Patents

Literature

175results about How to "High granulation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

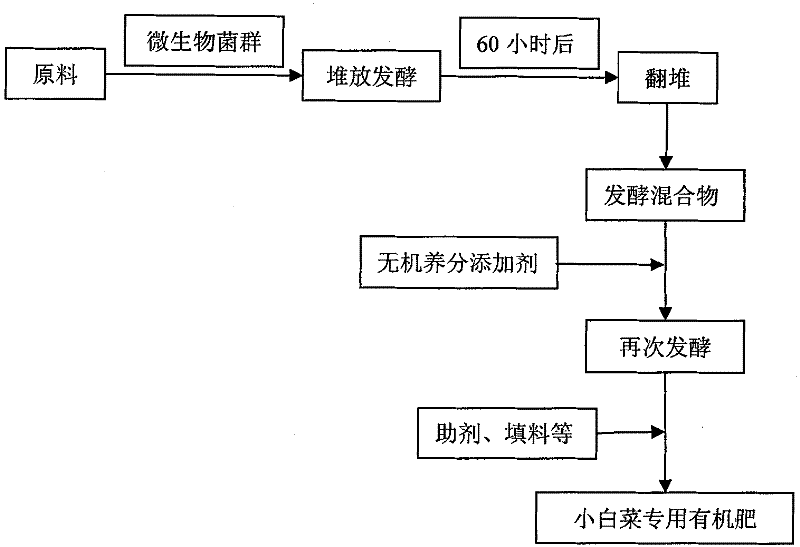

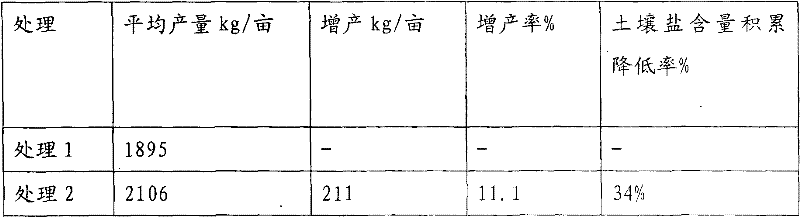

Pakchoi organic composite fertilizer

ActiveCN102351596AReasonable ratioFully absorb and utilizeBio-organic fraction processingOrganic fertiliser preparationSoil typeEffective microorganism

The invention relates to pakchoi organic composite fertilizer. The pakchoi organic composite fertilizer is characterized in that medium and trace elements needed by multiple plants are mixed with inorganic fertilizer and organic fertilizer; and simultaneously, auxiliary agents capable of improving an absorption and utilization rate for a plant and increasing fertilizer slow-release performances and effective microorganisms are added into the mixture to be prepared into specialized composite fertilizer particles through proper fermentation and processing. The pakchoi organic composite fertilizer has the advantages that scopes of suitable regions and soil types are wide; base fertilizer one-step application can be realized in fertilizer application and topdressing can be carried out later according to needs; pakchoi growth needs are satisfies; and effects of yield increase and harvest increase are realized.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

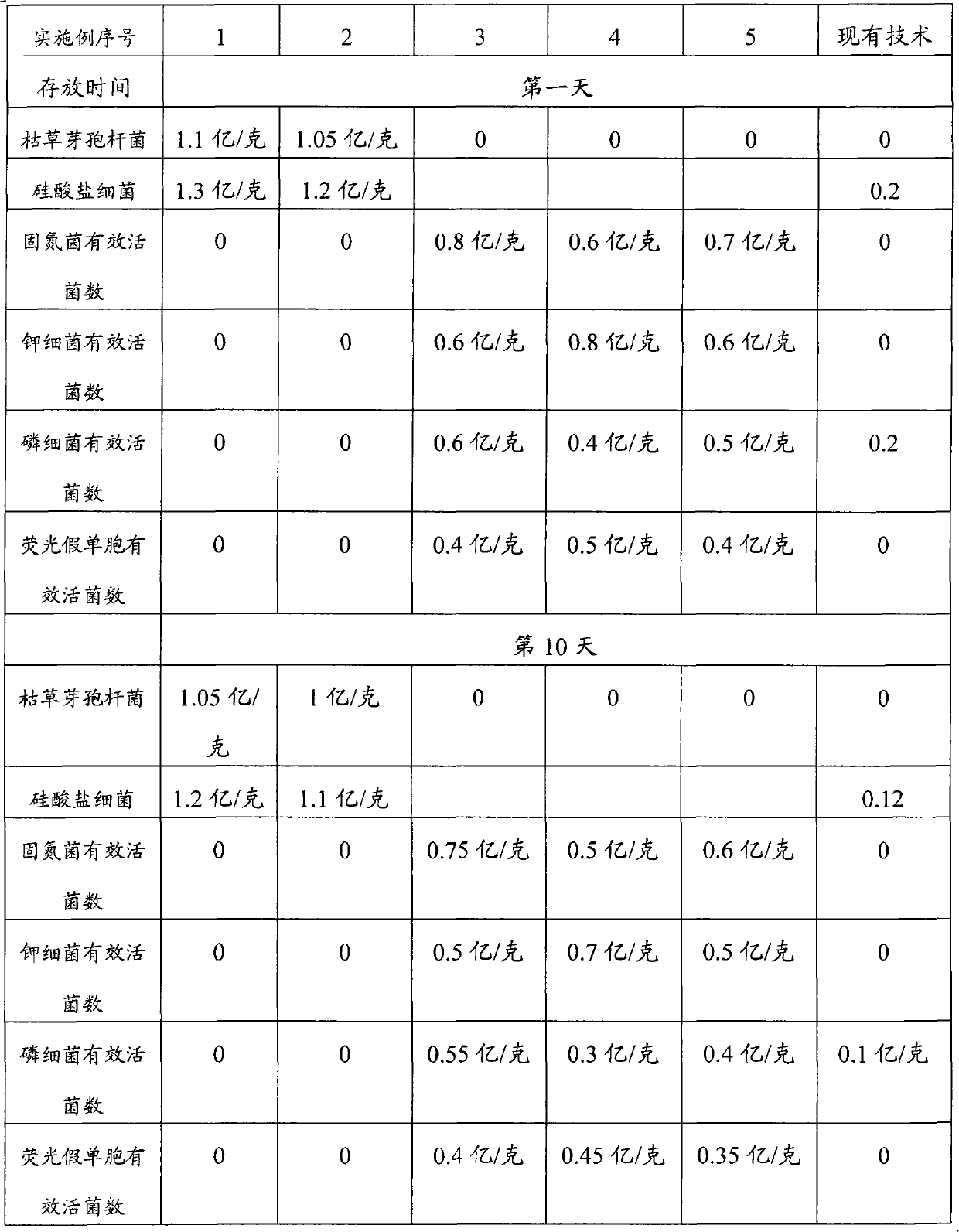

Biofertilizer and method for producing same

The invention belongs to the field of biofertilizer and relates to a biological organic-inorganic composite fertilizer and a production method thereof. The production method comprises the following steps: mixing a fermented Paenibacillus pabuli bacteria solution accounting for 65wt%-80wt% and a silicate bacteria solution accounting for 20wt%-35wt% to prepare a composite bacteria solution; then directly mixing the composite bacteria solution with organic materials, an inorganic fertilizer and an adhesive to adsorb; and mixing, crushing and screening to prepare the powdery biological organic-inorganic composite fertilizer, or mixing, crushing, granulating, drying and screening to prepare the granular biological organic-inorganic composite fertilizer. By adopting the method, the equipment investment and the equipment maintenance cost can be reduced, the labor and the labor intensity can be reduced, the transportation cost can be reduced and the production cost can be reduced; and the count of effectively live bacteria of single bacterium in the biofertilizer is above one million per gram and the count of total live bacteria is above 20 million per gram.

Owner:北京世纪阿姆斯生物技术有限公司

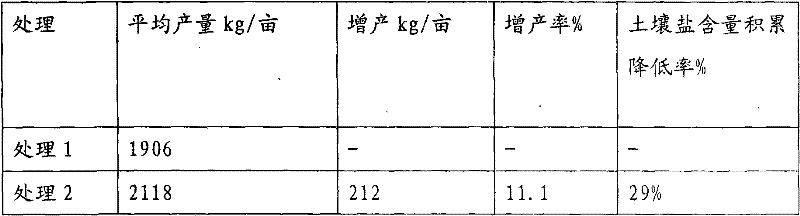

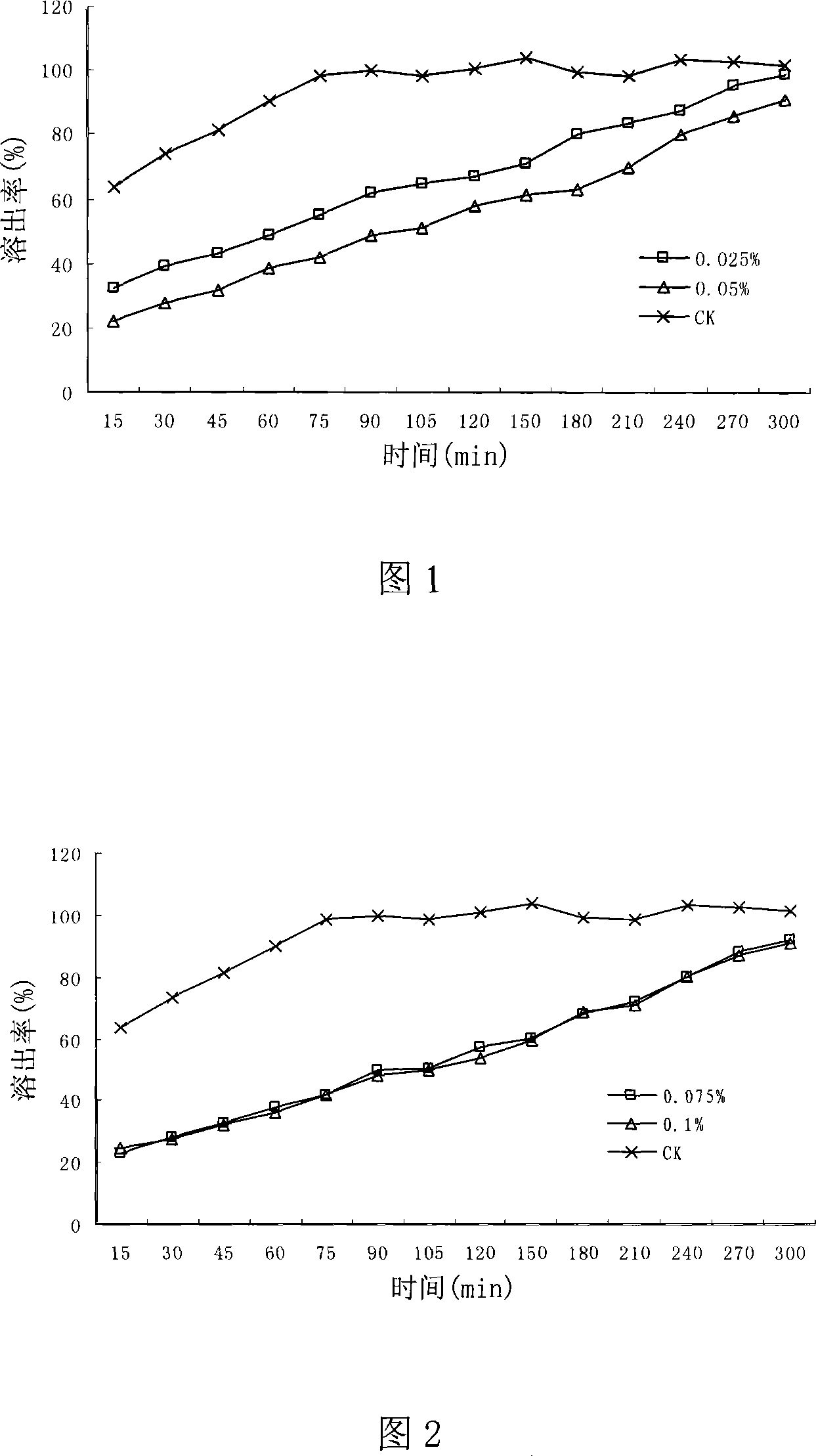

Poly-gama-glutamic acid building fertilizer

InactiveCN101117303AGood water solubilityImprove water absorptionFertiliser formsFertilizer mixturesDecompositionPoly(gamma-glutamic acid)

The invention relates to a poly-gamma-glutamic acid synergistic fertilizer for strengthening fertilizer effect, which belongs to the fertilizer field. The invention comprises graininess fertilizer which comprises the poly-gamma-glutamic acid. The contents of the poly-gamma-glutamic acid and fertilizer in weight are as follows: 0.01 to 1 percent of the poly-gamma-glutamic acid and the remained content is fertilizer. The contents of poly-gamma-glutamic acid of the invention are strictly controlled and the poly-gamma-glutamic acid can be conveniently fertilized. The poly-gamma-glutamic acid is combined with to make full use of the feature as absorption promoter of fertilizer of the poly-gamma-glutamic acid, therefore, crops output is further raised. The fertilizer is released slowly and prolonged by around 4 times compared with the traditional fertilizer in soil. The invention promotes crop absorption and inhibits fertilizer ingredient decomposition and loss, therefore, fertilizer use is directly decreased by more than 20 percent. The pollution to environment is reduced without excessive or inappropriate fertilization.

Owner:HUAZHONG AGRI UNIV

Special saline-alkali-soil improvement fertilizer prepared by modification with flue gas desulfurization gypsum and preparation method thereof

ActiveCN104355943ASolve the problem of difficult mechanized applicationSimple production processCalcareous fertilisersMagnesium fertilisersAlkali soilPhosphate

The invention discloses a special saline-alkali-soil improvement fertilizer prepared by modification with flue gas desulfurization gypsum and a preparation method thereof. The special improvement fertilizer comprises the following components in parts by weight: 40-80 parts of flue gas desulfurization gypsum, 1-3 parts of citric acid, 0.5-1.5 parts of magnesium sulfate, 1-5 parts of aluminum sulfate, 1-5 parts of ferrous sulfate, 10-30 parts of weathered coal, 10-20 parts of cattle manure or chicken manure, 1-5 parts of urea, 0.5-2.5 parts of ammonium sulfate, 1-3 parts of potassium sulfate, 1-3 parts of monoammonium phosphate, 0.1-0.5 part of zinc sulfate, 0.1-0.5 part of manganese sulfate and 3-10 parts of bentonite. The fertilizer is reasonable in design, provides an effective solution for inland saline-alkali soil of China, and has higher practical value and wide market prospects.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

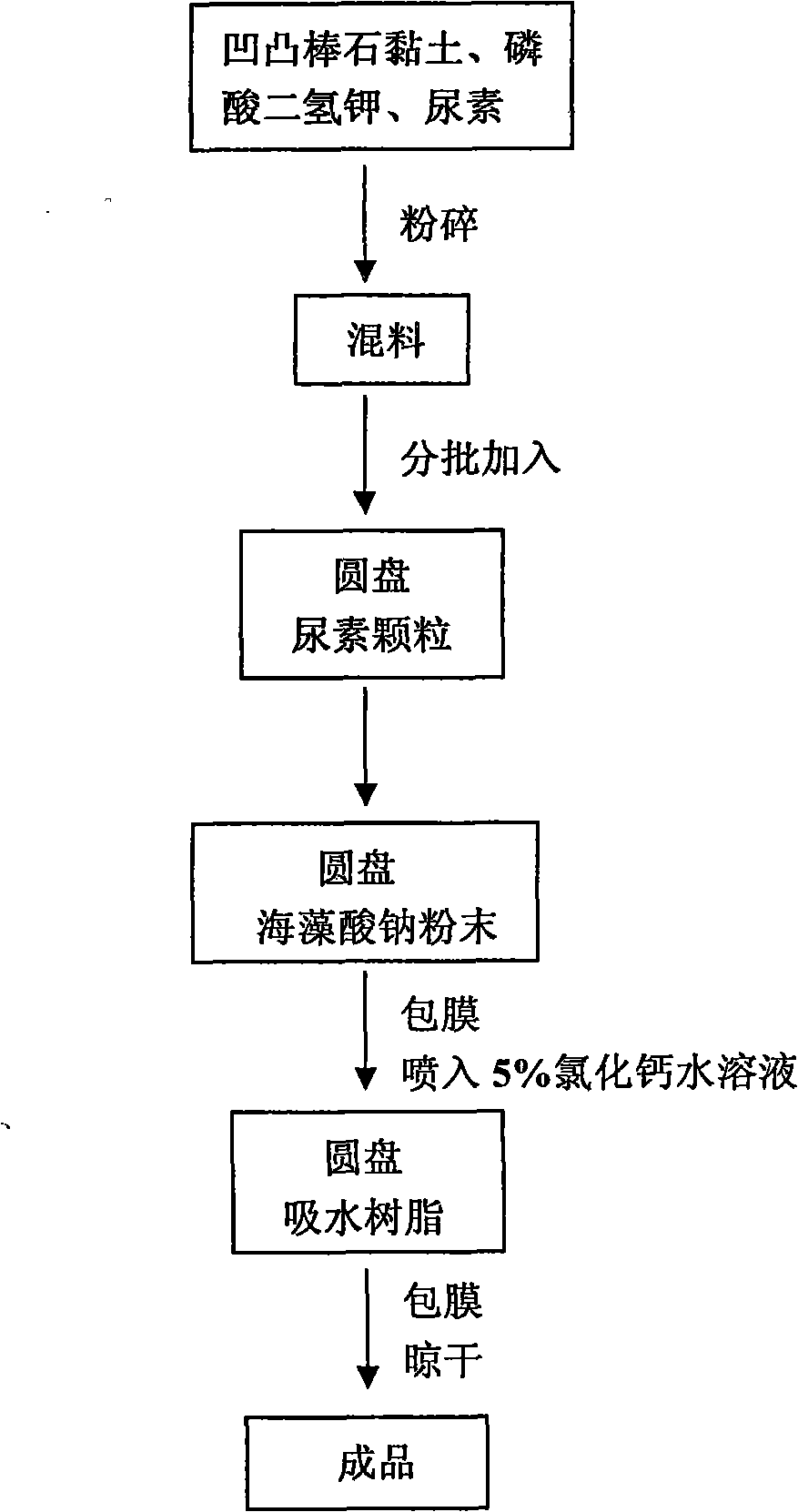

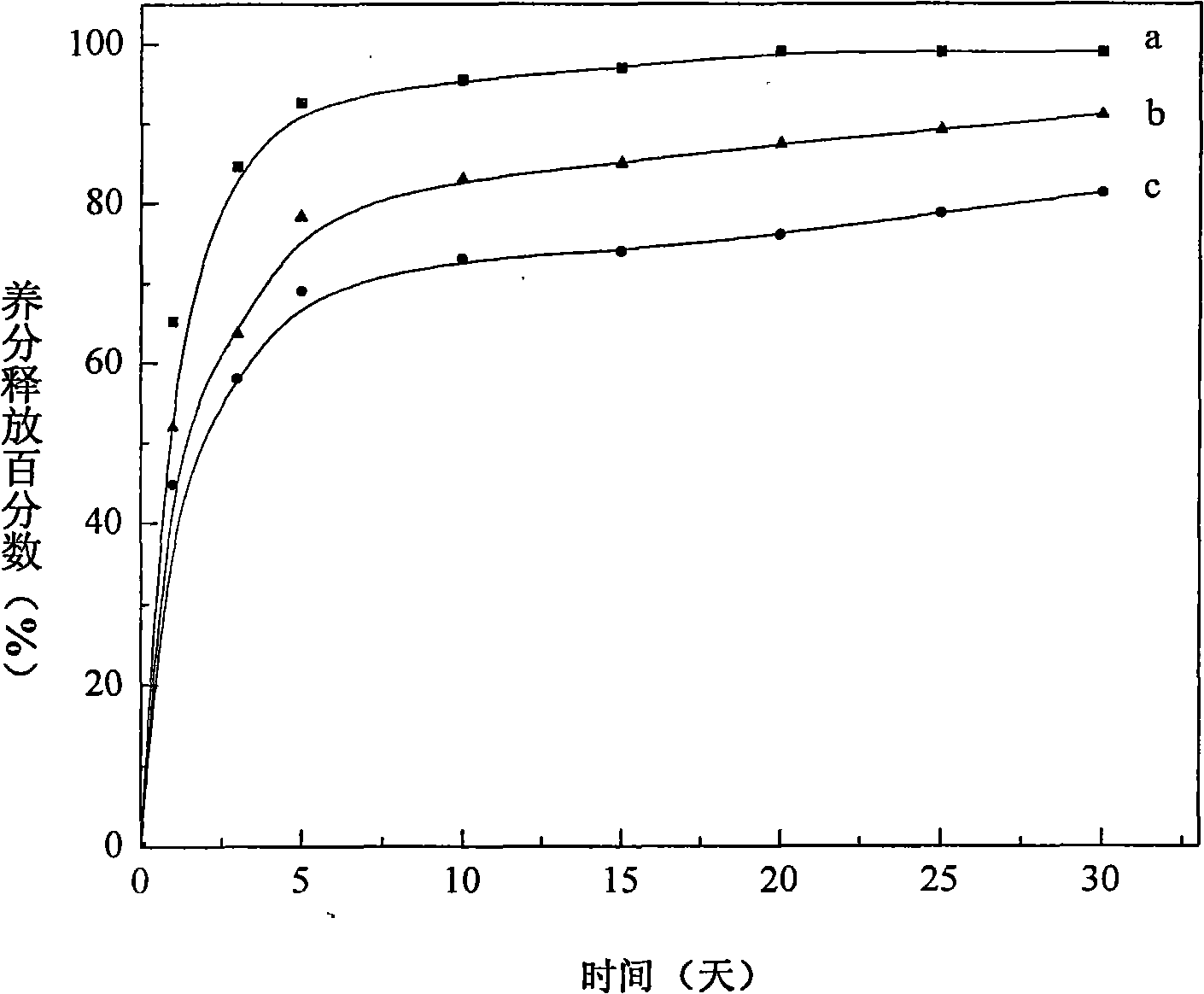

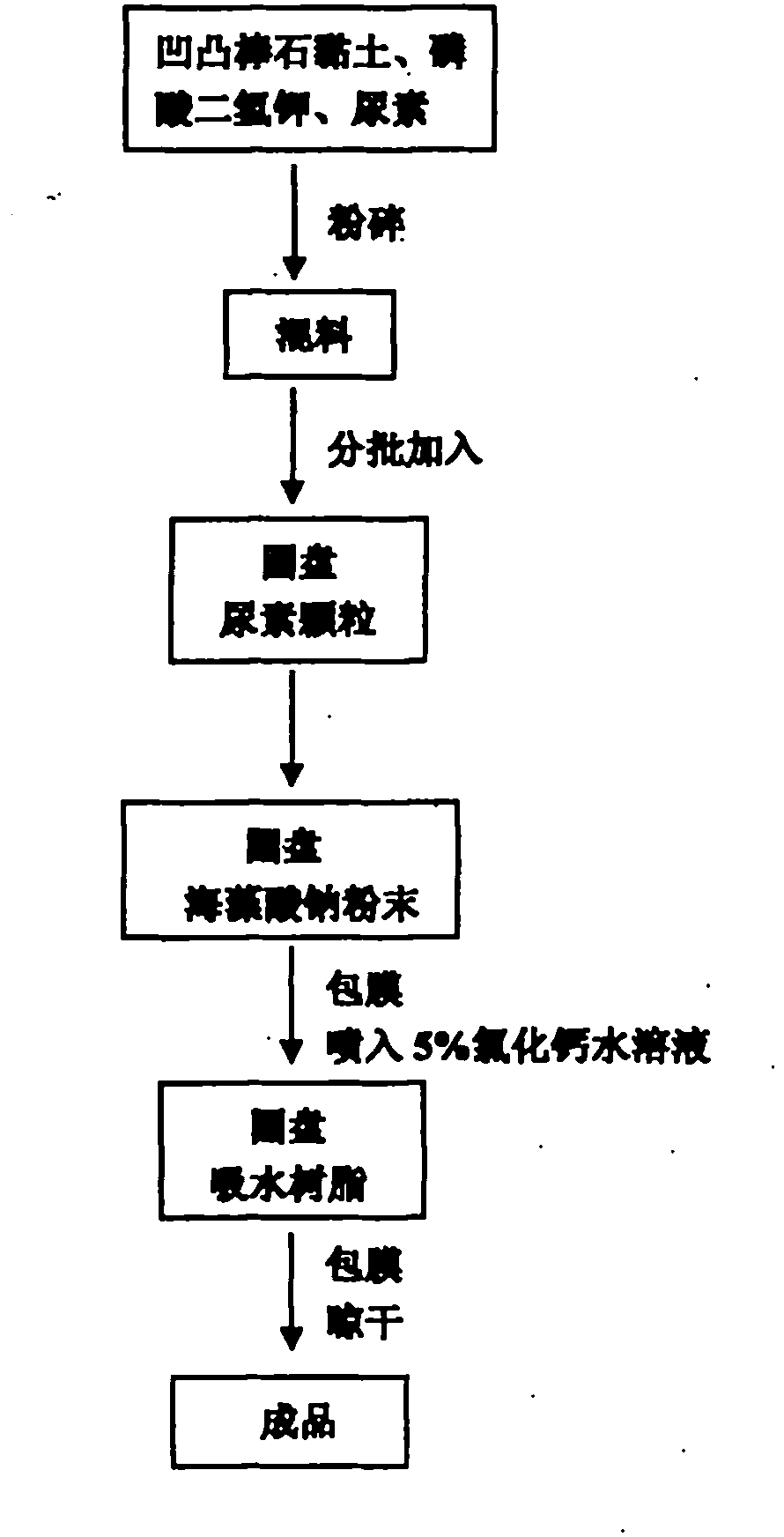

Method for preparing granular compound fertilizer

ActiveCN101891543AImprove adsorption capacityHigh granulation rateFertilizer mixturesCross-linkChloride

The invention relates to a method for preparing a granular compound fertilizer, which comprises the following steps of: rotating a disc granulator under the action of atomized water to wrap a mixture of attapulgite clay, urea and monopotassium phosphate on the outer layers of urea granules; adding sodium alginate powder into the disc granulator, rotating a disc to wrap the sodium alginate on the outer layer of the core of the fertilizer, spraying 5 percent aqueous solution of calcium chloride to perform cross linking with the sodium alginate, and taking the cross-linked sodium alginate as fertilizer inner layer envelopes; adding water-absorbing resin powder into the disc granulator, and rotating the disc to wrap the water-absorbing resin outside the fertilizer granules to form fertilizer outer layer envelopes; and drying the mixture to obtain the granular fertilizer. The granular compound fertilizer provides multiple nutrient elements for plants, and improves the sustained-release performance of the nutrient elements of the fertilizer. Meanwhile, the granular compound fertilizer has multiple functions of water absorption and retention, sustained release, soil regulation and the like through the combination of the fertilizer and the water-absorbing resin.

Owner:甘肃海瑞达生态环境科技有限公司

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

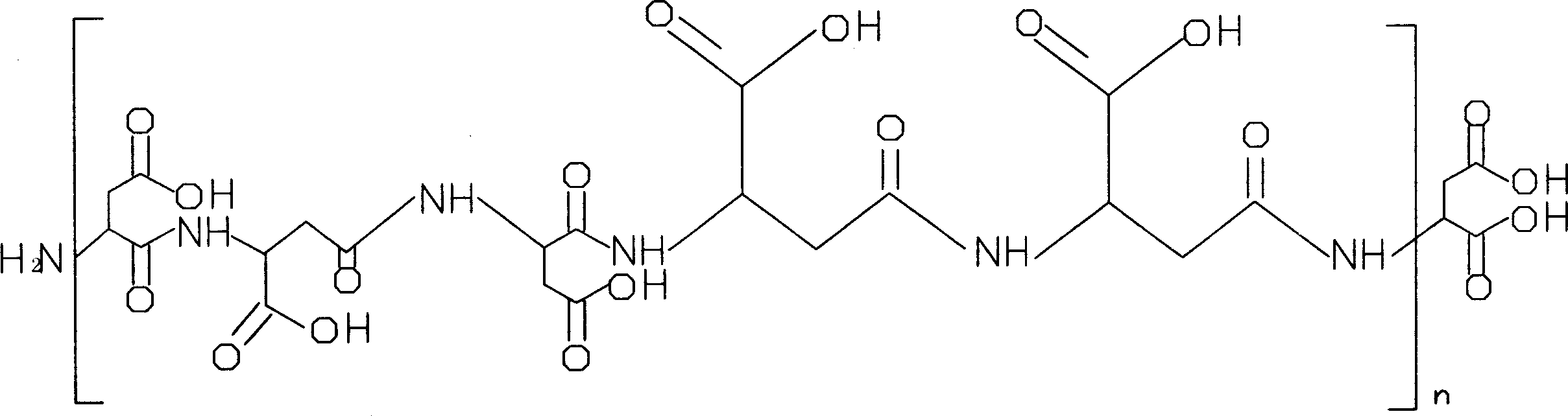

Polypeptide composite fertilizer and its production

InactiveCN101028984APrevent and delay lossIncrease profitUrea compound fertilisersPotassium fertilisersAqueous solutionChemistry

A composite polypeptite fertilizer for promoting growth, and improving crop quality and soil is prepared from a composite fertilizer and polyaminosuccinic acid or its salt through preparing composite fertilizer, preparing the aqueous solution of polyaminosuccinic acid or its salt, mixing and granulating.

Owner:SHOUGUANG LIFENG CHEM

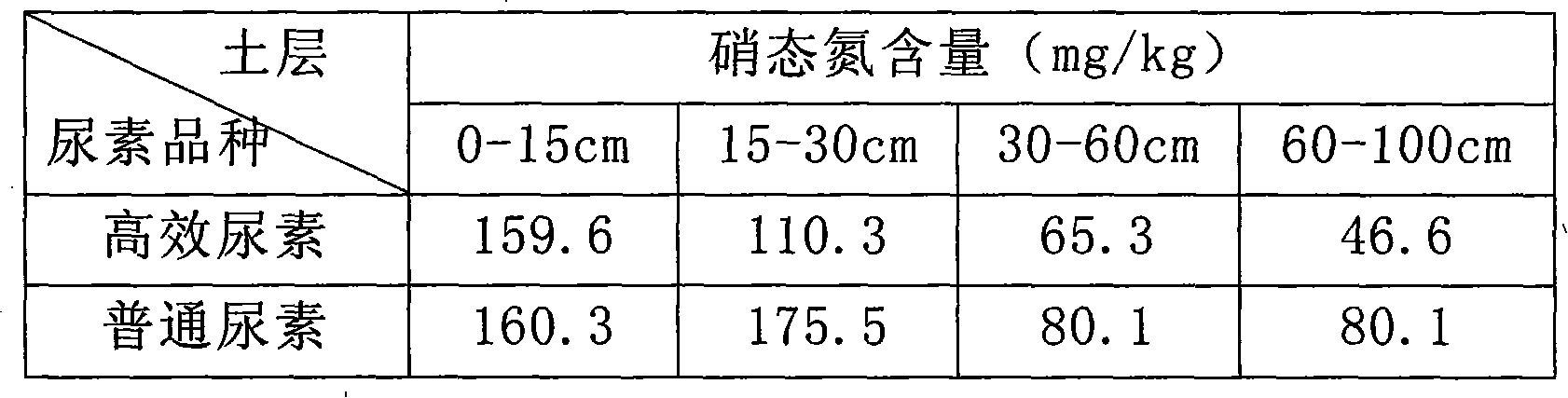

Highly effective carbamide and preparation method and application thereof

InactiveCN101157588APromote absorptionImprove stress resistanceAgriculture gas emission reductionUrea compound fertilisersChemical LinkageRelease time

The invention relates to a preparation method and application for efficient urea and a relative, and the preparation method and application is formed by the polymerization amino acid or the salt with a weight proportion of 0.01 to 2.0, urease inhibitor with weight proportion of 0.01 to 0.2, the nitrification inhibitor with weight proportion of 0.01 to 0.6, and the common urea with weight proportion of 97.2 to 99.97. The efficient urea is produced by adding the mixture solution of polymerization amino acid or the salt, the urease inhibitor and the nitrification inhibitor into the common urea at fusing state, and then mixing and granulating. The invention provides the application of the efficient urea in agriculture; for the field crop, the economic crop, the fruit and vegetable, and the flowers, the efficient urea can promote to comprehensively regulate the physiological and biochemical effect inside the plant so as to sufficiently excite the plant endogenous somatotropin and accelerate the nutrition producing, as well as improving the utilization and absorption of the urea, increasing the utilization rate by 20 percent to 60 percent. By the bonding effect of the polymerization amino acid or the salt molecule chemical bond and the effect of the urease inhibitor and the nitrification inhibitor, the invention slowly releases the urea in the soil, and increases the releasing time from 50 days up to around 120 days.

Owner:HEBEI THINK DO ENVIRONMENT CO LTD

Composite microbial agent and production method thereof

ActiveCN101993305AImprove performanceIncrease productivityFertilizer mixturesMicrobial agentEffective microorganism

The invention relates to a composite microbial agent and a production method thereof. The composite microbial agent consists of a granular material core, a paraffin protective coating and a microbial agent coating layer between the core and the protective layer. The excellent product structure can ensure that the effective microbe content in the composite microbial agent is high, and the product has stable properties and high fertilizer efficiency and meets the requirements of various crops; and compared with the conventional biofertilizer, the composite microbial agent can improve the yield of food crops by 10 to 15 percent, improve the yield of cash crops by 8 to 14 percent, improve the yield of vegetables by 15 to 20 percent, and improve the yield of fruits by 15 to 25 percent. Throughthe production method, the granulation rate of the product is 95 percent, the granule strength of the product is high, and because the water content of the granular material is low, the energy consumption in the energy process is reduced, the production efficiency of drying equipment is improved and the investment of the drying equipment is reduced.

Owner:领先生物农业股份有限公司

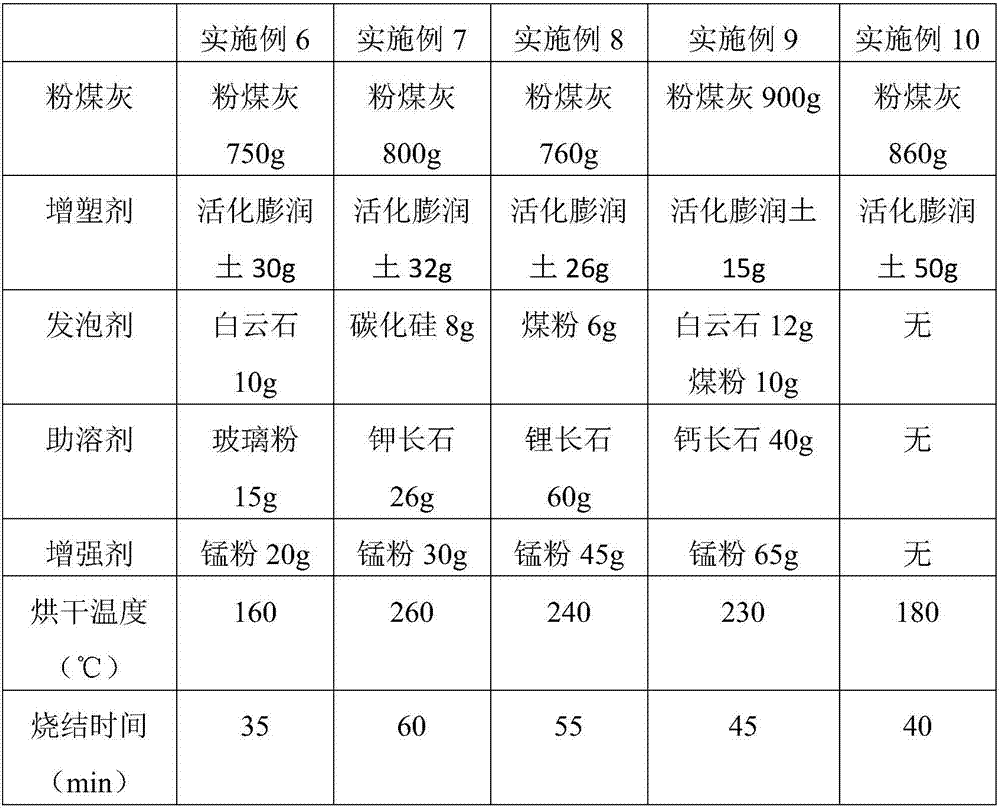

Light high-strength high mixing amount coal ash ceramsite and preparation method thereof

InactiveCN107417150AHigh granulation rateHigh strengthCeramicwareClaywaresPolymer scienceFoaming agent

The invention provides light high-strength high mixing amount coal ash ceramsite and a preparation method thereof. The ceramsite comprises the following components in parts by mass: 70-95 parts of coal ash, 1-5 parts of a plasticizer, 0-5 parts of a foaming agent, 0-10 parts of a fluxing agent and 0-10 parts of a reinforcing agent. The coal ash ceramsite provided by the invention is light in weight and high in strength, the density grade is as high as 600-900kg / m<3>, the cylinder pressure intensity is as high as 7-15MPa, the water absorption rate is as low as 3-5%, and damage is not easily caused; the coal ash ceramsite can be used for preparing lightweight aggregate high-performance concrete, building wall plates, bridges and pipelines; the coal ash ceramsite is relatively lowly required in Lightweight Aggregates and Its Testing Methods Part I: Lightweight Aggregates, the strength requirement of high-strength ceramsite of which the density range is 600-900kg / m<3> is 4-6.5MPa, and the water absorption rate is generally less than 20%.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD +1

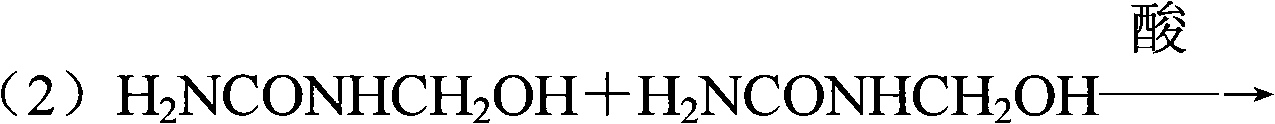

Production process of ureaformaldehyde humic acid organic fertilizer

InactiveCN103204745ASolve the shortcomings of high moistureHigh granulation rateFertilizer mixturesHardnessOrganic fertilizer

The invention belongs to the technical field of production of compound fertilizers, relating to a production process of ureaformaldehyde humic acid organic fertilizer. The production process comprises the steps of activating and fermenting organic raw materials, preparing granulating base stock, granulating, processing granules, coating and the like, wherein humic acid and dung of cows and sheep containing straws are fermented together; the disadvantage that moisture in dung is high is solved; the balling rate is high since activated humic acid is used for granulating; the water content is low; coal consumption is low when the ureaformaldehyde humic acid organic fertilizer is dried; the temperature is low; beneficial microbial strains in the organic raw material are effectively preserved; the ureaformaldehyde humic acid organic fertilizer has ureaformaldehyde humic acid film-forming property and slow-release property; the ureaformaldehyde humic acid organic fertilizer produced by using the process disclosed by the invention has slow-release property and high hardness which is averagely 5-7N higher than that of the ordinary humic acid organic fertilizer, is hardly pulverized, and is low in production cost and strong in production continuity and operability.

Owner:付增传

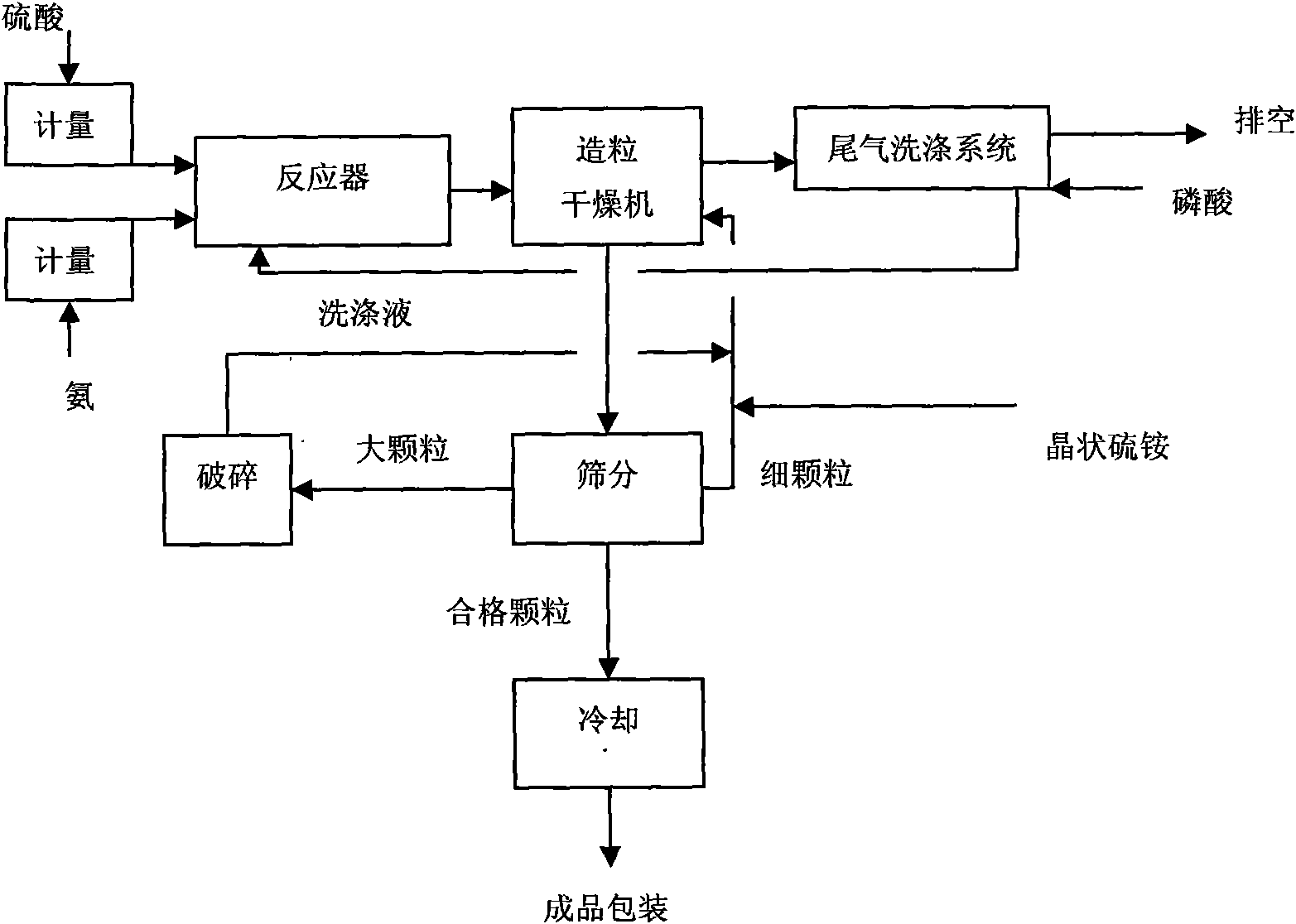

Method for producing granular ammonium sulfate by using crystalline ammonium sulfate or powdery ammonium sulfate

ActiveCN101648838AHigh strengthReduce lossesFertiliser formsAmmonium salt fertilisersPhosphoric acidSlurry

The invention relates to a method for producing granular ammonium sulfate by using crystalline ammonium sulfate or powdery ammonium sulfate. The method comprises the following steps: (1) adding the crystalline ammonium sulfate or the powdery ammonium sulfate into a granulating drier, using as mother material and forming a material screen or a material bed under the rotation of a rotary drum; (2) mixing sulfuric acid, ammonia, phosphoric acid and washing liquid in a tubular reactor, reacting, generating high-temperature slurry, spraying the slurry on the material screen or the material bed in agranulating machine after atomizing, and coating or sticking into particles; (3) after dedusting, washing the tail gas with the phosphoric acid and recycling the washing liquid; returning the collected dust to the granulating machine; (4) sieving material produced by the granulating drier to obtain particles of 1-4mm, which is a finished product of the granular ammonium sulfate; and returning theparticles greater than 4mm after being crushed and the particles smaller than 1mm to the granulating drier and recycling. The method can raise the temperature of a granulating material layer by the high-temperature slurry, improve the granulation rate of the mother material, lower the material return ratio, wash the tail gas with the phosphoric acid, reduce the loss of the ammonia, dry a productby reaction heat and save energy consumption; the generated product has high strength and little loss of nutrient components.

Owner:WENGFU (GRP) CO LTD

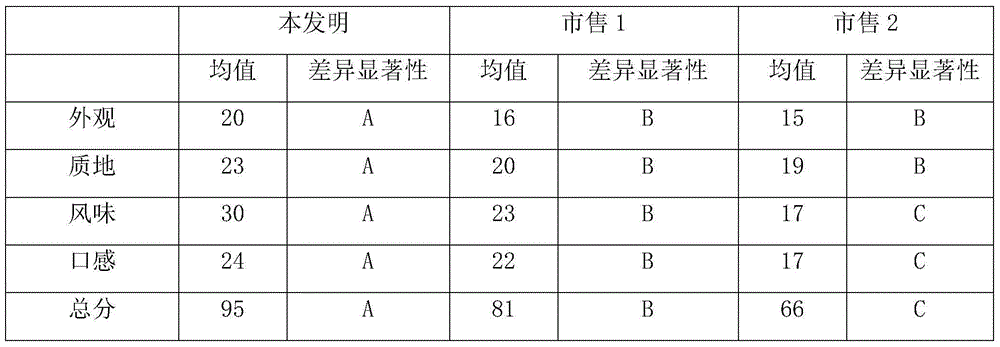

Edible grain, bean and potato coarse cereal rice composition and preparing method thereof

InactiveCN104855830AHigh economic valueImprove immunityNatural extract food ingredientsFood ingredient functionsHydrolysateEdible Grain

The invention discloses an edible grain, bean and potato coarse cereal rice composition and a preparing method thereof and belongs to the technical field of grain deep processing. According to the edible grain, bean and potato coarse cereal rice composition, broken rice is used as a main raw material, after ultrasonic cleaning, microwave curing, drying and sterilizing of the broken rice, the broken rice, grain powder with a special flavor, enzymatic hydrolysate and other functional raw materials are pelletized, and then grain arrangement and processing through a microwave drying device are carried out, so that the edible grain, bean and potato coarse cereal rice composition is obtained. The edible grain, bean and potato coarse cereal rice composition has a tissue structure, granularity, hardness and viscosity which are similar to those of rice, can be boiled and cooked with rice, has the taste and chewiness, which are similar to those of cooked rice, is unique in flavor, soft in fragrance, high in appetite attractiveness, easy to digest and comprehensive in nutrition, and can improve the immunity and disease resistance of the human bodies and improve the gastrointestinal function. The guarantee period is three times of that of commercial rice. More importantly, a shortcut is developed for the efficient value-added comprehensive utilization of the broken rice, the road for the deep processing of the broken rice is broadened, and the economical value of the broken rice is increased. Better social benefits and economic benefits are realized and a sustainable development road for the deep processing of agricultural byproducts and the effective solving of Three-Rural problems is explored.

Owner:敖汉旗北方粮仓农产品批发市场有限公司

Method for fertilizer granulation through molasses alcohol fermentation liquor

InactiveCN104030768ATurn waste into fertilizerSave waterFertilizer mixturesAlcoholCleaner production

The invention provides a method for fertilizer granulation through molasses alcohol fermentation liquor. Before granulation, the molasses alcohol fermentation liquor is mixed with a macro-element chemical fertilizer raw material, a medium-element chemical fertilizer raw material, a microelement chemical fertilizer raw material and organic raw materials so that crystal nuclei of particles can be formed, and then granulation is conducted in a granulation device. According to the method, the granulation efficiency of fertilizer is improved to a great extent, the production efficiency of the fertilizer is improved, the production cost is reduced, and clean production through comprehensive use of the molasses alcohol fermentation liquor is achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

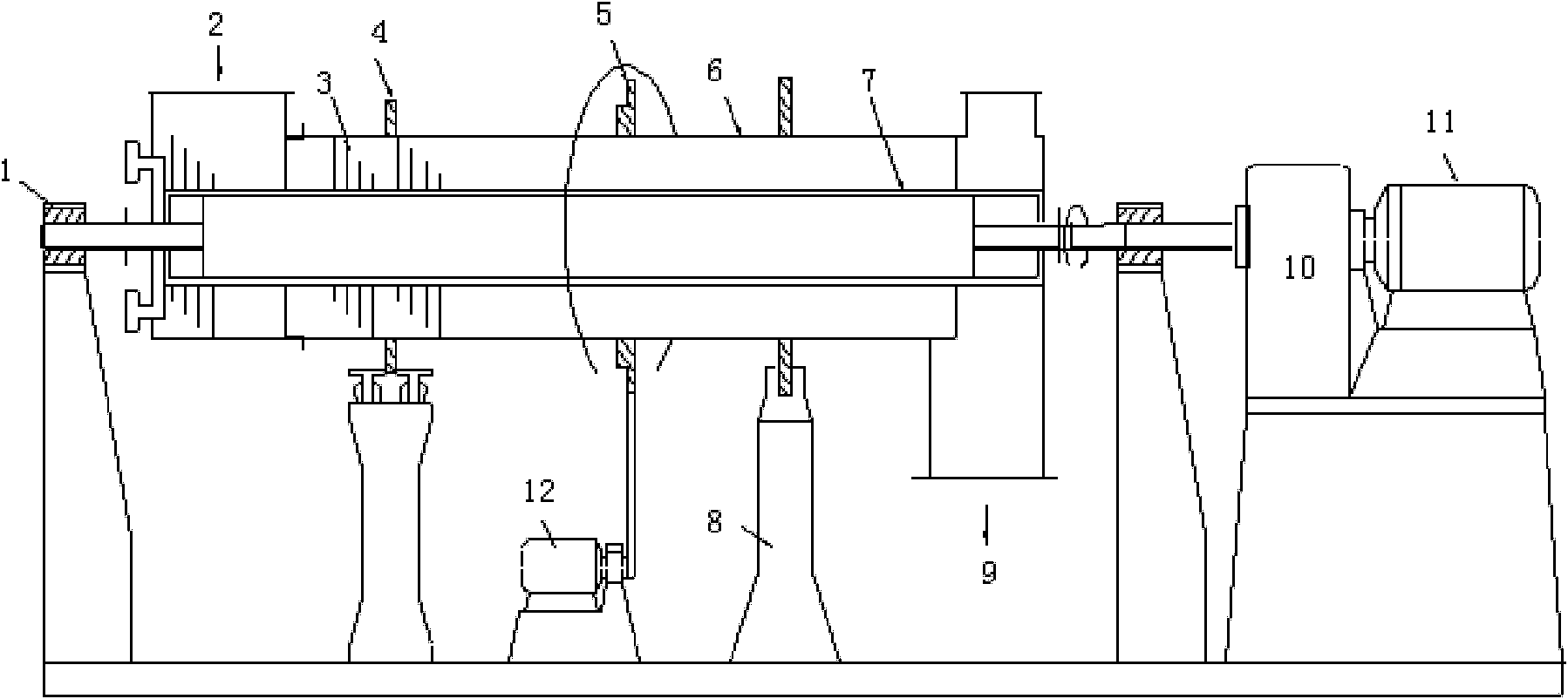

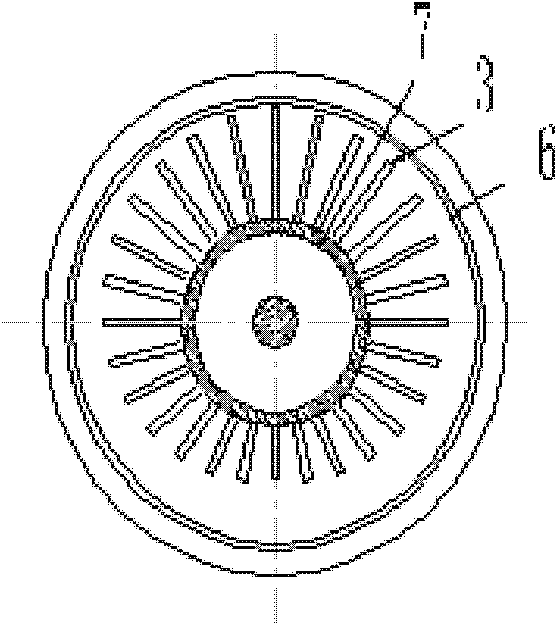

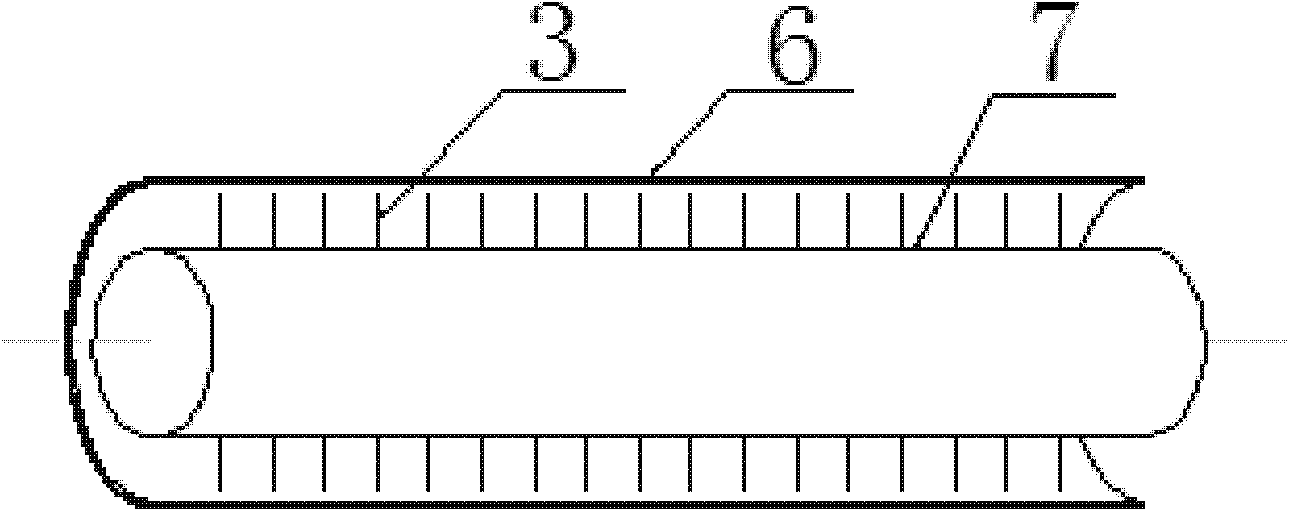

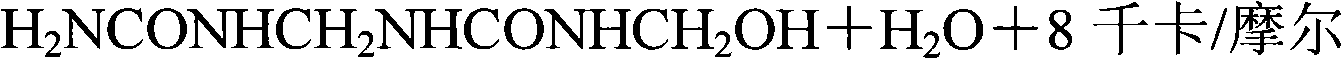

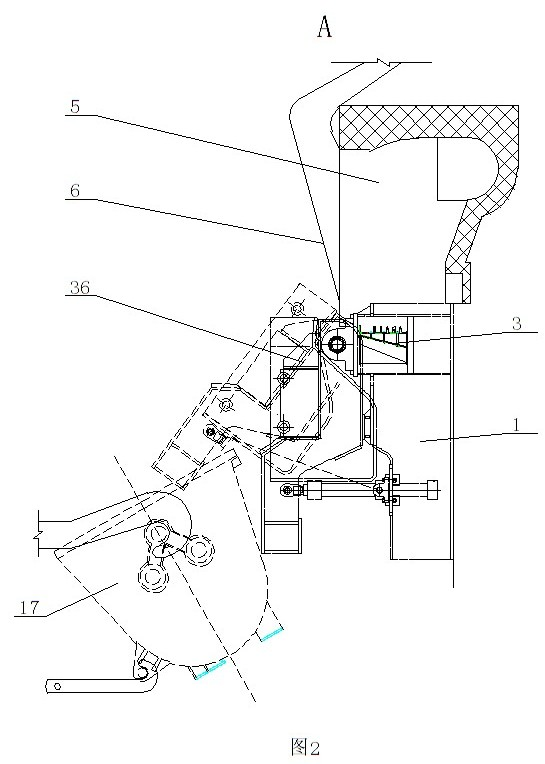

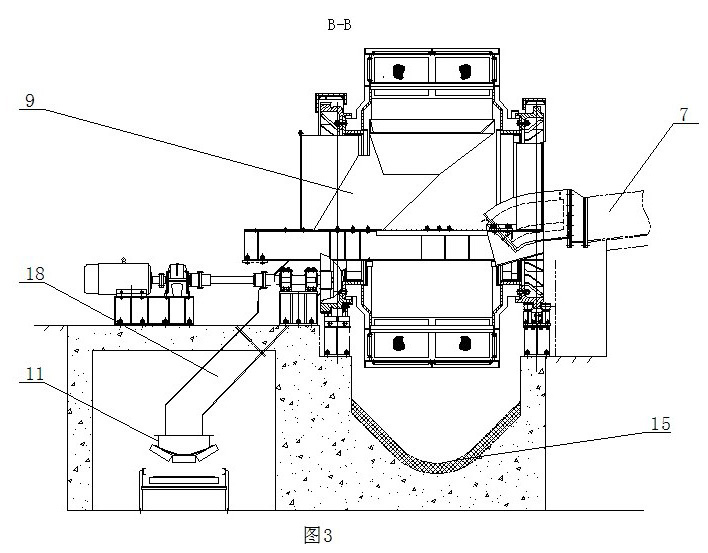

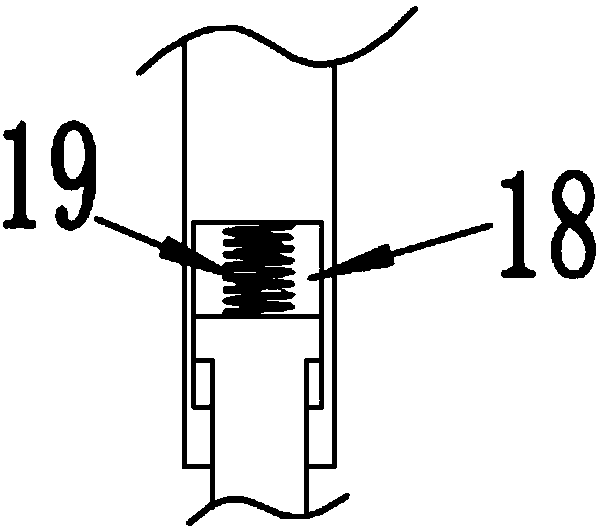

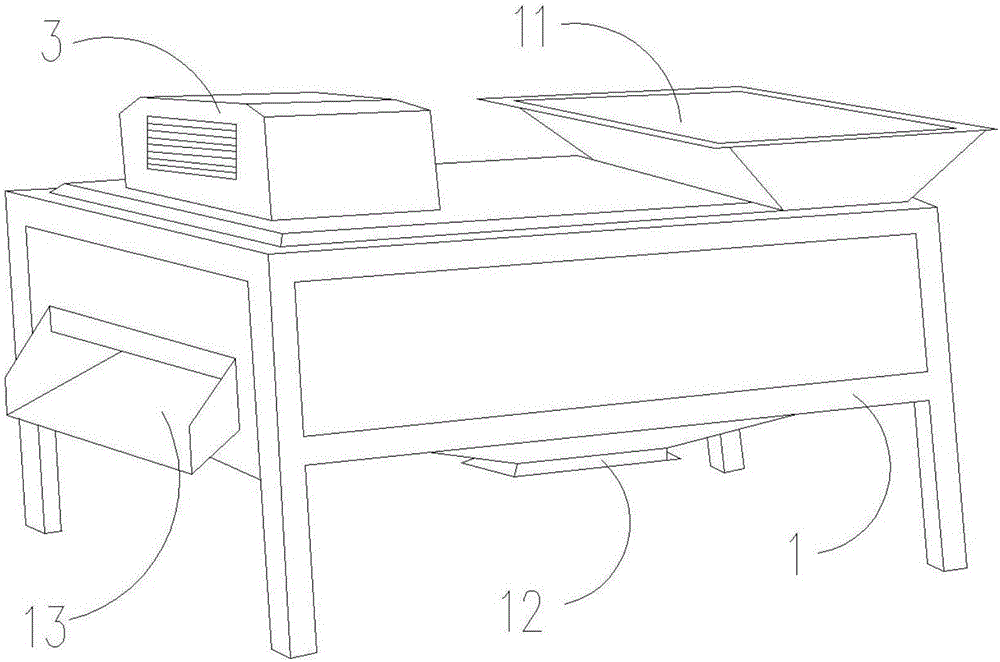

Telescopic compound fertilizer rotary drum granulator

ActiveCN102432404AReduce volumeSmall footprintFertiliser formsFertilizer mixturesStructural engineeringRaw material

The invention relates to a telescopic compound fertilizer rotary drum granulator comprising a support (1), a feeding port (2), a supporting wheel (4), a frame (8), and a discharging port (9). The frame (8) is provided with an inner cylinder (7) and an outer cylinder (6) sleeved on the inner cylinder (7), wherein the rotation directions of the inner cylinder (7) and the outer cylinder (6) are the same, but the rotation speeds of the inner cylinder (7) and the outer cylinder (6) are different. Granulating rods (3) are distributed in a threaded form on the outer wall of the inner cylinder (7). The inner cylinder (7) is arranged on the support (1) through a shaft, wherein the cylinder (7) can rotate. The outer cylinder (6) is arranged on the frame (8) through the supporting wheel (4). The feeding port (2) is arranged on one end of the outer cylinder (6), and the discharging port (9) is arranged on the other end of the outer cylinder (6). Compared to existing technologies, the granulator provided by the invention is advantaged in small volume, simple structure, high granulating rate, and no restriction on raw material performance. With the telescopic compound fertilizer rotary drum granulator provided by the invention, materials with any formula can be produced.

Owner:SHANGHAI RES INST OF CHEM IND

Method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation

InactiveCN101857513AIncrease temperatureReduce moistureFertilizer mixturesMixed materialsFORMALDEHYDE SOLUTION

The invention relates to a method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation, which comprises the following steps: heating and mixing urea and formaldehyde solution according to a mol ratio of (2 to 7) / 1 to be prepared into mixed material pulp with the temperature between 40 and 90 DEG C; introducing N, P and K fertilizers or filling materials and the like into a granulation device; after the mixed material pulp and ammonium sulphate are mixed in a pipeline according to a weight ratio of (5 to 30) / 1, spraying the mixture on solid materials in the granulation device for mixed granulation; simultaneously introducing ammonia for neutralization during the granulation; and obtaining the grain compound fertilizers, wherein the weight ratio of the mixed material pulp to the sulphuric acid is (5 to 30) / 1, the addition of the mixed material pulp sprayed on the solid materials accounts for 10 weight percent to 50 weight percent of the total material weight, and the quantity of the introduced ammonia accounts for 1 weight percent to 5 weight percent of the total material weight.

Owner:SHANGHAI RES INST OF CHEM IND

Slag quenching system and process

The invention discloses a slag quenching system, which comprises a tipping device, wherein the tipping device is provided with a tundish; the front of the tundish tipping device is provided with a granulator; an explosionproof quenching tank is arranged in the spraying direction of the granulator, and is connected with a dehydration and deslagging device through a sluiceway; a feed belt is arranged below a tapping device of the dehydration and deslagging device; one end of the feed belt is connected with a bunker; and a drainage ditch is arranged below the dehydration and deslagging device and is connected with a circulating water tank. A slag quenching process comprises the following steps of: 1, pouring slag of a slag ladle into the tundish; 2, pouring the slag in the tundish into the explosionproof quenching tank, quenching the slag by spraying water mist through the granulator, making granulated slag fall into the explosionproof quenching tank, flushing the explosionproof quenching tank to make the slag and water in the explosionproof quenching tank enter the sluiceway, and making the quenched slag enter the dehydration and deslagging device; and 3, making water separated by the dehydration and deslagging device fall into the drainage ditch and flow into the circulating water tank, and transporting the separated slag to the bunker for storage.

Owner:JIGANG INT ENG & TECH CO LTD

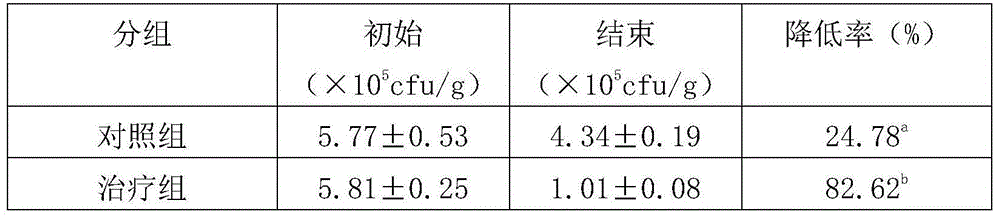

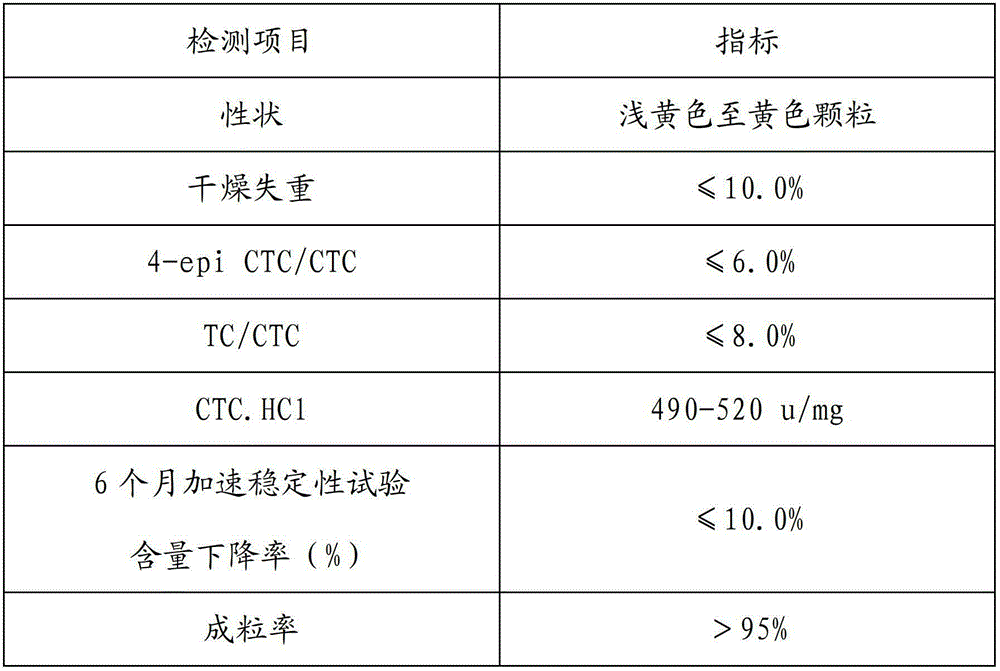

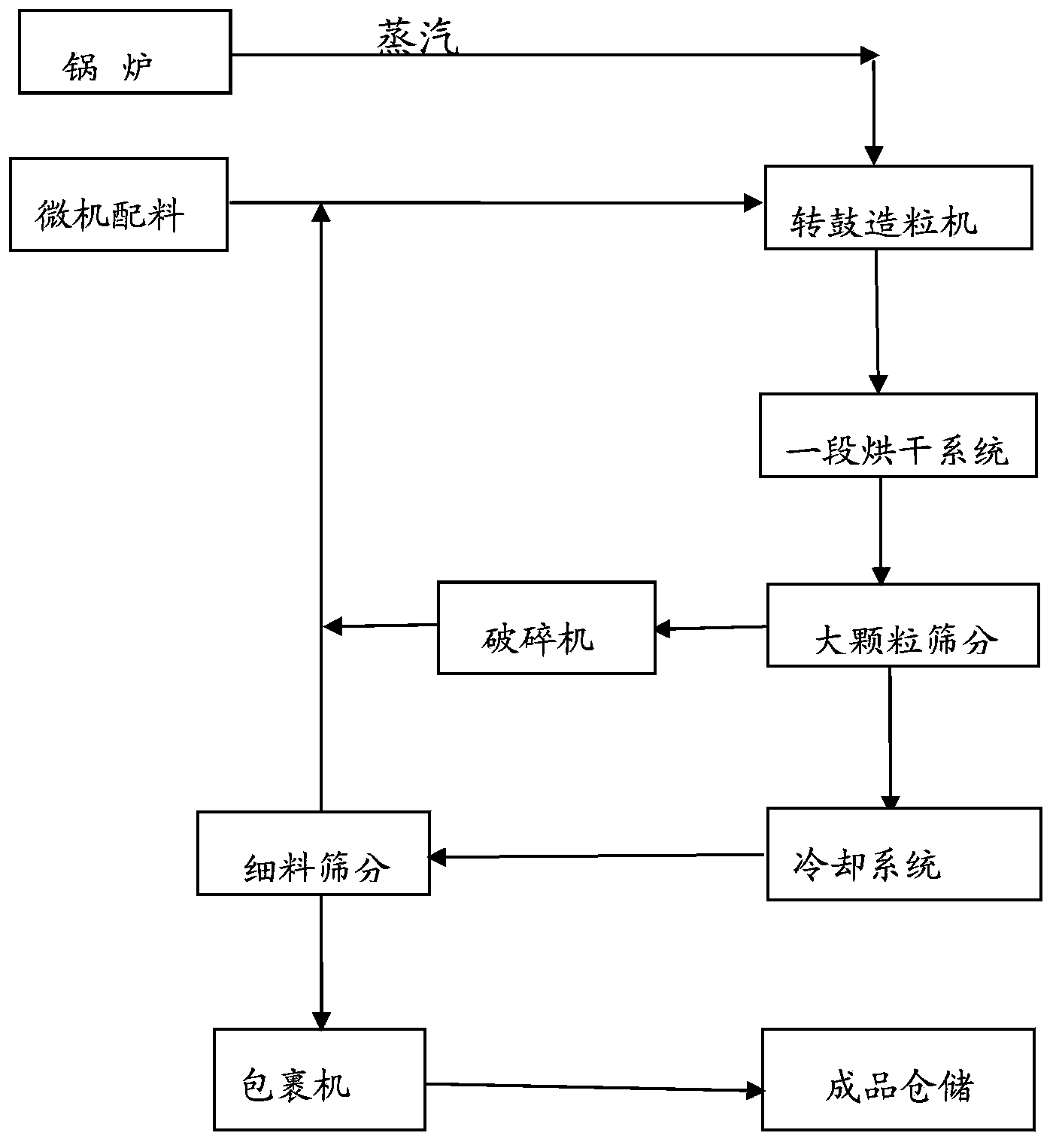

Formula of aureomycin hydrochloride premix granule and granulating process

ActiveCN102716092AReduce generationHigh granulation rateTetracycline active ingredientsPharmaceutical non-active ingredientsChlortetracycline hclStarch degradation

The invention discloses a formula of aureomycin hydrochloride premix granule, which is characterized in that the following components are included: 80 percent or less than 80 percent of aureomycin hydrochloride, 80 percent or less than 80 percent of soluble starch or starch degradation products, 20 percent or less than 20 percent of carbohydrates, and 30 percent or less than 30 percent of purified water. The invention further discloses a granulating process. After the adoption of the formula and the granulating process, the invention achieves that the aureomycin hydrochloride premix granule is uniform, has a mellow appearance, is unanimous in tincture and high in percentage of ripened grains, the stability of product quality is excellent, the normal working conditions during the aureomycin hydrochloride premix granulating process can be ensured, and the improvement to production efficiency and quality is facilitated.

Owner:PUCHENG CHIA TAI BIOCHEM

Disintegratable round-granule sulfur magnesium fertilizer and preparation method thereof

InactiveCN102775220AHigh granulation rateHigh in magnesiumFertiliser formsFertilizer mixturesBruciteWater content

The invention belongs to the field of agricultural fertilizers, and relates to a disintegratable round-granule sulfur magnesium fertilizer. Powdery brucite and sulfur powder are used as main raw materials, and a magnesium sulfate heptahydrate solution is used as a binding agent. The disintegratable round-granule sulfur magnesium fertilizer is prepared by granulating the following components in parts by mass: mixture of 90-95 parts of powdery brucite and 5-10 parts of sulfur as the dry material, and magnesium sulfate heptahydrate solution as the binding agent. After drying the round granules, the water content is less than or equal to 3%, the strength is greater than or equal to 2Kg / cm<2>, and the disintegration rate is greater than or equal to 95%. The magnesium sulfate heptahydrate solution is used as the binding agent to enhance the granulation rate; the 60-120 mesh powdery brucite and sulfur powder are mixed as the dry material; and granulation, screening, drying, cooling and packaging are carried out to prepare the spherical granules with the granular size of 2-4mm. The invention has the advantages of low cost, high magnesium content and high disintegration speed. The product is spherical granules, has the advantages of favorable disintegratability, uniform granularity and high strength, and can be conveniently mixed with other nitrogen-phosphorus-potassium fertilizers.

Owner:张浩

Environment-friendly nitrogen potassium dressing fertilizer containing various nitrogen elements and preparation method thereof

InactiveCN103382140AQuality improvementSolve the problem of difficult granulationFertilizer mixturesUrea nitratePlant growth

The invention discloses an environment-friendly nitrogen potassium dressing fertilizer containing various nitrogen elements and a preparation method thereof. The fertilizer comprises, by weight, at least 20% of urea, 5-7% of ammonium bicarbonate, 7-15% of ammonium sulfate, 10-14% of nitrate, at least 8% of potassium chloride, 7% of humic acid, 8-12% of sepiolite, 5-7% of calcium hydroxide, other materials containing trace elements and a plant growth regulator. In a granulating process, urea nitrate generated by reaction of nitrate and urea and sepiolite with viscosity are used as adhesive, water generated by decomposing of ammonium bicarbonate is used as a liquid phasor, steam is used for increasing the temperature of granulating materials, liquid phasor required by granulation is supplemented, and a material granulating process is finished. The final product contains nitrate nitrogen, ammonium nitrogen, amidonitrogen, organic matters, various medium trace elements and the plant growth regulator and achieves the purposes of improving soil, reducing soil salinity, improving nutrient element absorption of plants, increasing plant quality and productivity and improving plant disease resistance.

Owner:PANJIN STRONG FERTILIZER

Edible mushroom dreg activity and soil fertility regulating compound and preparation method thereof

InactiveCN106966806AQuality assuranceImprove metabolic activityCalcareous fertilisersAlkali orthophosphate fertiliserMonopotassium phosphateDrug biological activity

The invention provides an edible mushroom dreg activity and soil fertility regulating compound and a preparation method thereof. The compound is prepared from, by weight, 85-90 parts of edible mushroom dregs, 3-5 parts of wheat bran, 3-5 parts of insecticidal components, 3-5 parts of attapulgite, 0.5-1 part of monopotassium phosphate, 0.5-1 part of urea and 1-2 parts of lime. The live edible mushroom dregs are directly utilized, fermentation is not needed, the mycelium activity in the mushroom dregs is kept and improved on the basis that various nutrients are ensured, the quality of organic fertilizer, is improved, an organic biological activity function is improved, soil microbial communities and a soil environment are improved, the soil fertility is improved, and the crop yield and quality are improved.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI +2

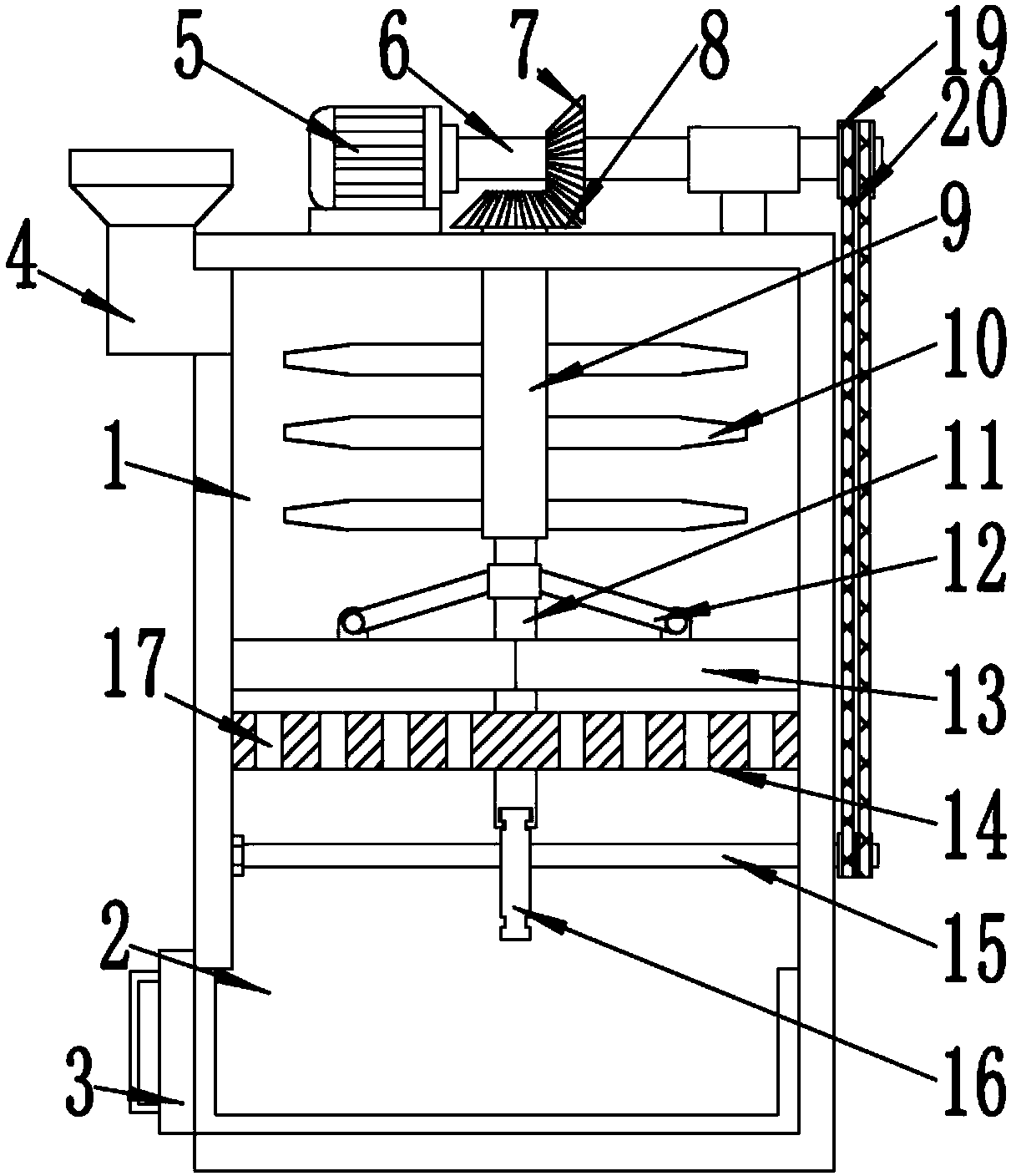

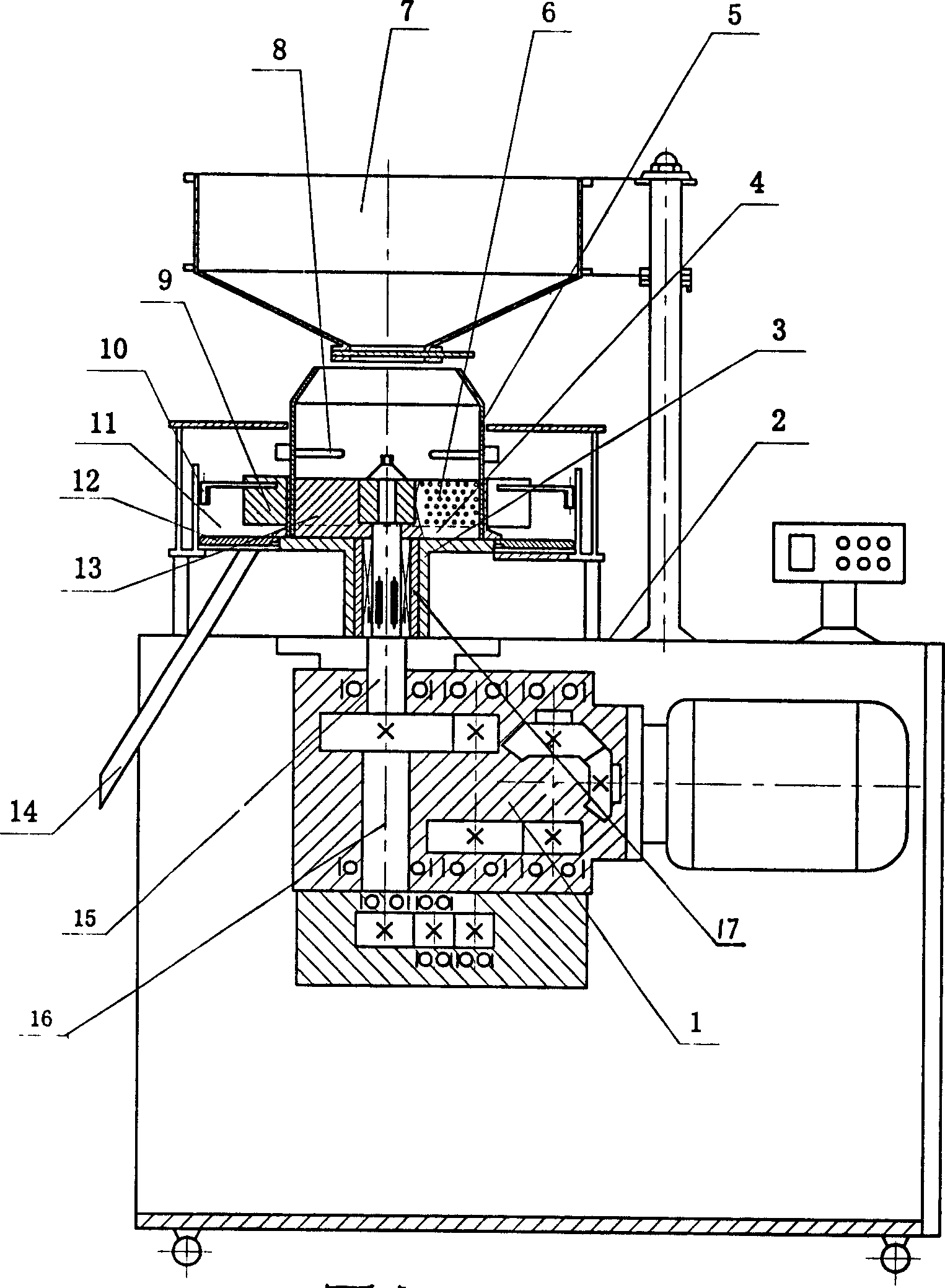

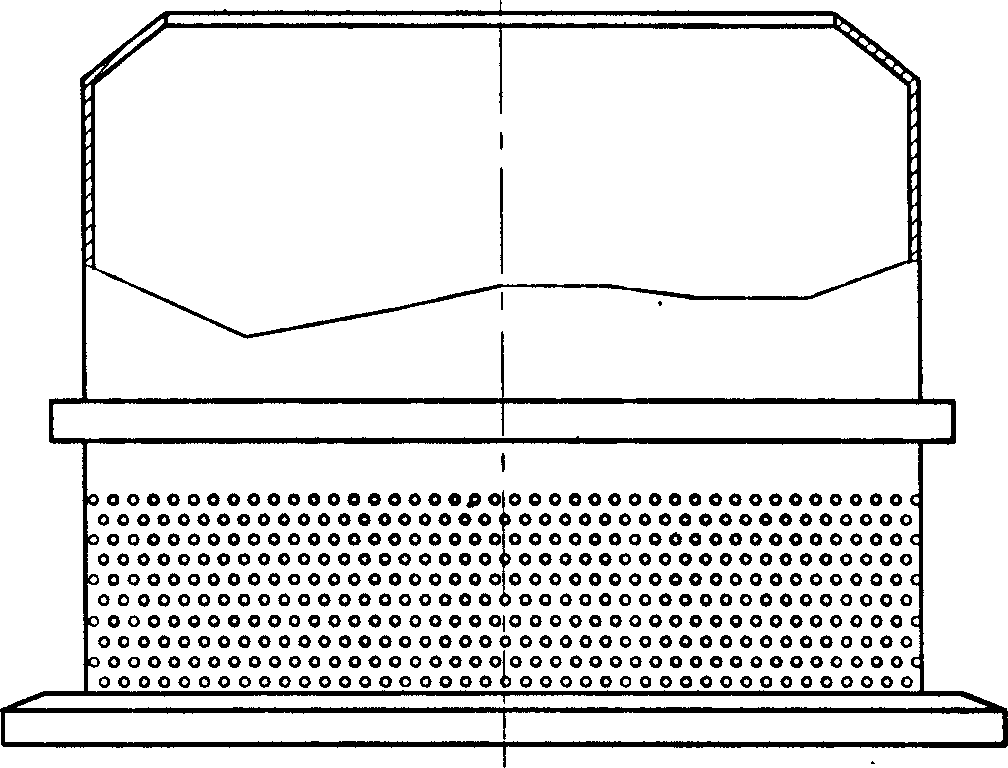

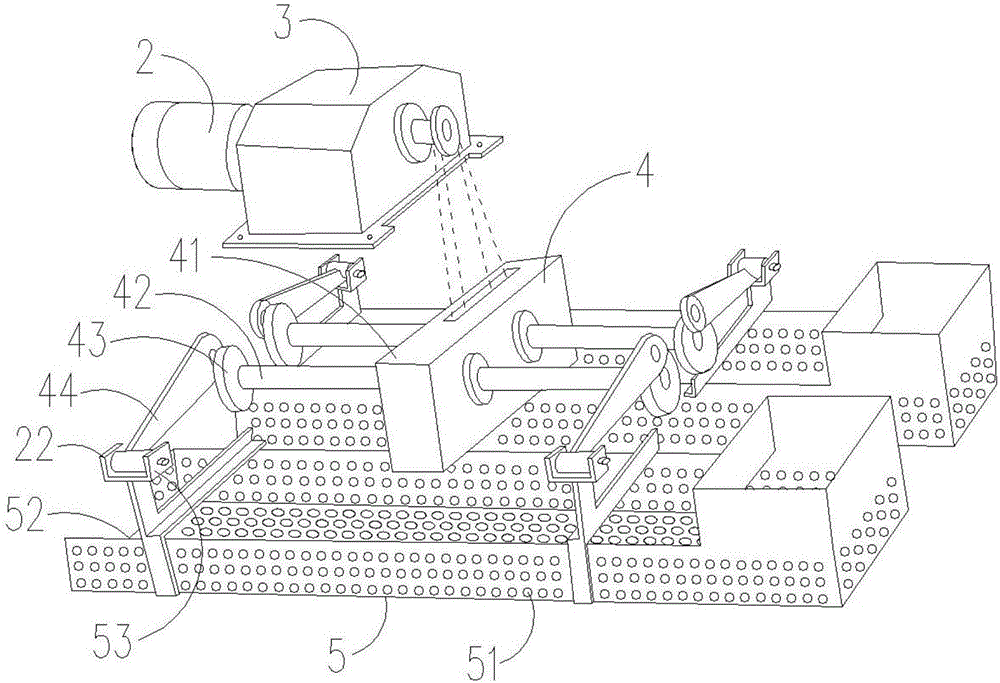

Granulating device for processing of feeds

ActiveCN107836740AImprove the mixing effectHigh granulation rateFeeding-stuffElectric machineryEngineering

The invention discloses a granulating device for processing of feeds. The granulating device comprises a stirring cavity, a collecting cavity, a pressing plate and a granulating plate, wherein a column rod is arranged on the inner side of the stirring cavity; the upper end of the column rod penetrates through an upper cover plate of the stirring cavity and is fixedly connected with a bevel gear B;the bevel gear B is meshed with a bevel gear A which is fixedly mounted on a first rotating shaft; the left end of the first rotating shaft is fixedly connected with an output end of a motor; and thepressing plate is also arranged on the inner side of the stirring cavity. The granulating device disclosed by the invention is novel in design; when arranged stirring rods rotate, raw materials of the feeds are stirred, so that the mixing effect of the feeds is improved, and the granulation rate is improved; when an arranged moving rod moves up and down, the pressing plate is driven to overturn upwards through the connecting rod, so that the falling of the raw materials of the feeds in the stirring cavity is realized, and the effect of intermittent discharging is realized; the situation thatthe granulating effect is influenced by that too many feeds are piled at the same time is avoided, so that the granulation rate of the feeds is improved; and the granulating device is high in practicality, and worthy popularizing.

Owner:彭阳县宝发动物营养食品有限公司

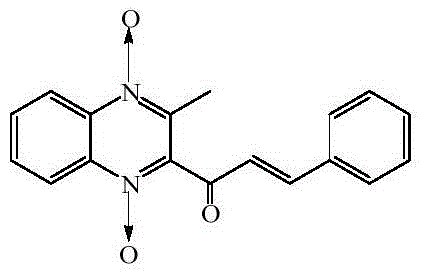

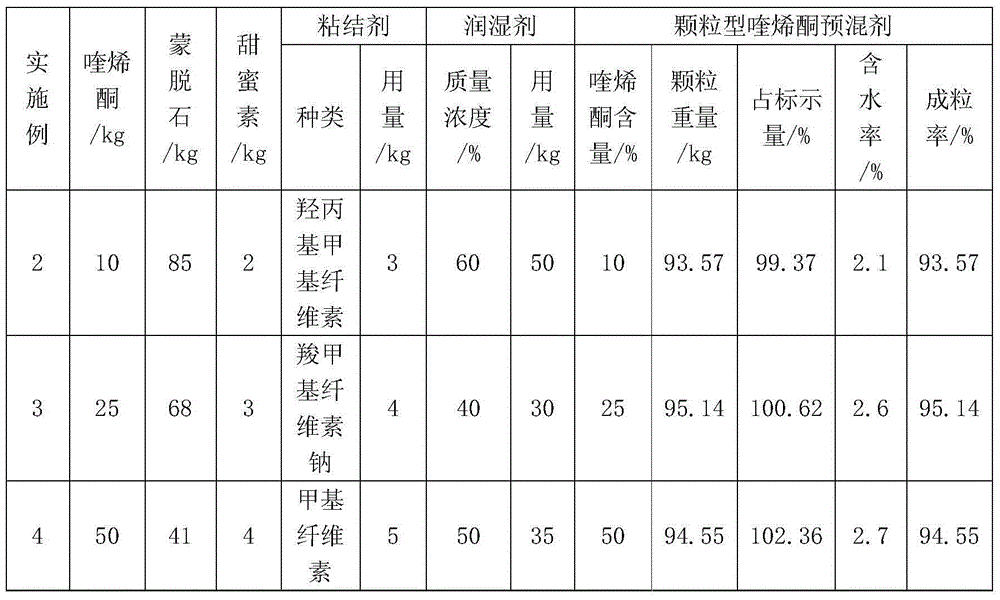

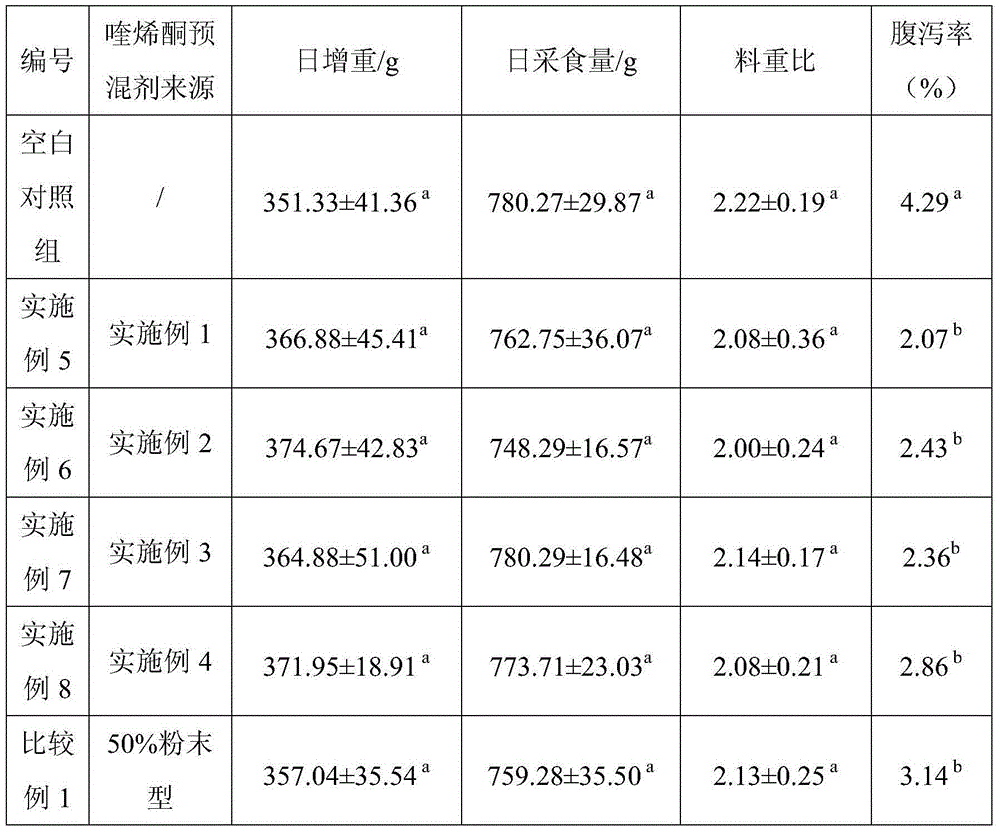

Granular quinocetone premix and preparation method thereof

InactiveCN104922074AUniform particlesEvenly dispersedOrganic active ingredientsMetabolism disorderGrowth promotionGranularity

The invention discloses a granular quinocetone premix which comprises the following components in parts by weight: 5 to 50 parts of quinocetone, 41 to 89 parts of montmorillonite, 2 to 4 parts of sodium cyclamate and 3 to 5 parts of bonder. A preparation method for the granular quinocetone premix comprises the following steps of: uniformly mixing the components and a wetting agent through a mixing machine, then pelletizing by a squeezing granulator, shot blasting by a spherical shot blasting machine, sieving and drying to obtain the granular quinocetone premix with granularity of 20 to 80 meshes. The quinocetone premix is uniform in granules, mellow and full in appearance, accordant in color and luster, good in fluidity and stable in product quality and can be mixed with feed uniformly as well as has better effects on diarrhea prevention and growth promotion of beasts and birds; the preparation method for the granular quinocetone premix has the advantages of high granulation rate, environment-friendliness, dust free and capability of effectively avoiding cross infections.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

Quick granule producing machine

InactiveCN1457975AQuality improvementEasy to cleanGranulation by material expressionShaping pressEngineeringSmall hole

The quick granule producing machine features its speed reducing mechanism with planetary hard cog surface spiral gear. The granule producing machine has solid shaft and hollow shaft rotating relatively via gear. There are main shaft flange on the hollow shaft, and cylindrical screen with stirring paddle and pores for medicine to pass through in the bottom. The solid shaft penetrates through the hollow shaft and cylindrical screen bottom, and on the solid shaft there are granule producing knifes mounted. In the bottom of the cylindrical screen, there are transport channel with cutting knifes mounted near the outer wall of the cylindrical screen. The granule producing machine has high granule producing efficiency and no pollution to medicine.

Owner:吴光明

Grape destemer

ActiveCN106108074AImprove the whole grain rateLess stemsFood treatmentDried fruitsAgricultural engineering

A grape destemer is composed of a rack, a motor, a gearbox, a transmission device and a screen basket. The motor, the gearbox and the transmission device are fixedly mounted on the rack, and the screen basket is hoisted in the rack. The motor is in transmission connection with the input end of the gearbox, the output end of the gearbox is in transmission connection with the transmission device, and a rocker arm of the transmission device is in transmission connection with the screen basket. A feed port is formed in the upper portion of the rack and located over the right end of the screen basket. A discharge port is formed in the bottom of the rack and located under the screen basket; a stem discharge opening is formed in the side of the rack and rightly faces the leftmost side of the screen basket. The grape destemer has the advantages that picked grape grains are high in complete grain rate, few fruit stems are brought out, and mixing of green fruits and dry fruits is avoided reasonably and effectively; the equipment technology of the grain stem removing process in the wine making process is remarkably improved, the production quality of wine is improved, the raw material use rate of the wine is increased, and the production equipment investment cost is reduced.

Owner:宁夏圆润葡萄酒有限公司

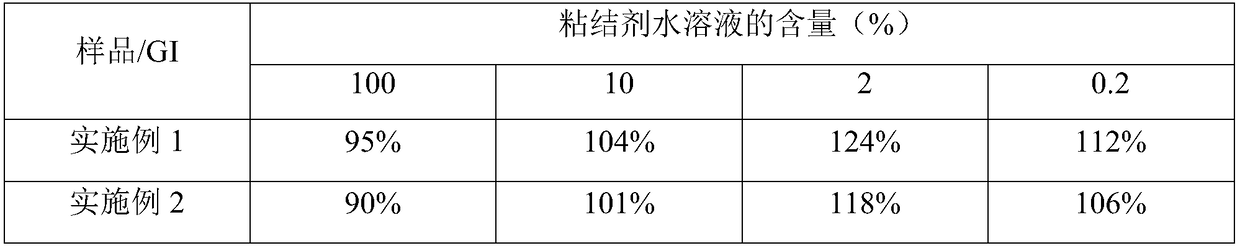

Functional sustained or controlled release fertilizer core based on bio-based adhesive and preparation method thereof

ActiveCN108516899AReduce dependencePromote degradationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCross-linkControl release

The invention discloses a functional sustained or controlled release fertilizer core based on a bio-based adhesive and a preparation method thereof. The bio-based adhesive is prepared through the steps that a biomass material is subjected to a liquidation reaction, bio-based polyalcohol is prepared, and the bio-based polyalcohol, a chain extender, a cross-linking agent and a curing agent are pre-mixed. The bio-based adhesive is prepared from regenerative biomass resources, dependence on petrification-based raw materials is reduced, good degradability is achieved, and meanwhile the bio-based adhesive is high in adhesive performance, good in heat resistance, high in water resistance, easy to spray and easy to dry. The functional sustained or controlled release fertilizer core prepared basedon the bio-based adhesive is high in granulation rate, large in particle strength, excellent in moisture absorption resistance, high in impact resistance, good in roundness, good in storage and transport performance and especially suitable for a coated sustained or controlled release fertilizer production process, the material fluidifying performance can be improved, the specific area of the fertilizer core is reduced, and the coating cost of controlled-release fertilizer is greatly reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for producing fertilizer through dilute molasses alcohol wastewater

A method for producing fertilizer through dilute molasses alcohol wastewater is characterized in that an alcohol wastewater spraying device is arranged above a raw material conveying belt in a fertilizer production line and sprays alcohol wastewater discharged at the tail end of the molasses alcohol distilling process on various fertilizer raw materials on the raw material conveying belt, the molasses alcohol wastewater and the various fertilizer raw materials enter a granulation device after being mixed, or molasses alcohol is sprayed on the molasses alcohol wastewater and the various fertilizer raw materials again on the granulation device, the molasses alcohol wastewater and the various fertilizer raw materials are bonded with short fibers in organic raw materials so that the diameter of particles can be increased in the rolling process of the granulation device, and then fertilizer granulation is achieved. By means of the method, dilute molasses alcohol fermentation liquor can be utilized cleanly without concentrating the molasses alcohol fermentation liquor in advance, and concentration equipment and energy are saved.

Owner:广西田东力源宝科技有限公司

Stevia organic compound fertilizer

InactiveCN104692895AHigh granulation rateImprove performanceFertilizer mixturesPhosphateMonopotassium phosphate

The invention relates to the fertilizer technical field, and in particular relates to a stevia organic compound fertilizer comprising the following raw materials by weight: 50-60 parts of stevia root stem and rod, 5-7 parts of clay, 10-20 parts of urea, 10-20 parts of ammonium hydrogen phosphate, 6-8 parts of potassium sulfate, 3-5 parts of potassium dihydrogen phosphate, 8-10 parts of polymer water absorbent resin and 20-30 parts of a biological organic fertilizer. The stevia organic compound fertilizer is green, pollution-free, non-toxic, harmless, free of any side effects, anti-drought, water holding, fertilizer maintaining, seedling maintaining, and capable of improving soil, prevents soil hardening, adjusts soil pH value to neutral, do not pollutes the environment, can effectively inhibit the occurrence and spread of root knot nematode, suppresses soil borne diseases, and can improve the quality of crops.

Owner:烟台鑫海耐磨胶业有限公司

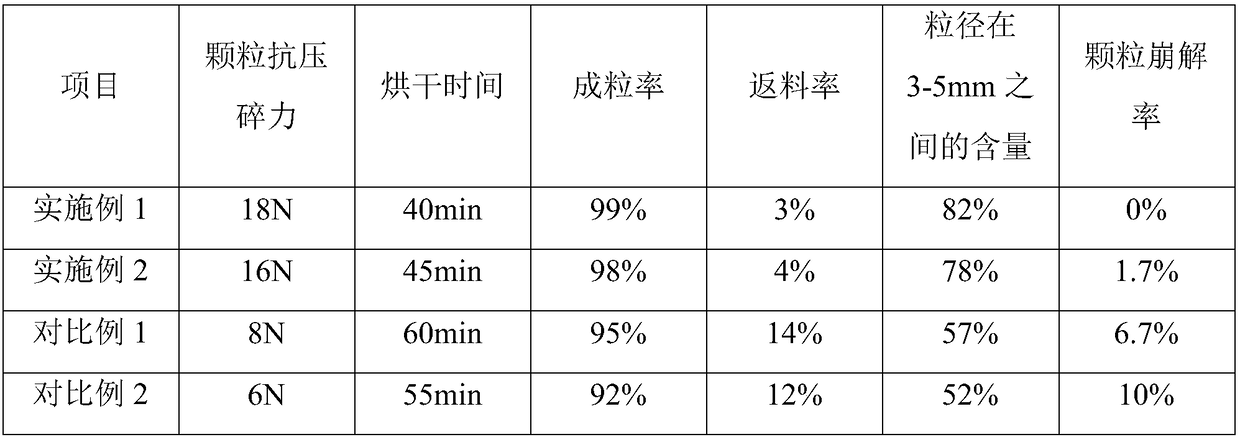

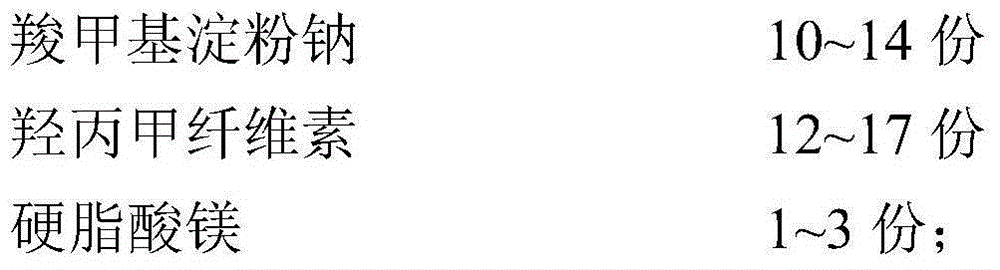

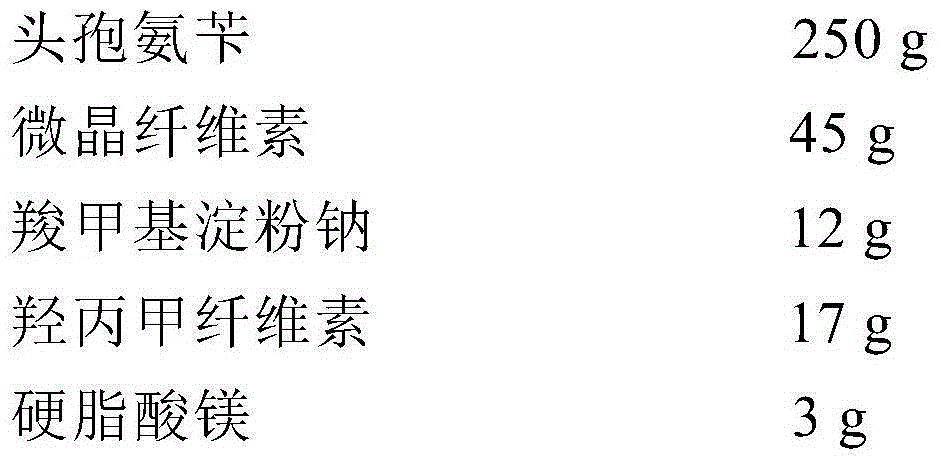

Cefalexin tablet and preparation method thereof

ActiveCN105106166AStable in natureEasy molding processAntibacterial agentsOrganic active ingredientsCefalexinReference product

The invention discloses a cefalexin tablet and a preparation method thereof. A dry granulating process is adopted, and not only is the degradation of beta-lactam rings achieved, but also the problem of low dissolution of products produced through conventional wet granulation is solved. The product is high in stability, a dissolution curve is similar to that of a reference product, and a production process is simple.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com