A kind of graphene airgel natural drying preparation method

A graphene aerogel, natural drying technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of limiting the macro size, increasing the production cost and difficulty of graphene aerogel, and achieving low difficulty and low preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of graphene airgel natural drying, as follows:

[0025] 1) Mix 10ml of graphene oxide solution with a concentration of 5mg / ml with 60μm reducing agent ethylenediamine (EDA) and 50μm mass fraction of 5% borax (Na 2 B 4 o 7 ) solutions, ultrasonically disperse the mixed solution for 30 minutes, take 1ml of the mixed solution in a 5ml container bottle, put the container bottle into a reaction kettle for hydrothermal reaction at 120°C for 14 hours to form a hydrogel.

[0026] 2) Dialyze the hydrogel obtained above with a volume fraction of 1% ethanol aqueous solution for 6 hours, place it in a -10°C refrigerator for 12 hours, and finally take out the frozen hydrogel under natural conditions (normal temperature and pressure) ) was dried for 24 hours to obtain graphene airgel with good shape and no large volume shrinkage. The concentration of graphene oxide solution, hydrothermal reduction time, water-alcohol ratio of dialysate and pre-freezing...

Embodiment 2

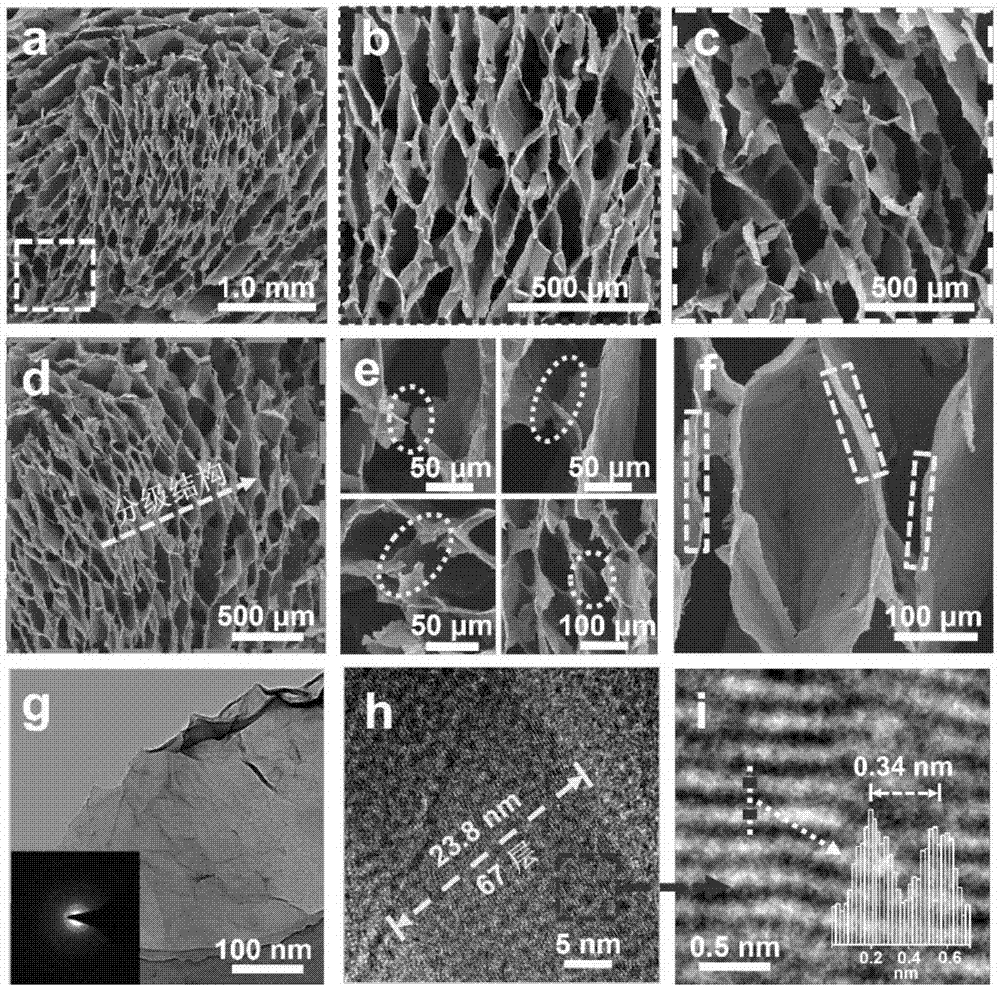

[0028] to combine figure 1 , SEM and TEM characterization tests of the internal porous structure of graphene airgel prepared by natural drying method, as follows:

[0029] The natural drying preparation method of graphene airgel proposed by the present invention is based on the reduction of capillary force produced by the natural volatilization of solvents and the bionic enhancement of the structural rigidity of the airgel itself. Due to the extrusion of ice crystal growth on the airgel structure in the pre-freezing process and the effect of liquid capillary tension in the natural drying process, the final graphene aerogel presents a unique shell-core structure, such as figure 1 as shown in a. The shell-core structure is composed of a regular honeycomb core structure in the middle and a loose shell structure around the periphery. The average pore size of the core structure is 100 microns, and the shell structure is 200 microns, such as figure 1shown in b-d. figure 1 e show...

Embodiment 3

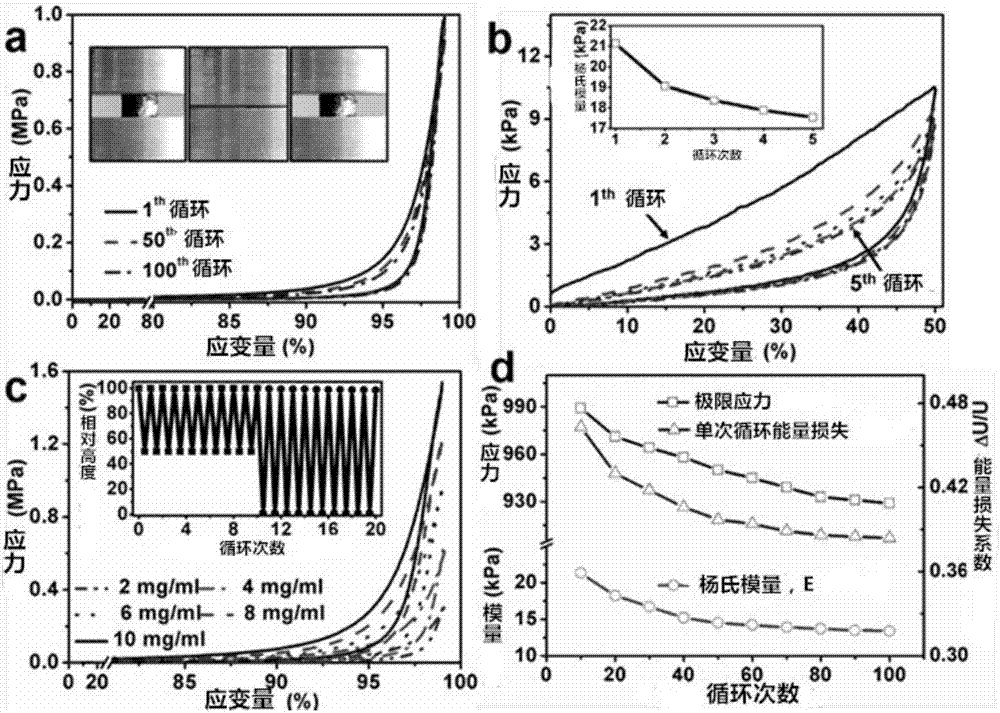

[0031] to combine figure 2 , the mechanical property test of graphene airgel prepared by natural drying method is as follows:

[0032] The graphene airgel prepared by the natural drying method of the present invention has a recoverable compression deformation characteristic of up to 99%, and an ultimate stress of up to 1MPa, such as figure 2 As shown in a, this performance is the highest level of graphene airgel research. figure 2 b shows that the graphene airgel material has a high initial structural stiffness, which avoids volume shrinkage and structural collapse caused by capillary stress during the natural drying process. By loading the material 100 times, it is proved that the graphene airgel has stable and excellent superelastic mechanical properties, such as figure 2 c, d shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com