Method for producing granular ammonium sulfate by using crystalline ammonium sulfate or powdery ammonium sulfate

A technology of crystalline ammonium sulfate and ammonium sulfate, applied in application, ammonium salt fertilizer, nitrogen fertilizer, etc., to achieve the effects of reducing ammonia loss, less nutrient deficiency, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

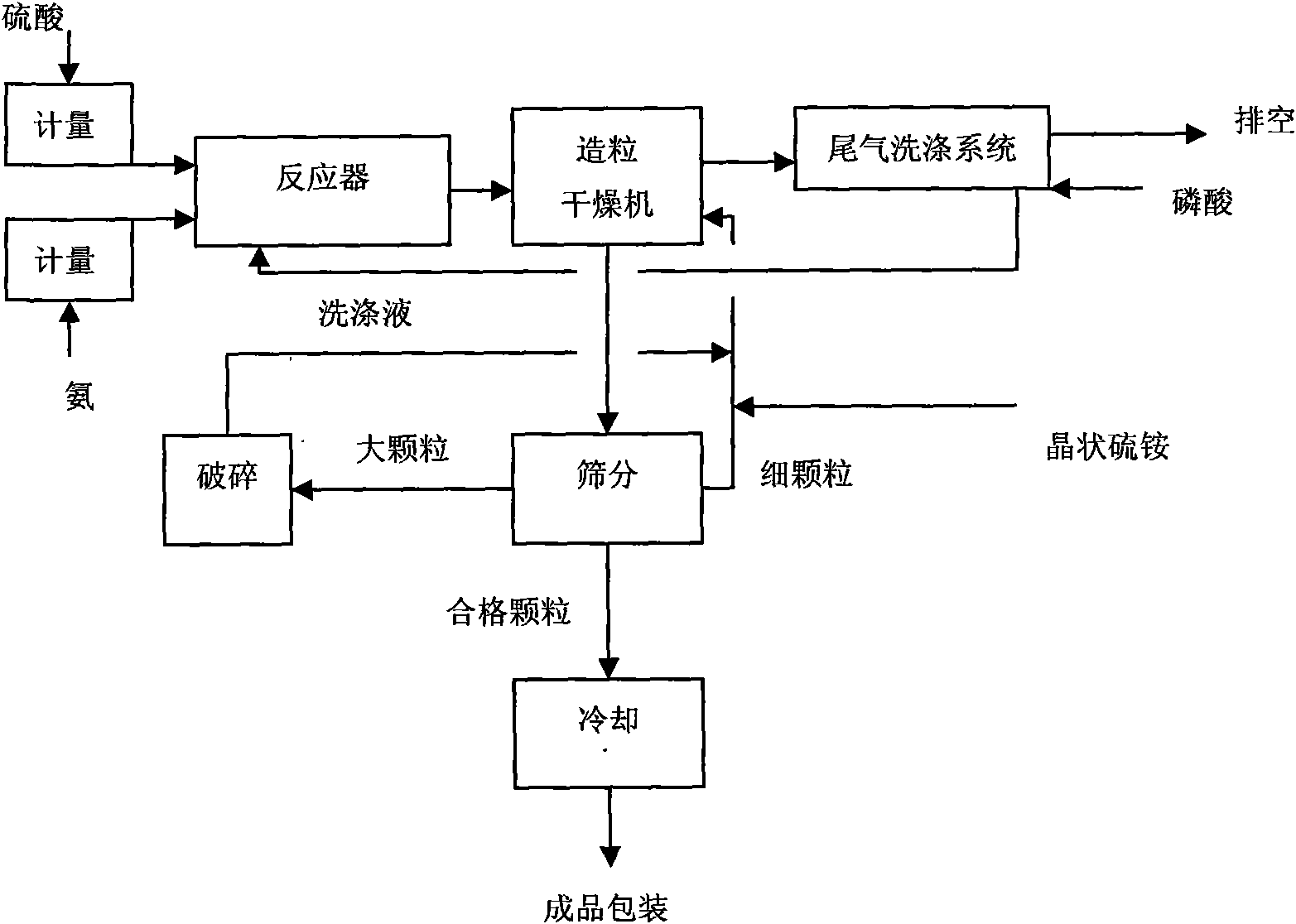

Method used

Image

Examples

Embodiment

[0020] Embodiment The Wengfu Phosphate Fertilizer Plant under Guizhou Wengfu (Group) Co., Ltd. adopts the inventive method to produce granular ammonium sulfate:

[0021] (1) Add crystalline ammonium sulfate or powdered ammonium sulfate into the drum granulation dryer as a master batch, start the granulation dryer, and the master batch is formed under the rotation of the drum of the granulation dryer at a speed of 4.3r / mind material curtain or bed;

[0022] (2) the sulfuric acid that is 98% by mass fraction, the ammoniacal liquor that is 20% by mass fraction, the phosphoric acid that is 30% by mass fraction are mixed reaction in tubular reactor according to the ratio of 13:5:1:4 to generate 300 DEG C High-temperature slurry, under the pressure condition of 0.6MPa (gauge pressure), the reaction slurry is atomized through the nozzle and then sprayed onto the material curtain or material bed in the granulator, coated or bonded into granules. The temperature of the granulated mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com