Preparation method of clean lignite-based semicoke barbeque charcoal

A production method, lignite semi-coke technology, applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of non-shedding of charcoal ash, difficult ignition, low heat utilization rate, etc., so as to reduce the ignition point and production cost, increase Molding rate and strength, effect of increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

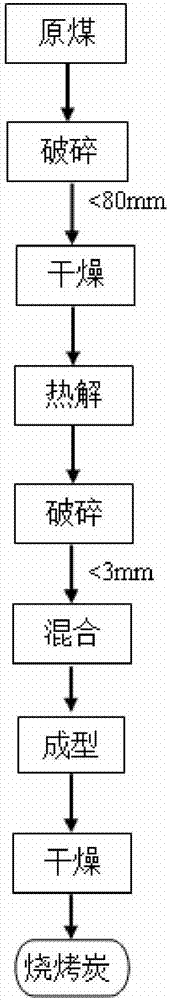

[0031] Embodiment 1: as figure 1 As shown, a lignite-based semi-coke clean barbecue charcoal preparation method contains the following steps:

[0032] Step a, preparing lignite semi-coke: crushing lignite to less than 80 mm, the crushed lignite is dried by dryer, pyrolysis reaction is carried out in pyrolysis furnace, and solid lignite semi-coke is produced, and lignite semi-coke is crushed Machine crushed to <3mm and sent to follow-up mixing;

[0033] Step b. Mixing: Stir and mix the solid semi-coke powder, binder, sulfur-fixing agent, etc. through the mixer, and send the mixed material and water into the wheel mill for rolling and secondary mixing to form a molding mixture ;

[0034] Step c, molding: transport the mixture to the molding machine through the conveyor, and make barbecue charcoal products of different shapes through the molding machine;

[0035] Step d, drying: transport the formed wet barbecue charcoal to a mesh belt dryer for drying;

[0036] Step e, packi...

Embodiment 2

[0044] Embodiment 2: as figure 1 As shown, a method for producing lignite-based semi-coke clean barbecue charcoal includes processes such as lignite crushing, drying, pyrolysis, semi-coke re-crushing, mixing, rolling, forming, and drying.

[0045] The invention has the processes of lignite crushing, drying, pyrolysis, semi-coke re-crushing, mixing, rolling, forming, and drying.

[0046] The lignite is crushed to less than 80mm, and the crushed lignite is dried by the dryer and pyrolyzed in the pyrolysis furnace to produce solid lignite semi-coke, which is then crushed to <3mm by the crusher and sent to the follow-up Mix and stir. The raw material used is lignite with high moisture content, high volatile content and low ignition point.

[0047] The solid semi-coke powder, binder, sulfur-fixing agent, etc. are stirred and mixed together by the mixer, and the mixed material and water are sent to the wheel mill for rolling and secondary mixing to form a molding mixture. Under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com