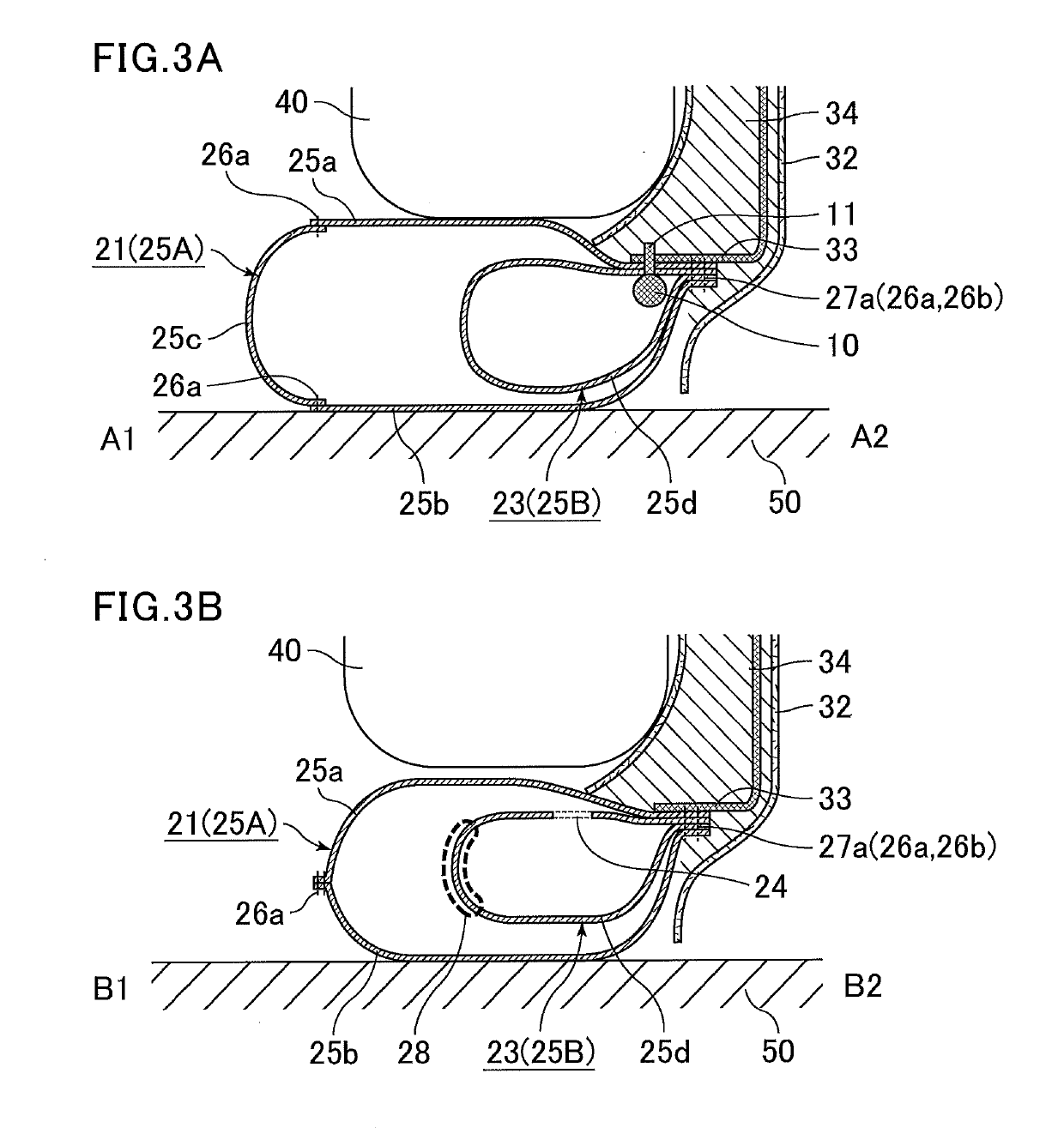

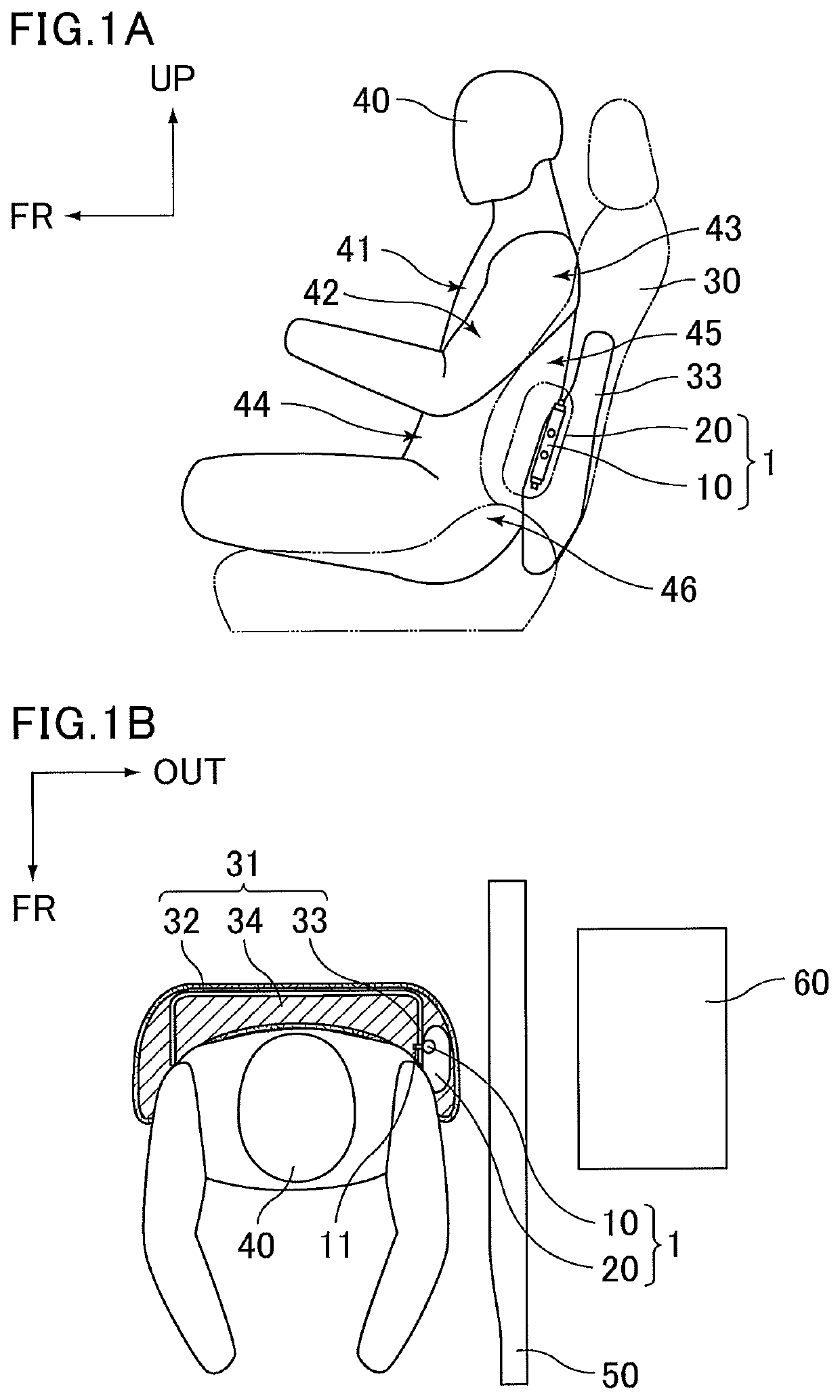

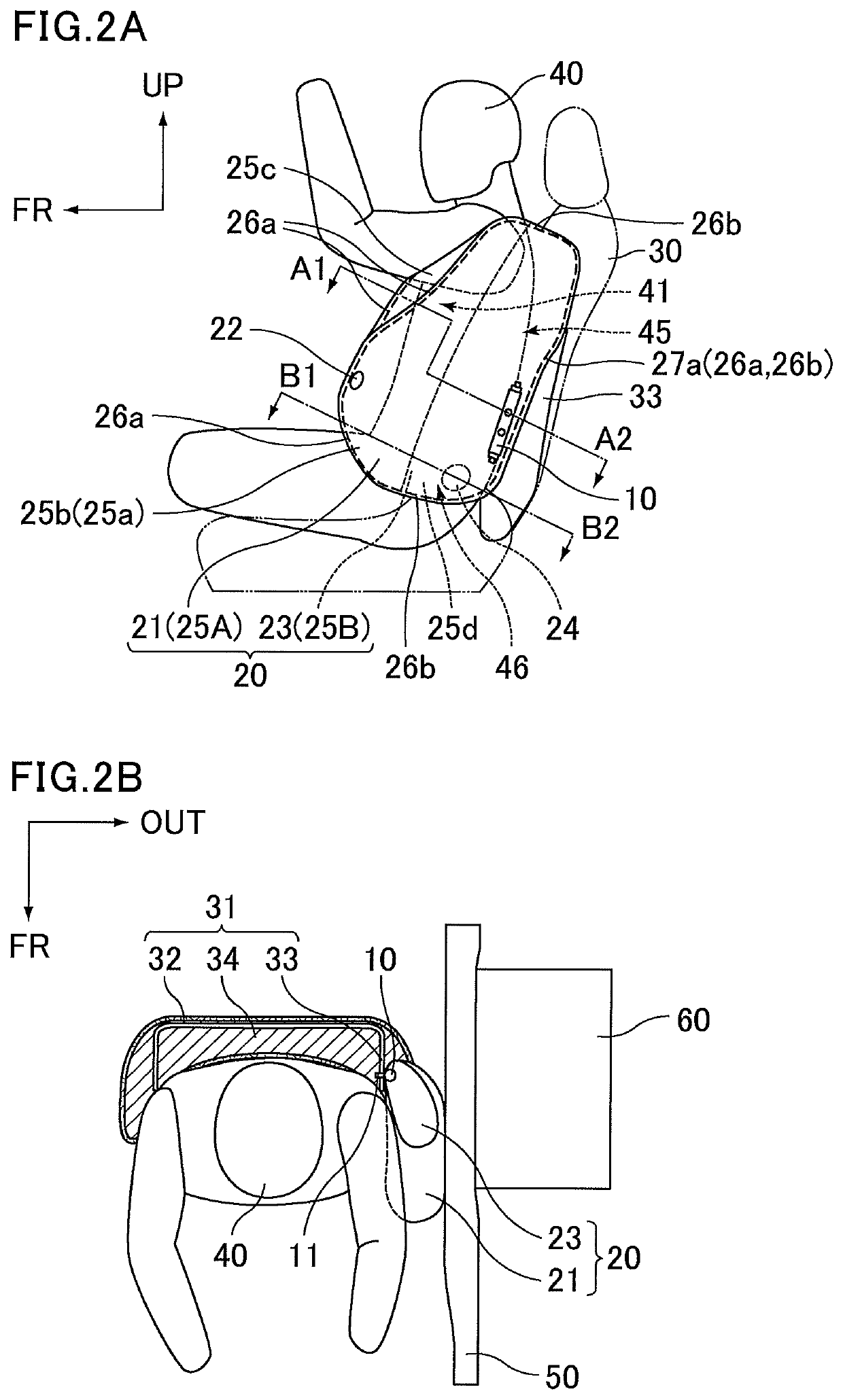

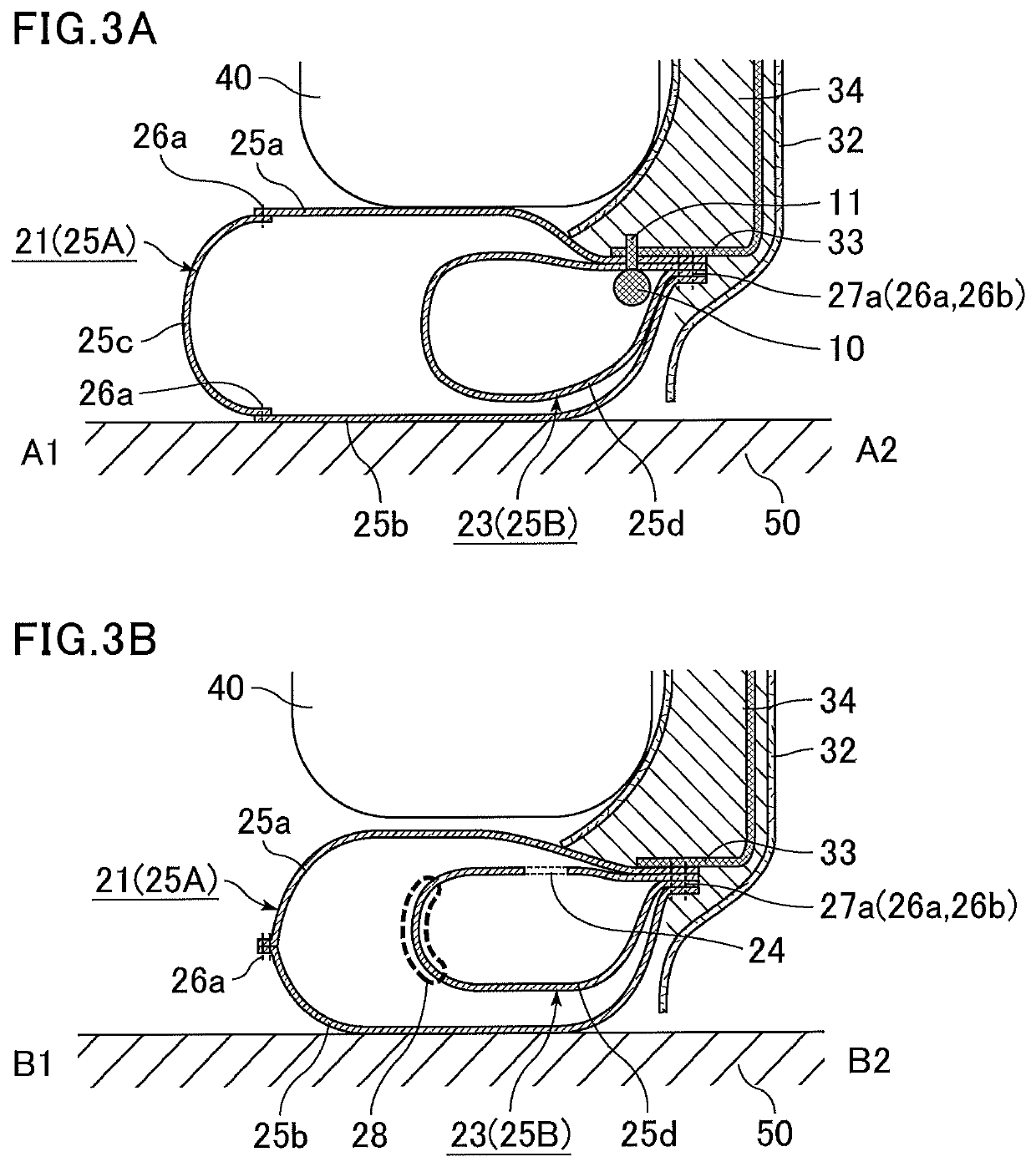

Side airbag device

ActiveUS20190241146A1High collision speedHigh impact energyPedestrian/occupant safety arrangementEngineeringLateral airbag

The side airbag device includes an inflator and a side airbag that is stored in a folded state in a side portion of a seatback of a vehicle seat and is inflatable and deployable in a space between a vehicle sidewall and a side portion of an occupant. The side airbag includes an outer bag and an inner bag. The inner bag houses the inflator and is disposed at a rear portion of the outer bag along an extending direction of the seatback. The outer bag is provided with a vent hole configured to communicate with an outside. The inner bag is provided with a gas circulating hole configured to communicate with the outer bag. The gas circulating hole is disposed at a position to be blocked by the outer bag when the side airbag in an inflated and deployed state is pressed between the occupant and the vehicle sidewall.

Owner:MAZDA MOTOR CORP +1

Air purifier

InactiveCN109078419AImprove filtration and purification efficiencyIncrease collision speedGas treatmentUsing liquid separation agentInlet channelAir purifiers

The invention relates to the field of air purification, and discloses an air purifier. A water tank is formed in the bottom of the cavity of the air purifier, a barrier wall which downwards extends into the water tank is formed between an air inlet and an air outlet, thus, an air inlet channel is formed between the air inlet and the water tank, an air outlet channel is formed between the water tank and the air outlet, the barrier wall is provided with a jet flow seam which is positioned below the liquid level of the water tank, and the jet flow seam is shrinking flow channel from the air inletchannel to the air outlet channel. The jet flow seam is in the design of the shrinking flow channel, air flows into the shrinking flow channel from the air inlet channel, the sectional dimension of aflowing path is suddenly reduced, and air flow is accelerated for the first time; and when air flows through the jet flow seam, the sectional dimension is further reduced, the air flow is acceleratedagain, after the air flow is accelerated twice, water-air mixing adequacy is also increased, and the air filtering and purifying efficiency is improved.

Owner:MIDEA GRP CO LTD

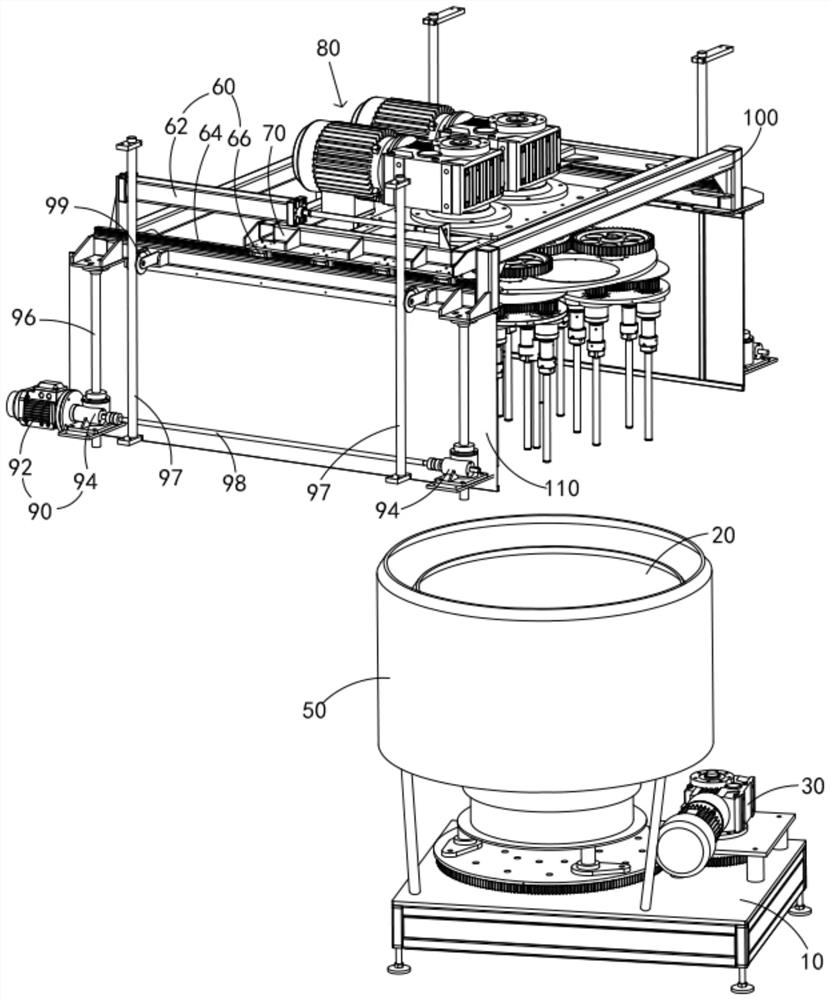

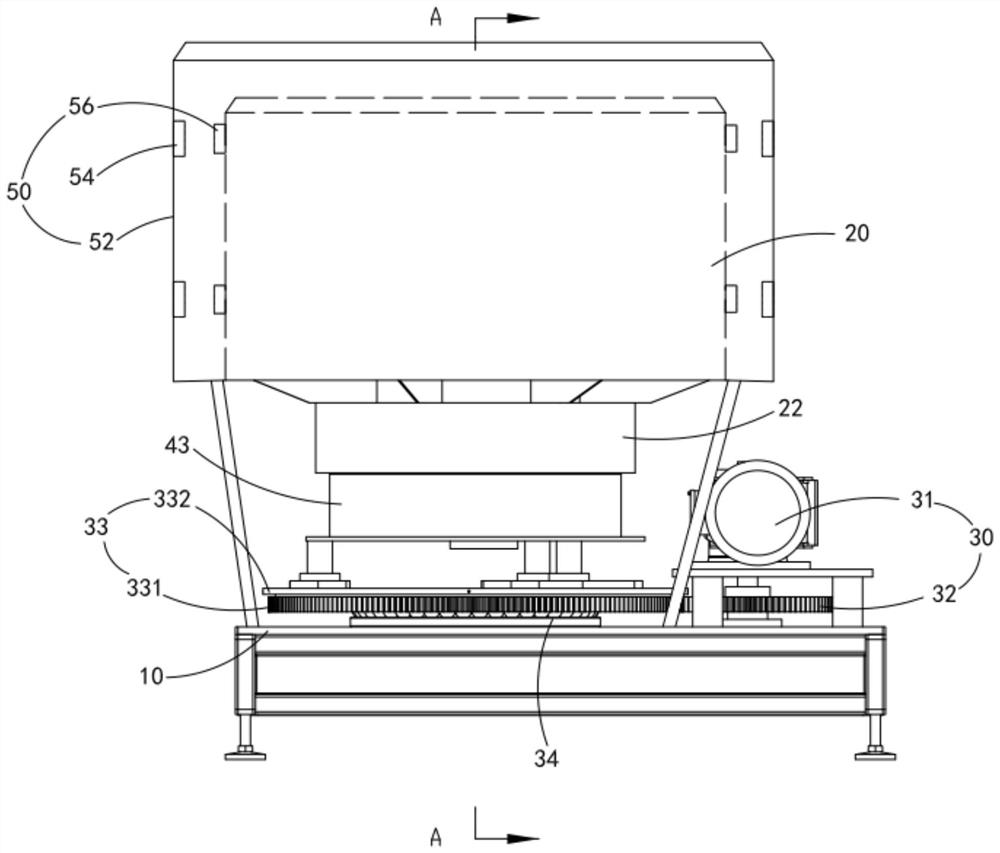

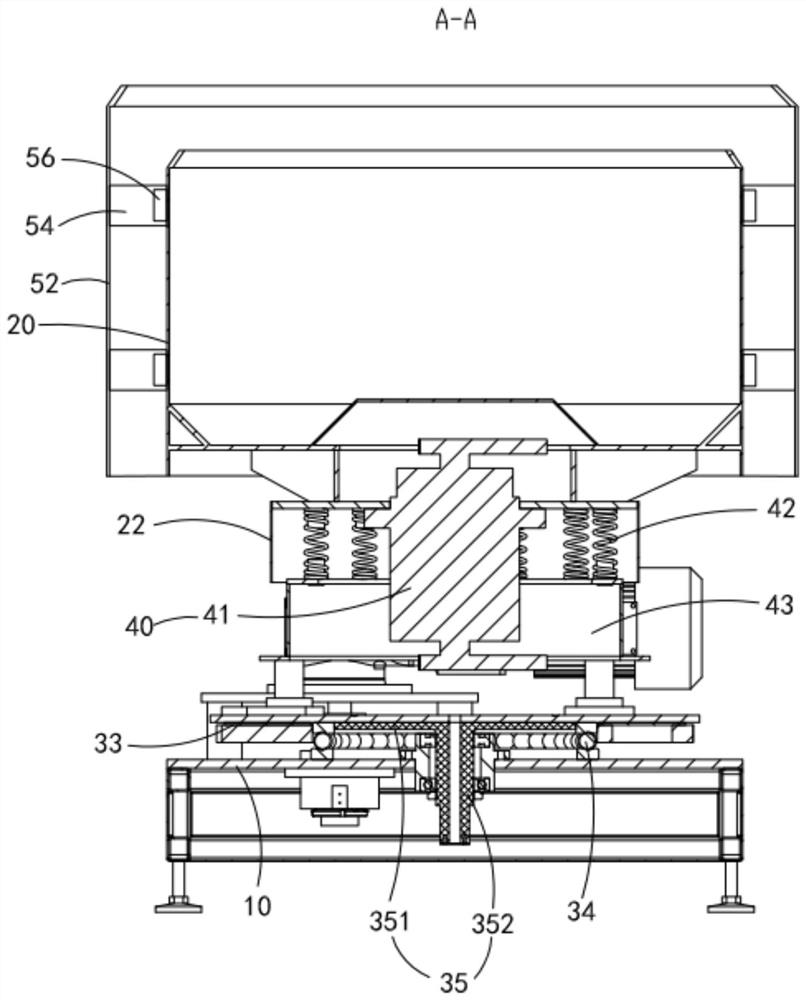

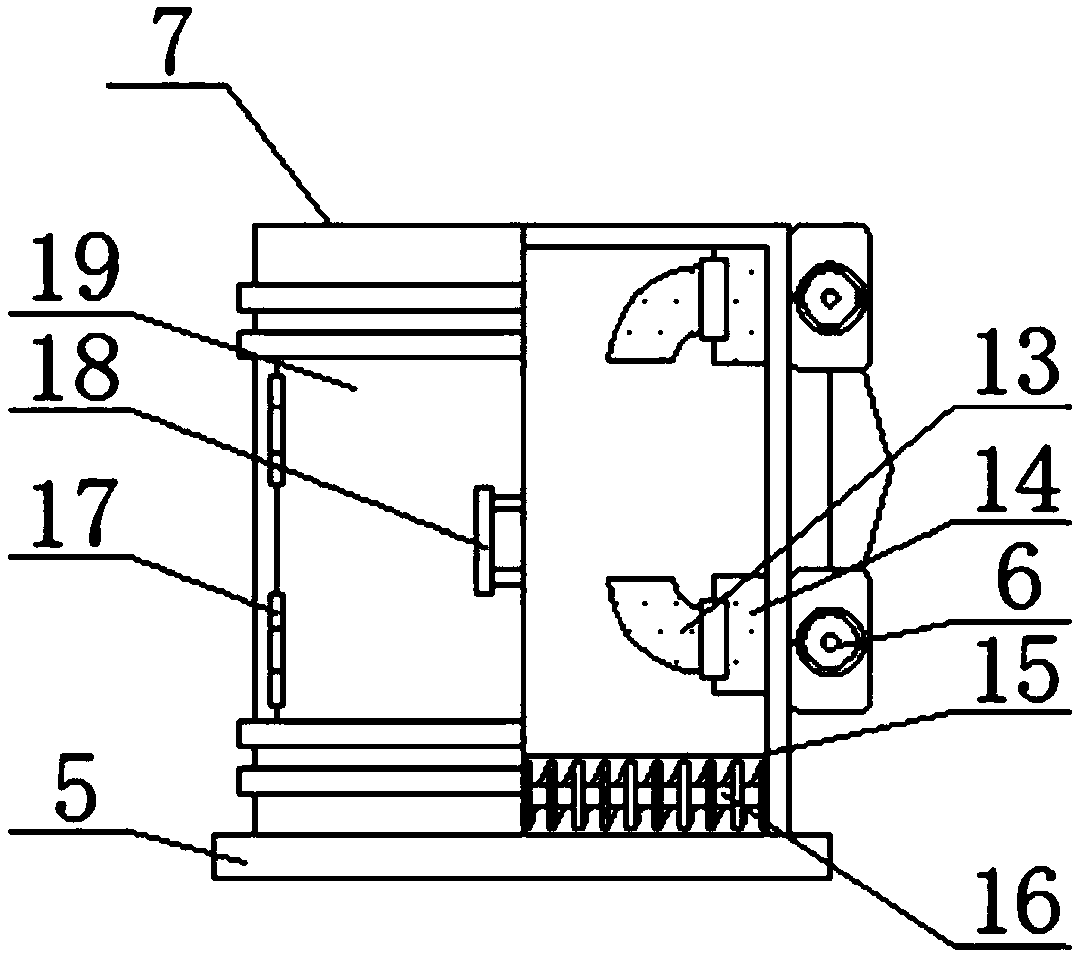

Balanced fluid grinding machine

PendingCN113043154AReduce security risksBig vibrationEdge grinding machinesGrinding carriagesElectric machineGear wheel

The invention discloses a balanced fluid grinding machine comprising a horizontal moving mechanism and a moving frame connected with the horizontal moving mechanism. A material rod driving mechanism is arranged on the moving frame. The balanced fluid grinding machine further comprises a grinding cavity mechanism arranged below the material rod driving mechanism. The grinding cavity mechanism comprises a bottom plate, a box body, a rotating assembly, a vibration assembly and a balance assembly. The vibration assembly is arranged on the box body. The rotating assembly is arranged on the bottom plate and comprises a rotating motor, a transmission gear set and a rotating disc, the rotating motor is in transmission connection with the transmission gear set, the rotating disc is meshed with the transmission gear set, the box body is arranged on the rotating disc, and the box body and the rotating disc are coaxially arranged. The balance assembly comprises an installation body arranged around the box body, first magnetic attraction pieces arranged on the installation body and second magnetic attraction pieces arranged on the box body, and the first magnetic attraction pieces and the second magnetic attraction pieces repel each other and correspond to each other in position. The balanced fluid grinding machine is good in grinding quality and high in efficiency.

Owner:深圳市佳利研磨设备有限公司

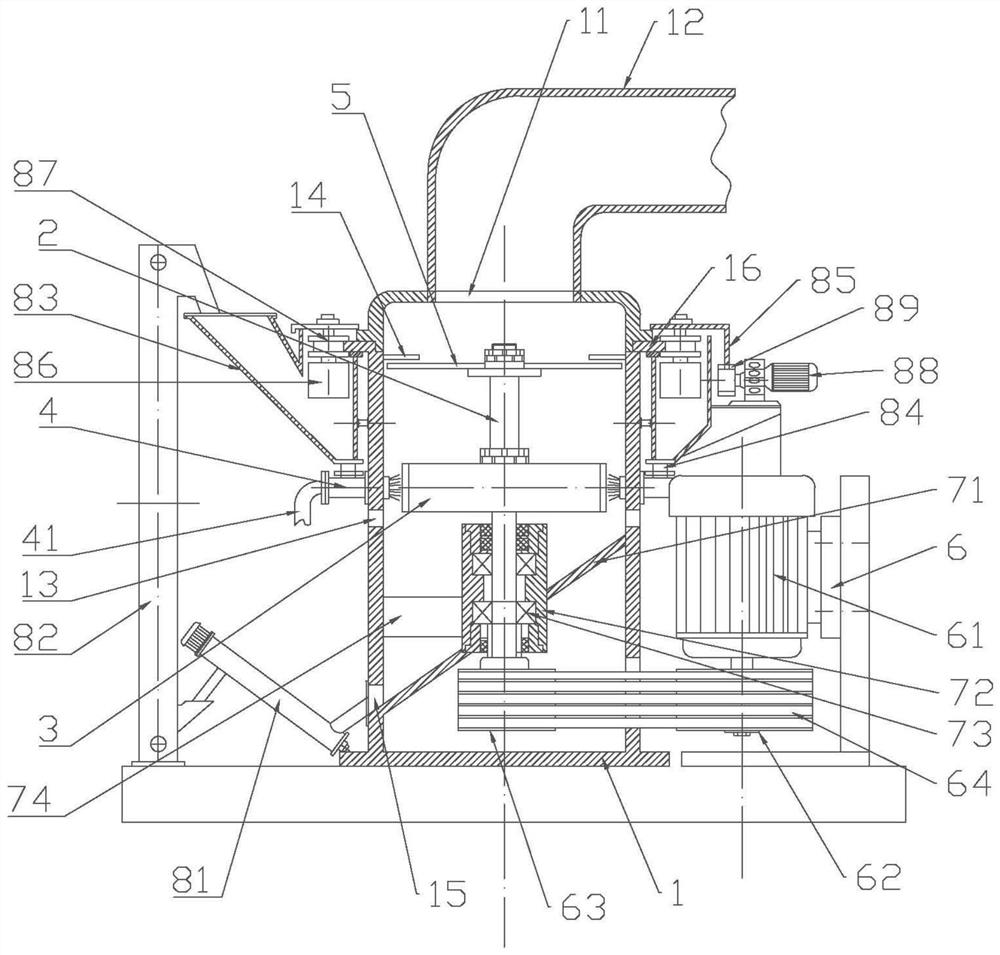

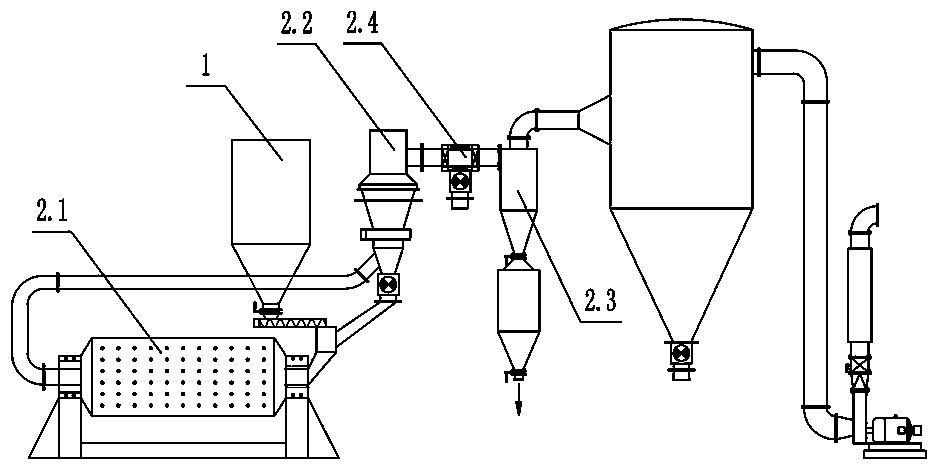

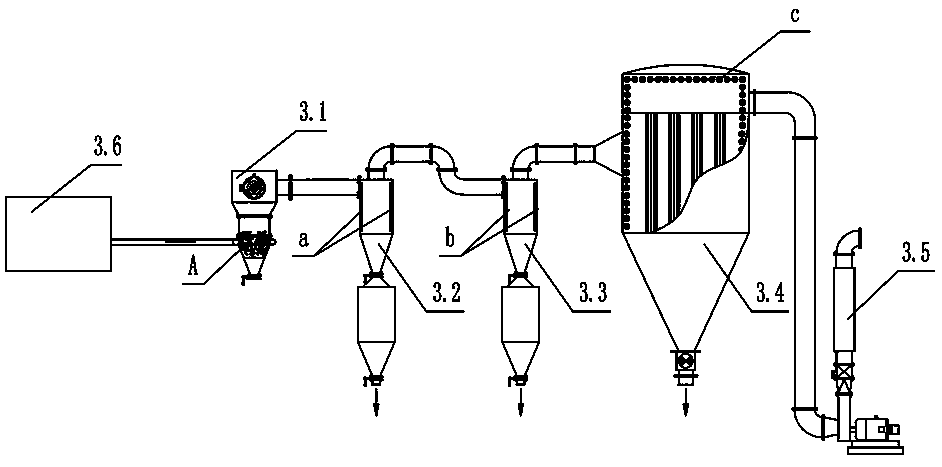

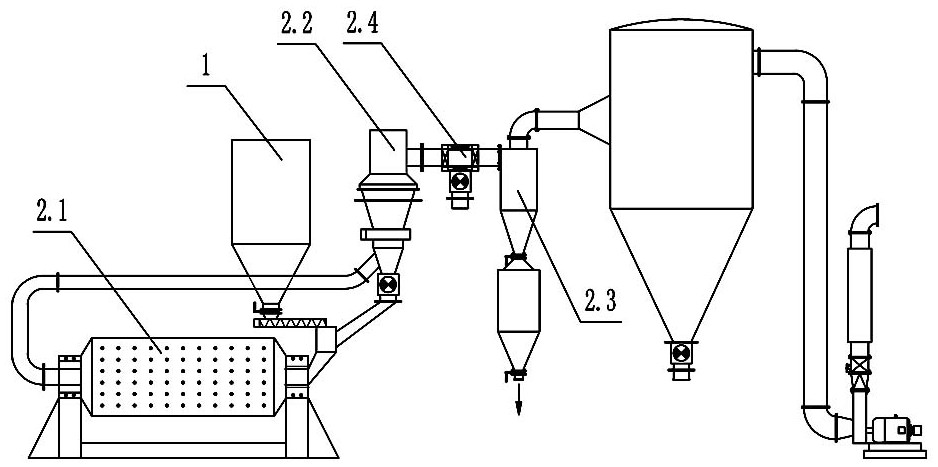

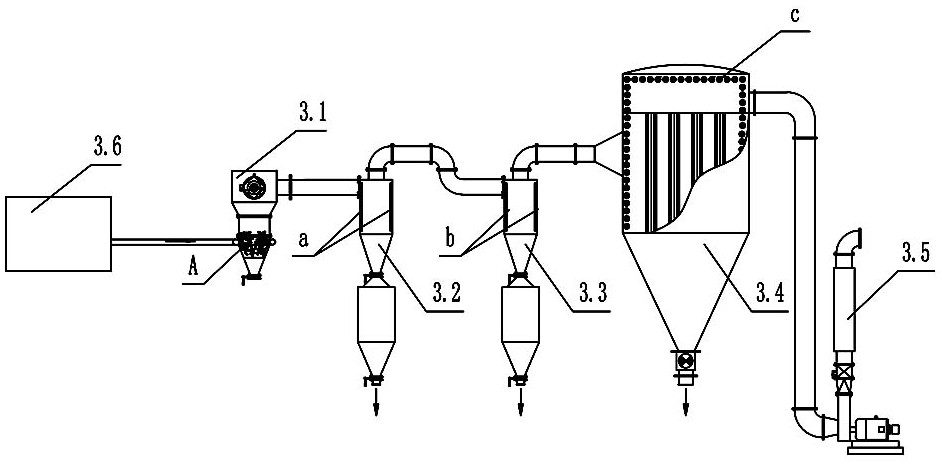

Pulpifying steam flow crushing and drying machine

PendingCN114453117AReduce drying processLow costDrying gas arrangementsGrain treatmentsProcess engineeringMechanical engineering

The invention relates to the technical field of material crushing and drying, in particular to a slurrying steam flow crushing and drying machine which comprises a slurry storage cylinder, a heater, an air mill and a drying and collecting machine which are sequentially communicated, the slurry storage cylinder is connected with a slurry inlet pump and a slurry inlet pipe, and the slurry inlet pump is connected with the slurry storage cylinder and the heater through the slurry inlet pipe; materials in the slurry storage cylinder are conveyed into the heater to be heated; the air mill comprises a machine shell, a main shaft, a rotating target, a plurality of Laval nozzles, a classifying screen and a first driving mechanism used for driving the main shaft to rotate, the main shaft is rotatably and longitudinally arranged in the machine shell, the main shaft penetrates through and fixes the rotating target and the classifying screen, the classifying screen is located above the rotating target, and the Laval nozzles are arranged around the circumferential side of the rotating target. Each Laval nozzle is communicated with an outlet of the heater through a steam slurry pipe; a discharging port is formed in the position, located above the classifying screen, of the machine shell and connected with a drying and collecting machine through a discharging pipe, and the drying and collecting machine is provided with an exhaust mechanism for conducting air draft on the discharging pipe. And the cost is low, and the crushing efficiency is high.

Owner:林焕

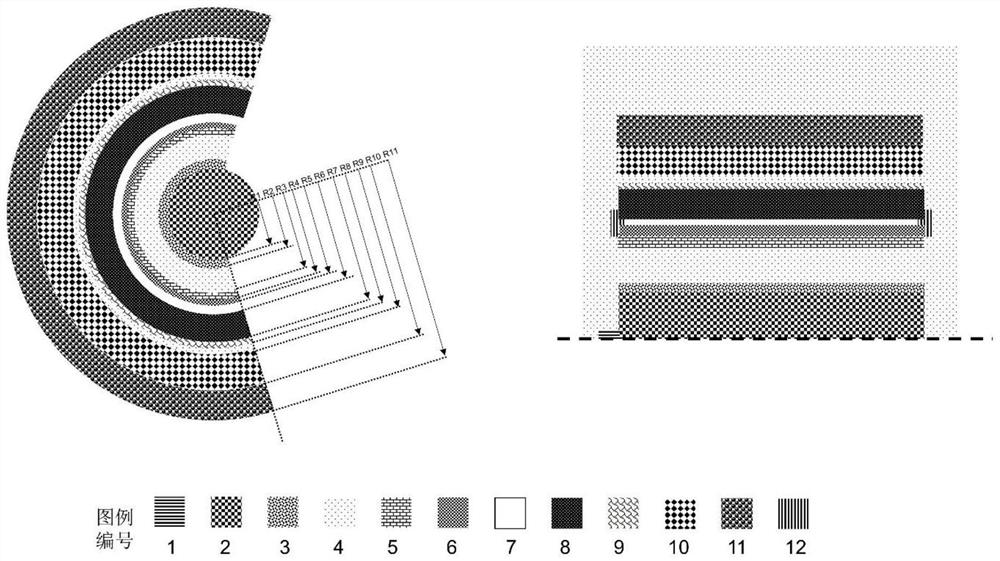

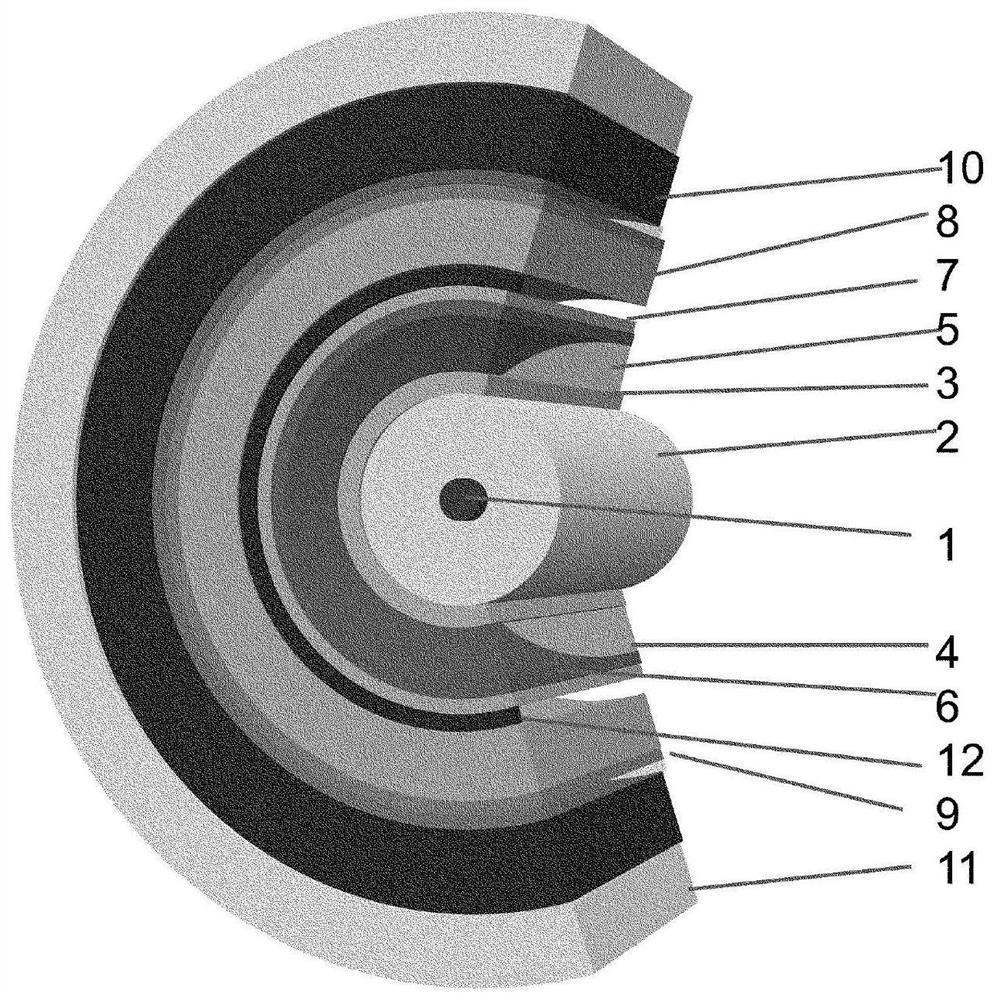

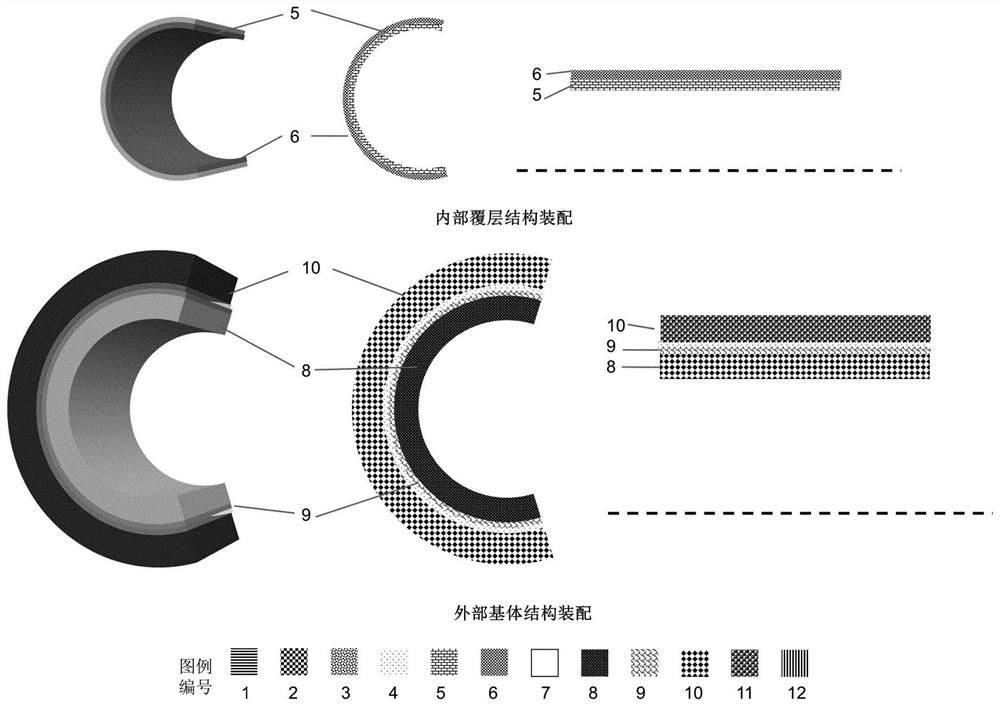

High-wave impedance self-restraint explosive welding method and device for dissimilar metal composite pipe

PendingCN114589389ASuppression of distortionSuppress irregular distortionNuclear energy generationMetal working apparatusDetonatorTEX-explosive

The invention discloses a high-wave impedance self-restraint explosive welding method and device for a dissimilar metal composite pipe. The device is sequentially and concentrically provided with selectable outer constraint explosive, an outer mold, a selectable outer constraint layer, an outer pipe, an inter-pipe gap, an inner pipe, a selectable protection pipe, a pressure transmitting medium, a charging pipe, explosive welding explosive and a detonator from outside to inside. In the inter-pipe gap between the outer pipe and the inner pipe, the supporting and sealing structures are fixed at the two ends of the inter-pipe gap, so that the gap is kept uniform and sealed; wherein the external base body structure comprises an outer mold, an outer restraint layer and an outer pipe; the internal coating structure comprises an inner tube and a protective tube; the explosive welding cartridge comprises a charging tube and explosive welding explosive. By means of the method and device, distortion of the explosive welding pipe can be restrained, the straightness of the composite pipe can be improved, collision damage between an outer pipe and an outer mold is reduced, the adjustable and controllable range of welding parameters is widened, the risk of crack generation is greatly reduced, and the gap distance between all structures is accurately limited.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Preparation method of moissanite blade material

ActiveCN109279607ASpeed up the collisionAvoid logistics vector shortageSilicon carbideGrain treatmentsMoistureDeep processing

The invention discloses a preparation method of a moissanite blade material. The preparation of a moissanite particle material with a diameter of 0.45-0.5 [mu]m is mainly carried out according to thesteps of ''hammer crusher crushing -> ball mill crushing -> steam flow medium crushing and grading -> moisture grading and impurity removal -> pressure filtration dewatering -> drying and packaging''.When the material is in an jet mill, the high temperature and high pressure water vapor and the silicon carbide medium balls work together, so that the collision speed of logistics is accelerated, the shortage of logistics vectors is avoided, the electrostatic aerosol layer generated on the surface of moissanite during the crushing process is effectively removed, and moissanite is crushed into ultra-fine micro-powders with a median particle size of 0.6 [mu]m. According to the preparation method, the crushing effect on the silicon carbide raw material is good, and the crushing efficiency is high, so that the method is beneficial to the deep processing production of moissanite, and new functions of the product can be further developed.

Owner:河南晟道科技有限公司

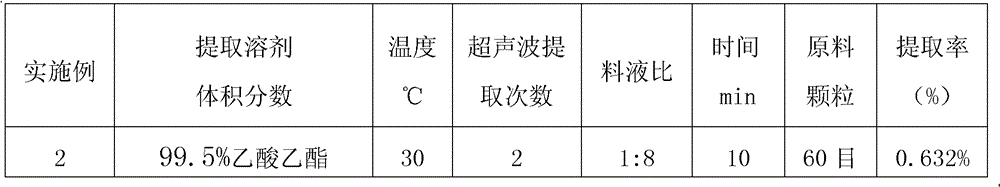

Process for extracting resveratrol from peanut sprouts

InactiveCN106349023AReduce dosageIncrease collision speedOrganic chemistryOrganic compound preparationSolubilitySolvent

The invention discloses a process for extracting resveratrol from peanut sprouts. The process includes: drying and crushing the peanut sprouts, ultrasonically extracting the resveratrol, and purifying to obtain resveratrol products. The process has the advantages that ethanol extraction is integrated with ultrasonic extraction, the ultrasonic extraction is used according to the feature that the resveratrol in the peanut sprouts is high in solubility in a weak-polarity solvent, the process is high in extraction efficiency, high in product purity and low in extraction cost and energy consumption, the solvent used in the process can be recycled, low in use amount and low in influence on environments, and the bioactivity of the resveratrol can be prevented from being destroyed during the extraction process.

Owner:安徽旺润生物科技有限公司

A high-pressure gas ejection collision device

Owner:SOUTHWEST JIAOTONG UNIV

Side airbag device

ActiveUS10882486B2Increase collision speedIncrease impact energyPedestrian/occupant safety arrangementLateral airbagMechanical engineering

The side airbag device includes an inflator and a side airbag that is stored in a folded state in a side portion of a seatback of a vehicle seat and is inflatable and deployable in a space between a vehicle sidewall and a side portion of an occupant. The side airbag includes an outer bag and an inner bag. The inner bag houses the inflator and is disposed at a rear portion of the outer bag along an extending direction of the seatback. The outer bag is provided with a vent hole configured to communicate with an outside. The inner bag is provided with a gas circulating hole configured to communicate with the outer bag. The gas circulating hole is disposed at a position to be blocked by the outer bag when the side airbag in an inflated and deployed state is pressed between the occupant and the vehicle sidewall.

Owner:MAZDA MOTOR CORP +1

A model experimental device for an icebreaker tank

ActiveCN110626463BIncrease collision speedHigh simulationVessel designingMarine engineeringClassical mechanics

The invention discloses an experimental device for a pool model of an icebreaker. The experimental device comprises a circulating water tank and a ship model mounting device. The circulating water tank comprises a U-shaped channel, a water pump and a connecting pipe. The U-shaped channel comprises two long straight sections and a turning section. One ends of the two long straight sections are separately connected to the turning section to form a U shape while the other ends of the two long straight sections are connected through the connecting pipe, and the water pump is arranged on the connecting pipe, so that a liquid in the water tan drives floating ices to move; the ship model mounting device comprises a top wall track arranged above the long straight sections of the U-shaped channel,two cross beams mounted on the top wall track and two hydraulic connecting rods separately mounted on the two cross beams. Based on an experimental principle of collision of the moving floating ice tothe navigational speed free ship model, a physical phenomenon of a ship in ice navigation can be simulated relatively truly, and defects that a conventional large ice pool is large in occupied area,long in construction period, high in building cost and the like can be also solved. The invention relates to the technical field of ship model experiments.

Owner:SOUTH CHINA UNIV OF TECH

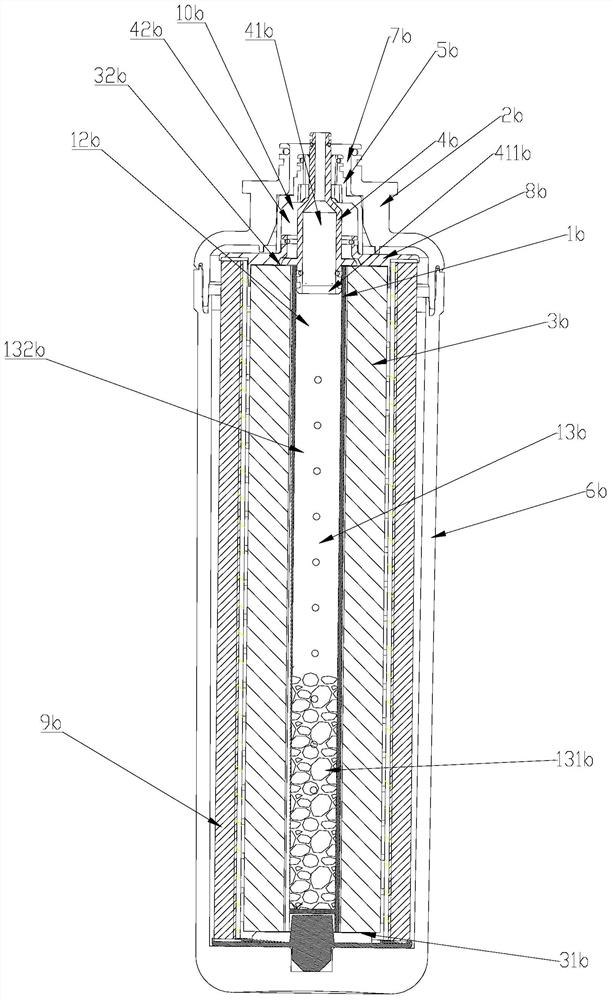

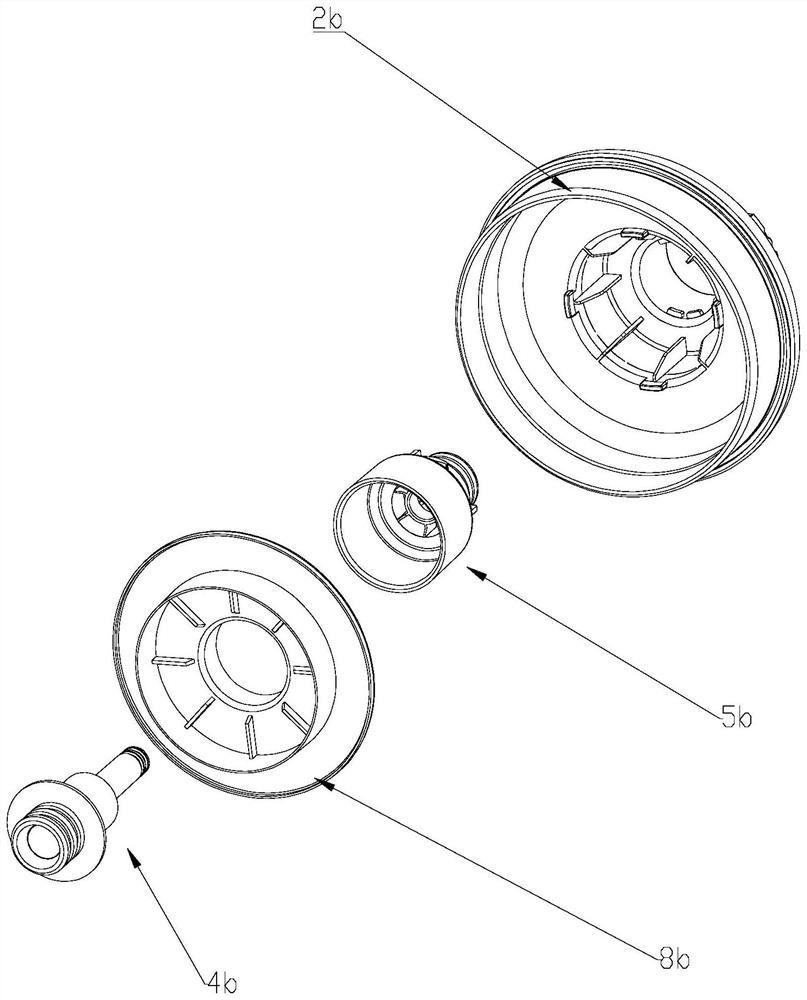

Bacteriostatic filter element

ActiveCN114573144AGuaranteed antibacterial propertiesIncrease water pressureTreatment involving filtrationMultistage water/sewage treatmentAnti bacterialAntibacterial effect

According to the antibacterial filter element provided by the invention, antibacterial substances in the antibacterial filter element are granular, can float and roll in a certain space under the action of water flow, and are in full contact with the water flow, so that the bacteriostasis is more sufficient, and meanwhile, the overall utilization rate of the antibacterial substances is also improved. A filling area and a turbulent flow area are arranged in the central pipe, and the filling area is filled with the antibacterial particles; when the antibacterial filter element works, water flow enters the flow passing channel from the water inlet end, and the antibacterial particles turn over towards the turbulent flow area from the filling area along with the water flow, so that the antibacterial particles float in the flow passing channel in a free manner, the antibacterial particles continuously sterilize along with the water flow, and the continuous sterilization can bring a better antibacterial effect; the water passing through the antibacterial particles is high in antibacterial property, and the number of bacterial colonies is lower.

Owner:JOYOUNG CO LTD

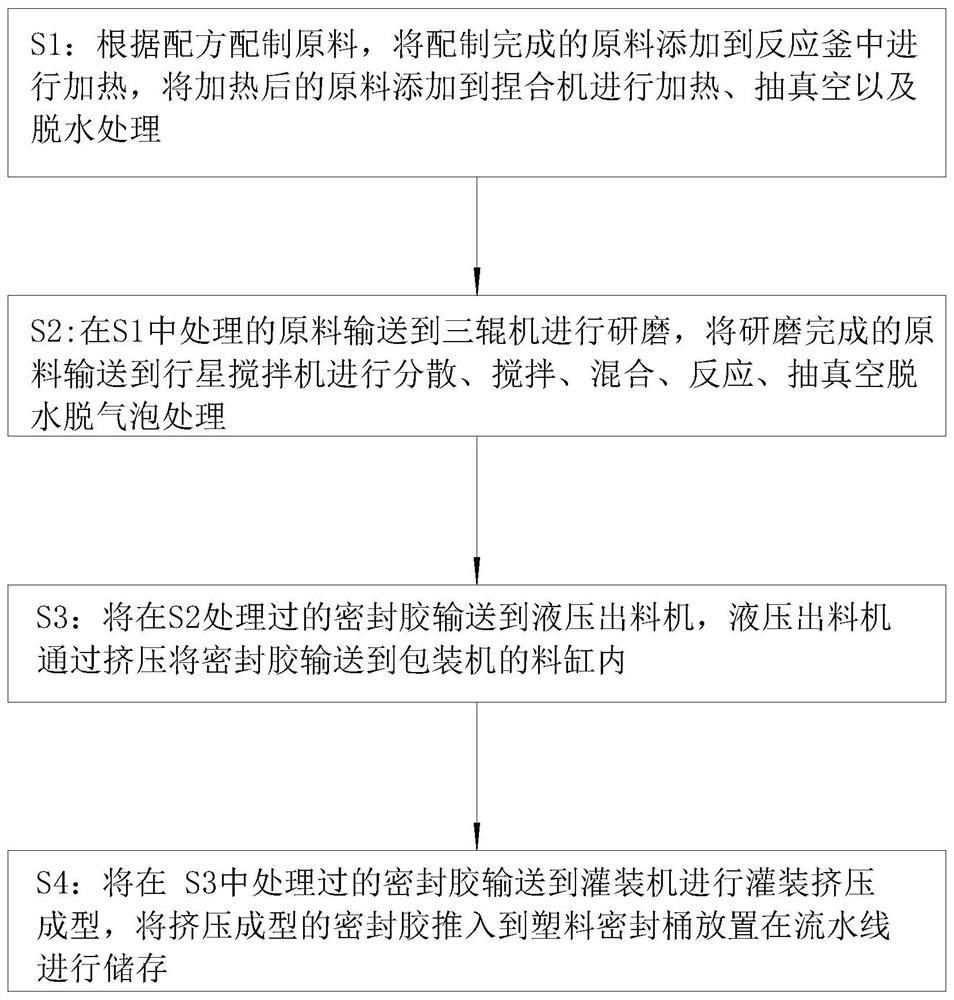

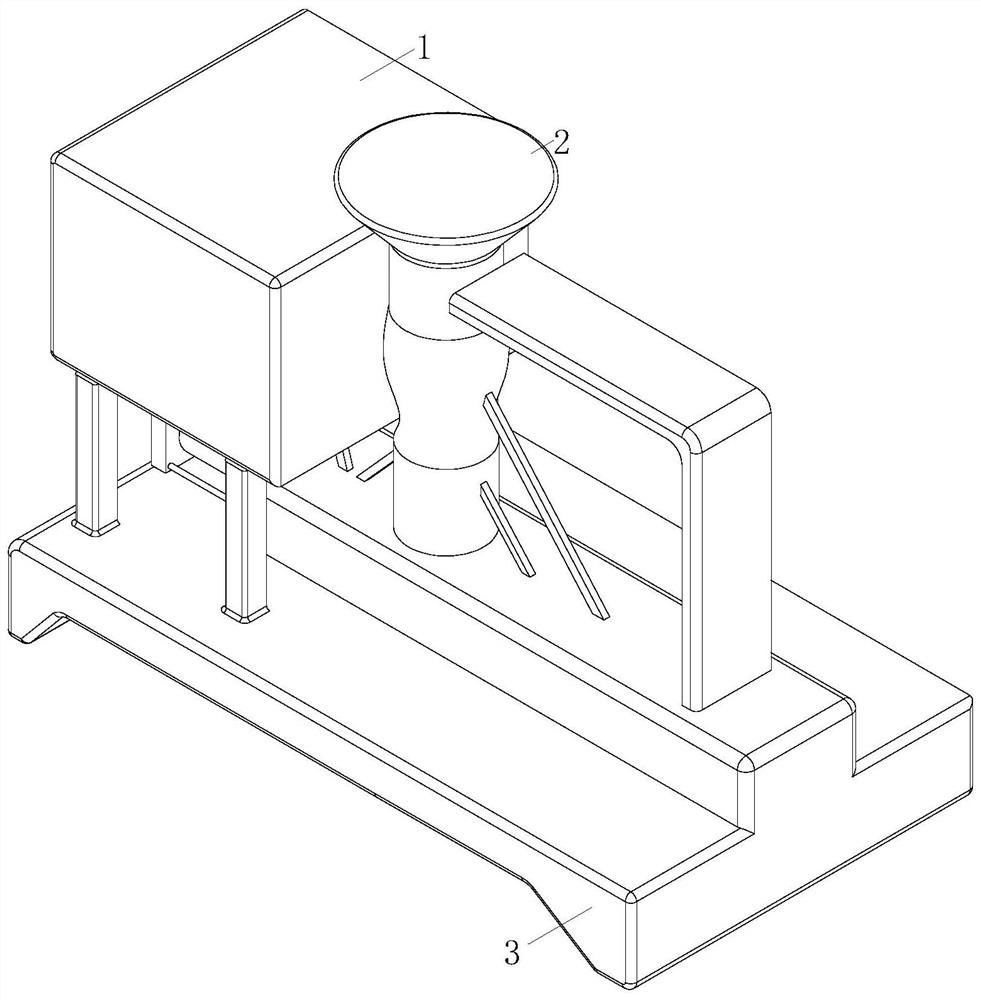

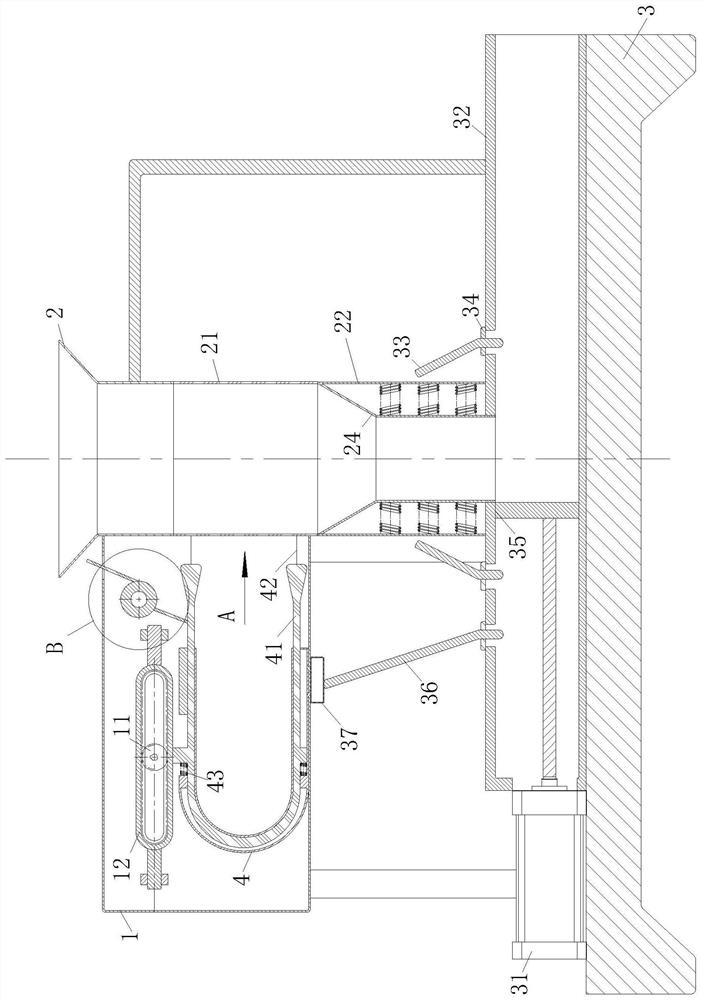

A kind of sealant processing technology

The invention belongs to the technical field of sealant production, and specifically relates to a sealant processing technology; including gears, racks, "U"-shaped pipes and "U"-shaped rods, through including gears, racks, "U"-shaped pipes and "U"-shaped rods. Under the joint action of the U-shaped rods, the "U"-shaped rods can rotate and impact the hose, so that the hose rotates and collides with the "U"-shaped rods to make the collision more uniform, so that the seals attached to both sides of the pipe wall The content of glue is reduced; the content of sealant attached to the pipe wall is reduced to increase the flow rate and flow rate of sealant during the filling process, thereby improving the efficiency of filling.

Owner:佛山市南海基亿有机硅实业有限公司

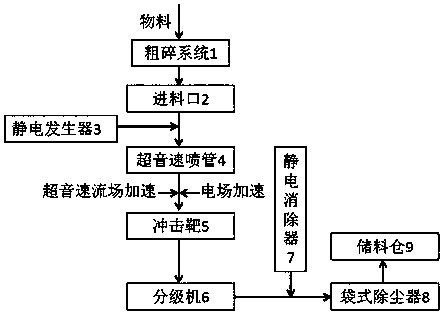

A Method of Improving the Acceleration Performance of Jet Mill Particles

ActiveCN106269139BImprove distribution characteristicsIncreased chance of collisionGrain treatmentsMulti fieldParticle acceleration

The invention discloses a method for improving the particle acceleration performance of an air jet mill. For the technical problem of how to achieve effective acceleration of particles in the air jet mill, the mode of supersonic flow field and electric field coupled acceleration is adopted to improve the material particle acceleration performance in air jet smashing. The method specifically includes the following steps that 1, materials are coarsely smashed to be 3 mm or smaller; 2, supersonic jet pipes in the air jet mill are manufactured with an insulating material, and outlets of the jet pipes are sleeved with annular iron blocks; 3, the supersonic jet pipes in a smashing cavity of the air jet mill are symmetrically distributed, and an impact target is arranged at the center of the smashing cavity; 4, positive voltage and negative voltage are applied to the annular iron blocks at the outlets of the jet pipes and the impact target respectively. By means of the method, multi-field coupled particle acceleration is achieved, and technical support is provided for further improving the smashing intensity and smashing efficiency of the air jet mill. Through process control of the technology, the material smashing intensity can be improved to 1.5-3 times, the particle size of materials can reach the submicron scale or even the nanometer scale, and the added value of materials can be effectively improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

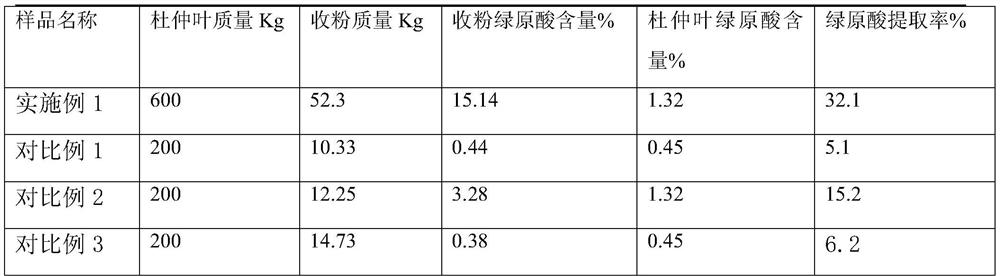

A kind of extraction method of chlorogenic acid in Eucommia leaves

ActiveCN108191658BIncrease contentImprove transfer rateOrganic compound preparationCarboxylic acid esters separation/purificationBiotechnologyActivated carbon

The invention relates to a method for extracting chlorogenic acid in Eucommia leaves, which comprises the following steps: step 1, crushing fresh leaves of Eucommia ulmoides into pulp and then sieving to obtain eucommia leaf slurry; Add an ethanol solution with a volume concentration of 95%; soak for 1 to 4 hours, squeeze through a plate and frame press, and collect the squeezed liquid; step 3, after the squeezed liquid obtained in step 2 is left to settle, filter to obtain clarification liquid, then recover ethanol under reduced pressure at 50-60°C until there is no alcohol smell, and obtain the extract; step 4, add activated carbon to the extract prepared in step 3, boil, filter, and obtain the filtrate; step 5, step 4 The obtained filtrate is spray-dried and powdered by cyclone to obtain chlorogenic acid powder. By adopting the method of the invention, the conversion rate of chlorogenic acid is improved, energy consumption is reduced, and cost is saved.

Owner:BAODING JIZHONG PHARMA

Preparation method for resveratrol

InactiveCN105152868AReduce dosageFast dissolutionOrganic chemistryOrganic compound preparationSolubilityNatural product

The invention relates to a technology for extracting effective ingredients from natural products and extracting resveratrol from mulberries. The technology comprises the steps that the mulberries are dried and smashed, and resveratrol is extracted through ultrasonic waves and purified to obtain the resveratrol. According to the technical scheme of the method, dual solvent and ultrasonic extraction and integration are adopted, the characteristic that the solubleness of the resveratrol in the mulberries is higher in weak polar solvent is utilized, and an ultrasonic extraction technology is utilized, so that the technology has the advantages of being high in extraction efficiency and product purity and low in extraction cost and energy consumption; the solvent used in the extraction process can be recycled and little in usage amount, so that the influence to the environment is lower, and the biological activity of the resveratrol is prevented from being destroyed in the extraction process.

Owner:CHONGQING DOUHAO BIOTECH

Technique for extracting resveratrol and pigment from grape skin

ActiveCN102491880BReduce dosageIncrease collision speedOrganic chemistryOrganic compound preparationSolubilityNatural product

The invention relates to a technique for extracting effective ingredients from a natural product, particularly a technique for extracting resveratrol and pigment from grape skin, which comprises the following steps: drying the grape skin, pulverizing, extracting resveratrol by ultrasonic waves, extracting pigment by ultrasonic waves, and purifying to obtain the resveratrol product and the pigment product. In the technical scheme provided by the invention, double solvents and ultrasonic extraction are integrated; the technical scheme provided by the invention has the advantages of high extraction efficiency, low extraction cost and low energy consumption by using the ultrasonic extraction technique according to the principle that the resveratrol and pigment in the grape skin have different solubilities in solvents with different polarities; the solvents used in the extraction process can be utilized cyclically, so that the solvent consumption is low, and the environmental influence is low, thereby avoiding destroying the bioactivities of the resveratrol and the pigment in the extraction process; and thus, the invention is suitable for extracting bioactive substances.

Owner:GANSU SHOULUSHAN PHARMA CO LTD

Efficient stirrer for lubricating oil production

InactiveCN113713677AImprove efficiencyIncrease collision speedRotating receptacle mixersTransportation and packagingThermodynamicsElectric machine

The invention discloses an efficient stirrer for lubricating oil production. The stirrer comprises a mixing device; the top of the mixing device is fixedly connected with a driving structure; a fixing frame is arranged on the surface of the mixing device; a base is arranged at the bottom of the fixing frame; a first motor is arranged at the center of the top of the base in a penetrating manner; an output shaft of the first motor is fixedly connected with the fixing frame; and one side of an inner cavity of the fixing frame is rotationally connected with a connecting shaft through a rotating shaft. Violent mixing is achieved by increasing the collision speed between fluids, the tank body can incline under the action of a second motor, and thus, the stirring efficiency is further improved. The stirrer for lubricating oil production has the advantage of efficient stirring, the stirring postures of the stirrer are diversified, the lubricating oil in the stirrer can form fluids with different speeds and directions, the fluids in the tank body collide intensely, the lubricating oil is uniformly mixed in the process, and the efficiency is higher.

Owner:凯珀瑞润滑科技(东台)有限公司

Preparation method of moissanite blade

ActiveCN109279607BConducive to deep processing productionIncrease collision speedSilicon carbideGrain treatmentsCarbide siliconHigh pressure water

The invention discloses a preparation method of a moissanite blade material. The preparation of a moissanite particle material with a diameter of 0.45-0.5 [mu]m is mainly carried out according to thesteps of ''hammer crusher crushing -> ball mill crushing -> steam flow medium crushing and grading -> moisture grading and impurity removal -> pressure filtration dewatering -> drying and packaging''.When the material is in an jet mill, the high temperature and high pressure water vapor and the silicon carbide medium balls work together, so that the collision speed of logistics is accelerated, the shortage of logistics vectors is avoided, the electrostatic aerosol layer generated on the surface of moissanite during the crushing process is effectively removed, and moissanite is crushed into ultra-fine micro-powders with a median particle size of 0.6 [mu]m. According to the preparation method, the crushing effect on the silicon carbide raw material is good, and the crushing efficiency is high, so that the method is beneficial to the deep processing production of moissanite, and new functions of the product can be further developed.

Owner:河南晟道科技有限公司

A pin-type double-cone truncated sand mill device

ActiveCN107626395BCompact structureReasonable structureGrain treatmentsSurface mountingElectric machinery

The invention relates to a rod pin type bifrustum-shaped sand mill device. The rod pin type bifrustum-shaped sand mill device comprises a rack, wherein a motor is arranged on the upper surface of therack; the output end of the motor is connected with a spindle component through a driving component; one end of the spindle component is supported by a bearing base component; a sand mill barrel bodycomponent is arranged at the outer end of the bearing base component through a sealing device; a stirrer connected with the spindle component is arranged inside the sand mill barrel body; rollers arearranged on two sides of the sand mill barrel body component; a guide rail bracket for the rollers to run is arranged on the upper surface of the rack. The rod pin type bifrustum-shaped sand mill device disclosed by the invention has the advantages of compact and reasonable structure and convenience in operation; a barrel body with a conical structure is adopted, and the inner part of the barrel body is matched with the pin rod type stirrer for grinding materials, so that good milling effect and high working efficiency are realized.

Owner:WUXI HOPE LIGHT IND EQUIP TECH

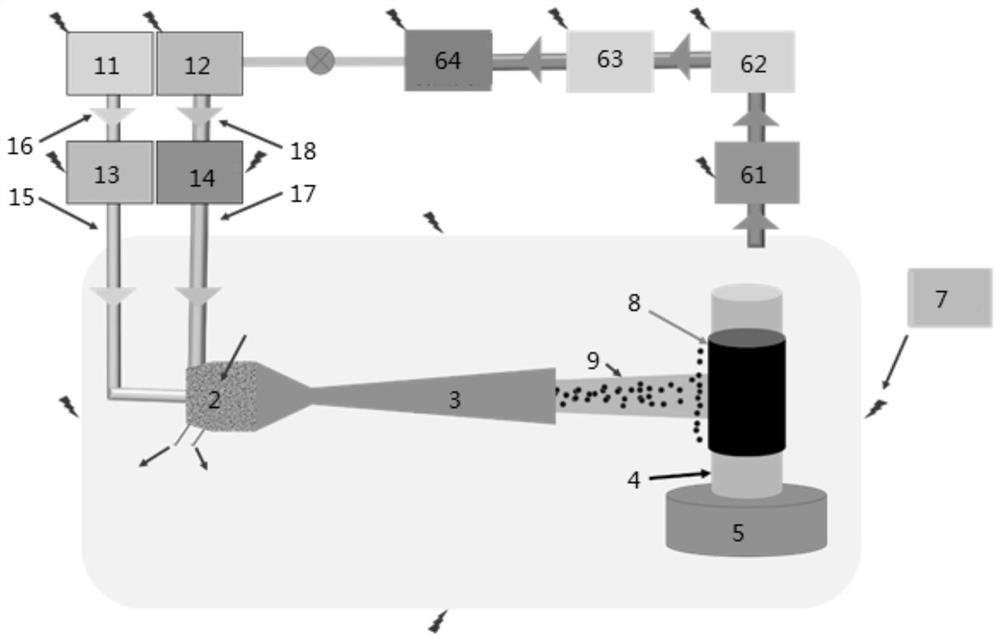

Hydrogen power metal solid deposition device and method

ActiveCN114653971AAccelerate the effectAvoid contactAdditive manufacturing apparatusPressure inorganic powder coatingMetallurgyGas heater

The invention discloses a hydrogen power metal solid deposition device and method, and belongs to the technical field of metal solid deposition. The device comprises a material conveying system, a Laval nozzle and a hydrogen recovery system, the material conveying system comprises a powder feeder and a gas heater, and the powder feeder and the gas heater are both connected with an inlet of a Laval nozzle arranged in the closed spraying chamber. The hydrogen recovery system is connected with the closed spraying chamber and an inlet of the gas heater so that hydrogen can circulate under the closed condition. Sprayed hydrogen in the closed spraying chamber is recycled through the hydrogen recycling system and enters the gas heater to be heated, and then the hydrogen serves as accelerating gas to continue to accelerate micron-sized powder particles to be sprayed, so that the micron-sized powder particle accelerating effect and the collision deposition performance can be remarkably improved efficiently at low cost; and the oxygen content of the additive metal deposition body is reduced, and the mechanical, electrical and magnetic properties of the metal deposition body are greatly improved.

Owner:GUANGDONG INST OF NEW MATERIALS

Improved shot blasting machine for aluminum alloy castings

InactiveCN109664206AExtended service lifeImprove processing efficiencyImpeller wheelsRotor bladesImpellerEngineering

The invention discloses an improved shot blasting machine for aluminum alloy castings. The improved shot blasting machine comprises a dust remover, a shot blasting machine body, a protecting door, a blasting head and springs; an electric hoist is arranged at the left end of the top of the shot blasting machine body; a guiding rail is arranged above the electric hoist; a supporting frame is arranged below the guiding rail; and an elevator is arranged at the right end of the guiding rail. A shot collecting groove is formed inside an original shot blasting machine, blasted steel shots can be better collected and can be conveyed out of a shot blasting chamber by the aid of a screw conveyor, and thus the smoothness of treatment of the castings inside the shot blasting chamber is kept; meanwhile, independent blade clamping grooves are formed in impellers inside a shot blasting device, are fixed by the aid of spring clamping plates and are convenient to dismount, so that blades can be changedseparately in case of failure, the blade changing speed is increased, and the utilization degree of the blades is increased; and the two impellers are arranged, so that the collision speed of the steel shots is increased, the casting treatment ability is improved, the service life of the shot blasting machine is longer, and the machining efficiency is higher.

Owner:京山市鑫源铜铝业股份有限公司

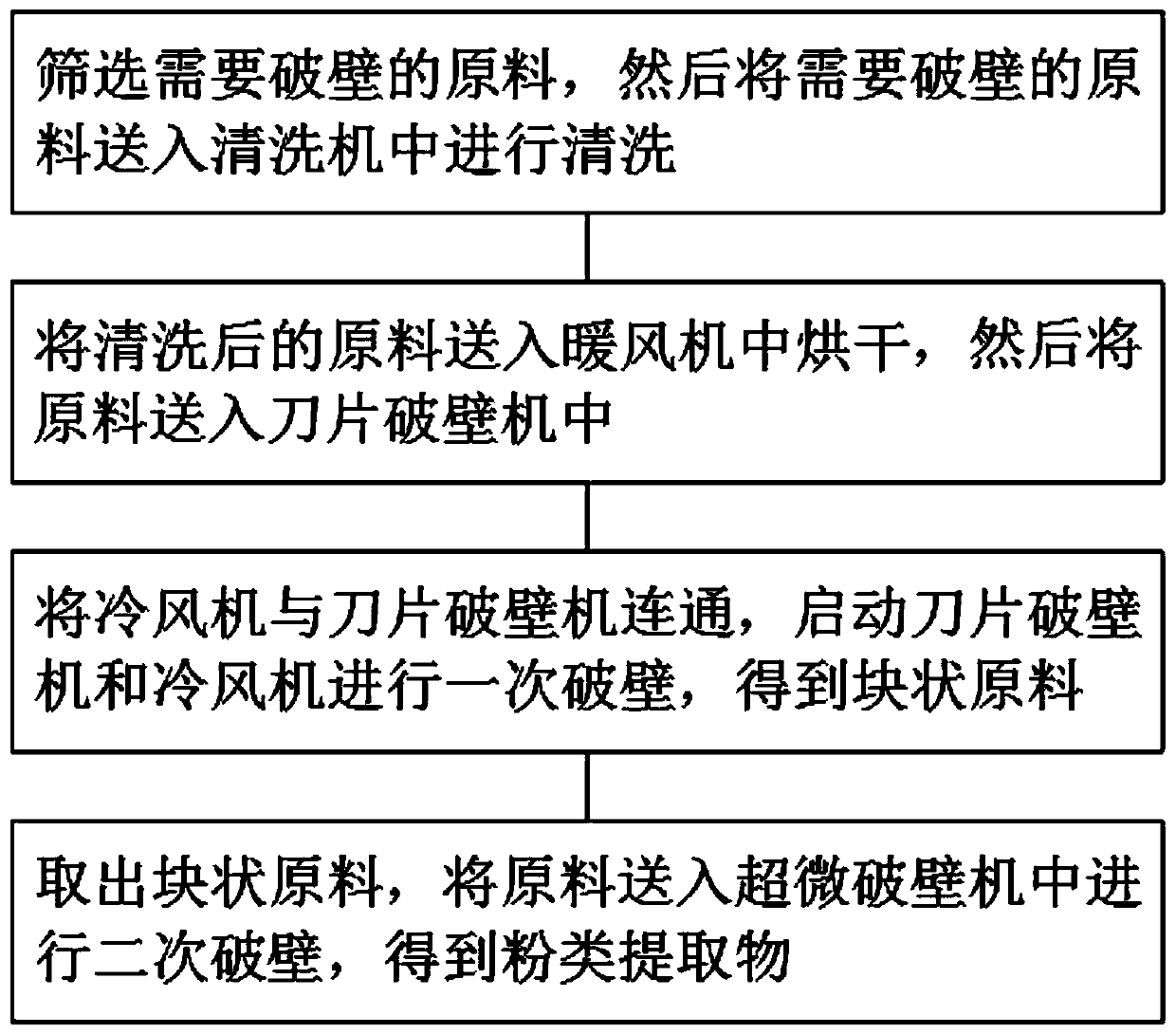

Wall breaking method for extracting fruit, vegetable and grain powder

The invention discloses a wall breaking method for extracting fruit, vegetable and grain powder. The wall breaking method comprises the steps that to-be-wall-broken raw materials are screened, and then the to-be-wall-broken raw materials are sent into a cleaning machine for cleaning; the cleaned raw materials are sent into an air heater for drying, and then the raw materials are sent into a bladewall breaking machine; an air cooler is connected with the blade wall breaking machine, the blade wall breaking machine and the air cooler are started for primary wall breaking, and block raw materials are obtained; and the block raw materials are taken out. According to the wall breaking method for extracting the fruit, vegetable and grain powder, firstly the large pieces of the raw materials arecrushed into small pieces by the blade wall breaking machine, then the wall breaking treatment is conducted by an ultra-fine wall breaking machine, the wall breaking speed can be increased, meanwhilewall breaking is more complete, the nutrient loss in the fruits, vegetables and grains is reduced, in the crushing process of the blade wall breaking machine, cold air is introduced, the temperatureof a blade during crushing can be directly decreased, the influence of high temperature on the fruits, vegetables and grains is reduced, and better use prospects are brought.

Owner:永奥(上海)健康科技有限公司

Feeding-type decoring device for ginkgo fruit medicinal material

The present invention discloses a feeding-type decoring device for a ginkgo fruit medicinal material. The feeding-type decoring device includes a treatment box; a feeding hole is formed in a middle position at the top of the treatment box, and the bottom of the feeding hole is fixedly connected with a decoring frame; one side of the treatment box is fixedly connected with a motor; an output shaftof the motor is fixedly connected with a rotating shaft; through holes are formed in two sides of the decoring frame, and the rotating shaft penetrates through the insides of the through holes; a blocking seat is fixedly connected to the middle position of the outer wall of the rotating shaft; two sides close to the middle position of the rotating shaft are fixedly connected with spiral blades; and the bottom of the treatment box is fixedly connected with a decoring cylinder. According to the feeding-type decoring device, ginkgo fruits are agitated by using the spiral blades so as to be drivento come into collision against the inner wall of the decoring frame, and thus, it is convenient to primarily dehusk and quantitatively discharge the ginkgo fruits; and the ginkgo fruits are extrudedto be decored by extruding a bulge, so that it is convenient to lead the decored ginkgo fruits out by virtue of a discharging pipe, and convenience is provided for discharge.

Owner:石文仙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com