Fractionation process for cracking gas from oxidation pyrolysis of gaseous hydrocarbon

A technology for fractional separation and gaseous hydrocarbons, which is applied in the field of fractional separation of cracked gas and can solve the problem of high cost of acetylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

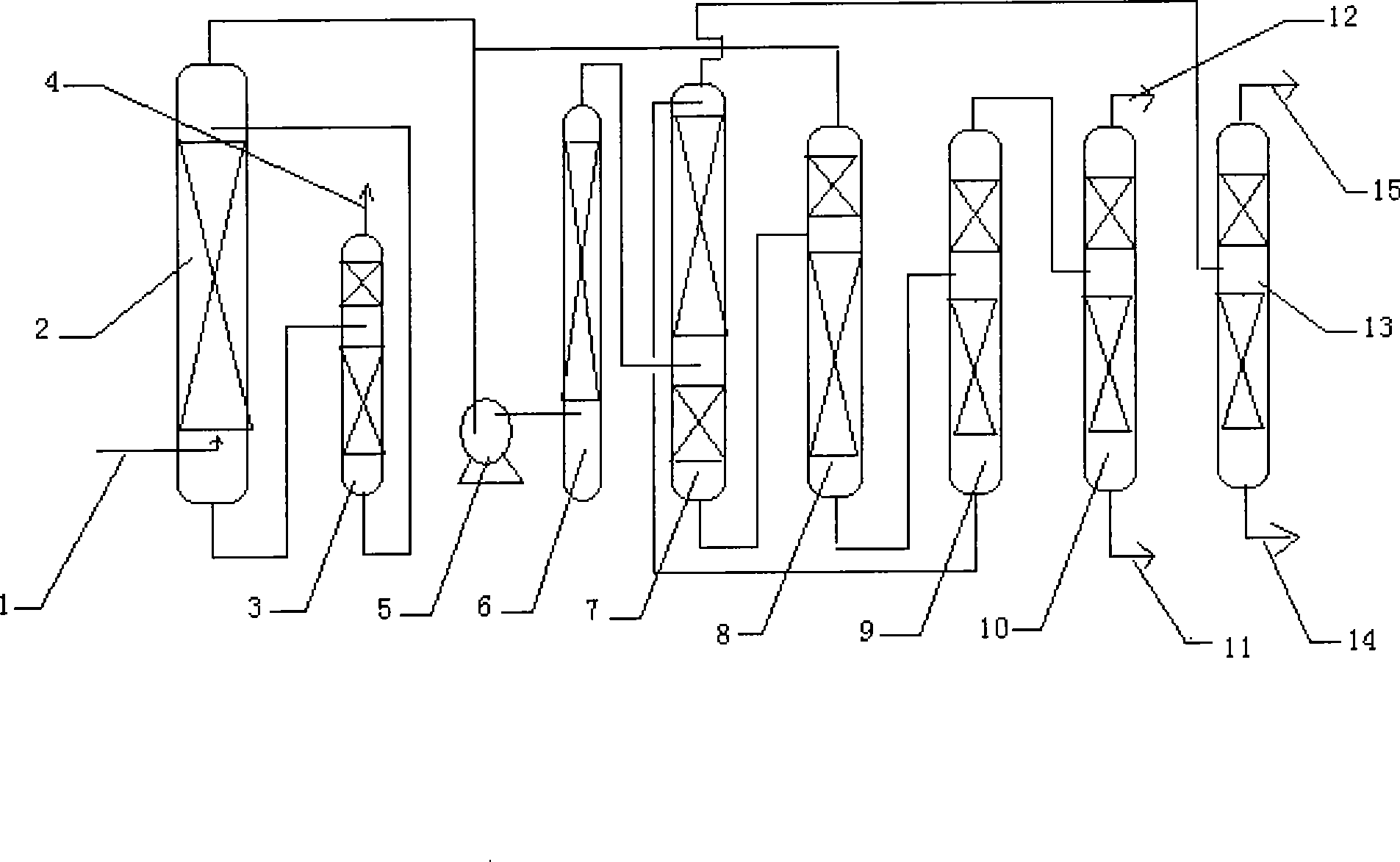

[0012] Below in conjunction with accompanying drawing, the present invention is described in detail: the pyrolysis gas of gaseous hydrocarbon oxidation pyrolysis to make acetylene enters oil washing tower (2) by cracking gas inlet (1) earlier and removes higher alkyne, carbon three hydrocarbons and carbon black, and compresses The machine (5) is pressurized to 0.4-1.5MPa, and after deoiling through the activated carbon adsorption tower (6), the acetylene and a small amount of other insoluble components are dissolved by the absorbed solvent in the acetylene absorption tower (7); the remaining gas enters the ethylene The separation tower (13) reclaims the concentrated ethylene product from the ethylene outlet (14), and the tail gas from the synthesis gas outlet (15) is used as synthesis gas to synthesize methanol; the solvent dissolved in acetylene and a small amount of other components enters the flash tower (8) After the insoluble components are removed, the crude acetylene gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com