Boiler decoking agent

A decoking agent and boiler technology, applied in fuel additives, petroleum industry, solid fuel, etc., can solve problems such as high combustion temperature, flameout and shutdown, and affect the safe operation of coal-fired power plants, so as to solve secondary pollution and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

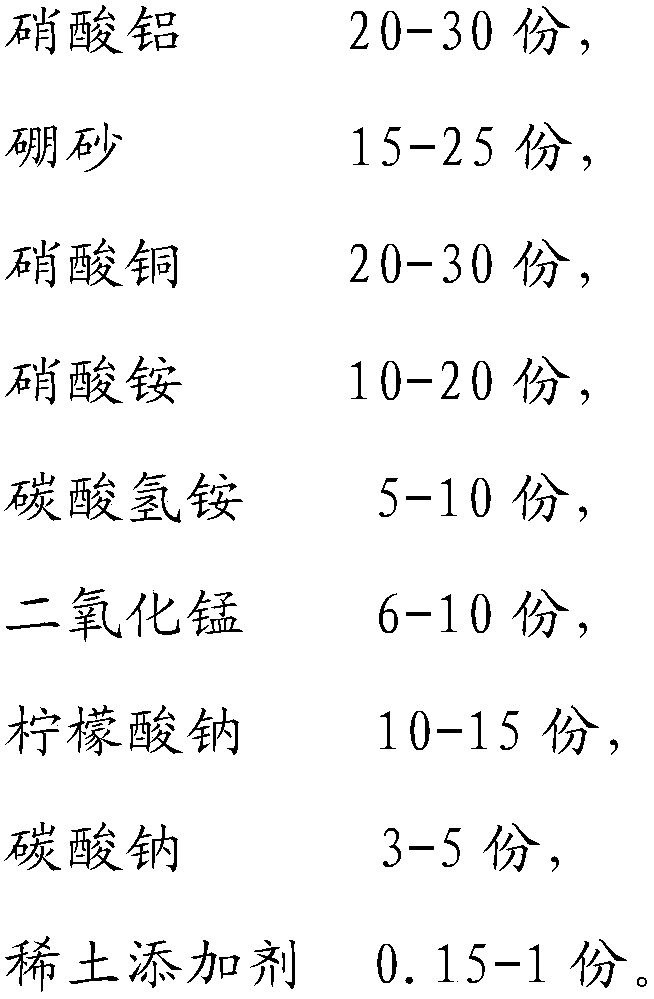

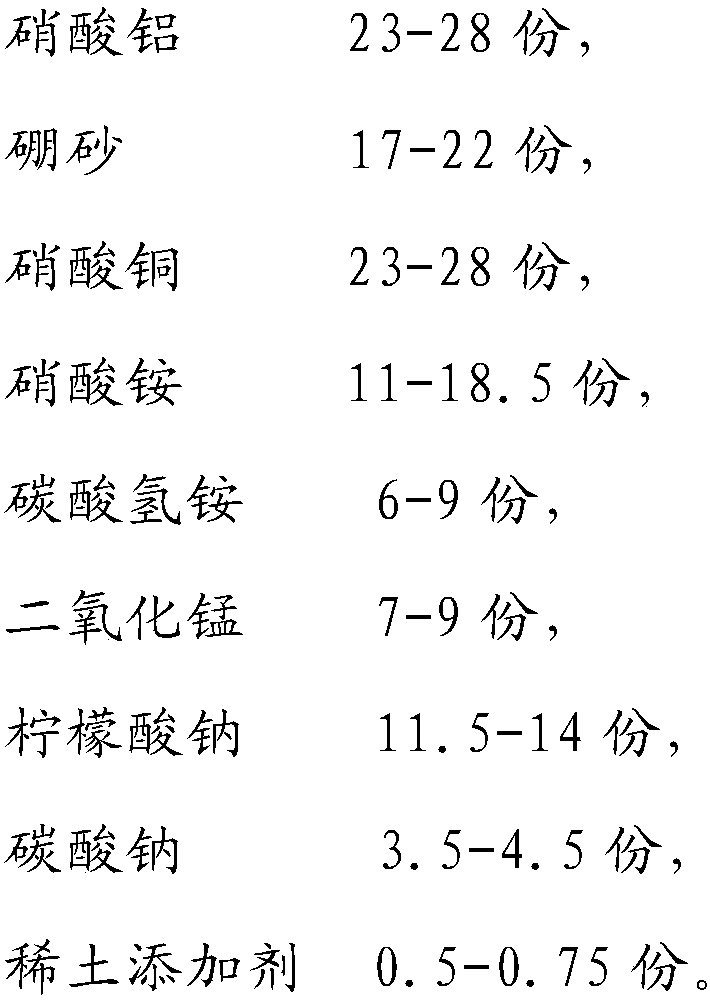

Method used

Image

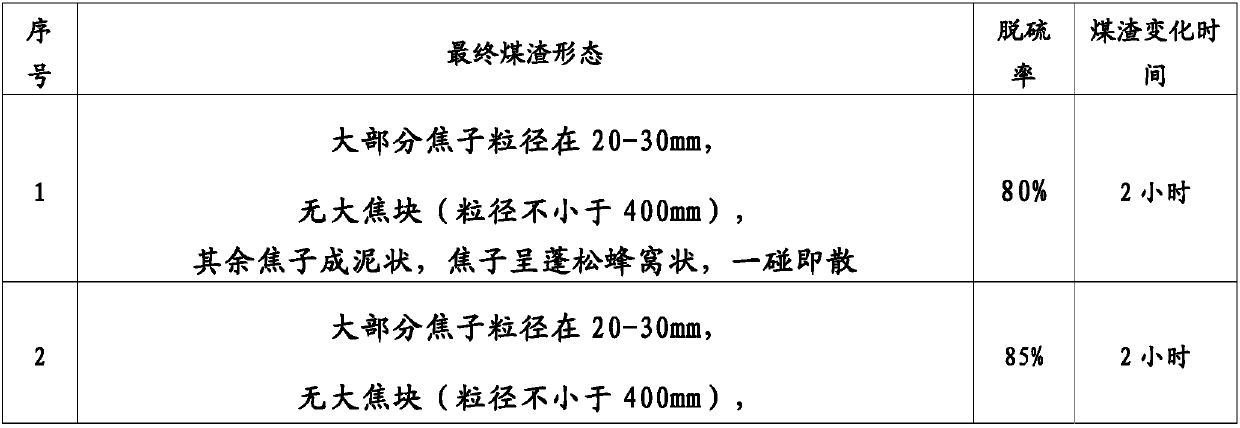

Examples

Embodiment 1

[0024] A boiler decoking agent, its composition and weight percent are: 20 parts of aluminum nitrate, 15 parts of borax, 15 parts of copper nitrate, 20 parts of ammonium nitrate, 10 parts of ammonium bicarbonate, 6 parts of manganese dioxide, 10 parts of sodium citrate parts, 5 parts of sodium carbonate, and 0.15 parts of rare earth additives.

[0025] The above-mentioned boiler decoking agent is a solid particle with a particle size of 250 mesh formed by mixing the above-mentioned components.

Embodiment 2

[0027] A boiler decoking agent comprising the following components in parts by weight: 20 parts of aluminum nitrate, 21 parts of borax, 28 parts of copper nitrate, 15 parts of ammonium nitrate, 9 parts of ammonium bicarbonate, 8 parts of manganese dioxide, sodium citrate 15 parts, 3 parts of sodium carbonate, 1 part of rare earth additive.

[0028] The above-mentioned boiler decoking agent is a solid particle with a particle size of 300 mesh formed by mixing the above-mentioned components.

Embodiment 3

[0030] A boiler decoking agent comprising the following components in parts by weight: 20 parts of aluminum nitrate, 25 parts of borax, 21 parts of copper nitrate, 20 parts of ammonium nitrate, 8 parts of ammonium bicarbonate, 10 parts of manganese dioxide, sodium citrate 10 parts, 4.5 parts of sodium carbonate, 0.5 parts of rare earth additives.

[0031] The above-mentioned boiler decoking agent is a solid particle with a particle size of 280 mesh formed by mixing the above-mentioned components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com