Patents

Literature

40 results about "Oxidative pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidative pyrolysis includes a pyrolysis step that was found to be an important part of the oxidation mechanism.

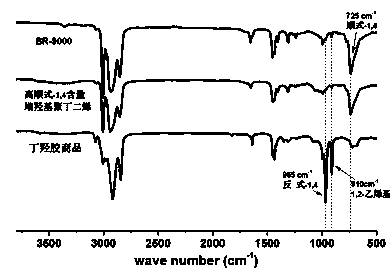

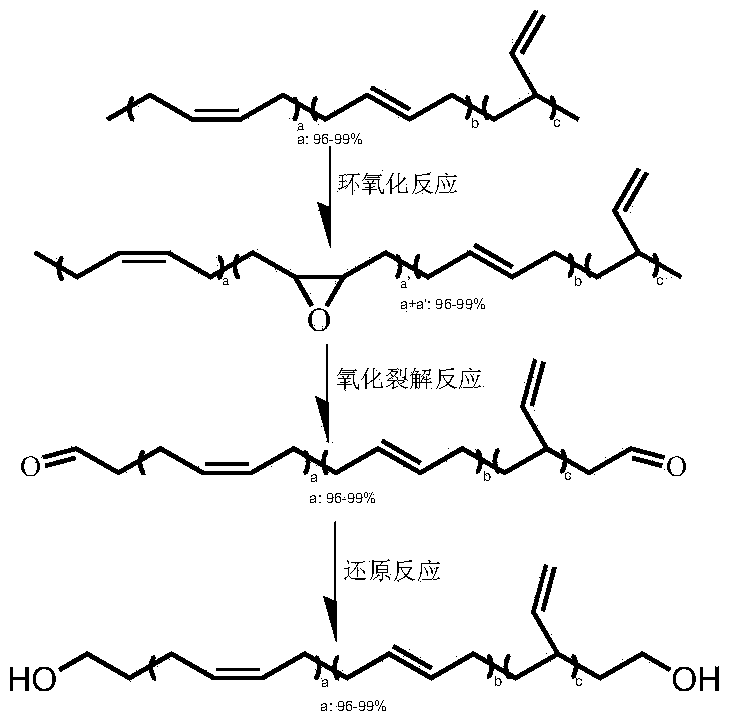

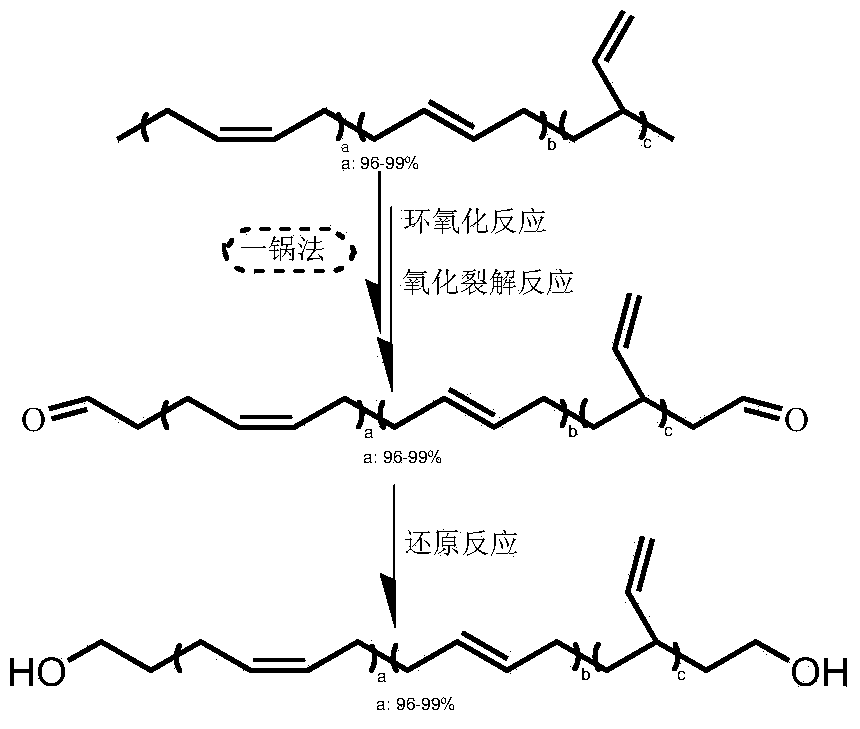

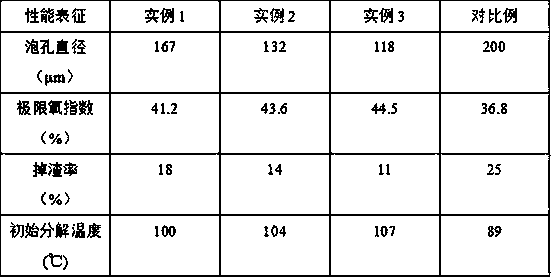

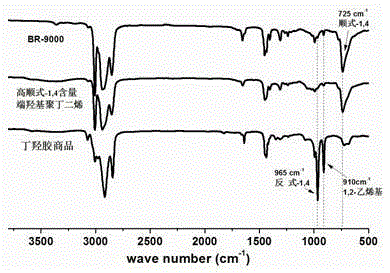

High-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and preparation method thereof

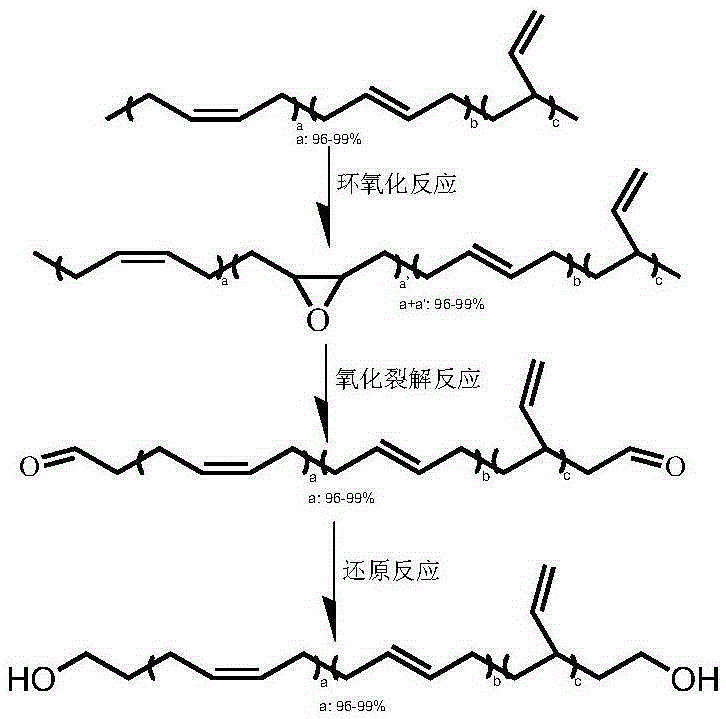

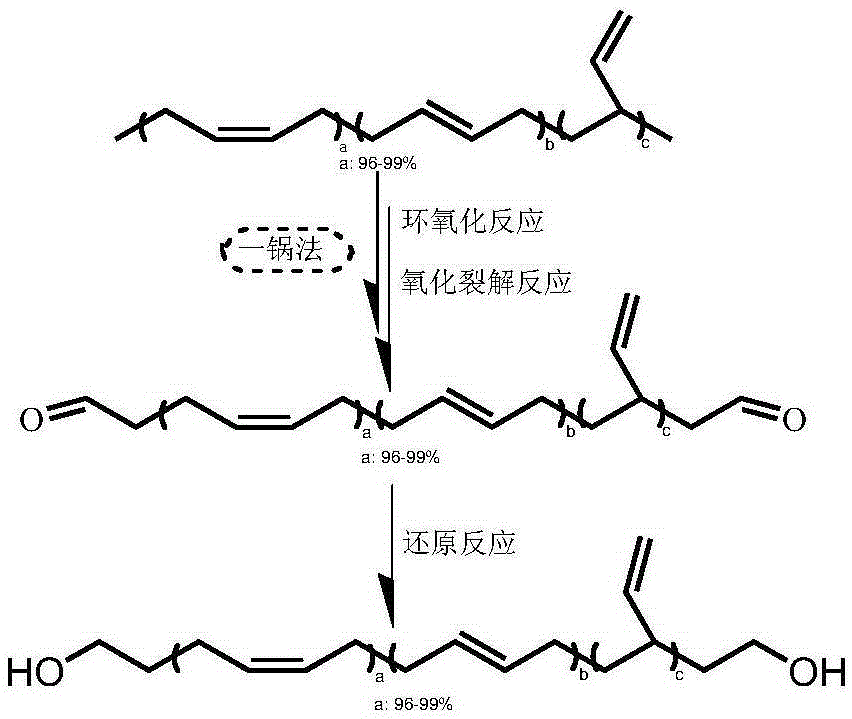

The invention discloses a high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and a preparation method thereof. The method includes following steps: (1) preparing epoxidized butadiene rubber from butadiene rubber; (2) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the epoxidized butadiene rubber; (3) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the butadiene rubber in a one-pot manner; (4) reducing the high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber to prepare the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber. In the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber is prepared from the butadiene rubber and the content of cis-1,4 can reach 95.0-99.0%. A number-average molecular weight of the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be regulated between 2000 g / mol and 10000 g / mol. A molecular weight distribution is 1.2-3.0 and a degree of functionality is 1.9-2.2. On the basis of excessive supply in raw rubber of butadiene rubber and increased tensing situation of petroleum sources, by means of the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be prepared through oxidative pyrolysis of the butadiene rubber, so that the method has a quite important practical significance.

Owner:ZHEJIANG UNIV

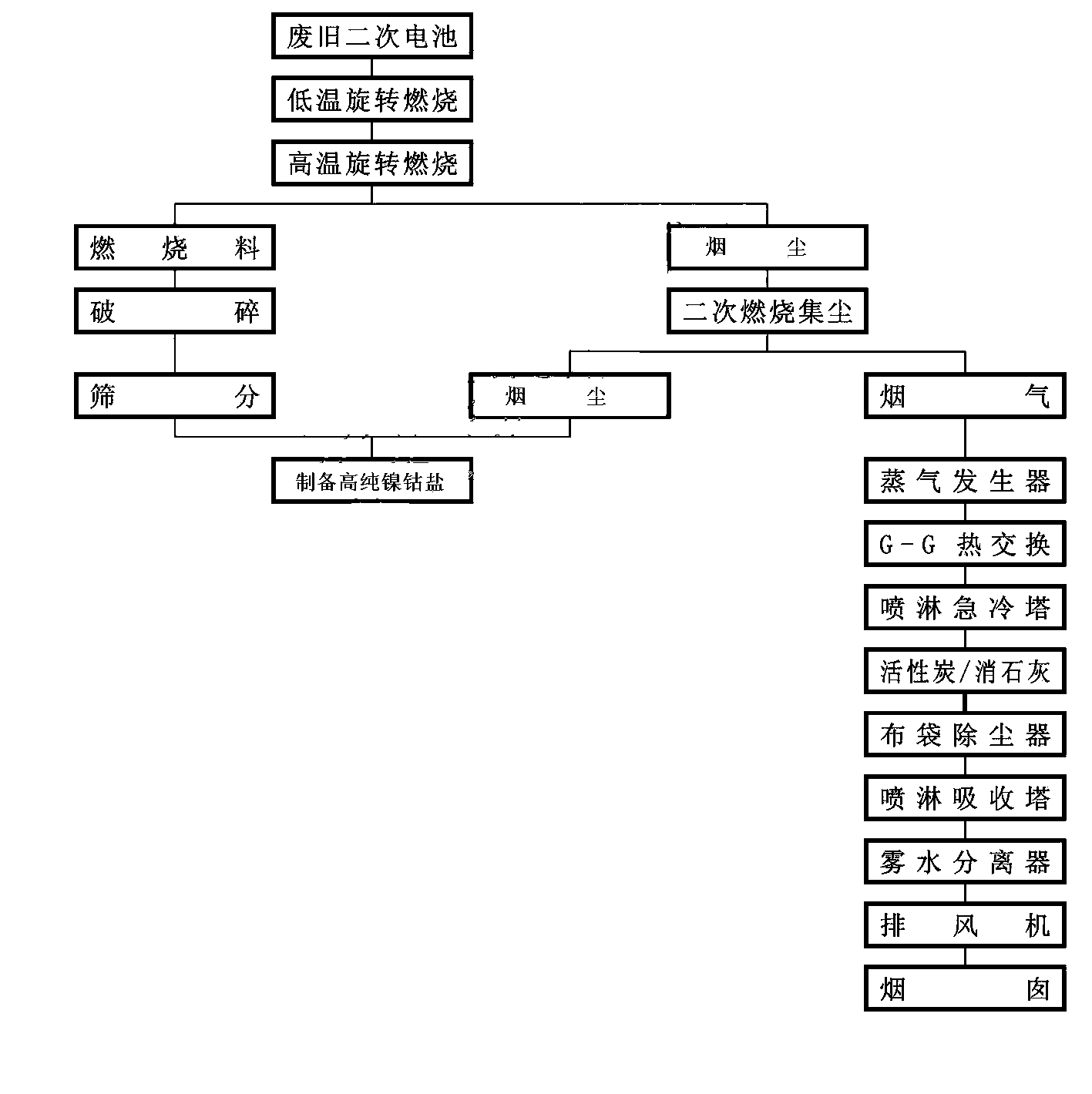

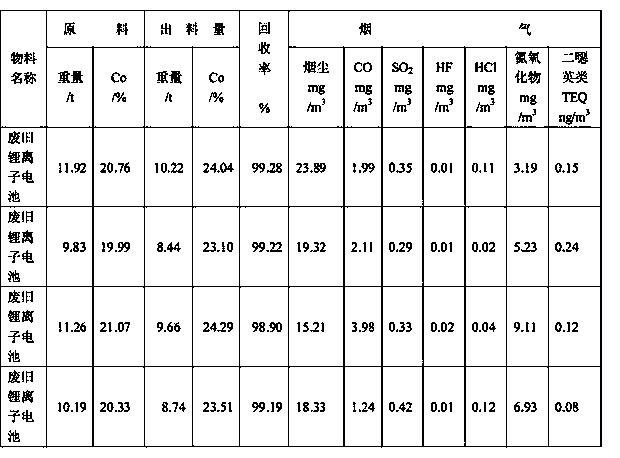

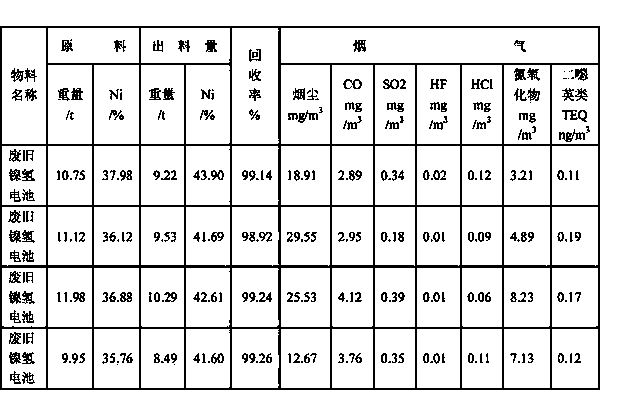

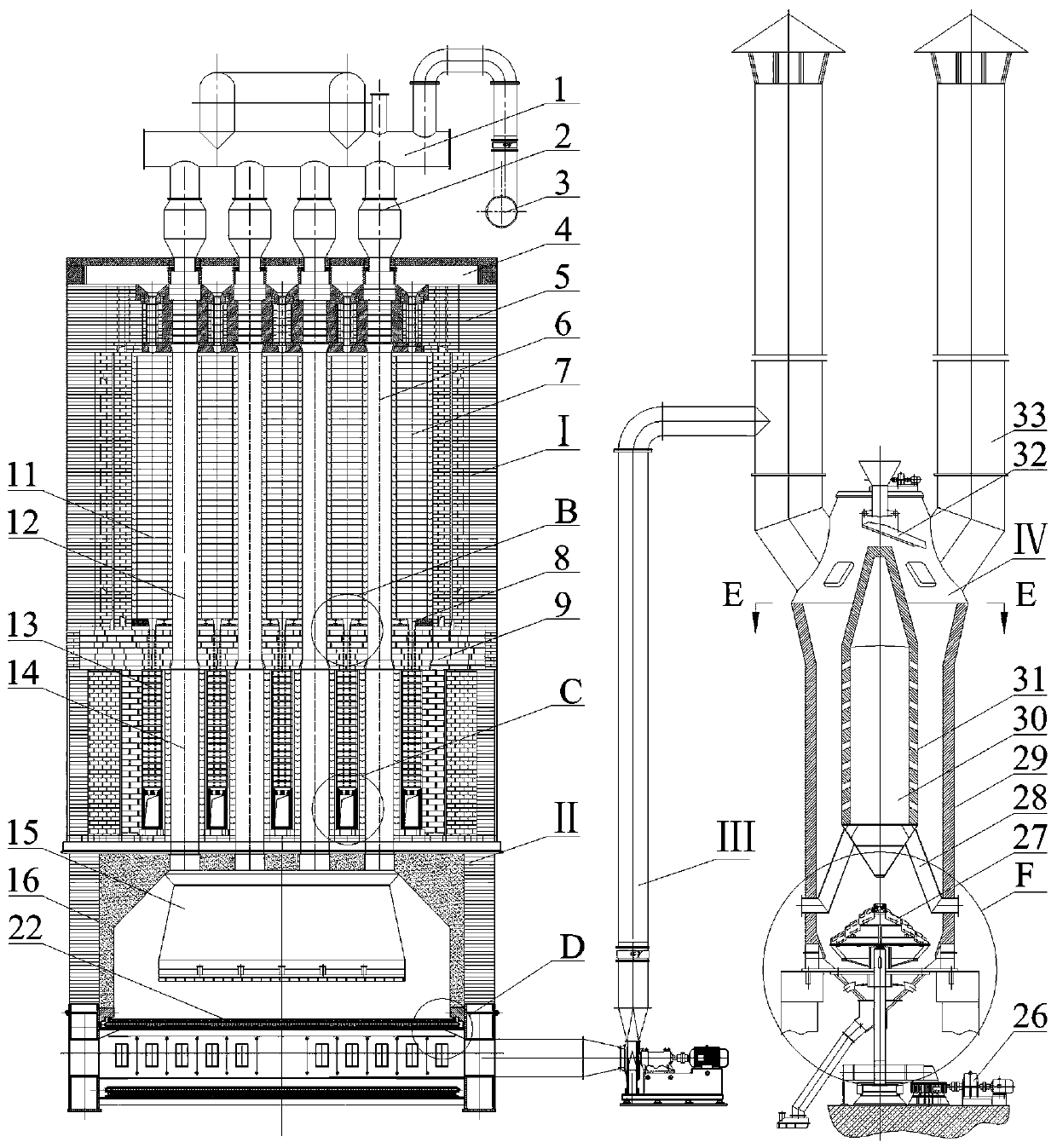

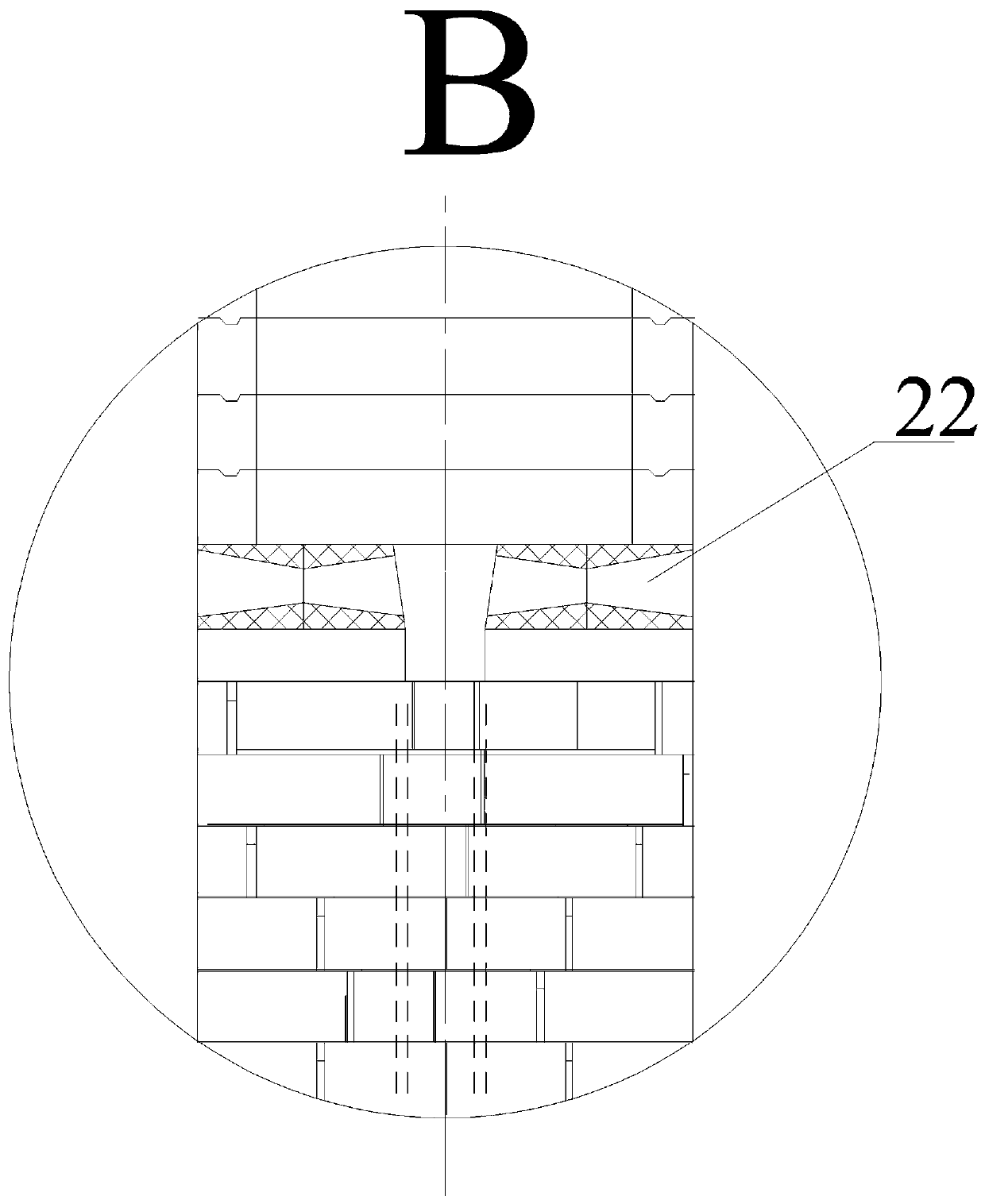

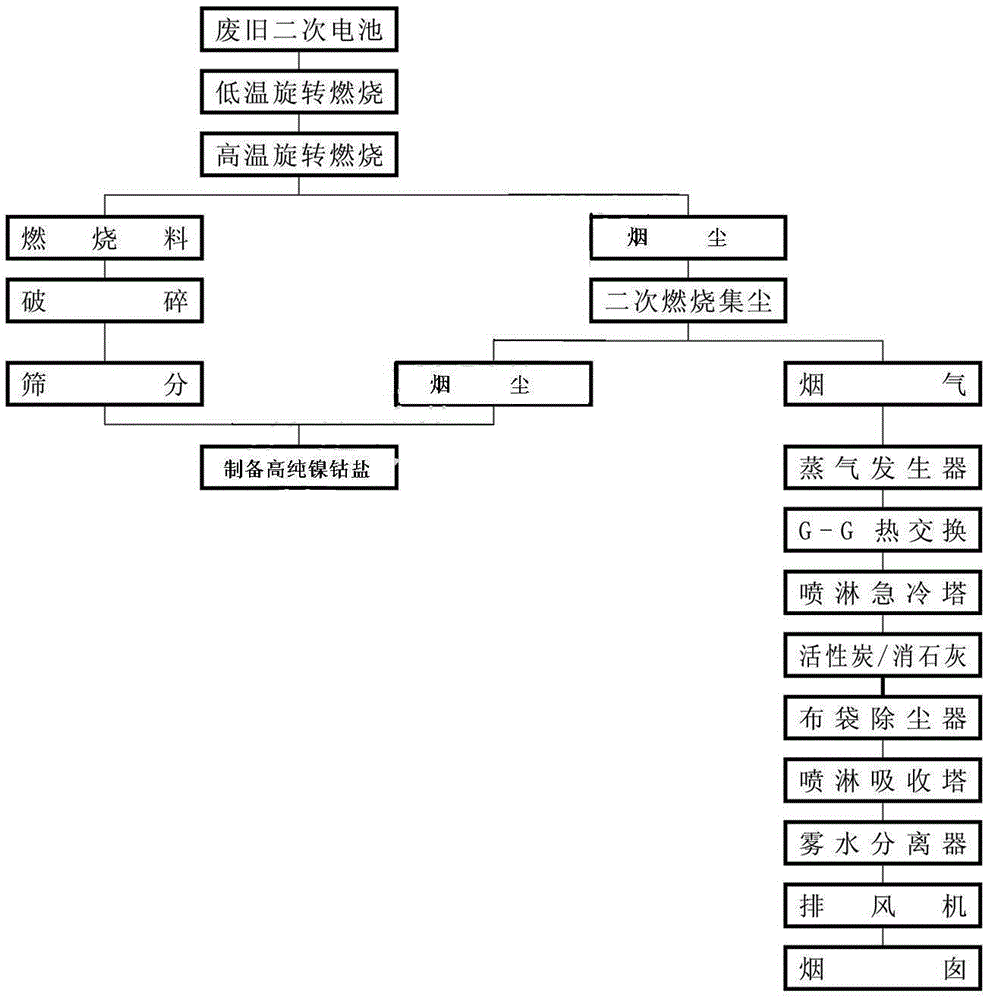

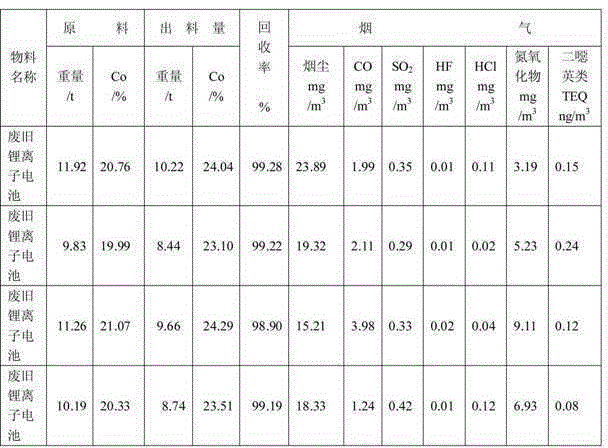

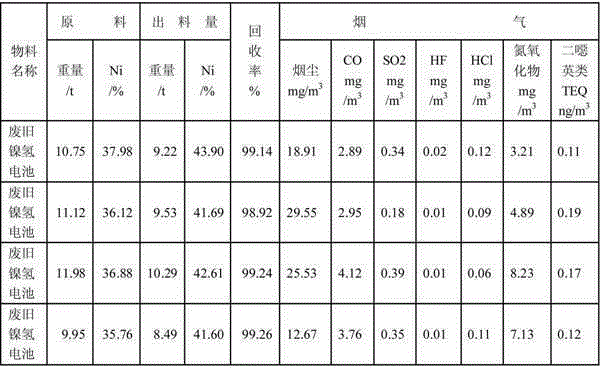

Method for treating waste secondary battery

ActiveCN103730704AAvoid explosionFully oxidative combustionWaste accumulators reclaimingBattery recyclingChemical industryFurnace temperature

The invention belongs to the technical fields of wet metallurgy and chemical industry production and discloses a method for treating a waste secondary battery. The method comprises the following steps: performing two-stage combustion in a rotary kiln, maintaining the furnace temperature to be at 100-150 DEG C, roasting the waste secondary battery on the furnace front, and remaining for 30-60 minutes to ensure that a sealing ring in the waste secondary battery is fully pyrolyzed and damaged, so that hydrogen and an organic solvent in the battery are released; and burning the materials in a hearth on the rear of a combustion chamber of the furnace body, maintaining the temperature to be at 300-500 DEG C, fully oxidizing, pyrolyzing and burning organic matters in the wastes, and effectively controlling generation of ozone and nitrogen oxides, so that the produced gas achieves the odor-free, stink-free and completely-combusted effects. The treatment method provided according to the invention is reasonable in design, the operations of burning and breaking are sequentially performed, the breakage rate is high, the recycling rate of valuable elements is high, a high-temperature burning explosion accident can be avoided, and the method is safe, pollution-free and suitable for popularization.

Owner:GANZHOU HIGHPOWER TECH CO LTD

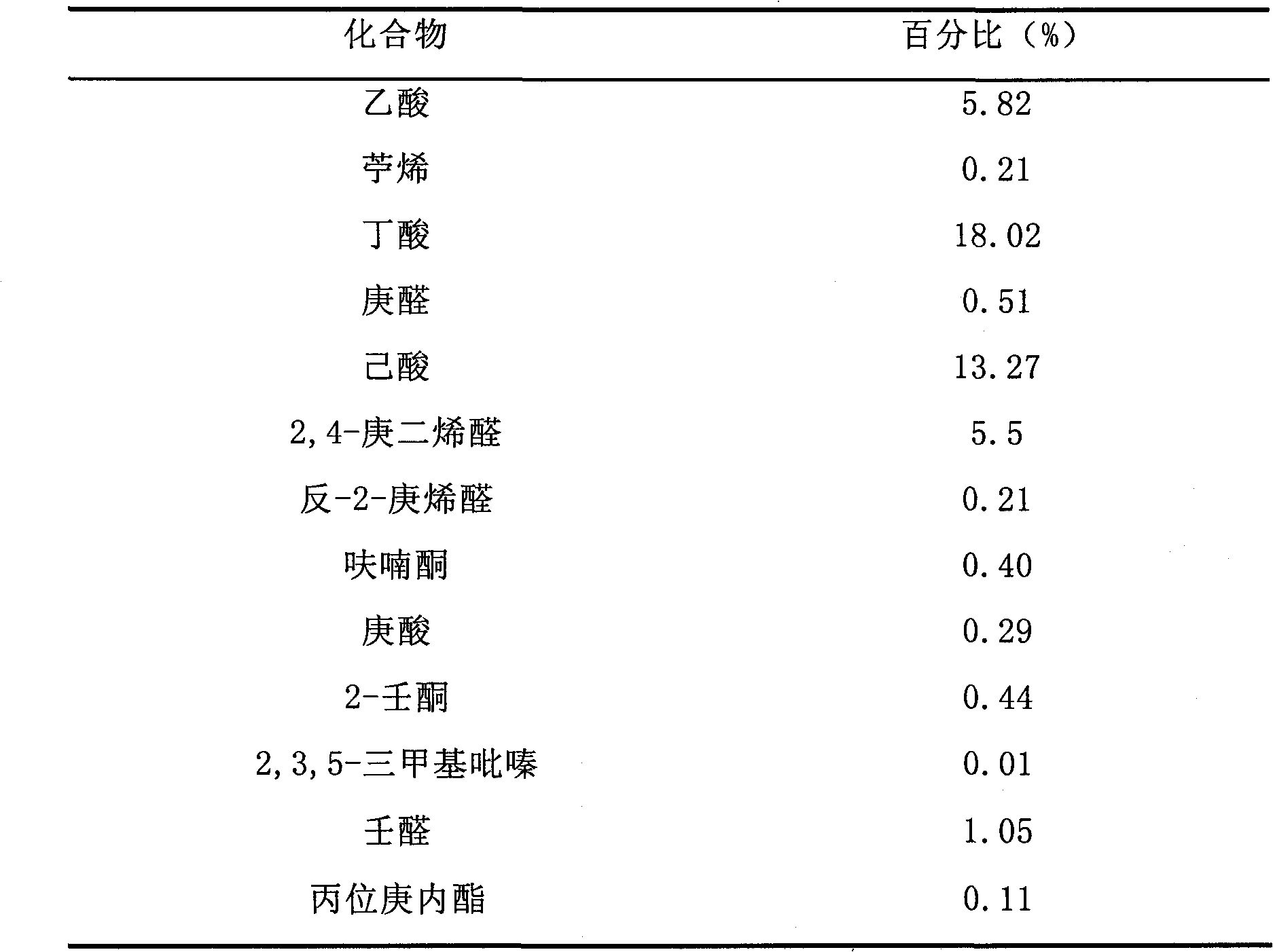

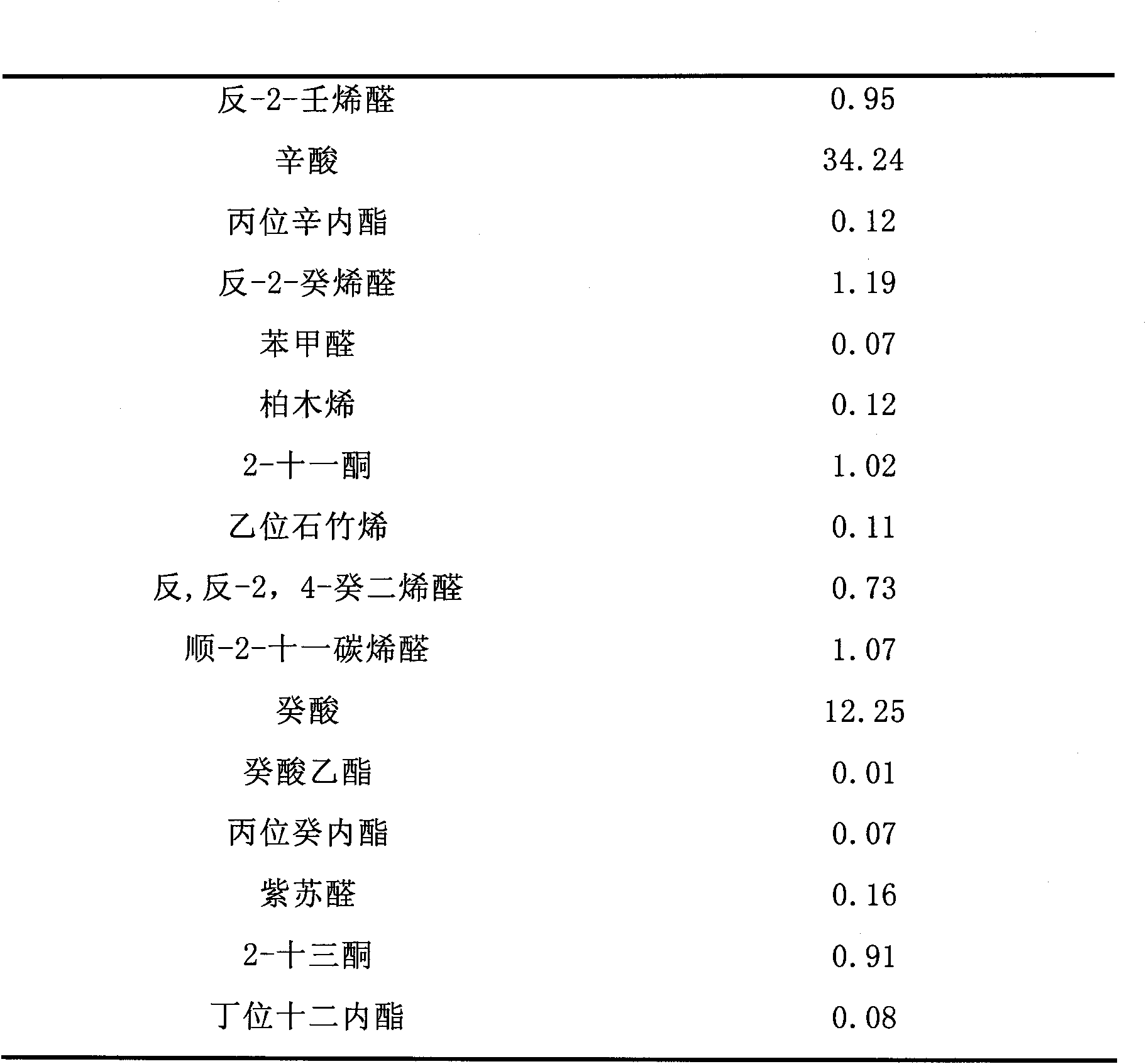

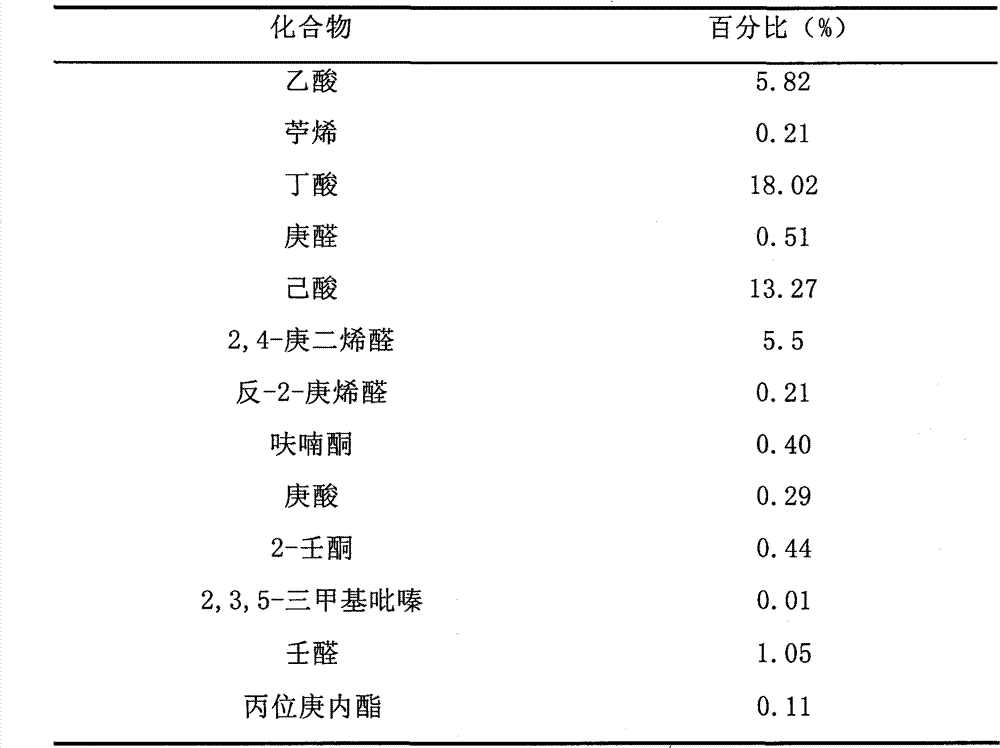

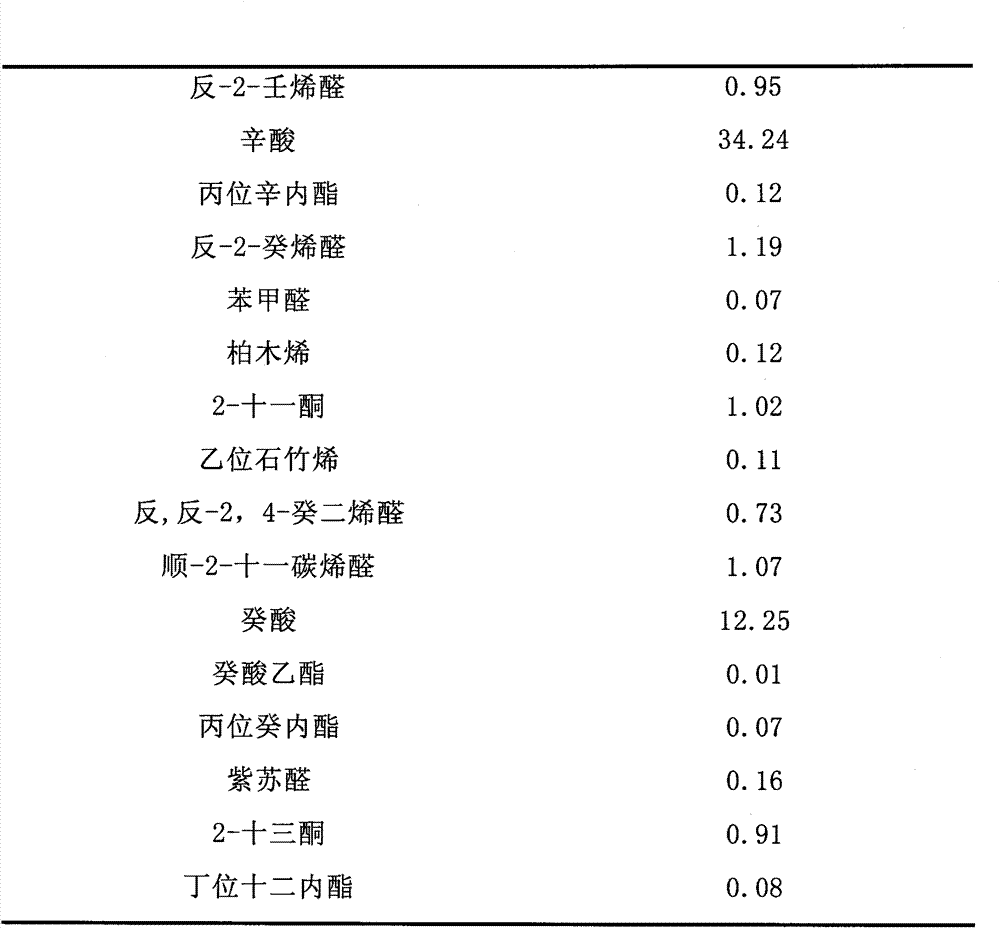

Preparation method for natural cream flavour

ActiveCN102308969AIncrease profitEasy to processFood preparationEnzymatic hydrolysisAdditive ingredient

The invention discloses a preparation method for a natural cream flavour, which is a method for preparing the cream flavour by way of the dry fractionation of cream in combination with the oxidative pyrolysis technology and the enzymatic hydrolysis technology. The preparation method includes the following steps: cream is adopted as material, and the cream is divided into a component A and a component B within different melting point ranges according to the melting point of each component in the cream or the different intersolubilities of the cream under different temperatures, and therefore is separated; the air is then added under the stirring condition, so that the component A can be heated and oxidated, and thereby oxide C is produced; the component B and the oxide C are mixed and enzymatically hydrolyzed, and thereby the cream flavour is prepared. The method fractionates the different components of the cream, and pertinently carries out oxidation and oxidative pyrolysis, the cost can be greatly saved, the high-yield and high-efficiency cream flavour can be obtained, the technique for preparing the cream flavour by utilizing the technique provided by the invention and enzyme source is simple, and is suitable for industrialized production, the product has the advantages of both zymolyte and oxide, and the aroma is mellow, rich, strong and natural.

Owner:SHANGHAI AIPU VEGETABLE TECH +1

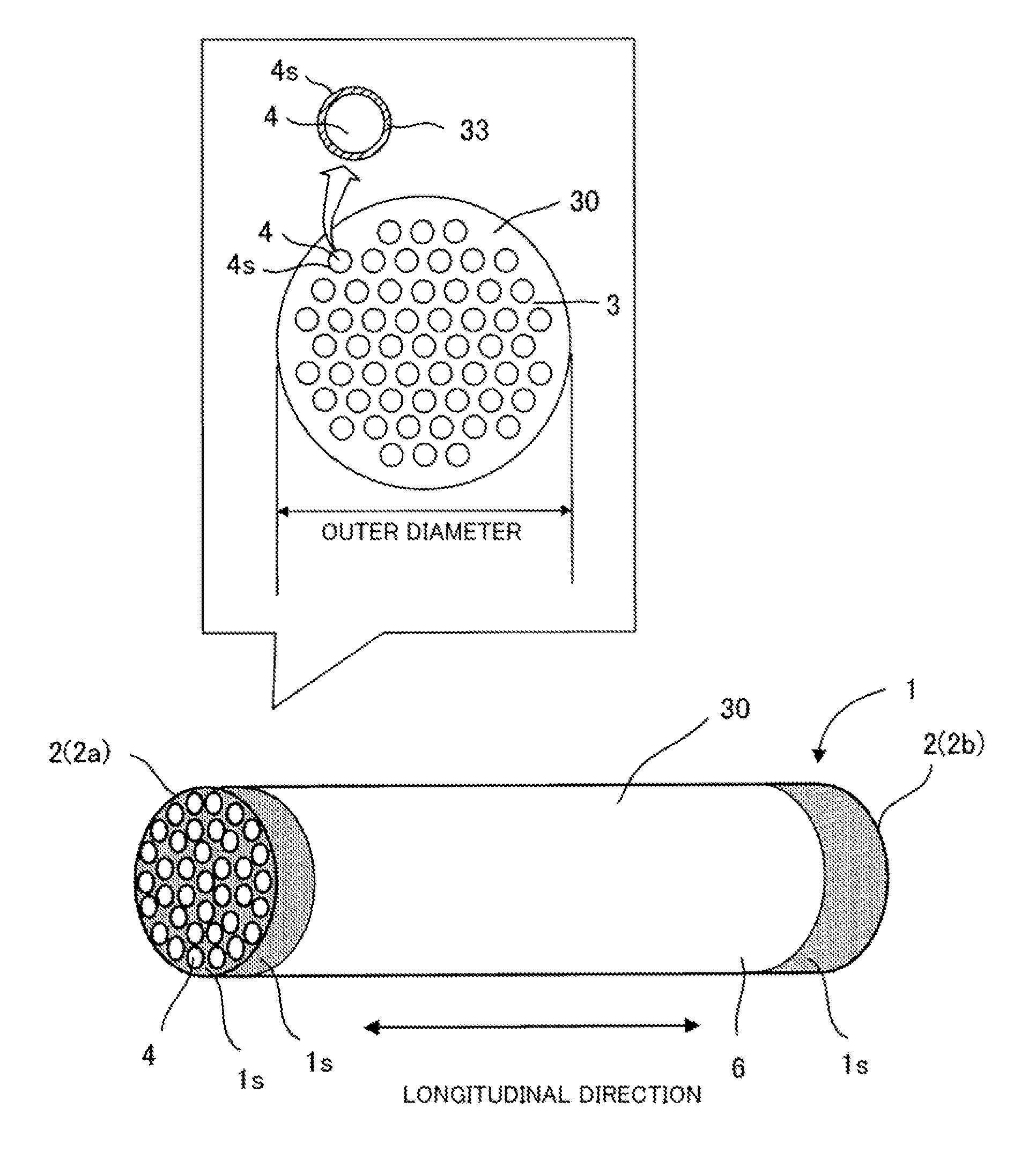

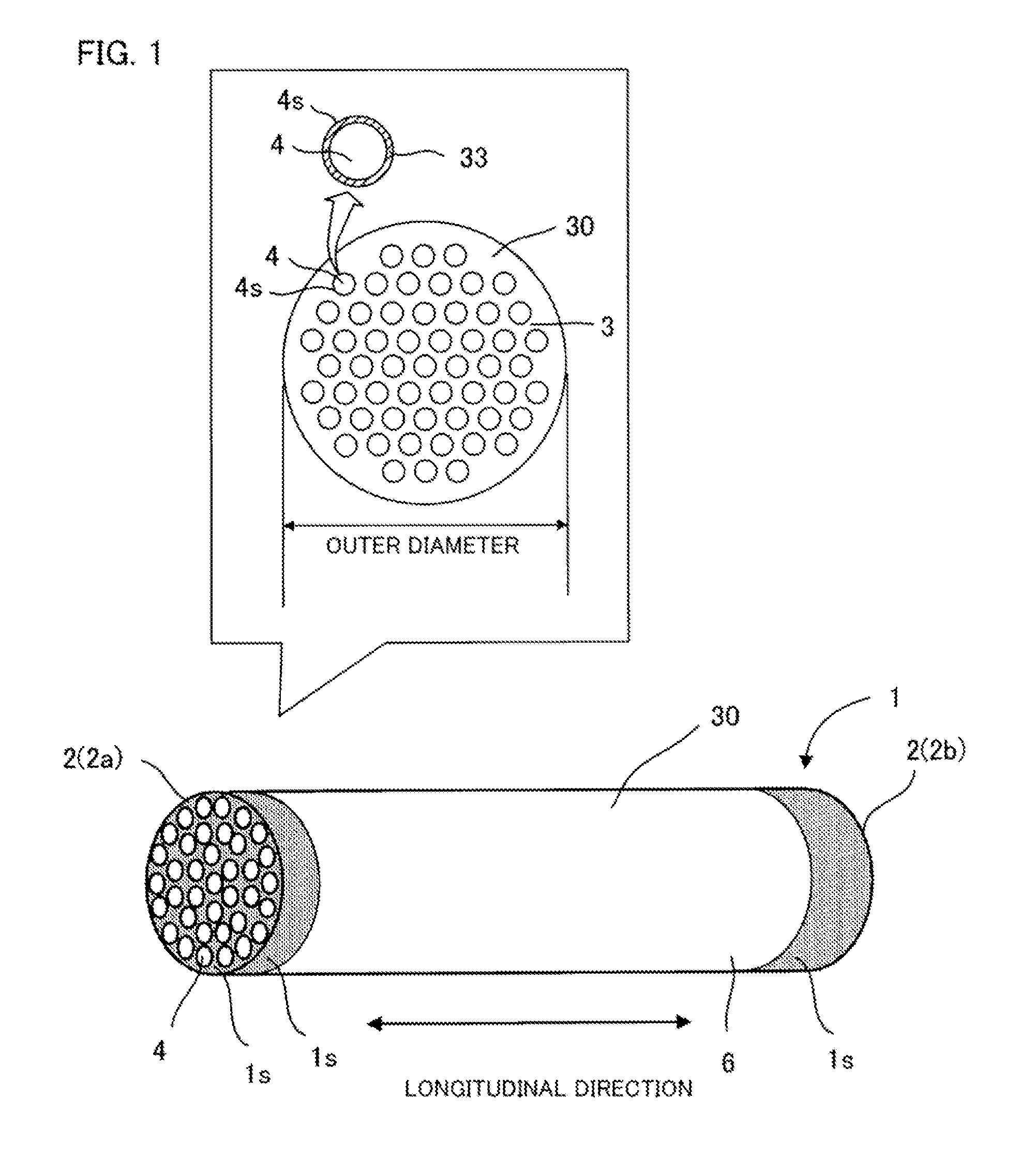

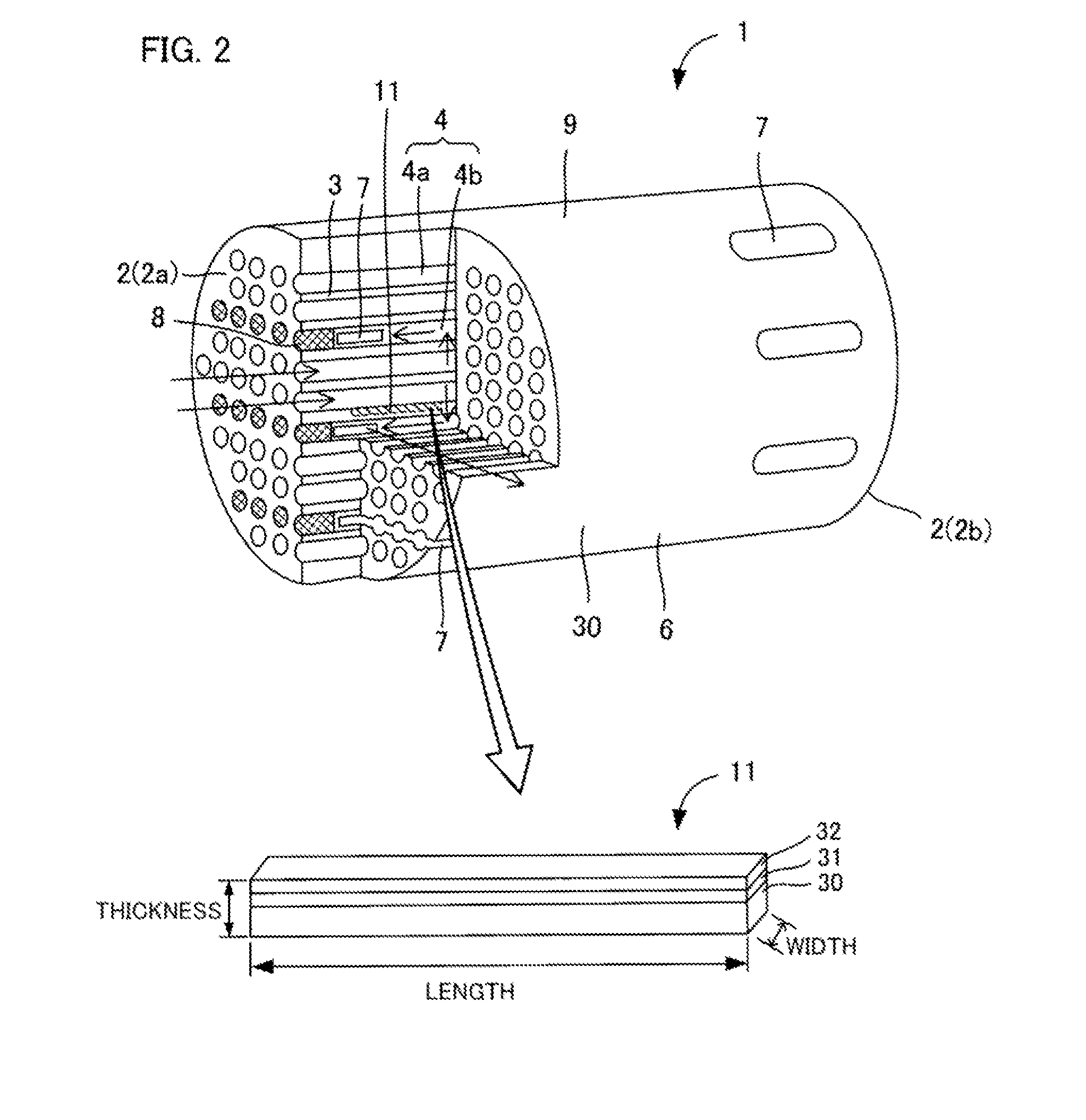

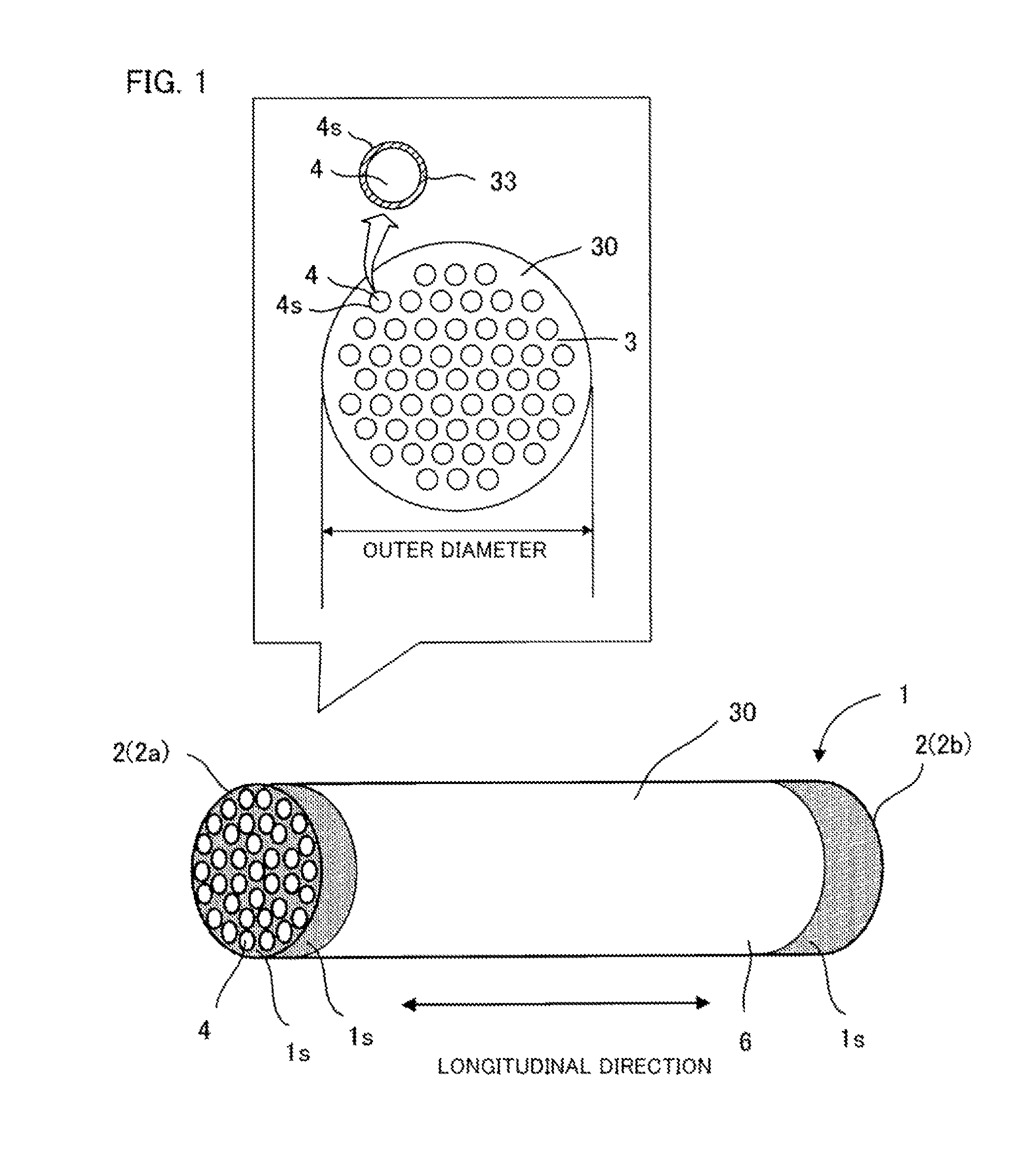

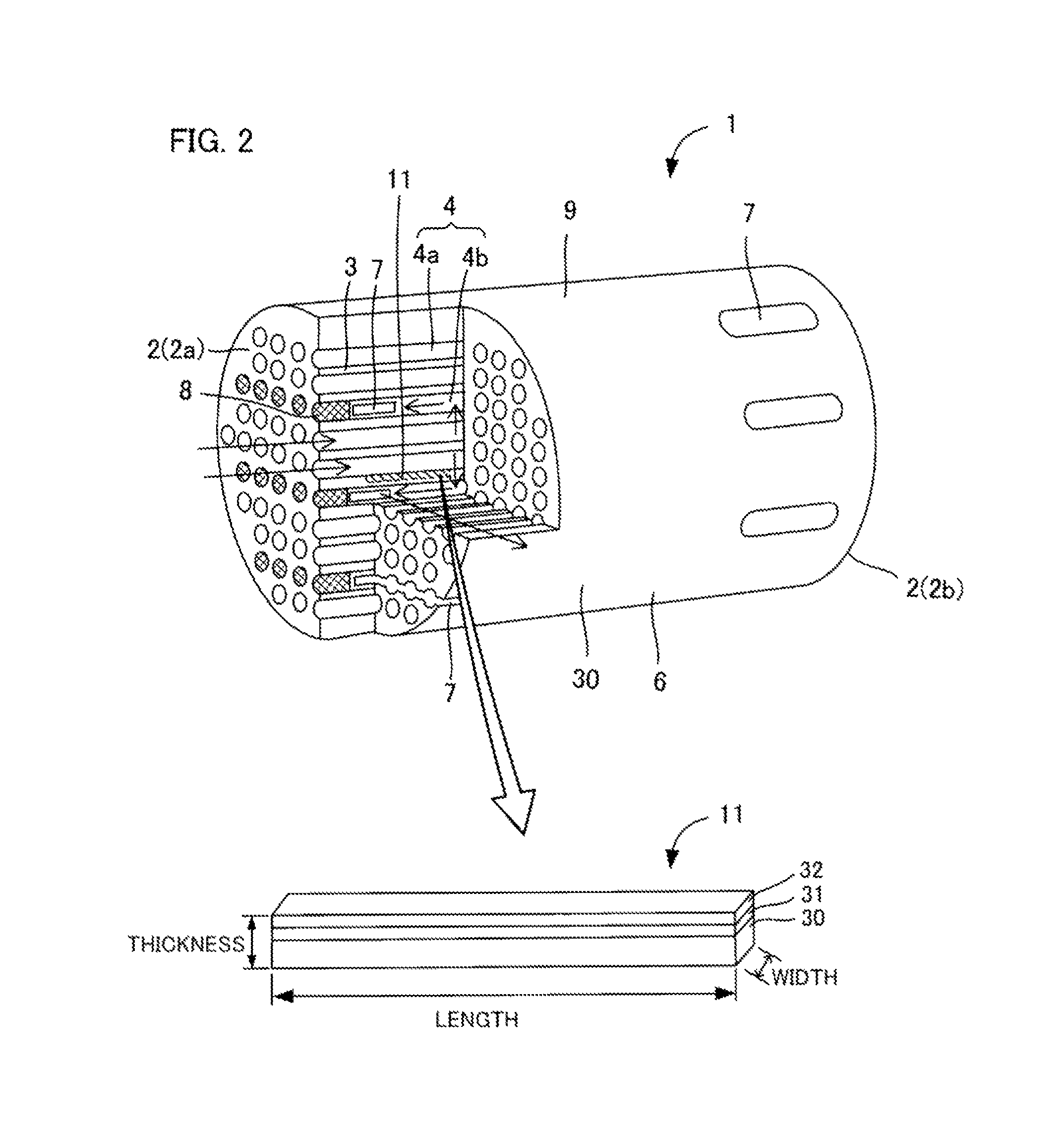

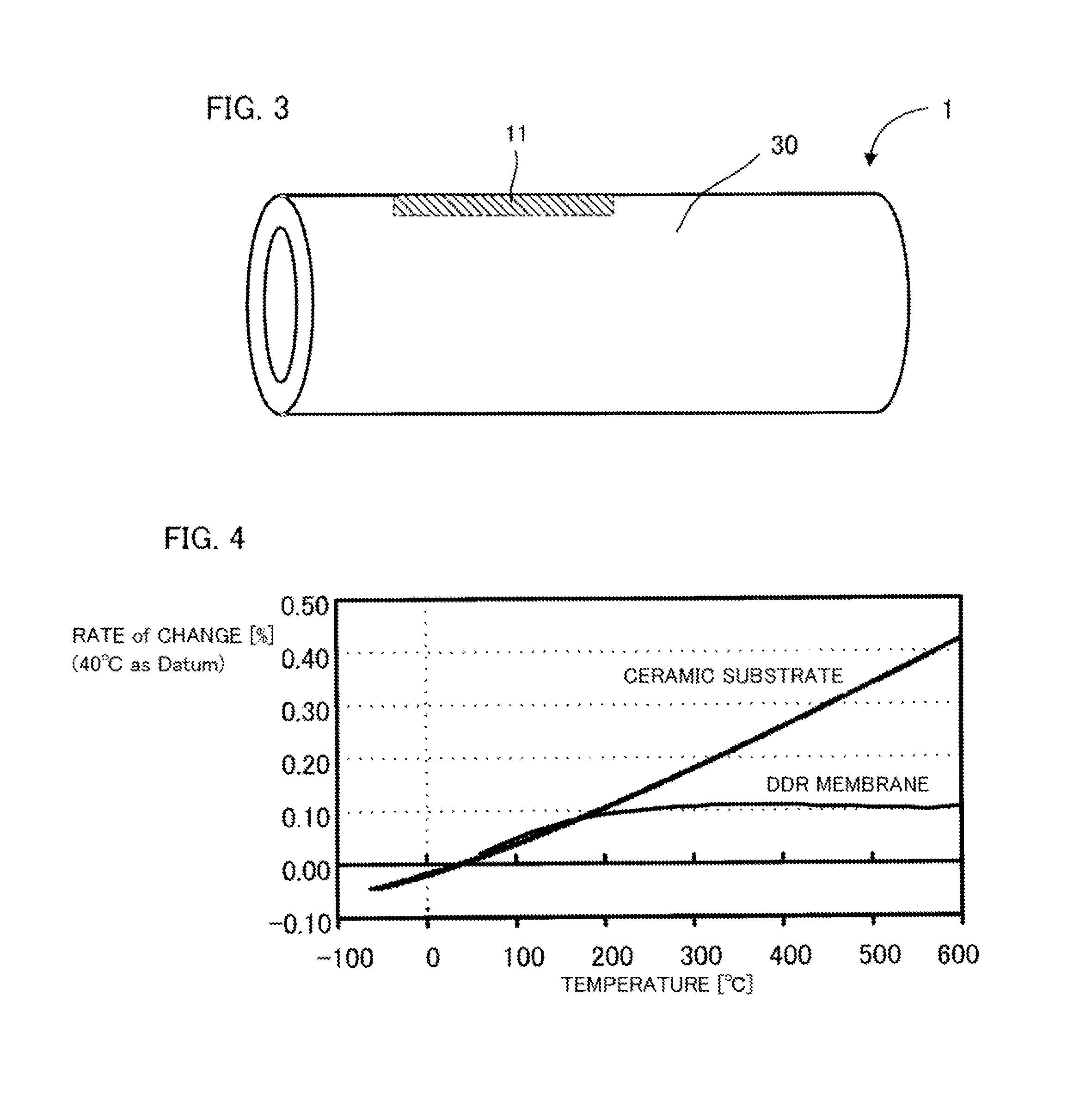

Zeolite membrane regeneration method

ActiveUS20150224487A1Restore permeation amountLowering separation coefficientSemi-permeable membranesMembranesThermal expansionOxidative pyrolysis

Provided is a simple method for regenerating a zeolite membrane which has been exposed to water. The method for regenerating a zeolite membrane is a method for regenerating a zeolite membrane which is formed on a ceramic porous body and subjected to removal treatment of structure directing agent. Heating is performed at a regeneration temperature at which the difference in ratio of thermal expansion amount between the ceramic porous body and the zeolite membrane is 0.3% or less when 40° C. is set as datum. The regeneration temperature is preferably a temperature not exceeding the oxidative pyrolysis temperature of the structure directing agent used in the formation of the zeolite membrane.

Owner:NGK INSULATORS LTD

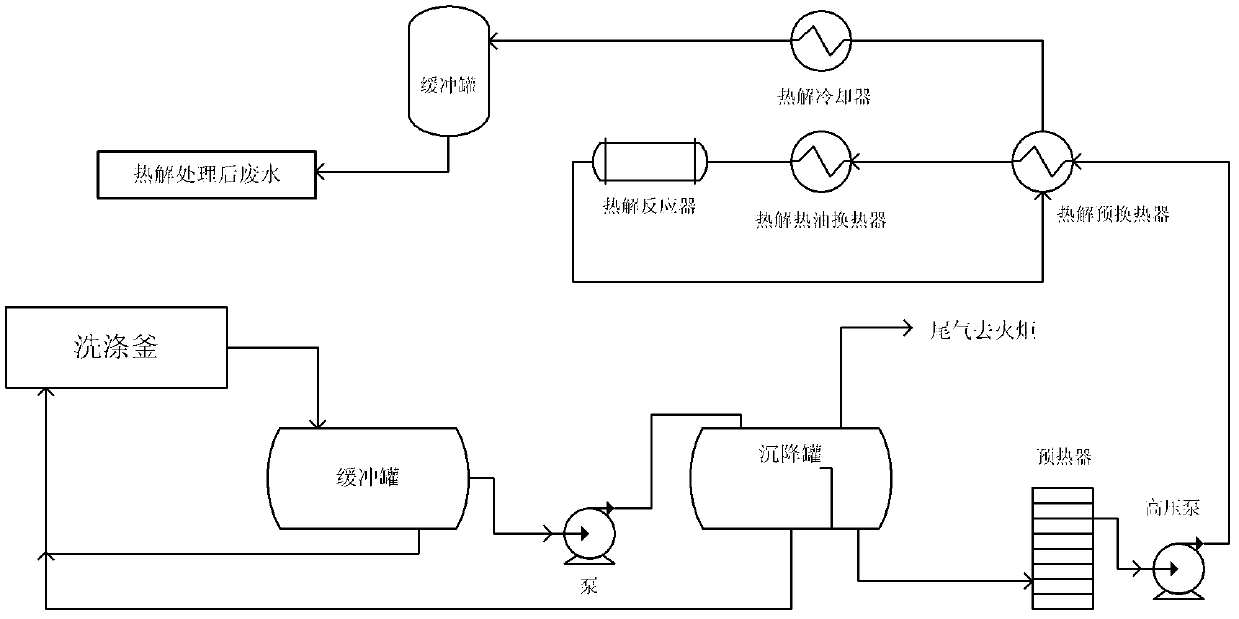

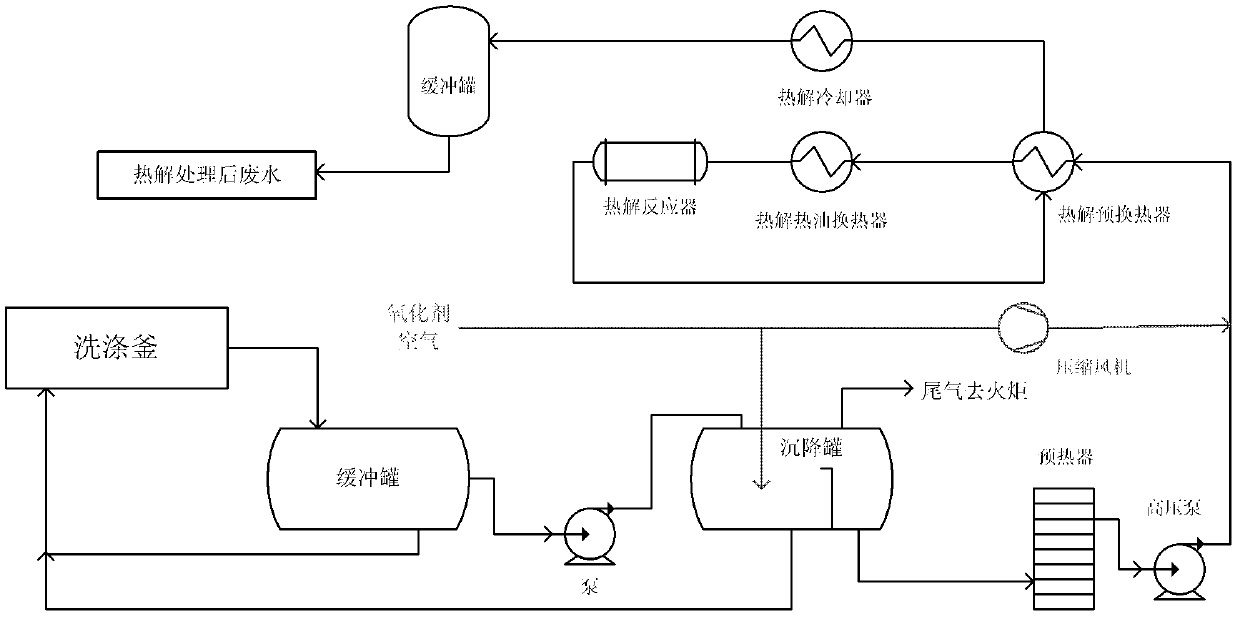

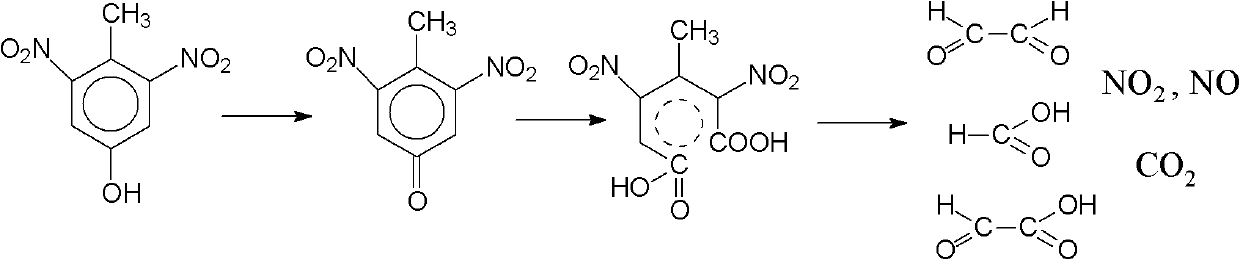

Oxidative pyrolysis process of dinitrotoluene wastewater

ActiveCN102649597BReduce foulingLow running costWater contaminantsNature of treatment waterNitro compoundAfter treatment

The invention discloses an oxidative pyrolysis process of dinitrotoluene wastewater. The oxidative pyrolysis process comprises the following steps of: passing wastewater from a washing kettle through a buffer tank, a settling tank, a preheater, a high pressure pump, a pyrolytic preliminary heat exchanger, a pyrolytic hot oil heat exchanger, a pyrolysis reactor, a pyrolysis cooler and a buffer tank to be discharged, wherein an oxidant is added at an inlet of the settling tank and / or the pyrolytic preliminary heat exchanger; and the oxidant is added into the pyrolytic preliminary heat exchanger through pressurization. According to the process, the chromaticity of the wastewater processed by the oxidative pyrolysis process is reduced by 25-30 percent in comparison with the conventional process, the scaling in the heat exchanger of the system can be effectively reduced, the operation cost can be reduced, and the content of aromatic nitro compounds (dinitrotoluene, nitrocresol and the like) in the wastewater after treatment is reduced by 25-30 percent compared with that in the conventional process.

Owner:SHANGHAI BASF POLYURETHANE +1

Preparation method and application of Co3O4 NP/CD/Co-MOF composite material

InactiveCN109759143ASimple preparation processEasy to industrializeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectrochemistryCobalt

The invention discloses a preparation method of aCo3O4NP / CD / Co-MOF composite material and application of electrocatalysis based on the composite material, and belongs to the technical fields of nanocatalysis, nanomaterials and the like. The preparation method mainly comprises the following steps: reacting cobalt nitrate, glucose, triethylene diamine and terephthalic acid at room temperature to obtain Co-MOF / glucose flaky microcrystals; performing oxidation and pyrolysis on the microcrystals under microwave irradiation to obtain a Co-MOF composite material with semiconductor Co3O4 nanoparticlesand carbon dot CD which are co-doped, namely, the Co3O4 NP / CD / Co-MOF composite material. The composite material has the advantages of low raw material cost for preparation, simple preparation process, low reaction energy consumption and industrial application prospect. The catalyst has high electrochemical activity for the electrocatalytic nitrogen fixation to form ammonia.

Owner:UNIV OF JINAN

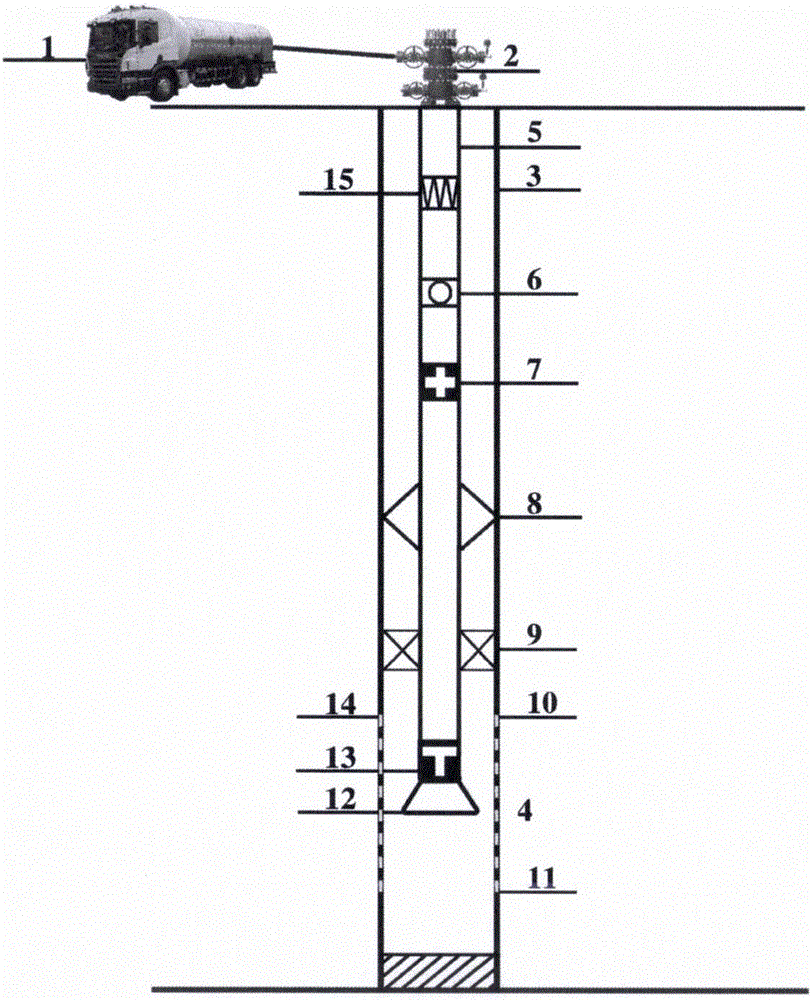

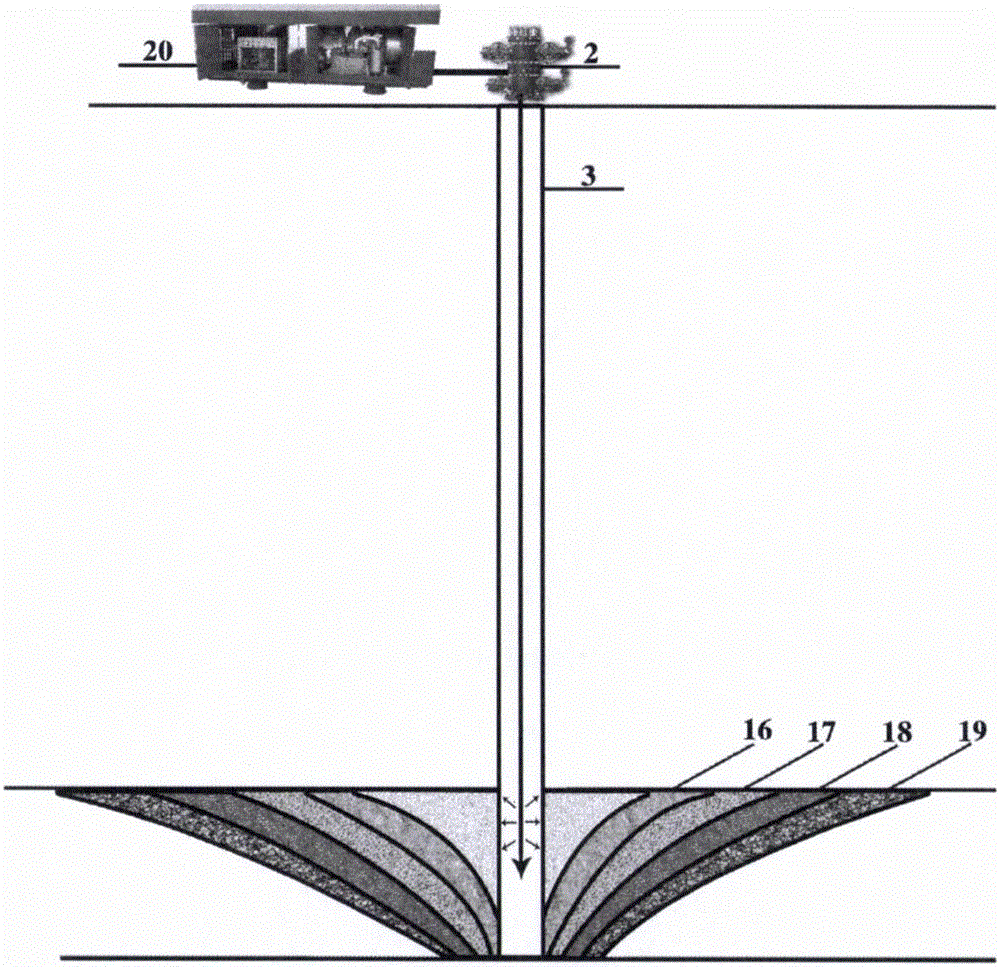

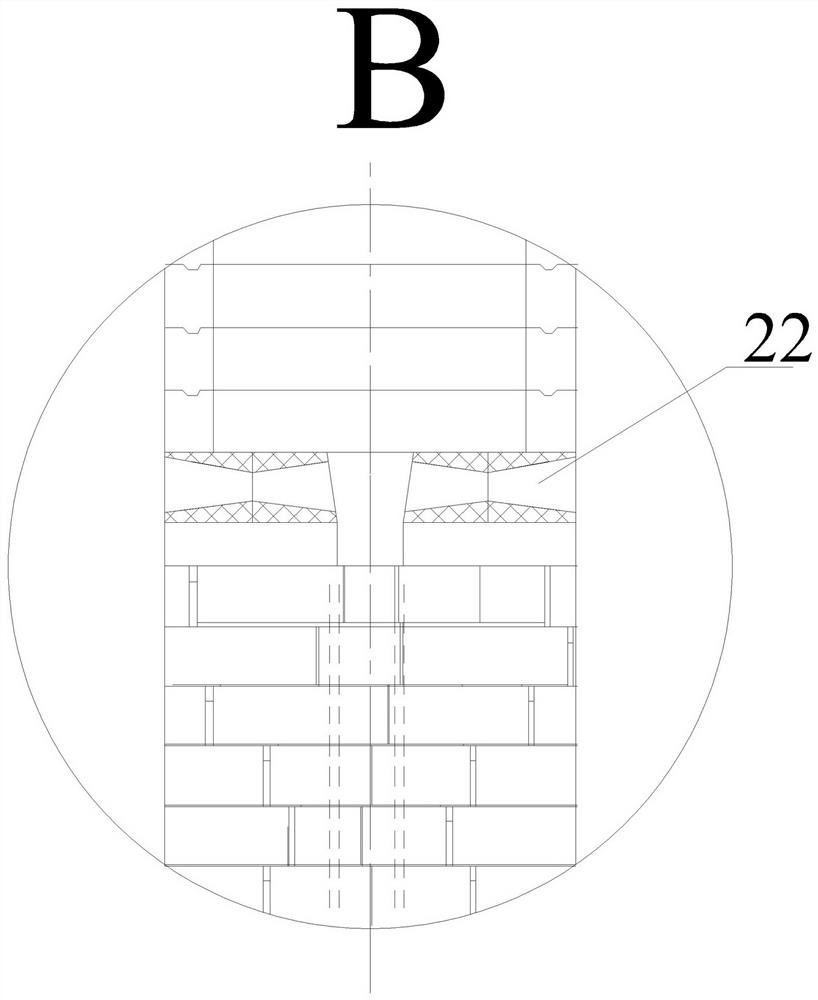

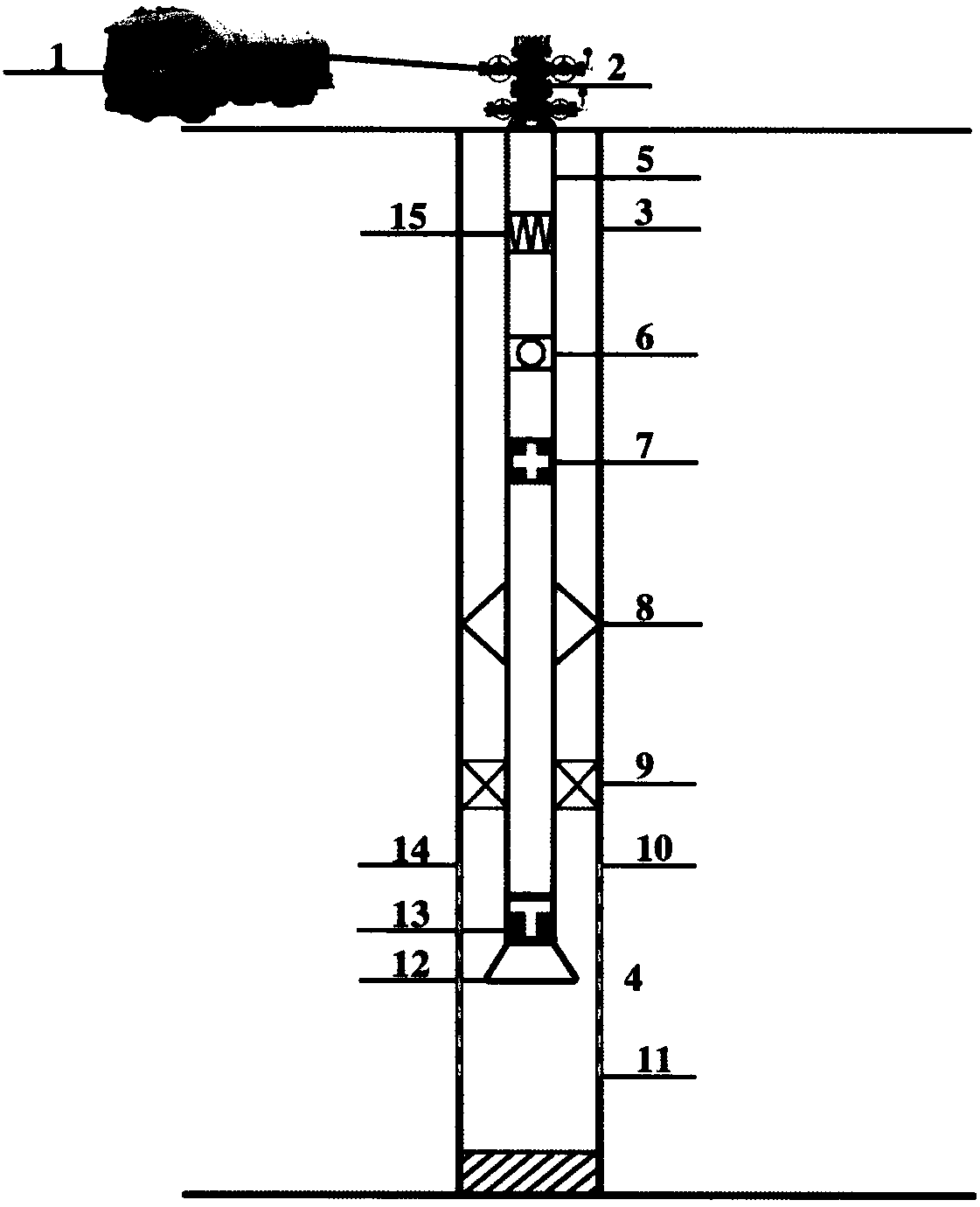

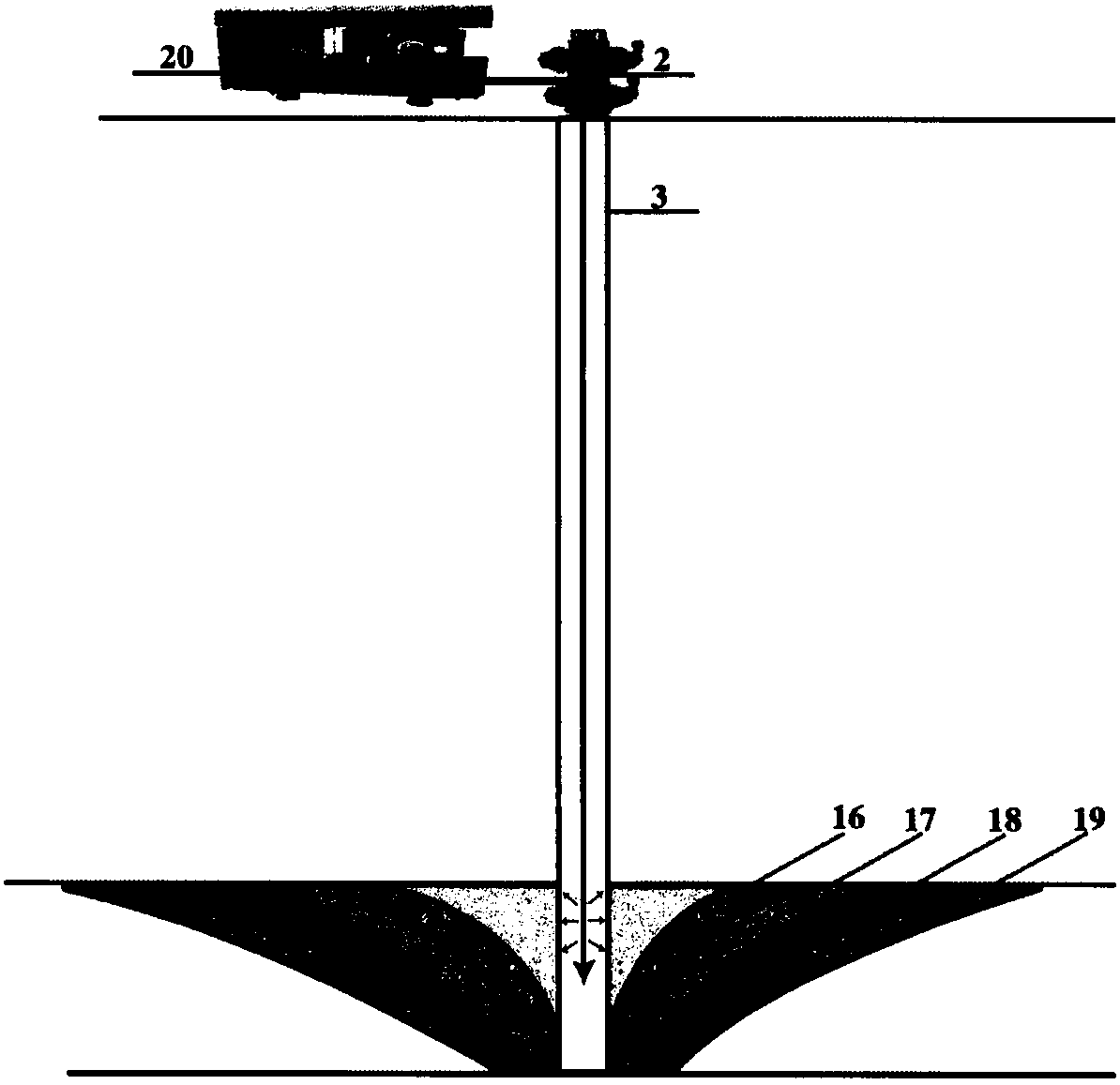

Method for injecting high-pressure air into low-permeability reservoir to perform oxidative pyrolysis and displacement of oil

The invention provides a method for injecting high-pressure air into a low-permeability reservoir to perform oxidative pyrolysis and displacement of oil. Before air displacement for oil extraction is performed, high-temperature hot water is firstly injected to form a first slug, then three-phase nitrogen foam is injected to form a second slug, an injected air and the three-phase nitrogen foam mixed-phase substance serves as a third slug, then high-pressure air is injected to perform air displacement for oil extraction, and high-pressure air injection is conducted on stratum under the pressure of 25-50 MPa. The method can effectively conduct viscosity reduction and cooling on formation oil at the initial stage of the air displacement, a round oxidative pyrolysis zone is rapidly formed in the oil layer, the liquidity of the crude oil in an oil reservoir is improved, the low-permeability reservoir originally difficult to develop is improved, and the recovery rate is improved in a long-acting mode. The method is suitable for the low-permeability reservoir, the optimum condition is the reservoir depth of 1300-4900 meters, the reservoir thickness is more than 2.5 meters, the reservoir temperature is greater than 55 degrees, the oil saturation is above 30%, the permeability is greater than 1 millidarcy, and the connectivity is above 80%.

Owner:中嵘能源科技集团有限公司

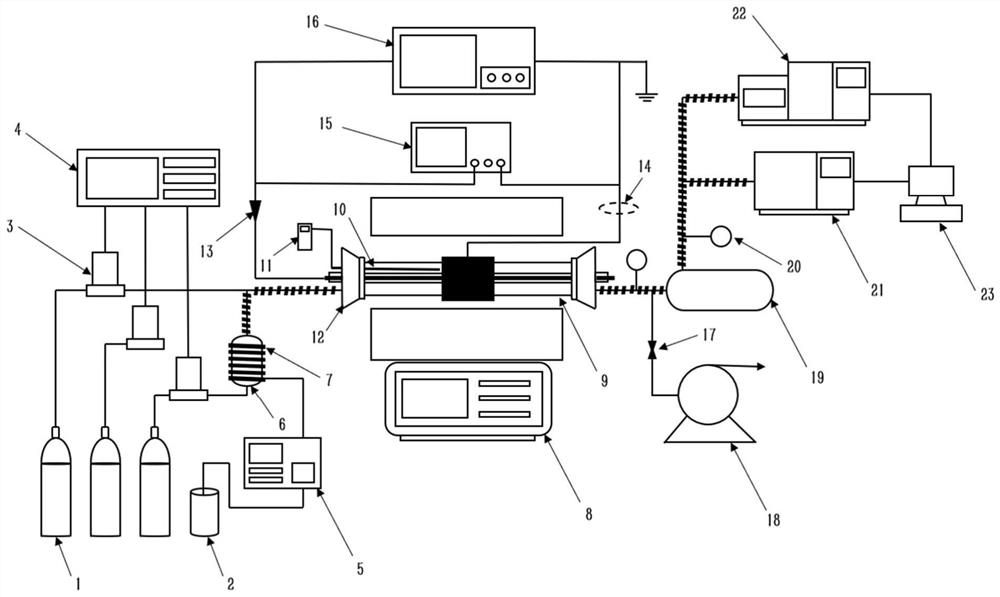

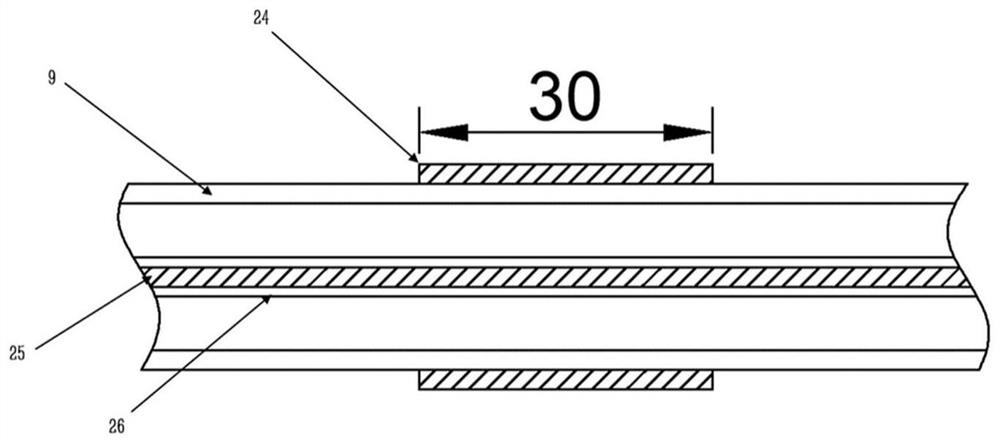

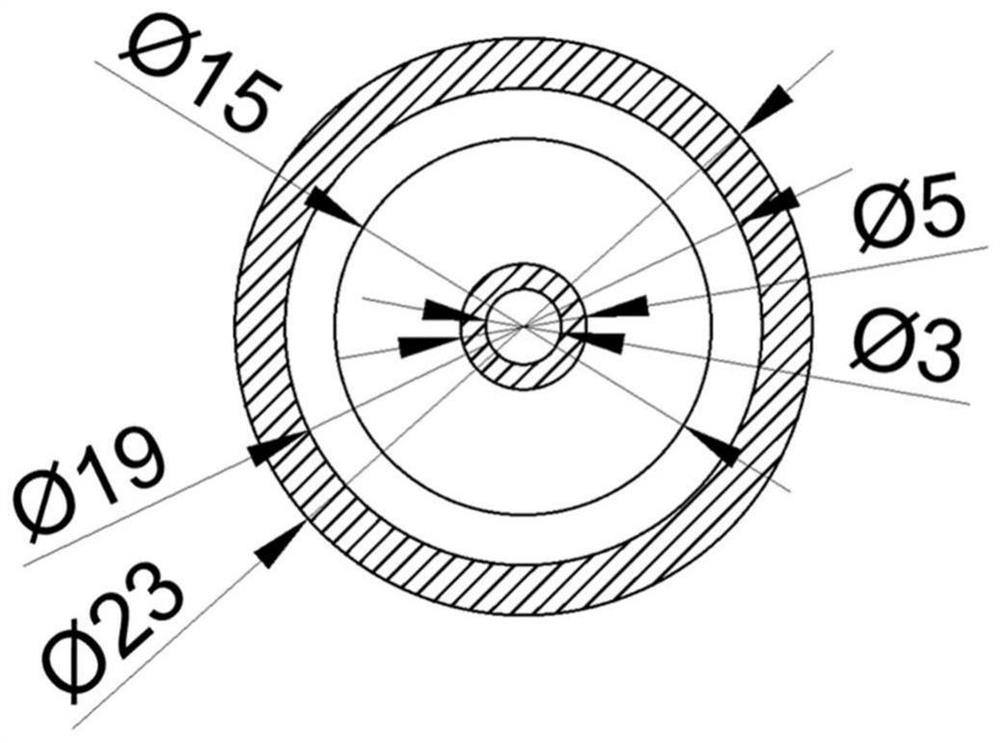

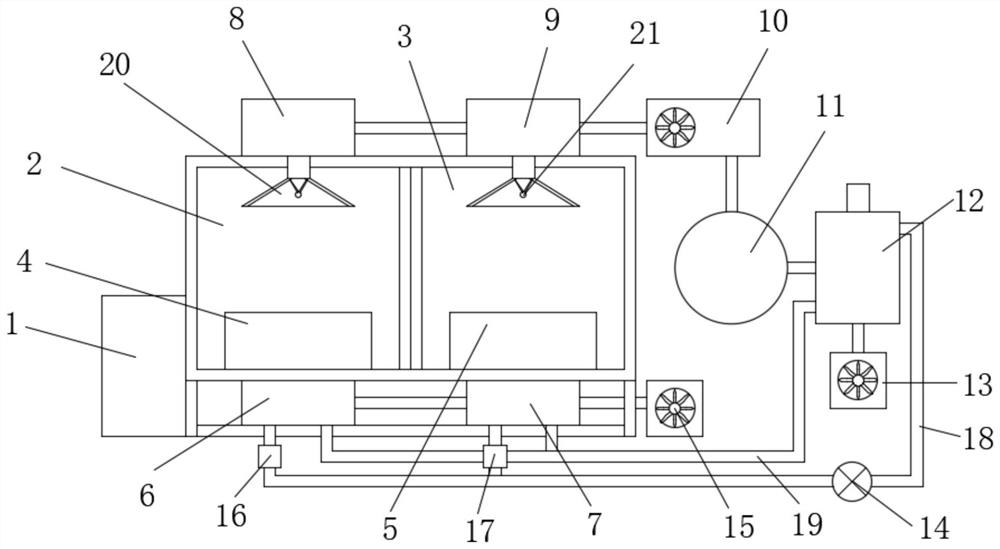

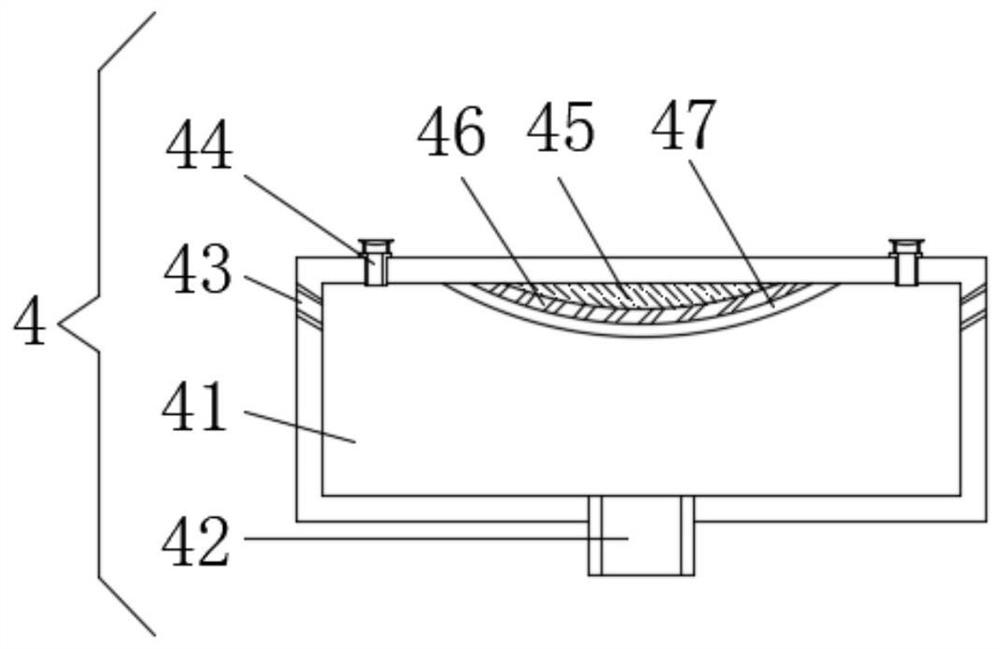

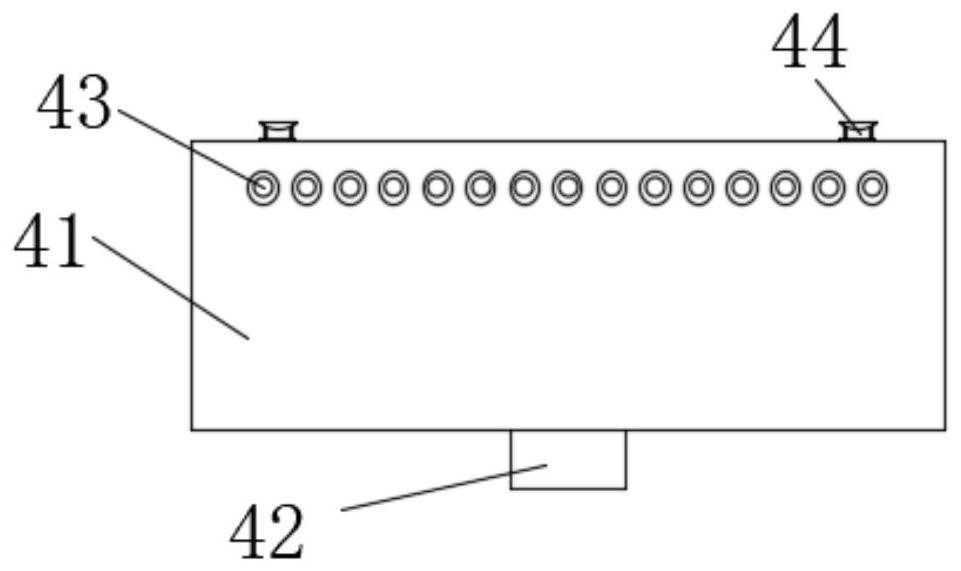

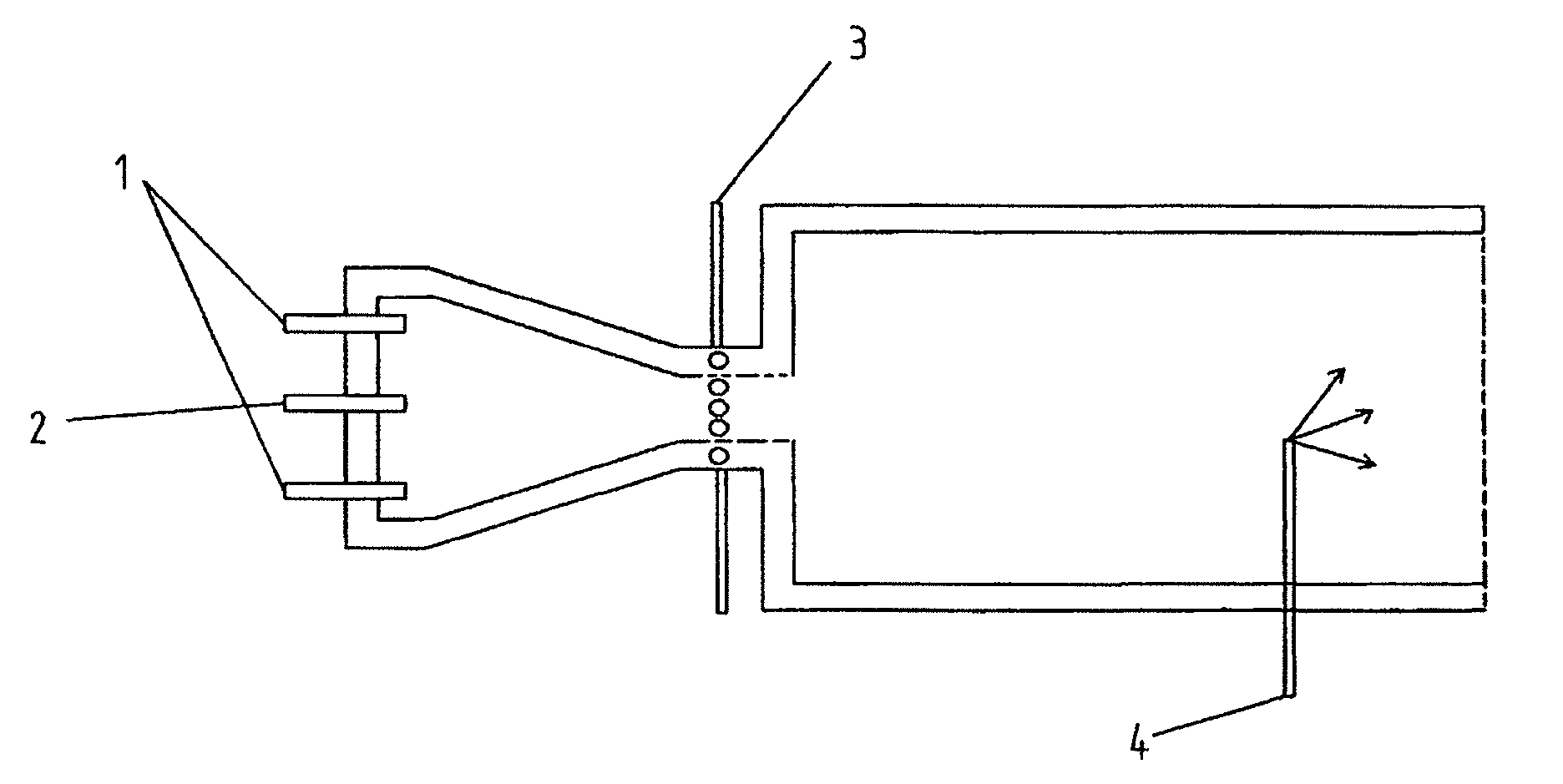

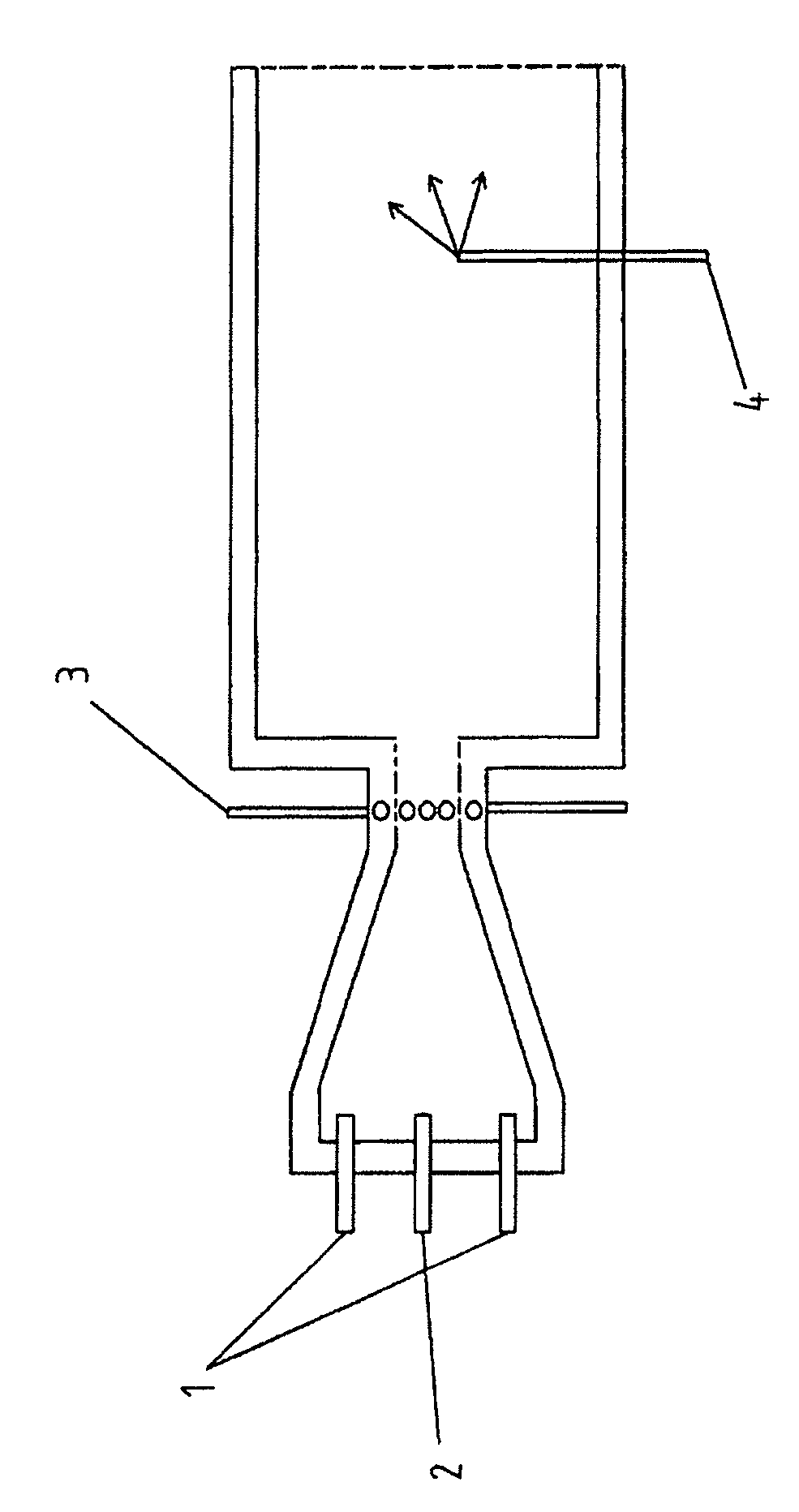

Plasma-assisted experimental platform for oxidation, pyrolysis and reforming of gas-liquid fuel

PendingCN113533583ASmooth detection and analysisUniform discharge electric fieldComponent separationChemical reaction kineticsThermodynamics

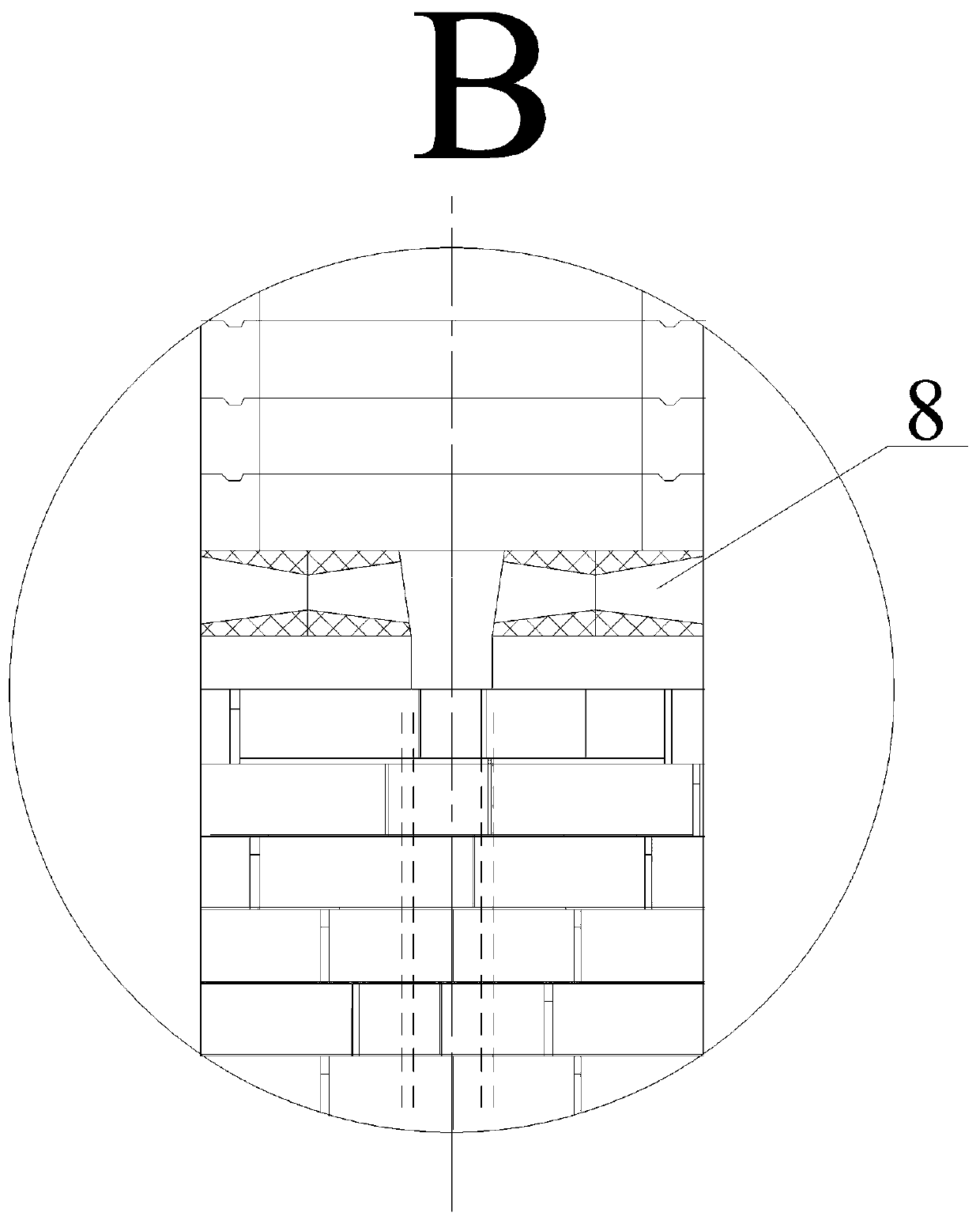

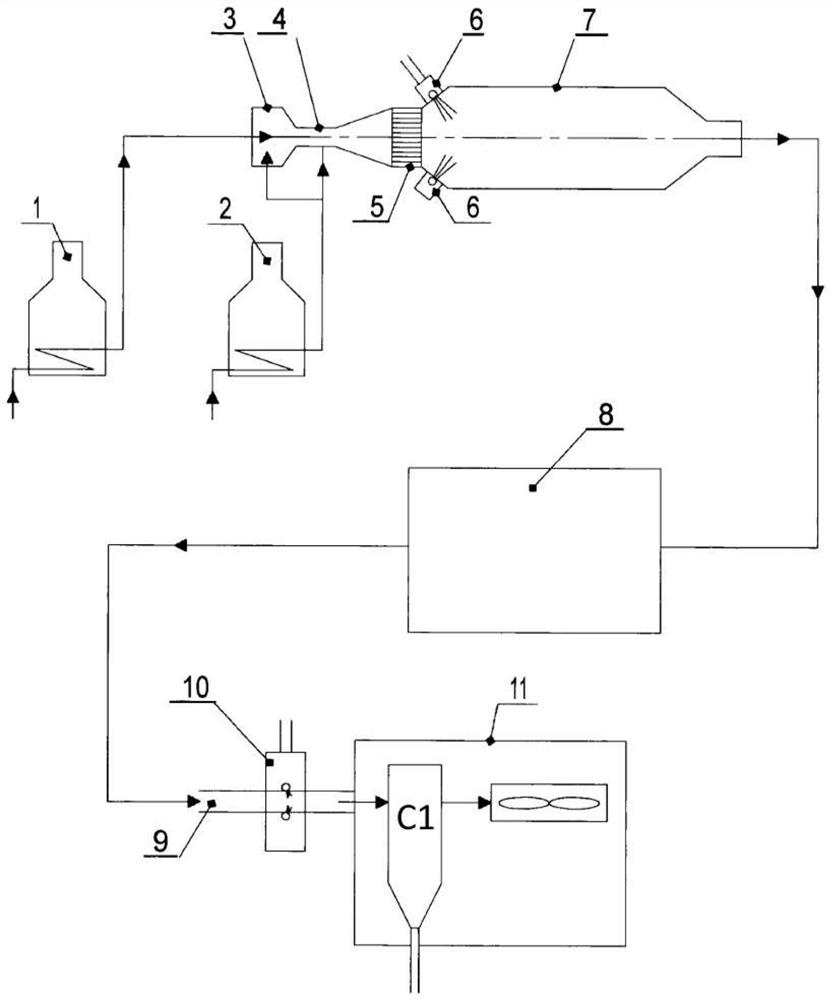

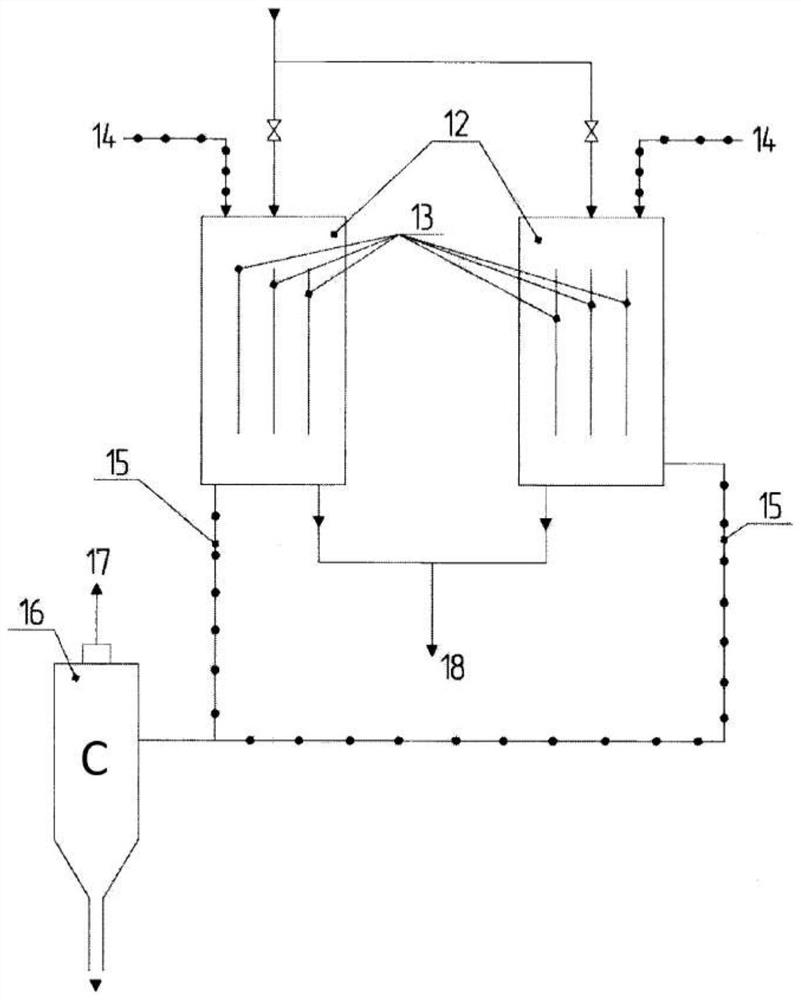

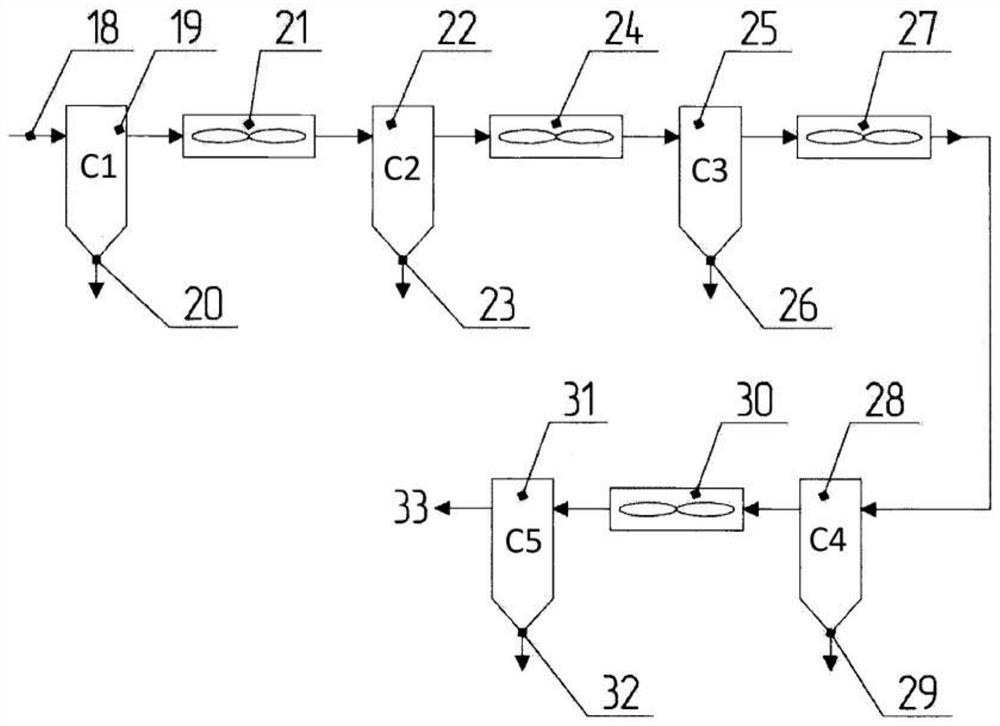

The invention discloses a plasma-assisted experimental platform for oxidation, pyrolysis and reforming of gas-liquid fuel. The platform comprises a gas inlet system, a reaction system, a power supply system, an exhaust system and a product detection system. The gas inlet system is provided with a liquid fuel pump and an evaporation tank which are used for liquid fuel sample injection and evaporation; the reaction system comprises a quartz flow tube with a double-layer dielectric barrier discharge structure and an electric heating furnace, and uniform, high-energy and high-density non-equilibrium plasma can be obtained at different temperatures; the power supply system can meet the requirements of various discharge forms; and a piston type negative pressure gas collecting device contained in the product detection system can meet the requirement for experiments in a negative pressure environment. The invention provides an experimental platform and method for plasma-assisted oxidation, pyrolysis and reforming in a wide pressure and temperature range and in various power supply forms, and is beneficial to the research of gas-liquid fuel about plasma-combustion chemical reaction kinetics and the development of related mechanisms.

Owner:XI AN JIAOTONG UNIV

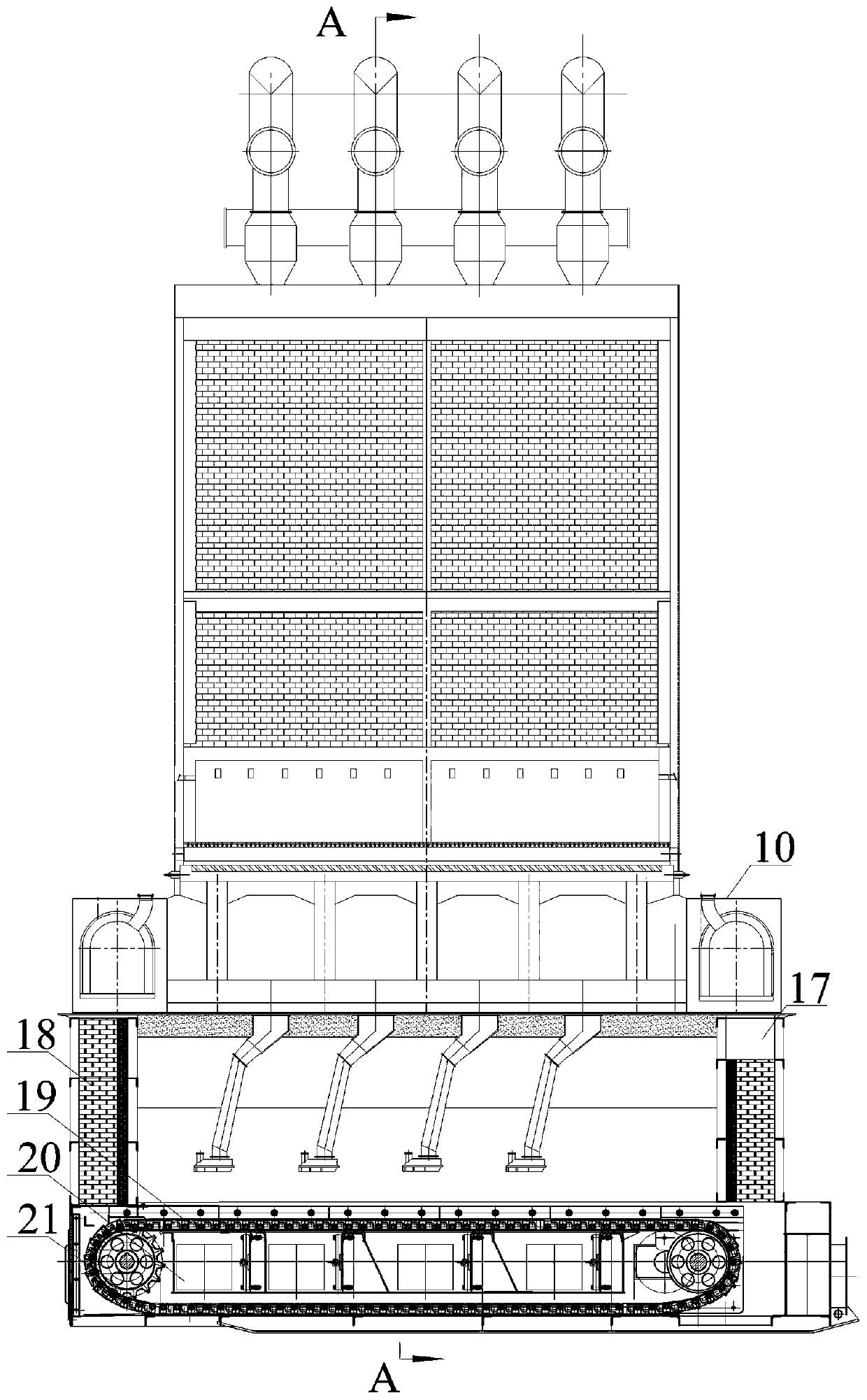

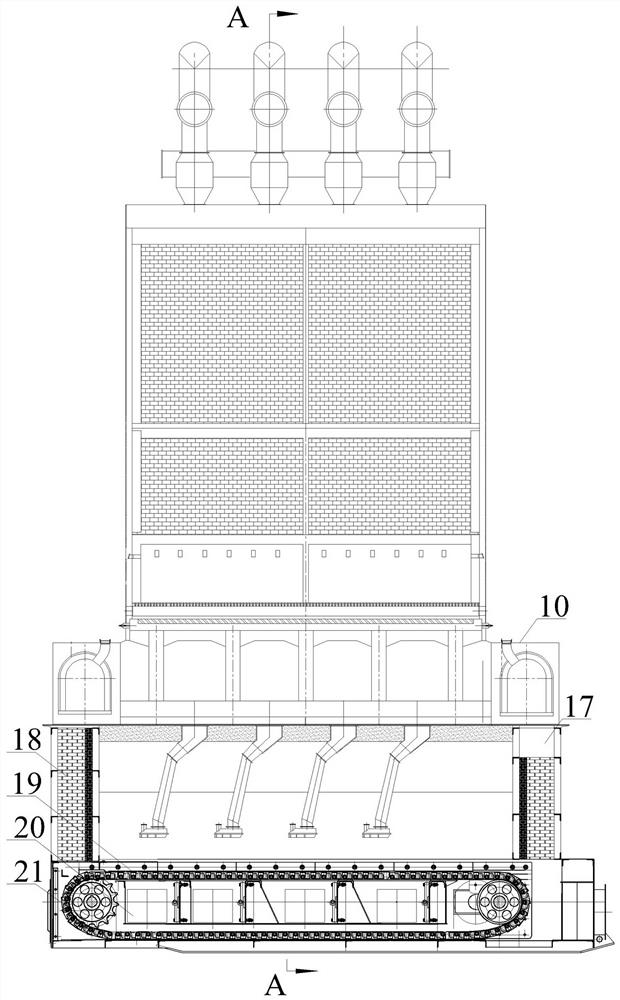

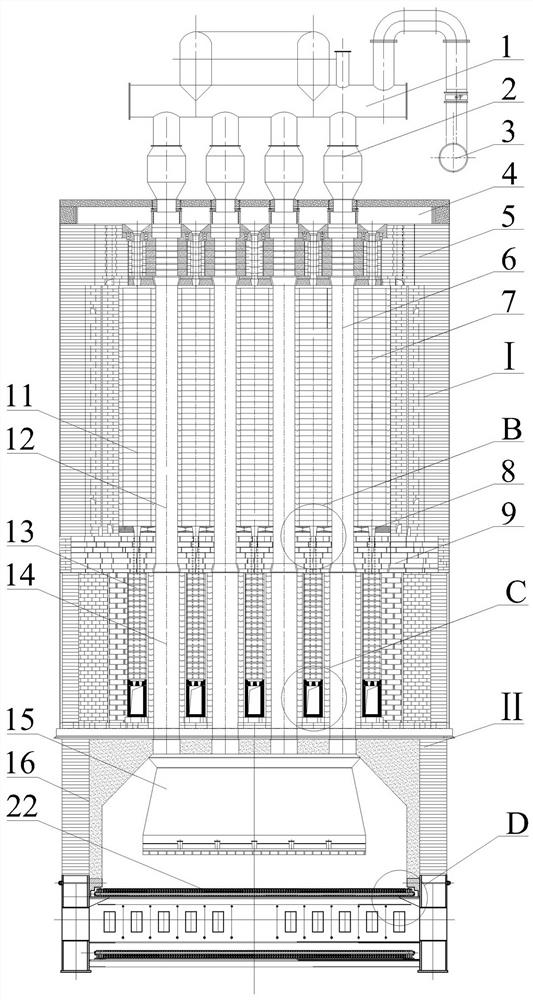

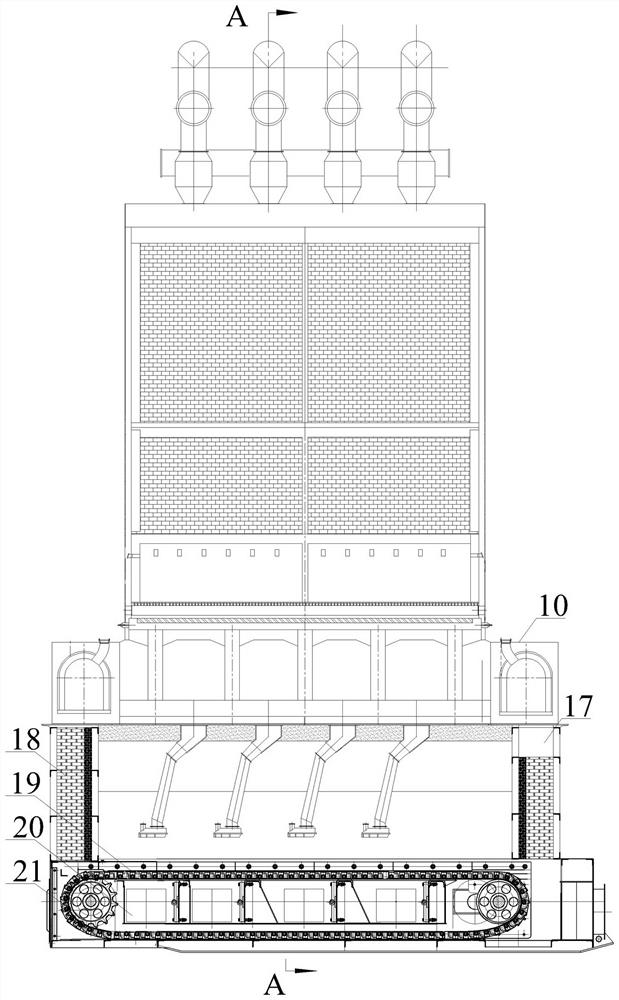

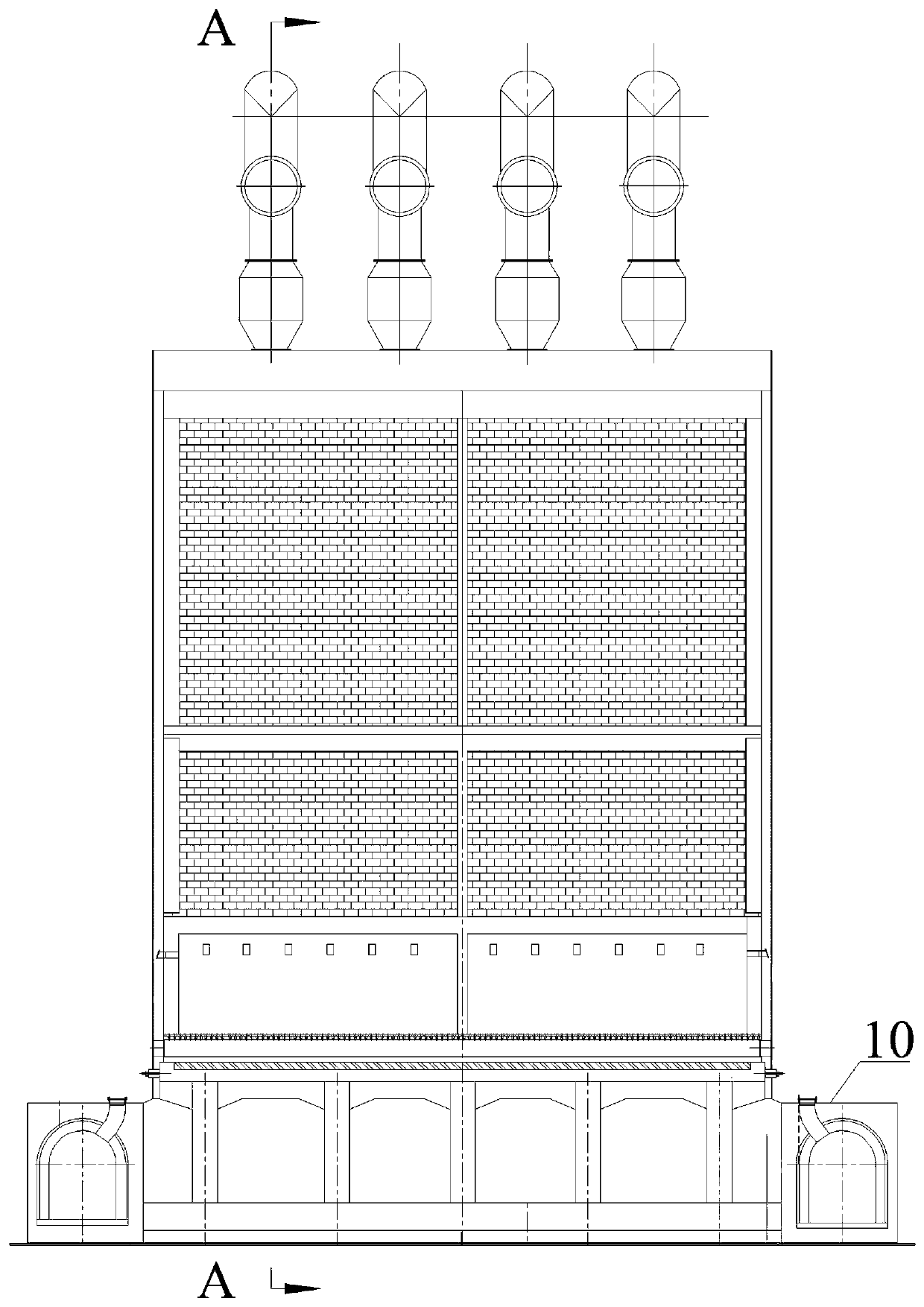

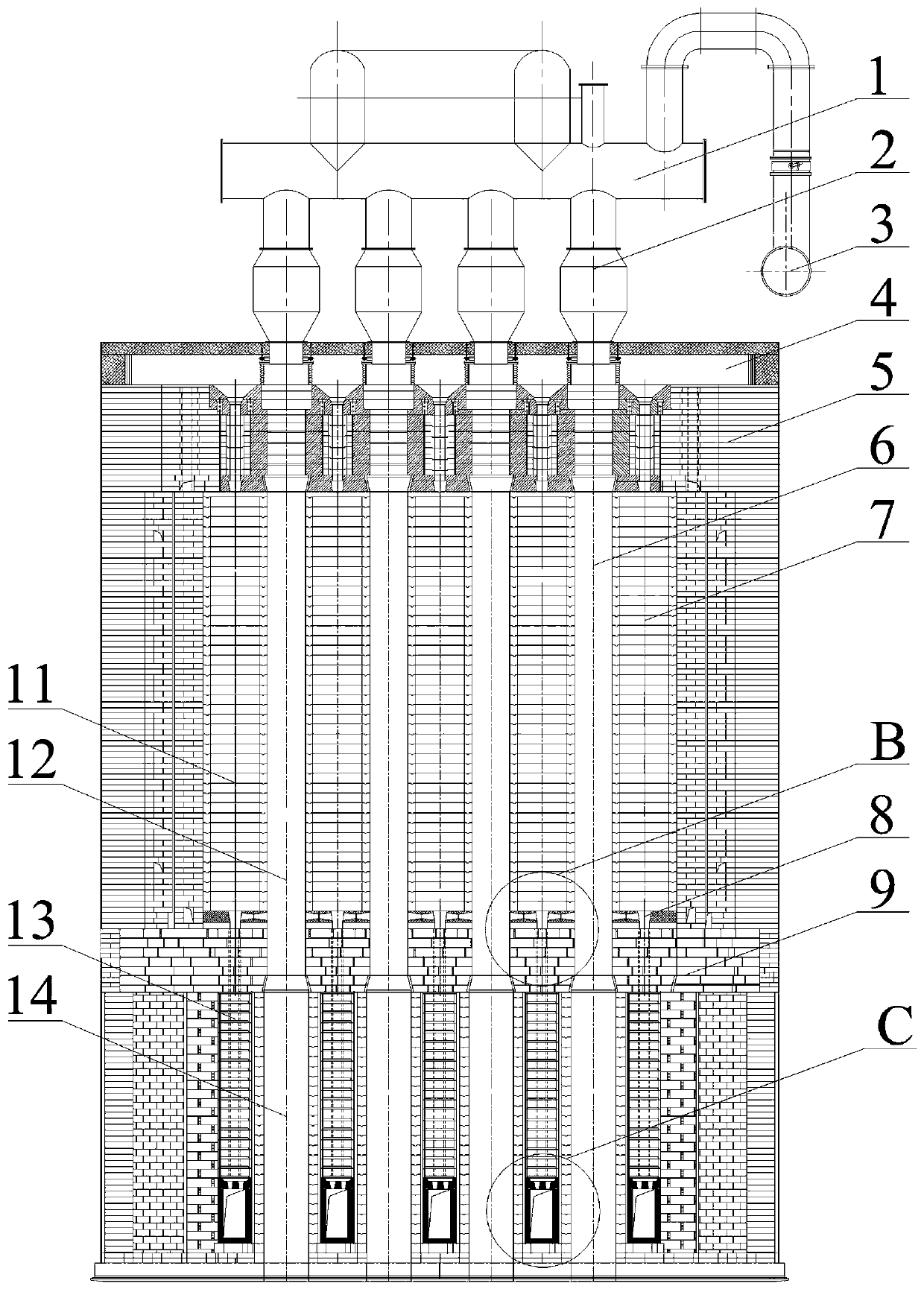

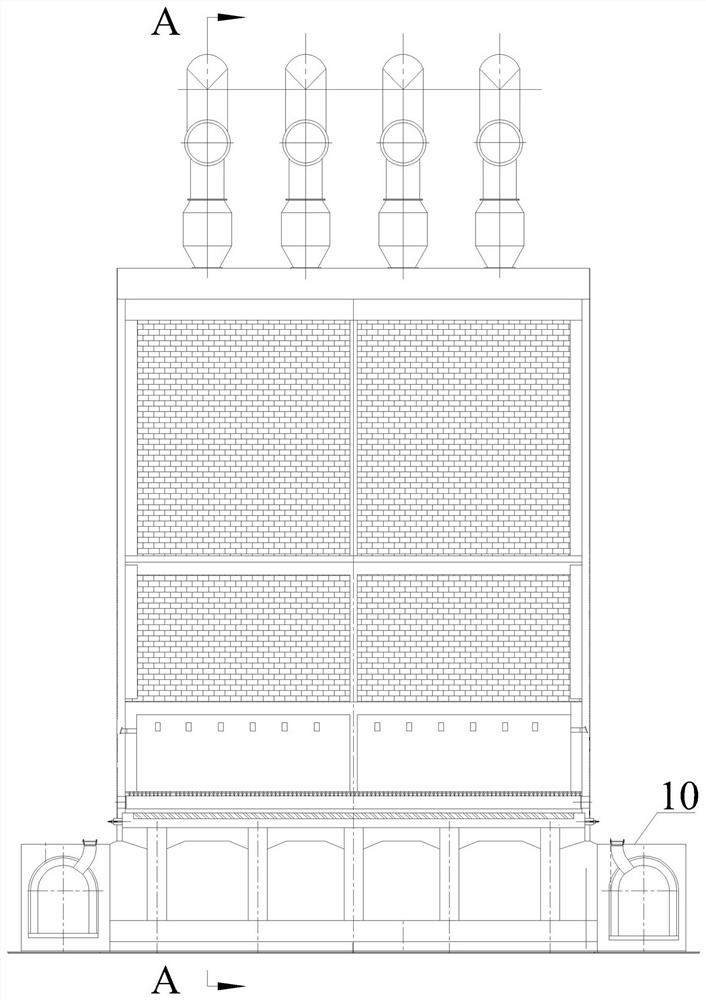

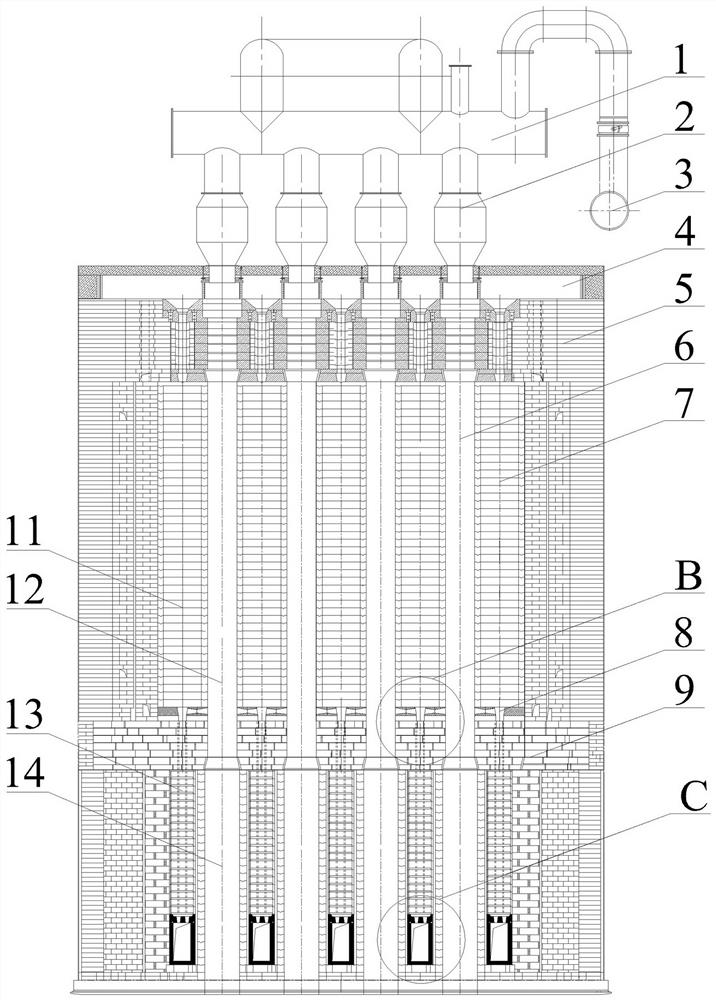

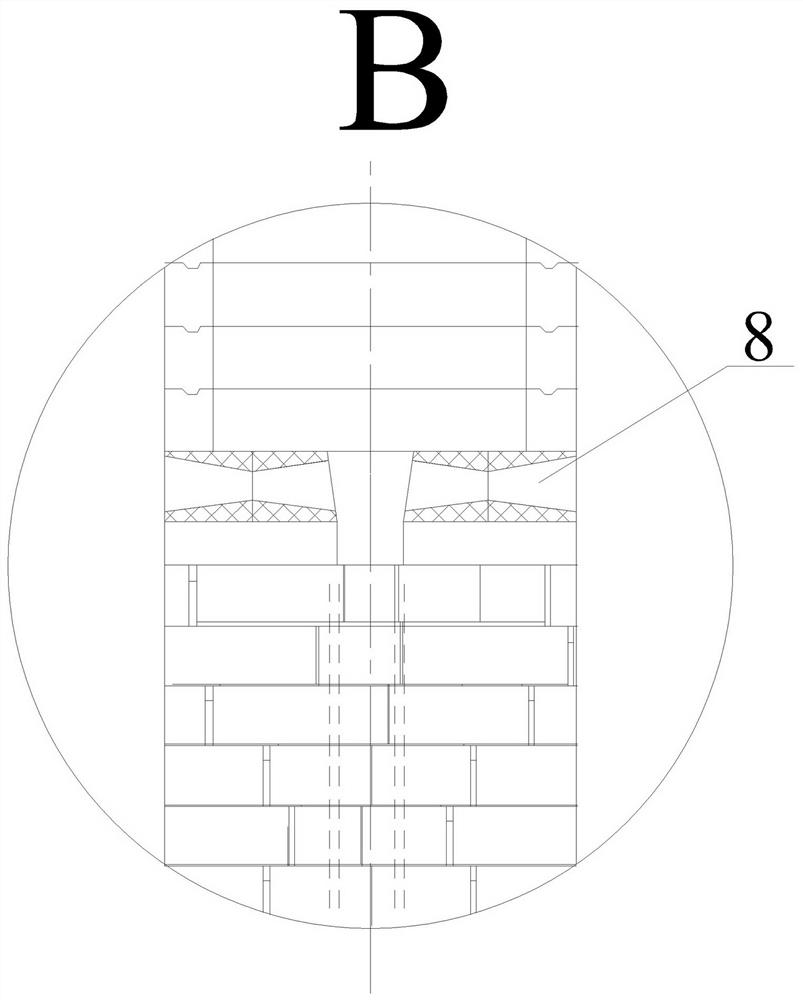

Cyclic regeneration process system for governing VOCs exhaust gas

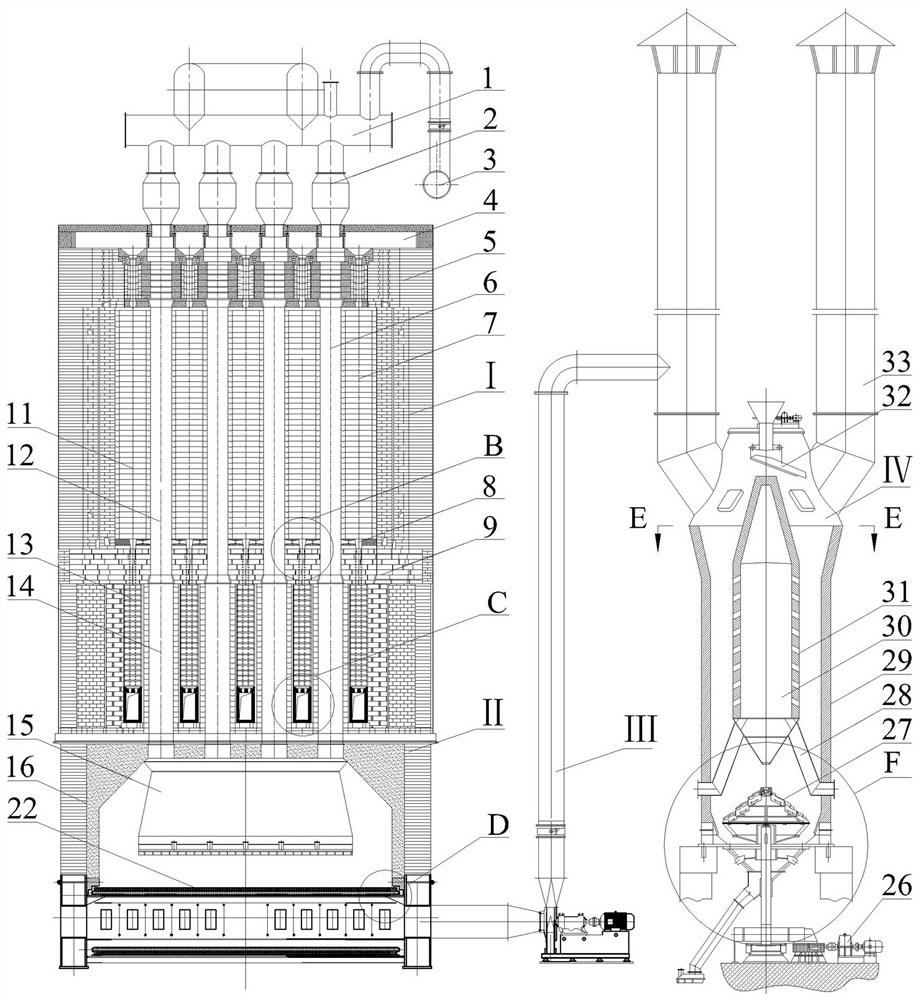

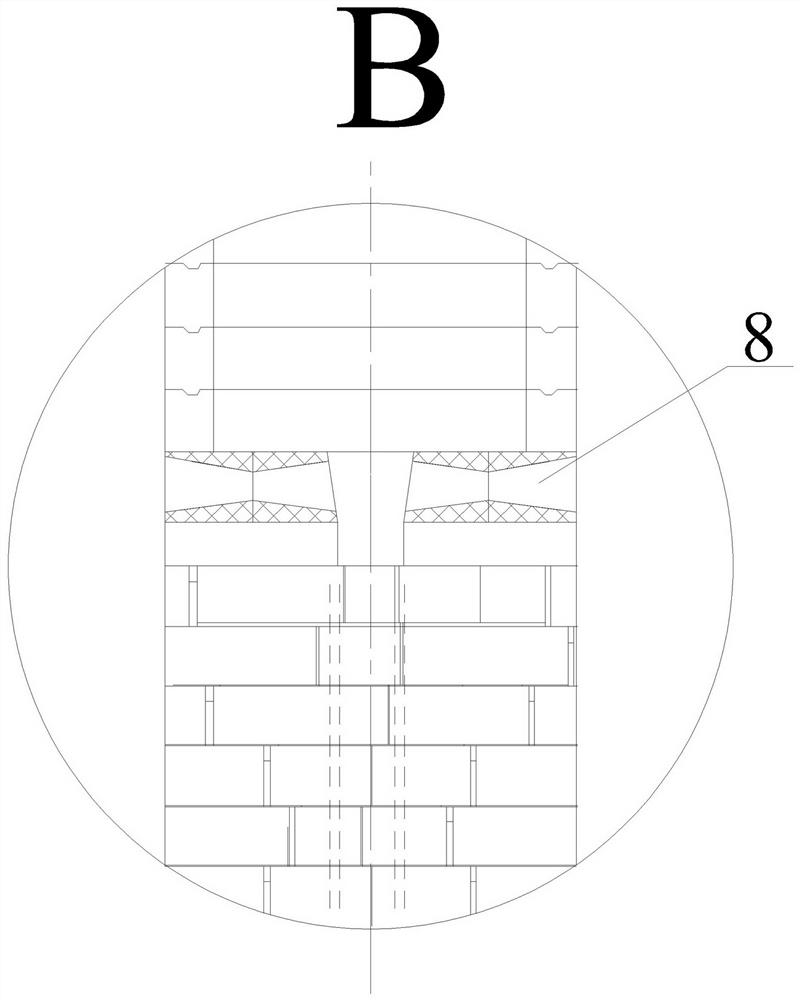

ActiveCN109745824ALower ignition pointImprove the heating effectOther chemical processesDispersed particle separationProcess systemsBrick

The invention relates to the technical field of environmental protection, in particular to a cyclic regeneration process system for governing VOCs exhaust gas. The system is characterized by comprising a desorption pyrolyzing furnace, a chain transmission grate bed, an induced draught system and an adsorbent moving bed. The desorption pyrolyzing furnace comprises a desorption pyrolyzing furnace body and a material supply system. The desorption pyrolyzing furnace body is provided with a flame path and a vertical path, high-temperature glue gas circulates in the flame path, an adsorbent moves tofall off in the vertical path, and the flame path and the vertical path are built adjacently. The material supply system comprises a storage tank and an air injection container. The air injection container introduces tail gas discharged by the flame path into a purging adsorbent, is then mixed with desorbed VOCs exhaust gas and is then conveyed to a pyrolyzing room to be oxidized and pyrolyzed through a grate brick in the bottom of a desorption room. The chain transmission grate bed comprises material legs and a chain transmission grate bed body. A kiln box and a chain transmission grate bedrow are designed on the chain transmission grate bed, an exhaust port is formed in the kiln box, the chain transmission grate bed row comprises a chain wheel, a chain, a grate row and an air distributing plate, and the induced draught system is responsible for introducing and conveying tail gas of an exhaust barrel of the adsorbent moving bed into the air distributing plate of the chain transmission grate bed.

Owner:ZIBO PENGDA ENVIRONMENTAL PROTECTION TECH

A kind of treatment method of waste secondary battery

ActiveCN103730704BAvoid explosionFully oxidative combustionWaste accumulators reclaimingBattery recyclingNitrogen oxidesElectrical battery

The invention belongs to the technical field of hydrometallurgy and chemical production, and discloses a method for treating waste secondary batteries. By burning in two stages in a rotary kiln, the furnace temperature is first maintained at 100-150°C, and the waste secondary batteries are The front part of the furnace is roasted for 30-60 minutes to ensure that the sealing ring of the waste secondary battery is fully pyrolyzed and destroyed, so that the hydrogen and organic solvent in the battery can be released; Maintain at 300~500°C to fully oxidize, pyrolyze, and burn the organic matter in the waste, and effectively control the generation of odor and nitrogen oxides, so that the generated gas can achieve the effect of no peculiar smell, no foul smell, and complete combustion. The treatment method provided by the invention has a reasonable design, is incinerated first and then crushed, has a high crushing rate, a high recovery rate of valuable elements, can avoid high-temperature incineration and explosion accidents, is safe and pollution-free, and is suitable for popularization.

Owner:GANZHOU HIGHPOWER TECH CO LTD

Intelligent energy-saving and emission-reducing system of drying furnace

ActiveCN112902570AAvoid levelingAvoid brick crackingDrying gas arrangementsDrying chambers/containersOrganic solventPhysical chemistry

The invention discloses an intelligent energy-saving and emission-reducing system of a drying furnace. The intelligent energy-saving and emission-reducing system comprises a main controller, a flash drying chamber, a constant temperature chamber, a first fresh air machine, a concentration runner device and a pyrolyzing furnace, wherein the flash drying chamber and the constant temperature chamber are fixedly arranged side by side, and the main controller is fixedly arranged on the outer wall of the left side of the flash drying chamber; paint on the surface of a device can be subjected to flash drying through the flash drying chamber, so that a curing film layer is formed on the surface of the paint, and the phenomenon of leveling is avoided; the paint between the surface of the device and the curing film layer can be evaporated to be dry at a constant speed through the constant temperature chamber at a constant temperature, so that the drying speed is increased, and meanwhile, the problems of paint brick cracking and air holes caused by too fast drying are avoided; air containing organic solvent gas is concentrated through the concentration runner device and then is guided into the pyrolyzing furnace, so that the organic solvent gas is subjected to oxidation pyrolysis, and the pollution is reduced; and through a heat conduction pipe and a cold return pipe, heat generated when the pyrolyzing furnace is used for carrying out oxidation pyrolysis on the organic solvent gas is recycled, so that the energy consumption is reduced.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

Zeolite membrane regeneration method

ActiveUS9205417B2Restore permeation amountLowering separation coefficientMembranesSemi-permeable membranesThermal expansionOxidative pyrolysis

Provided is a simple method for regenerating a zeolite membrane which has been exposed to water. The method for regenerating a zeolite membrane is a method for regenerating a zeolite membrane which is formed on a ceramic porous body and subjected to removal treatment of structure directing agent. Heating is performed at a regeneration temperature at which the difference in ratio of thermal expansion amount between the ceramic porous body and the zeolite membrane is 0.3% or less when 40° C. is set as datum. The regeneration temperature is preferably a temperature not exceeding the oxidative pyrolysis temperature of the structure directing agent used in the formation of the zeolite membrane.

Owner:NGK INSULATORS LTD

Low-odor rubber product

The invention discloses a low-odor rubber product, comprising, ethylene propylene diene monomer rubber, modified neoprene, carbon black N550, an activator, plasticizer 2240, a filling agent, zinc oxide, dispersant 935P, polyethylene glycol, stearic acid, sulfur, a promoter, and odor absorber RT500. Through the coordination of the modified neoprene with ethylene propylene diene monomer rubber, carbon black, odor absorbent RT500, zinc oxide, activator and the like, the low-odor rubber product has no fouling odor, never produces stimulating odor during long-term usage, and also has the good properties of weatherability, fire resistance, ozone resistance, heat resistance, oxidative pyrolysis resistance, oil resistance, solvent resistance, aging resistance, and shock resistance.

Owner:ANHUI TAIDA AUTOMOTIVE PARTS

Preparation method of phoenix tree flower essential oil and anti-tumor application thereof

The invention relates to a preparation method of phoenix tree flower essential oil and an anti-tumor application thereof. The preparation method comprises the following steps: drying phoenix tree flowers in the shade, crushing and screening the phoenix tree flowers by a 20-mesh sieve, putting into an extraction cylinder for cycle extraction, and collecting an extractant after vacuum analysis with a separation kettle, so as to obtain the phoenix tree flower essential oil. The method disclosed by the invention is less in elapsed time and high in yield, and more ingredients are extracted, oxidization and pyrolyzation of the essential oil are prevented, and the quality of the essential oil is improved. The essential oil obtained by the method disclosed by the invention has relatively good anti-tumor activity, and a new way is opened up for development and application of a new generation of anti-tumor drugs with a natural source.

Owner:NANJING ZELANG MEDICAL TECH

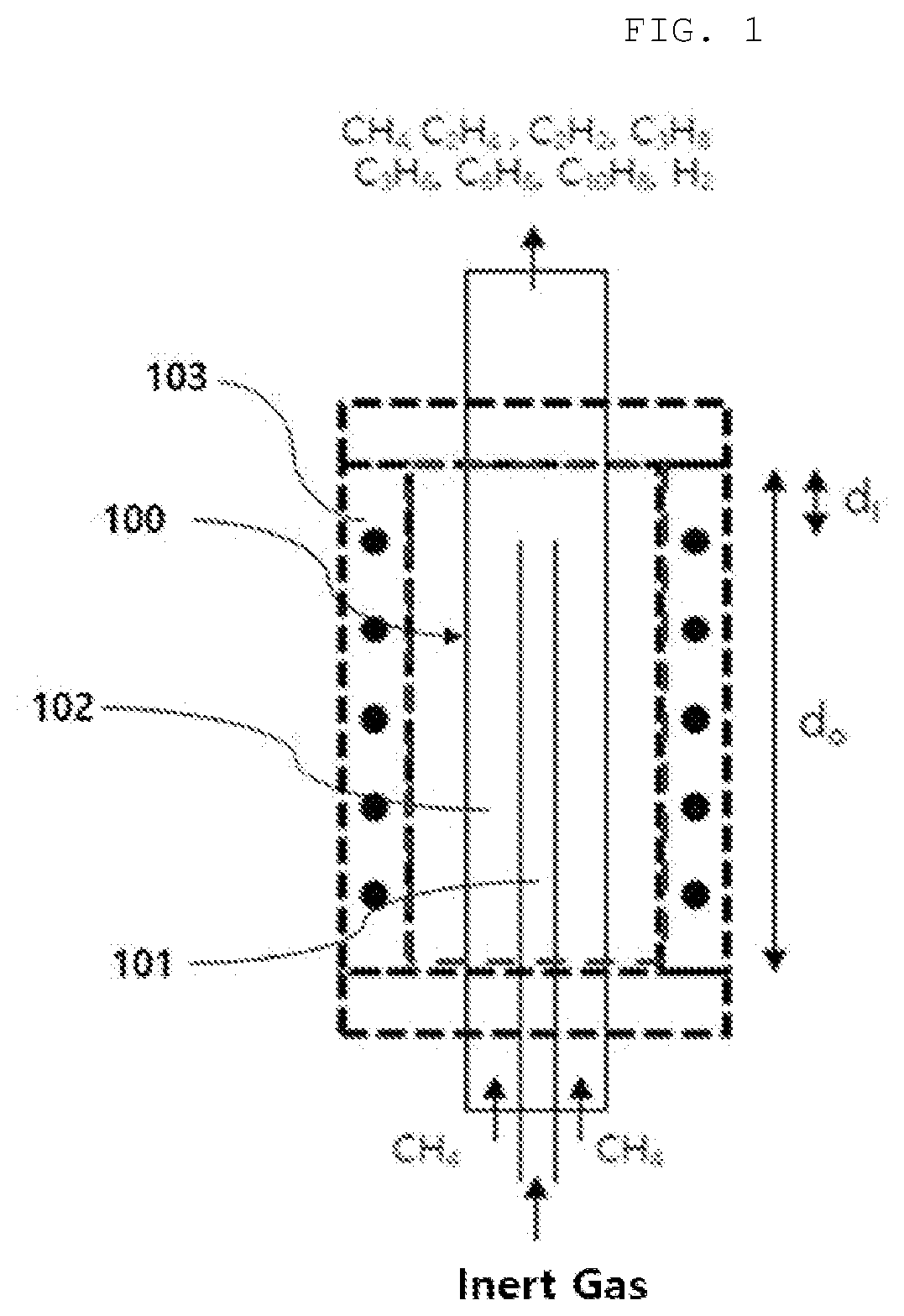

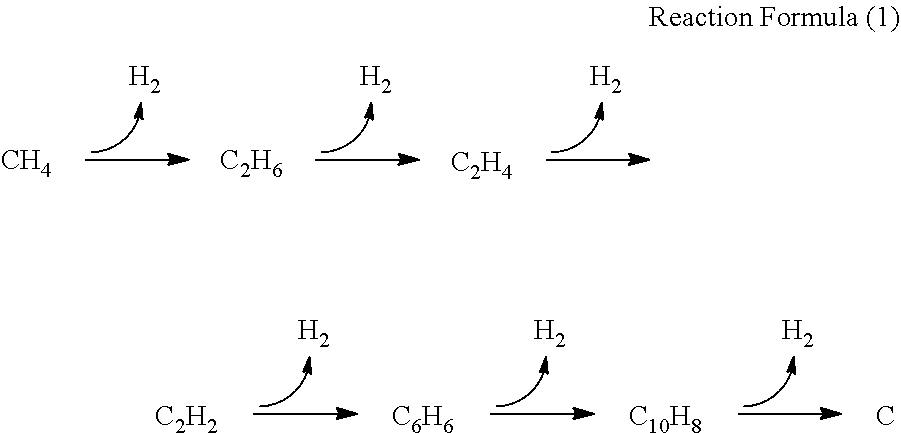

Reactors for Preparing Valuable Hydrocarbons and Hydrogen From Methane Through Non-Oxidative Pyrolysis

ActiveUS20210309589A1Speed up the conversion processMaximizing selectivityHydrogen separation using solid contactHigh temperature gas-gas reactionHydrocotyle bowlesioidesNon oxidative

According to this disclosure, there is provided a pyrolysis reaction system and a direct non-oxidative methane coupling process using the same by which it is possible to reach the selectivity for good C≤10 hydrocarbons and at the same time to inhibit coke from being generated while a good methane conversion is maintained during direct conversion of methane into C2+ hydrocarbons through non-oxidative pyrolysis.

Owner:SK INNOVATION CO LTD

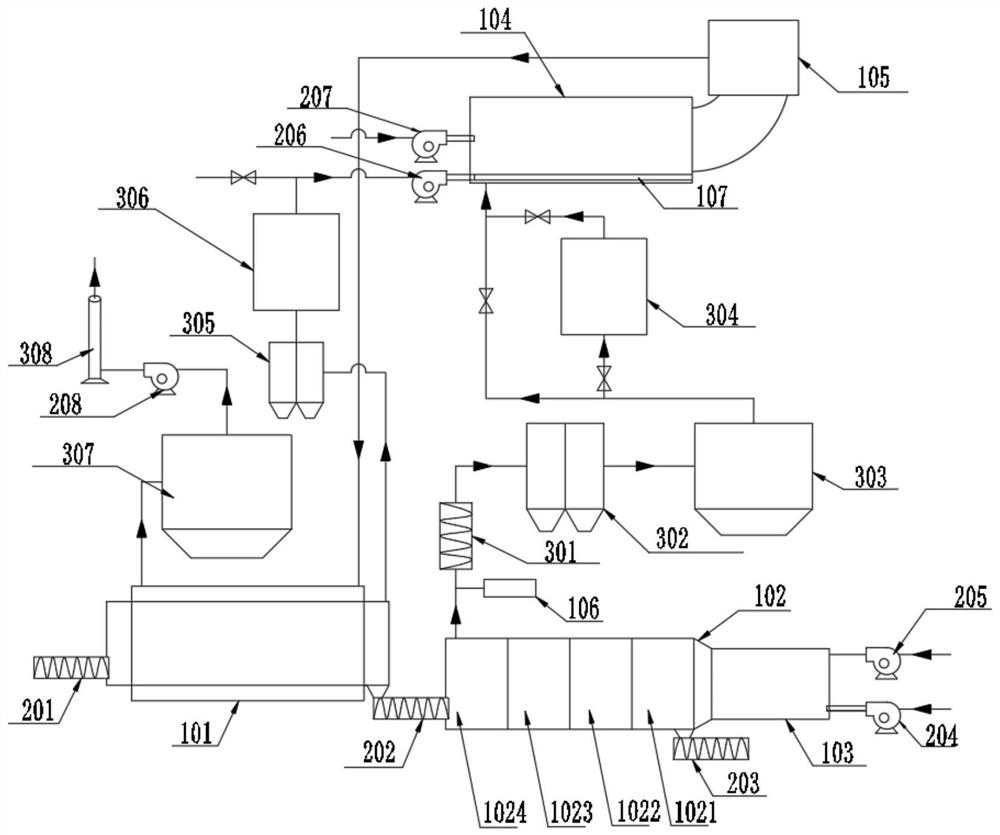

High-temperature oxidation, pyrolysis and thermal desorption integrated oily sludge treatment apparatus and process technology

PendingCN113772915AHigh thermal efficiencyAvoid cloggingCombination devicesSludge treatment by de-watering/drying/thickeningOil sludgeOxidative pyrolysis

The invention discloses high-temperature oxidation pyrolysis and thermal desorption integrated aged oil sludge treatment apparatus and process technology. The high-temperature oxidation pyrolysis and thermal desorption integrated aged oil sludge treatment apparatus comprises an indirect heating drying kiln, and a raw material conveying device A is mounted at the feeding end of the indirect heating drying kiln; a raw material conveying device B is connected between the discharging end of the indirect heating drying kiln and a feeding opening of an oxygen-controlled thermal desorption unit in a communicated mode; a raw material conveying device C is installed at a discharging opening of the oxygen-controlled thermal desorption unit; an oxygen-controlled hot air generator is arranged at a combustion opening of the oxygen-controlled thermal desorption unit; oily sludge is directly heated through oxygen-controlled high-temperature flue gas; the oily sludge is subjected to high-temperature oxidation at the tail end of the oxygen-controlled thermal desorption unit, so that oil is thoroughly removed, heat energy is released, and the heat efficiency is improved on the basis of direct heat exchange; a flue gas electric heating system is arranged for flue gas discharged from the oxygen-controlled thermal desorption unit, so that the flue gas is prevented from condensing and blocking equipment; and oil products are recycled after the oil-containing and dust-containing flue gas subjected to thermal desorption is purified, and the recycled oil is high in quality and can be recycled.

Owner:新疆沃森环保科技有限责任公司

Carbon black, method for the production thereof, and use thereof

ActiveUS9493659B2Increase contentNarrow aggregate size distributionPigmenting treatmentNon-macromolecular organic additionPolymer scienceAdhesive

Owner:EVONIK CARBON BLACK GMBH

A kind of preparation method and application of cuo nanoparticle doped cu-mof/carbon dot composite catalyst

InactiveCN109622053BSimple preparation processLow costOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesAir atmospherePtru catalyst

The invention discloses a preparation method of a Cu-MOF / carbon dot composite catalyst doped with CuO nanoparticles and the application of the catalyst for electrocatalytic nitrogen reduction at room temperature, belonging to the technical fields of catalytic technology and nanocomposite materials. The main step is to convert the ligand H 6 L solution and Cu(NO 3 ) 2 3H 2 O and glucose were blended to obtain a raw material mixture; the raw material mixture was heated at 90°C for 2 days to obtain a glucose-doped polynitrogen Cu-MOF crystal; the glucose-doped polynitrogen Cu-MOF crystal was placed in the air atmosphere of a tube furnace Oxidation-pyrolysis at 300 °C for 2 h to prepare CuO nanoparticles-doped Cu-MOF / carbon dot composite catalyst. The raw materials used in the preparation of the catalyst have low cost and simple process, and the catalyst is used for electrocatalytic reduction of nitrogen into ammonia at room temperature, and has good catalytic performance and industrial prospect.

Owner:UNIV OF JINAN

Pyrolysis harmless treatment method for sulfur-containing cyanidation leaching tailings

InactiveCN114713591APromote degradationReduce oxidationSolid waste disposalTransportation and packagingCyanide compoundCyanide level

The invention relates to a pyrolysis harmless treatment method for thiocyanation-containing leaching tailings, which comprises the following steps: adding a thiocyanation-containing leaching tailings filter cake obtained by filter pressing into a rotary kiln, heating, oxidizing and decomposing the thiocyanation-containing leaching tailings by utilizing the characteristic that a cyanogen-containing compound is easy to decompose at a high temperature, and driving materials in the rotary kiln to turn over when the rotary kiln rotates, and the self-crushing effect is achieved, and the oxidation reaction speed of cyanide is increased. By controlling the highest pyrolysis temperature and adjusting the pyrolysis atmosphere in the kiln, the concentration of oxygen and CO is controlled within a proper range, oxidation of sulfides in the tailings can be avoided, the content of SO2 in pyrolysis flue gas reaches the emission standard, the content of toxic leaching total cyanide in the treated tailings reaches the related standard of class I general solid waste, and the method is suitable for industrial production. And clean and efficient harmless treatment of the thiocyanation tailings is realized.

Owner:BACKFILL ENG LAB SHANDONG GOLD MINING TECH CO LTD

Preparation method for natural cream flavour

The invention discloses a preparation method for a natural cream flavour, which is a method for preparing the cream flavour by way of the dry fractionation of cream in combination with the oxidative pyrolysis technology and the enzymatic hydrolysis technology. The preparation method includes the following steps: cream is adopted as material, and the cream is divided into a component A and a component B within different melting point ranges according to the melting point of each component in the cream or the different intersolubilities of the cream under different temperatures, and therefore is separated; the air is then added under the stirring condition, so that the component A can be heated and oxidated, and thereby oxide C is produced; the component B and the oxide C are mixed and enzymatically hydrolyzed, and thereby the cream flavour is prepared. The method fractionates the different components of the cream, and pertinently carries out oxidation and oxidative pyrolysis, the cost can be greatly saved, the high-yield and high-efficiency cream flavour can be obtained, the technique for preparing the cream flavour by utilizing the technique provided by the invention and enzyme source is simple, and is suitable for industrialized production, the product has the advantages of both zymolyte and oxide, and the aroma is mellow, rich, strong and natural.

Owner:SHANGHAI AIPU VEGETABLE TECH +1

A VOCS waste gas adsorbent desorption pyrolysis process

ActiveCN109745823BLower ignition pointEmission reductionOther chemical processesDispersed particle separationSorbentExhaust fumes

The invention relates to the technical field of environmental protection, in particular to a desorption pyrolysis process of a VOCs waste gas adsorbent. Its characteristics are: start the feeding system to feed materials to the vertical channel, the adsorbent moves continuously in the vertical channel from top to bottom under the action of gravity, and the air injection header reuses the tail gas discharged from the fire channel to purge the adsorption in the vertical channel and then mixed with the desorbed VOCs waste gas and sent to the pyrolysis chamber for oxidative pyrolysis through the grate brick at the bottom of the desorption chamber. The excess oxygen in the gas oxidizes and pyrolyzes it, and the tail gas flows into the smoke exhaust header, and the exhaust gas is collected by the air injection header and re-entered into the vertical channel. The return ratio is designed to be 1:10; the air distribution plate will pass through the VOCs exhaust gas The exhaust tail gas treated by the environmental protection purification facility is introduced, and the tail gas flows into the adsorbent that is purged and cooled and paved on the chain-driven grate bed row through the gap between the adjacent grate bed rows, and quickly completes the process of mass transfer and heat transfer with the adsorbent particles, and then Then it is discharged through the smoke outlet of the kiln box.

Owner:宋丽 +2

A method of high-pressure air oxidative cracking flooding into low-permeability reservoirs

ActiveCN106050200BImprove liquidityIncrease gas injection rateFluid removalEngineeringOxidative pyrolysis

The invention provides a method for injecting high-pressure air into a low-permeability reservoir to perform oxidative pyrolysis and displacement of oil. Before air displacement for oil extraction is performed, high-temperature hot water is firstly injected to form a first slug, then three-phase nitrogen foam is injected to form a second slug, an injected air and the three-phase nitrogen foam mixed-phase substance serves as a third slug, then high-pressure air is injected to perform air displacement for oil extraction, and high-pressure air injection is conducted on stratum under the pressure of 25-50 MPa. The method can effectively conduct viscosity reduction and cooling on formation oil at the initial stage of the air displacement, a round oxidative pyrolysis zone is rapidly formed in the oil layer, the liquidity of the crude oil in an oil reservoir is improved, the low-permeability reservoir originally difficult to develop is improved, and the recovery rate is improved in a long-acting mode. The method is suitable for the low-permeability reservoir, the optimum condition is the reservoir depth of 1300-4900 meters, the reservoir thickness is more than 2.5 meters, the reservoir temperature is greater than 55 degrees, the oil saturation is above 30%, the permeability is greater than 1 millidarcy, and the connectivity is above 80%.

Owner:中嵘能源科技集团有限公司

A process system for treating vocs exhaust gas circulation and regeneration

ActiveCN109745824BLower ignition pointImprove the heating effectOther chemical processesDispersed particle separationProcess systemsOxidative pyrolysis

The invention relates to the technical field of environmental protection, in particular to a recycling process system for treating VOCs waste gas. It is characterized in that it includes a desorption pyrolysis furnace, a chain drive grate bed, an air induction system, and an adsorbent moving bed; the desorption pyrolysis furnace includes a desorption pyrolysis furnace body and a feeding system; the desorption pyrolysis furnace body There are fire passages and vertical passages designed, the fire passages are for the circulation of high-temperature flue gas, and the vertical passages are for the moving and falling of the adsorbent. The fire passages and vertical passages are adjacent to each other; the feeding system includes storage tanks, air injection headers, The tail gas discharged from the flue is introduced into the purge adsorbent, and then mixed with the desorbed VOCs waste gas and sent to the pyrolysis chamber for oxidation and pyrolysis through the grate brick at the bottom of the desorption chamber; the chain drive grate bed includes material legs and chain drive grate bed body; The chain drive grate bed body is designed with a kiln box and a chain drive grate bed row. The kiln box is designed with a smoke exhaust port. The chain drive grate bed row includes a sprocket, a chain, a grate bed row, and an air distribution plate. The exhaust gas from the exhaust tube of the moving bed is introduced into the air distribution plate of the chain drive grate bed.

Owner:ZIBO PENGDA ENVIRONMENTAL PROTECTION TECH

Light flame-retardant phenolic foam material and preparation method thereof

The invention relates to a light flame-retardant phenolic foam material and a preparation method thereof and belongs to the technical field of heat-preservation materials. According to the preparationmethod, double bonds in linseed oil molecules are enabled to join in reactions to be a part of a polymer structure, so that a modified phenolic resin solid is of an interpenetrating polymer network structure, the thermal resistance and the thermal stability of a phenolic resin are effectively improved, titanium diboride is coated by the phenolic resin, the titanium diboride is subjected to oxidation-reduction reactions with an oxygen-containing gas at a high temperature, elements of C and O in a pyrolysis gas are absorbed and converted into solid products such as irregular titanium and TiO2,and relatively intense oxidative pyrolysis of a resin substrate is inhibited; in addition, the resin substrate is embedded into a framework of phenolic foams, the density of the framework is improved,the integrity of a phenolic foam high-temperature pyrolysis product is improved, the residual weight and the strength of a composite material after high-temperature pyrolysis are increased, and the flame retardancy and the fireproof properties of the composite materials are remarkably improved.

Owner:常州琨瑶纺织品有限公司

Preparation of flavouring powdery fat

The invention provides a method for preparing flavored powder without oil. The method uses refined oil and natural seasoning materials containing protein, active peptide, carnosine, amino acid, nucleotide and vitamin as main raw materials, and includes the following main technical processes: (1) Oxidative pyrolysis of refined oil; (2) Maillard reaction of pyrolysis oil and natural seasoning to obtain flavor oil; (3) Embedding flavor oil microcapsules and drying powder to obtain Taste powder without fat product. The product not only contains high fat, but also contains complex natural seasonings, which have multiple flavoring and flavoring effects.

Owner:广州市味研生物工程科技有限公司

High cis-1,4 content hydroxyl terminated polybutadiene liquid rubber and preparation method thereof

The invention discloses a high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and a preparation method thereof. The method includes following steps: (1) preparing epoxidized butadiene rubber from butadiene rubber; (2) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the epoxidized butadiene rubber; (3) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the butadiene rubber in a one-pot manner; (4) reducing the high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber to prepare the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber. In the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber is prepared from the butadiene rubber and the content of cis-1,4 can reach 95.0-99.0%. A number-average molecular weight of the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be regulated between 2000 g / mol and 10000 g / mol. A molecular weight distribution is 1.2-3.0 and a degree of functionality is 1.9-2.2. On the basis of excessive supply in raw rubber of butadiene rubber and increased tensing situation of petroleum sources, by means of the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be prepared through oxidative pyrolysis of the butadiene rubber, so that the method has a quite important practical significance.

Owner:ZHEJIANG UNIV

VOCs waste gas adsorbent desorption pyrolyzing furnace running method

ActiveCN109675404ALower ignition pointEmission reductionGas treatmentOther chemical processesBrickDesorption

The invention relates to the technical field of the environment protection, and specifically relates to a VOCs waste gas adsorbent desorption pyrolyzing furnace running method. The method is characterized by comprising the following steps: a material feeding system is started to feed material for a sprue, wherein the adsorbent continuously moves in the sprue from top to bottom under the gravity effect, an air injection and collection tank recycles the tail gas discharged by a flame path to blow the adsorbent in the sprue, and then the adsorbent is mixed with the desorbed VOCx waste gas to be transferred to a pyrolyzing chamber to perform pyrolysis through a grate brick at the bottom of a desorption chamber; the high-temperature flue gas is sent to the pyrolyzing chamber through a flue collection path to mix with the desorbed VOCs waste gas; the excessive oxygen in the high-temperature flue gas oxidizes and pyrolyzes the mixed gas, the tail gas flows into the smoke exhaust and collection tank, and is then discharged to a chimney after performing waste heat recovery.

Owner:泉州市泉腾机械科技有限公司

Method of hydrocarbon pyrolysis and device for implementing same

InactiveCN113614207AMeet the requirement of singularityThermal non-catalytic crackingCarbon preparation/purificationChemical reactionThermodynamics

The invention relates to oxidative pyrolysis of hydrocarbon feedstock. A method of oxidative pyrolysis comprises heating hydrocarbon feedstock, heating a steam-oxygen mixture, combusting the hydrocarbon feedstock in vapors of the steam-oxygen mixture in a special reactor, rapidly cooling the resulting incomplete combustion products of the chemical reactions in two steps, and then sending the cooled steam-gas mixture into a fractionation unit. A device for hydrocarbon pyrolysis comprises a chamber for mixing the steam-oxygen mixture and the feedstock, a pyrolysis chamber and a coking reactor, a device for heating the hydrocarbon feedstock and a device for heating the steam-oxygen mixture which are connected to the mixing chamber, a coking reactor supplied with a device for feeding cooling liquid into the pyrolysis gas stream, a separation unit connected to the coking reactor, and a fractionation unit equipped with an additional device for feeding cooling liquid. The technical result is highly cost-effective and environmentally friendly recovery of heavy petroleum residues by rapid coking that produces a high-quality coke, and the production of aromatic compounds without the construction or use of separate specialized installations.

Owner:尤里杰弗拉基米罗维奇费申科

Process for enhancing gasoline octane boosters, gasoline boosters, and gasolines

A process for preparing a gasoline octane boosting composition, including contacting a pyrolysis oil with a non-thermal oxygen plasma to produce an oxidized pyrolysis oil; and mixing the oxidized pyrolysis oil with a gasoline additive to produce the gasoline octane boosting composition. The gasoline octane boosting composition can be used in a gasoline blend.

Owner:SABIC GLOBAL TECH BV

A vocs exhaust gas adsorbent desorption pyrolysis furnace

ActiveCN109745822BLower ignition pointEmission reductionOther chemical processesDispersed particle separationFlue gasSorbent

The invention relates to the technical field of environmental protection, in particular to a VOCs waste gas adsorbent desorption pyrolysis furnace. Its features are: including desorption pyrolysis furnace body and feeding system; the desorption pyrolysis furnace body is designed with fire passage and vertical passage, the fire passage is for the circulation of high-temperature flue gas, the vertical passage is for the moving and falling of adsorbent, the fire passage and vertical passage are The road is adjacent to the building masonry; the middle partition arch divides the desorption pyrolysis furnace body into upper and lower areas, namely the upper desorption pyrolysis area and the lower heat storage area; the feeding system includes storage tanks, air injection headers, air injection The header box introduces the tail gas discharged from the flue into the purge adsorbent, and then mixes with the desorbed VOCs waste gas and sends it to the pyrolysis chamber for oxidation and pyrolysis through the grate brick at the bottom of the desorption chamber.

Owner:苏州科晓环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com