Oxidative pyrolysis process of dinitrotoluene wastewater

A dinitrotoluene, pyrolysis technology, applied in the direction of oxidized water/sewage treatment, water pollutants, natural water treatment, etc., can solve the problems of high chromaticity of wastewater, serious scaling of heating heat exchangers, etc., and reduce operation Cost, effect of reducing fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

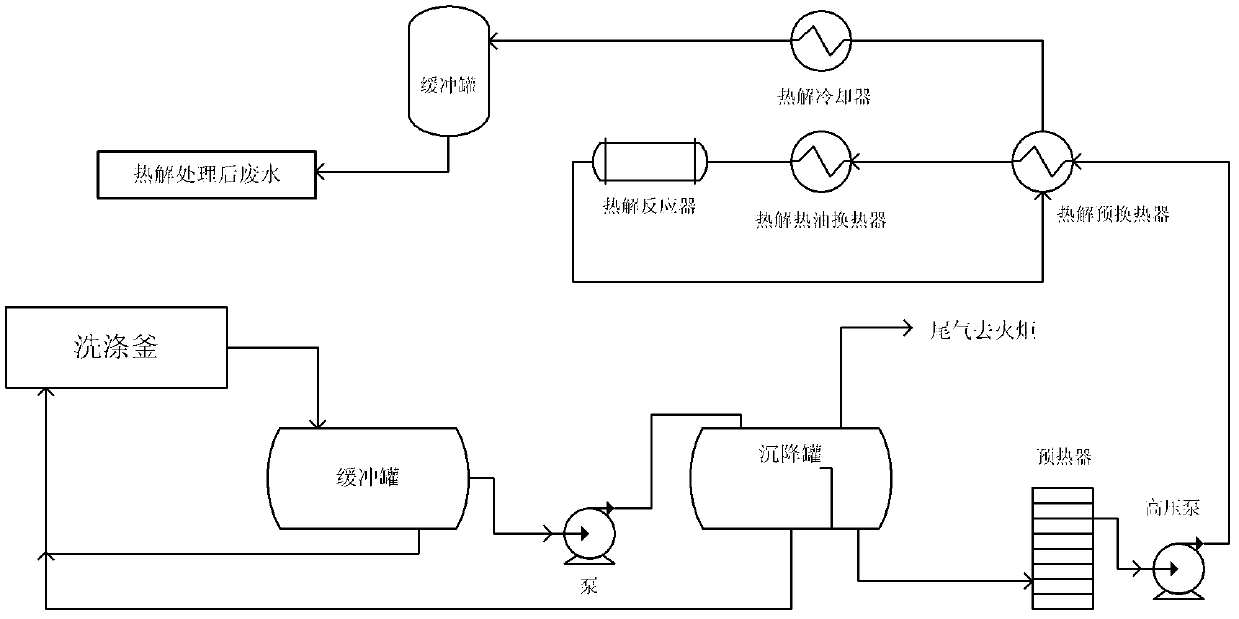

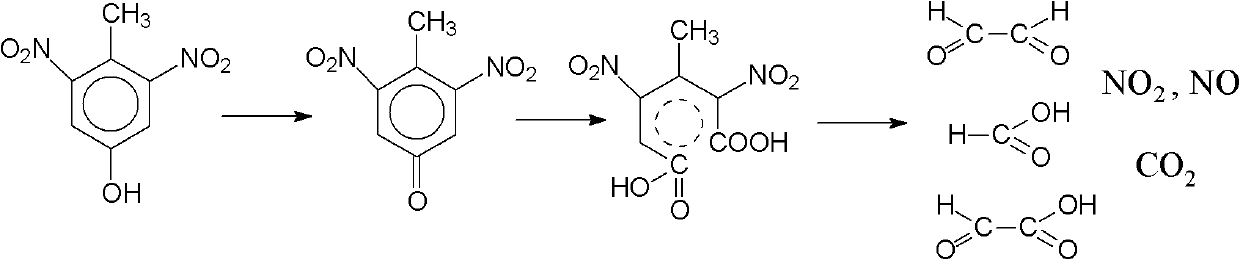

[0024] Wastewater from the washing tank is discharged through the buffer tank, settling tank, preheater, high-pressure pump, pyrolysis pre-heat exchanger, pyrolysis heat oil heat exchanger, pyrolysis reactor, pyrolysis cooler, and buffer tank, among which , the oxidant is added at the inlet of the settling tank and / or the pyrolysis pre-heat exchanger, and is added by pressurization when entering the pyrolysis pre-heat exchanger. Wherein, the waste water from the washing tank is the waste water from the alkaline washing section of dinitrotoluene in the dinitrotoluene process in the prior art. In the present invention, the oxidant is one or more of air, oxygen and hydrogen peroxide. In the pressurized addition, when the oxidant is a liquid oxidant, the inlet of the pyrolysis pre-heat exchanger is pressurized by a pump; when the oxidant is a gaseous oxidant, the inlet of the pyrolysis pre-heat exchanger is pressurized by a compression fan. The process conditions in the settling ...

Embodiment 2

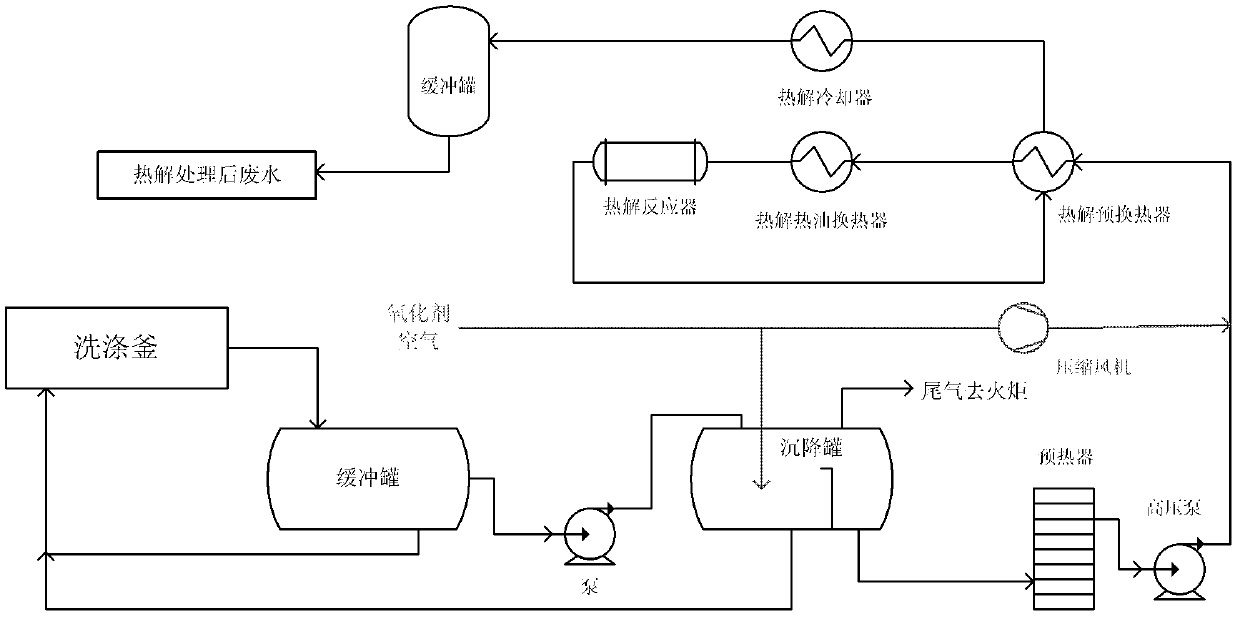

[0029] Wastewater from the washing tank is discharged through the buffer tank, settling tank, preheater, high-pressure pump, pyrolysis pre-heat exchanger, pyrolysis heat oil heat exchanger, pyrolysis reactor, pyrolysis cooler, and buffer tank, among which , the oxidant is added at the inlet of the settling tank and / or the pyrolysis pre-heat exchanger, and is added by pressurization when entering the pyrolysis pre-heat exchanger. Wherein, the waste water from the washing tank is the waste water from the alkaline washing section of dinitrotoluene in the dinitrotoluene process in the prior art. In the present invention, the oxidant is one or more of air, oxygen and hydrogen peroxide. In the pressurized addition, when the oxidant is a liquid oxidant, the inlet of the pyrolysis pre-heat exchanger is pressurized by a pump; when the oxidant is a gaseous oxidant, the inlet of the pyrolysis pre-heat exchanger is pressurized by a compression fan. The process conditions in the settling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com