Silicon based titanium dioxide electroluminescent device and method for producing the same

An electroluminescent device, titanium dioxide technology, applied in electrical components, semiconductor devices, circuits, etc., to achieve the effect of simple structure and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

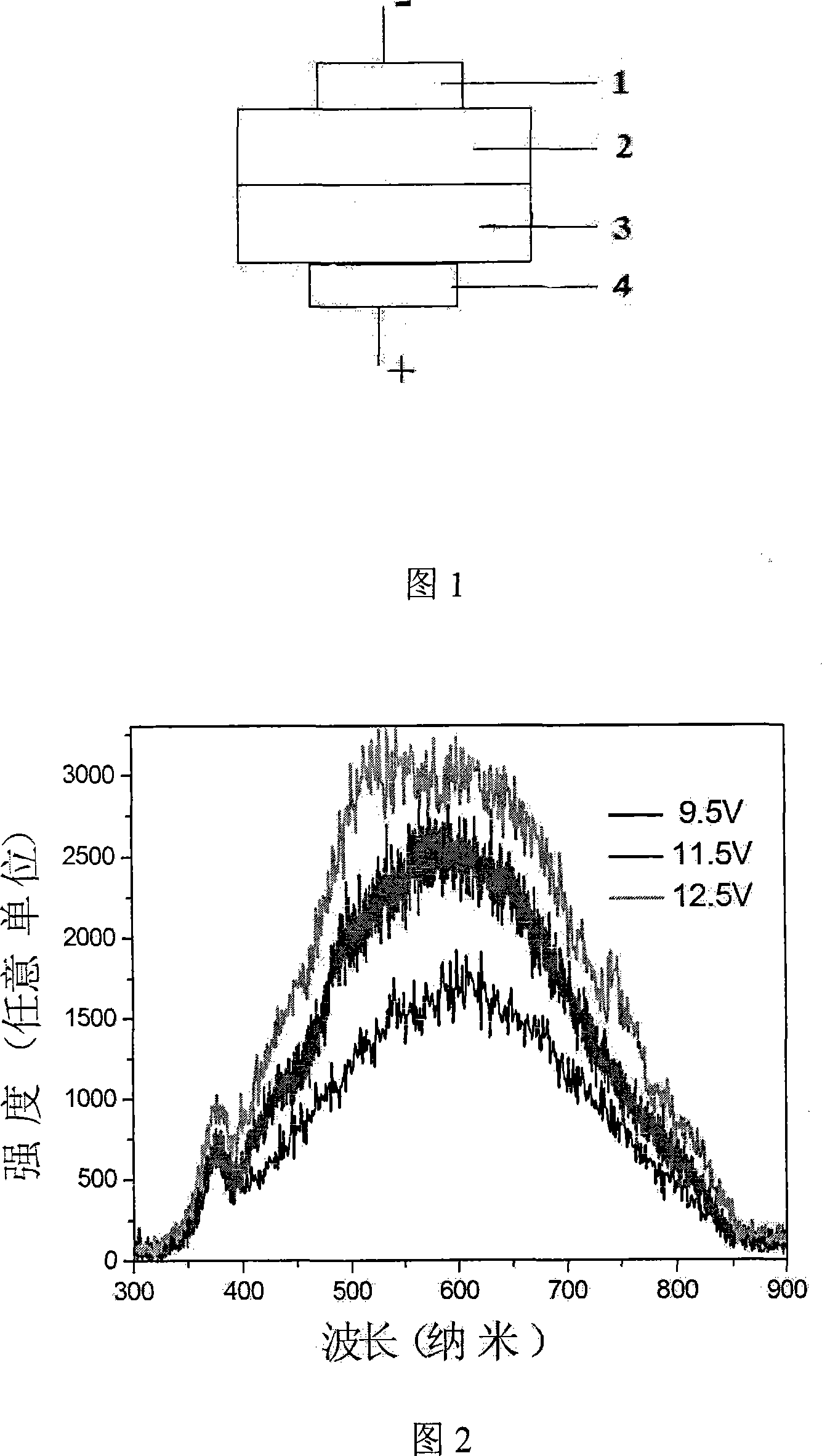

[0016] Take the following process steps: 1) Clean P-type with a resistivity of 0.005 ohm cm and a size of 15×15mm 2 , a silicon wafer with a thickness of 675 microns, after cleaning, put it into the reaction chamber of the DC reactive magnetron sputtering device, and the vacuum degree of the reaction chamber is pumped to 5×10 -3 Pa; Deposit TiO with a thickness of about 100nm on a silicon wafer by reactive DC sputtering 2 When sputtering the thin film, a Ti metal target with a purity of 99.9% is used, the substrate temperature is 100°C, the sputtering power is 70W, and the 2 Mixed gas with Ar, O 2 The flow ratio of Ar and Ar is 1:3, and the working pressure is 0.7Pa; 2) in TiO 2 A 50nm-thick ITO electrode is sputtered on the film, and a 100nm-thick Al is deposited on the back of the silicon as an ohmic contact electrode, both of which have an area of 10×10mm 2 .

Embodiment 2

[0017] Embodiment 2 takes the following process steps: 1) cleaning N-type , with a resistivity of 0.5 ohm cm and a size of 15×15mm 2 , a silicon wafer with a thickness of 675 microns, after cleaning, put it into the reaction chamber of the DC reactive magnetron sputtering device, and the vacuum degree of the reaction chamber is pumped to 5×10 -3 Pa; Deposit TiO with a thickness of about 200nm on a silicon wafer by reactive DC sputtering 2 Thin films, when sputtering, use a Ti metal target with a purity of 99.9%, a substrate temperature of 300°C, a sputtering power of 100W, and an O 2 Mixed gas with Ar, O 2 The flow ratio with Ar is 1:2, and the working pressure is 5Pa; 2) in TiO 2 A 50nm-thick ITO electrode is sputtered on the film, and a 100nm-thick Au is deposited on the back of the silicon as an ohmic contact electrode, both of which have an area of 10×10mm 2 .

Embodiment 3

[0019] Take the following process steps: 1) Clean P-type with a resistivity of 50 ohm.cm and a size of 15×15mm 2 , a silicon wafer with a thickness of 675 microns, after cleaning, put it into the reaction chamber of the DC reactive magnetron sputtering device, and the vacuum degree of the reaction chamber is pumped to 5×10 -3 Pa; Deposit TiO with a thickness of about 150nm on a silicon wafer by reactive DC sputtering 2 Thin films, when sputtering, use a Ti metal target with a purity of 99.9%, a substrate temperature of 400°C, a sputtering power of 120W, and an O 2 Mixed gas with Ar, O 2 The flow ratio with Ar is 1:1, and the working pressure is 10Pa; 2) in TiO 2 A 50nm-thick ITO electrode is sputtered on the film, and a 100nm-thick Al is deposited on the back of the silicon as an ohmic contact electrode, both of which have an area of 10×10mm 2 .

[0020] Figure 2 shows the electroluminescence (EL) spectra of the device obtained by the above method measured at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com