Patents

Literature

110results about How to "Conducive to large-scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

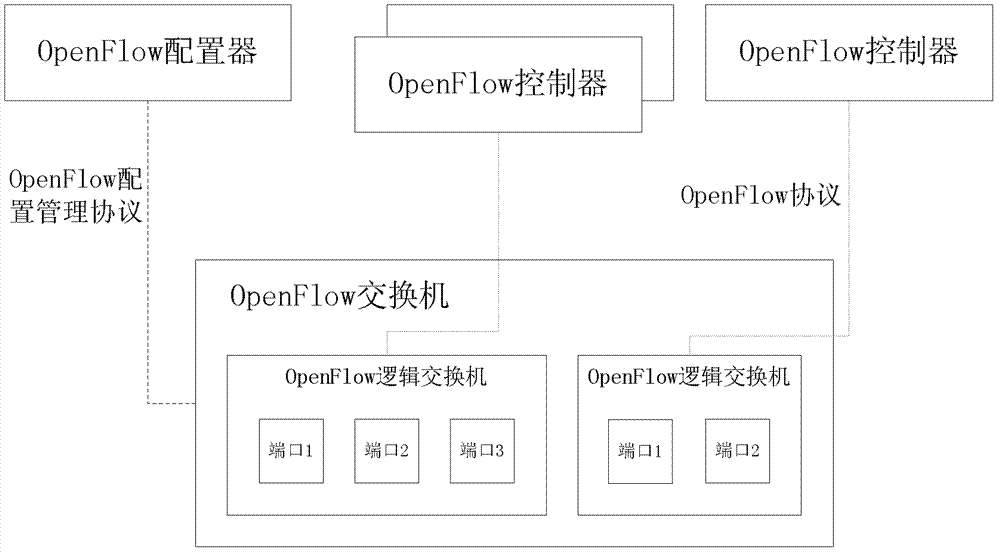

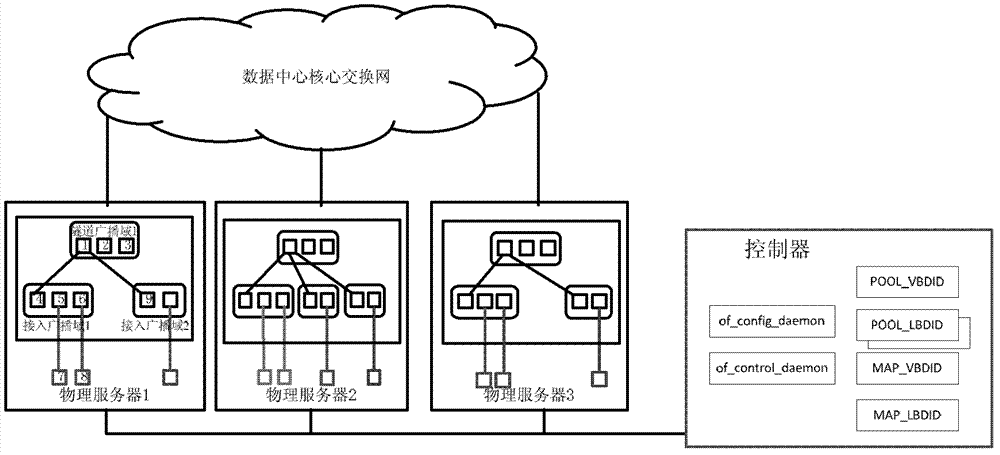

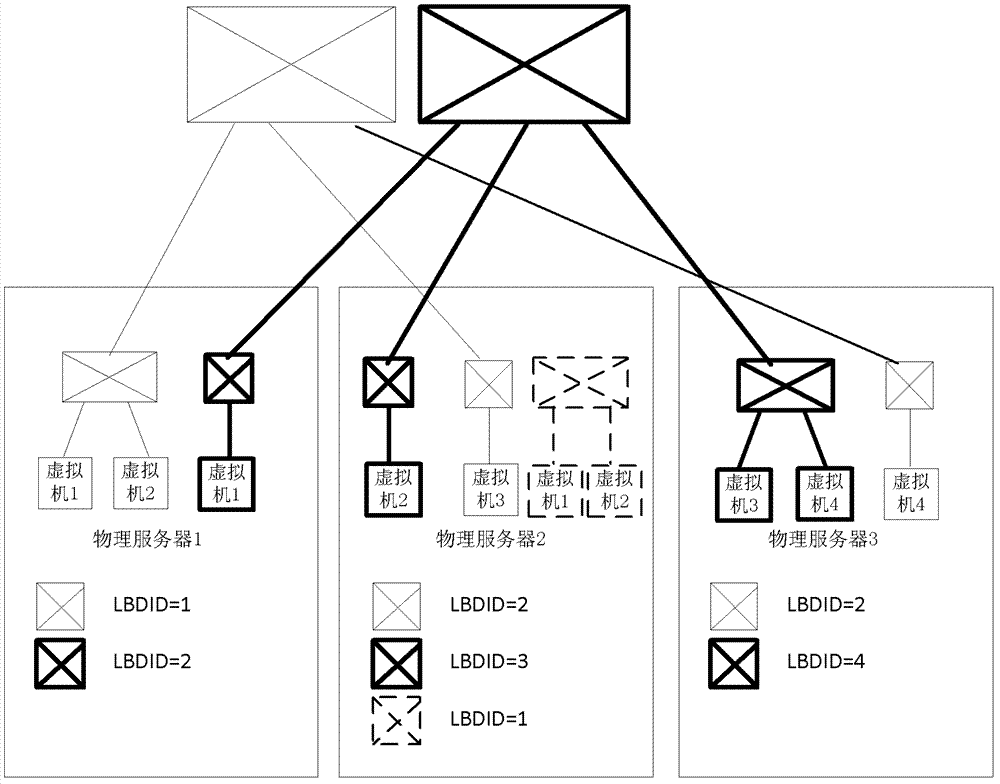

System and method for managing virtual network in cloud computation data center

ActiveCN102710432AEffective isolationRelieve pressureNetworks interconnectionTraffic capacityBroadcast domain

The invention discloses a system and a method for managing a virtual network in a cloud computation data center, and relates to the technical field of network system structures and network communication protocols. The system comprises physical servers and a controller, the physical servers are connected with a core switching network of the data center, each physical server is provided with at least one switch supporting OpenFlow related protocols and is connected with the controller, and the controller builds the virtual network, maintains configuration of the virtual network and a mapping relation among the virtual network, a virtual broadcast domain and a local broadcast domain, and configures and controls the switches of the physical servers. By the aid of the system and the method, pressure on broadcasting and double-layer address tables and forwarding tables of the core switching network of the data center can be effectively reduced, large-scale management is facilitated, flows of different users can be effectively isolated, security is strengthened, and configuration of the virtual network of the data center can be quickly and flexibly changed along with dynamic distribution of virtual resources.

Owner:北京云杉世纪网络科技有限公司

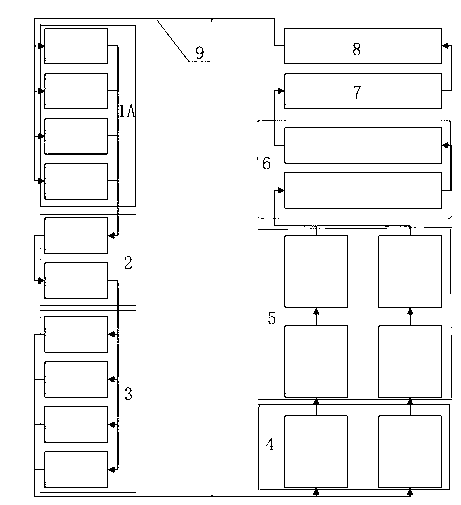

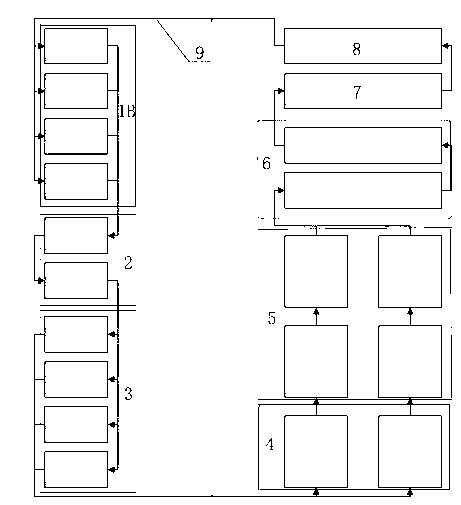

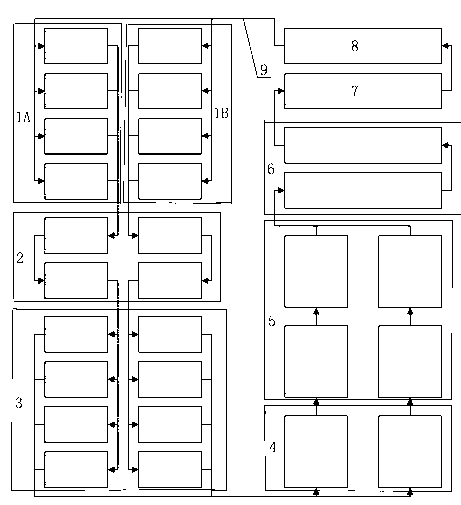

Planting and raising system of ecological circulating water as well asplanting and raising method usingsame

ActiveCN102835319AEasy to handleEfficient treatment and recycling of aquaculture sewageAnimal housingPisciculture and aquariaLive foodLivestock breeding

The invention discloses a planting and raising system of ecological circulating water as well as a planting and raising method using the planting and raising system, belonging to the technical field of ecological agriculture. The system comprises an aquaculture area and / or livestock breeding area, a live food culturing area, an auxiliary aquaculture area, a fertilizer feeding area, a crop planting area, a submerged plant cultivating area, a filtering area and a sterilizing-activating area, wherein the aquaculture area and / or livestock breeding area, the live food culturing area, the auxiliary aquaculture area, the fertilizer feeding area, the crop planting area, the submerged plant cultivating area, the filtering area and the sterilizing-activating area form a water circulating body by means of circulating waterways arranged. The invention is an high-efficient and energy-saving planting and raising system integrating the aquaculture, the crop plantation and the solar comprehensive utilization.

Owner:中山开拓生态农业科技有限公司

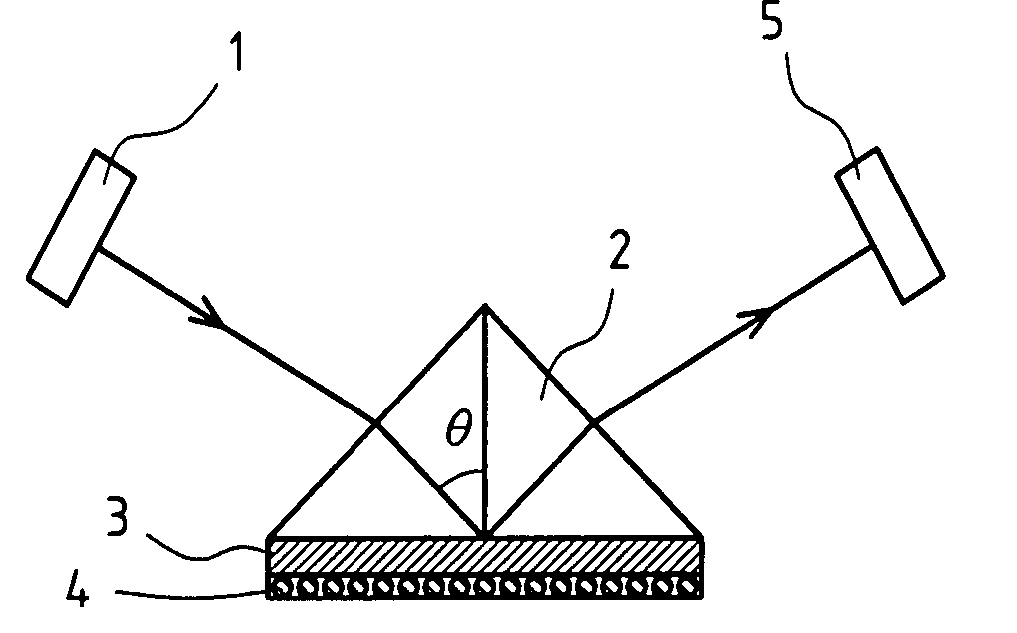

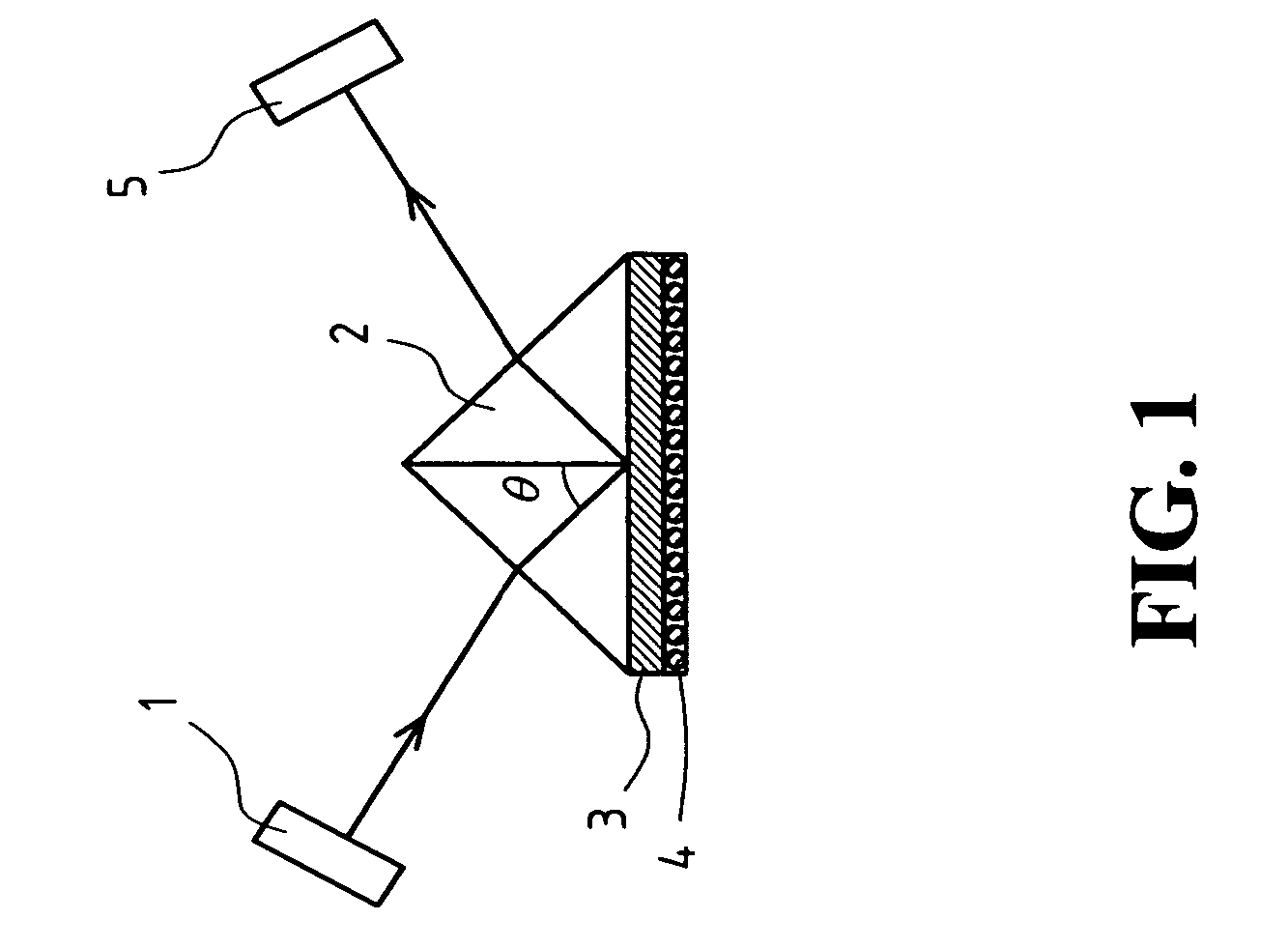

Surface plasmon resonance sensor with high sensitivity

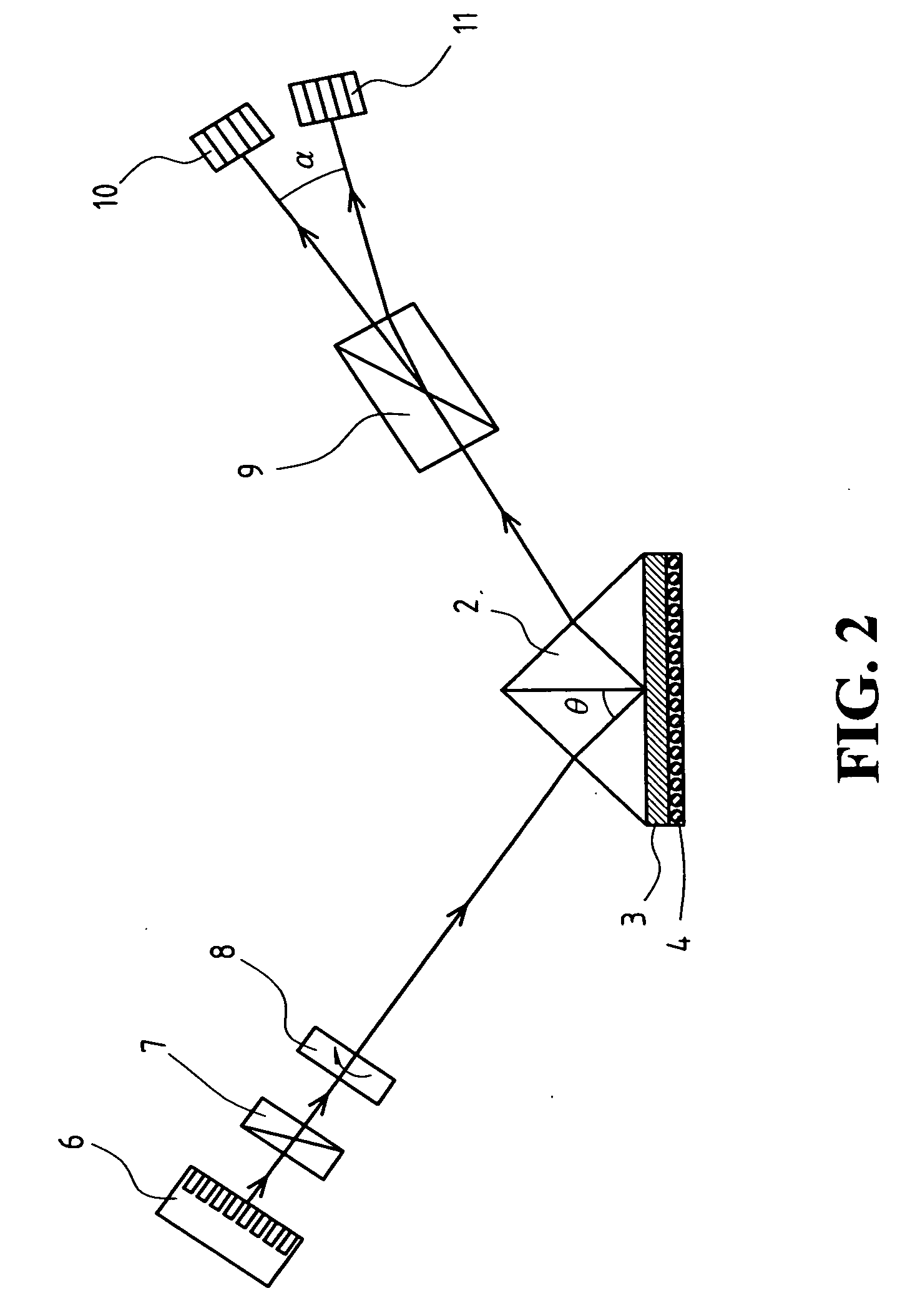

InactiveUS20060197952A1High sensitivityImprove sensor sensitivityScattering properties measurementsManufacturing cost reductionSurface plasmon resonance imaging

A high-sensitivity SPR (surface plasmon resonance) sensor includes at least a prism having a first surface on which a metallic layer and a metallic nanoparticle layer are sequentially formed. A light source projects an incident light into the prism through a second surface of the prism. The light is reflected by the metallic layer and the metallic nanoparticle layer and leaves the prism through a third surface of the prism. A light detector detects the reflected light. The SPR sensor has an extensive detection range as compared with the conventional ones and is applicable in the detection of gas, chemical substance, and biomolecule. Moreover, the SPR sensor is advantageous in arranging fabrication process consistently, controlling film thickness, improving product quality, and decreasing fabrication cost.

Owner:NAT CENT UNIV

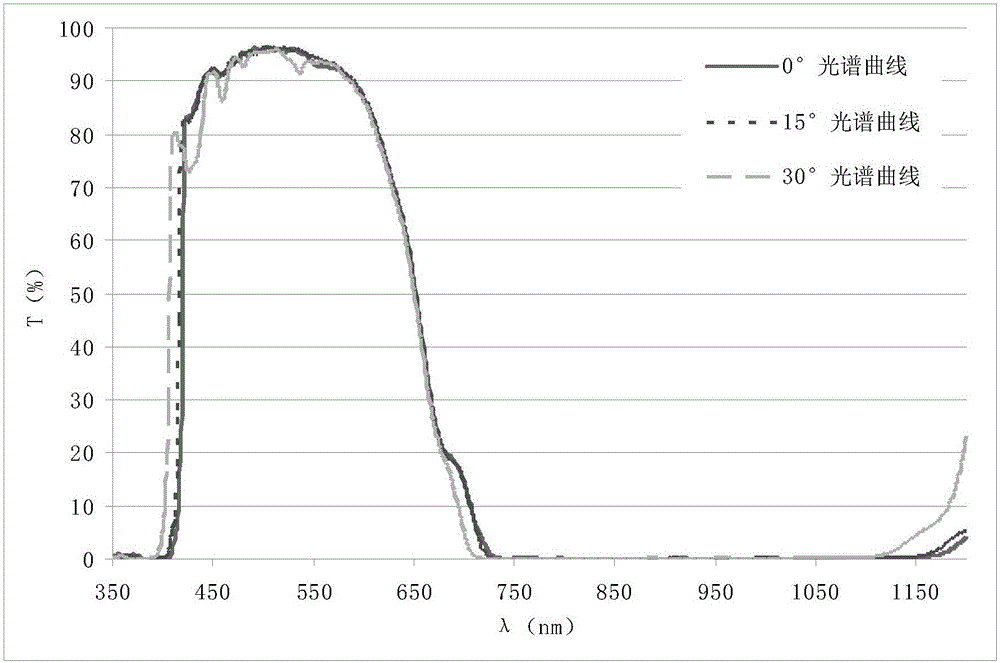

Color optical filter insensitive to incident angle and preparation method for the same

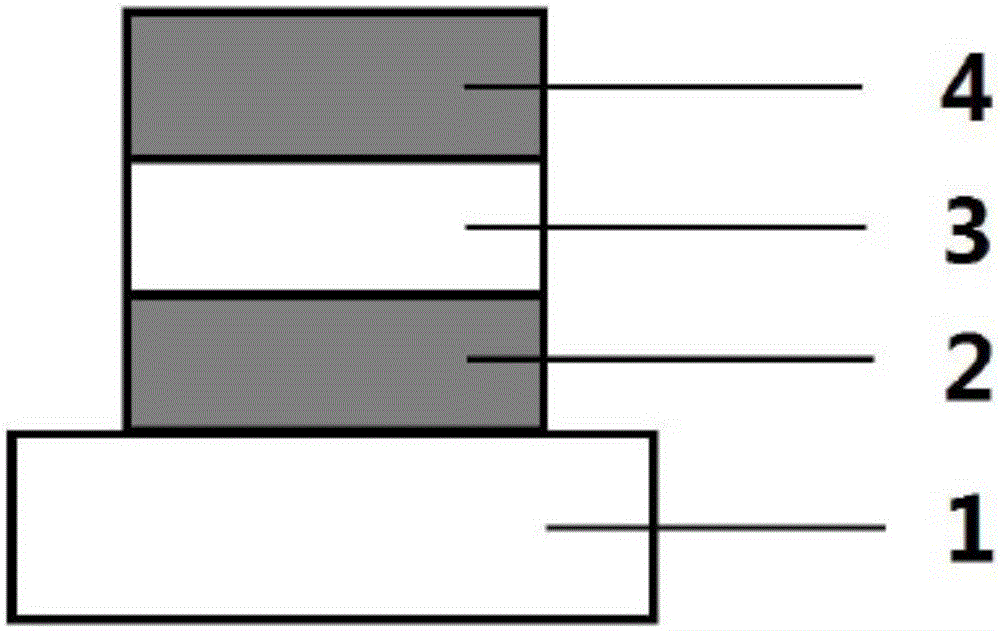

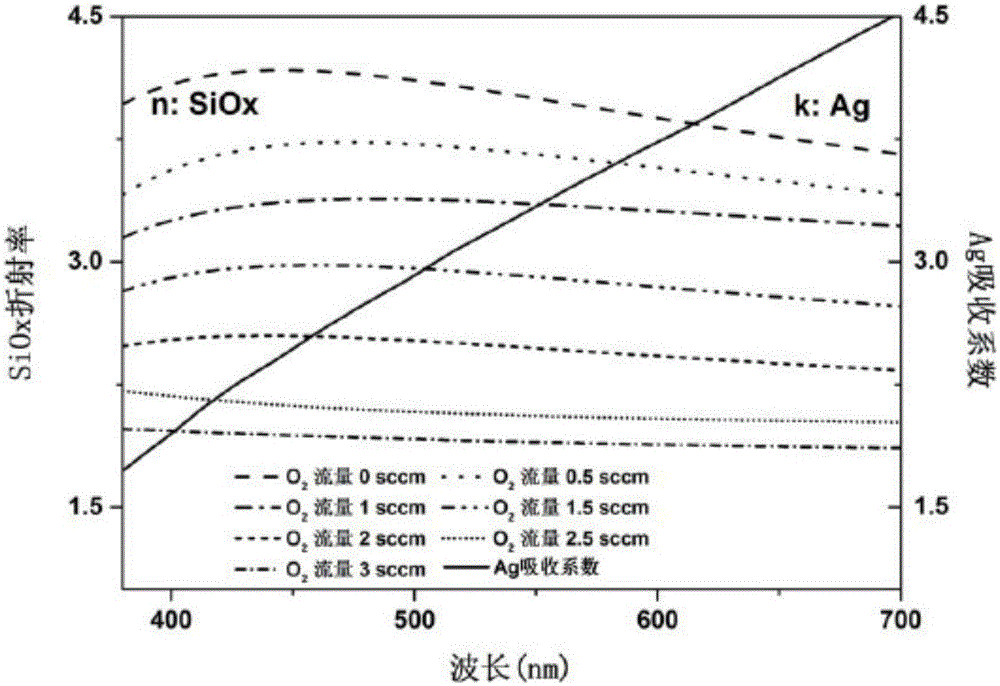

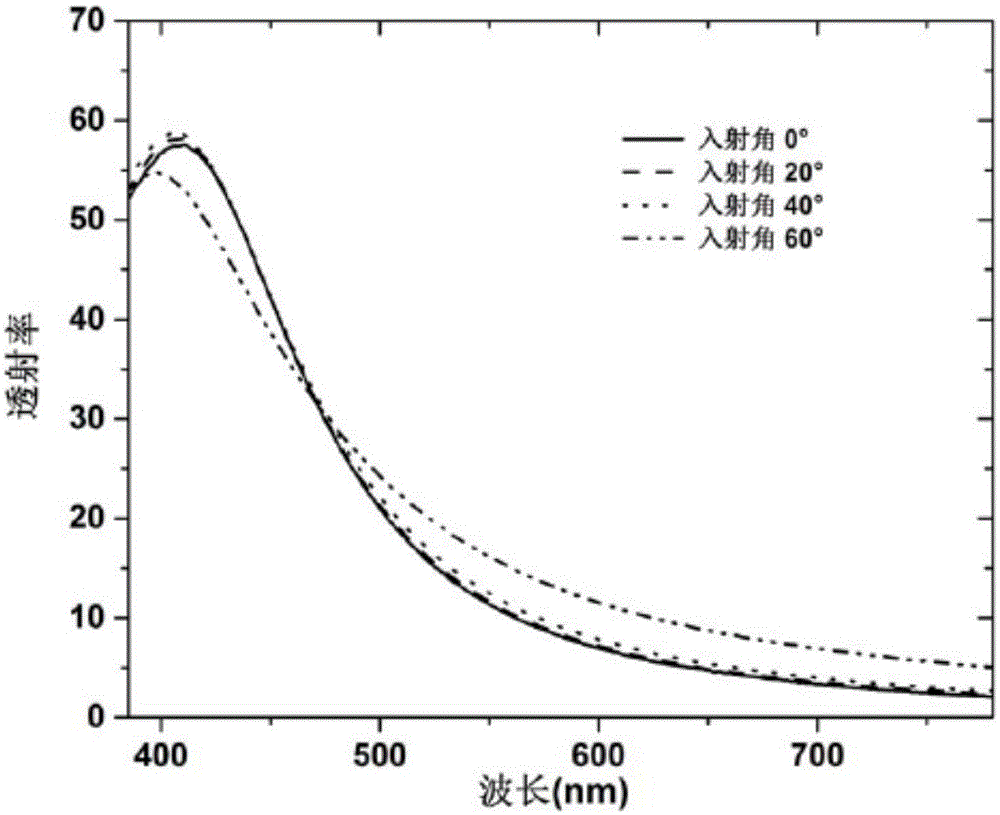

ActiveCN105137518ALow costSuitable for large-area batch productionOptical elementsLiquid-crystal displayColor printing

The invention discloses a color optical filter insensitive to an incident angle and a manufacture method thereof. The color optical filter comprises a substrate; a metal film, a medium film and a metal film are successively arranged on the substrate; the three layers of films constitute a harmonic structure; the material of the medium film is made of the silicon-enriched silicon oxide SiOx or silicon-enriched silicon nitride SiNy, wherein the value ranges of the x and the y are as follow:0<x&1t,0<y*&1t;and 4 / 3, The manufacture method for the color optical filter insensitive to the incident angle is simple in preparation, low in cost, and applicable to mass production and batch production. The invention is hopefully and widely applied in the fields of liquid crystal display, color printing, sensor detection, anti-counteracting, etc.

Owner:上海高能煜镀科技有限公司

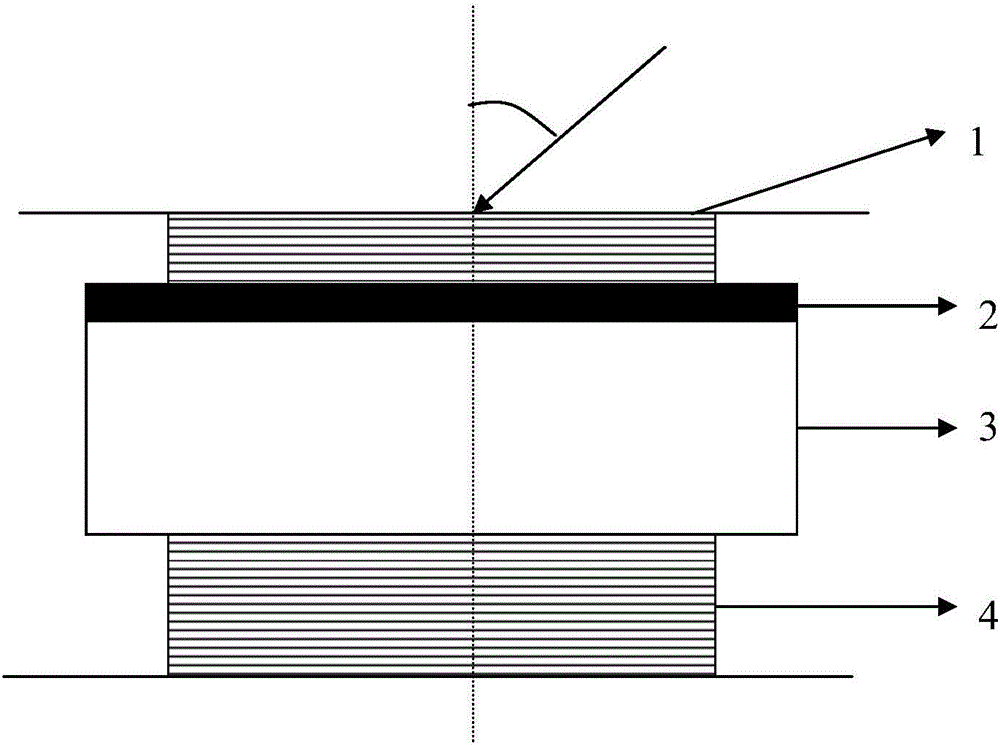

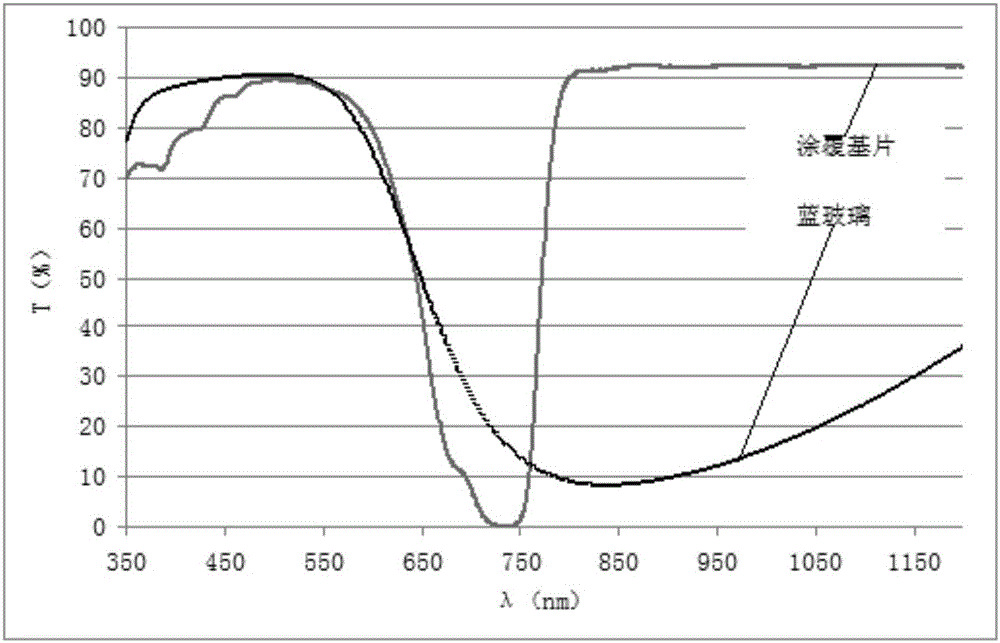

Mixing absorption type infrared cut-off filter and preparation method thereof

InactiveCN105911625AReduce manufacturing costImprove cutting efficiencyOptical filtersCamera filtersInfrared cut-off filterWave band

The invention discloses a mixing absorption type infrared cut-off filter and a preparation method thereof. The mixing absorption type infrared cut-off filter comprises a glass substrate; the upper surface of the glass substrate is provided with a coating adhesive layer possessing visible light absorption characteristics; the coating adhesive layer is provided with an antireflection film layer; the lower surface of the glass substrate is provided with an infrared cut-off film layer. The invention provides a visible region high transmittance and infrared band cut-off ultralow angle effect filter, which can realize lower edge aberration in wide angle incidence.

Owner:ZHEJIANG CRYSTAL OPTECH

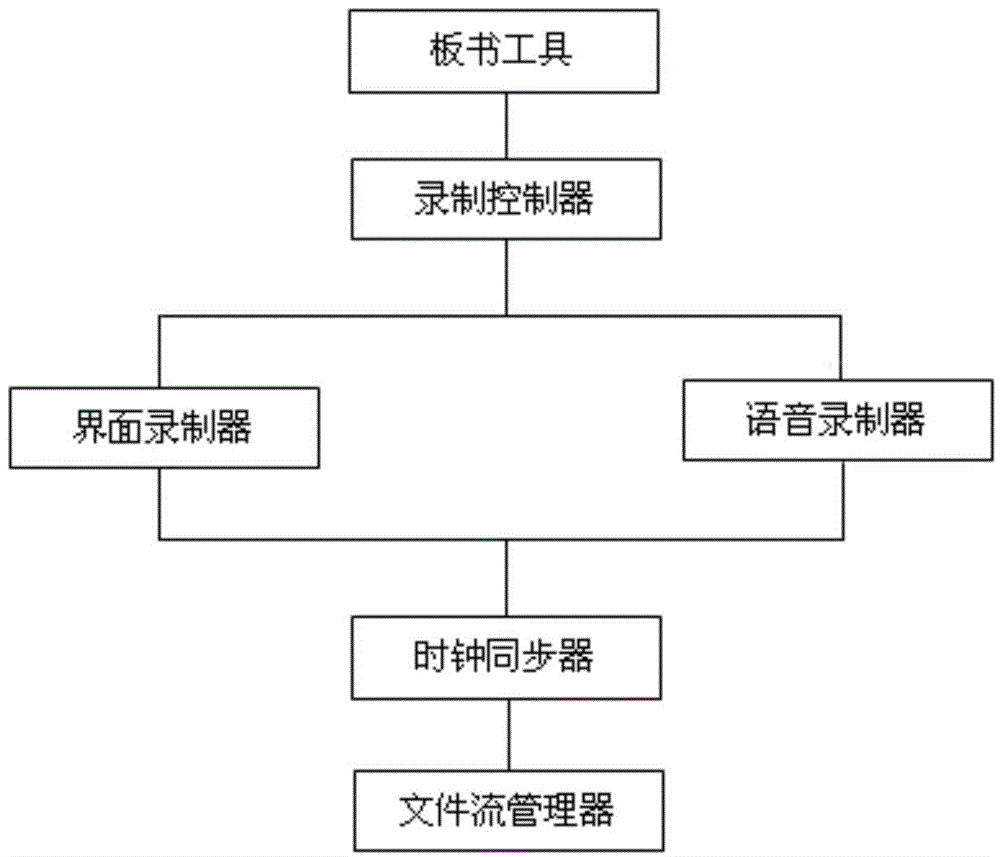

Micro video course making system and method

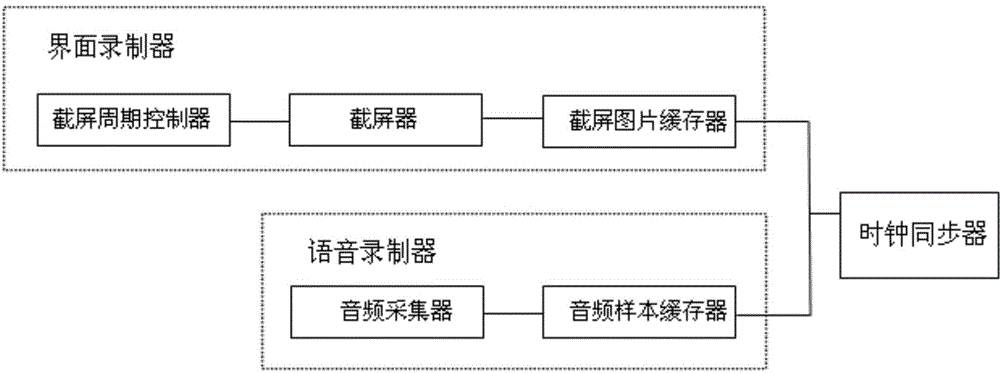

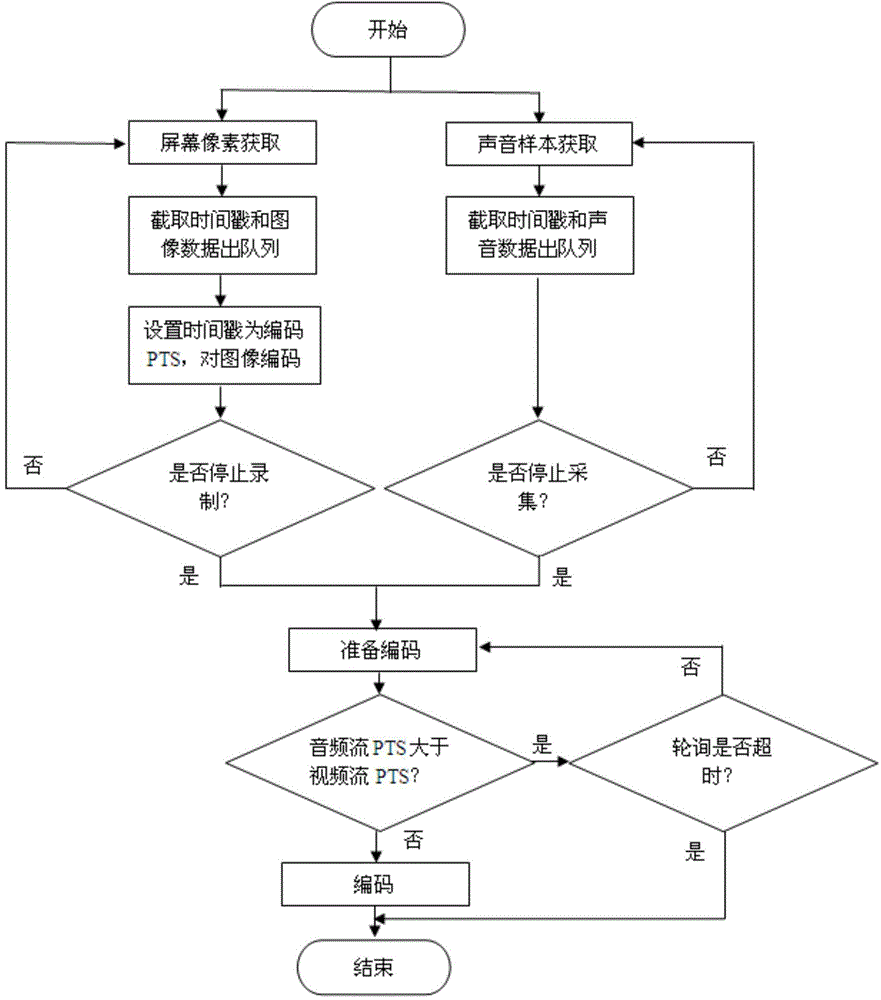

InactiveCN104581346AOvercome defects such as poor recording effectExtensive Online TeachingSelective content distributionReal time displayAudio frequency

The invention discloses a micro video course making system which is used for recording teaching blackboard writing demonstration and phonetic explanation. The micro video course making system comprises a blackboard-writing tool, a recording controller, an interface recorder, a voice recorder, a clock synchronizer and a file flow manager. The blackboard-writing tool is used for providing an input interface for user operation. The recording controller is used for receiving and displaying the user operation in a screen in real time and meanwhile controlling the screen intercepting time and parameter. The interface recorder intercepts the user operation and / or program operation state in the screen in the teaching blackboard writing demonstration process according to the set parameter and obtains image samples. The voice recorder is used for obtaining audio samples generated in the phonetic explanation process. The clock synchronizer is used for keeping time synchronization of the image sample and the audio sample. The file flow manager is used for generating video data and audio data and thus generating video / audio files for micro video course teaching. The making system is high in integration degree and capable of being operated by a single person, and videos and the audios are synchronized. The invention further discloses a micro video course making method.

Owner:EAST CHINA NORMAL UNIV +1

Preparation method of rear-earth magnesium alloy product

The invention relates to a preparation method of a rear-earth magnesium alloy product. The preparation method comprises the following steps of: placing dehydrated rear-earth chlorate in a melting electrolysis device; adding dehydrated magnesium chloride, potassium chloride and titanium dichloride for dispersing, mixing and carrying out melting electrolysis, so that rear-earth magnesium intermediate alloy is generated by co-electrodeposition of rear-earth ion and magnesium ion at a negative electrode; burdening and mixing the rear-earth magnesium intermediate alloy and the metal magnesium in a smelting device, wherein a molar ratio of the rear-earth metal to the magnesium is (0.1-1.0):100; heating up the rear-earth magnesium alloy mixture for melting, immersing the smelting agent inside the melt and stirring, increasing the temperature to 780 DEG C and stewing for 20 minutes for dividing the melt into an upper layer, a middle layer and a lower layer, wherein the middle melt layer is used as the rear-earth magnesium alloy melt; casting after pre-cooling, cooling and forming, and carrying out surface treatment after carrying out mechanical processing and thermal processing, so that a compact proactive film layer is covered on the surface of the rear-earth magnesium alloy product. The preparation method of the rear-earth magnesium alloy product is high in preparation efficiency, safe and reliable in process, environment-friendly and low in energy consumption.

Owner:YANGZHOU FENG MING METAL PROD

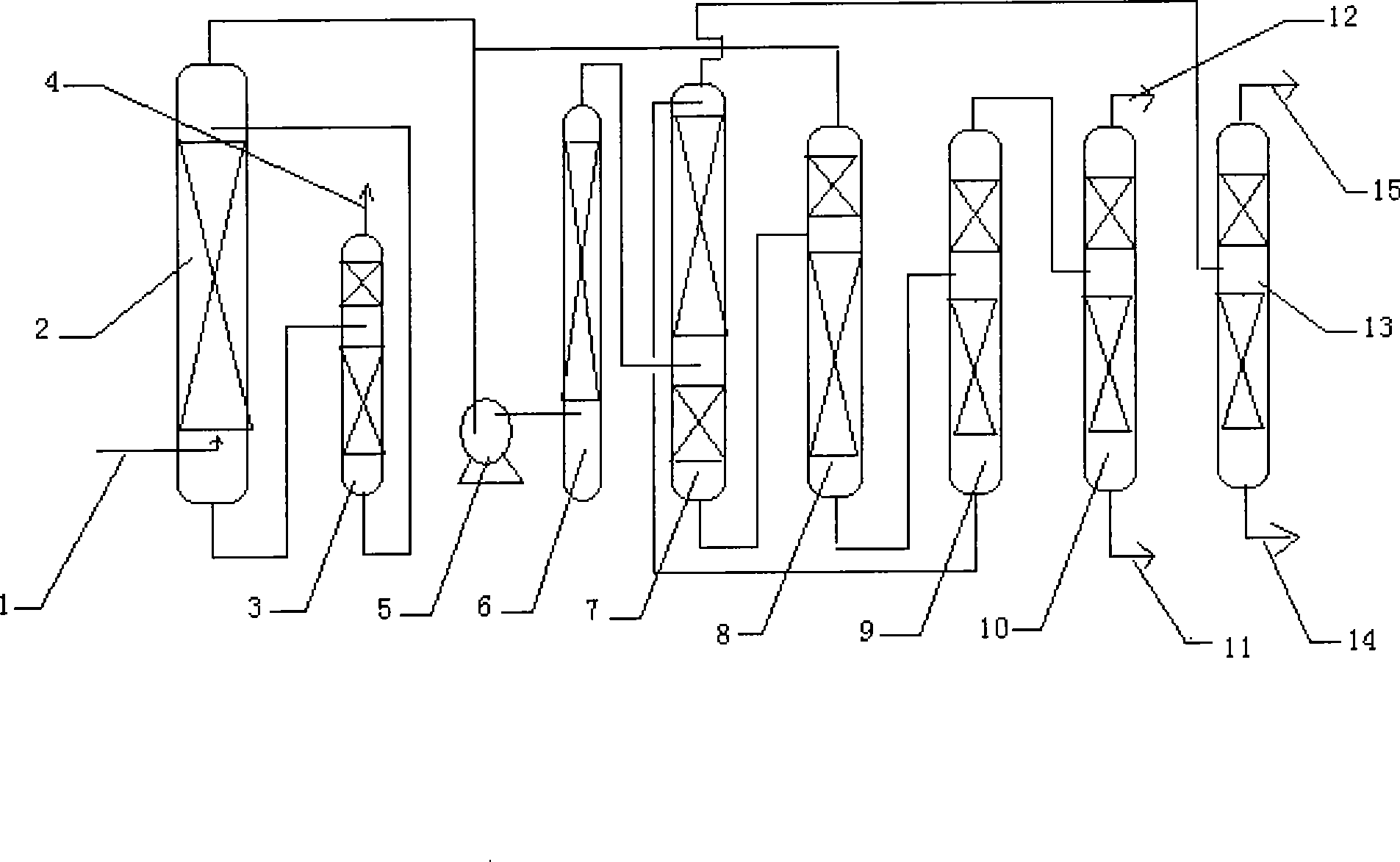

Fractionation process for cracking gas from oxidation pyrolysis of gaseous hydrocarbon

InactiveCN101486625ANo dischargeReasonable workmanshipDistillation purification/separationHydrocarbonsDesorptionFractionation

The invention provides a fractionation technique for the cracking gas obtained through the oxidation thermal decomposition of gaseous hydrocarbon and used for preparing acetylene. The cracking gas obtained through the oxidation thermal decomposition of gaseous hydrocarbon and used for preparing acetylene first goes through an oil washing tower to remove higher alkyne, C3 hydrocarbon and carbon black, and is pressurized to 0.4MPa to 1.5MPa through a compressor and deoiled through an activated carbon adsorption tower, thus dissolving acetylene and a few other indissoluble components through an absorbed solvent in the adsorption tower; the rest gases go in an ethylene separation tower to recycle concentrated ethylene products and tail gas is taken as synthesis gas; after the solvent dissolving acetylene and a few other indissoluble components enters a flashing tower to remove the indissoluble components, crude acetylene gas is obtained through the separation of an acetylene desorption tower; the indissoluble components are cycled before returning to the compressor and pure acetylene products are obtained after the crude acetylene gas is refined in a carbon dioxide tower; the wash oil saturated with higher alkyne, C3 hydrocarbon and carbon black goes back to normal pressure, flows to a wash oil purifying tower and higher alkyne and C3 hydrocarbon are obtained at the top of the tower and return to serve as gaseous hydrocarbon raw material.

Owner:SHANDONG UNIV OF SCI & TECH

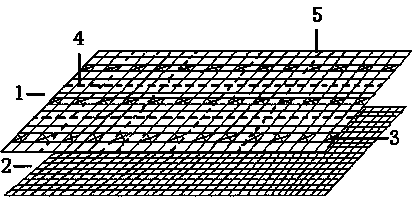

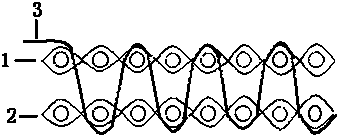

UHMWPE (Ultra High Molecular Weight Polyethylene Fiber) summer sleeping mat and manufacture method thereof

InactiveCN104305786AImprove thermal conductivityLightweight is obviousSynthetic resin layered productsMulti-ply fabricsSurface layerEngineering

The invention discloses an UHMWPE (Ultra High Molecular Weight Polyethylene Fiber) summer sleeping mat and a manufacture method thereof. The summer sleeping mat is of double-layer structure consisting of a surface layer and an inner layer. The surface layer has relatively large gaps among yarn and relatively large gaps among monofilaments, and is formed by UHMWPE filament yarn or arranging UHMWPE with common textile materials at intervals, or weaving UHMWPE with composite yarn with common textile materials as warps and wefts, and the UHMWPE content is not less than 50%. The inner layer is composed of common hydrophilic textile materials. The surface layer and the inner layer are formed by connecting the surface layer and the inner layer to a double-layer organization structure or replacing the surface layer and the inner layer with double-layer organization structure, or formed by sewing two single-layer fabrics into a whole. Folding strips are reserved by extracting warps and wefts in warp and weft directions, and the surface layer and the inner layer are subjected to antibacterial and anti-mosquito technology treatment. The summer sleeping mat has significant and durable cool contact feeling, is easy to fold and carry, light in weight, and dry enduringly, and has antibacterial and insect prevention functions.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP +1

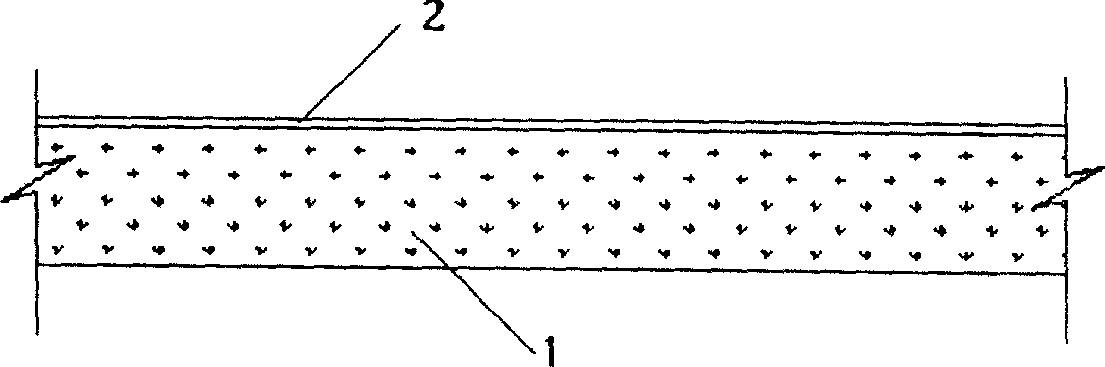

Color pavement formed by spraying on porous polymer concrete facing and construction method therefor

A colorful road plated with porous polymer concrete face and relative construction first mix polymer, broken stone and stuff uniformly to form polymer porous concrete material, lay to form polymer porous concrete face 1, mix uniformly the colorful face, and plate colorful face on the face of porous polymer concrete face layer 1 to form a colorful face layer 2, while the colorful face layer 2 is adhered with the porous polymer concrete face layer 1, to form a colorful road. The inventive road has high strength, better deformation property, abrasion resistance or the like, while the color can adjust via different fields.

Owner:易志坚

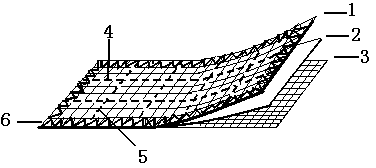

UHMWPE (Ultra High Molecular Weight Poly Ethylene) fiber composite summer sleeping mat and manufacturing method thereof

InactiveCN104287537AImprove thermal conductivityLightweight is obviousSynthetic resin layered productsWoven fabricsFiberSurface layer

The invention discloses a UHMWPE (Ultra High Molecular Weight Poly Ethylene) fiber composite summer sleeping mat and a manufacturing method thereof. The summer sleeping mat comprises a mat surface layer, a sweat absorption layer and a mat bottom coating layer, wherein the mat surface layer is prepared from UHMWPE, or is prepared by arranging the UHMWPE and higher-water-absorption common textile materials at intervals or is prepared by using the UHMWPE and higher-water-absorption fiber composite yarns as warp and weft yarns, and is subjected to anti-bacterial and insect-preventing treatment; the sweat absorption layer is made of a high-water-absorption fabric and is arranged between the mat surface layer and the mat bottom coating layer; the mat bottom coating layer is a common hydrophilic fabric with certain abrasion resistance, is sewn in an edge coating manner, covers the sweat absorption layer and the mat surface layer and is sewn around the mat surface layer. The mat has an obvious and ensuring contact feeling of coolness, is easy to fold and carry, is light in weight, and has the anti-bacterial and insect-preventing functions; the mat surface is dry and comfortable for a long time.

Owner:PAP LOGISTICS EQUIP RES INST +1

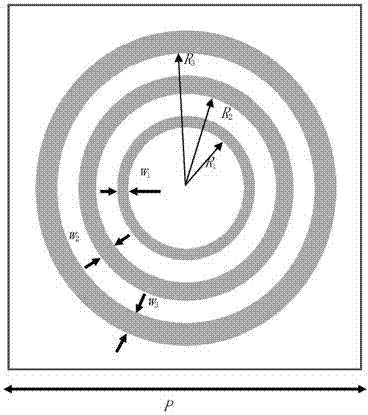

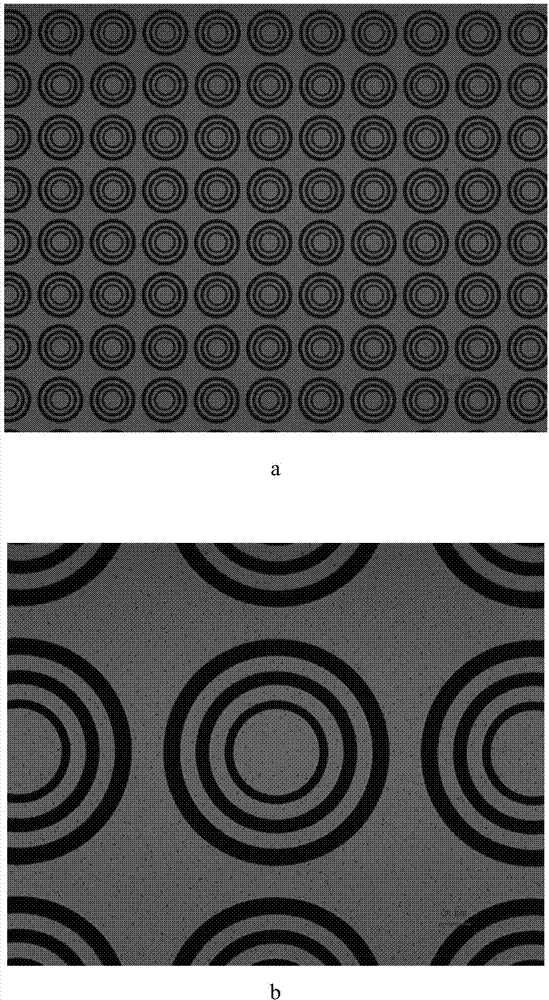

Multiband terahertz filter and manufacture method of multiband terahertz filter

ActiveCN104505561AImprove out-of-band rejection performanceGood polarization insensitivityWaveguide type devicesOut of band rejectionControllability

The invention relates to a multiband terahertz filter. The terahertz filter comprises a substrate and a metal film which are arranged in sequence from bottom to top, wherein a periodic structure is etched on the metal film; the periodic structure consists of n concentric annuli; n is a wave band quantity of the terahertz filter; the widths of the n concentric annuli are gradually increased from circle centre to outside. The invention also discloses a manufacture method of the multiband terahertz filter. As passing bands are increased, the multiband terahertz filter provided by the invention has the advantages of having good out-of-band rejection performance of the middle passing bands, polarization insensitivity and wide acceptance angle, and realizing the controllability of filtering frequency band and wave band quantity of the filter; the manufacture method is simple to operate; the multi-step technologies of the manufacture method all refer to conventional operations in the semiconductor field; the large-scale and integrated production is easy.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

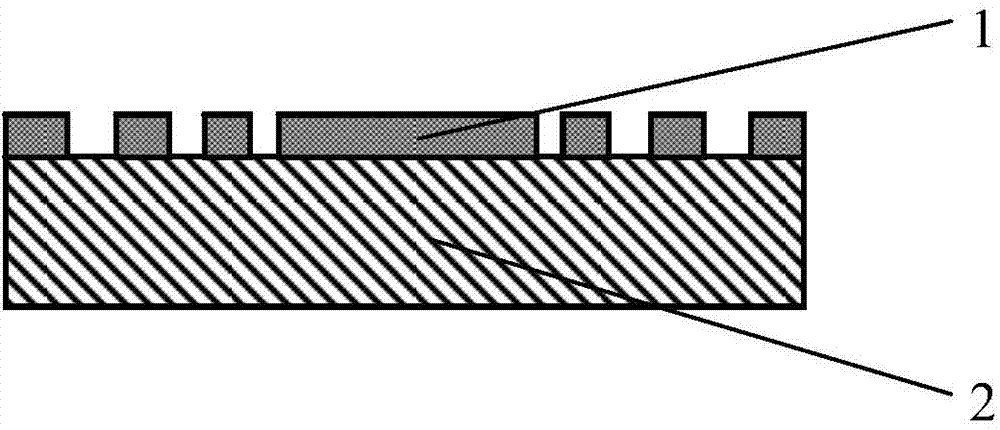

Solar cell adopting metal transparent electrode and preparation of solar cell

InactiveCN104934539AEasy to synthesizeConducive to large-scaleFinal product manufactureSolid-state devicesElectronic transmissionTitanium

A solar cell adopting a metal transparent electrode comprises a metal counter electrode layer, a metal transparent electrode layer and an active calcium titanium ore bed positioned between the metal counter electrode layer and the metal transparent electrode layer; an electronic transmission layer or a hole transmission layer can be arranged between the metal counter electrode layer and the active calcium titanium ore bed; a hole transmission layer or an electronic transmission layer is arranged between the metal transparent electrode layer and the active calcium titanium ore bed; and a semiconductor compact layer can be further arranged between the electronic transmission layer and the metal transparent electrode layer. The solar cell adopts a metal nanowire net conductive thin film with high light transparency as the metal transparent electrode layer, wherein the conductivity, the light transparency and the flexibility of the metal nanowire net conductive thin film are greatly superior to those of semiconductor metallic oxide.

Owner:HUANENG CLEAN ENERGY RES INST +1

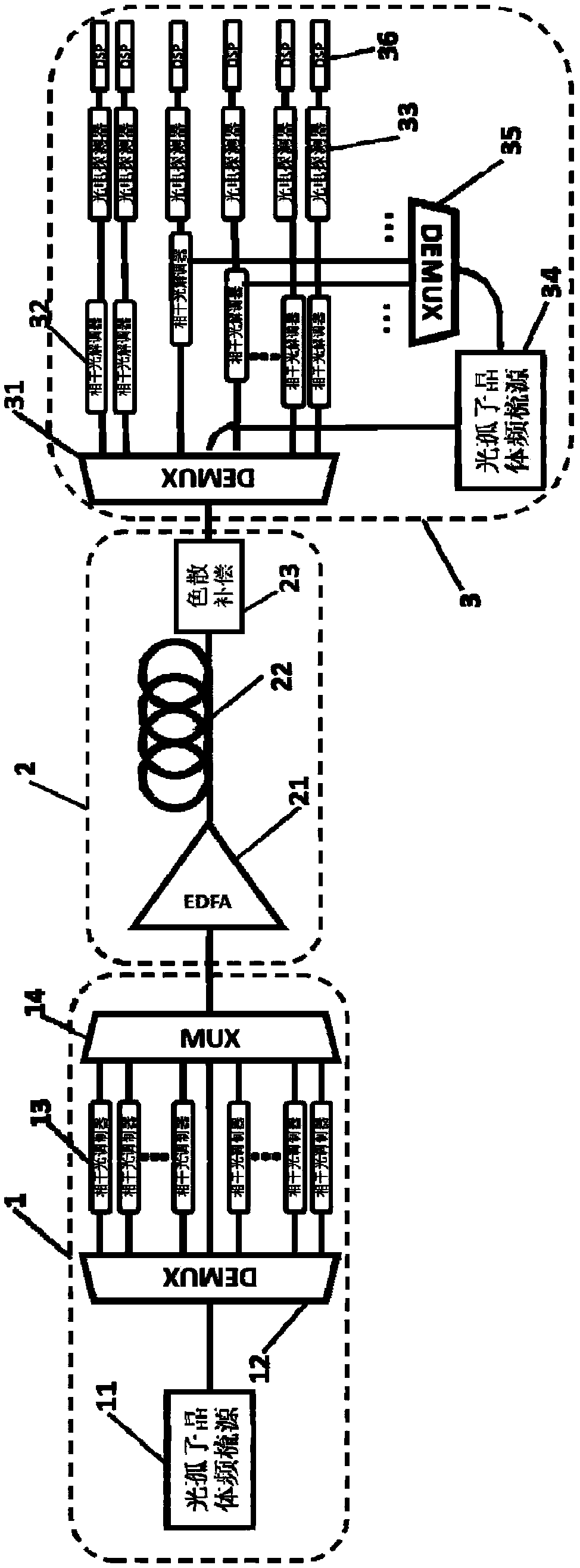

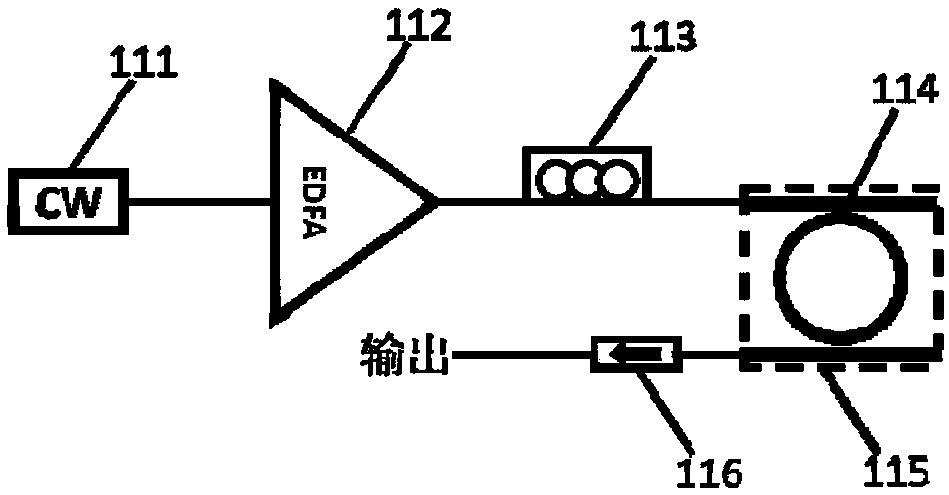

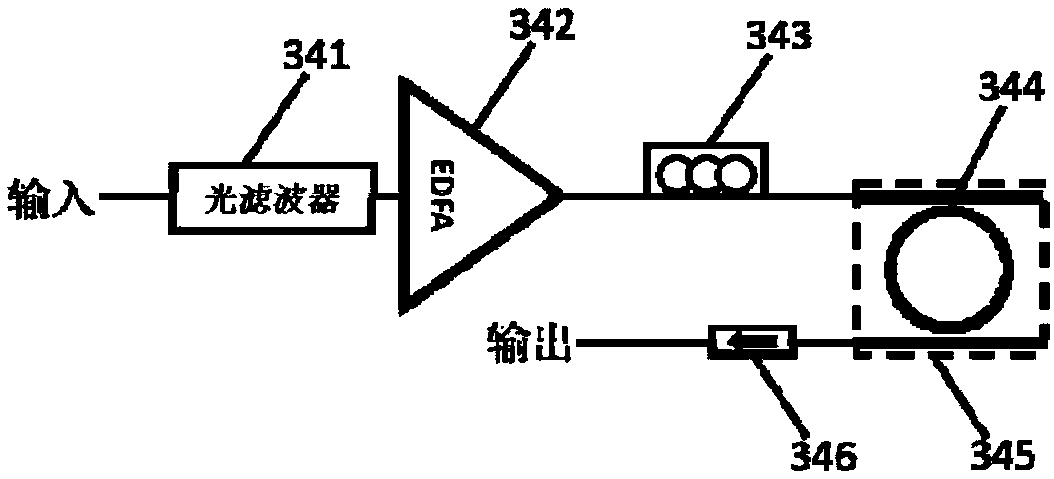

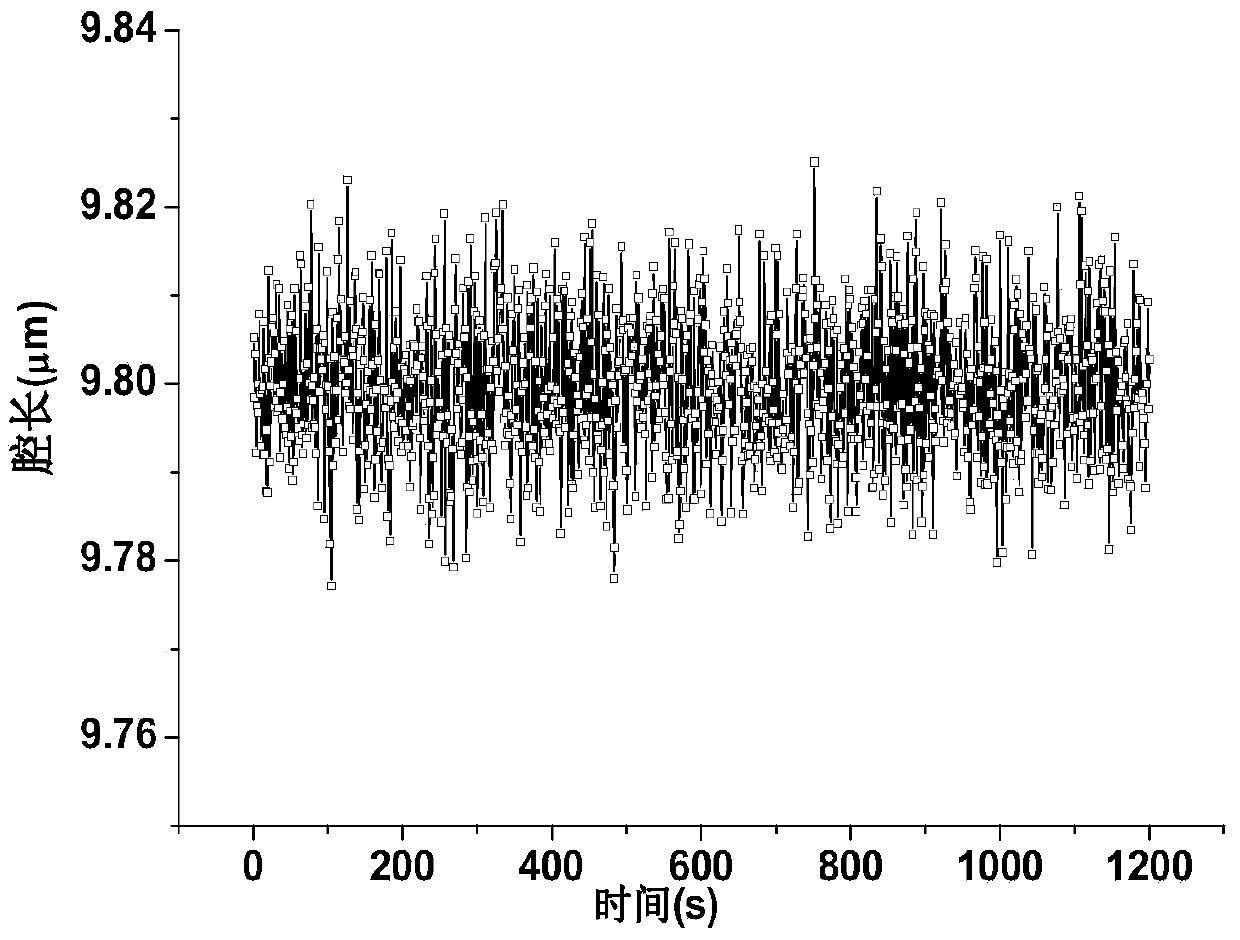

Coherent optical communication system based microcavity optical soliton crystal frequency comb

PendingCN108347283AReduce demandLow costElectromagnetic transmittersElectromagnetic receiversPhysicsLight source

The invention belongs to the technical field of coherent optical communication systems, and provides a coherent optical communication system based on a microcavity optical soliton crystal frequency comb for solving the problems of high laser cost, and poor consistency of local oscillator light and signal light frequency in the existing coherent optical communication system technology. According tothe coherent optical communication system provided by the invention, an optical soliton crystal frequency comb is used as a light source of the communication system at a transmitting end, dozens or more optical carriers can be generated at the same time, thereby reducing the demand for the narrow linewidth laser at the transmitting end of the coherent optical communication system, and compared with the traditional coherent optical communication system, the cost is greatly reduced; another optical soliton crystal frequency comb source is used for providing a local oscillator light signal for acoherent optical demodulator at a receiving end, and the two optical soliton crystal frequency comb sources in the system use the light signal emitted by the same laser as the pumping light, becausethe local oscillator light and the optical carrier signal have approximately the same frequency, so the consistency is good, the coherence is good, the emission wavelength of the laser does not need to be accurately controlled, and the performance requirements of the system for the laser is reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

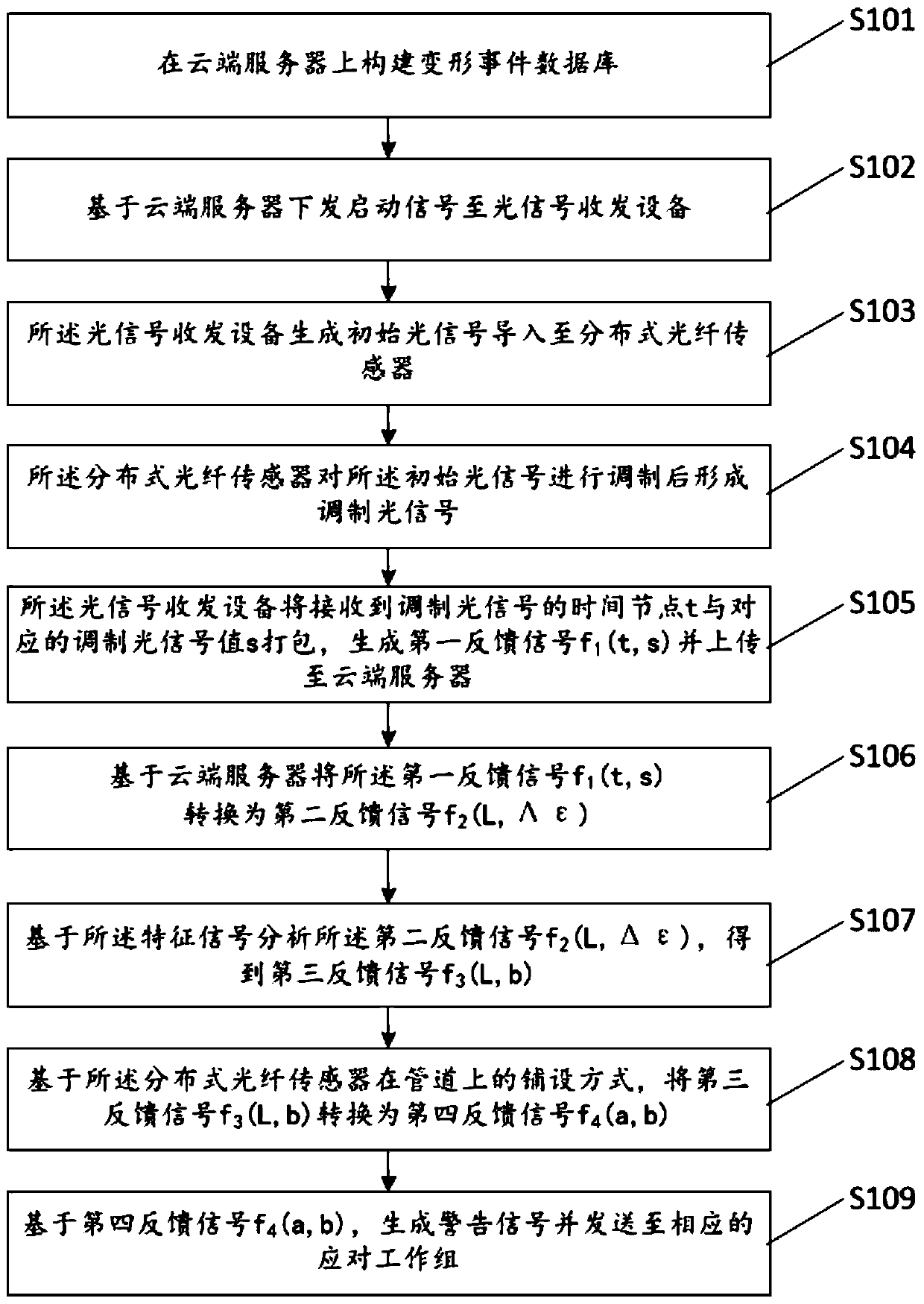

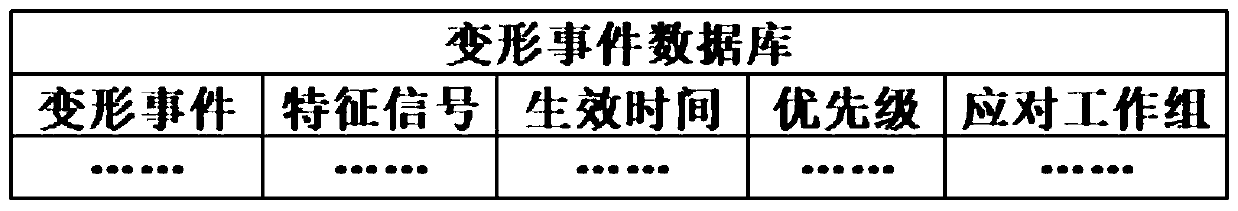

Pipeline deformation monitoring method and system

ActiveCN109827519AAccurate identificationFast data processingDigital data information retrievalPipeline systemsDeformation monitoringComputer science

The invention provides a pipeline deformation monitoring method and system. The system comprises a cloud server, an optical signal transmit-receive device, and a distributed optical fiber sensor. According to the pipeline deformation monitoring method, an event database is set, so that a deformation event can be accurately identified; sequence identification codes are set, so that modulated optical signals measured at different time points can be identified; and a d-t database and the like are set, so that the data processing speed of the cloud server can be increased, and high processing speed and a good event identification effect can be realized. The optical signal transmit-receive device of the system is simple in structure, low in production and maintenance cost, can be favorably popularized and applied on a large scale, and has high practicality in actual use.

Owner:广东聚源管业实业有限公司

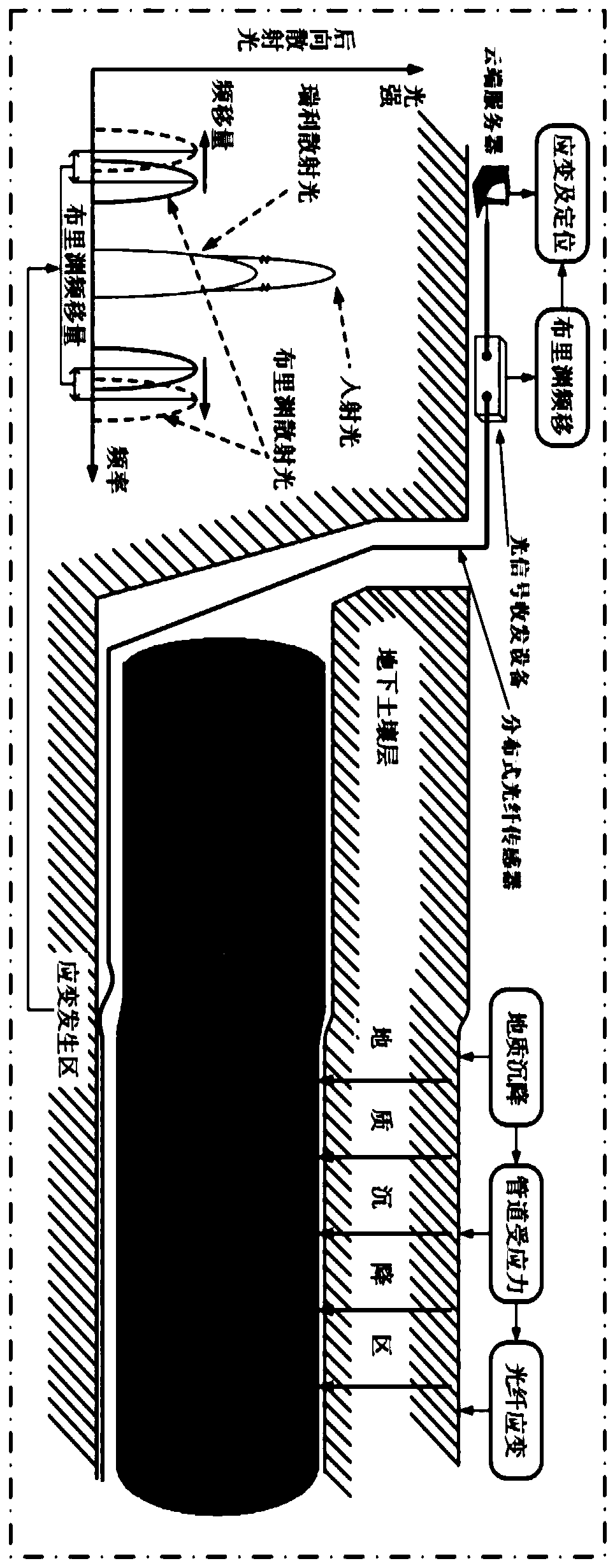

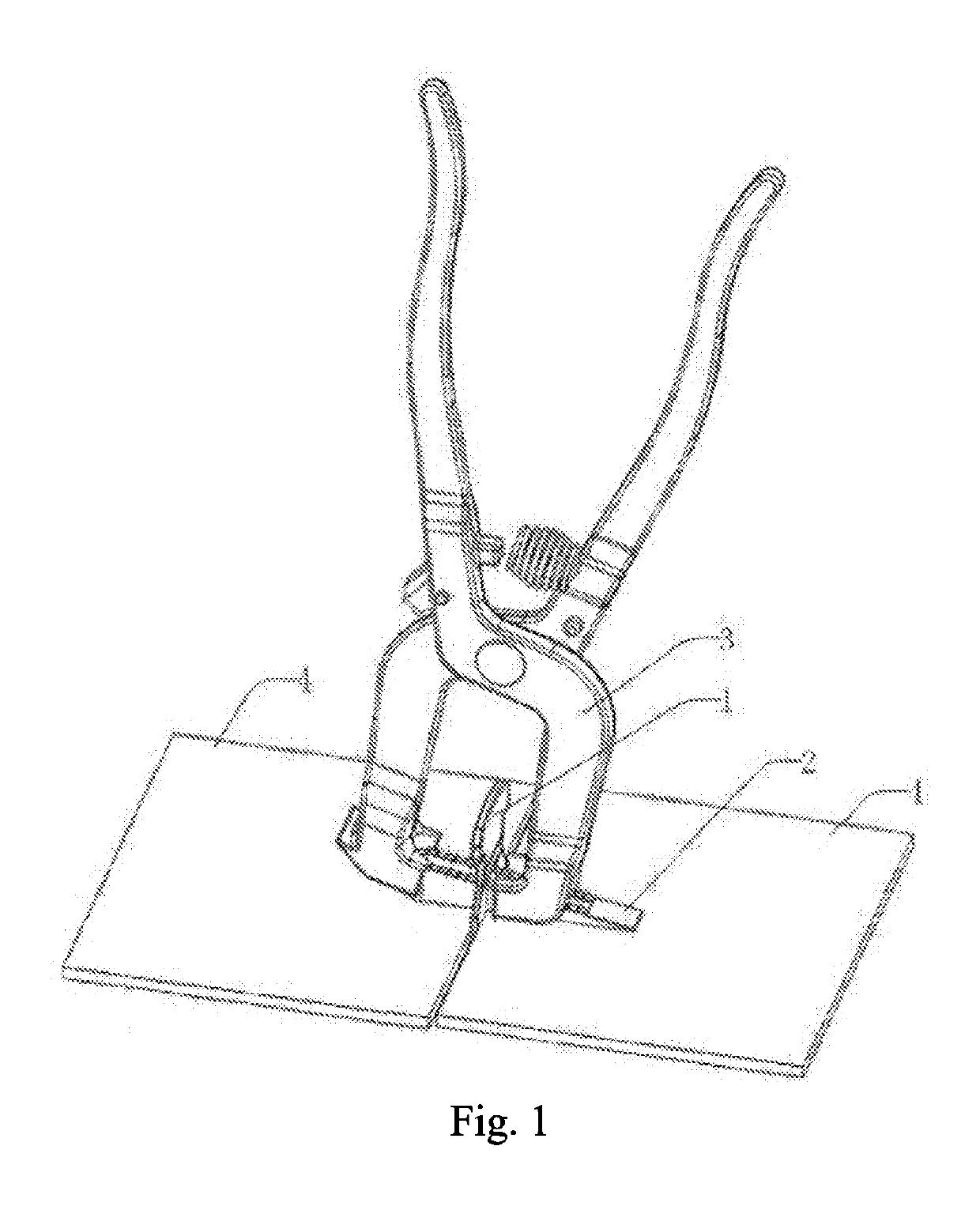

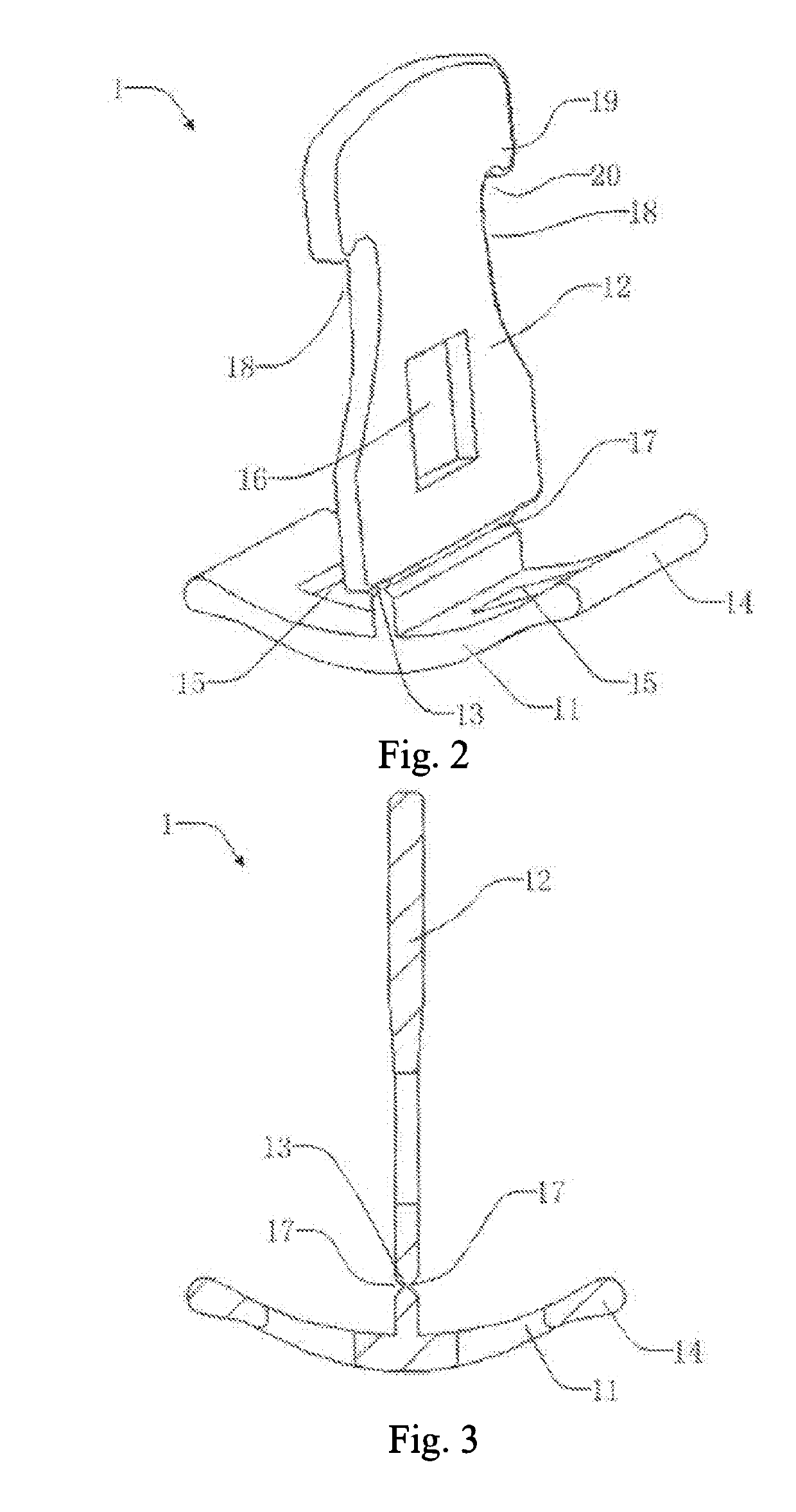

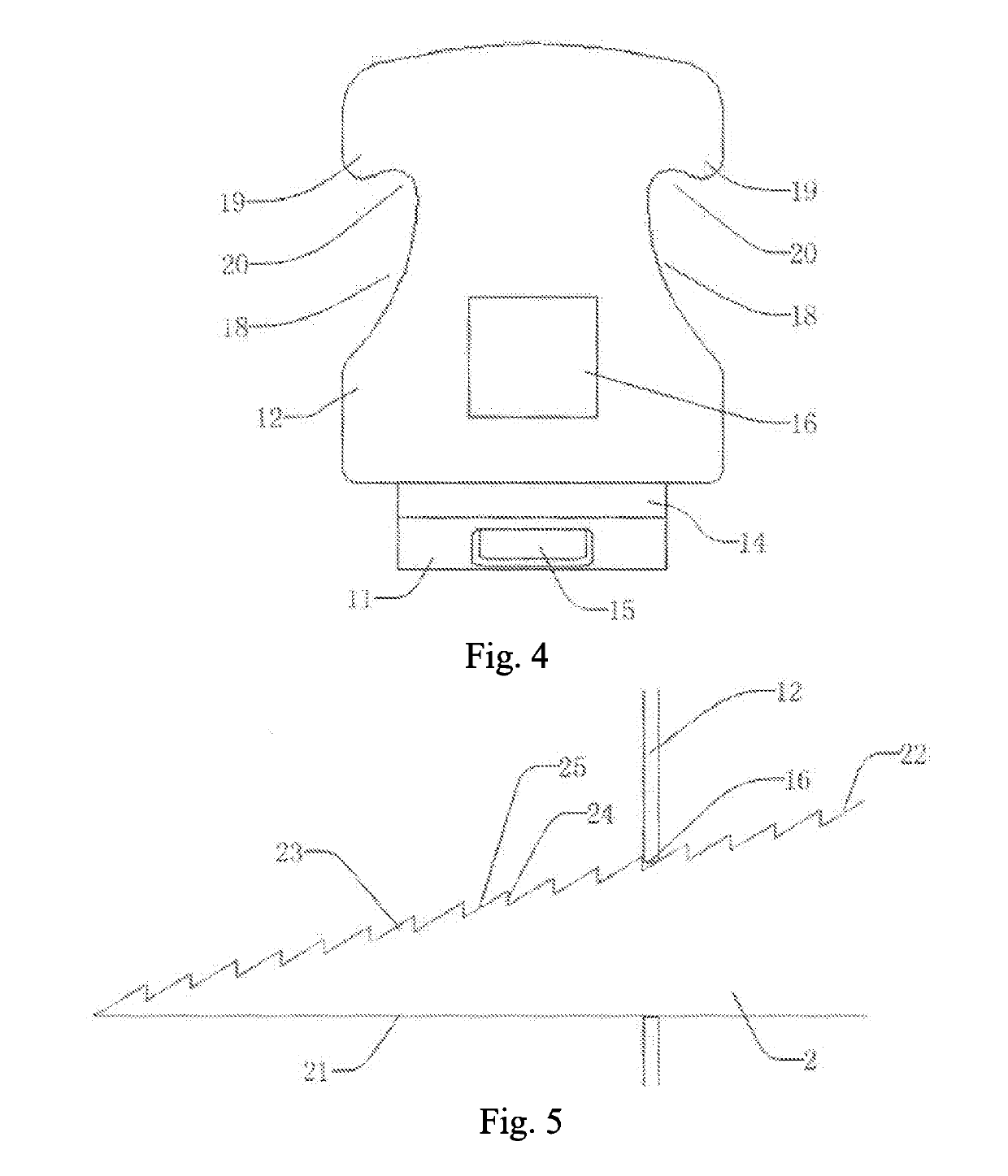

Ceramic tile leveling bracket, pushing and clamping pliers and ceramic tile leveling and laying system

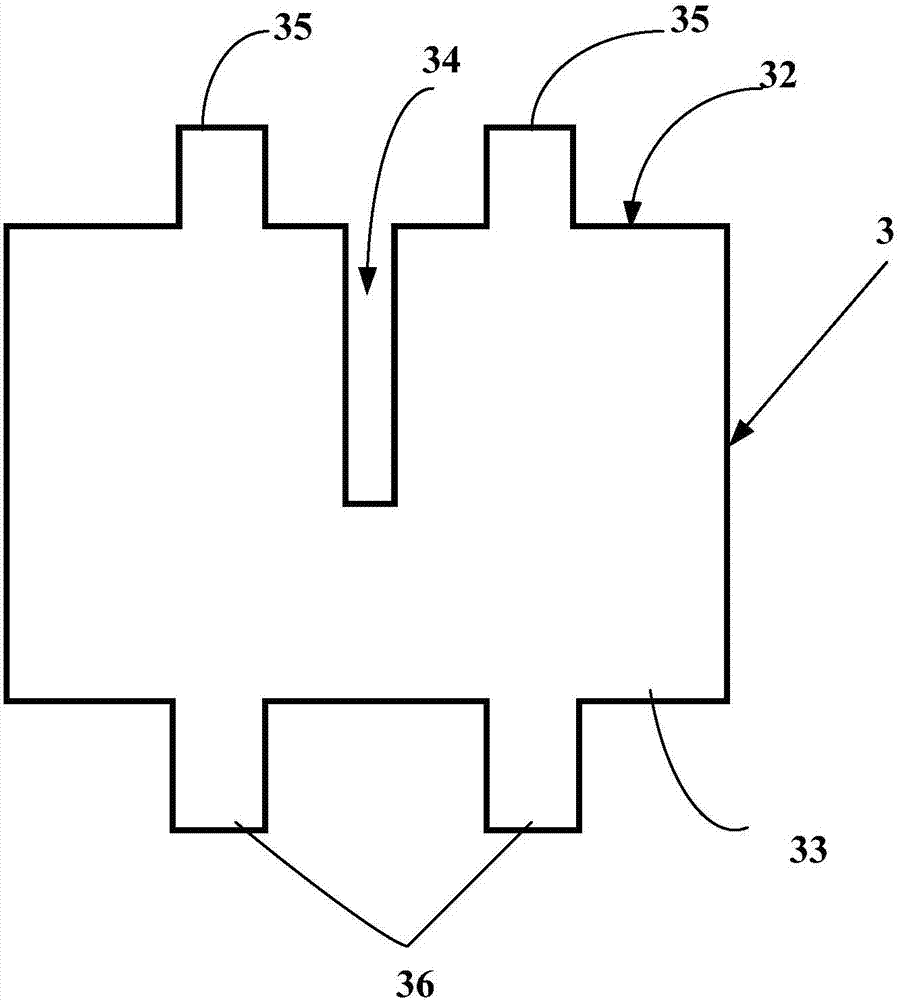

Disclosed are a ceramic tile leveling bracket, pushing and clamping pliers and a ceramic tile leveling and laying system. The ceramic tile leveling and laying system comprises: a ceramic tile leveling bracket (1), an insertion block (2) and pushing and clamping pliers (3), wherein the ceramic tile leveling bracket (1) is provided at the junction between two adjacent ceramic tiles (4), one end of the insertion block (2) is inserted into an insertion block through hole (16) of the ceramic tile leveling bracket (1), and the pushing and clamping pliers (3) push and clamp the insertion block (2) into the insertion block through hole (16), so that an insertion block bottom surface (21) is tangent to upper surfaces of the two ceramic tiles (4). The ceramic tile leveling and laying system is easy to operate, and helps to improve the laying efficiency and laying quality.

Owner:HANGZHOU GREAT STAR IND CO LTD

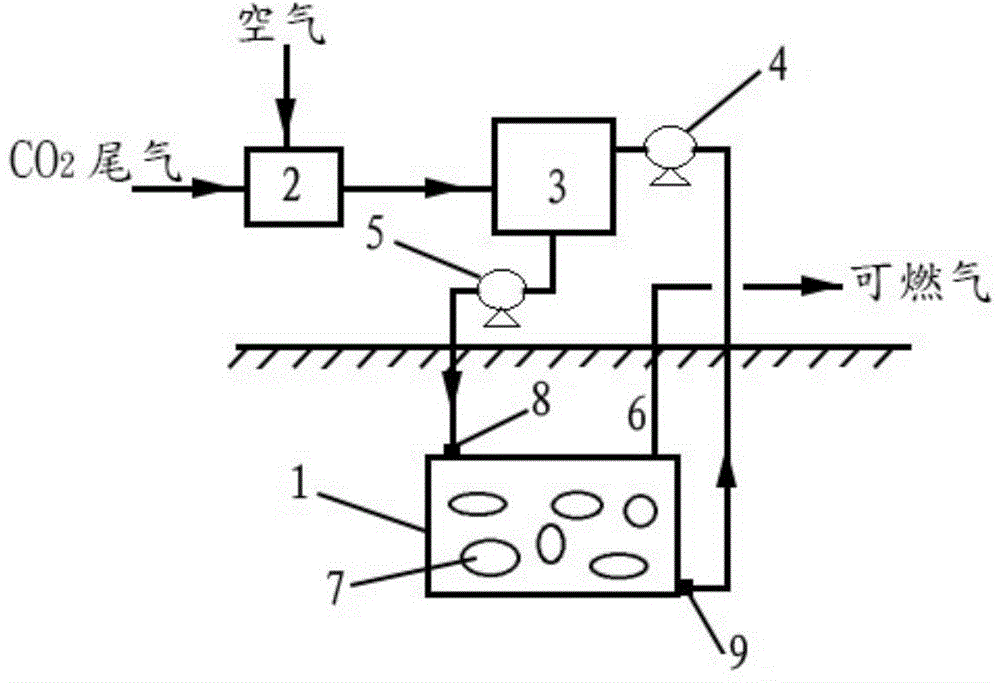

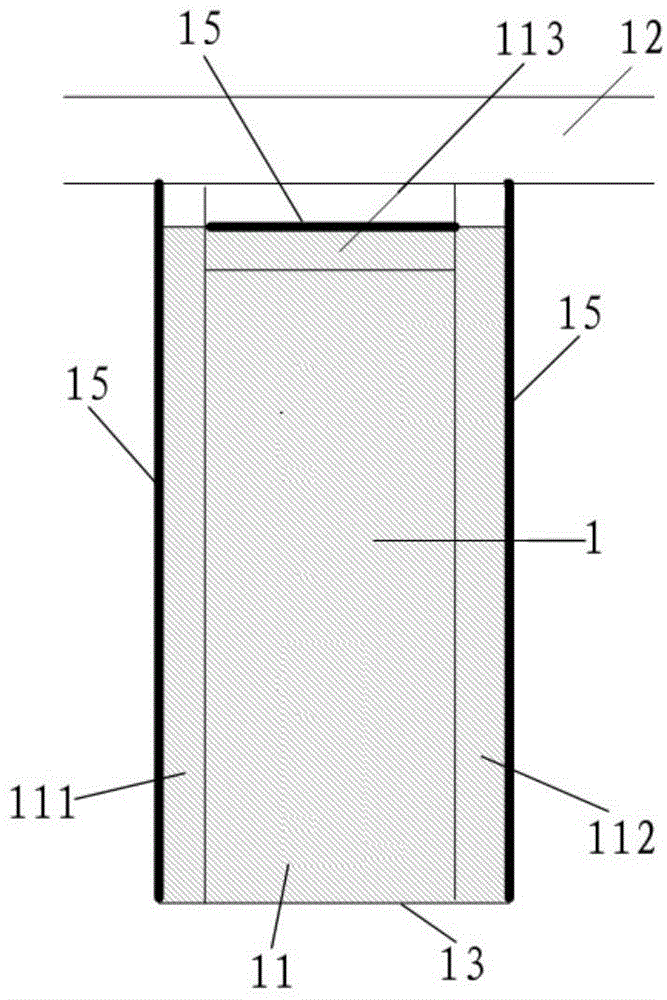

Coal-mine-goaf-based carbon dioxide underground sealing method and system

ActiveCN104962476AConducive to large-scaleEasy to implement continuouslyBioreactor/fermenter combinationsBiological substance pretreatmentsWater sourceAqueous solution

The invention discloses a coal-mine-goaf-based carbon dioxide underground sealing method, belonging to the field of carbon dioxide emission reduction. The method comprises the following steps: injecting a CO2 exhaust-air mixture into a microalgae culture unit as a CO2 source, injecting the algae-containing water solution into an underground sealed space which is formed by reconstructing a coal mine goaf, separating microalgae from the water solution, and drawing the water solution out of the underground sealed space as a water source of the microalgae culture unit. The invention also discloses a coal-mine-goaf-based carbon dioxide underground sealing system. The underground sealed space reconstructed from the coal mine goaf is utilized to implement separation between the microalgae and water, thereby avoiding the problems of water body pollution and low separation cost in the traditional microalgae culture which needs to add the flocculant. The microalgae are fixed into the underground sealed space, thereby avoiding the problem of high cost due to demands for constructing the injection well and monitoring well in the traditional CCS technique, avoiding the problem of CO2 leakage, and further implementing low-cost safe reliable emission reduction of CO2.

Owner:CHINA SHENHUA ENERGY CO LTD

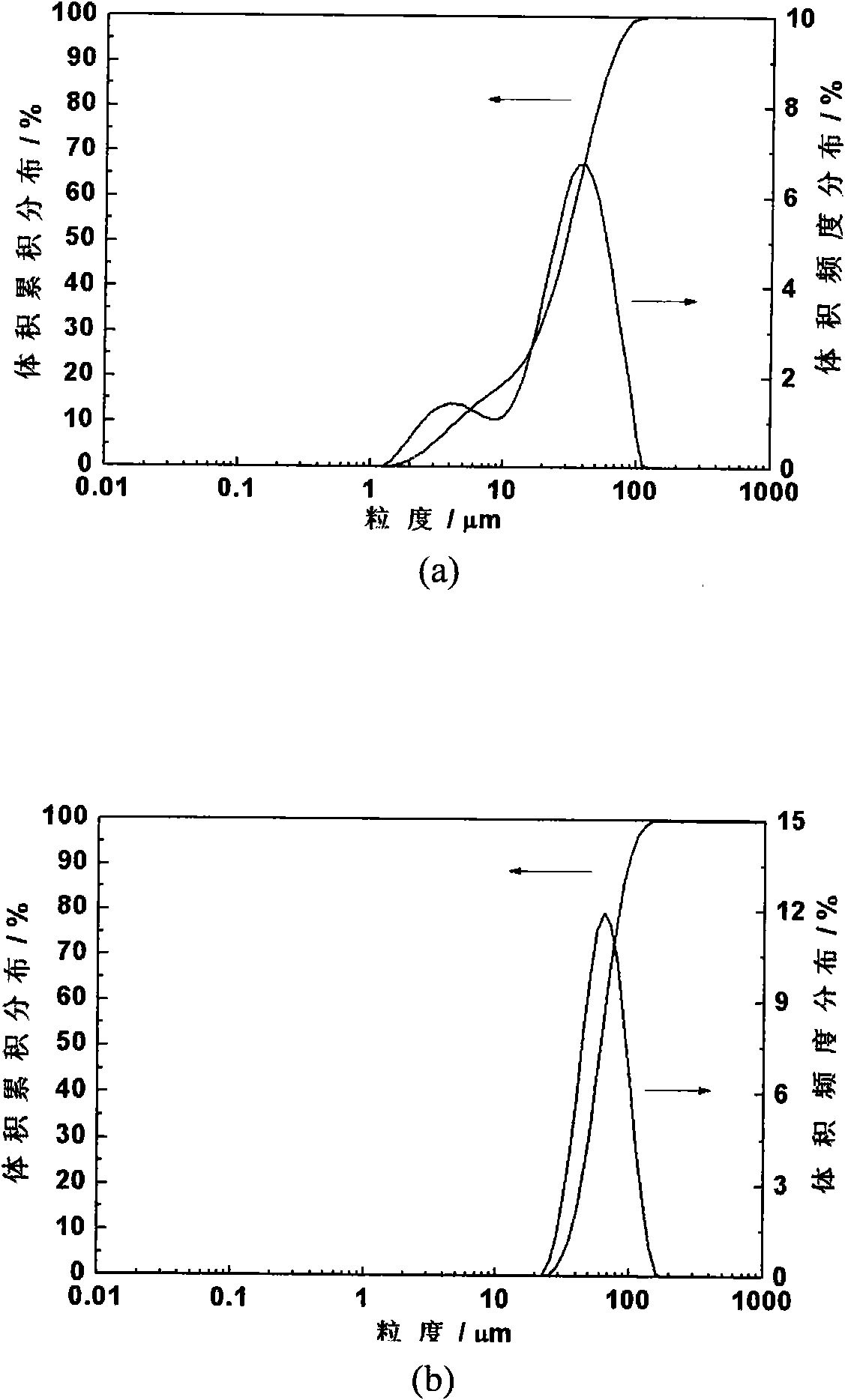

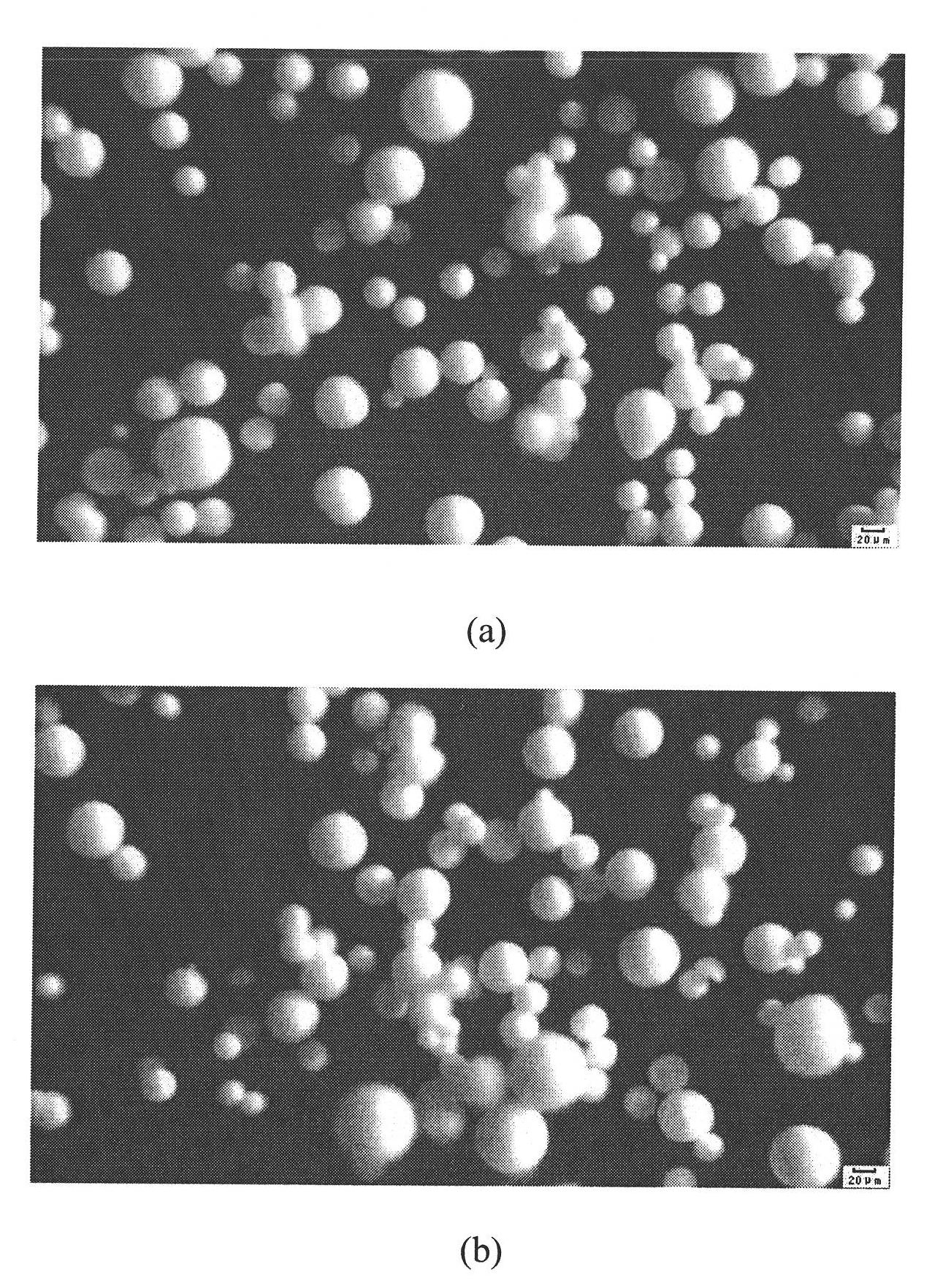

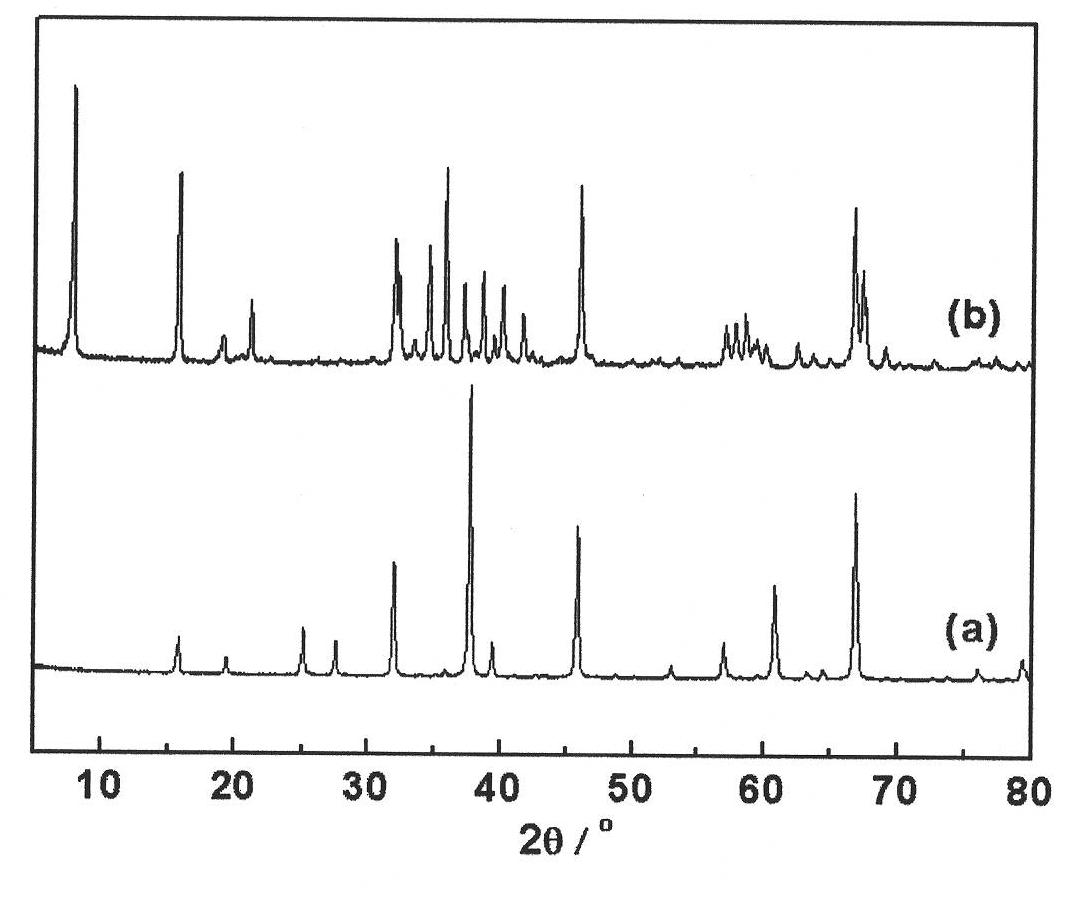

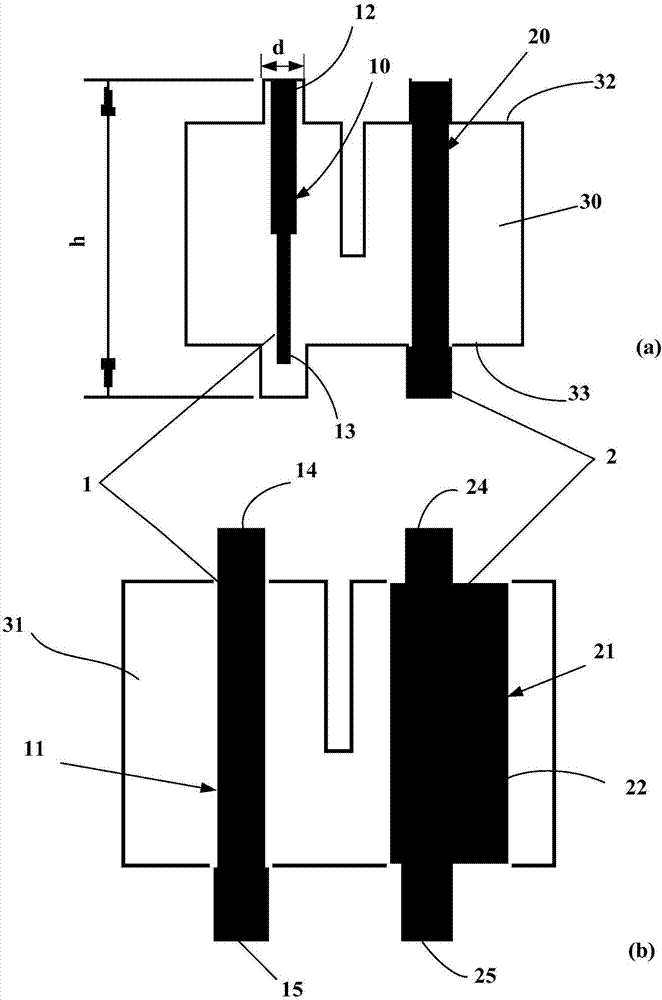

Method for preparing beta-Al2O3 precursor powder by spray drying taking water as medium

The invention relates to a method for preparing beta-Al2O3 precursor powder by spray drying taking water as a medium. The method is characterized by comprising the following steps of: performing ball milling on the medium with deionized water; adding a little amount of water-based dispersing agent; uniformly mixing the mixture by a mechanical ball milling method to obtain slurry; performing spraydrying on the slurry to obtain uniformly-mixed raw material powder particles; and performing high-temperature calcinations treatment on the powder after spray drying to obtain the beta-Al2O3 precursor powder which comprises Na precursor powder and Li precursor powder. The method adopts a water-based slurry spray drying method to solve the problem of potential safety hazard and environmental problem in the process of drying alcohol system slurry and can obtain the mixed powder with high sphericity, high flowability and uniform distribution of particle sizes. The method can obtain the beta-Al2O3 precursor powder with higher activities by performing high-temperature treatment on the powder at the temperature of between 800 and 1,250 DEG C, and is suitable for molding and preparing beta-Al2O3electrolytic ceramic components with high performance.

Owner:上海电气企业发展有限公司

Feed structure, antenna unit and multi-array antenna

PendingCN107171062AMiniaturizationHigh gainRadiating elements structural formsAntennas earthing switches associationControl theoryMechanical engineering

The invention discloses a feed structure, an antenna unit and a multi-array antenna. The feed structure comprises supporting sheets and feed baluns; the maximum height of each supporting sheet is 16-19mm in the vertical direction; the feed balun is attached to the surface of the corresponding supporting sheet in the vertical direction; and each feed balun comprises a positive electrode balun and a grounding balun. By means of thinning the positive electrode balun and thickening the grounding balun, the optimized antenna performance can be obtained, and the compact antenna structure and the large-scale antenna are formed.

Owner:TONGYU COMM INC

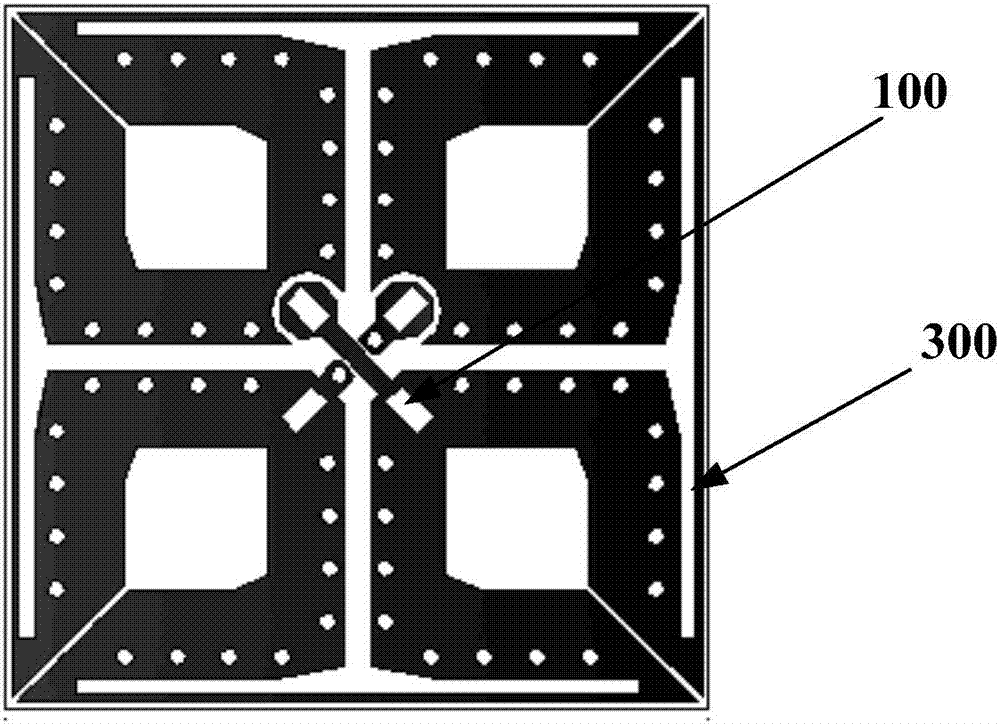

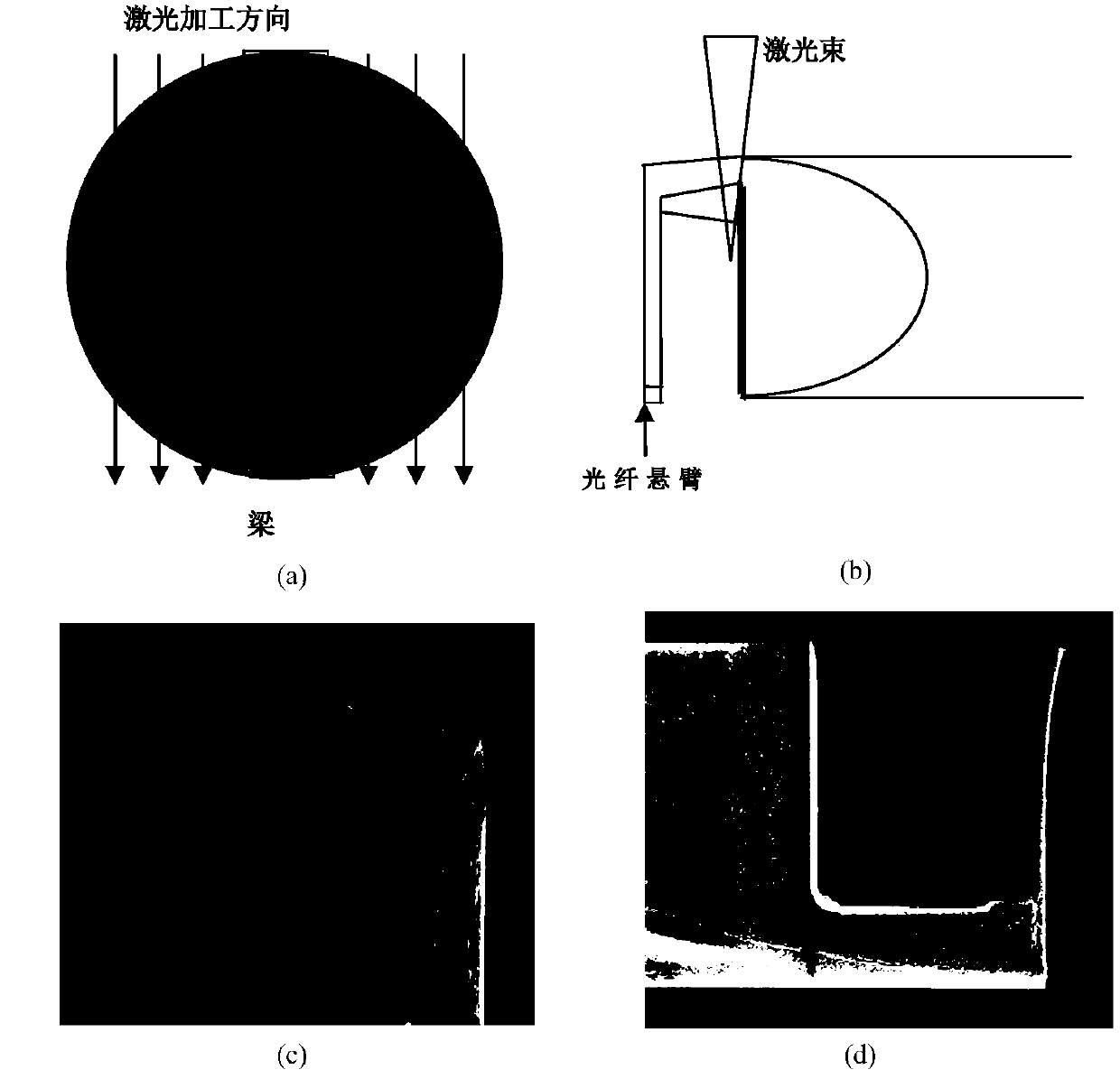

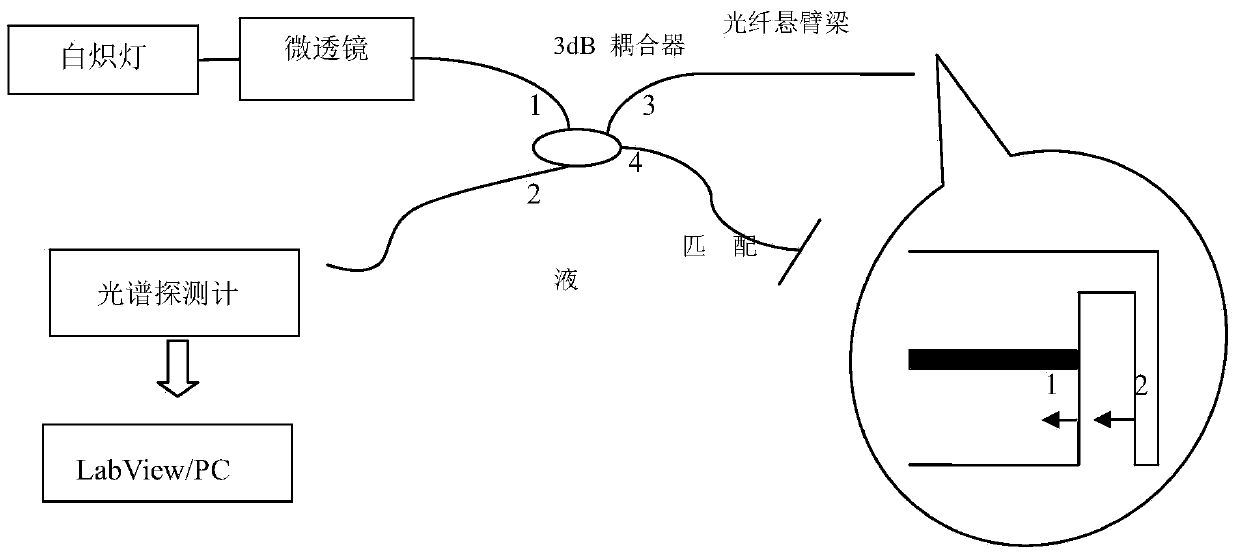

Optical fiber cantilever beam sensor for food pathogenic bacteria and detection method

InactiveCN104215607AEasy to integrateReduce detection stepsPhase-affecting property measurementsAntigenBroadband

The invention provides an optical fiber cantilever beam sensor for food pathogenic bacteria and a detection method. A single-mode optical fiber is etched by using ultra-short laser pulse and a cantilever beam with a rectangular shape is finally formed on one end face of the single-mode optical fiber; a Fabry-Perot cavity is formed by the cantilever beam and the end face of the single-mode optical fiber; after a process of plating a gold film on the surface, pathogenic antigens to be detected are uniformly adsorbed on the surface of the cantilever beam; the optical fiber cantilever beam sensor is completely immersed into a solution containing pathogenic antigens; the cantilever beam is deformed and bent due to the specific bonding of the antibodies and the antigens; the size of the deformation amount reflects concentration information of the pathogenic bacteria in a solution to be detected; a signal demodulating system takes a common incandescent light bulb as a light source to generate broadband spectral information; the standard Fabry-Perot cavity is formed by one face of the cantilever beam and the end face of the single-mode optical fiber; and lengths of two faces in phase information can be demodulated. The optical fiber cantilever beam sensor has the advantages of high sensitivity, high detection speed and small needed detection samples.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

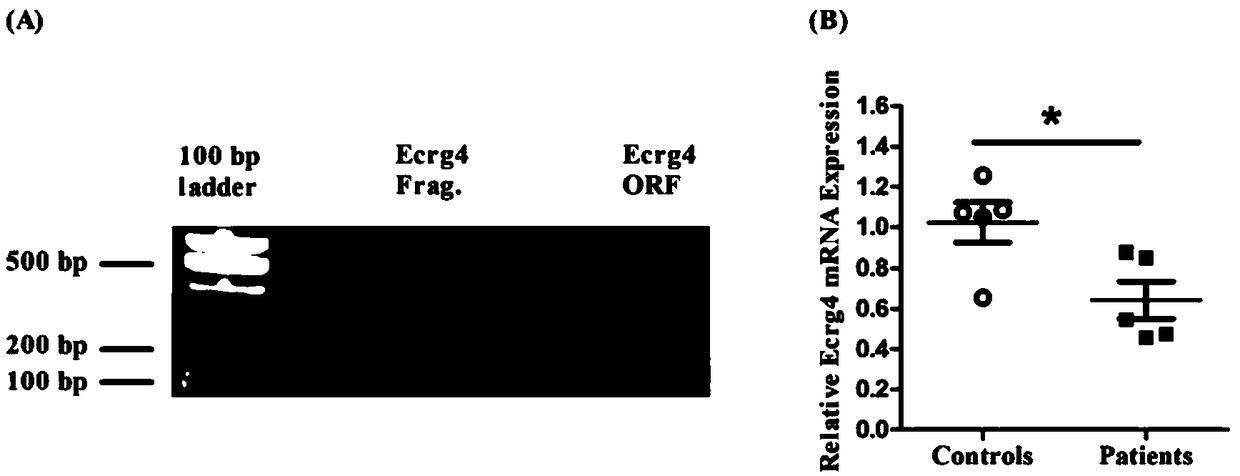

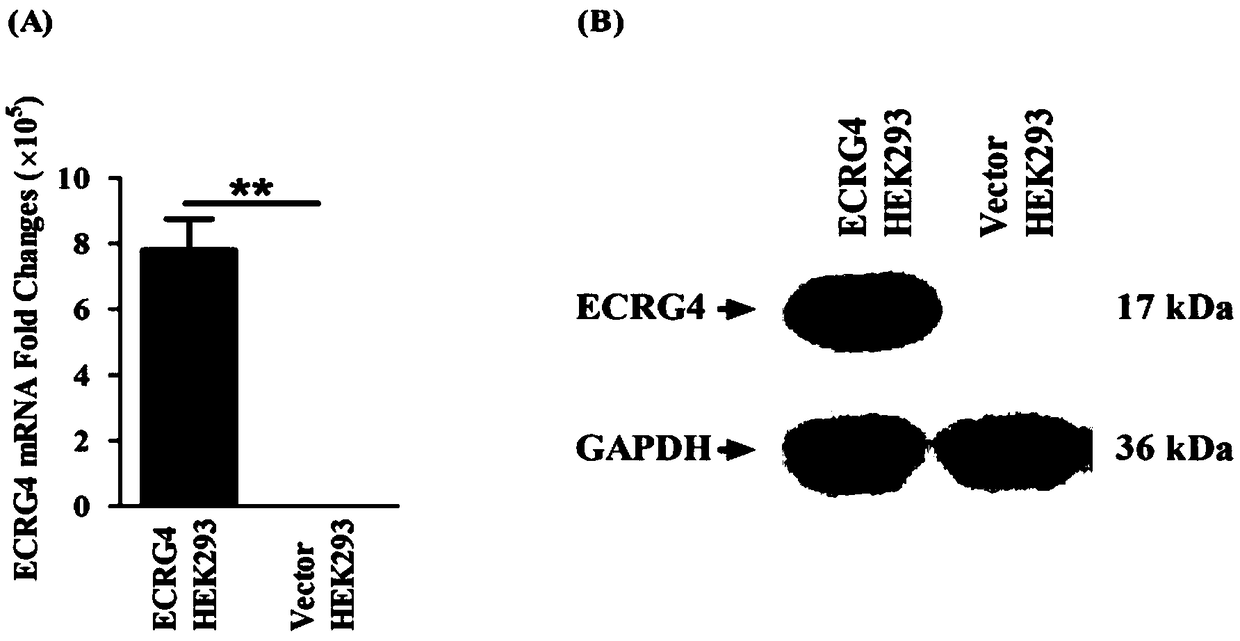

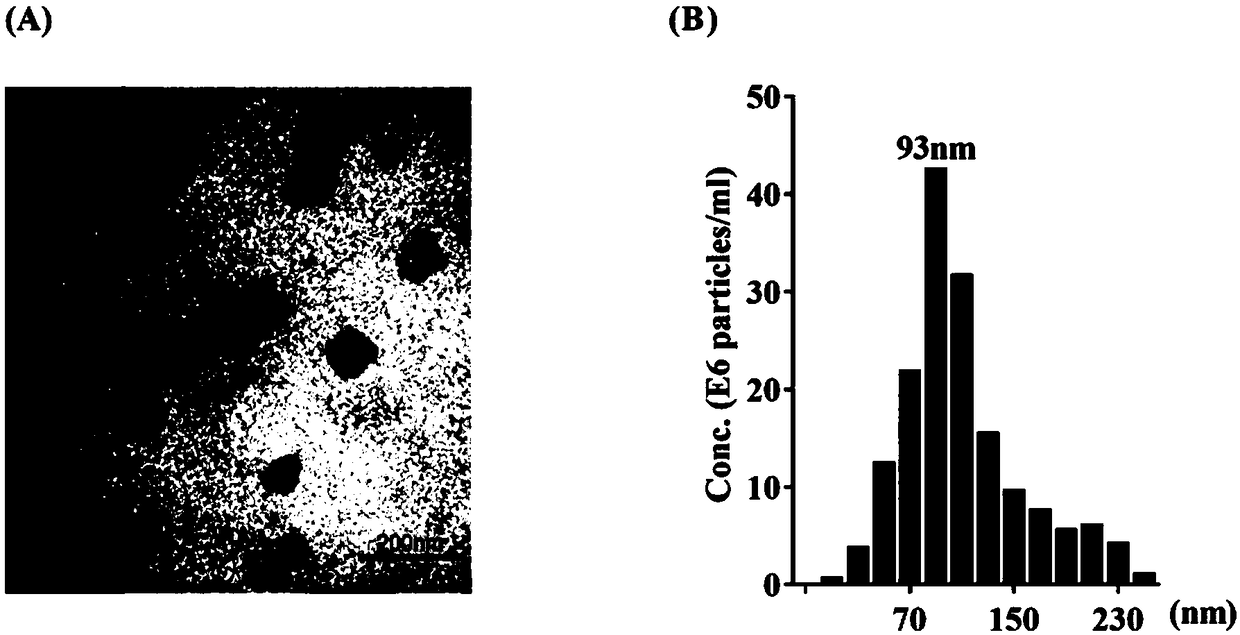

Exosome containing ECRG4 mRNA and preparation method and application of exosome

ActiveCN108753726AHigh expressionGrowth inhibitionGenetically modified cellsFermentationWilms' tumorSide effect

The invention discloses an exosome containing ECRG4 mRNA and a preparation method and application of the exosome. The exosome is loaded with ECRG4 mPNA generated by a cell for overexpression of an ECRG4 gene, and can convey the ECRG4 mPNA in a recipient cell, so that the expression level of the recipient cell ECRG mRNA is remarkably improved, and the proliferation / growth of a tumor cell, the angiogenesis and the expression of inflammatory response related genes are inhibited; meanwhile, the compatibility of the exosome and the recipient cell is high, the immunoreaction and the inflammatory response of a recipient are not caused, and toxic and side effects of gene treatment can be remarkably reduced; the exosome can remarkably inhibit the proliferation / growth of the tumor cell; and the exosome has a positive effect of treating tumor diseases.

Owner:SOUTHWEST MEDICAL UNIVERISTY

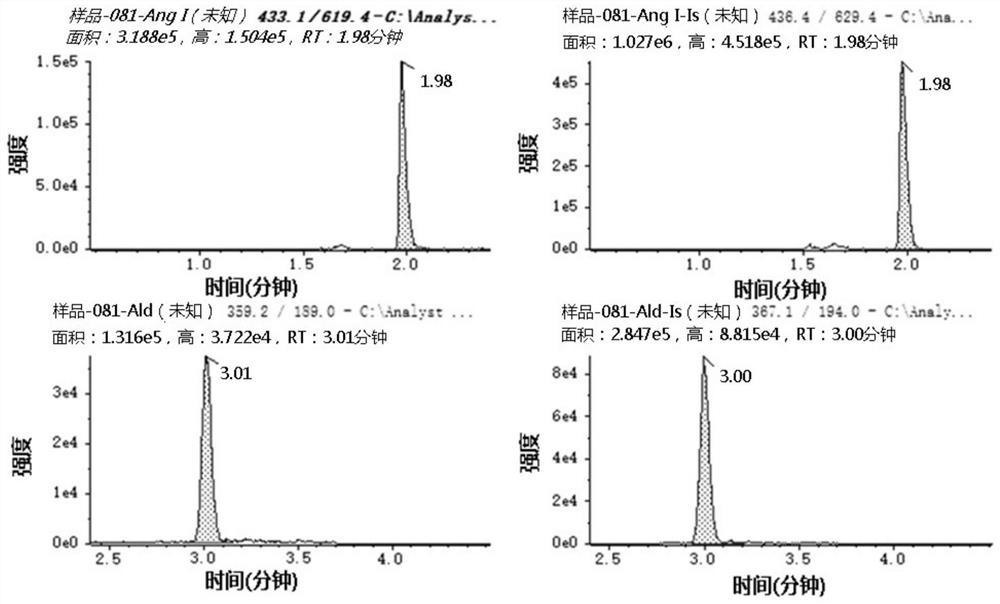

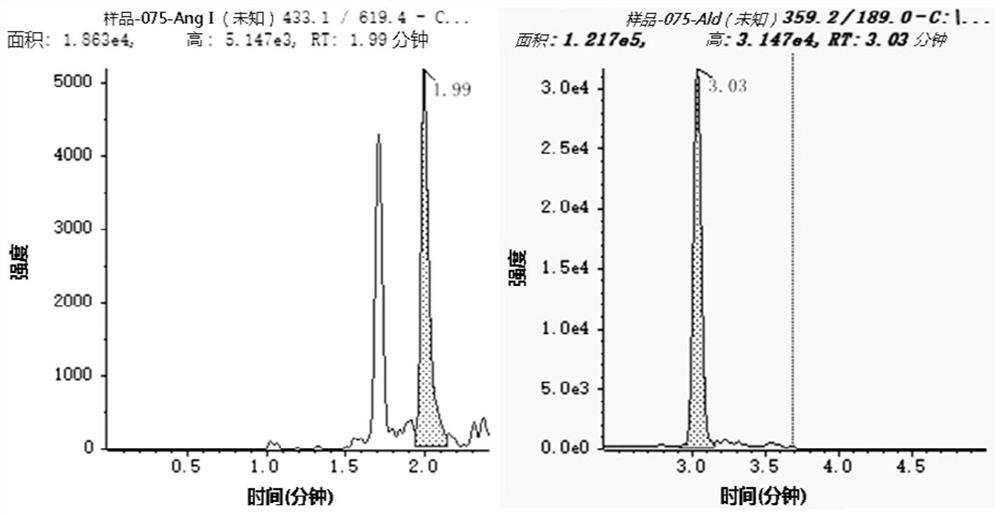

Method for synchronously determining angiotensin I and aldosterone in sample

PendingCN112014509AConducive to large-scaleEasy to operateComponent separationFluid phaseSolid phase extraction

The invention relates to a method for synchronously determining angiotensin I and aldosterone in a sample. Specifically, the invention provides the method for synchronously determining the contents ofangiotensin I (Ang I) and aldosterone (Ald) in a sample. The method comprises the following steps: (a) carrying out solid-phase extraction treatment on the sample; and (b) analyzing the sample treated in (a) through liquid chromatography tandem mass spectrometry, and determining the amount of Ang I and the amount of Ald therein, wherein the mass spectrum adopts a positive ion mode and negative ion mode switching mode for scanning. The invention also provides a system for synchronously determining angiotensin I and aldosterone content in the sample, and methods and systems for obtaining the aldosterone content and ratio (ARR)of the aldosterone to renin activity in the sample.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV +2

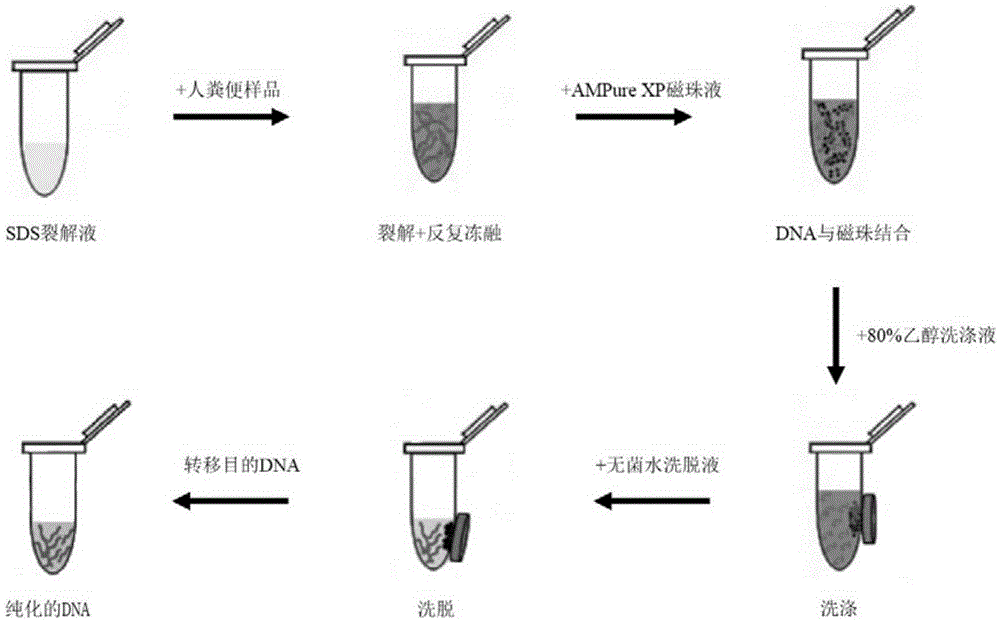

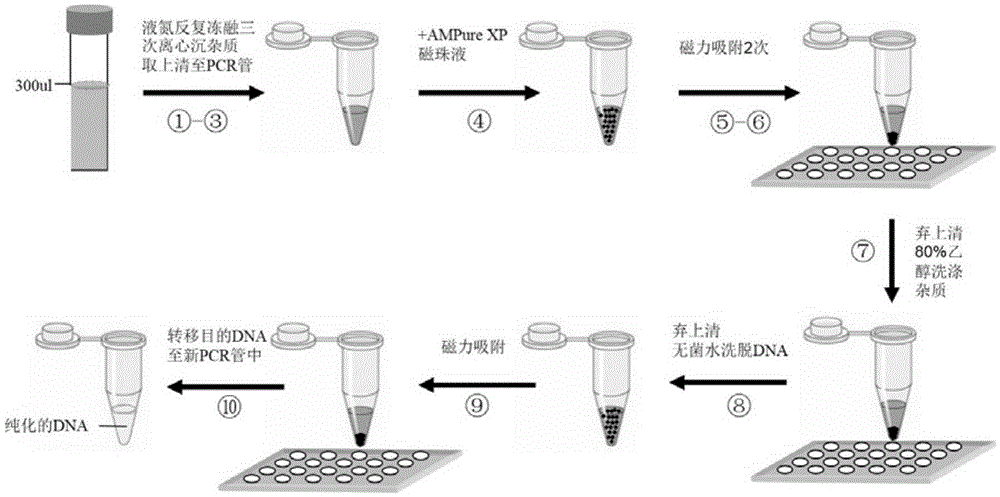

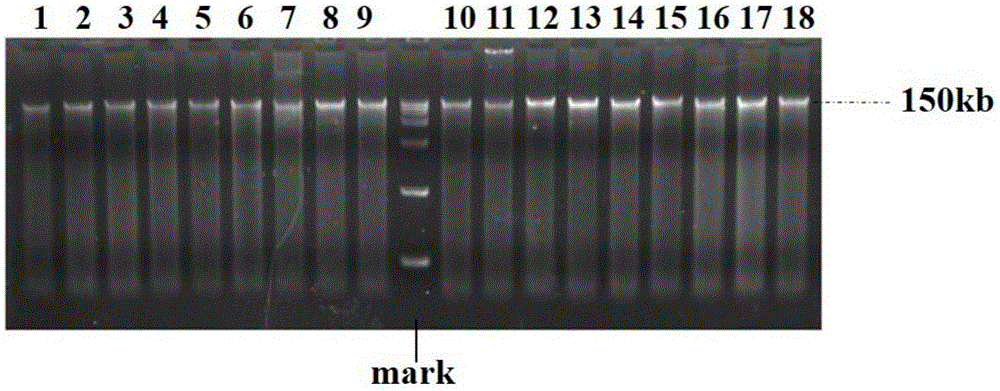

Simple method for fast extracting human fecal bacterium DNA

The invention discloses a simple method for fast extracting human fecal bacterium DNA. The simple method sequentially includes the following steps that hot-cold rupturing treatment is carried out on a human fecal sample to rupture cells; the DNA is captured through AMPure XP magnetic bead liquid; magnetic force adsorption of magnetic beads and a magnetic separation frame is used for removing impurities and purifying the DNA. According to the extracting method, as a physical method (liquid nitrogen freeze thawing) and magnetic bead purification are organically combined, one operator can extract about 100 samples at the same time within one hour, which has great significance in comprehensively and fast researching people group intestinal floras and related disease occurrence mechanisms.

Owner:HANGZHOU GUHE INFORMATION TECH CO LTD

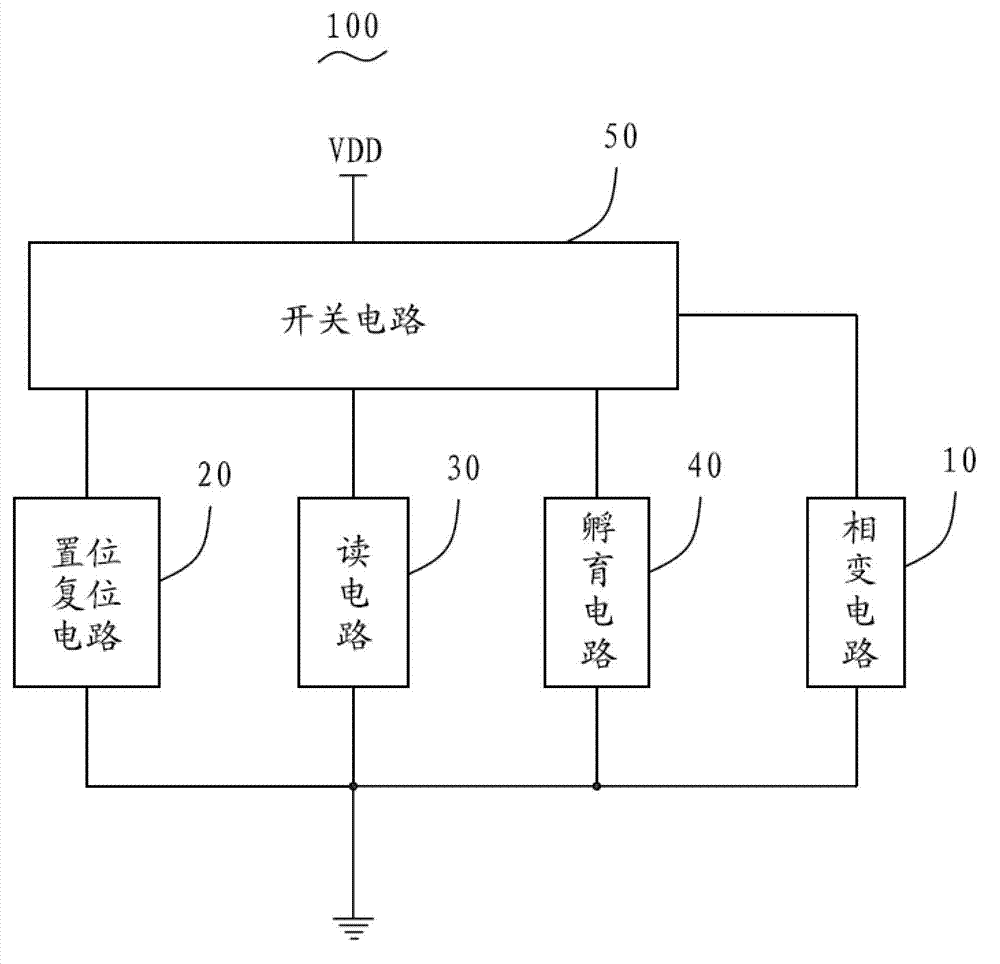

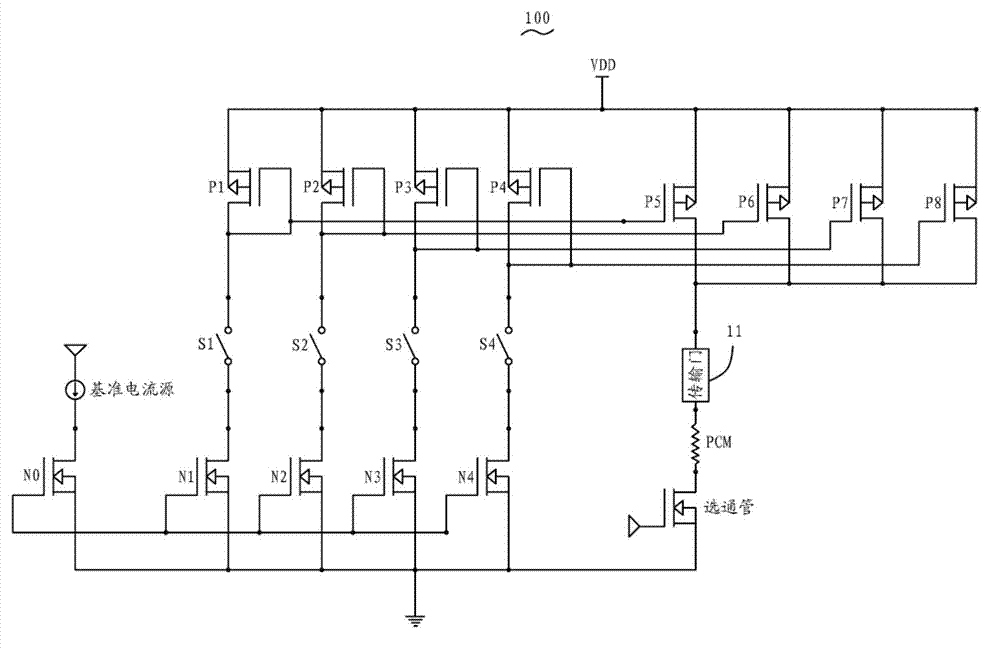

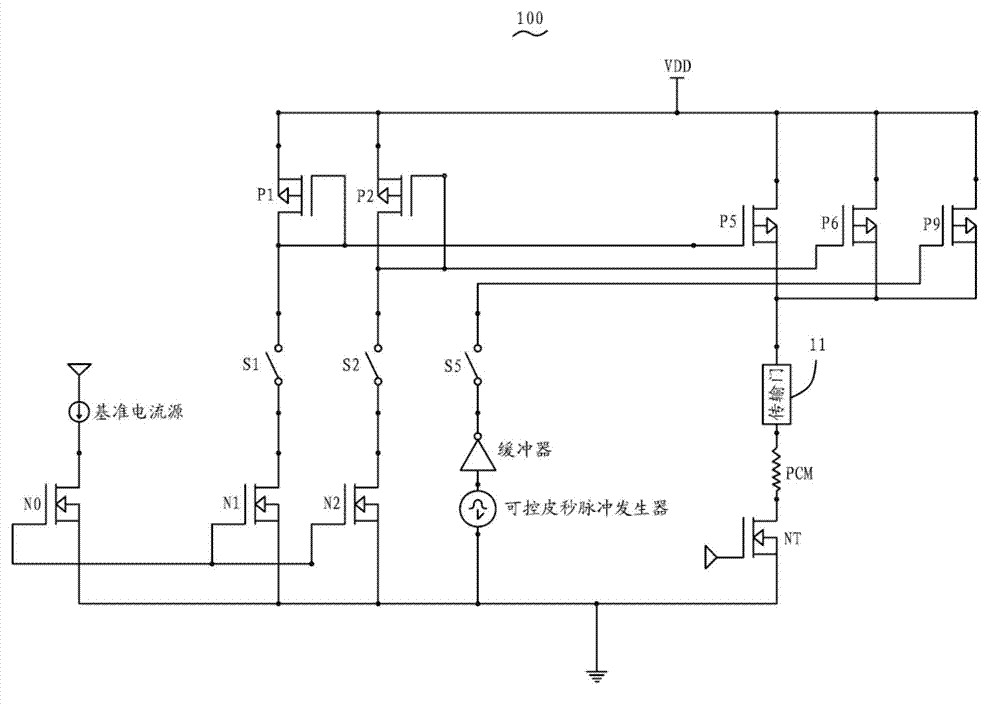

Phase change memory driving circuit and setting and resetting method

ActiveCN103093816AFast phase changeReduce power consumptionRead-only memoriesDigital storagePhase-change memoryNanosecond

The invention provides a phase change memory driving circuit which comprises a phase change circuit, a setting and resetting circuit used for providing setting current and resetting current, a reading circuit used for providing reading current, and a switching circuit used for controlling a pulse timing sequence of operating current, wherein one end of each of the phase change circuit, the setting and resetting circuit and the reading circuit are connected with the switching circuit, and the other ends of the phase change circuit, the setting and resetting circuit and the reading circuit are grounded. The phase change memory driving circuit also comprises an incubation circuit, wherein the incubation circuit is used for providing nanosecond order incubation current for the phase change memory; and one end of the incubation circuit is connected with the switching circuit, and the other end of the incubation circuit is grounded. According to the phase change memory driving circuit, the phase change speed of the phase change memory is increased, and the power consumption is reduced, so that large-scale production of the phase change memory can be realized. The invention also provides a setting and resetting method for the phase change memory.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

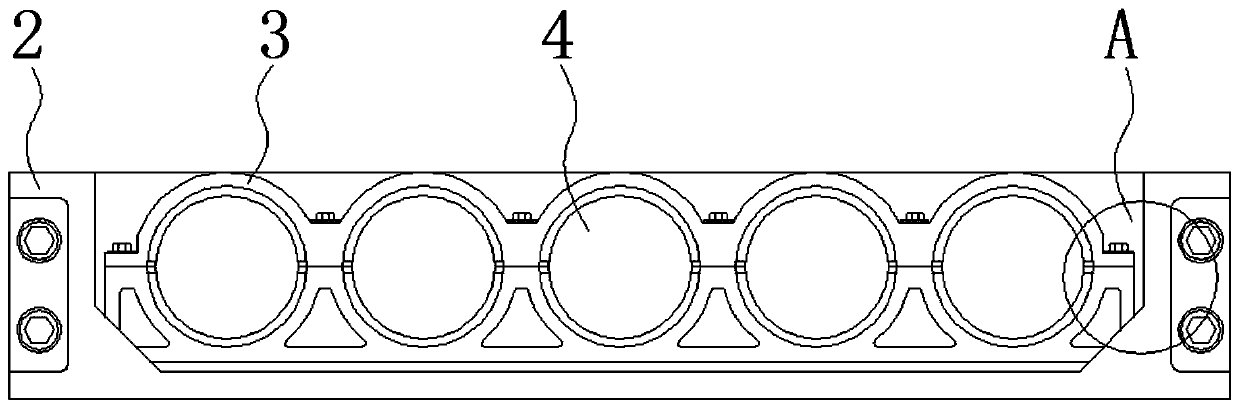

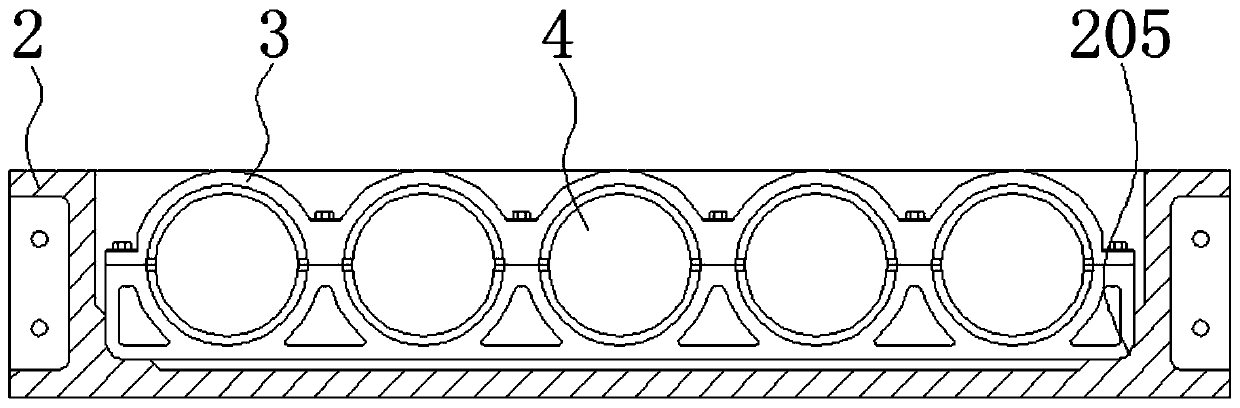

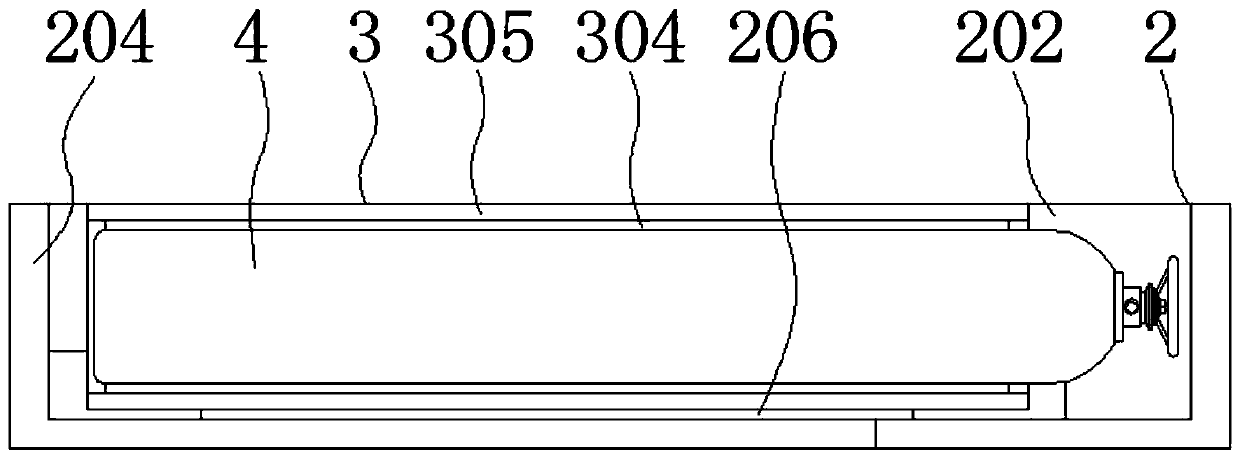

Highly integrated passenger car hydrogen cylinder group structure

PendingCN110065386APossibility to achieve great rangeIncrease storage capacityFuel supplyVehicle frameFuel cells

The invention relates to the technical field of a hydrogen cylinder group installation mode, in particular to a highly integrated passenger car hydrogen cylinder group structure. The highly integratedpassenger car hydrogen cylinder group structure includes a car frame and a hydrogen cylinder body. A framework mechanism is arranged at the bottom of the middle part of the car frame. A fixed mechanism includes a fixed plate, lightening holes, fixed screws, a rubber blanket, a movable pressing plate and connecting screws. The fixed screws are mounted at the rear end of the fixed plate, the fixedmechanism is internally provided with thehydrogen cylinder body. According to the highly integrated passenger car hydrogen cylinder group structure, the improved hydrogen cylinder group realizes the possibility of a large range of a small car without occupying layout space, and the design basis for miniaturization of a fuel cell passenger car is provided, and compared with the traditional layout mode of a hydrogen cylinder group, hydrogen storage capacity is greatly improved, the driving range of a whole car is improved, the NEDC driving range of the whole car reaches more than 800km, and useneeds of people are effectively met.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

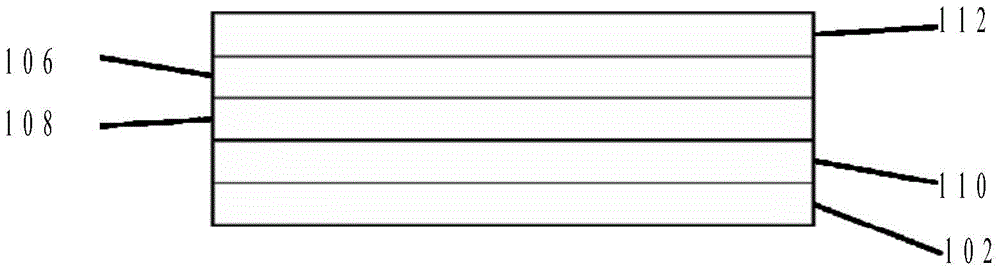

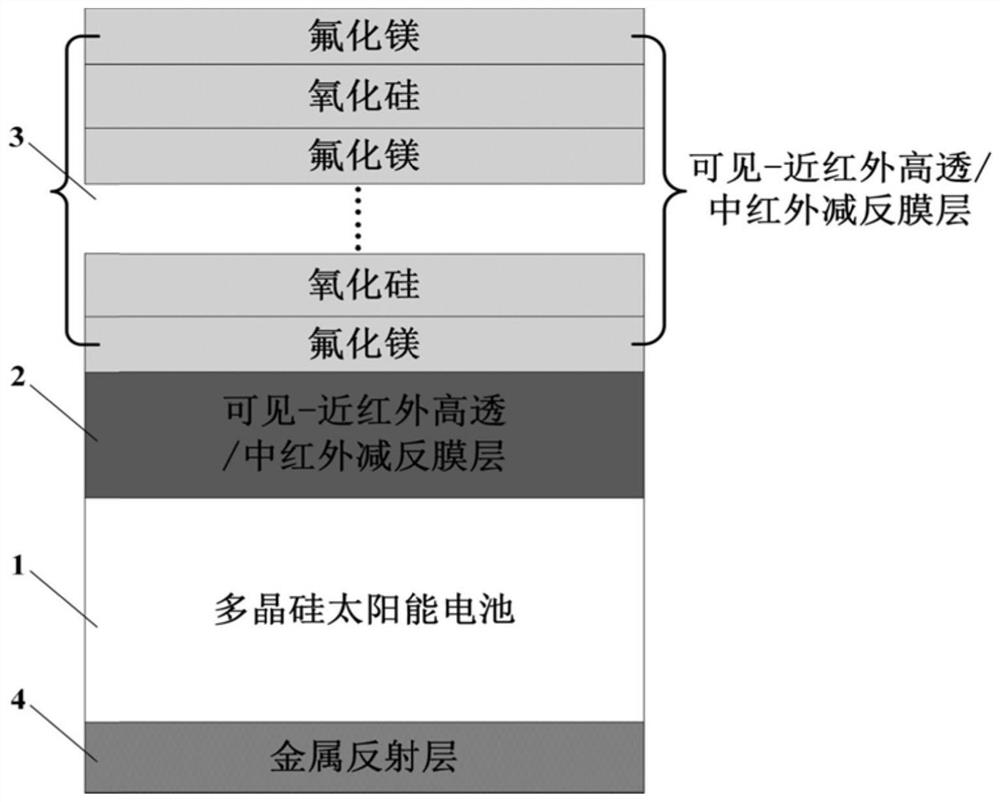

Silicon based titanium dioxide electroluminescent device and method for producing the same

InactiveCN101097980ASimple structureEasy to implementSemiconductor devicesTitanium metalSputter deposition

The invention discloses a silicon-base titania electroluminescent device, wherein the front face of the silicon substrate is deposited with a TiO2 film and a transparent ITO electrode from down to up, the back of the silicon substrate is deposited with a Ohm contact electrode. And the preparation comprises that first washing P-type or N-type silicon slice to be input into a reaction room of direct-current reaction magnetic-control splash device, vacuuming the reaction room, using pure titanium metal as target, using O2 and Ar as splash gas, to process splash deposition to obtain a TiO2 film, then splashing an ITO electrode on the TiO2 film, depositing an Ohm contact electrode at the back of the silicon substrate. The invention has simple structure and preparation, while the electroluminescent lighting peak is around 370nm and 600nm. The preparation is compatible with prior silicon device plane art, which support the batch production with low cost.

Owner:ZHEJIANG UNIV

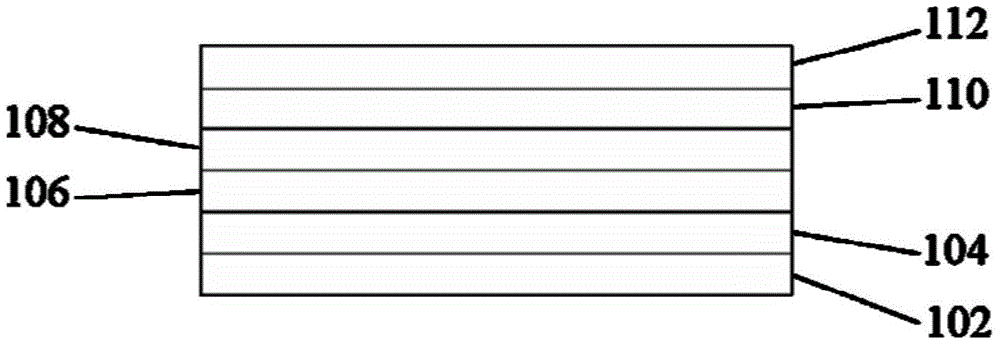

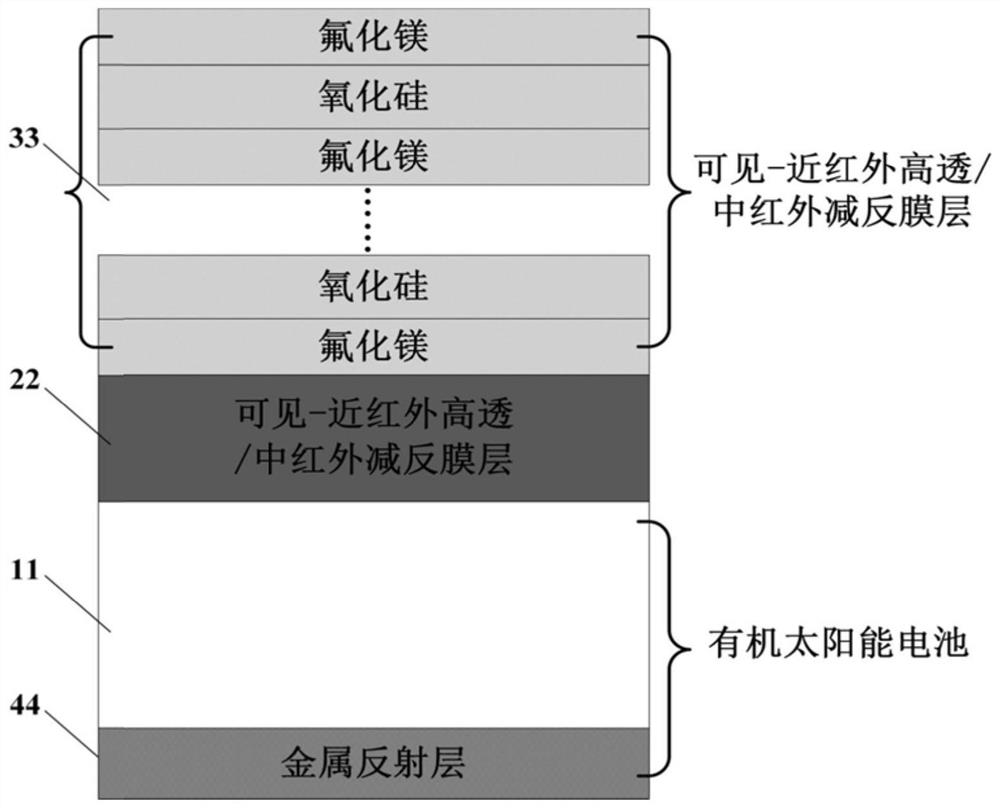

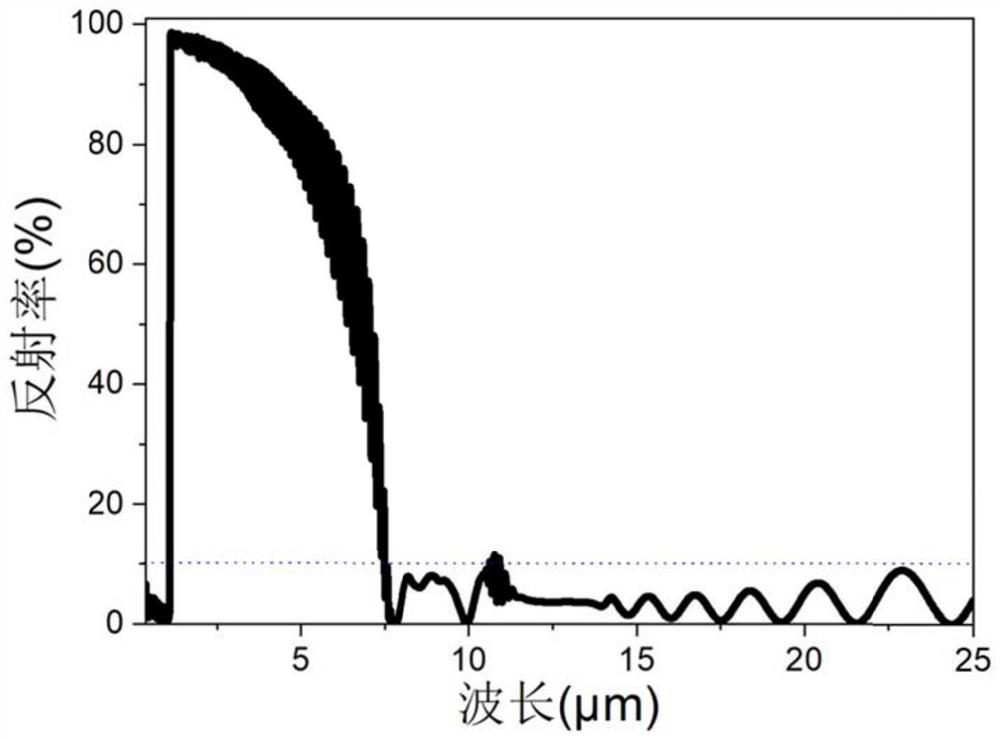

Radiation refrigeration solar cell module

ActiveCN112086522AWork lessImprove survivabilitySolid-state devicesSemiconductor/solid-state device manufacturingMiddle infraredElectrical battery

The invention discloses a radiation refrigeration solar cell module, which comprises a solar cell, and the bottom surface of the solar cell is provided with a metal reflection layer; the top surface of the solar cell is provided with a visible near-infrared high-transmittance / intermediate-infrared absorption film layer and a visible near-infrared high-transmittance / intermediate-infrared anti-reflection film layer, and the visible near-infrared high-transmittance / intermediate-infrared absorption film layer is located between the top surface of the solar cell and the visible near-infrared high-transmittance / intermediate-infrared anti-reflection film layer. Light is incident from the visible near-infrared high-transmittance / intermediate-infrared anti-reflection film layer. Therefore, the radiation refrigeration solar cell is expected to be widely applied to the aspects of photovoltaic power generation, electromagnetic detection, energy utilization, refrigeration and the like, and contributes to the fields of national economy, social development, science and technology, national defense construction and the like in China.

Owner:ZHEJIANG UNIV

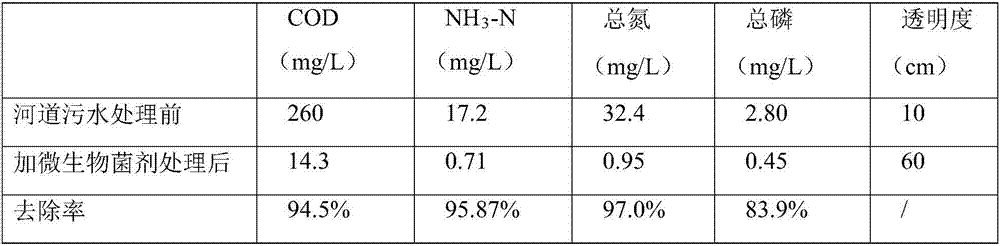

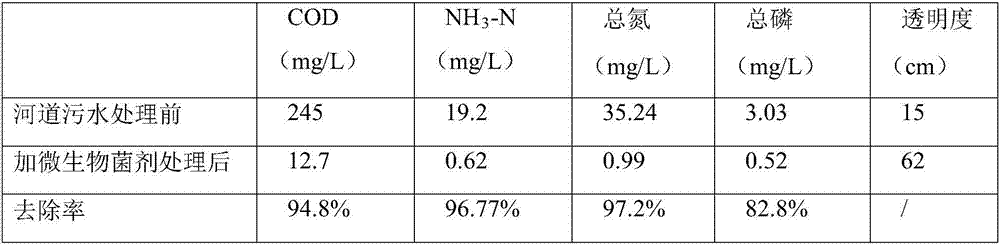

Compound microbial agent for river regulation, preparation method of compound microbial agent and river sewage treatment method

InactiveCN106987535AAdaptableGrowth inhibitionFungiBacteriaBacillus licheniformisSuspended particles

The invention discloses a compound microbial agent for river regulation, a preparation method of the compound microbial agent and a river sewage treatment method. In the compound microbial agent, a microbial agent A is made by mixing of five fermentation liquors formed by single culture of bacillus megaterium CCTCC NO.M2012352, bacillus subtillis CGMCC NO.1.2162, bacillus licheniformis CGMCC NO.1.6510, bacillus amyloliquefaciens CGMCC NO.1.7463 and phanerochaete chrysosporium BKM-F1767; a microbial agent B is made by mixing of two fermentation liquors formed by single culture of debaryomyces hansenii CGMCC NO.5770 and saccharomyces cerevisiae CGMCC NO.3003. The compound microbial agent has advantages that amino nitrogen and nitro nitrogen in water can be degraded, phosphorus concentration is decreased, and precipitation of solid suspended particles, bacterial cells and colloid particles in water is realized.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

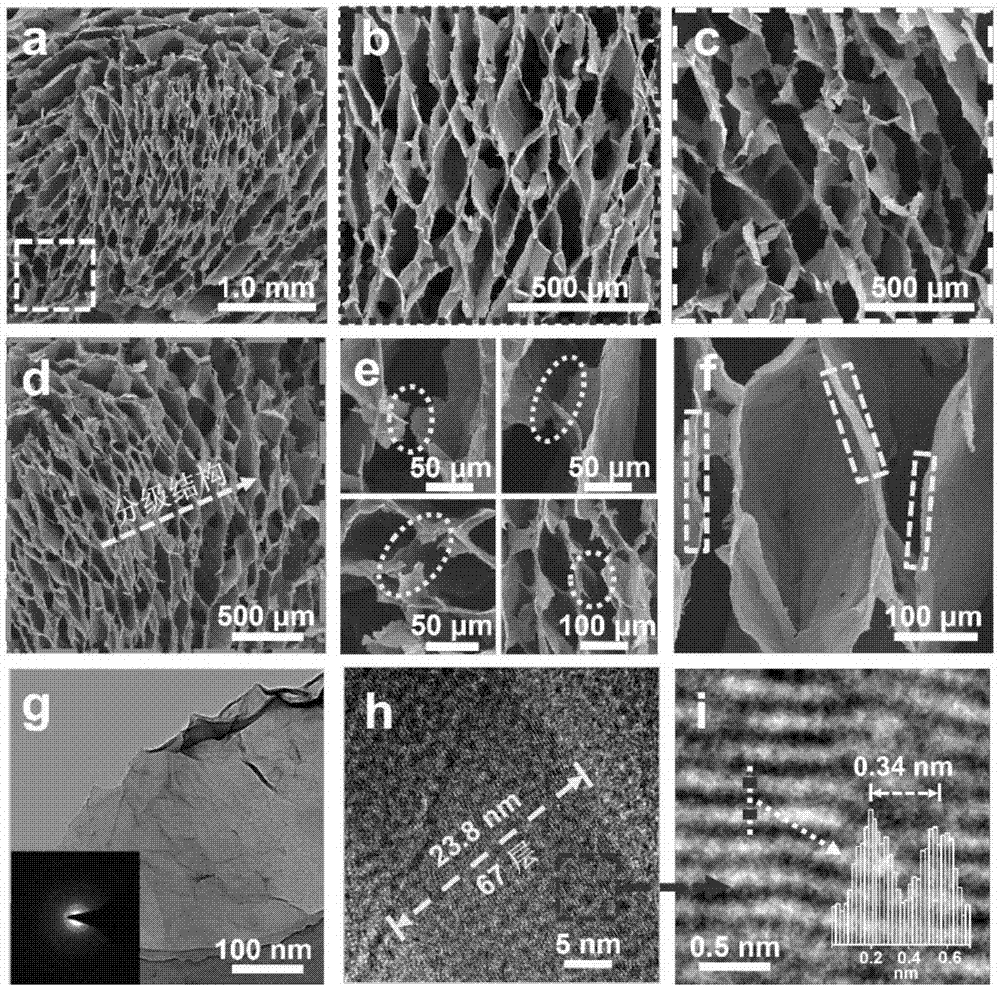

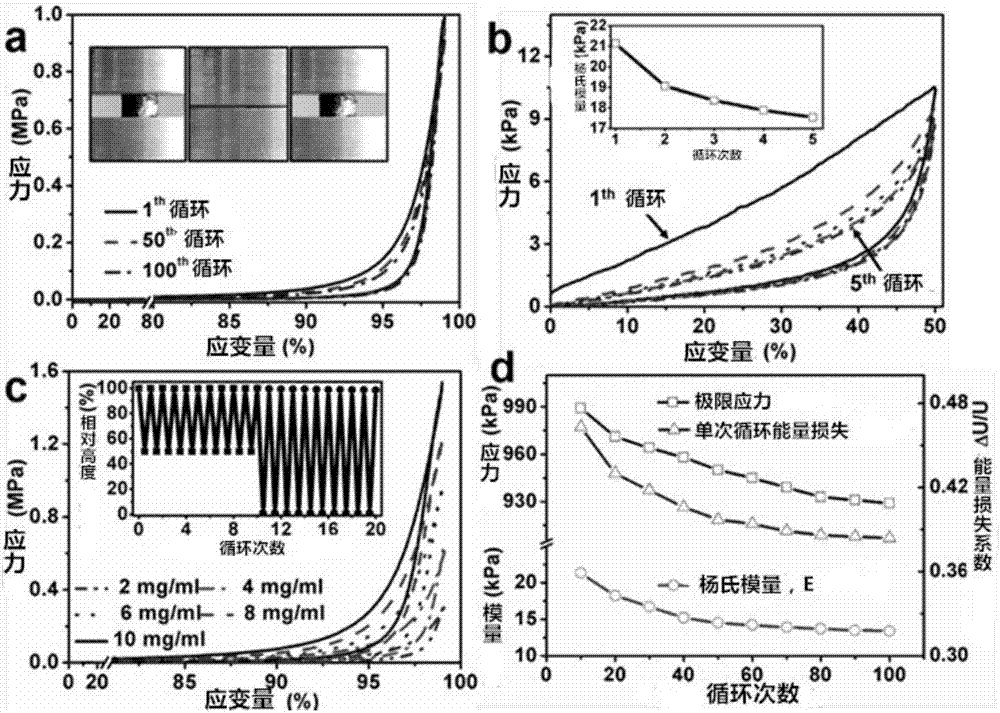

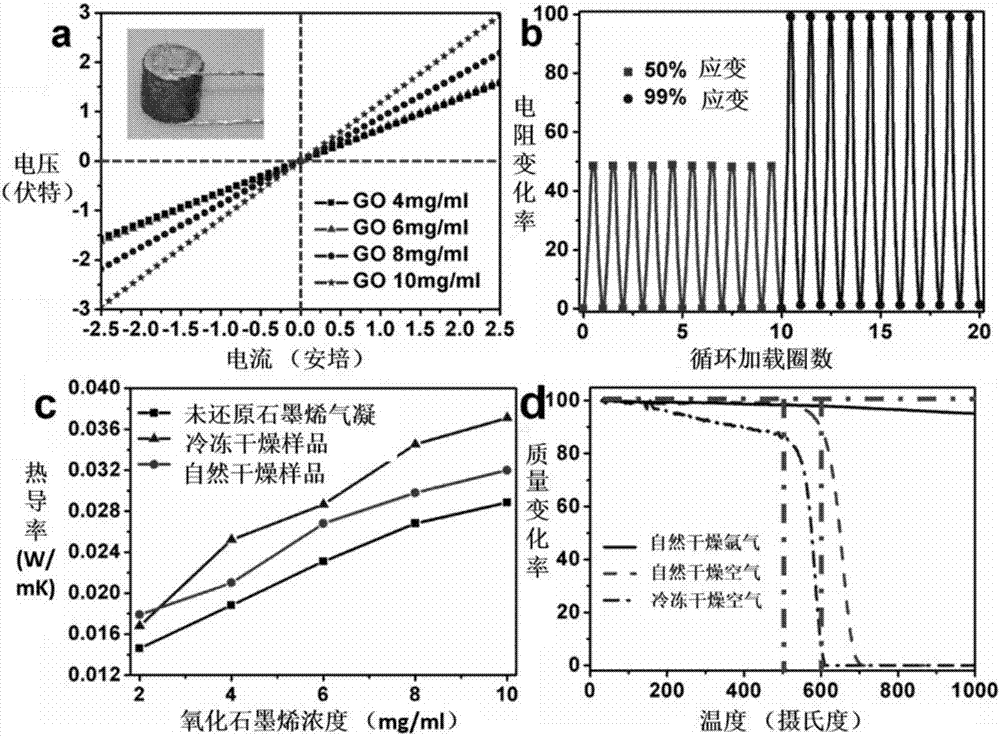

A kind of graphene airgel natural drying preparation method

ActiveCN106006615BConducive to large-scaleFacilitating large-scale preparationGrapheneEthylenediaminePolymer science

Owner:HARBIN INST OF TECH

Graphite solid waste recycling method

The invention relates to a graphite solid waste recycling method, which is characterized by comprising the following steps: (1) mechanically scrubbing graphite tailings for 0.2-1 hour; (2) feeding into a high-temperature kiln, and calcining at 650-900 DEG C for 1-3 hours; (3) after calcining, pouring into a cold water pool, then transferring to a flotation machine, adjusting the pH value of the ore pulp to 2-3 by using HCl or H2SO4, adding a collecting agent with the weight of 20-50g / t of the ore pulp, and carrying out reverse flotation operation; (4) drying the flotation tailings, transferring into a reaction kettle, and carrying out acid leaching for 4-8 h at a temperature of 30-80 DEG C; (5) washing with deionized water to be neutral, and drying at 110-150 DEG C for 2-4 hours; (6) after drying, feeding into a high-gradient magnetic separator, and carrying out strong magnetic operation, wherein the magnetic separation intensity is 1T-1.6 T; and (7) grinding the magnetic separation product into a white powder product with the particle size of 400-2500 meshes. According to the invention, the prepared quartz powder with the purity of 99-99.5% is uniform in particle size and stable in property, and can be used as filler to be applied to the industries of plastics, coatings, adhesives, rubber and the like.

Owner:凯盛石墨碳材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com