Energy-saving grinder swirler closed-loop system and control method

A closed-circuit system, cyclone technology, applied in instruments, scientific instruments, liquid/fluid solid measurement, etc., can solve problems such as low detection accuracy, no optimal control means, and inability to meet optimal control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

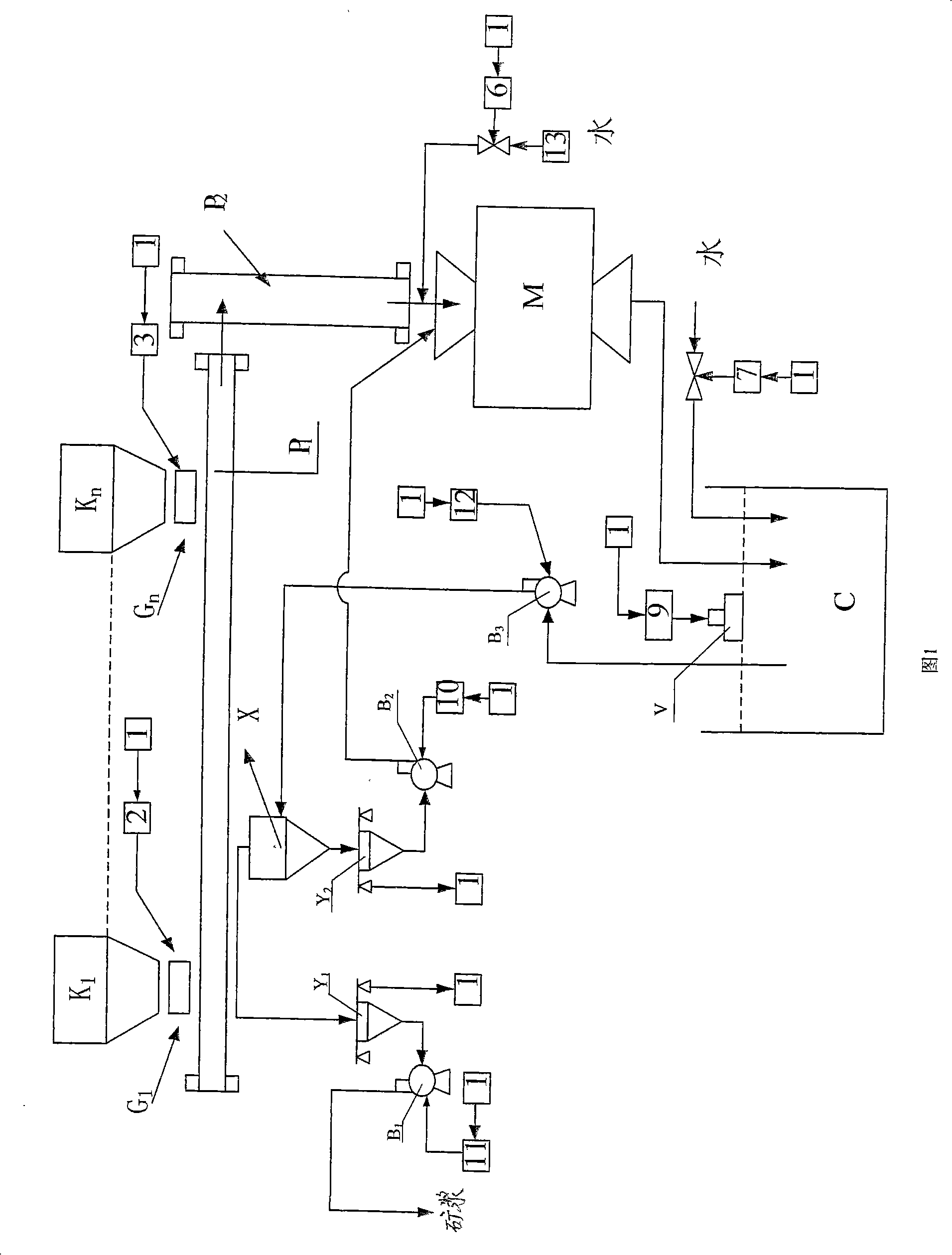

[0080] The energy-saving mill cyclone closed circuit system provided by the present invention includes feeders G1-G n , Conveyors P1, P2, Grinding Machine M and Cyclone X, and Controller (1), Frequency Converter (2), (3), (10), (11), (12), Sand Pump B1~ B3, liquid level gauge V, motor actuators (6), (7), in which the overflow and sand settling pipelines of the cyclone X are respectively equipped with four parameters of weighing type slurry flow, particle size, concentration, and grade online detection integrated chemical device Y1, Y2, as shown in Figure 1, wherein:

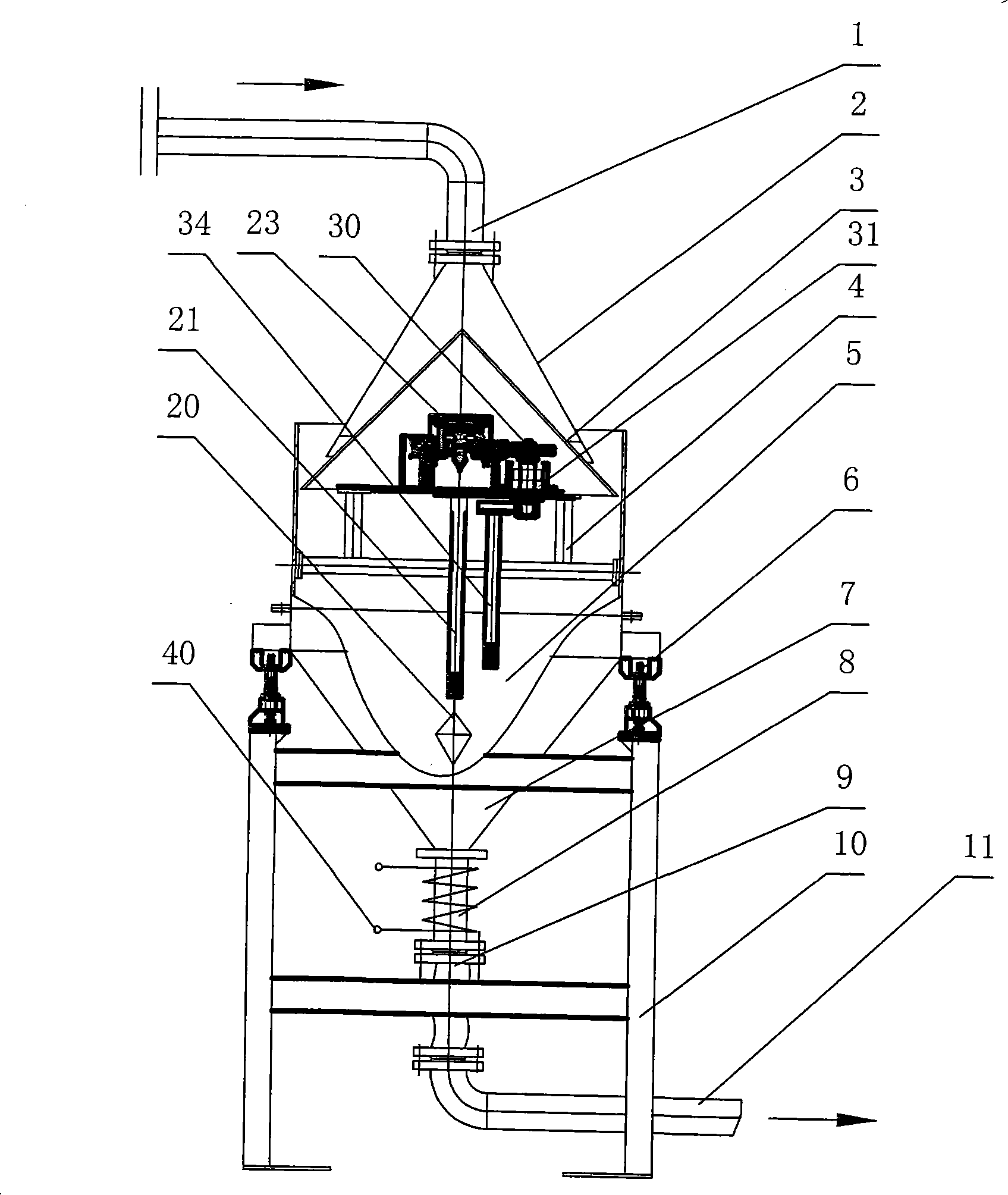

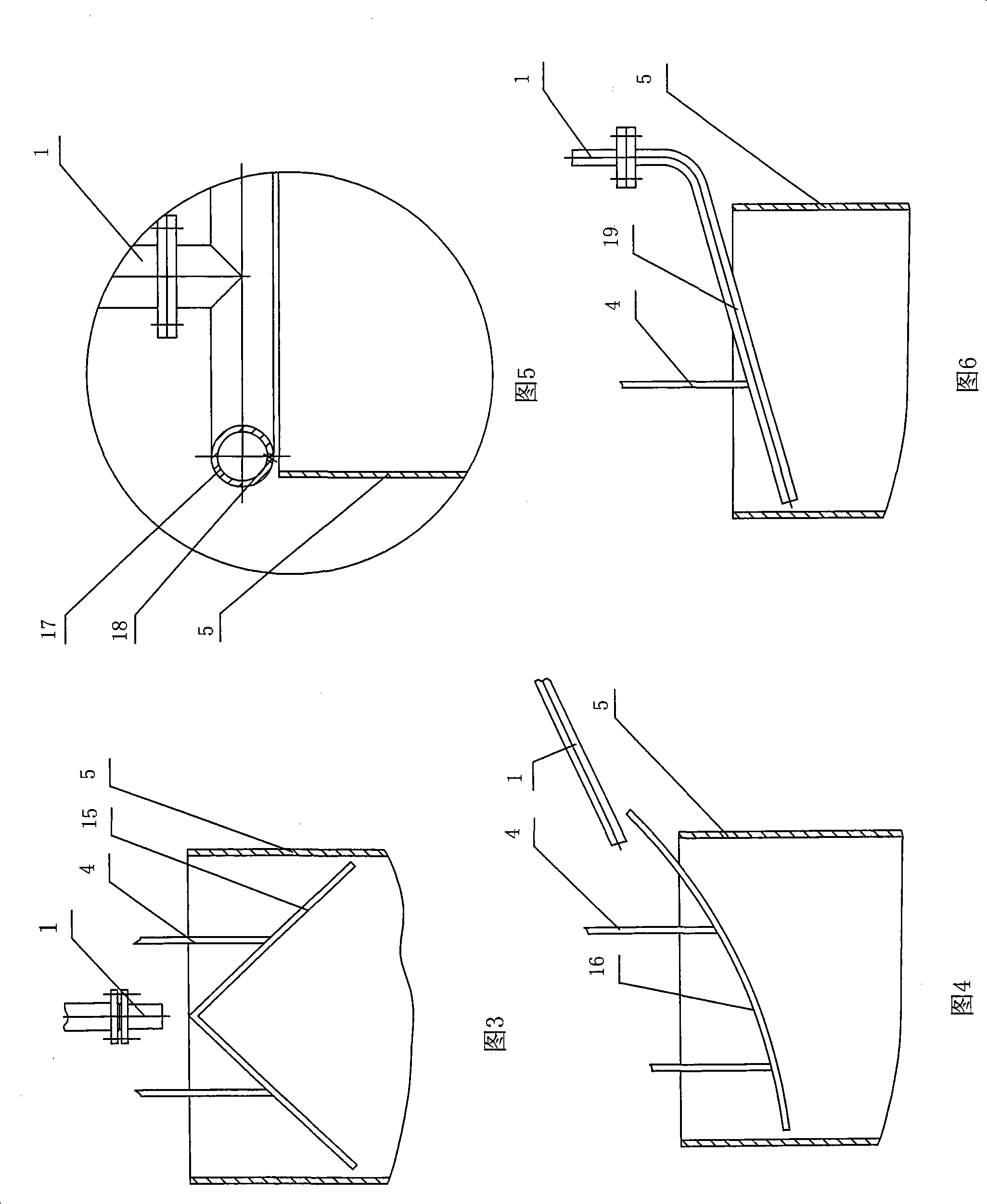

[0081] Y1 and Y2 include: a pulp container 5 with a feed port and a discharge port is placed on the support 10 through a load cell 6, and a pulp flow detection device with a soft connection 9 is provided at the discharge port 8, and the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com