Pulpifying steam flow crushing and drying machine

A pulverizing dryer and steam flow technology, applied in dryers, drying gas arrangement, drying and other directions, can solve the problems of difficulty in achieving large-scale mills, limited impact speed and strength, and heat not used for drying, etc. Achieve the effect of saving drying process, improving crushing efficiency and high impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

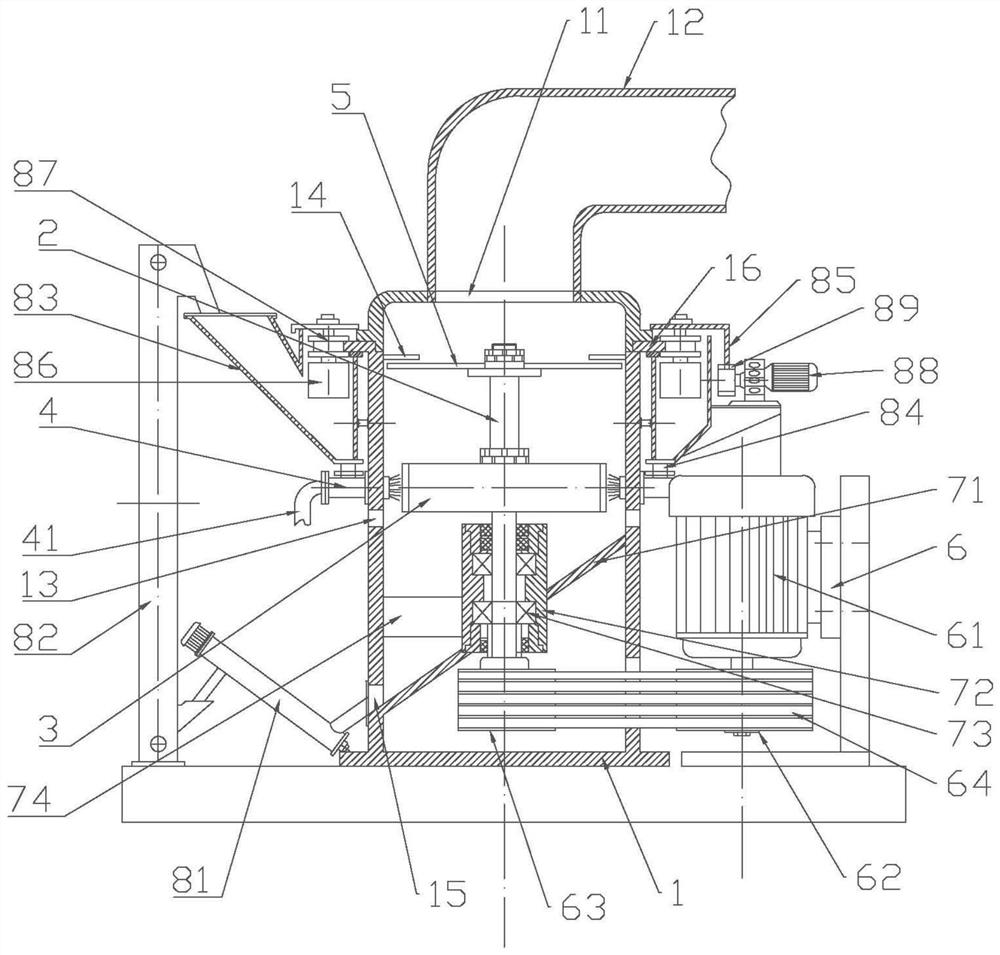

[0048] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

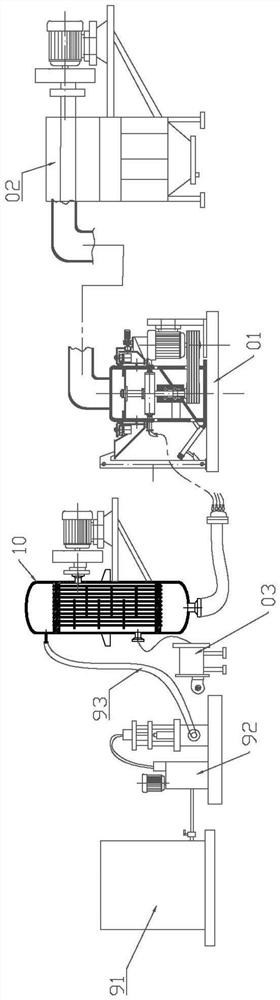

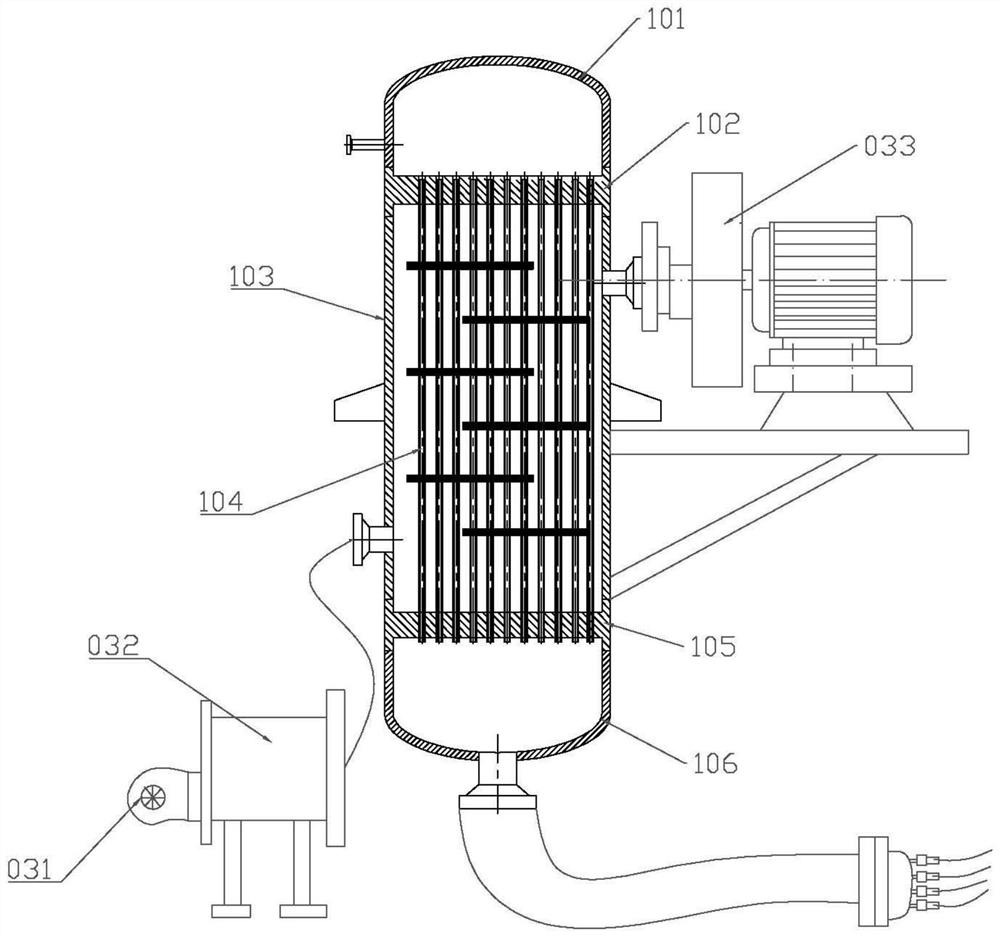

[0049] The pulping steam flow pulverizing dryer of the present embodiment, as Figure 1 to Figure 6As shown, it includes a slurry storage tank 91, a heater 10, an air mill 01 and a drying collector 02 connected in sequence from left to right. The slurry storage tank 91 is used to store wet mud materials, and the slurry storage tank 91 is connected with a slurry feeding Pump 92 and slurry inlet pipe 93, slurry inlet pump 92 is preferably a plunger pump, and slurry inlet pump 92 is connected to the inlet of the slurry storage cylinder 91 and the heater 10 through the slurry inlet tube 93, so as to transport the slurry material in the slurry storage cylinder 91 Entering the heater 10 for heating, the solid content of the slurry can be from 5% to 85%, and the preferred solid content is 50% to 70%.

[0050] The heater 10 includes an upper tube box 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com