VOCs waste gas adsorbent desorption pyrolyzing furnace running method

An operation method and technology of a pyrolysis furnace, applied in the operation field of VOCs waste gas adsorbent desorption pyrolysis furnace, can solve problems such as leakage, no solution for electrothermal purification filter element, VOCs waste gas sealing failure, etc., and reduce pollutant emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

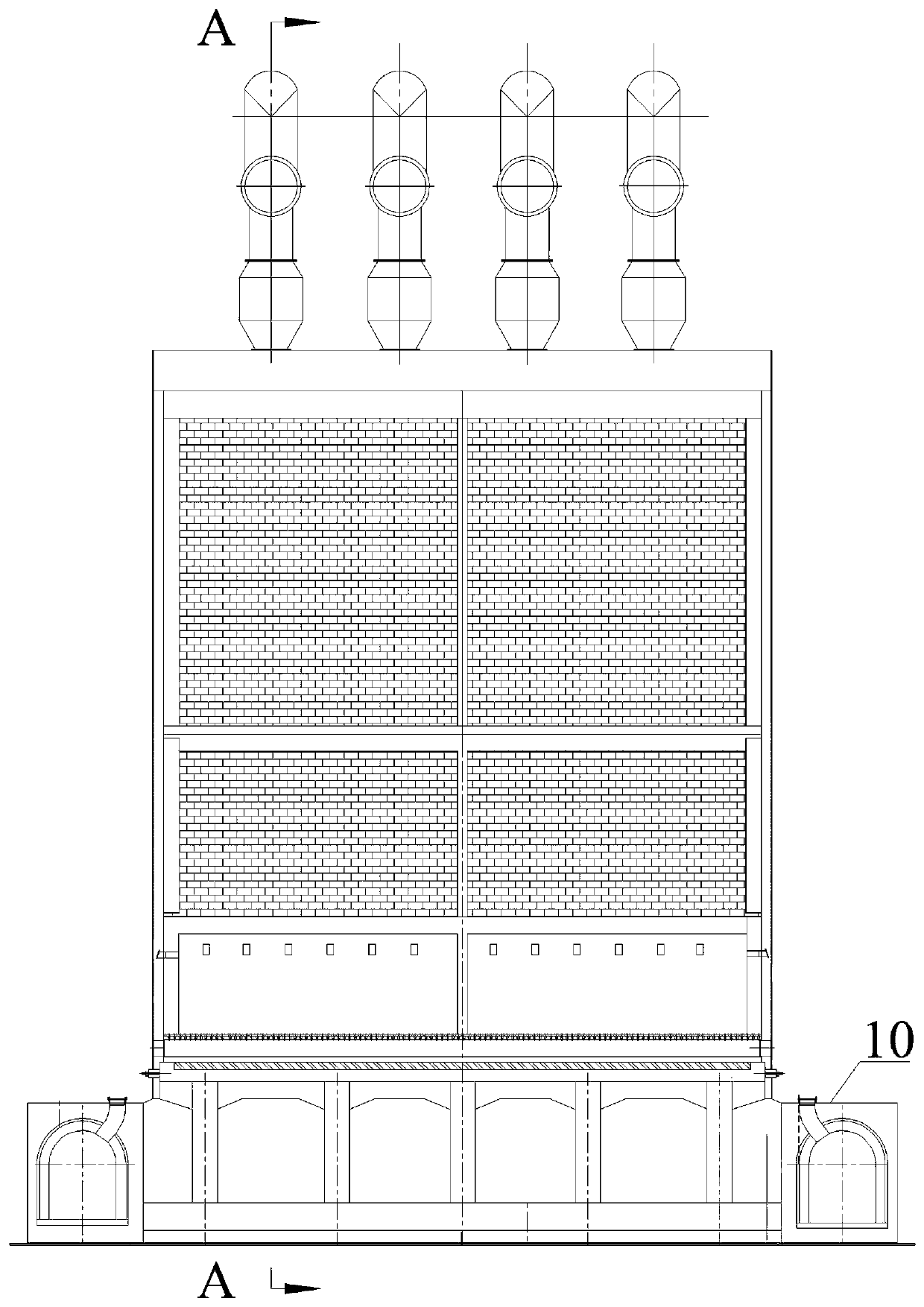

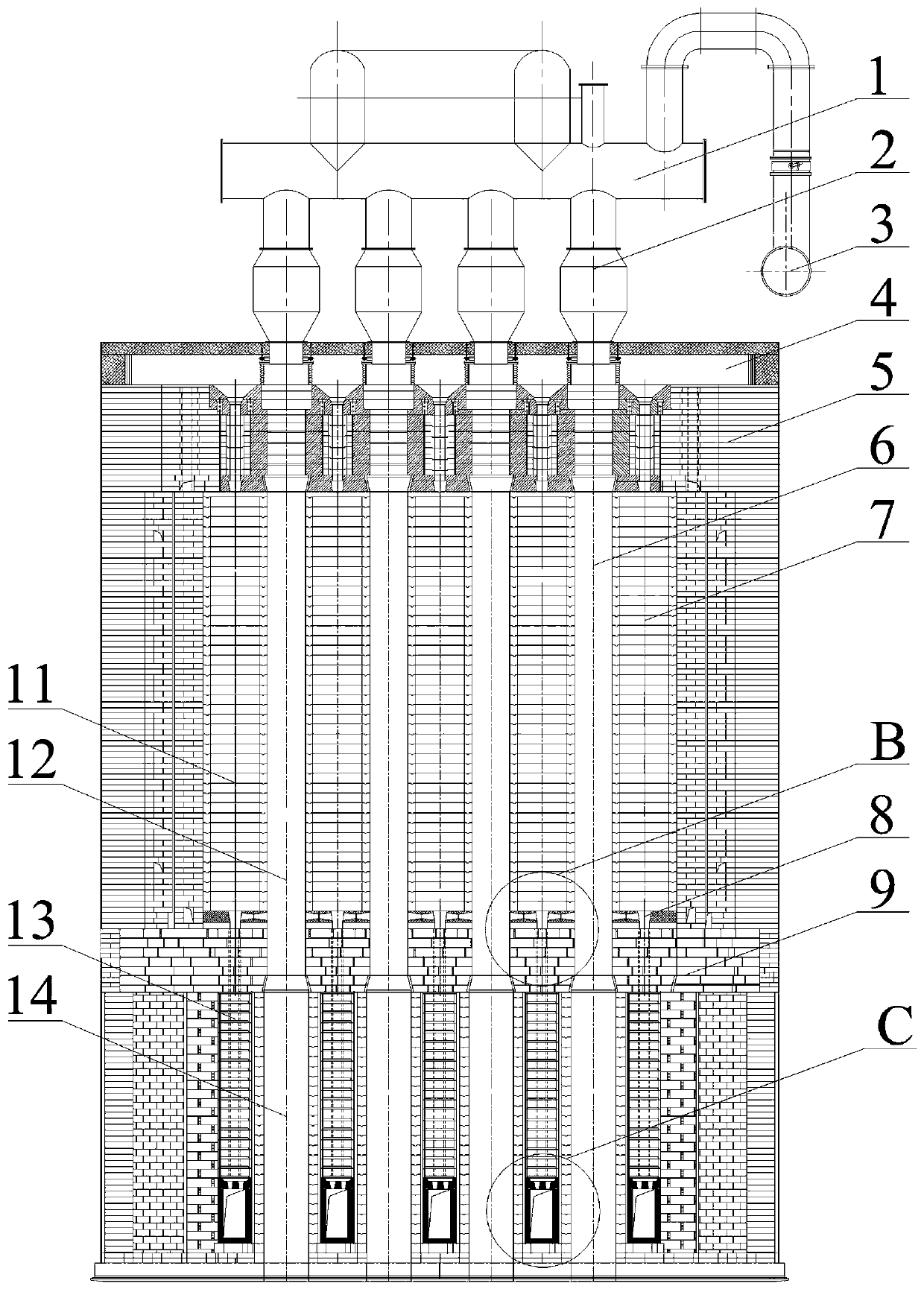

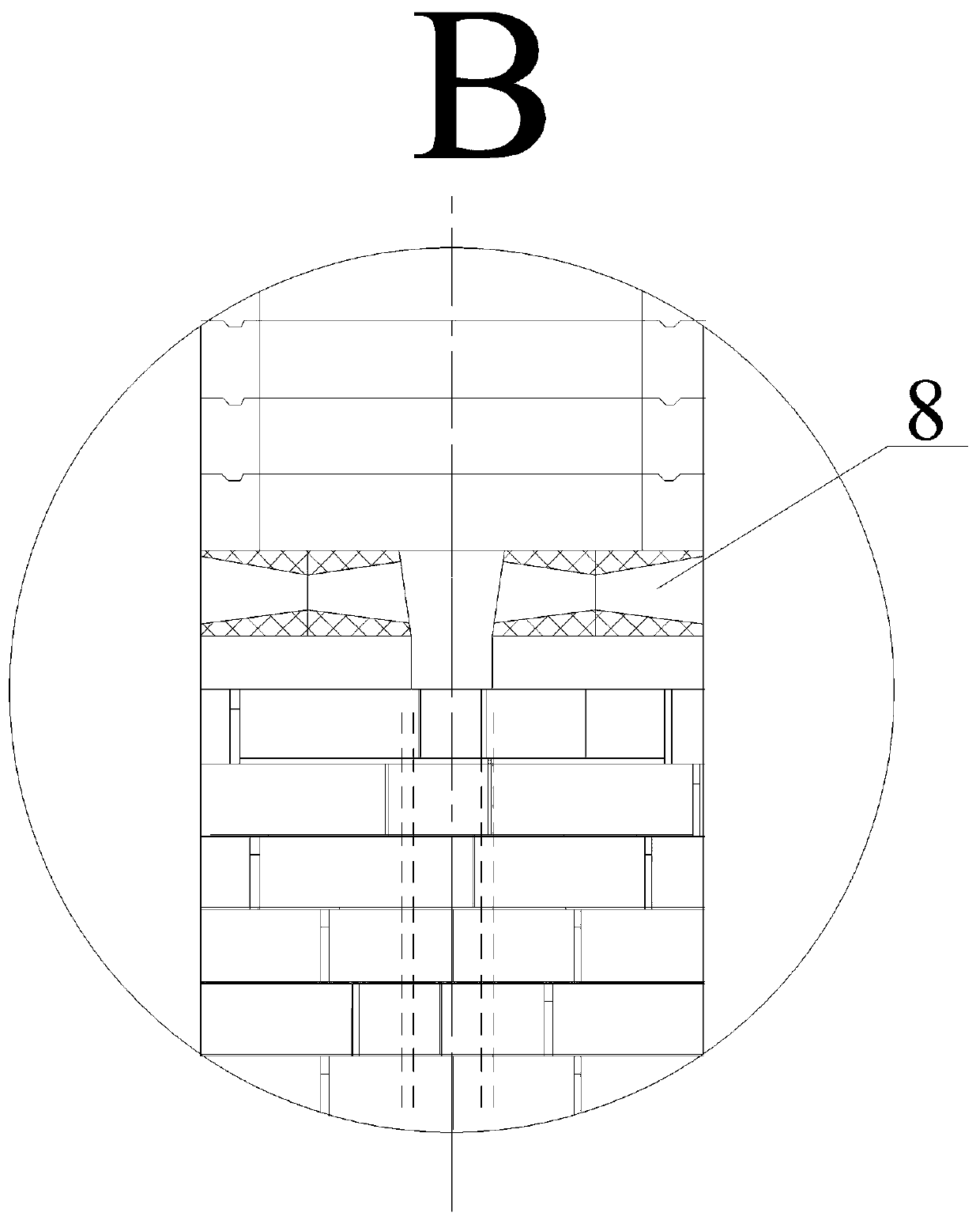

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a VOCs exhaust gas adsorbent desorption pyrolysis furnace operation method is characterized in that: step 1, filling the fire channel 7 in the desorption pyrolysis furnace body 5 with high alumina ball fillers, the diameter of the high alumina ball filler particles is 20 ~25mm, transport the adsorbent to be desorbed to the vertical channel 6 in the desorption pyrolysis furnace body 5 through the feeding system 1, cut off the flue collection channel 10 to test the working condition of the desorption pyrolysis furnace body 5, and then collect The box 3 introduces the air flow from the storage tank to the vertical channel 6 to ensure that the air flow does not escape from the bottom of the vertical channel 6 and smoothly passes through the grate brick 8 and flows into the smok...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com