High-efficiency energy-saving solid mixed fuel moulding technology

A solid fuel, high-efficiency and energy-saving technology, applied in the direction of solid fuel, fuel, biofuel, etc., can solve the problems of unsatisfactory mixing effect and the inability to fully reflect the advantages of co-combustion, so as to avoid excessive demand, mechanical performance and waterproof Good performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

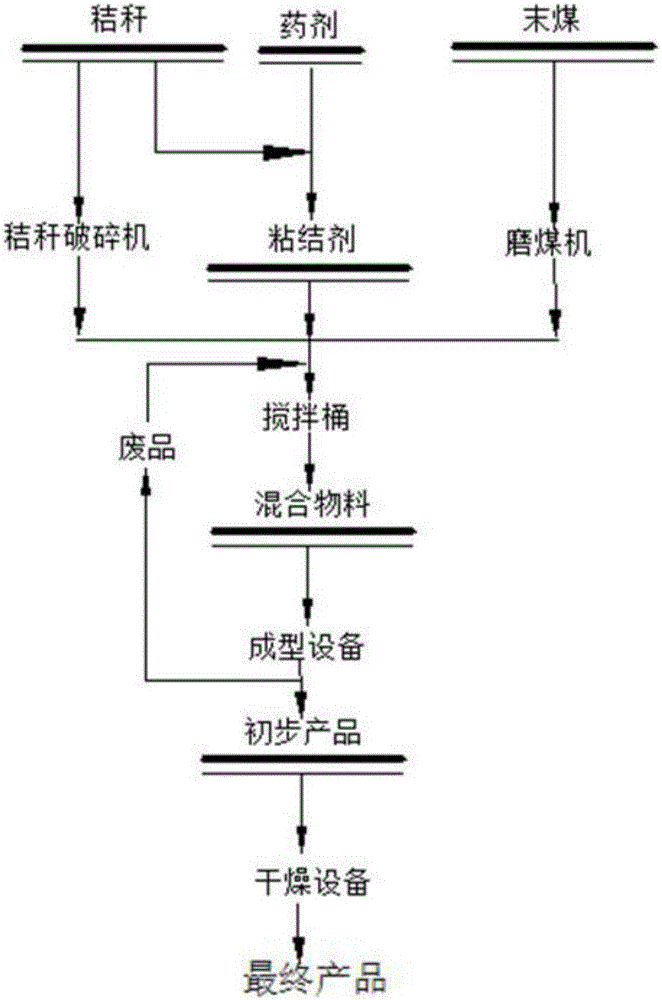

[0015] Such as figure 1 Shown, the high-efficiency energy-saving mixed solid fuel production technique of the present invention, it comprises the steps:

[0016] a. Mixing operation: choose biomass and fine coal. The biomass is forest waste, crop straw and animal manure. First, dry the biomass naturally until the water is 20% and remove dust, and then use a scissor crusher Crushed and sieved to 2-7mm, the fine coal is crushed to a diameter of 2-3mm by a reversible impact hammer crusher using the two-end grinding process; the mass ratio of crushed biomass and fine coal is 25%-30% Utilize the feed pipe to drop into the mixing tank, and add 10% composite high-efficiency binder to obtain the mixture, and stir for 10 min in the mixing tank at a speed of 8r / min; the manufacturing process of the composite high-efficiency binder is: After the biomass straw is crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| drop strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com