Patents

Literature

101 results about "Return ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

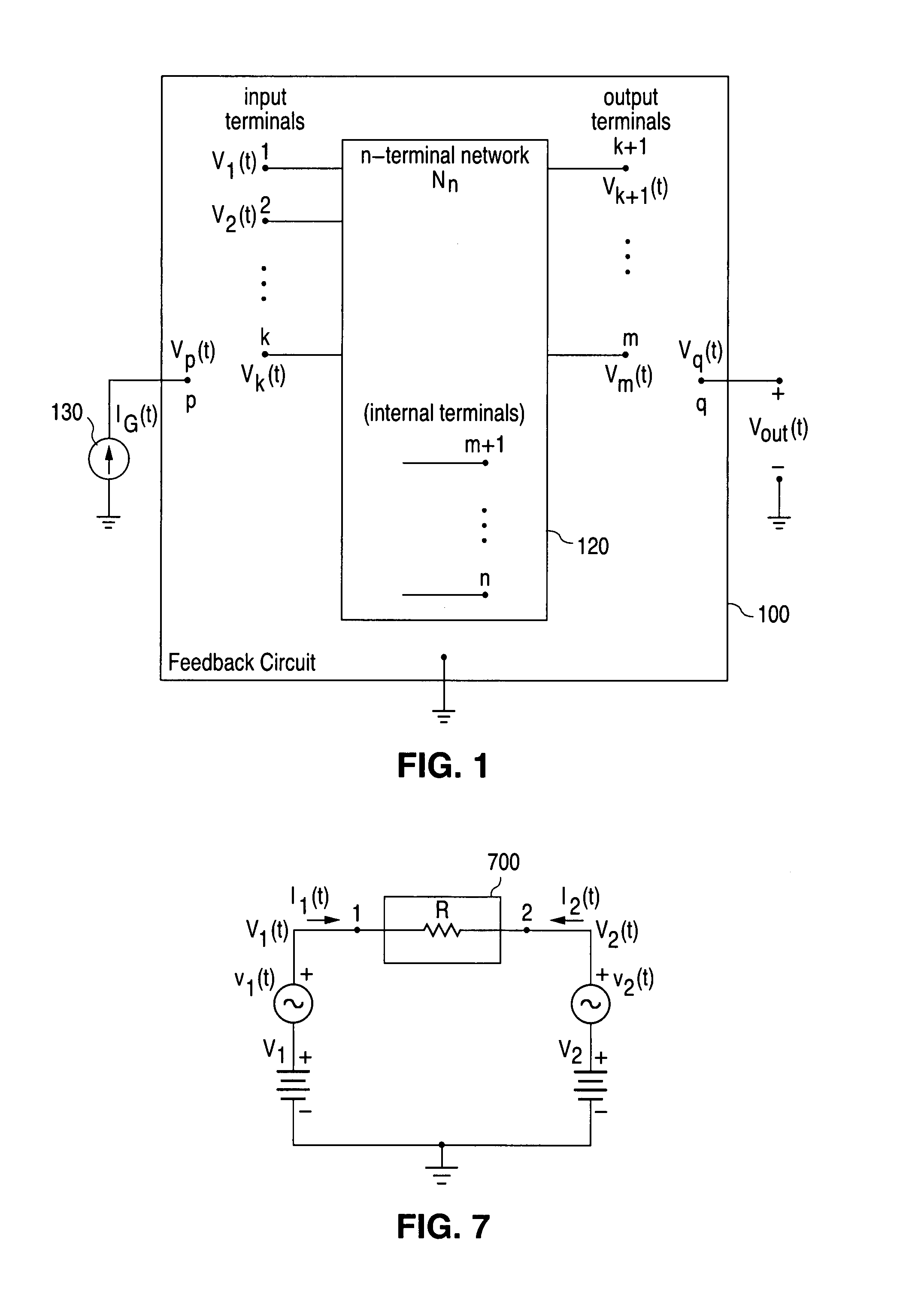

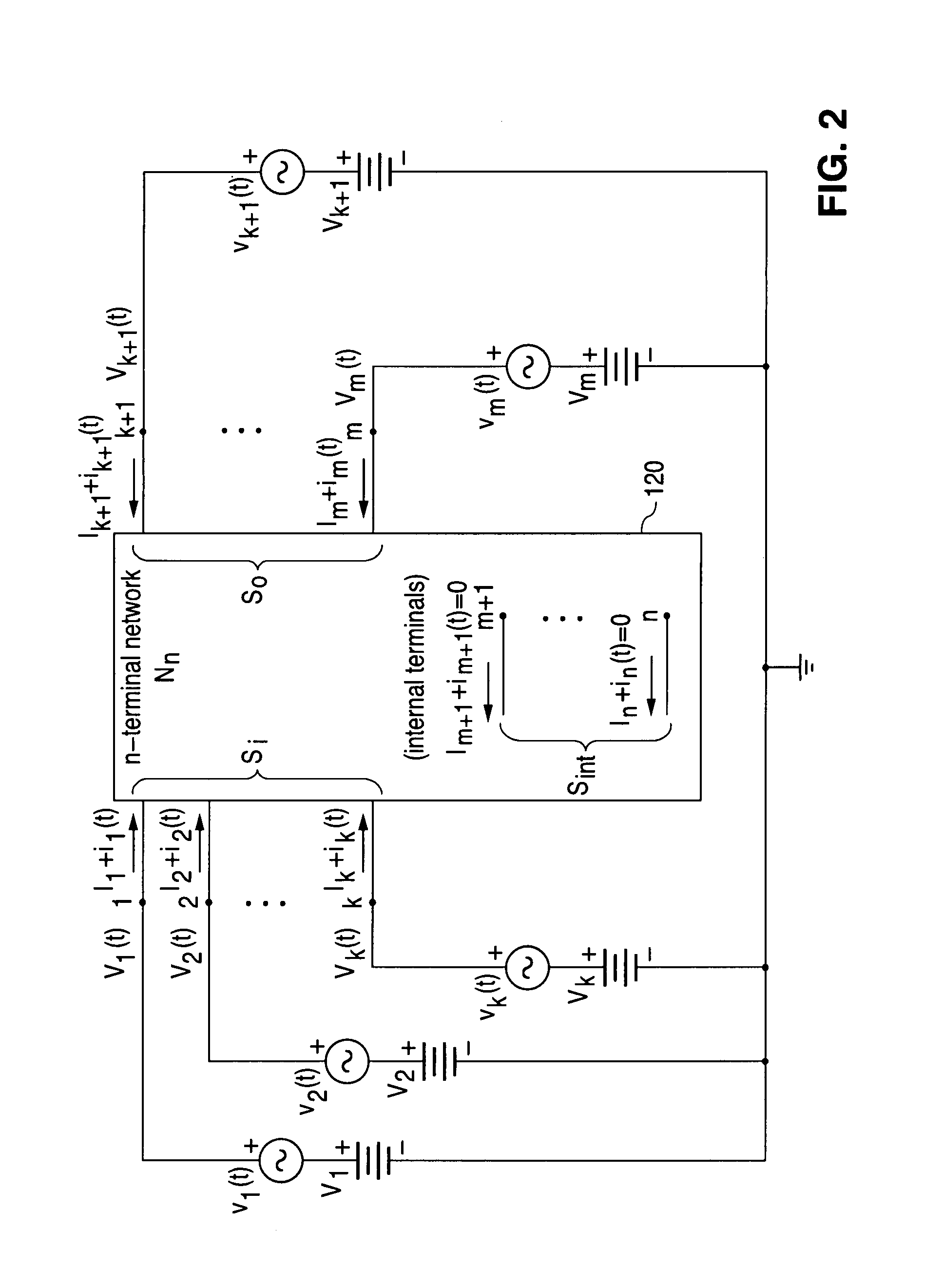

The return ratio of a dependent source in a linear electrical circuit is the negative of the ratio of the current (voltage) returned to the site of the dependent source to the current (voltage) of a replacement independent source. The terms loop gain and return ratio are often used interchangeably; however, they are necessarily equivalent only in the case of a single feedback loop system with unilateral blocks.

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759AImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

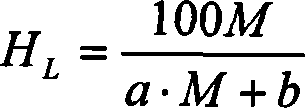

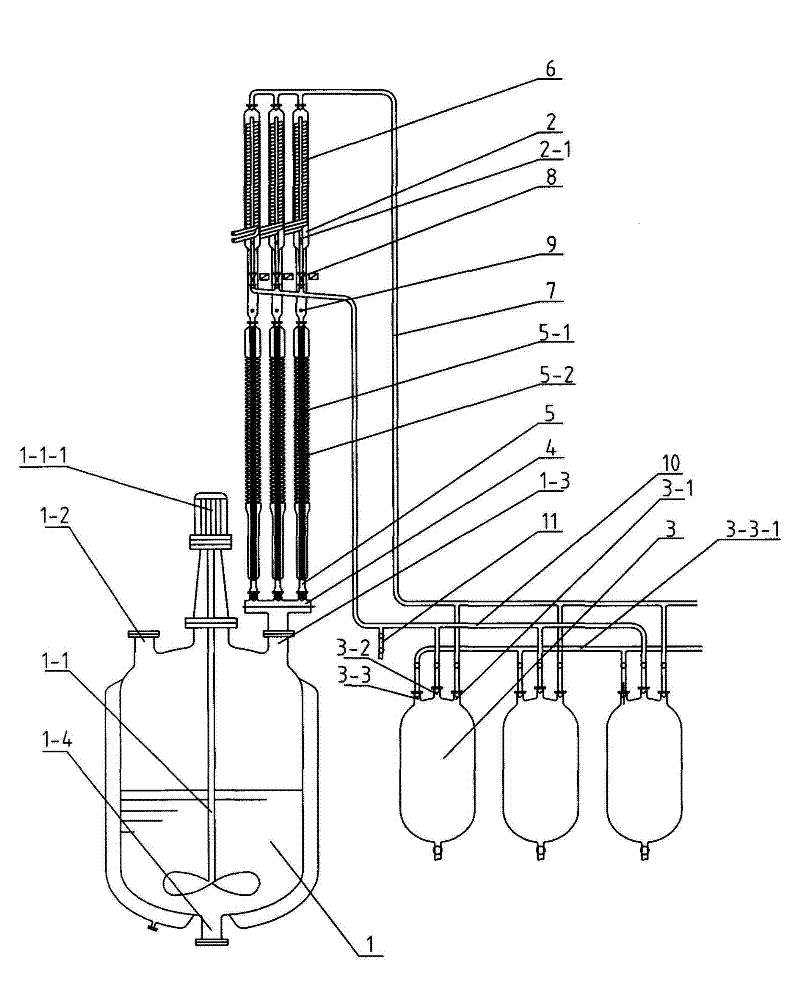

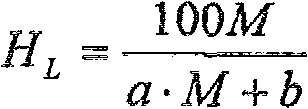

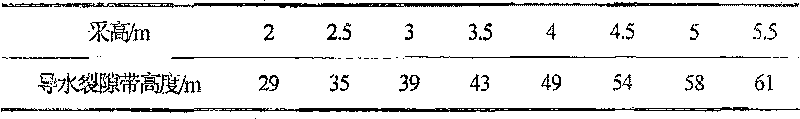

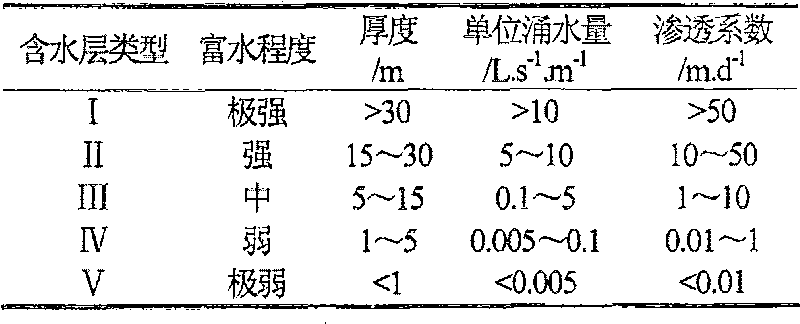

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

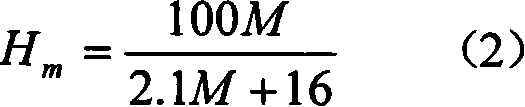

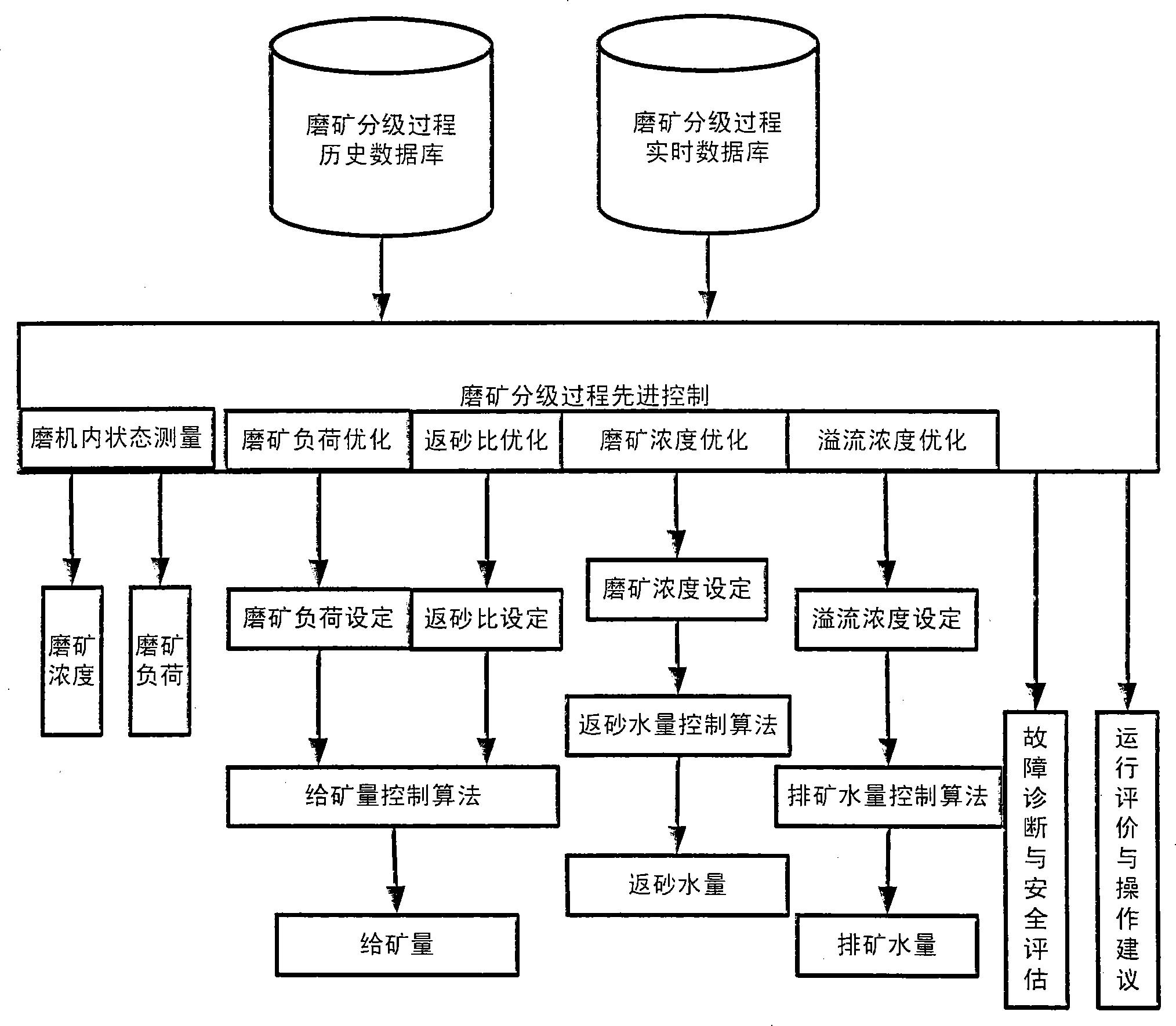

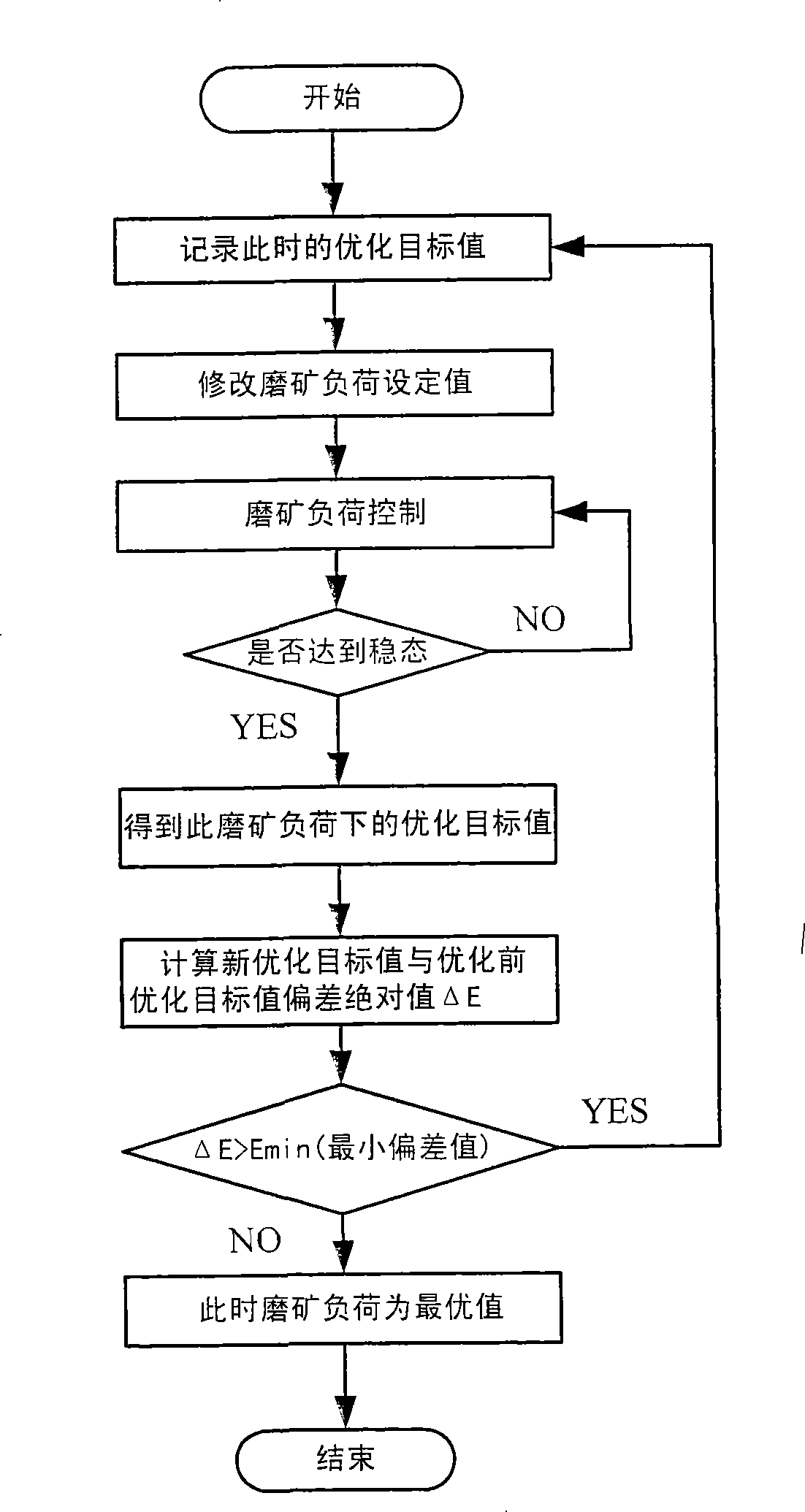

Optimization control method for grind grading process

InactiveCN101244403ARealize online measurementImprove pass rateElectric testing/monitoringGrain treatmentsComing outWater volume

The invention discloses an optimal control method for grinding and grading mineral powder, which is characterized in that: the grinding load and grinding concentration is obtained by sampling grinding-grading process signal, with the help of the advanced control and through testing the state in the grinder; the optimal grinding load, the optimal sand-returning ratio, the optimal grinding concentration and the optimal overflow concentration are obtained through the grinding load optimization, the sand-returning ratio optimization, the grinding concentration optimization and the overflow concentration optimization; the feeding quantity is obtained through the control algorithm of the feeding quantity ; the sand-returning water volume is obtained through the control algorithm of the sand-returning water volume; the discharging water volume is obtained through the control algorithm of the discharging water volume. The optimal control method has advantages that: the global optimization to the grinding-grading process is realized; and meanwhile the diagnosis is done to reveal the fault of the grinding-grading process; the appraisal and analysis is executed in the grinding-grading process; reasonable advice is come out; continuous, stable, safe and economic running is ensured; so the method is widely used in the grinding-grading process and similar wet milling process in other industry crafts.

Owner:徐宝平

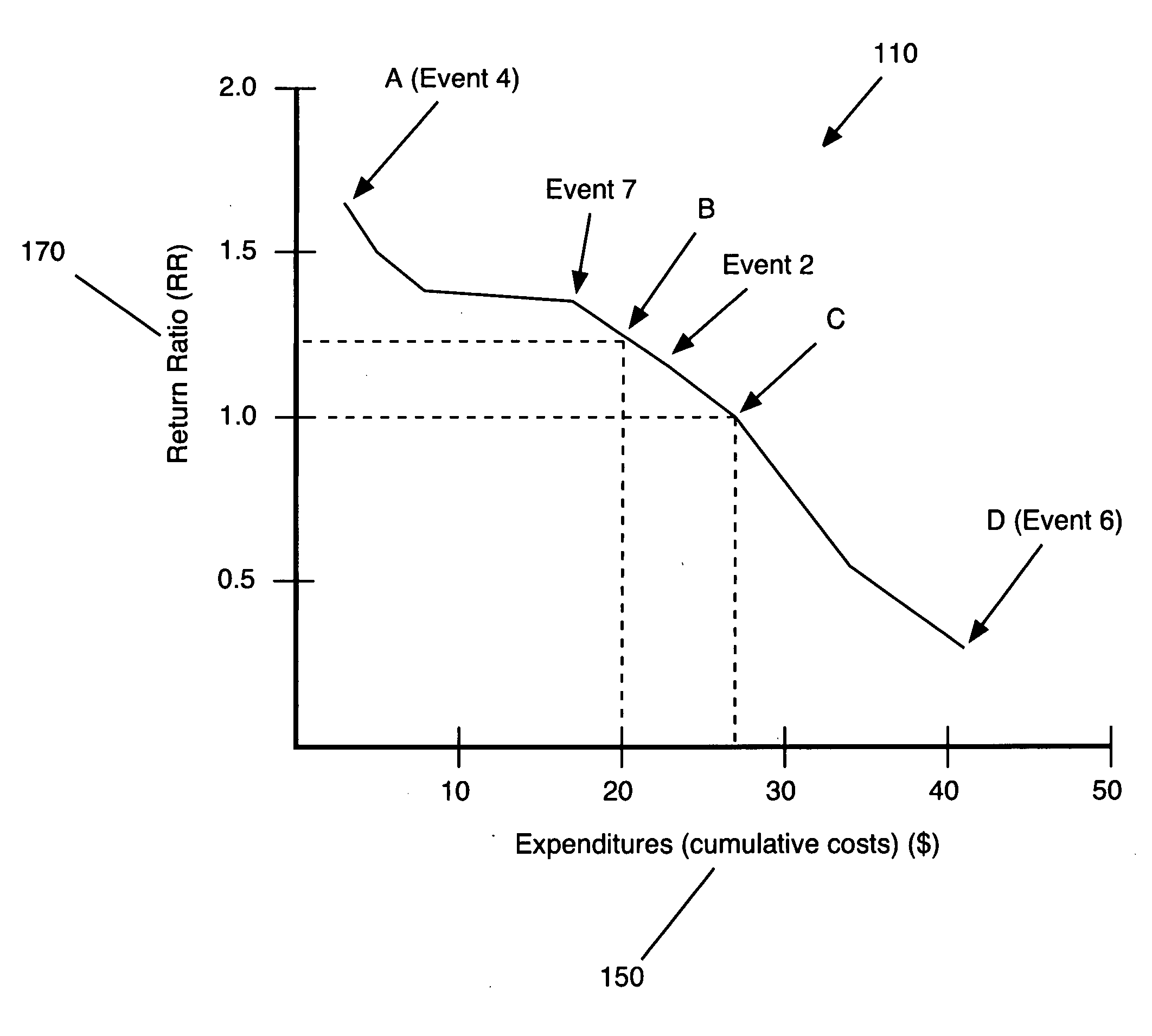

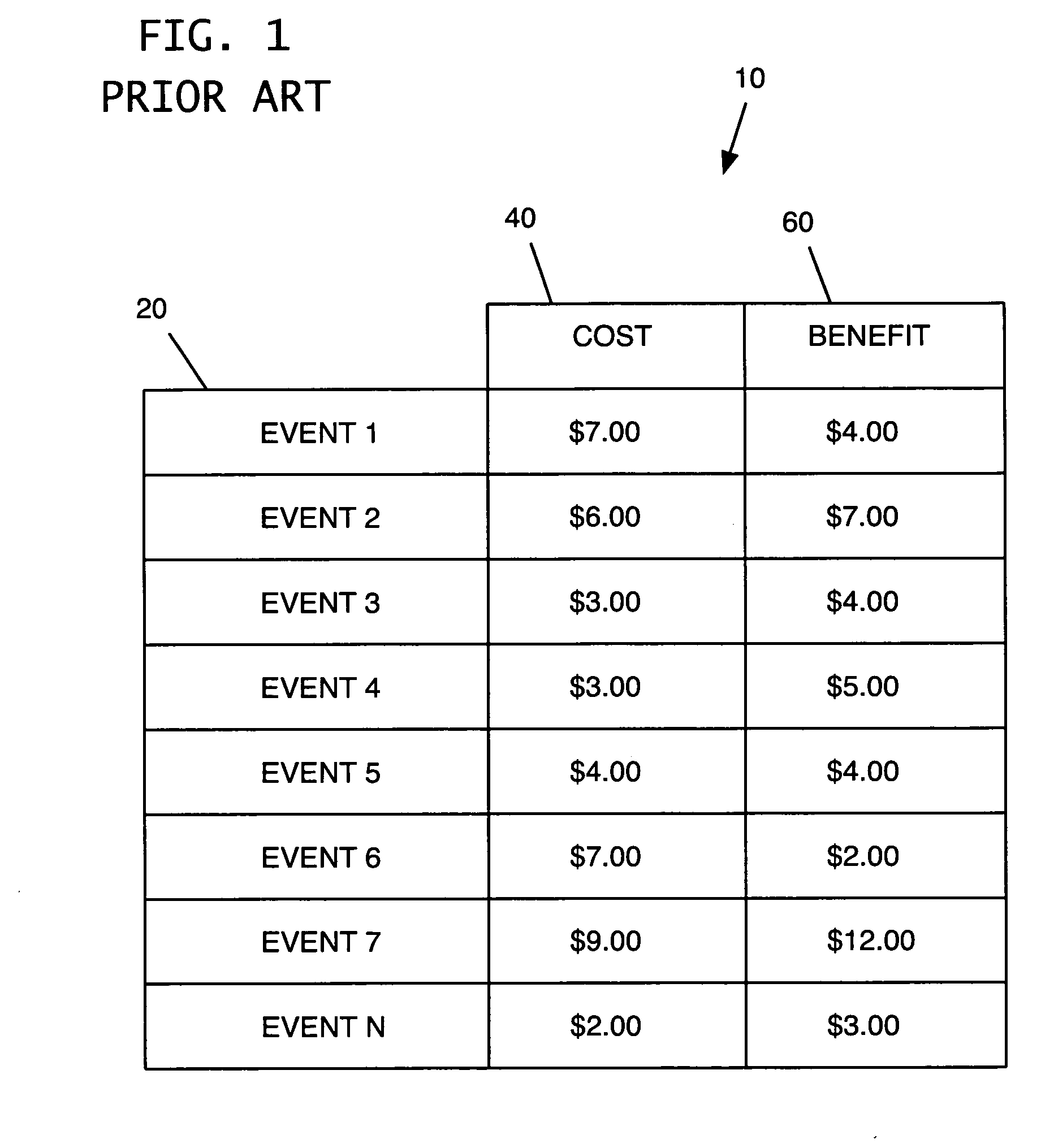

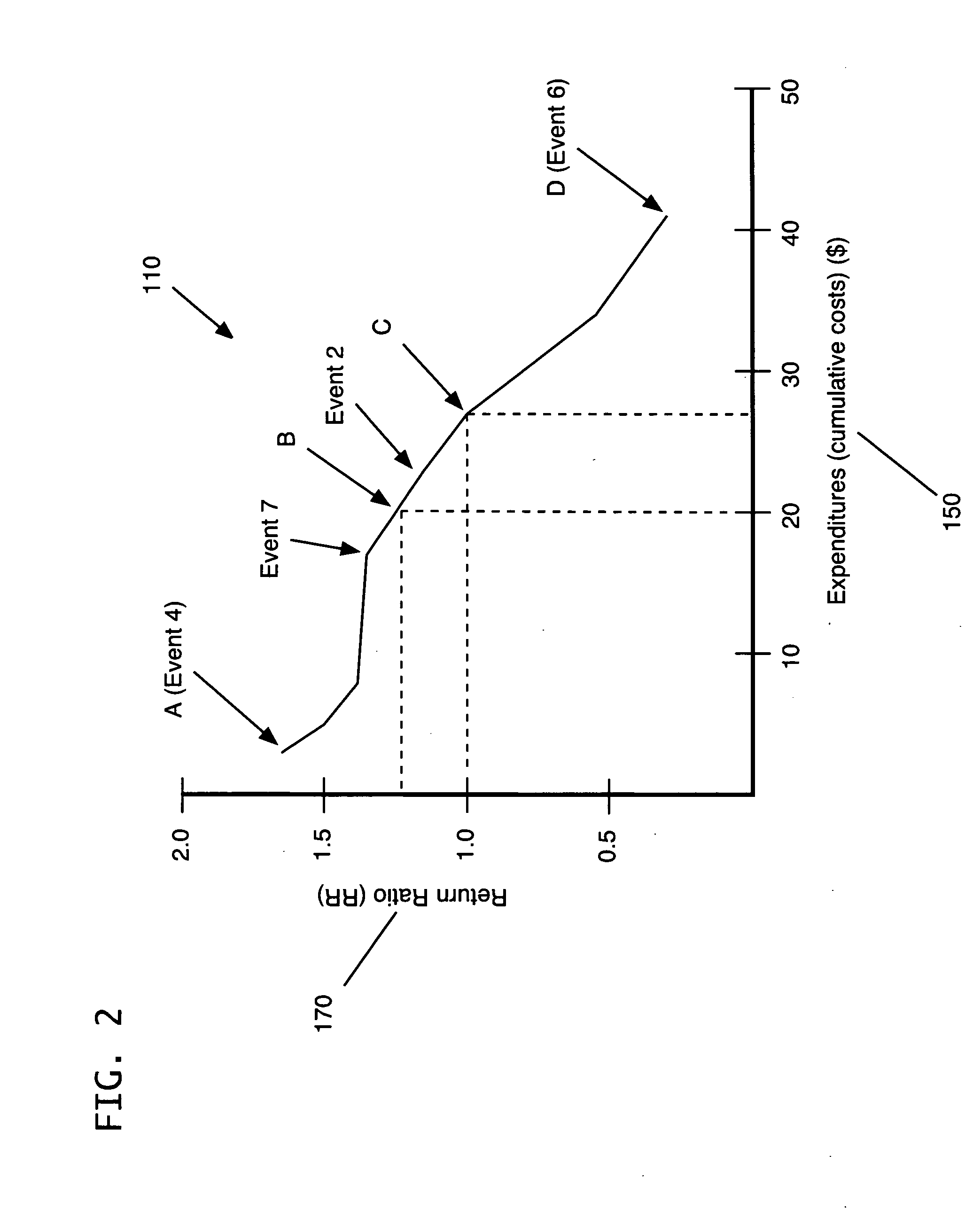

Method, system, and program product for graphically representing a marketing optimization

The invention provides a method, system, and program product for graphically representing a marketing optimization. In one embodiment, the method includes: selecting from a plurality of promotion events a promotion event having the highest return ratio (RR); graphically displaying the RR of the selected promotion event as a function of a cumulative cost of all selected promotion events; and repeating the selecting and graphically displaying steps from among unselected promotion events.

Owner:IBM CORP

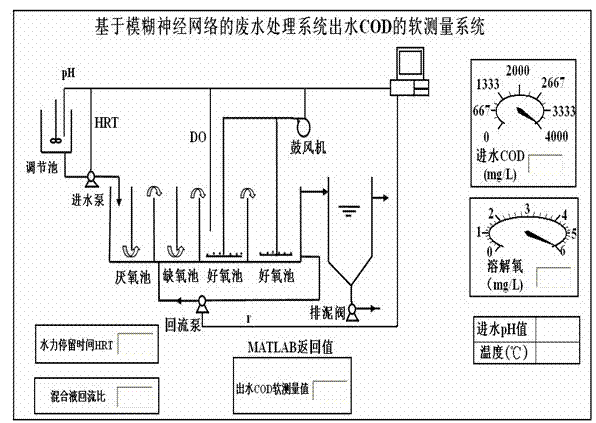

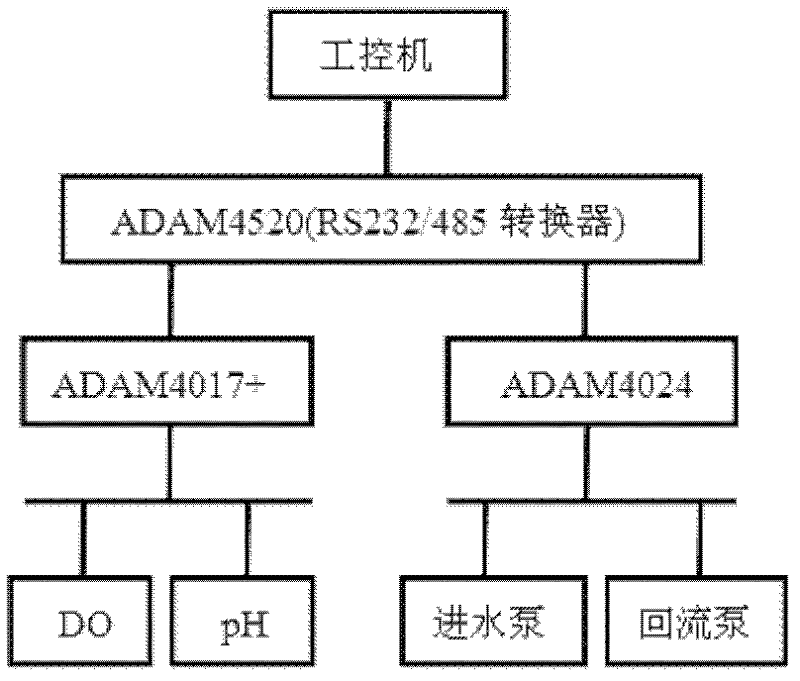

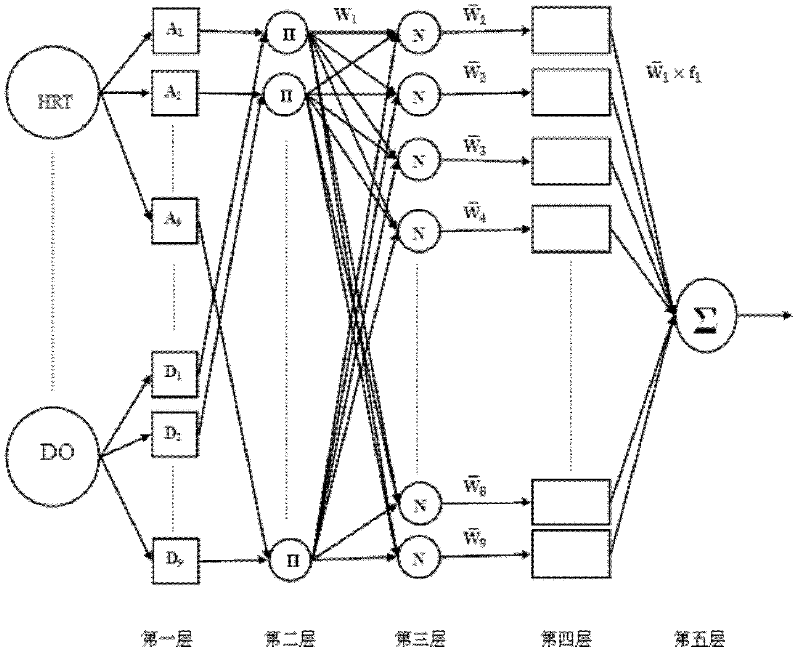

Soft-sensing method and system for effluent COD of a wastewater treatment system

InactiveCN102262147ASimple structureImprove forecast accuracyTesting waterNeural learning methodsWater qualityNetwork model

The invention relates to a method and system for soft measurement of effluent COD in a wastewater treatment system, comprising the following steps: (1) measuring HRT, pH value of influent water, DO of an aerobic pool, reflux ratio r of a mixed solution, and actual effluent COD value; 2) Collect the above-mentioned data samples, use the adaptive fuzzy C-means clustering algorithm to cluster the data, establish a COD fuzzy neural network model according to the number of clusters obtained, and train the model until the error meets the requirements; (4 ) Embed the trained fuzzy neural network model into the industrial computer, and realize the data communication between the MATLAB software and the configuration software MCGS through OPC technology, so as to realize the online real-time monitoring of COD in the effluent of the wastewater treatment system. The invention can solve the problems of high price, difficult maintenance and lagging measurement of the COD measuring instrument for the soft measurement of the COD of the effluent of the wastewater treatment system, and truly realize the online real-time monitoring of the effluent quality.

Owner:SOUTH CHINA UNIV OF TECH

Energy-saving grinder swirler closed-loop system and control method

InactiveCN101251396ASolve online detection problemsEasy to handleMaterial analysis by measuring buoyant forcesMaterial analysis by observing immersed bodiesReturn ratioClosed loop

The invention provides an energy-saving type closed circuit system and a control method for a mill swirler. The energy-saving type closed circuit system comprises a feeder, a conveyor, an ore miller and the swirler. The invention is characterized in that: a weighing type pulp multi-parameter online detection integration device is arranged on the overflow and desilting pipeline of the swirler. The energy-saving type closed circuit system and the control method for the mill swirler provide a better solution for the problem of the online detection of key parameters such as flow rate, density, grain size, grade, etc. with high detection accuracy and good reliability. The energy-saving type closed circuit system and the control method for the mill swirler can further make use of the detected accurate parameters to determine data such as the feeding amount of the miller, the circulating load of the miller, the grinding concentration of the miller, the pulp density in a pump bath, the sand return ratio, etc., thereby completely reaching the aims of maximally improving the processing capacity of a miller table, saving energy and reducing consumption with the precondition of ensuring the qualified overflow grain size (pulp product) of the swirler through the data matched with the control device and the operation module in the prior art.

Owner:罗放明

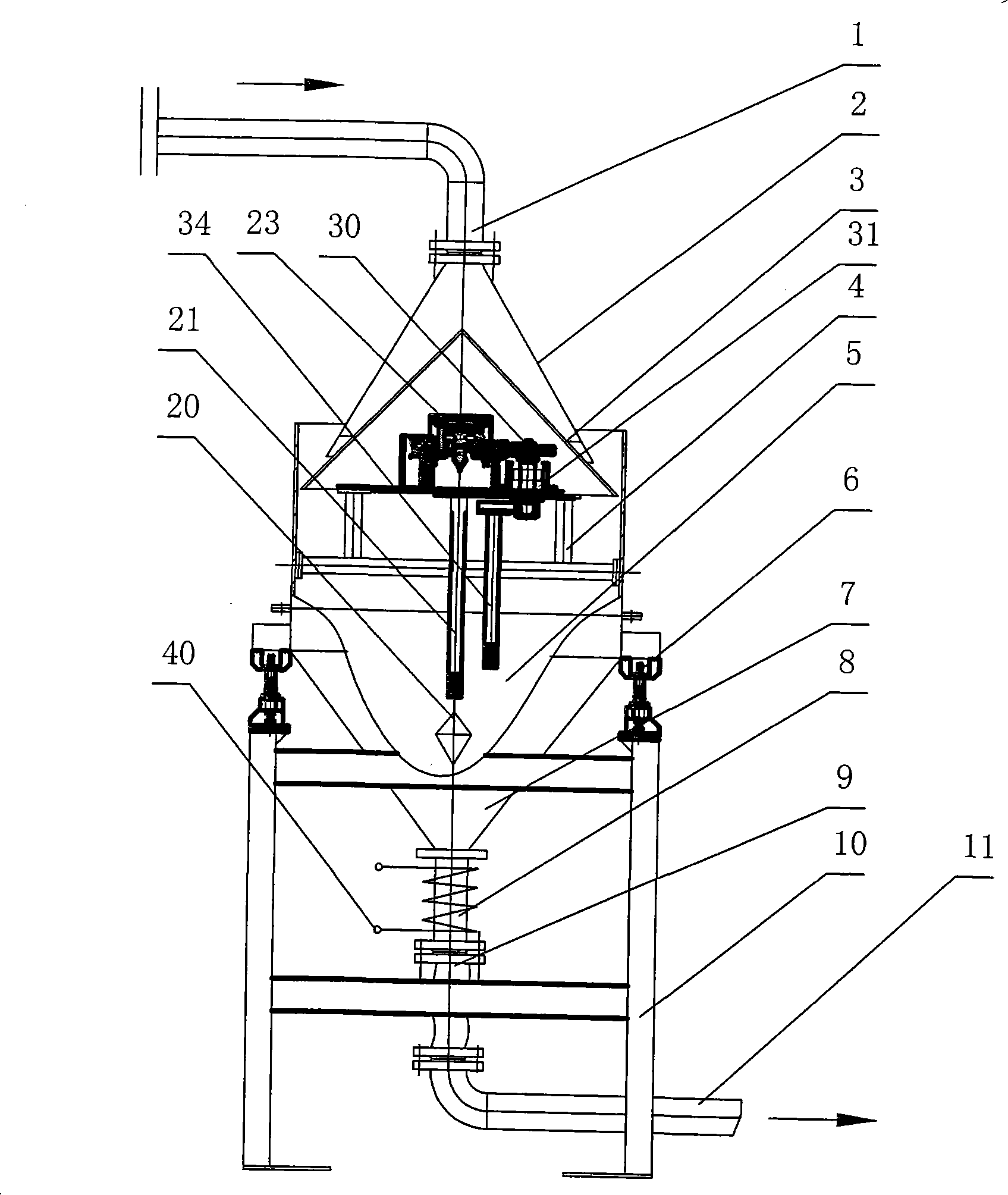

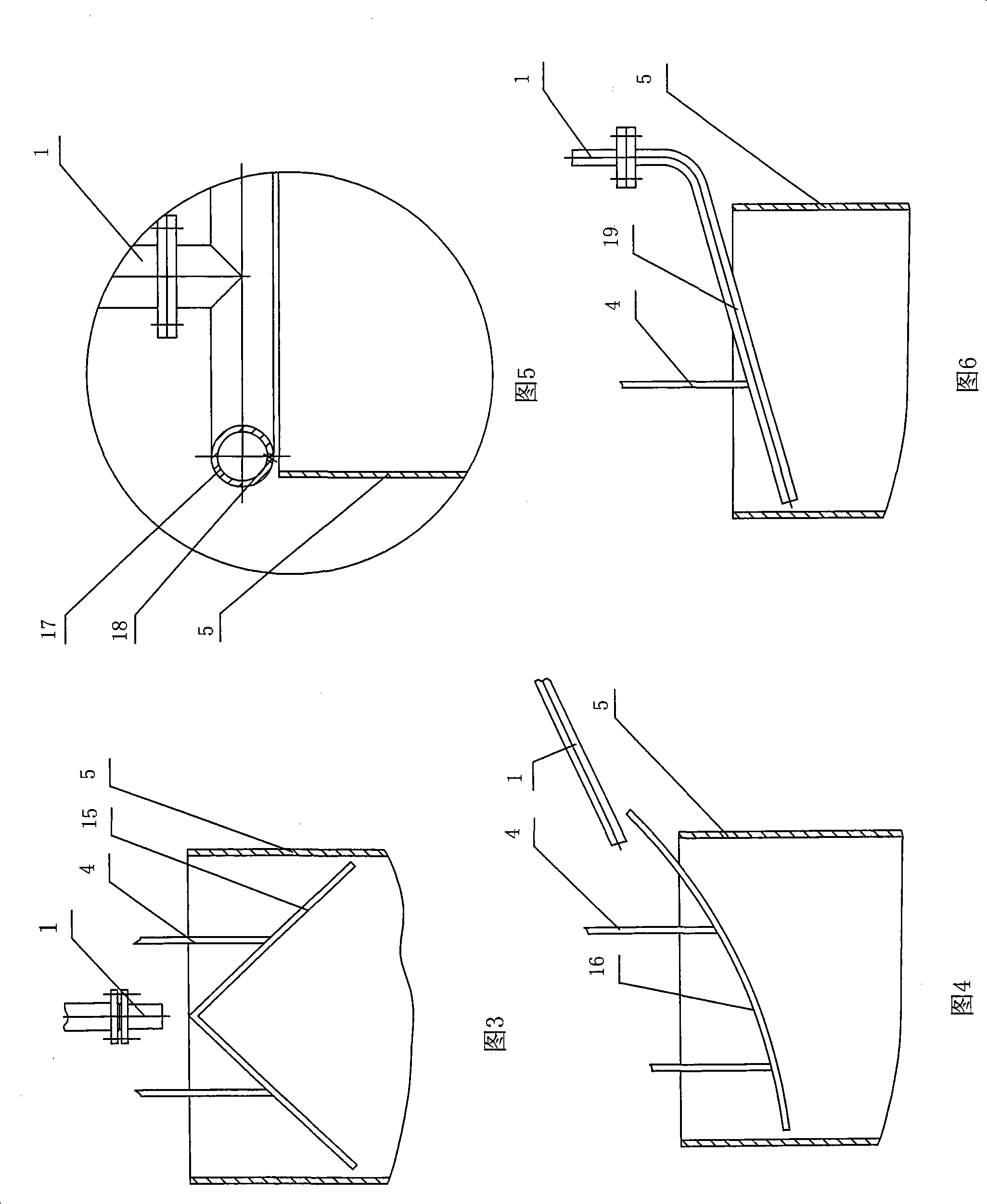

Method for optimizing controlling denitrification and phosphorus release in double precipitation pool by A*/O technique

ActiveCN101130447AWeaken the floating phenomenonHigh trafficTreatment with aerobic and anaerobic processesLine sensorSludge

The invention discloses a denitrifying and phosphoric discharge optimum controlling means in A2 / O craft secondary settling tank in waste water biological treating system domain, which is characterized by the following: using DO on-line sensor, nitrate on-line sensor and sludge level gage; monitoring on line; indicating generating degree of denitrifying and phosphoric discharge in the secondary settling tank; adjusting discharge of inner circulating pump when the measured value higher than setting range; increasing inner circulating ratio; controlling the density of water inlet nitrate in the secondary settling tank; adjusting discharge of the sludge circulating pump when the measured value of the sludge level gage deviate setting range; enlarging sludge return ratio; decreasing height of the sludge layer; providing reliable operating condition for water outlet emission standard of A2O craft; realizing high efficiency and low consumption.

Owner:SDIC XINKAI WATER ENVIRONMENT INVESTMENT CO LTD

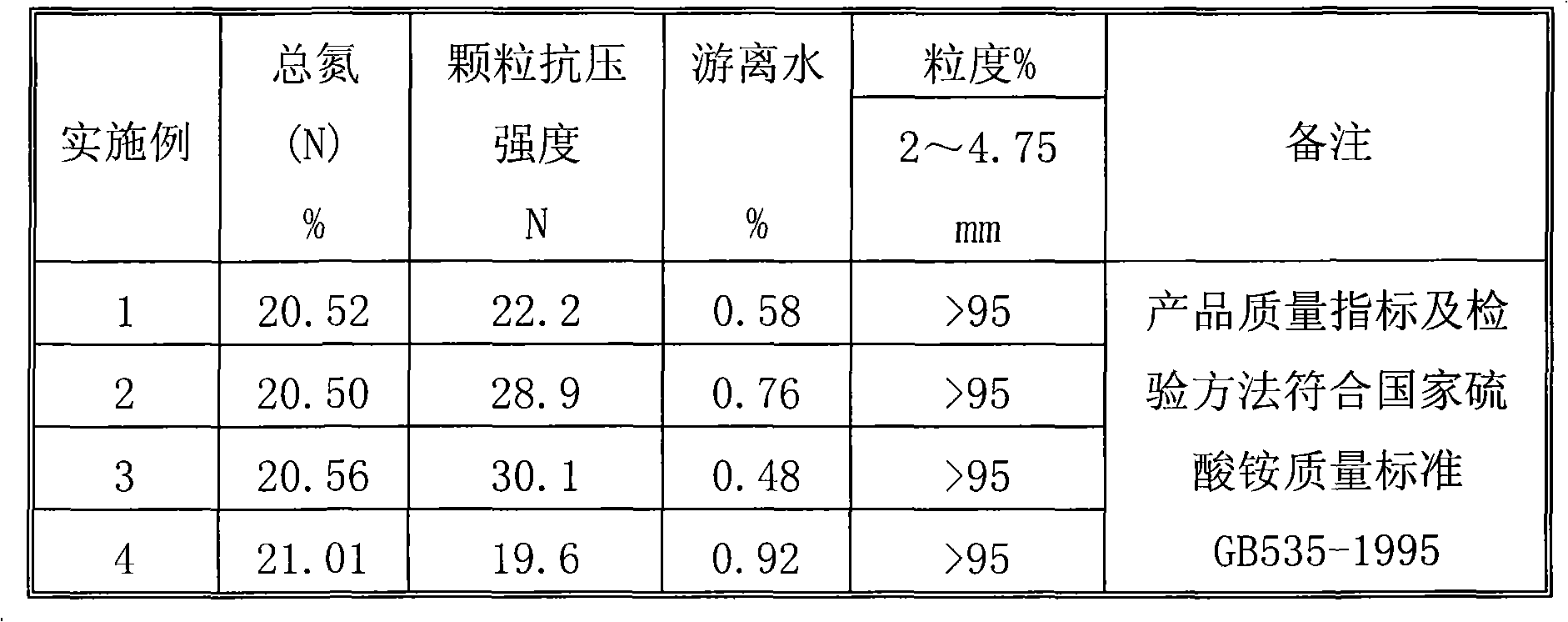

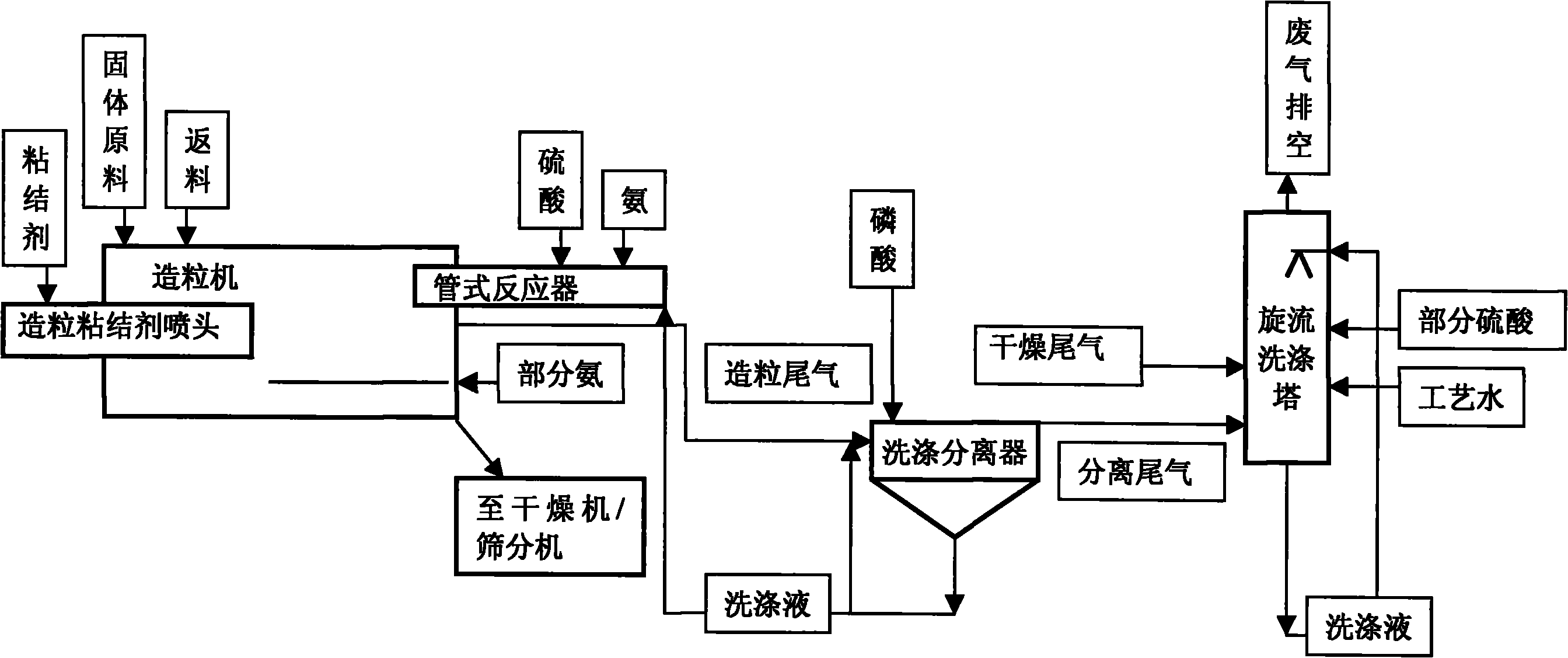

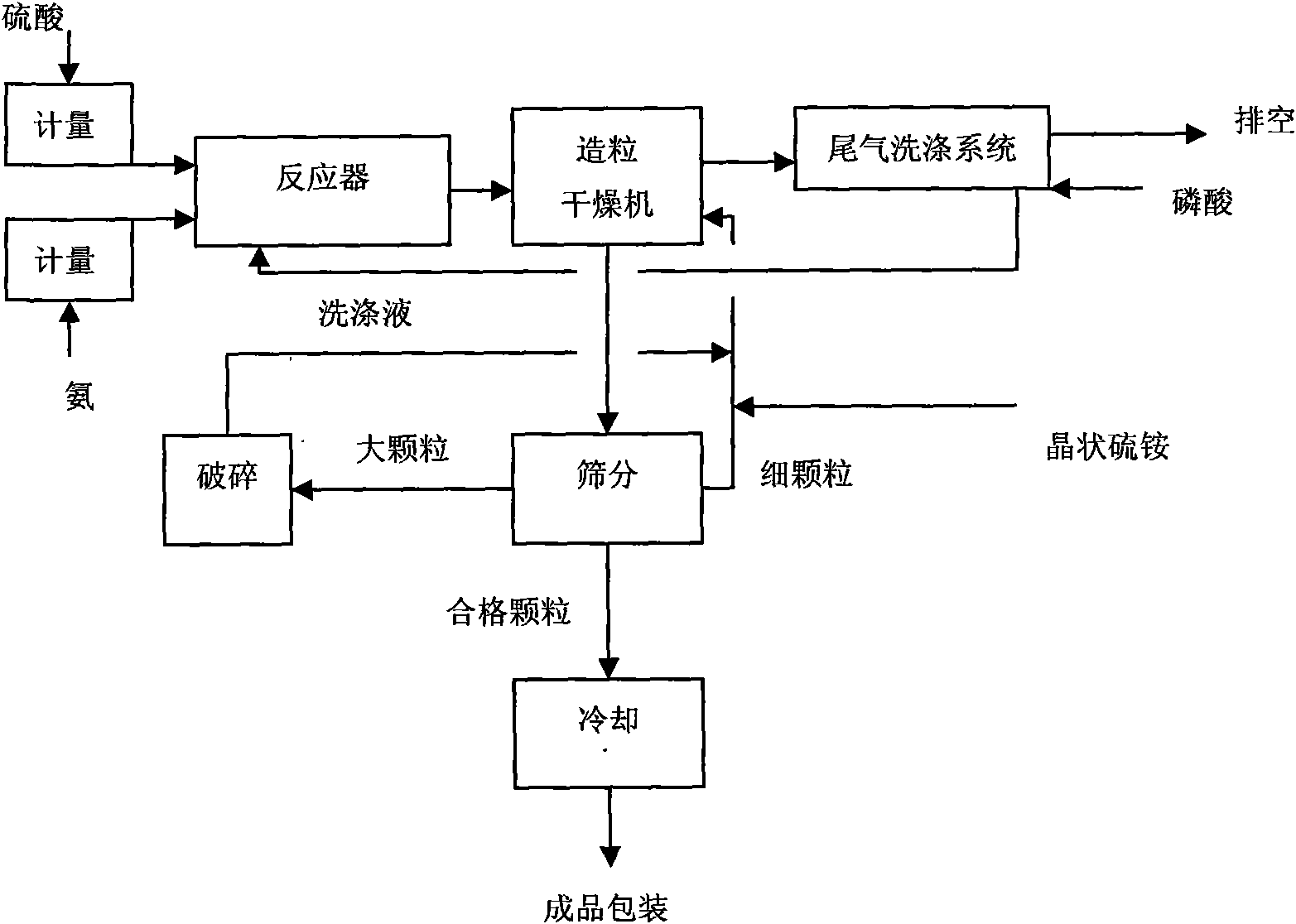

Preparation method of large-particle ammonium sulfate

InactiveCN101850989AReduce reaction loadControl water balanceAmmonium salt fertilisersAmmonia compoundsSlurryWater balance

The invention relates to a preparation method of large-particle nitrogenous fertilizers, in particular to a preparation method of large-particle ammonium sulfate, which comprises the following steps: firstly, adding 25-60 parts by weight of sulfuric acid, 7.6-16.5 parts by weight of ammonia and washing liquid from a gas-liquid separator to a tubular reactor for neutralization reaction; spraying high-temperature slurry formed after the reaction into a pelletizer; wherein, simultaneously, a solid material bed which comprises 20-70 parts by weight of solid material and rolls together with returns in the pelletizer can be installed in the pelletizer; spraying a pelleting binder through a spray nozzle and spraying the ammonium through an ammonium spraying shaft for pelleting to form wet solid material; fractionating the dried material after entering a sieving machine to sieve qualified particles and then cooling the particles to obtain the product. The invention reduces the reaction load of the tubular reactor; the system returns ratio is reduced, and the water balance is easier to control; simultaneously, the production cost is reduced, and recycling and the high-value utilization of industrial byproducts are realized by utilizing by-product powdery ammonium sulfate.

Owner:河北天人化工股份有限公司

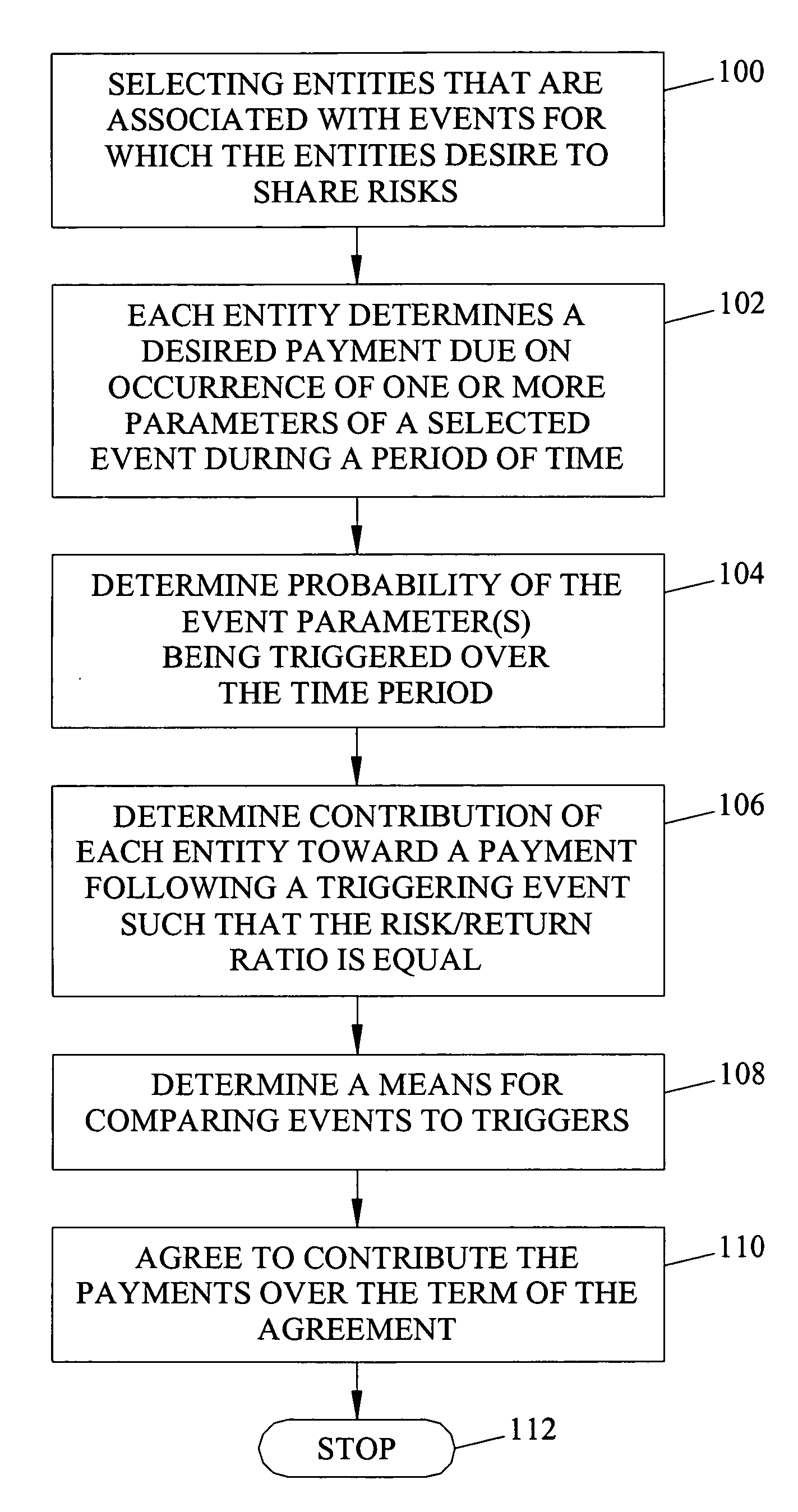

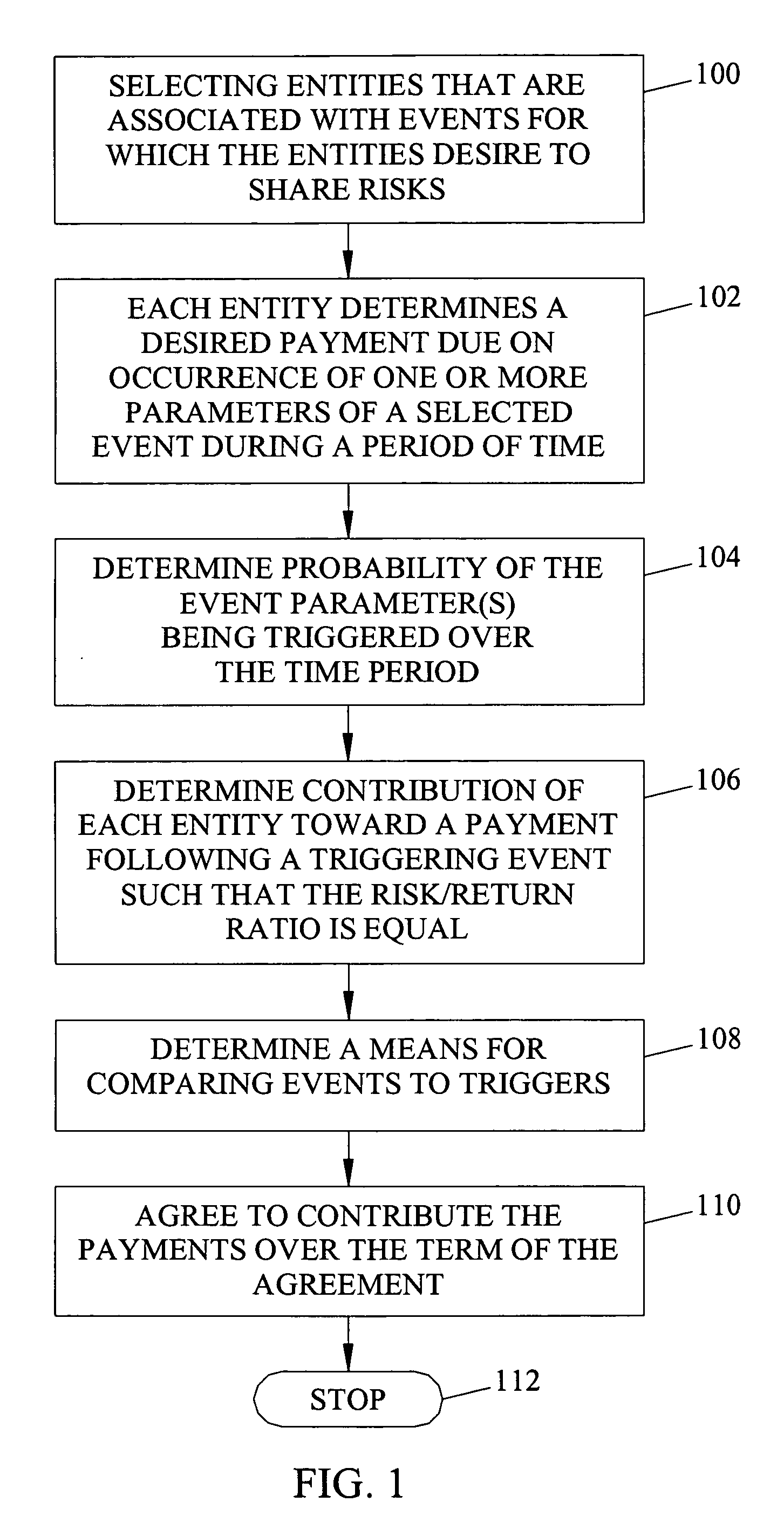

Collaborative risk sharing methods and related products

Collaborative risk sharing methods and related products are disclosed. According to one method, first and second entities can agree to share different risks associated with occurrences of first and second events, respectively. First and second probabilities of an occurrence the first and second events, respectively, can be determined. Further, the method may include a step for assigning first and second values for payment of the first and second entities, respectively, on the occurrence of the first and second events, respectively. The method can also include a step for determining first and second contributions of the first and second entities, respectively, towards the payment on the occurrence of the first and second events, respectively. The first and second entities can have an equal risk / return ratio. The risk / return ratio can be based on the first and second probabilities and the first and second values.

Owner:REIS EVAN

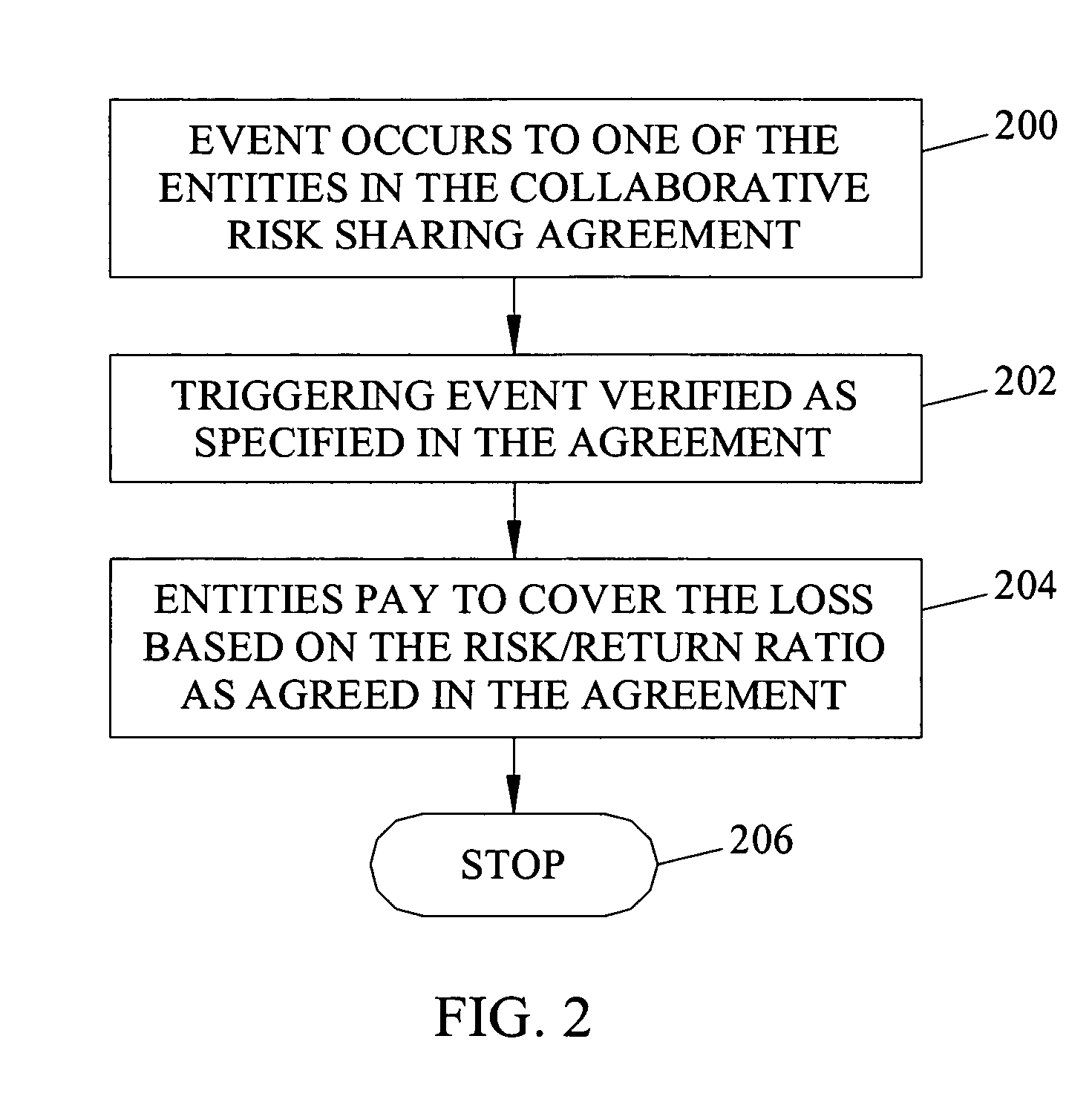

Whole-thermal reclaiming type thermal-drive solution ventilation processor set by using evaporative cooling of return air

ActiveCN1865789AGuaranteed concentrationEnergy recovery in ventilation and heatingLighting and heating apparatusEvaporative coolerEnergy technology

The invention relates to a recycle thermal-driving solution fan, which uses reflux air to vaporize and cool. Wherein, said invention comprises gas-liquid direct-contact modules (A-G), sheet heat exchanger, solution self-circulate pump, fan valve, and water pump; the upper channel is formed by the modules (A, B, C, D); the lower channel is formed the modules (E, F, G); the upper modules (B, C, D) is relative to the lower layer modules (E, F, G) to form three-stage heat recycles; each stage of upper and lower modules are connected by the sheet heat exchanger; the solution is cooled to be sprayed in the lower modules (E, F, G), to directly contact the air to dehumidify the air; and the dense solution enters into the lower modules (E, F, G); the upper module (A) contains the vaporizing cooling process between air and cold water, to generate cold water into the lower air cooler to reduce the temperature of air.

Owner:TSINGHUA UNIV +1

Method for producing granular ammonium sulfate by using crystalline ammonium sulfate or powdery ammonium sulfate

ActiveCN101648838AHigh strengthReduce lossesFertiliser formsAmmonium salt fertilisersPhosphoric acidSlurry

The invention relates to a method for producing granular ammonium sulfate by using crystalline ammonium sulfate or powdery ammonium sulfate. The method comprises the following steps: (1) adding the crystalline ammonium sulfate or the powdery ammonium sulfate into a granulating drier, using as mother material and forming a material screen or a material bed under the rotation of a rotary drum; (2) mixing sulfuric acid, ammonia, phosphoric acid and washing liquid in a tubular reactor, reacting, generating high-temperature slurry, spraying the slurry on the material screen or the material bed in agranulating machine after atomizing, and coating or sticking into particles; (3) after dedusting, washing the tail gas with the phosphoric acid and recycling the washing liquid; returning the collected dust to the granulating machine; (4) sieving material produced by the granulating drier to obtain particles of 1-4mm, which is a finished product of the granular ammonium sulfate; and returning theparticles greater than 4mm after being crushed and the particles smaller than 1mm to the granulating drier and recycling. The method can raise the temperature of a granulating material layer by the high-temperature slurry, improve the granulation rate of the mother material, lower the material return ratio, wash the tail gas with the phosphoric acid, reduce the loss of the ammonia, dry a productby reaction heat and save energy consumption; the generated product has high strength and little loss of nutrient components.

Owner:WENGFU (GRP) CO LTD

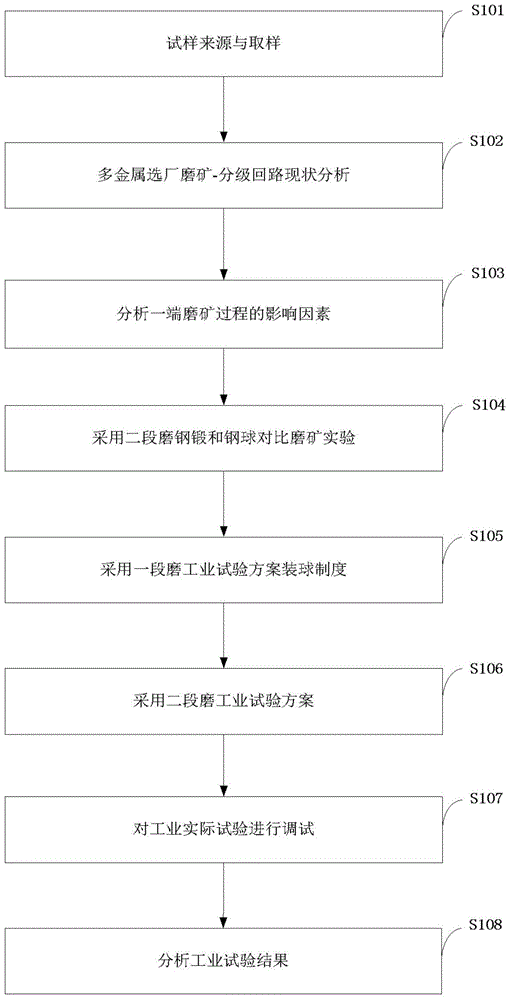

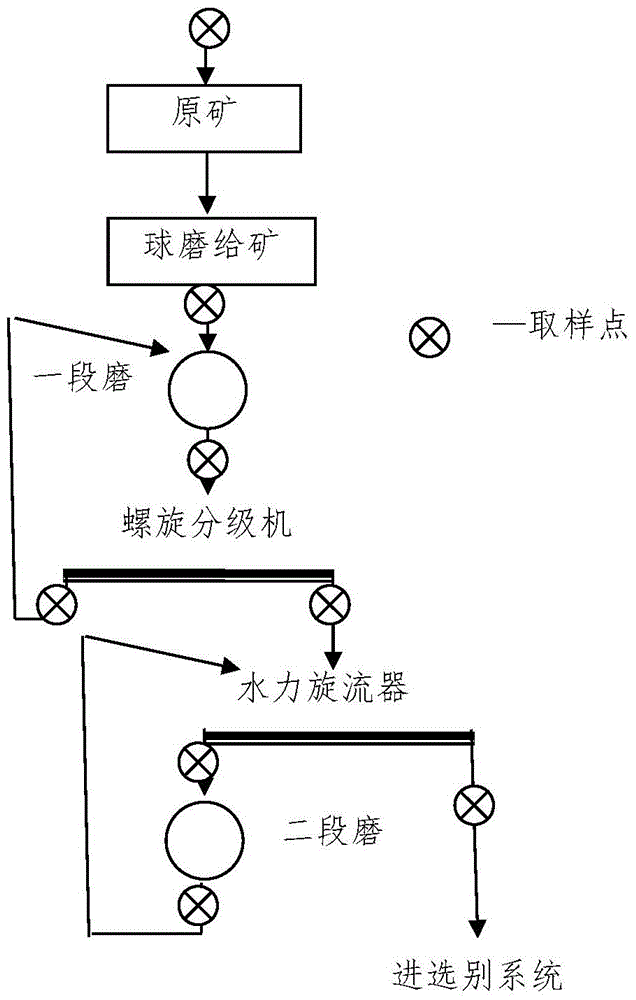

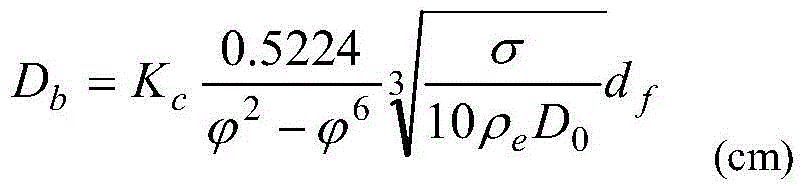

Multi-metal ore-separating and ore-grinding grading optimization test method

InactiveCN104028364AReduce unit consumptionImprove featuresGrain treatmentsWet separationReturn ratioSteel ball

The invention discloses a multi-metal ore-separating and ore-grinding grading optimization test method. The method includes the steps of determining a sample source and carrying out sampling, carrying out multi-metal ore-separating and ore-grinding grading circuit current situation analysis, analyzing influence factors of a primary ore-grinding process, carrying out a secondary steel forging and steel ball comparison ore-grinding experiment, adopting a primary grinding industrial test scheme ball loading system, adopting a secondary grinding industrial test scheme, debugging an industrial actual test and analyzing an industrial test result. The multi-metal ore-separating and ore-grinding grading optimization test method includes the steps of multi-metal ore embedment characteristic analysis, ore mechanical performance testing and researching, steel ball diameter calculation carried out when ore is broken and accurate ball loading experiment verification. According to the method, steel ball unit consumption is reduced, work noise of a grinding machine is lowered, work efficiency is improved, the utilization coefficient, the primary grading sand return ratio, grading quality efficiency and grading quantity efficiency of the grinding machine are improved, the qualified granulometric class is increased by 2-6 percentage points, the ratio of excessively crushed ore is reduced by 2 percentage points, and the quality characteristic of secondary overflowing products is improved.

Owner:JIANGXI UNIV OF SCI & TECH

Aerobic treatment method applied in antibiotic wastewater treatment

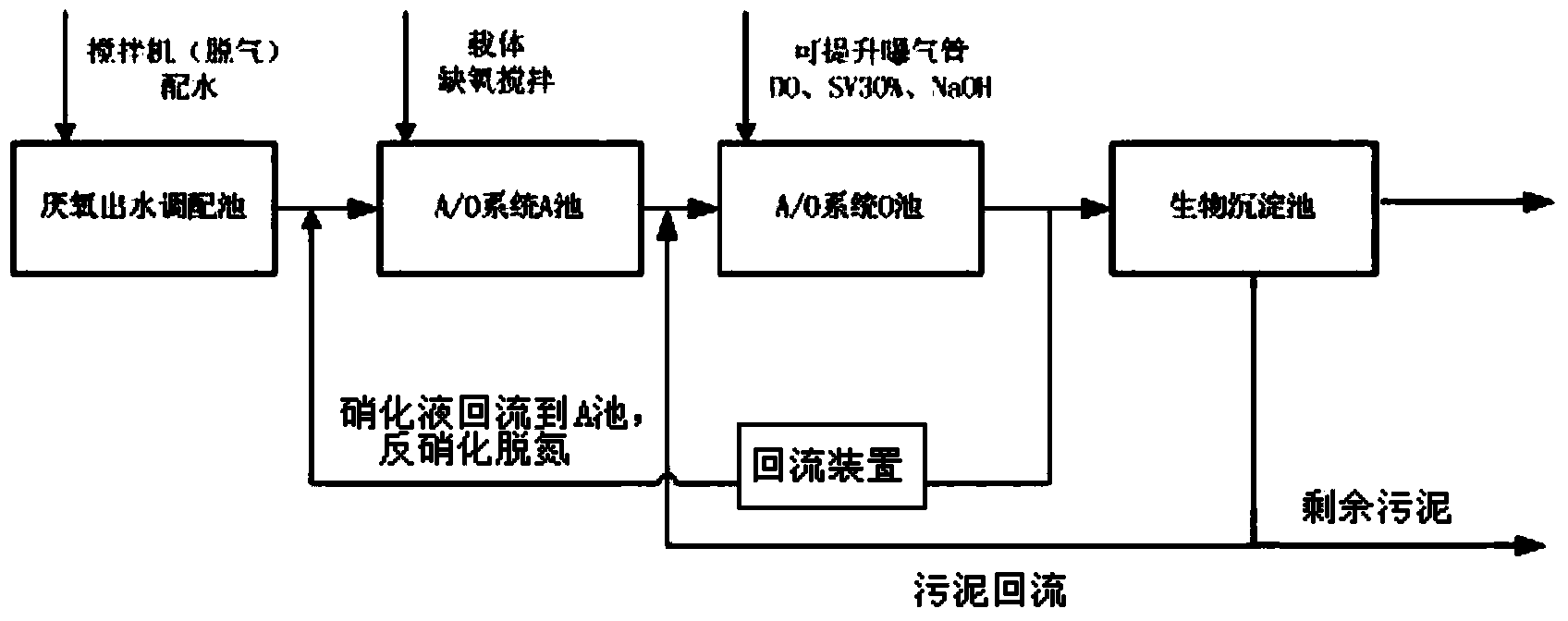

ActiveCN103508559AImprove removal efficiencySustainable biological treatmentBiological water/sewage treatmentSludgeNitration

The invention discloses an aerobic treatment method applied in antibiotic wastewater treatment, and applied in a wastewater treatment A / 0 biochemical system. The A / 0 biochemical system comprises a pool A, a pool O, a reflowing device and a biological setting pond. A preposed efficient microorganism A / O denitrification system is established in an aerobic interior of the biochemical system; an aerobic hydrolysis pool (the pool A) and an aeration oxidization pool (the pool O) are built in a biochemical pool, and are filled with efficient microbial preparation; the optimal environment is created to continuously enlarge cultivation and domestication. The removal of ammonia nitrogen and total nitrogen is mainly implemented in a continuous flow treatment manner with the methods of strengthening the stirring of the pool A and the aeration of the pool O and controlling the reflowing of nitration liquid and the sludge return ratio, and most COD is simultaneously degraded, so that the purpose of degrading various pollutants is achieved; through the technology, the removal efficiency of various pollutants is more than 95%.

Owner:PUCHENG CHIA TAI BIOCHEM

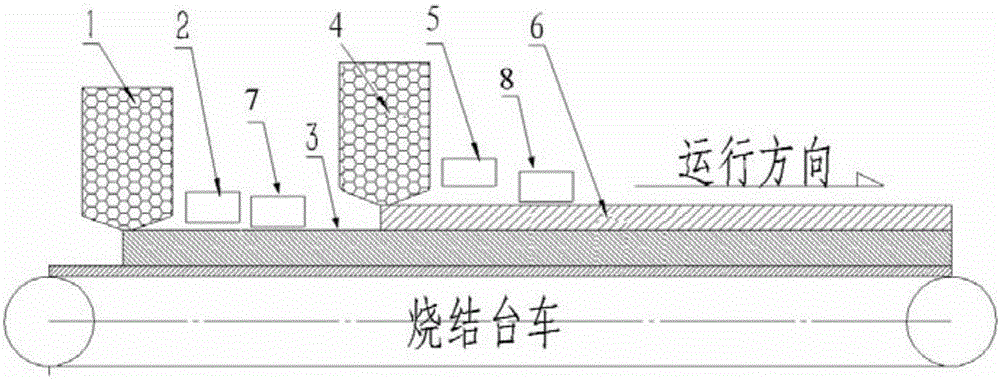

Ultra-thick bed sintering method for reducing sinter return ratio and employing presintering

The invention discloses an ultra-thick bed sintering method for reducing sinter return ratio and employing presintering; ignition temperature is optimized, a suitable amount of insulation covers are provided, high-oxygen hot air is introduced, surface ignition quality of upper and lower beds of sinter can be effectively improved, mineralizing time of surface sinter can be extended, and cold brittleness of the sinter is reduced; through reasonable coal allocation and water regulation for the upper bed of sinter mixture and reducing the amount of rolls of a distributor, better breathability is provided for the upper bed of sinter mixture; according to the features of the upper bed of mixture, bed combustion and particle size deviating is inhibited, and the bed never combusts too fast; through comprehensive technical means, it is possible to effectively decrease the return ratio of the upper bed of sinter and the whole bed of sinter.

Owner:ANGANG STEEL CO LTD

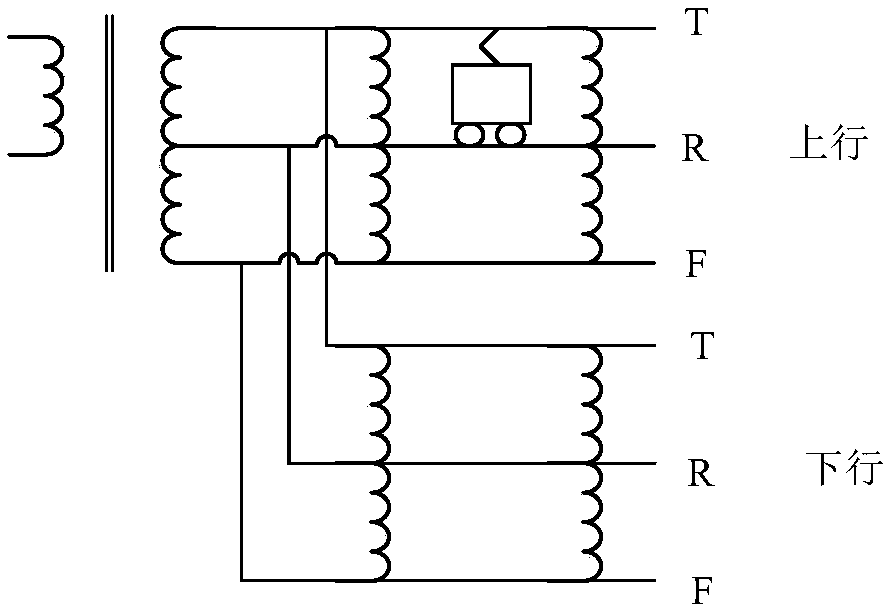

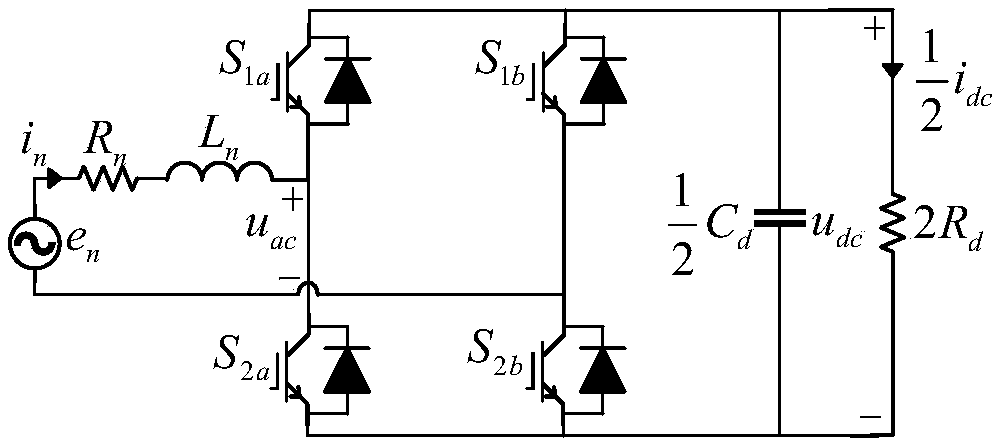

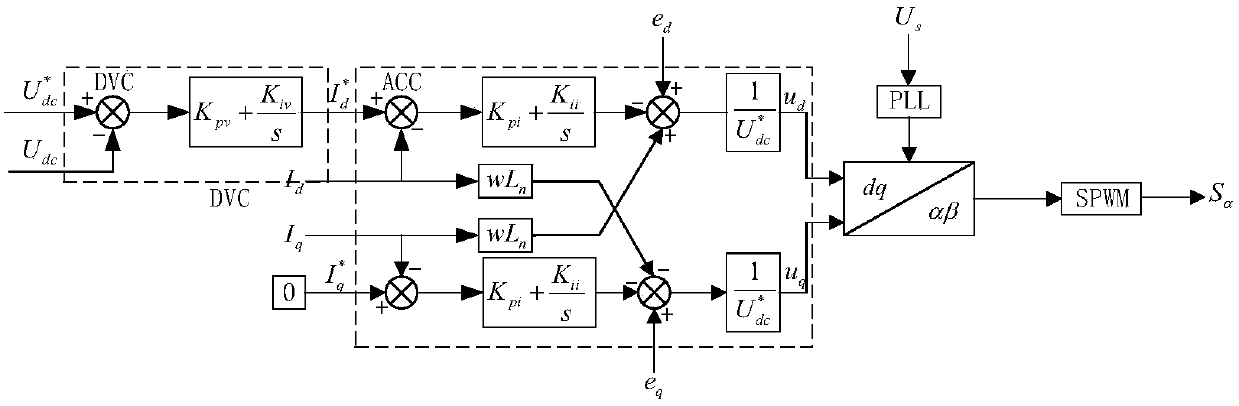

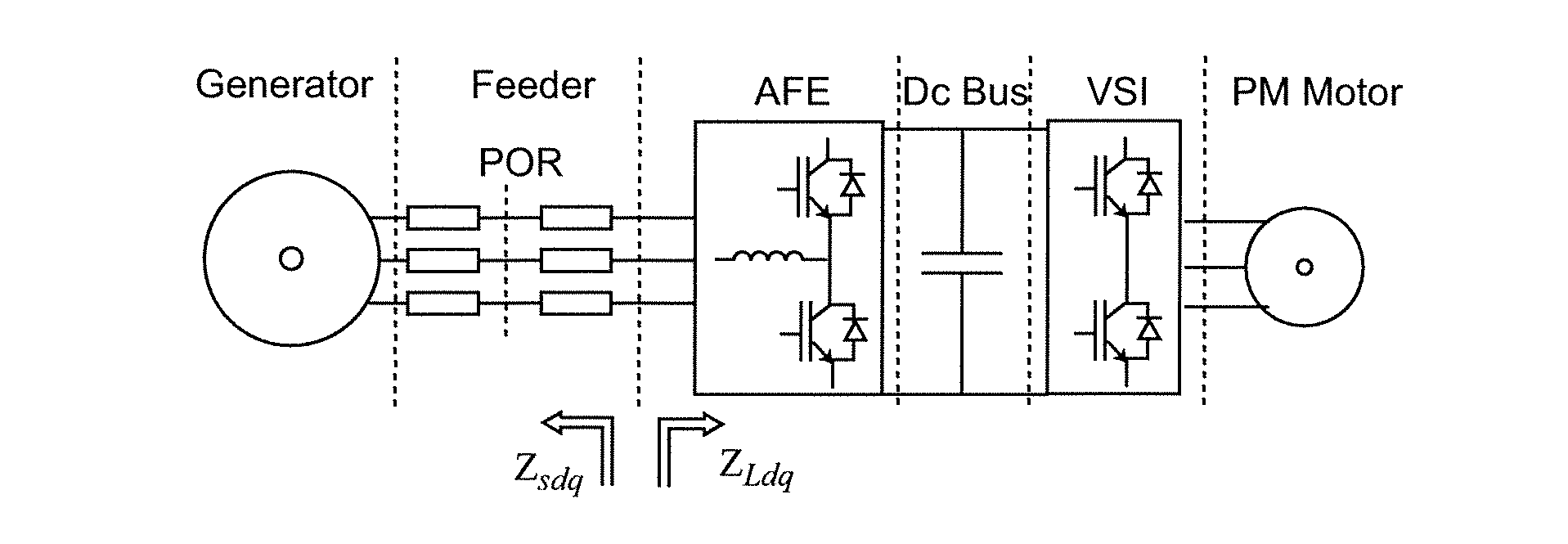

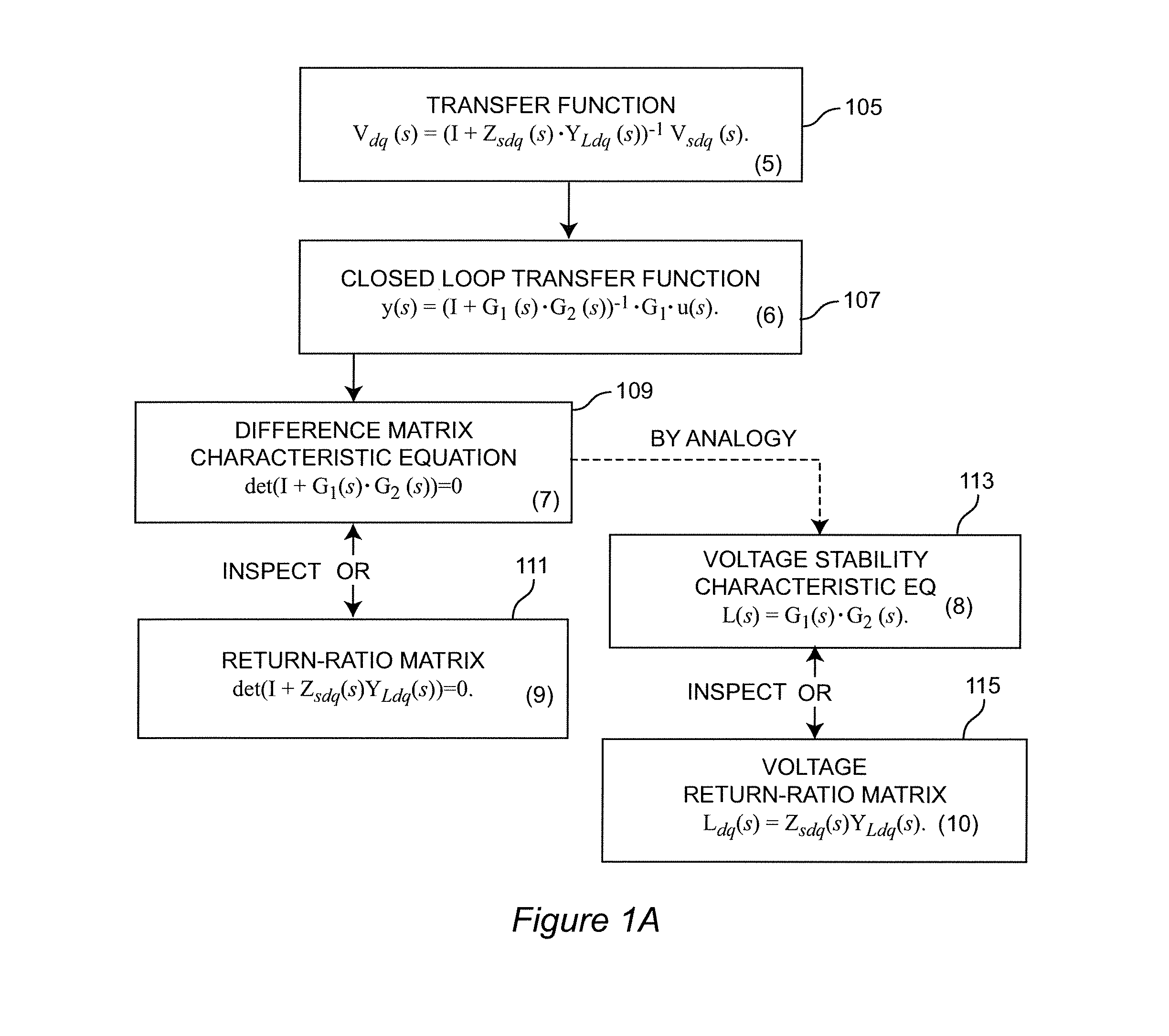

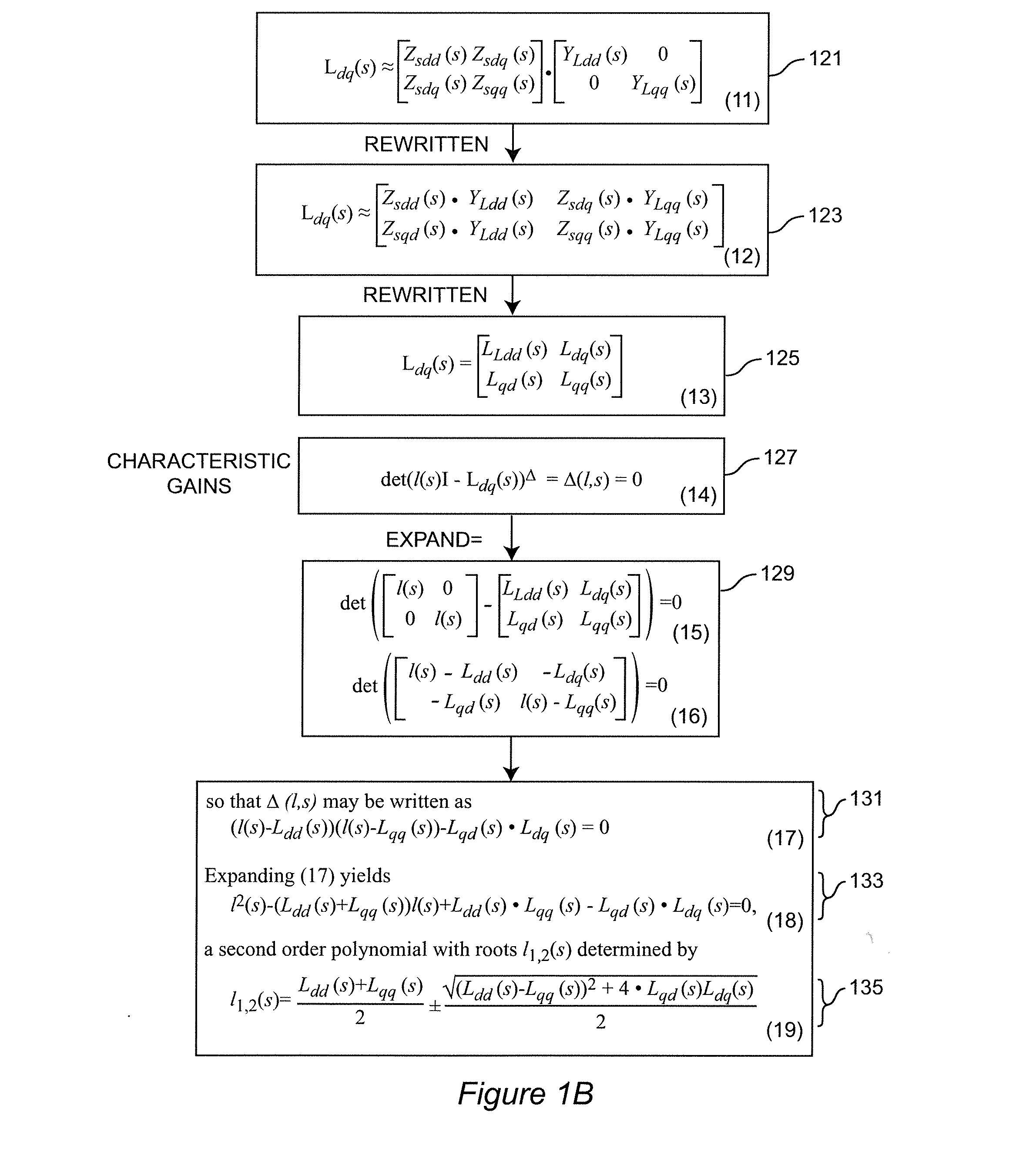

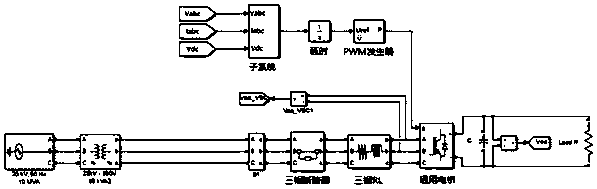

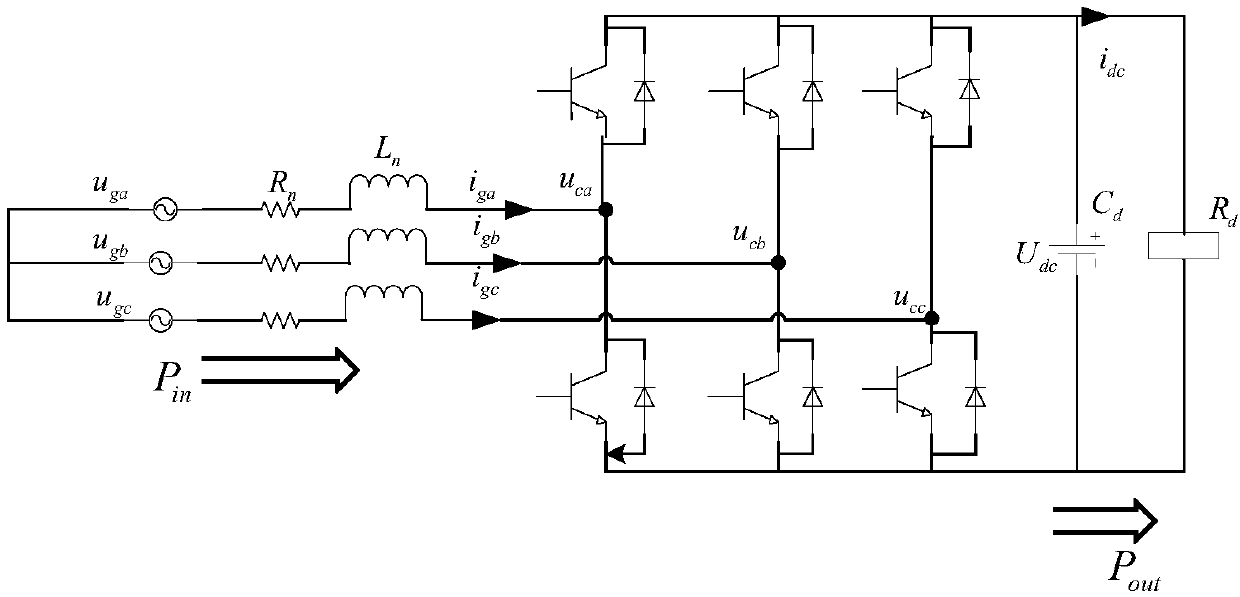

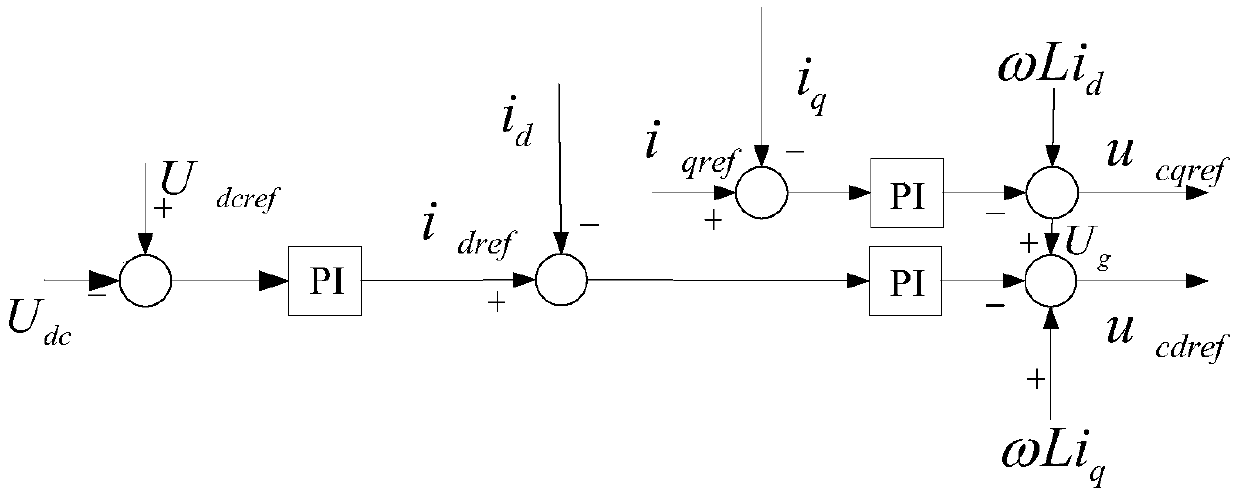

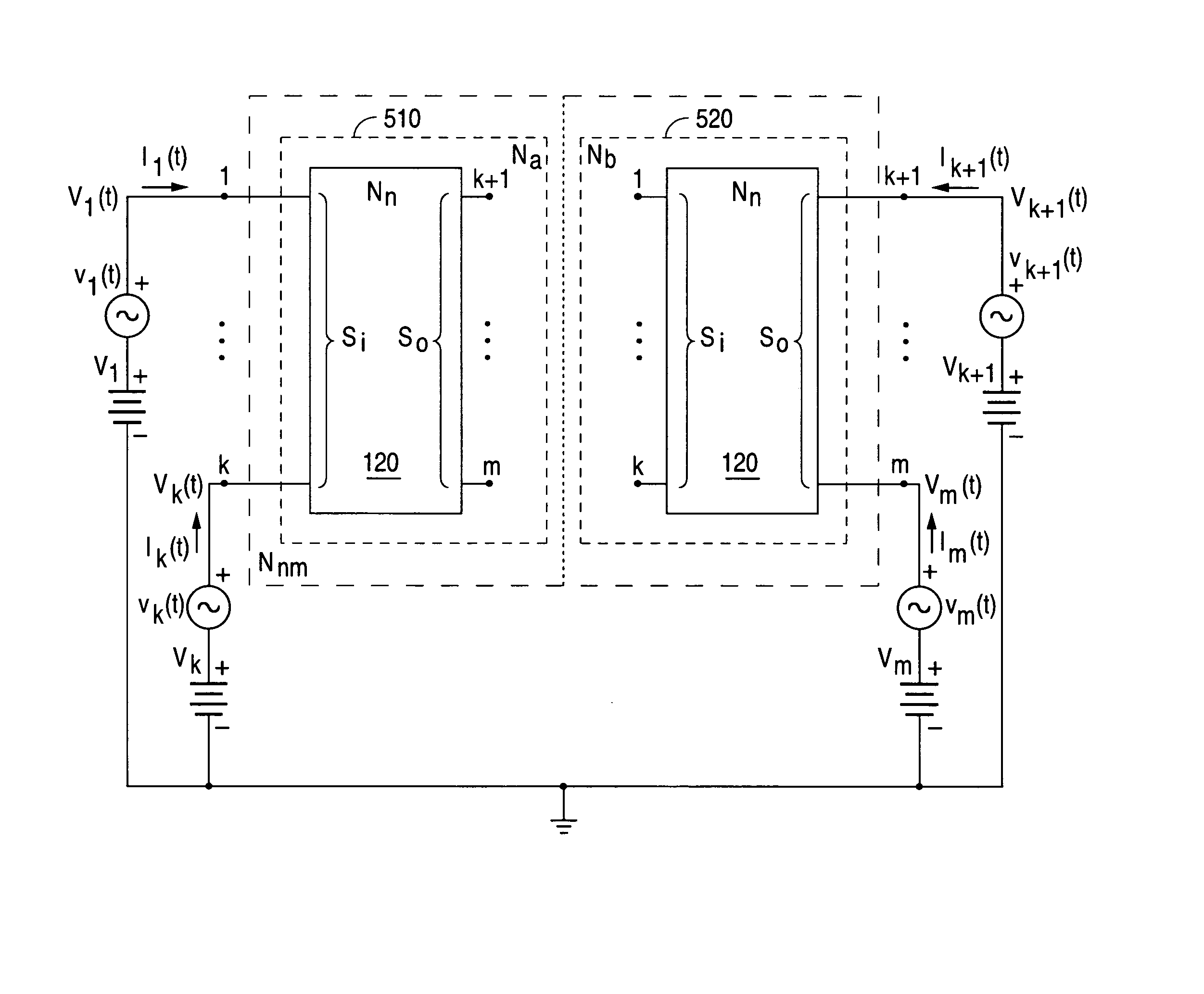

Tractor-network coupled system stability criterion calculation method based on impedance return ratio matrix

ActiveCN107565545ANarrow the restricted areaReduce conservatismAc network circuit arrangementsEngineeringStability criterion

The invention discloses a tractor-network coupled system stability criterion calculation method based on an impedance return ratio matrix. A high-speed rail vehicle network cascade system is used as arepresentative MIMO cascade system. The method includes the following steps: deducing the equivalent front-stage output impedance of the system; deducing the equivalent back-stage input impedance ofthe system; calculating the overall transfer function of the system, and getting a return ratio matrix and a transposed matrix thereof; estimating the feature value of the return ratio matrix and thefeature value of the transposed matrix of the return ratio matrix, and limiting the distribution area; and setting a forbidden zone for the distribution area of the feature values, and getting a lessconservative MIMO system stability criterion. The criterion can be used to simply and effectively analyze the stability of the MIMO cascade system, and is much less conservative than the existing singular value criterion, norm criterion or the like.

Owner:SOUTHWEST JIAOTONG UNIV

Method of Evaluating and Ensuring Stability of AC/DC Power Systems

Approximating loci of eigenvalues or characteristic gains of a return ratio matrix of a model of a multi-phase power converter circuit by the loci of the d-d and q-q elements of said synchronous frame of reference applied to said model, allows determination and assessment of stability of the circuit or forbidden operational parameters of the combination of an AC power source and a power converter at an interface thereof by application of a standard Nyquist stability criterion.

Owner:VIRGINIA TECH INTPROP INC +1

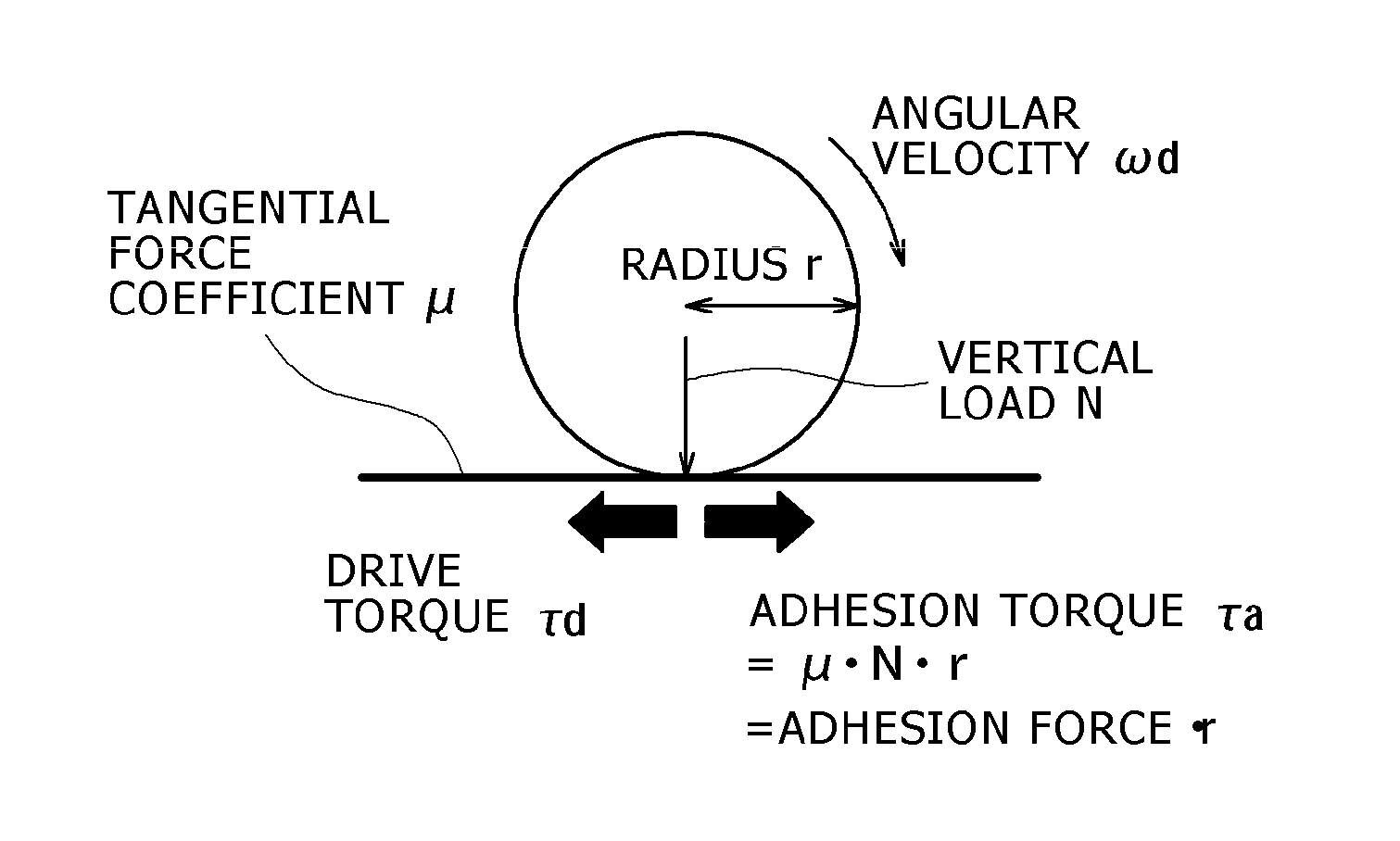

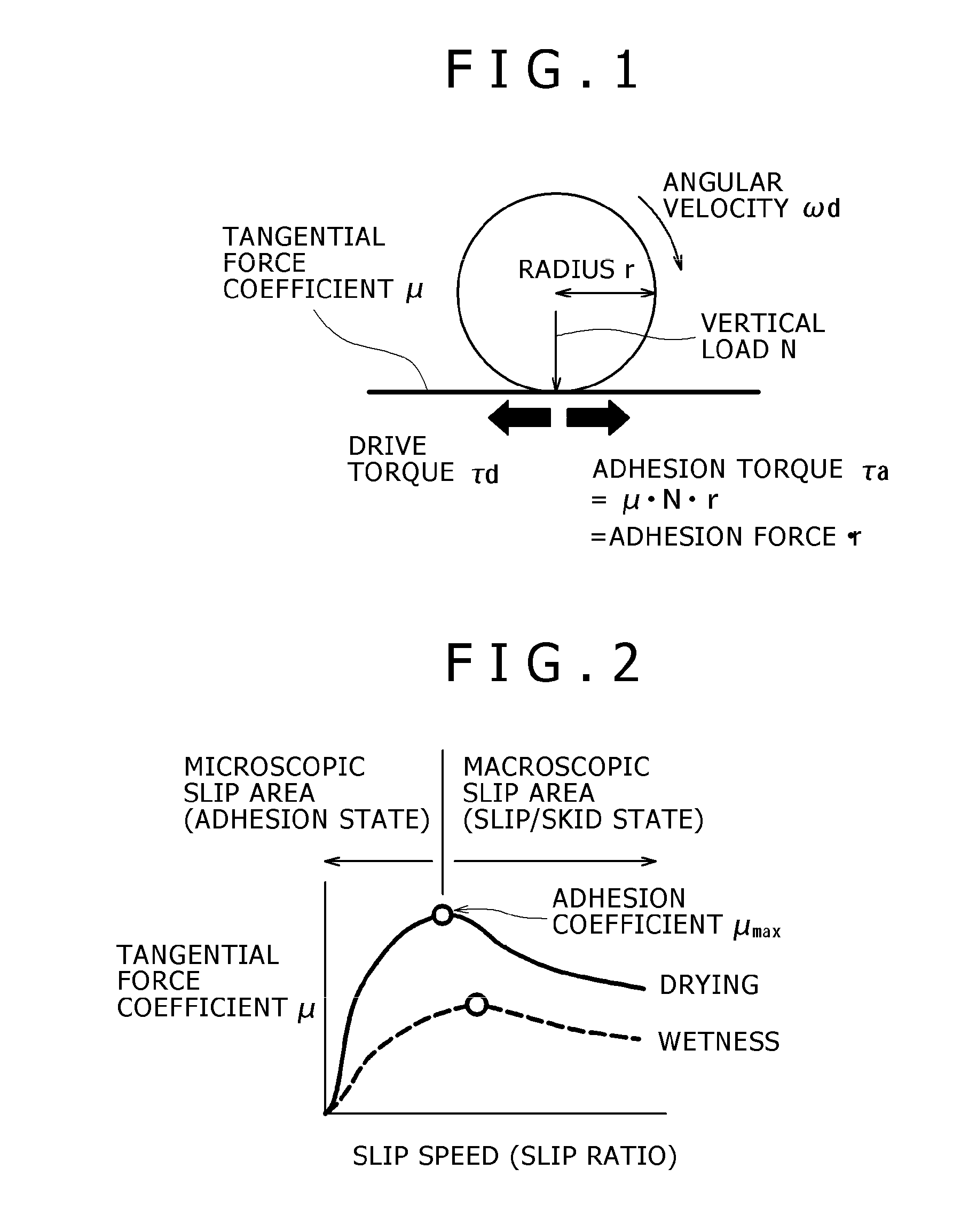

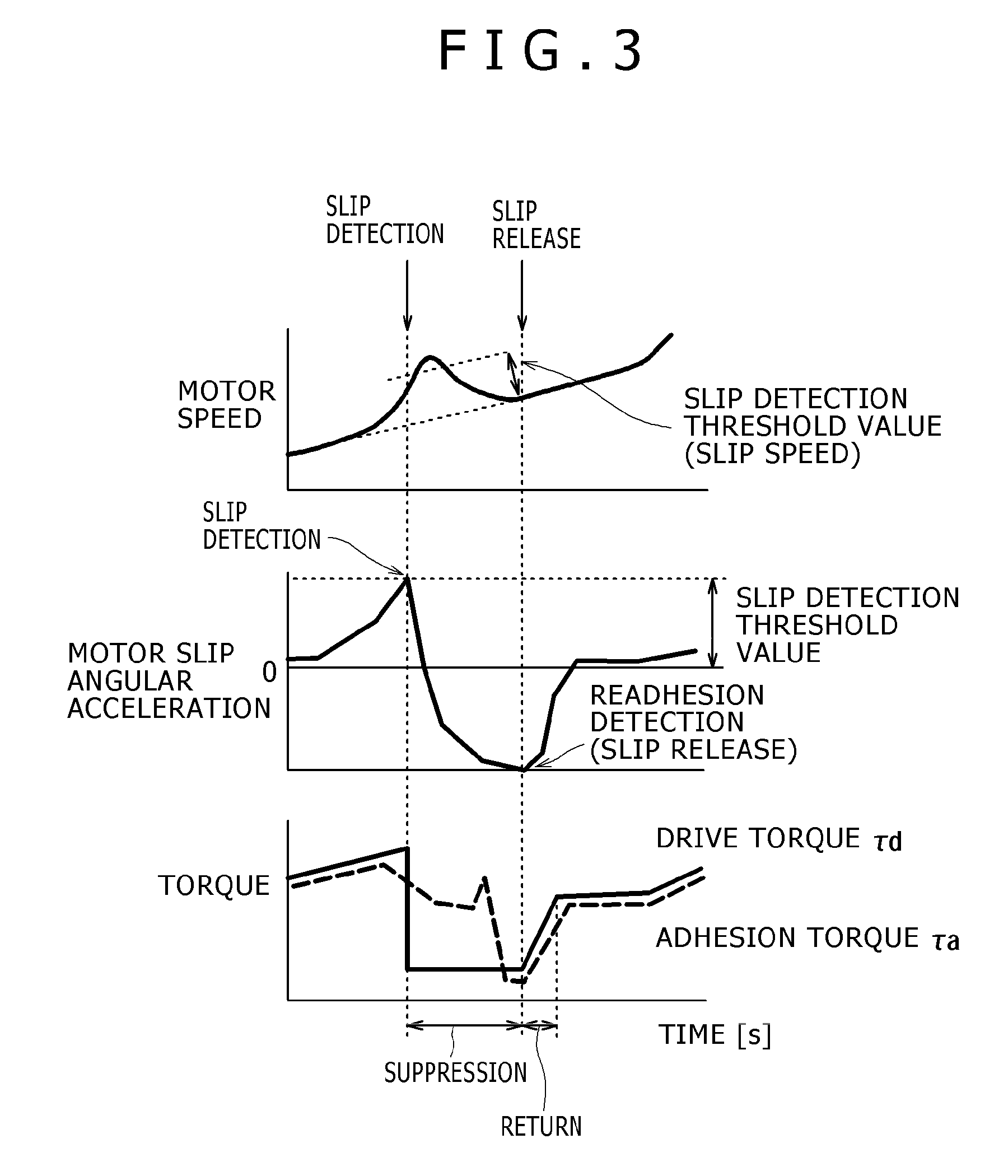

Control device for electric rolling stock

ActiveUS20130238176A1Improve acceleration performanceImprove deceleration performanceSpeed controllerElectric devicesAdhesion coefficientReturn ratio

In order to minimize a calculation load and surely obtain a maximum adhesion torque, estimated adhesion torques are always stored, an maximum value is obtained from the stored plural estimated adhesion torques immediately before slip / skid is detected when detecting the slip / skid, and the maximum value is set as a maximum adhesion torque. The maximum adhesion torque immediately before the slip / skid is detected is compared with a value of the estimated adhesion torque when the slip / skid is detected. When the calculated value exceeds a threshold value, it is determined as a condition where an adhesion coefficient drastically drops, and a suppression / return ratio of the torque is switched to a lower value than that under a condition where the adhesion coefficient does not drastically drop. The value of the torque at the time of suppression or return is set to a smaller value to surely suppress the slip / skid.

Owner:HITACHI LTD

Multilevel defoaming method of evaporator

A multilevel defoaming method of an evaporator relates to a multilevel defoaming method for vapor-liquid separation of secondary steam in the evaporator in the aluminium oxide manufacturing process. The invention is characterized in that baffled defoamers are additionally installed on air outlet pipes of a flash evaporator and a forced effect steam pipe defoamer to carry out a multilevel choke flow and defoaming on the secondary steam. In the method, the treatment result of the secondary water alkalinity is obvious after the secondary steam is treated by multilevel defoaming; when the evaporator is in operation, the secondary water alkalinity is lower and steady with little fluctuation; when starting up the evaporator, the secondary water alkalinity drops rapidly and can be qualified in half an hour, thus dramatically decreasing the generation of disqualified water and improving the return ratio; a down spout is dispensed with by changing the installation angle and direction; a secondary steam control gate can be turned up progressively after the secondary water alkalinity is lowered, thus improving the degree of vacuum of the evaporator separating chamber, decreasing the boiling point of the solution and improving the evaporation efficiency.

Owner:中铝矿业有限公司 +1

Harmonic instability analysis method for double-fed fan grid-side converter

ActiveCN108847670AImprove the operating environmentSuppress harmonic instabilitySingle network parallel feeding arrangementsWind energy generationInstabilityEngineering

The invention discloses a harmonic instability analysis method for a double-fed fan grid-side converter, comprising the following steps: firstly, building a harmonic model for the double-fed fan grid-side converter; secondly, only considering influence of a current control loop and grid-side impedance, and building an output admittance small signal model under a d axis according to the model in the step 1; thirdly, building a return ratio matrix under the influence of the d axis according to the model in the step 2; fourthly, obtaining an output impedance closed loop transfer function under adq axis and a return ratio matrix thereof according to the model in the step 2; and fifthly, respectively extracting characteristic values of the return ratio matrixes obtained in the step 3 and the step 4, and carrying out harmonic instability analysis on each parameter according to a generalized Nyquist criterion. The method disclosed by the invention can simply and visually judge and control influence of parameters as well as conversion trends of inductances and resistances at a grid side and an alternating current side on system stability.

Owner:SOUTHWEST JIAOTONG UNIV

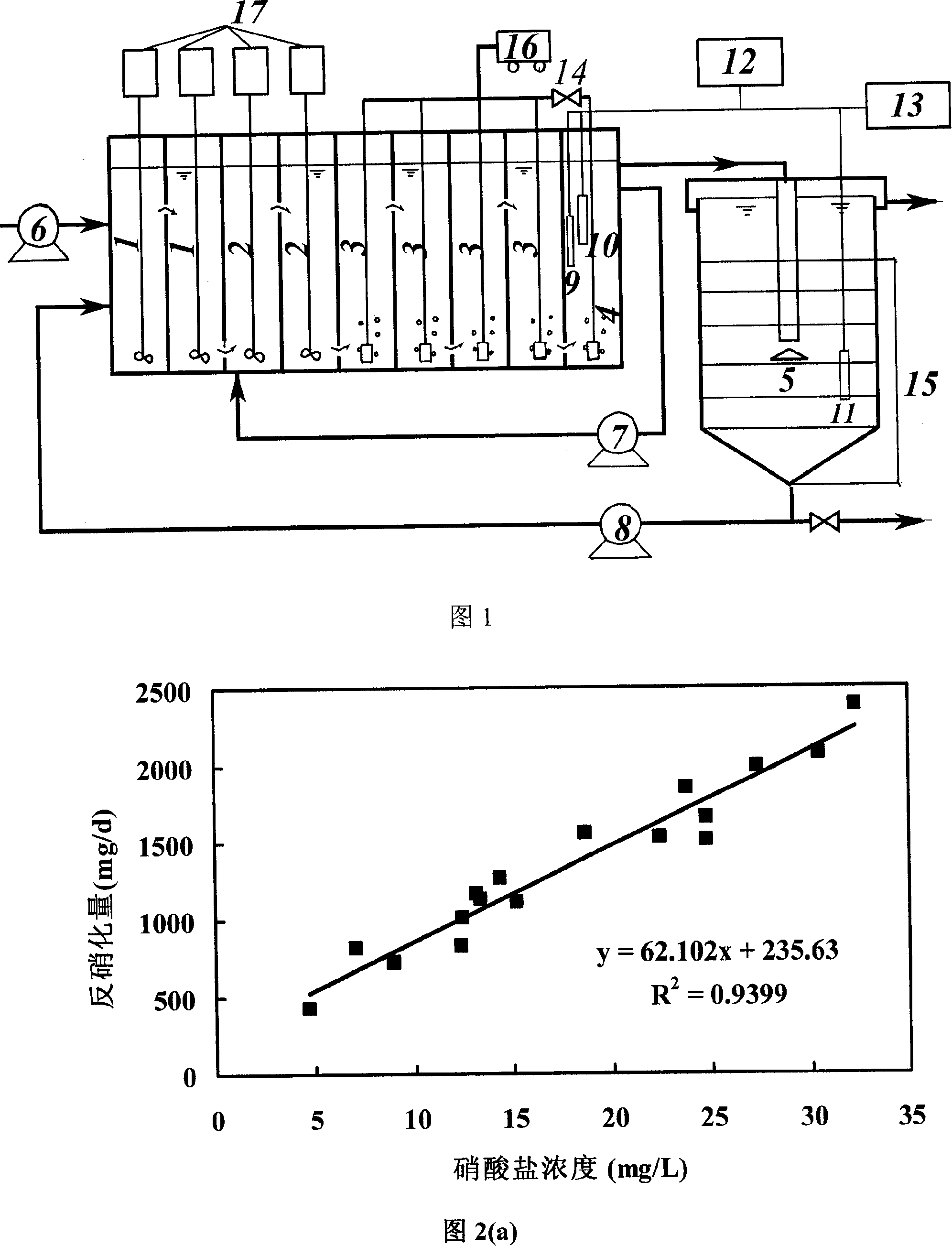

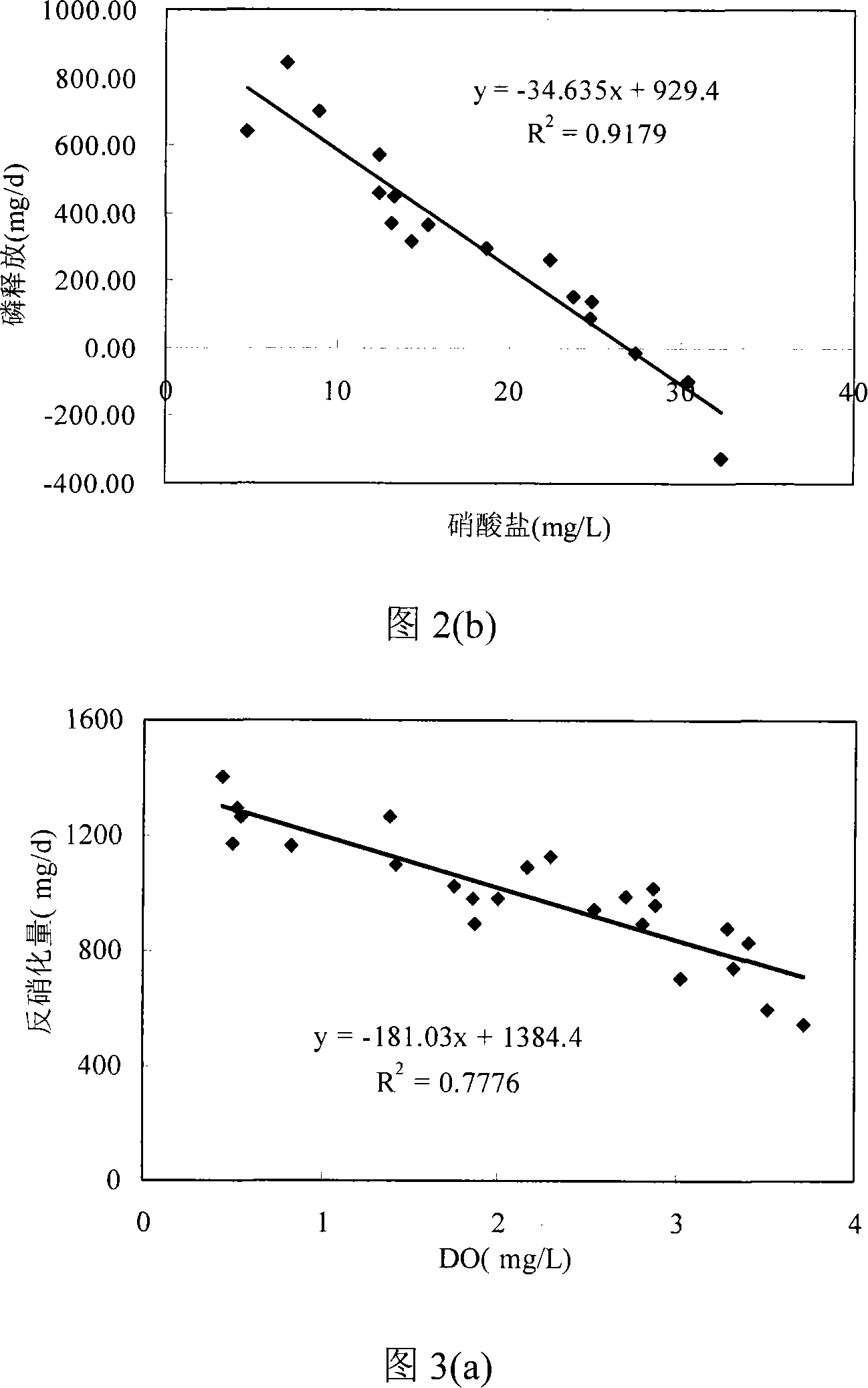

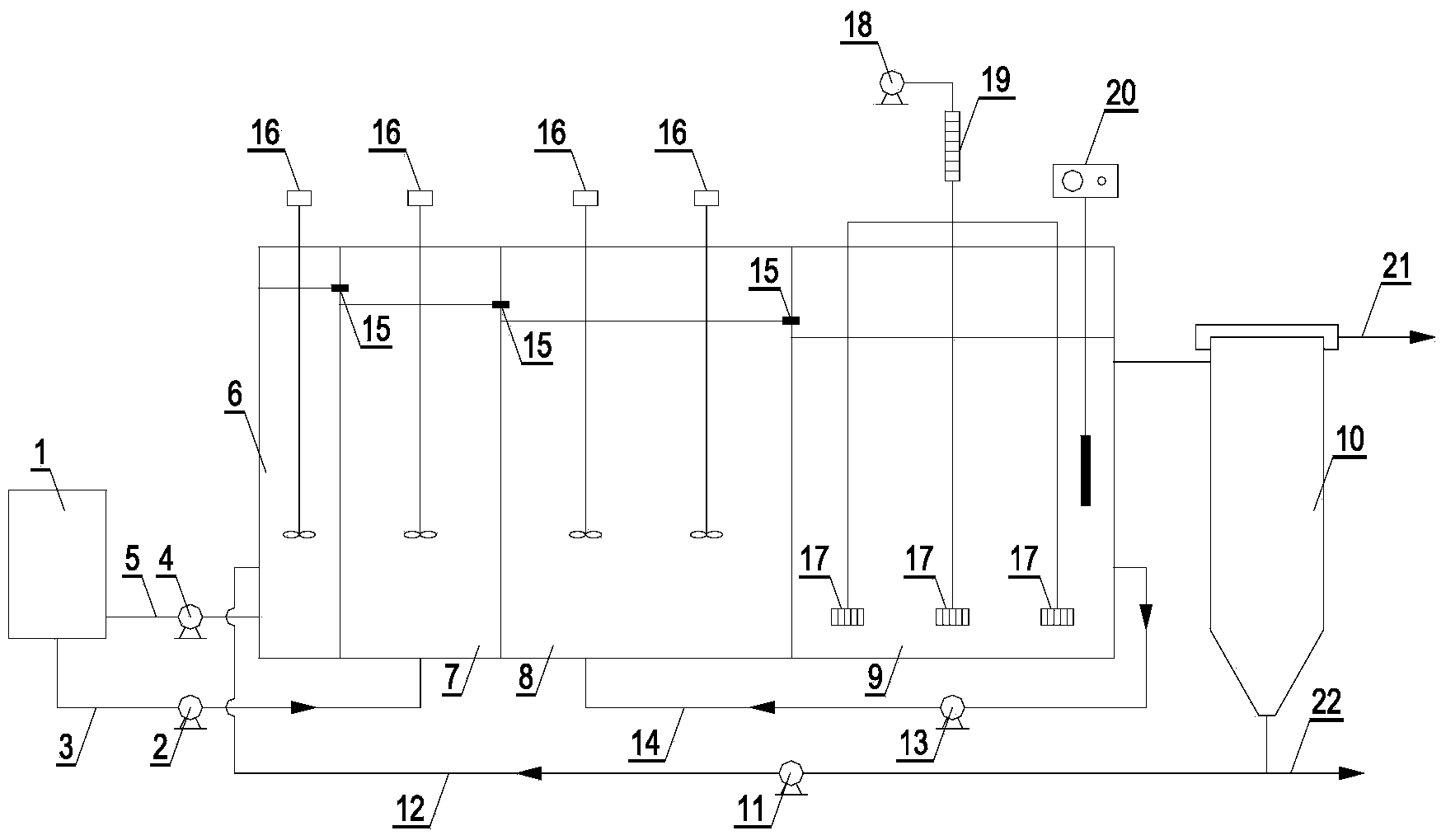

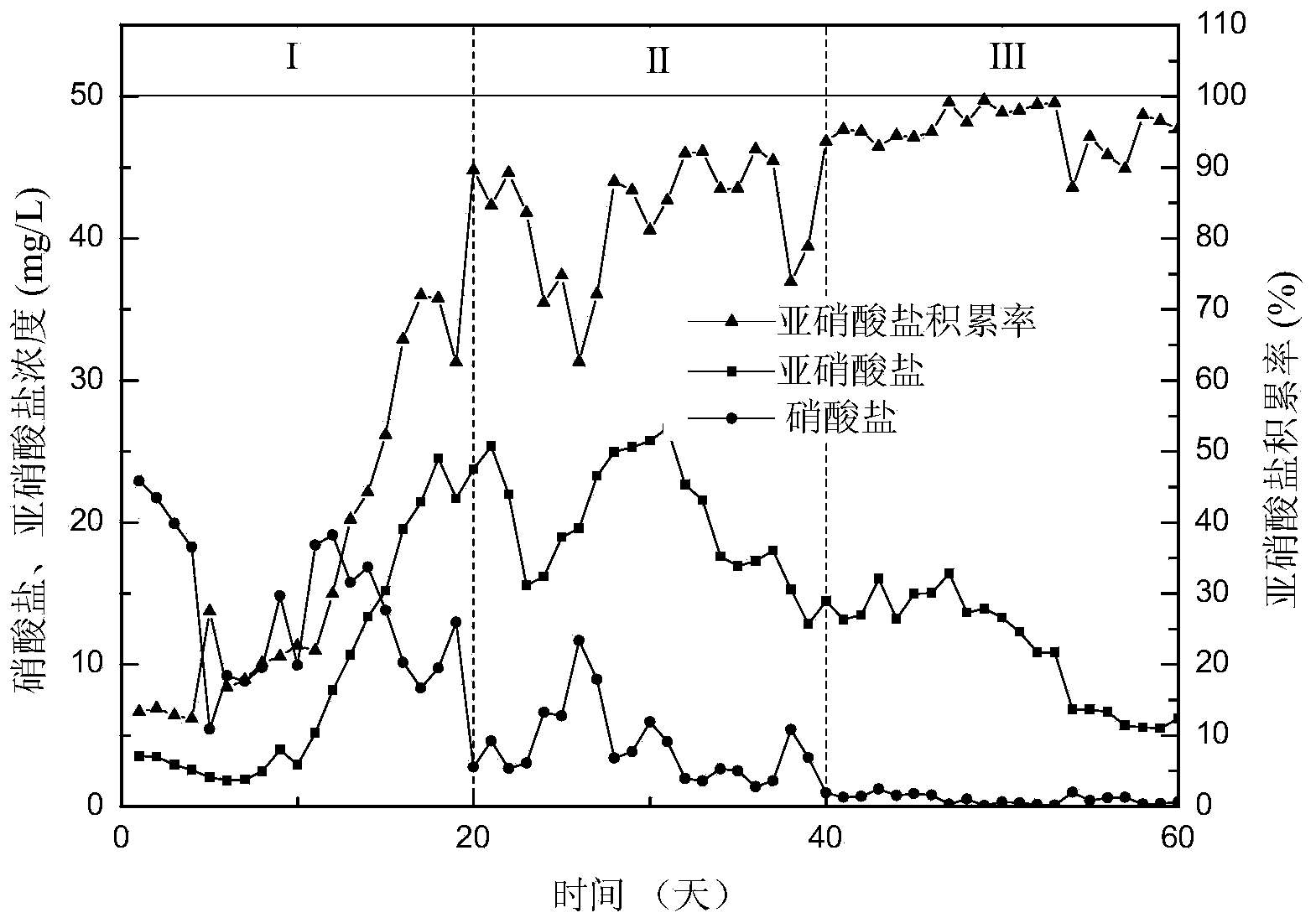

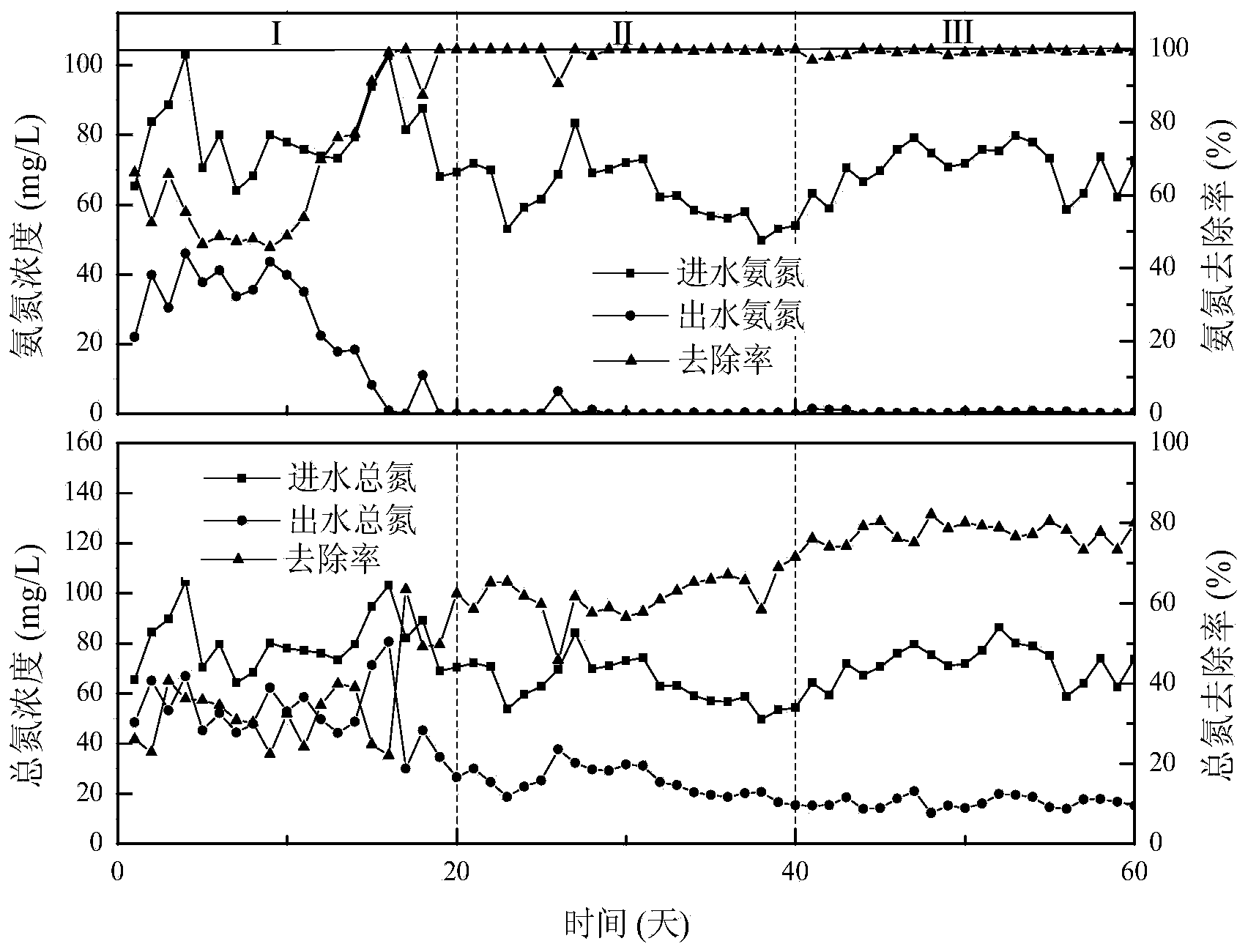

Method for achieving short-cut denitrification by continuous flow sewage treatment system

ActiveCN103833134AReduce processing costsReduce eutrophicationTreatment with aerobic and anaerobic processesRefluxNitrogen removal

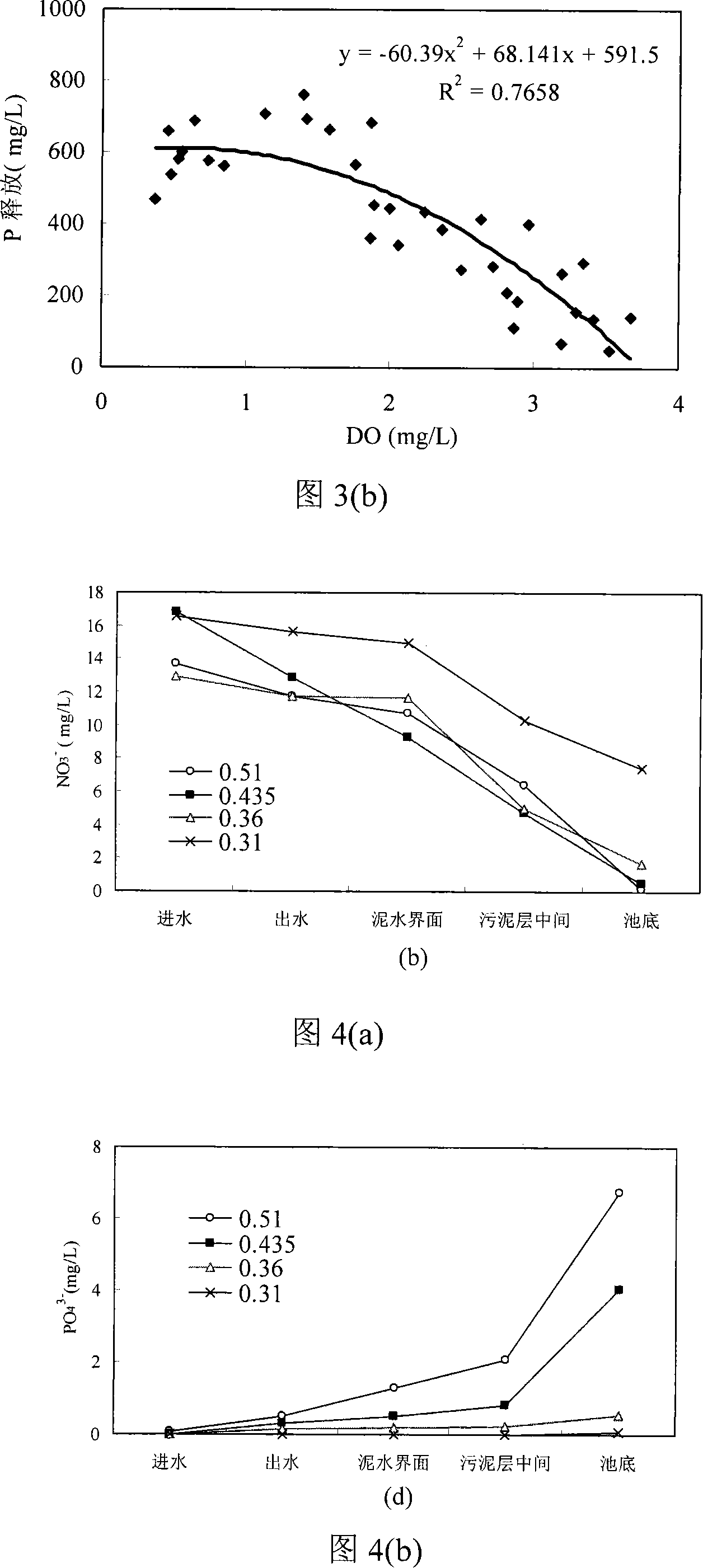

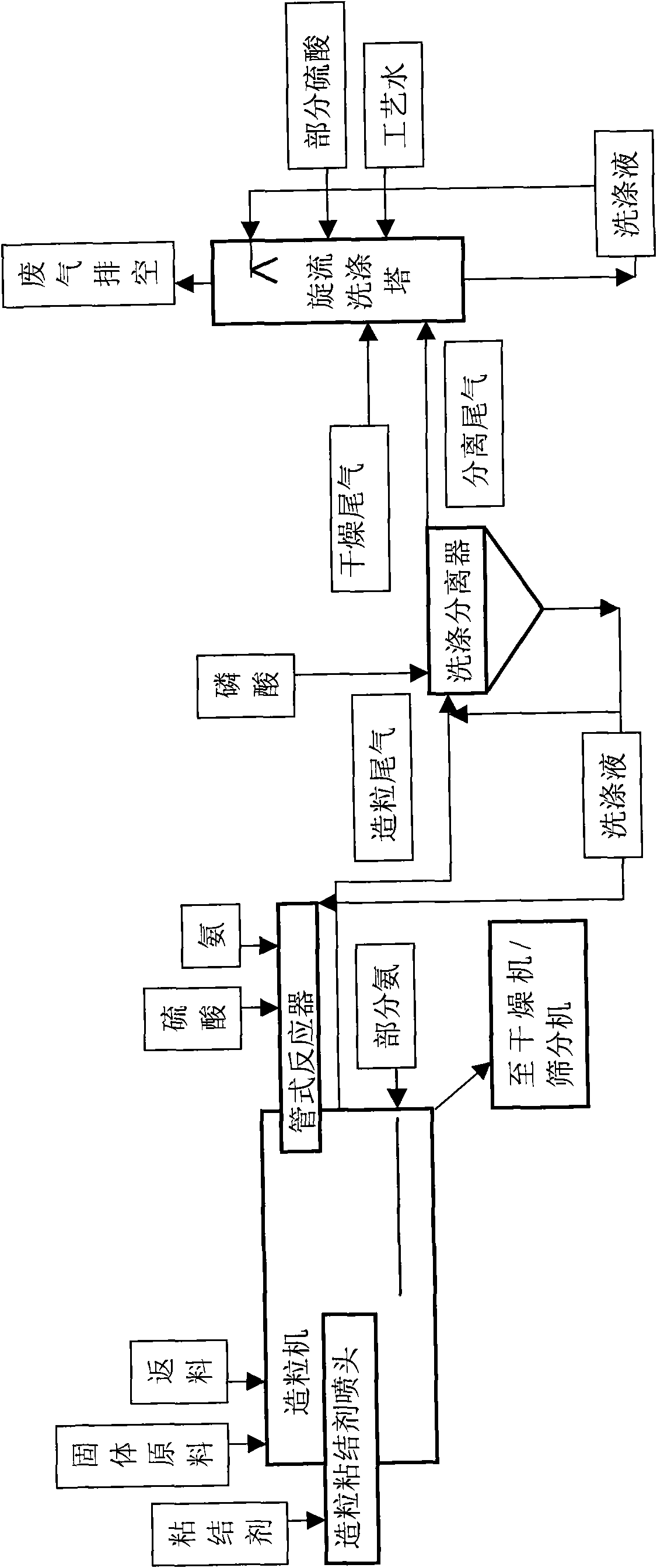

The invention discloses a method for achieving short-cut denitrification by a continuous flow sewage treatment system, and belongs to the field of biological sewage treatment. The short-cut denitrification is an economical and efficient biological sewage nitrogen removal method, and is achieved in an intermittent denitrification treatment system at present, but is difficultly achieved by most of continuous flow treatment systems for nitrogen and phosphorus removal in practical application due to the complexity of operation and control. By adopting the continuous flow nitrogen and phosphorus removal system for processing domestic sewage, the short-cut denitrification is achieved by controlling the sludge return ratio, the nitrated liquid reflux ratio and the hydraulic retention time of an aerobic zone under the operation condition that the dissolved oxygen concentration at normal temperature is 1-2mg / L, the accumulation rate of nitrite is stably maintained at 90%, the ammonium-nitrogen removal rate can be up to over 95%, and the total phosphorus removal rate can be up to over 90%. By adopting the method, the problem that the short-cut denitrification is applied to the biological sewage nitrogen and phosphorus removal system for the continuous flow in the past is solved, the application range of the short-cut denitrification is expanded, and the method can be used for guiding the biological sewage nitrogen and phosphorus removal system for the continuous flow to achieve operation and control of the short-cut denitrification.

Owner:山西国环环境科技有限公司

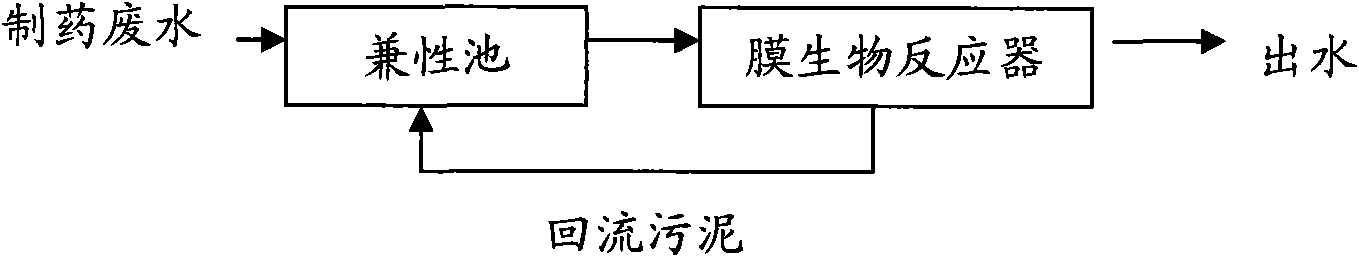

Method for treating fermentative pharmaceutical wastewater

ActiveCN101885555AEasy to handleLower Disposal CostsMultistage water/sewage treatmentNature of treatment waterActivated sludgeOxygen

The invention relates to a method for treating industrial wastewater, in particular to a method for treating fermentative pharmaceutical wastewater. The method comprises the following steps of: inletting the pharmaceutical wastewater into a facultative pond; performing biochemical treatment on the pharmaceutical wastewater; and performing aerobic biological treatment on outlet water of the facultative pond by using a membrane bioreactor. The method is characterized in that: the concentration of activated sludge in the membrane bioreactor is 15,000 to 20,000 mg / L; the hydraulic retention time of the membrane bioreactor is 8 to 15 hours which is 1 / 2-1 / 4 of that of a conventional aerobic treatment process; a sludge return pump is arranged in the reactor; a sludge-water mixture in the reactor is returned to the facultative pond in a return ratio of 100 to 300 percent, so that the effect of treating persistent organic pollutant components in the fermentative pharmaceutical wastewater is improved; and a hollow fiber membrane module is used for replacing a secondary sedimentation tank to separate sludge and water. The method for treating the fermentative pharmaceutical wastewater has the advantages of less residual sludge, long sludge removing period, reduction of sludge treatment cost, simple operation, high automation degree and high capacity of resisting impact load.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

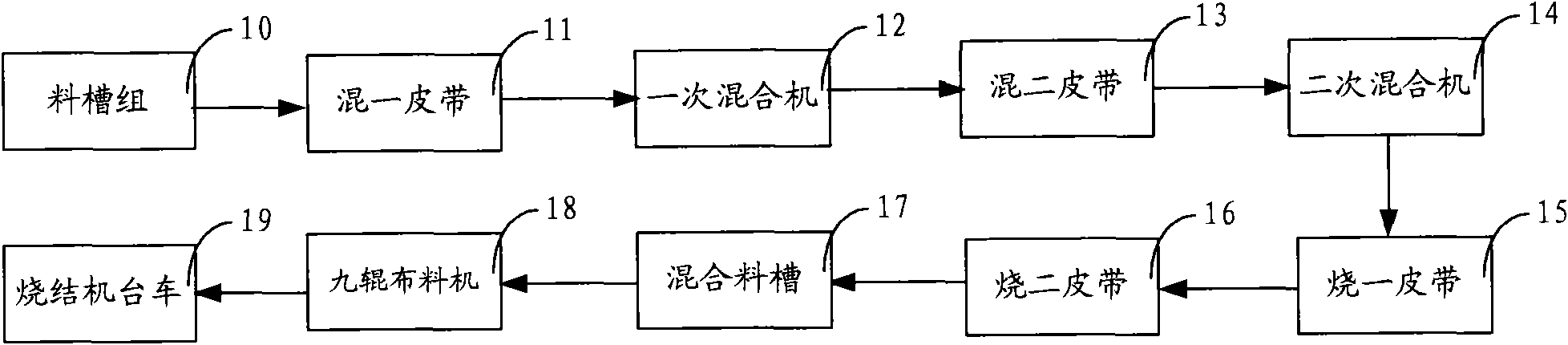

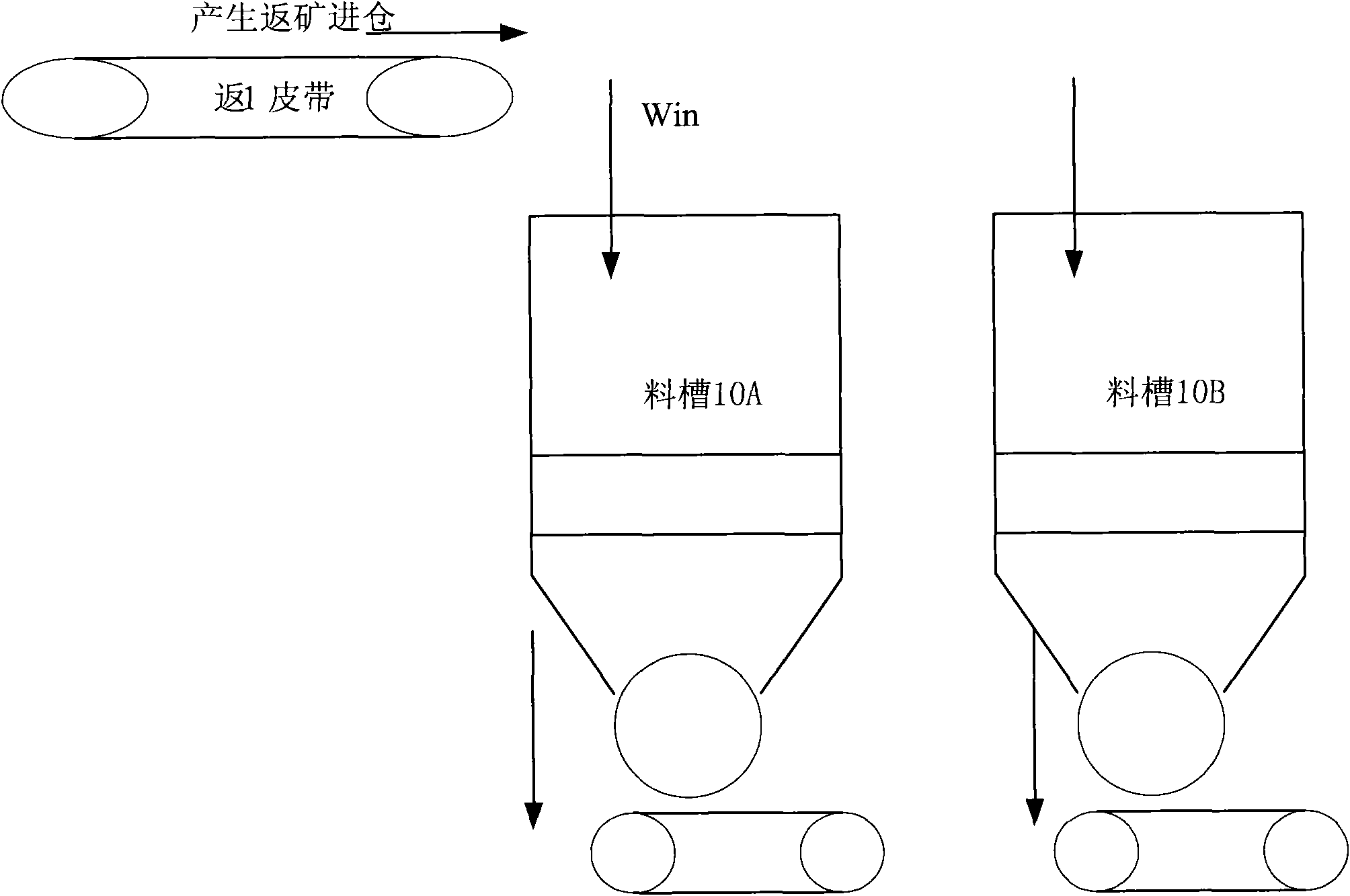

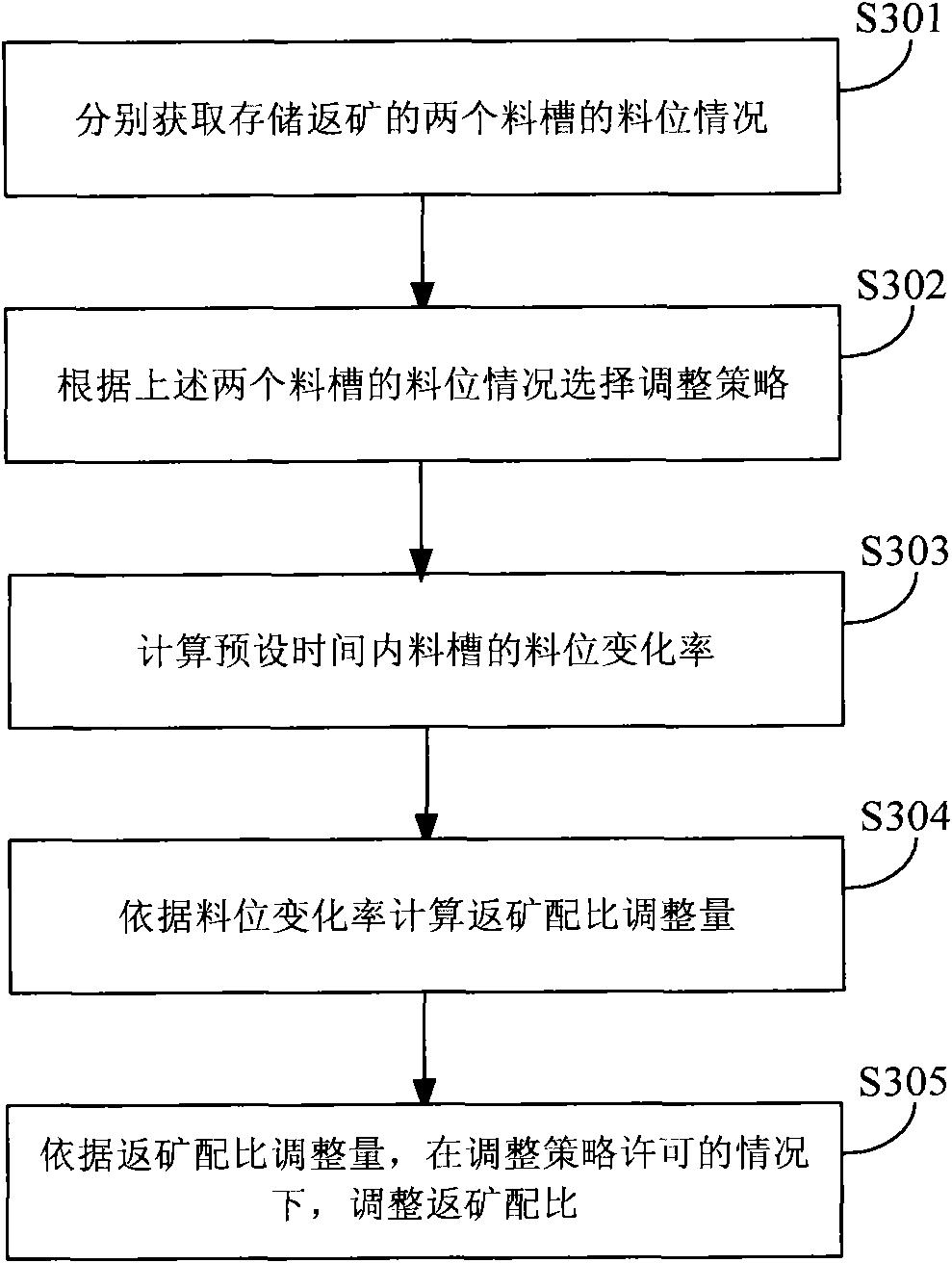

Sinter return fine adjustment method and system

ActiveCN101914672ARealize fine adjustmentMeet the requirements of evenly using the return oreMixer accessoriesFurnace typesReturn ratioIndustrial engineering

The invention relates to a sinter return fine adjustment method, which comprises the following steps of: respectively acquiring material level conditions of two material tanks for storing return fine; selecting no reduction of a return fine ratio, no increase of the return fine ratio or allowance of adjustment according to the material level conditions of the two material tanks; calculating a material level change rate of the material tanks in preset time, and calculating a return fine ratio adjustment quantity according to the material level change rate and an average total feeding quantity; if selecting the allowance of adjustment, adjusting the return fine ratio according to the return fine ratio adjustment quantity; if selecting no reduction of the return fine ratio and the ratio adjustment quantity is positive, adjusting the return fine ratio according to the return fine ratio adjustment quantity; and if selecting no increase of the return fine ratio and the ratio adjustment quantity is negative, adjusting the return fine ratio according to the return fine ratio adjustment quantity. The invention also provides a sinter return fine adjustment system. The method and the system realize refined adjustment of the return fine and meet the requirement of uniformly using the return fine.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

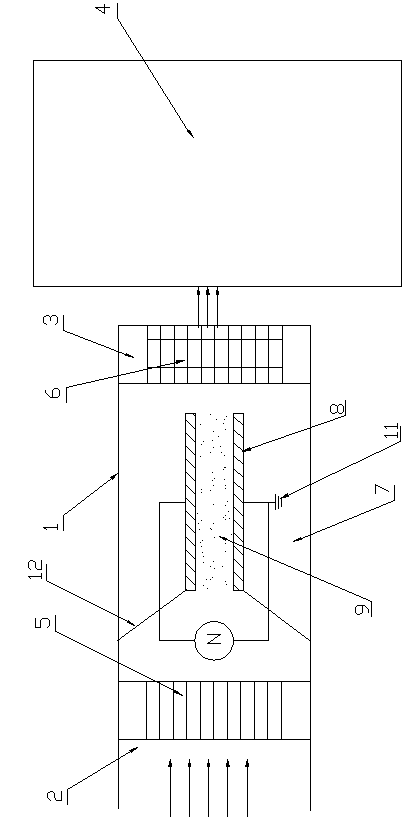

Plasma air purification method for sterilizers

ActiveCN103480025AReliable purificationImprove return air efficiencyCombination devicesDeodrantsReturn ratioEngineering

The invention relates to a plasma air purification method for sterilizers. A casing is included; an air inlet and an air outlet are formed in the casing; an electrostatic dust collection filter screen is arranged at the air inlet; an adsorption device with filtering holes is arranged at the air outlet; a plasma generation chamber is arranged inside the casing between the air inlet and the air outlet; a plasma generation device is mounted in the chamber, and at least includes two parallel comb-shaped plate electrodes; a discharge zone is formed between the adjacent plate electrodes; one of the adjacent plate electrodes is connected with a power source, and the other of the adjacent plate electrodes is connected with the ground; the comb-shaped plate electrode near to the casing wall in the plasma generation device is connected with the inner wall of the casing, at the end near to the air inlet, through a guide plate. Through the arrangement of the plasma generation device, air entering a sterilization room can be reliably sterilized and purified, the clearance between the adjacent comb-shaped plate electrodes is big, and the air return ratio is high; besides, diameters of the filtering holes of the air inlet and the air outlet are well adapted, the disassembly and cleaning are easy, and the service cycle is long.

Owner:LIANYUNGANG YOUYUAN MEDICAL EQUIP MFG

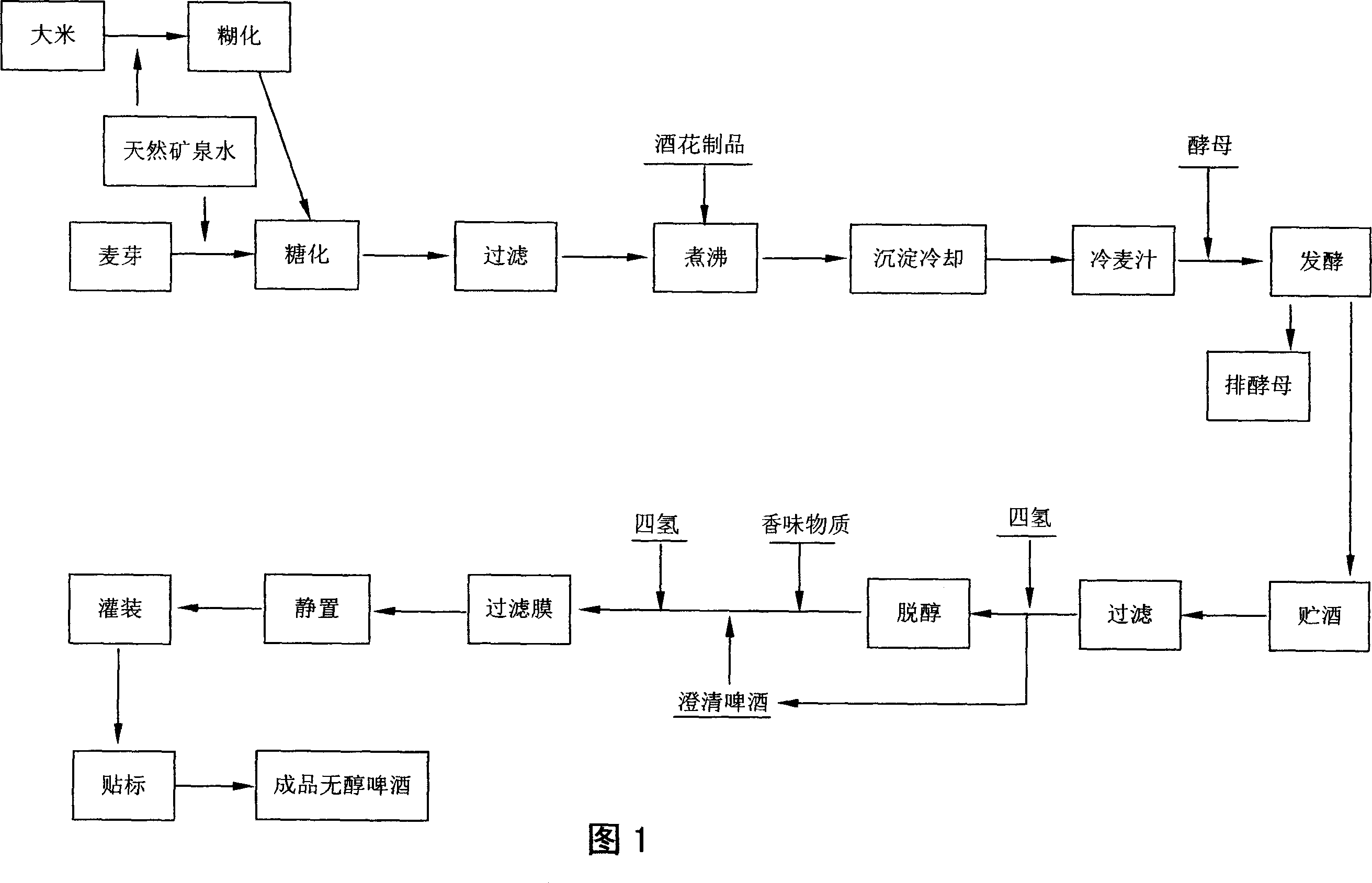

Method of improving non-alcohol beer flavour

The present invention is method of improving taste of alcohol-free beer and relates to beer making technology. The alcohol-free beer is made with Australia malt, rice and natural mineral water as main materials. Through the using hops product, controlling the fragrant matter and clarified beer returning ratio, lowering the acidity of the alcohol-free beer produced through low temperature distilling process, raising the compatibility between the fragrance and the taste, controlling the final bitter matter content in alcohol-free beer in 10-14 BU and controlling the final alcohol content in 0.4-0.5 vol %, alcohol-free beer with rich fragrance and good taste is produced.

Owner:BEIJING YANJING BREWERY

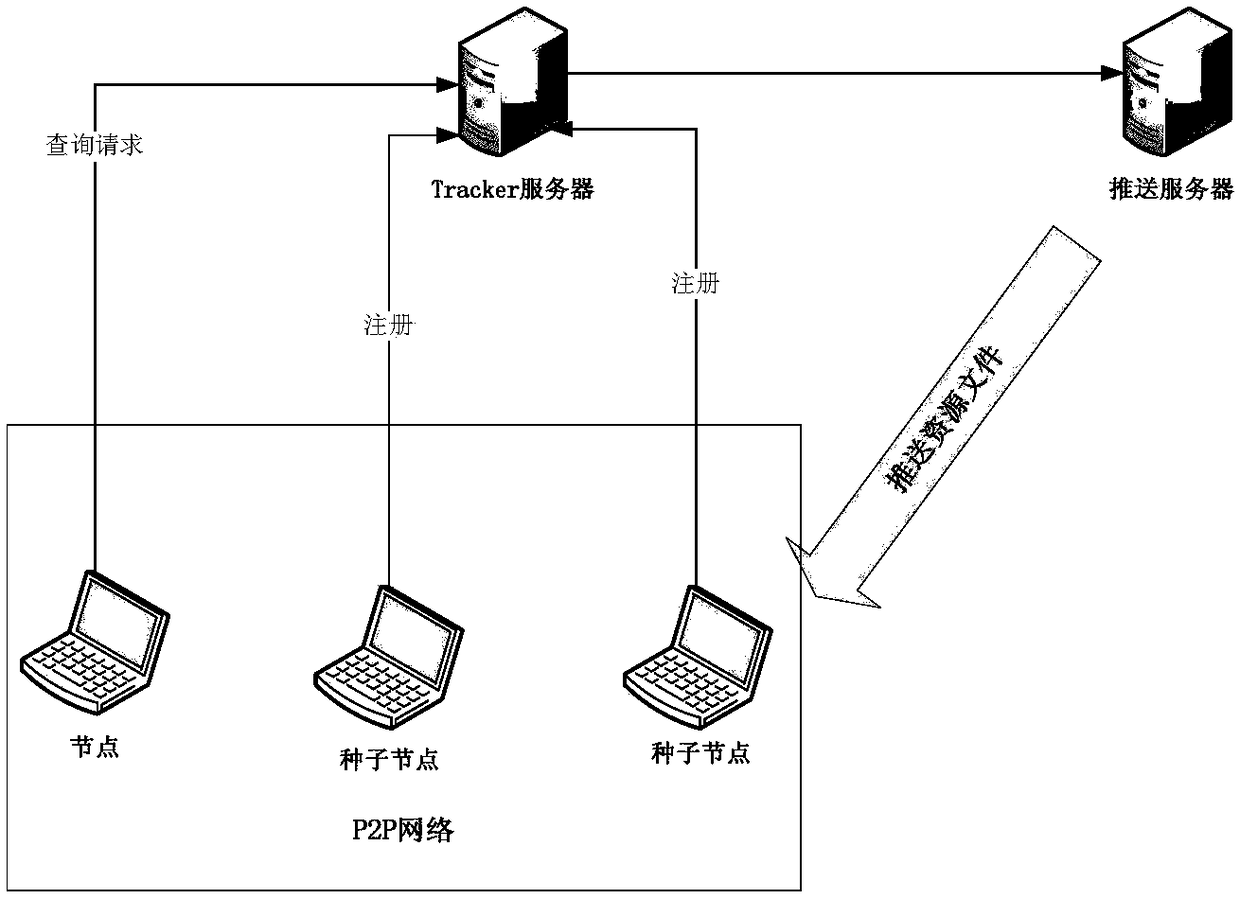

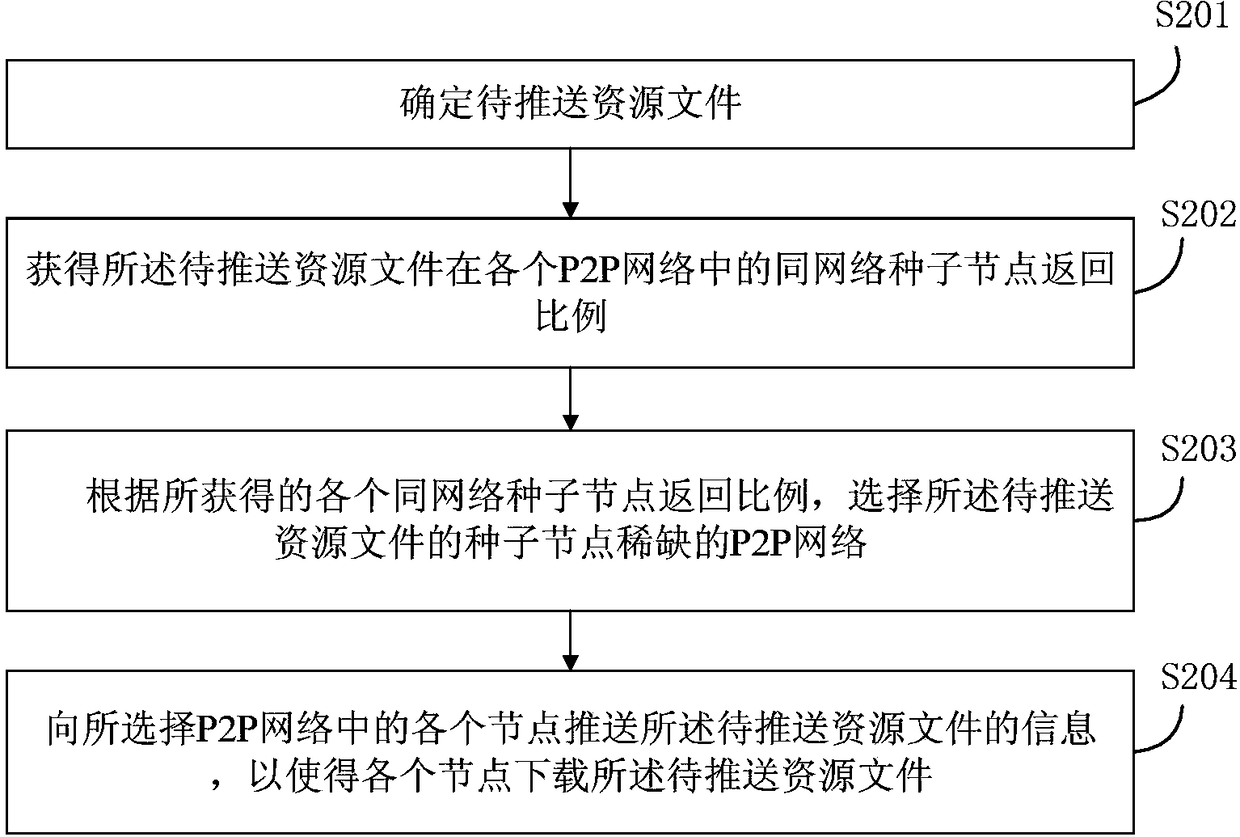

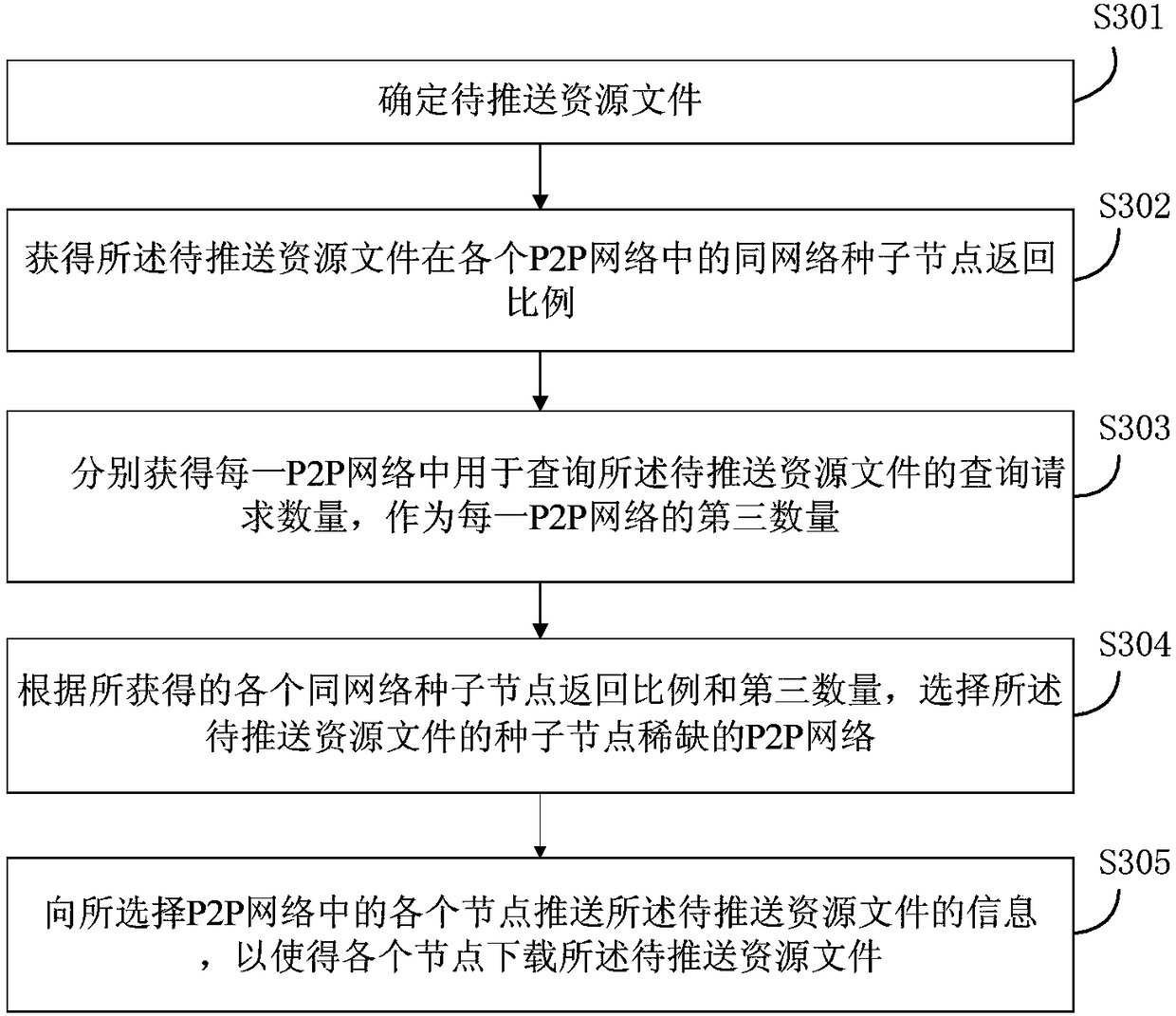

Information pushing method and device

The embodiment of the invention provides an information pushing method and device. The method includes the steps of determining a to-be-pushed resource file; obtaining the co-network seed note returnratio of the to-be-pushed resource file in each P2P network, wherein the co-network seed note return ratio of one resource file in one P2P network is determined according to the seed note number whichbelongs to the P2P network in the response result of a query request and the seed note sum in the response result; selecting the scarce seed note-containing P2P network of the to-be-pushed resource file; pushing the information of the to-be-pushed resource file to each note in the selected P2P network to make each note update the to-be-pushed resource file. By using the scheme to conduct information pushing, uniform distribution of the seed notes of the resource file between all the P2P networks can be achieved, therefore application of a P2P technology is ensured, and bandwidths are saved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

System and method for breaking a feedback loop using a voltage controlled voltage source terminated subnetwork model

ActiveUS7334199B1Amplifier modifications to reduce noise influenceDigital computer detailsSoftware emulationReturn ratio

A system and method is disclosed for breaking a feedback loop by replacing at least one component in the feedback loop with a model containing two physically disconnected subnetworks that have terminals that are connected to ground with voltage controlled, voltage sources (VCVSs). Dependent source parameters of the VCVSs control lateral signal transfer though the model allowing the feedback loop to be opened or closed. The model maybe used in a software simulation in which a replicate circuit is used to set and maintain a closed-loop bias on the open-loop circuit. Small-signal analysis of the equivalent open-loop circuit allows extraction of transfer functions that yield a return ratio RR(s) corresponding to the modeled component.

Owner:NAT SEMICON CORP

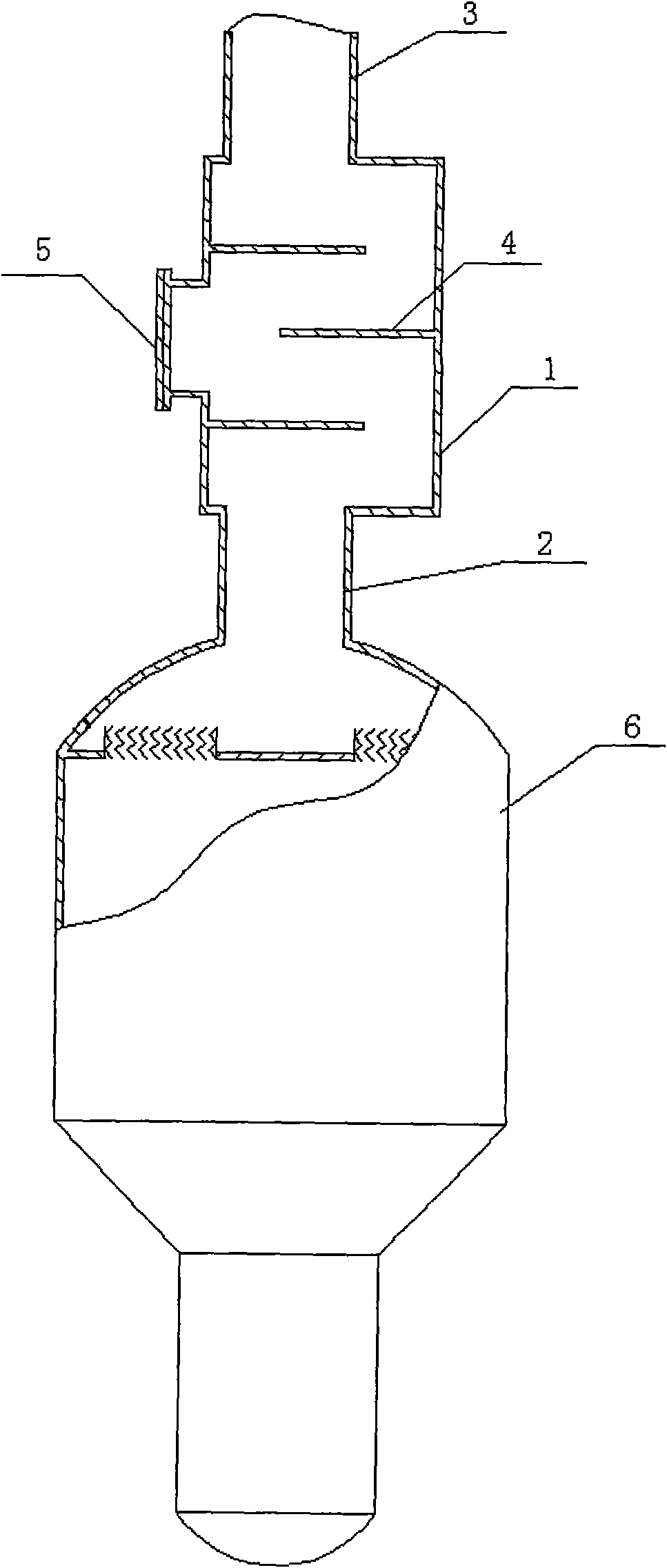

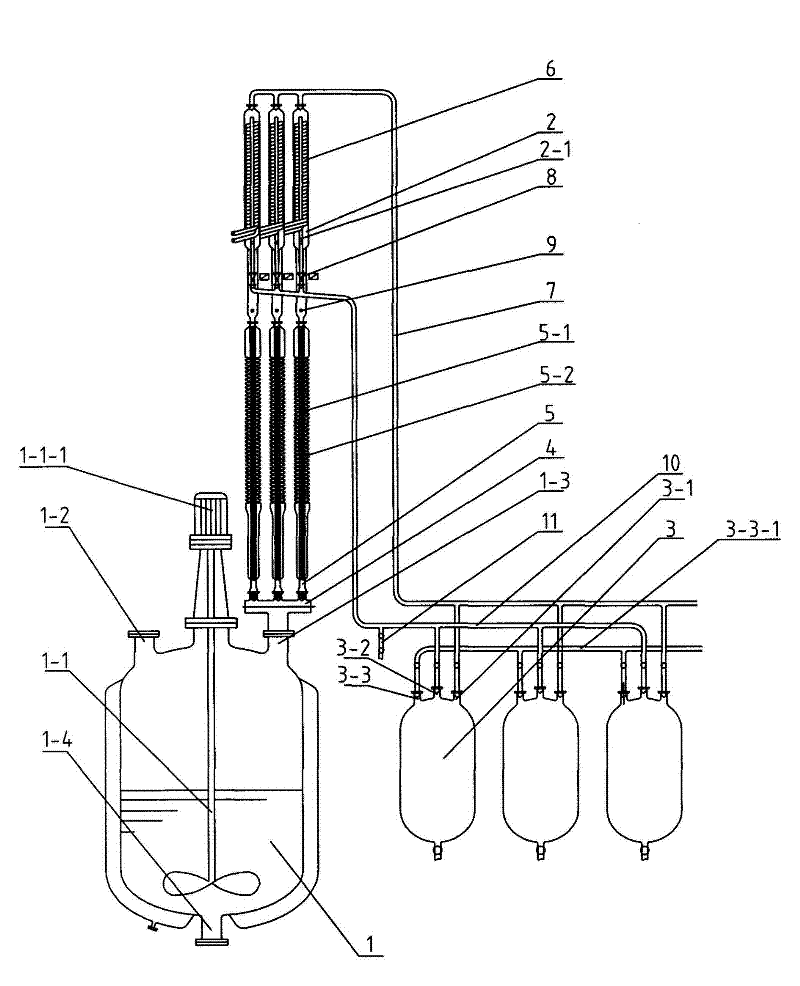

Cluster rectification device

ActiveCN102441289ABeautiful appearanceReduce ascent heightFractional distillationDistribution controlReturn ratio

The invention discloses a cluster rectification device which comprises a tower kettle, a plurality of rectification heads and a plurality of collecting / metering grooves, wherein the tower kettle is provided with a feed inlet, a gas-phase discharge outlet and a residual material outlet and comprises a second pipe; the gas-phase discharge outlet of the tower kettle is connected in parallel and communicated with a plurality of small-bore cluster rectification towers by a cluster rectification disc distribution platform, and the other end of each cluster rectification tower is respectively communicated with the rectification heads; each rectification head is provided with a condenser, and an air outlet of the rectification head is communicated with a first pipe communicated with a vacuum system; an air outlet of each collecting / metering groove is respectively communicated with the first pipe, and liquid inlets of the collecting / metering grooves are converged on the second pipe; each rectification head is provided with a return pipe communicated with the top of the rectification head, and the return pipes are respectively communicated with the second pipe; the rectification head is also provided with a synchronous multi-backflow distribution controller for controlling return ratio; and a rectification-tower thermal-insulating layer is arranged outside each cluster rectification tower, and the middle part of the cluster rectification tower is provided with a rectification-tower packing layer. The device disclosed by the invention can lower the tower height and reduce the production cost, and has the characteristic of low energy consumption.

Owner:常州克罗蒂娜化工技术有限公司

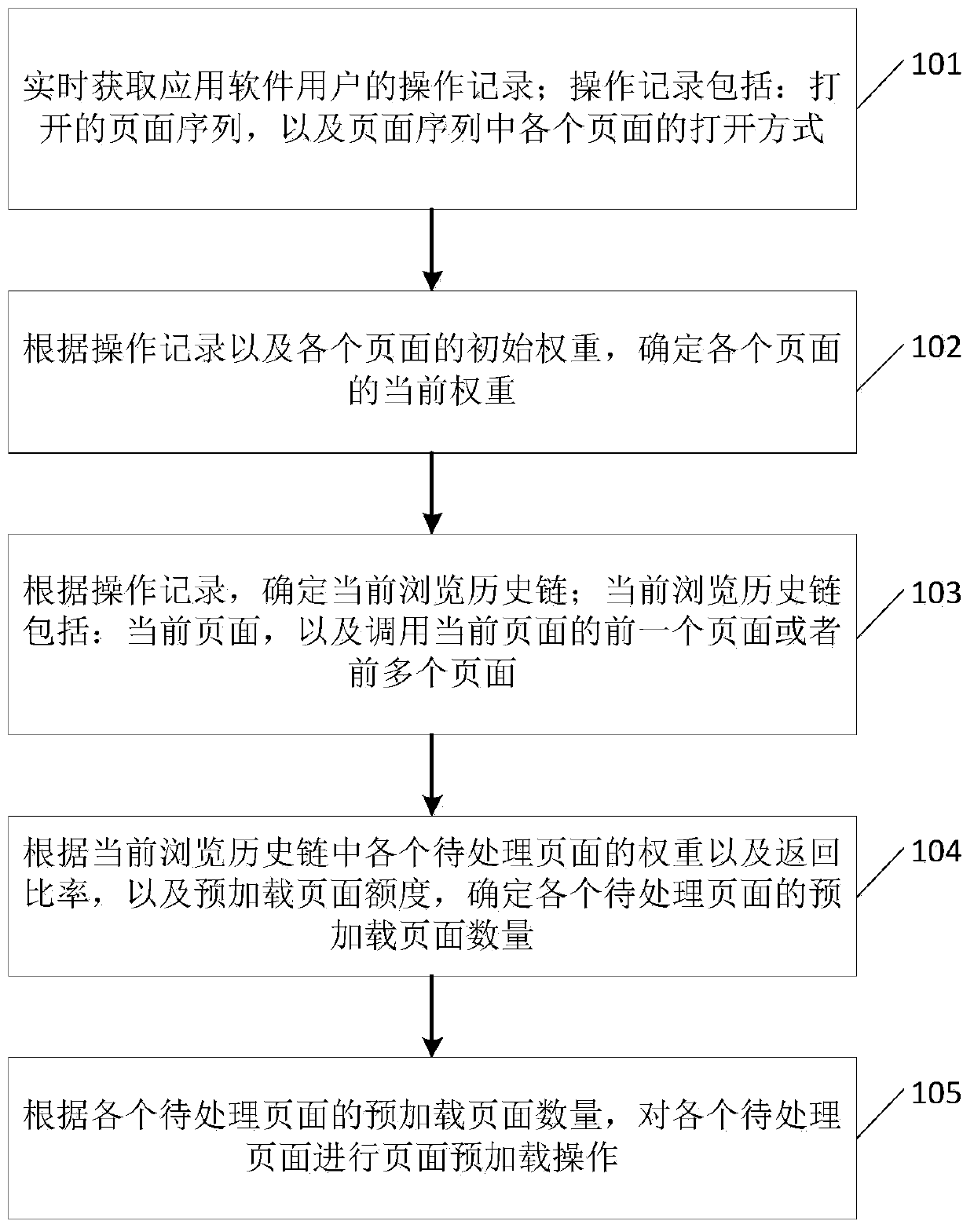

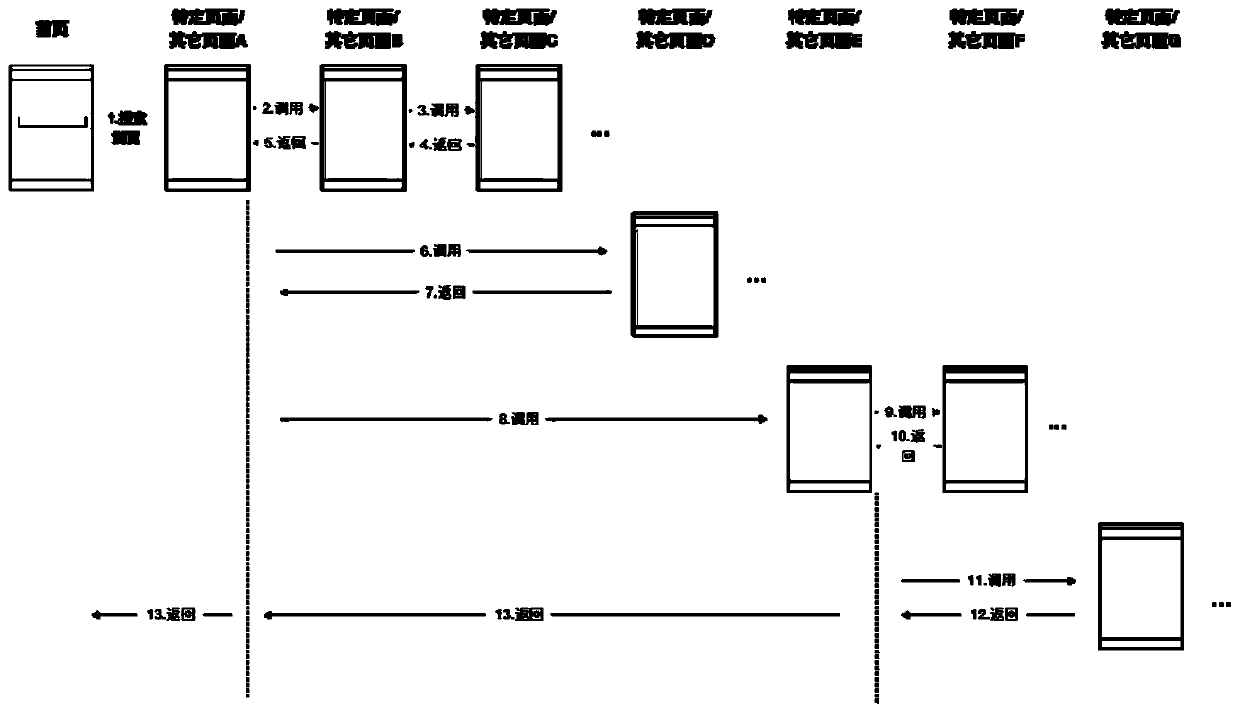

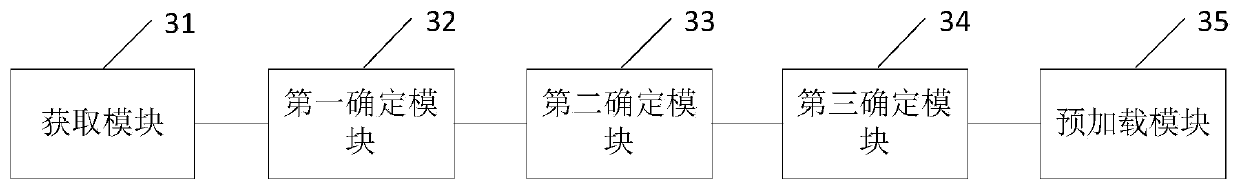

Page preloading method and device

ActiveCN110069739AAvoid duplicationAvoid operabilityWebsite content managementSpecial data processing applicationsReturn ratioApplication software

The invention provides a page preloading method and device. The method comprises: acquiring an operation record of an application software user in real time, wherein the operation record comprises anopened page sequence and an opening mode of each page in the page sequence; determining the current weight of each page and the current browsing history chain according to the operation record and theinitial weight of each page, wherein the current browsing history chain comprises a current page, and a previous page or a plurality of previous pages for calling the current page; determining the number of preloaded pages of each to-be-processed page according to the weight and the return ratio of each to-be-processed page in the current browsing history chain and the amount of the preloaded pages; carrying out the page preloading operation on each to-be-processed page according to the number of the preloaded pages of each to-be-processed page, so that the number of the preloaded pages can be distributed among a plurality of pages according to the operation record of a user, repeated preloading and releasing operations in scenes such as searching are avoided, and the preloading accuracyis improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Multiplex rare-earth ferroalloy (RERAFe#-[2]) powder and method for preparing same

InactiveCN1603444AStable and controllable rare earth contentHigh recovery ratePositive pressureRare earth

The invention involves more than a kind of Yuan thin crude iron (RERAFe2) to gather the diamond dust and its the preparation method, should gather the diamond dust at least wilfully to select two kinds in oxidized rare earth Nd2O3, Dy2O3, Tb4O7, to make the oxidized rare earth blend for the raw material according to per cent by weight processing, then joins calcium metal grain of Ca again, powdered iron Fe, the chlorination salt (NaCl or CaCl2), makes the oxidized rare earth two blends according to the per cent by weight mix, this two blends take the reducing agent by the calcium metal grain of Canada chlorination salt, after stirs, the argon Ar clean positive pressure protection heats up carries on the return to original state proliferation response, soaks after cooling with the NH4Cl watery solution to the solution assumes the brown, Again uses the acetic acid watery solution to clean the PH value to assume the neutrality, finally filters except the moisture content and drying namely makes gathers the diamond dust. Should gather the diamond dust to be possible to take the key metal preparation rare earth permanent-magnet material, has the craft simply, the production cost low, the non- environmental pollution, the metal content is stable controllably, the alloy returns-ratio higher characteristic.

Owner:NINGBO KONIT IND

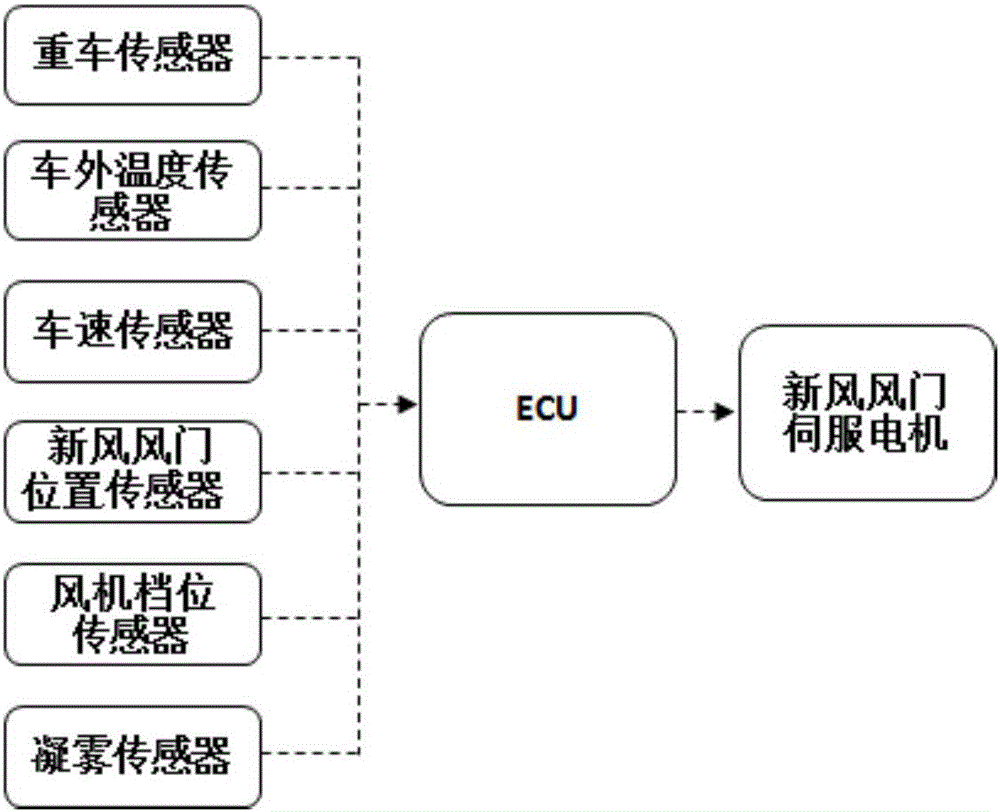

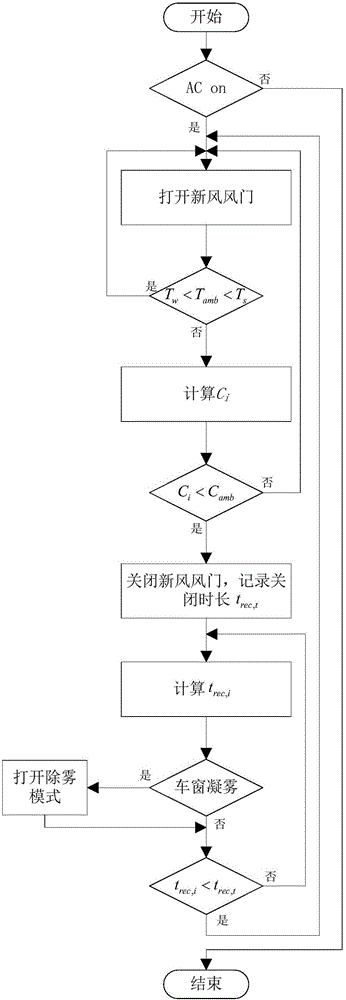

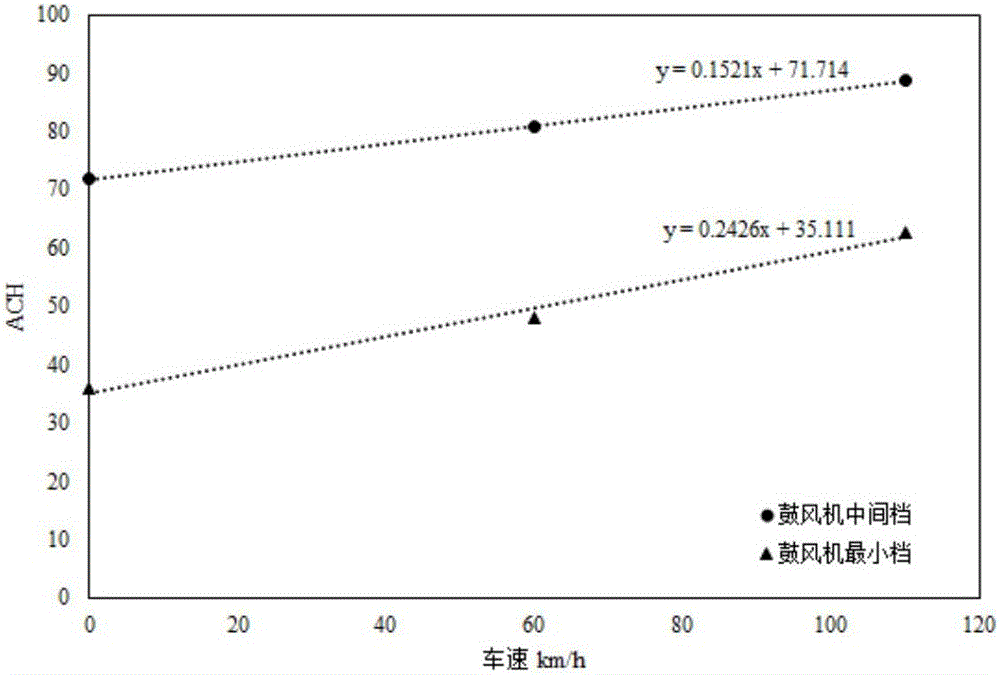

Vehicle air conditioner fresh air ventilation door energy-saving control method and system

ActiveCN106004322AReduce heat loadReduce energy consumptionAir-treating devicesVehicle heating/cooling devicesFresh airEngineering

The invention discloses a vehicle air conditioner fresh air ventilation door energy-saving control method and system. According to the method, the environment temperature outside a carriage is measured after a vehicle air conditioner is started at first, a fresh air ventilation door is opened continuously if the environment temperature is within a set range, and a calculated value of the carbon dioxide concentration in the carriage is calculated and compared with a set value of the carbon dioxide concentration when the environment temperature is not in the set range; and when the calculated value of the carbon dioxide concentration is smaller than the set value of the carbon dioxide concentration, the fresh air ventilation door is closed and reopened when the requirements are met. The vehicle air conditioner can be automatically switched to be in an air return mode when the outside air temperature is high than the set range, the vehicle fresh air thermal load is lowered, defogging is achieved through the method that all return air is cooled and dehumidified through an indoor evaporator and then heated in the season for congealing fog, energy loss caused by opening of the fresh air ventilation door due to defogging is avoided, and a sensor is used for judging the time of the fresh air ventilation door have to be opened, so that the opening time of the fresh air ventilation door is shortened, energy consumption of the vehicle air conditioner is obviously reduced, and the endurance mileage is increased.

Owner:SHANGHAI JIAO TONG UNIV

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759BImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com