Patents

Literature

45results about How to "Easy molding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polrvinyl chloride (PVC) tube composition for medicine and preparation method thereof

InactiveCN101955616AImprove thermal stabilityImprove mechanical propertiesCatheterPolyvinyl chlorideBiocompatibility Testing

The invention discloses a polrvinyl chloride (PVC) tube composition for medicine and a preparation method thereof. The composition comprises the following components in parts by weight: 80 to 100 parts of PVC paste resin, 25 to 40 parts of plasticizer, 5 to 40 parts of room-temperature ionic liquid, 5 to 10 parts of CaCO3, 2 to 5 parts of Ca / Zn stabilizer and 0.5 to 2 parts of diluent. The preparation method comprises the following steps: stirring the 80 to 100 parts of the PVC paste resin, 25 to 40 parts of the plasticizer, 5 to 40 parts of the room-temperature ionic liquid and 0.5 to 2 parts of the diluent at the temperature of 40 to 80 DEG C for 5 to 25min; and cooling the mixture to the normal temperature, adding 5 to 10 parts of the CaCO3 and 2 to 5 parts of the Ca / Zn stabilizer to the mixture and continuing stirring for 5 to 10min to obtain the PVC tube composition for medicine. The raw materials of the synthesized medical tube of the invention have high thermal stability, mechanical property, durability, biocompatibility and the like and are suitable for producing various medical catheters and easy to process and mould.

Owner:NINGBO UNIV

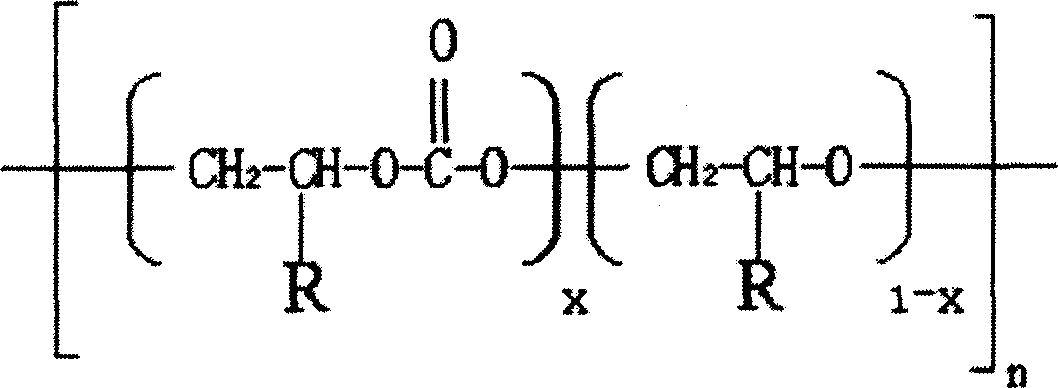

Poly-sebacic acid glycerine ester biodegradable shape memory polymers and preparation method

InactiveCN101508766ALarge deformationHigh deformation recovery rateBiocompatibility TestingConnective tissue

The invention relates to a poly sebacic-co-propanetriol ester biodegradable shape memory polymer and a preparation method thereof. The invention relates to a biodegradable shape memory polymer and the preparation method thereof. A product of the invention is formed by the copolymerization and the cross linking of sebacic acid and propanetriol. The method is as follows: a. a preformed polymer is prepared; and b. the product is obtained by moulding, cross linking and solidifying. The product has the advantages of large deformation, the high restoration ratio of deformation and good biocompatibility. The shape restoration temperature is 0 DEG C to 45 DEG C; the tensile strength is 0.5-10MPa; and the degradation time is 30 to 300 days. The poly sebacic-co-propanetriol ester biodegradable shape memory polymer can be used as material for repairing human body soft tissue injury, such as cornea, retina, skin, blood vessel, connective tissue, islet tissue, musculature, nervous tissue, etc. The method has simple technology and convenient operation.

Owner:HARBIN INST OF TECH

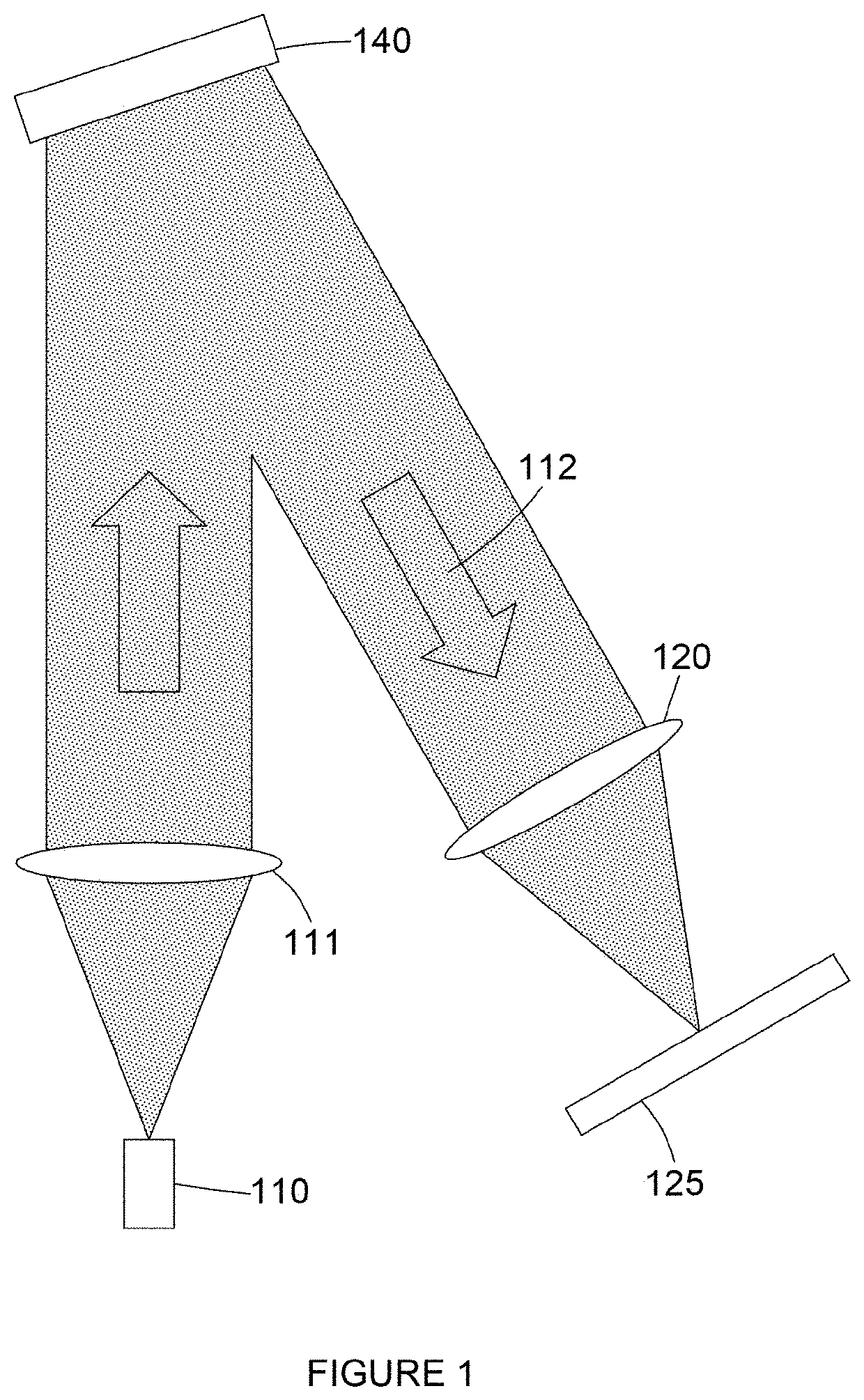

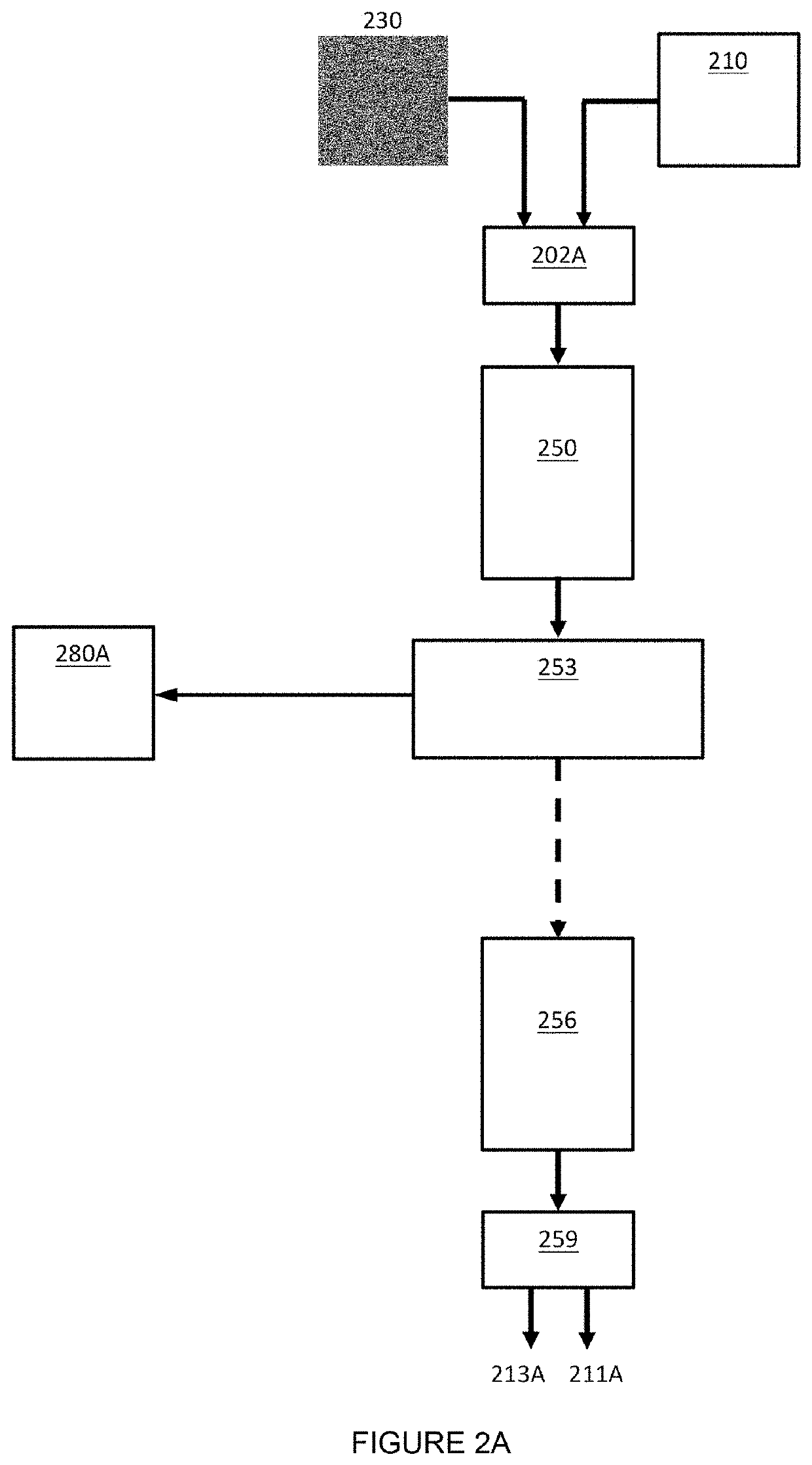

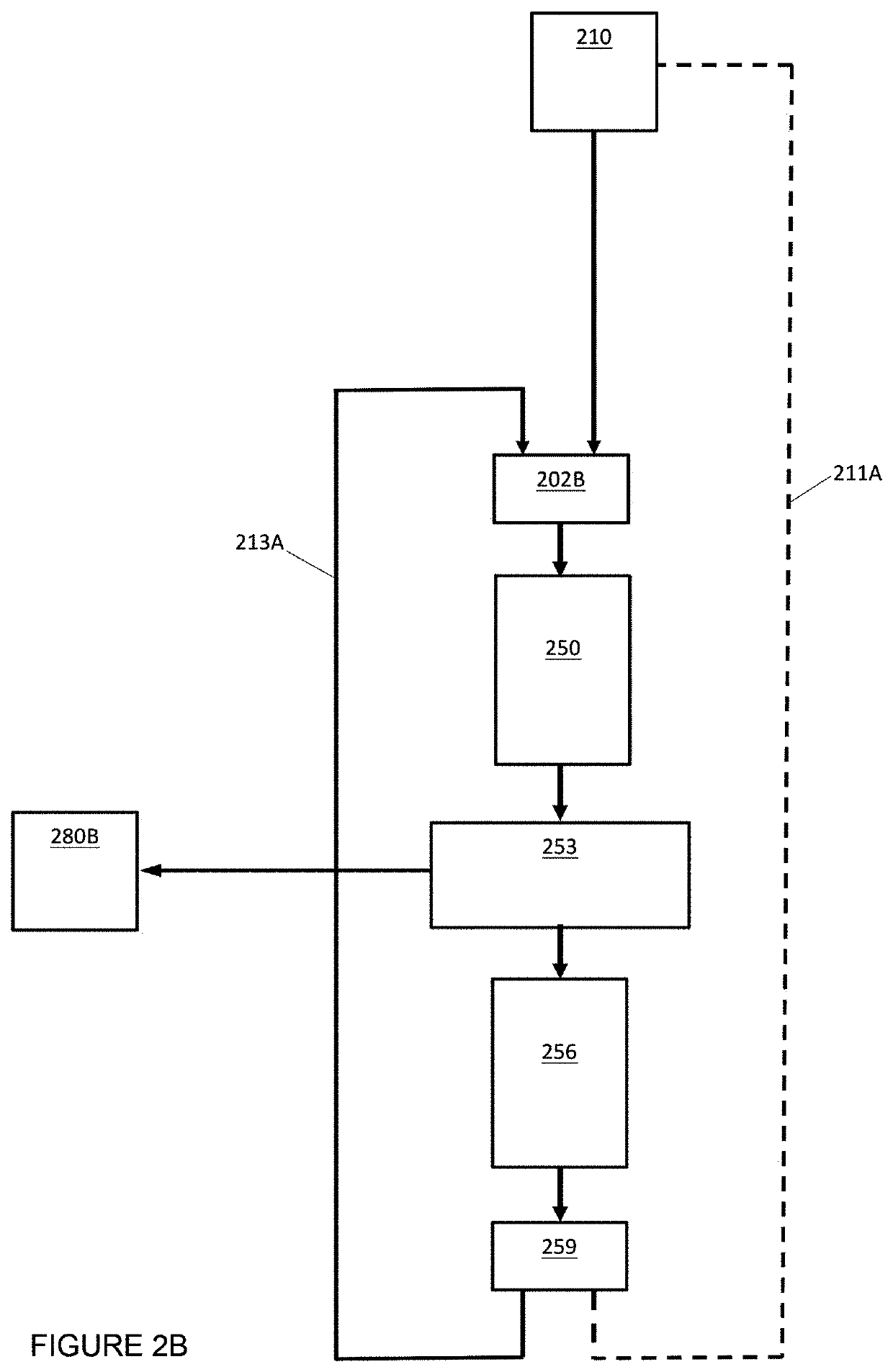

Head-Up Display

ActiveUS20200103670A1Improve image qualityReduce risk of damageOptical filtersProjectorsHead-up displayOptical power

The disclosure provides in one aspect a head-up display for a vehicle. The head-up display comprises a picture generating unit, an optical system and a light-selective filter. The picture generating unit is arranged to display a picture on a screen. The optical system is arranged to receive light of the picture. The optical system comprises at least one optical element having optical power arranged to form a magnified image of the picture. The light-selective filter is transmissive to light of the picture and reflective to other light. The light-selective filter is disposed between the optical system and the screen. The light-selective filter has a first surface arranged to receive light from the optical system and a second surface arranged to receive light of the picture from the screen.

Owner:ENVISICS LTD

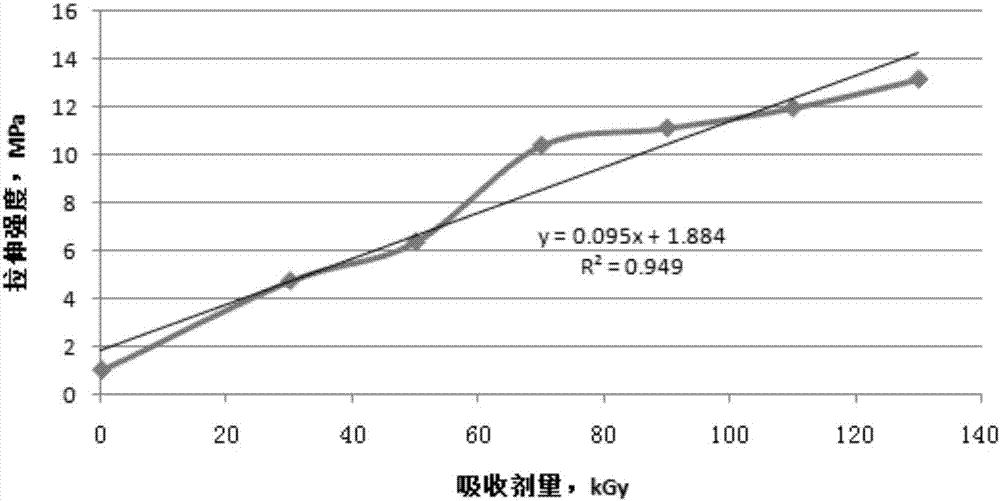

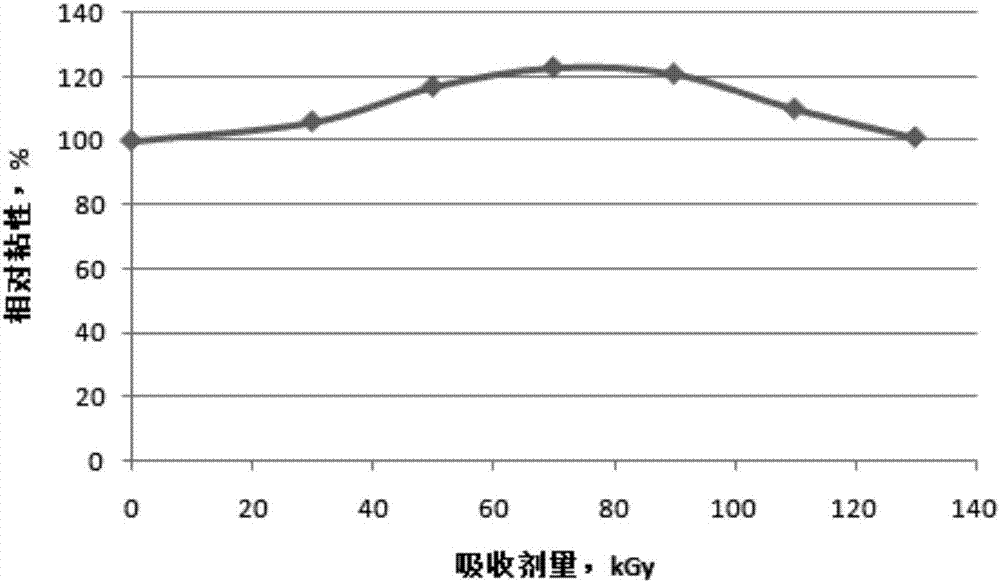

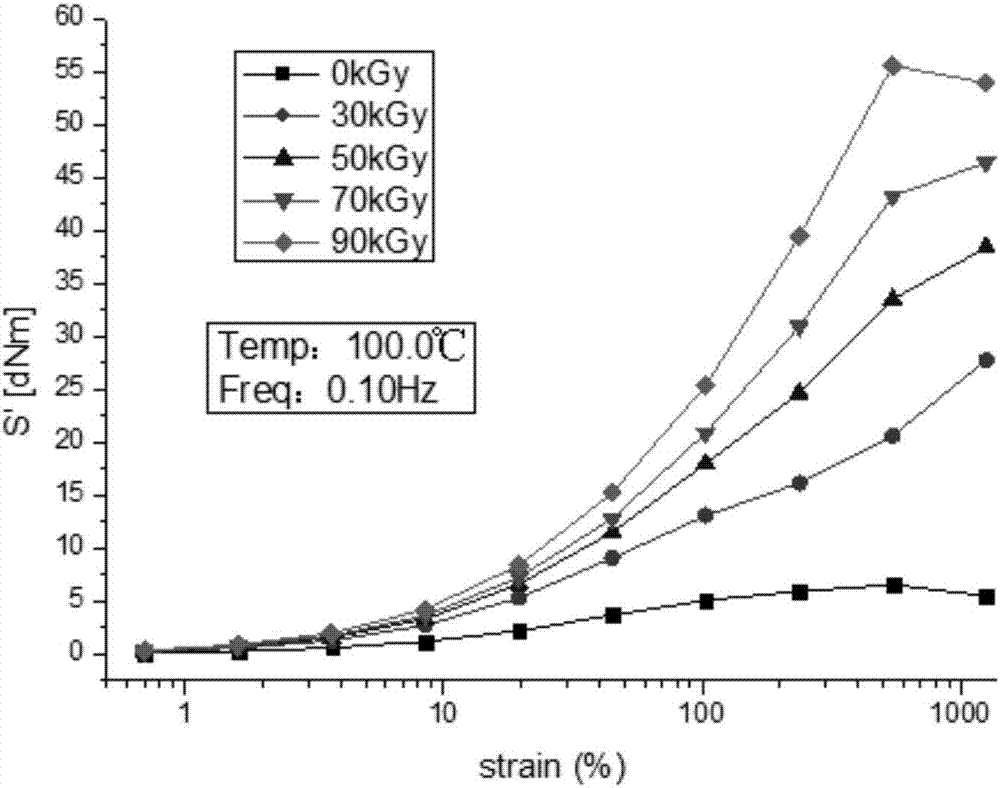

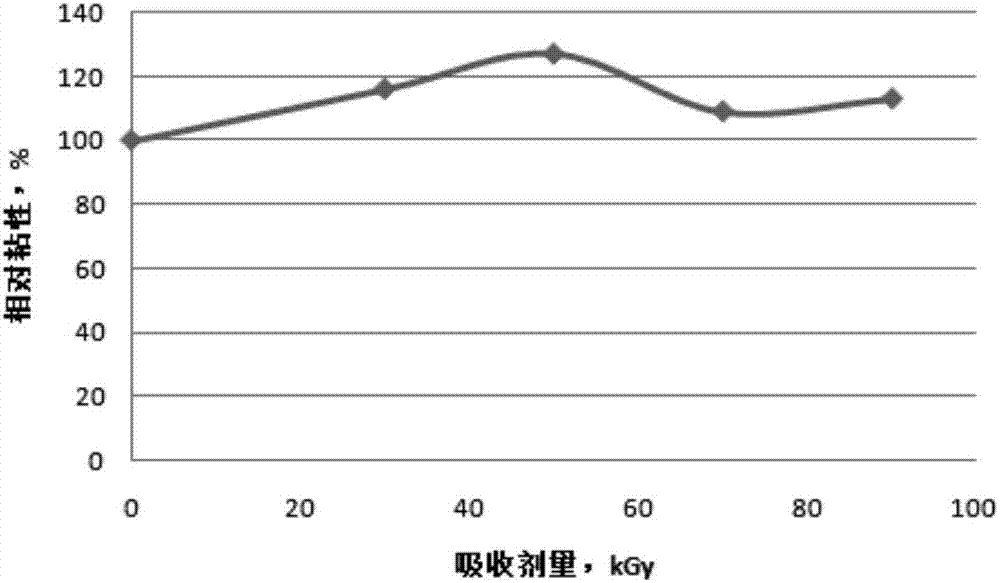

Self-adhered type anti-neutron composite shielding material as well as preparation method and application thereof

ActiveCN107082965AControl the degree of pre-crosslinkingImprove shielding effectShieldingFlat articlesVulcanizationActive agent

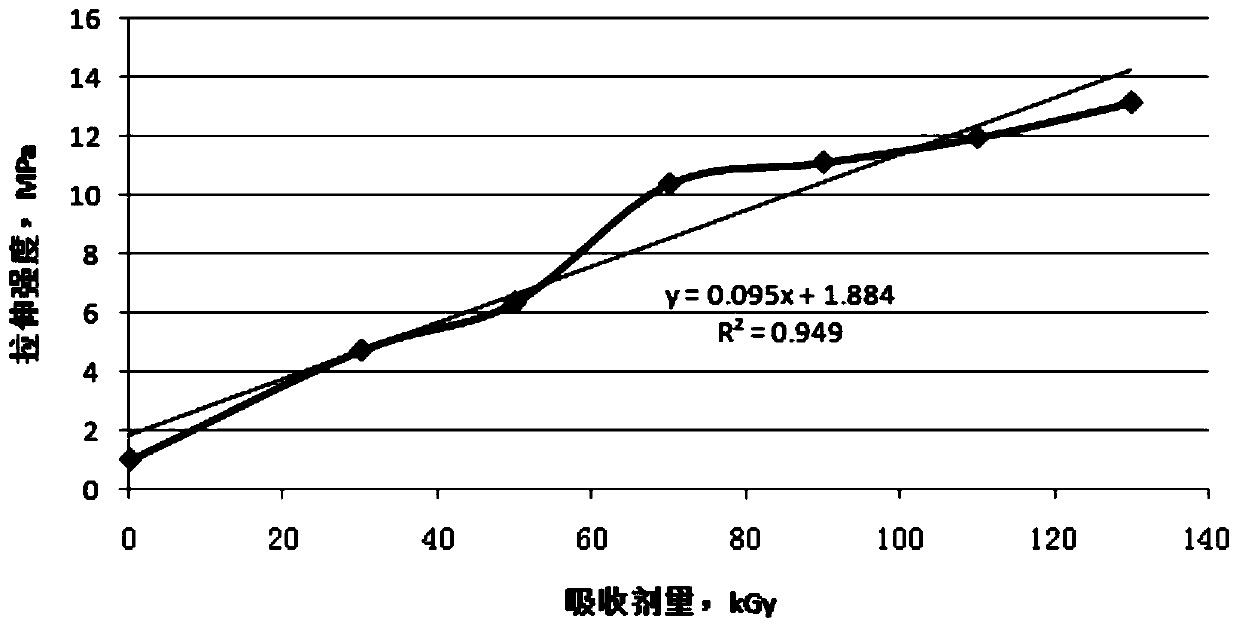

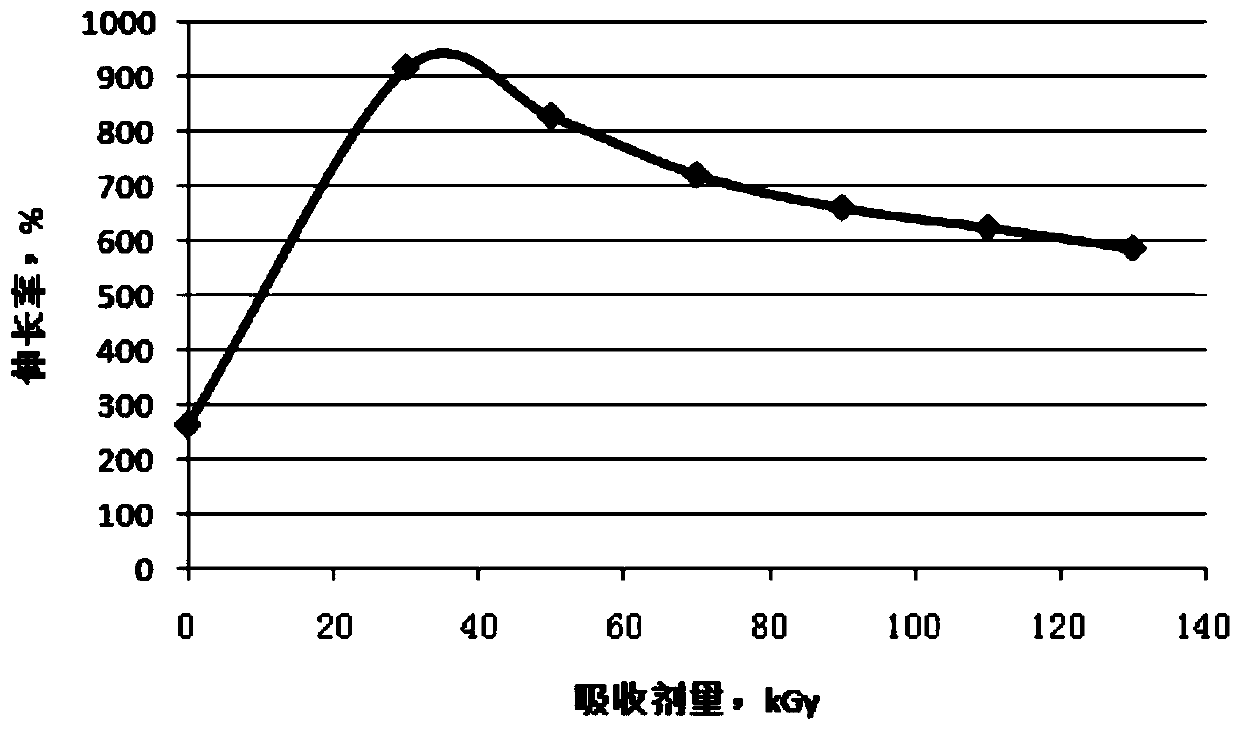

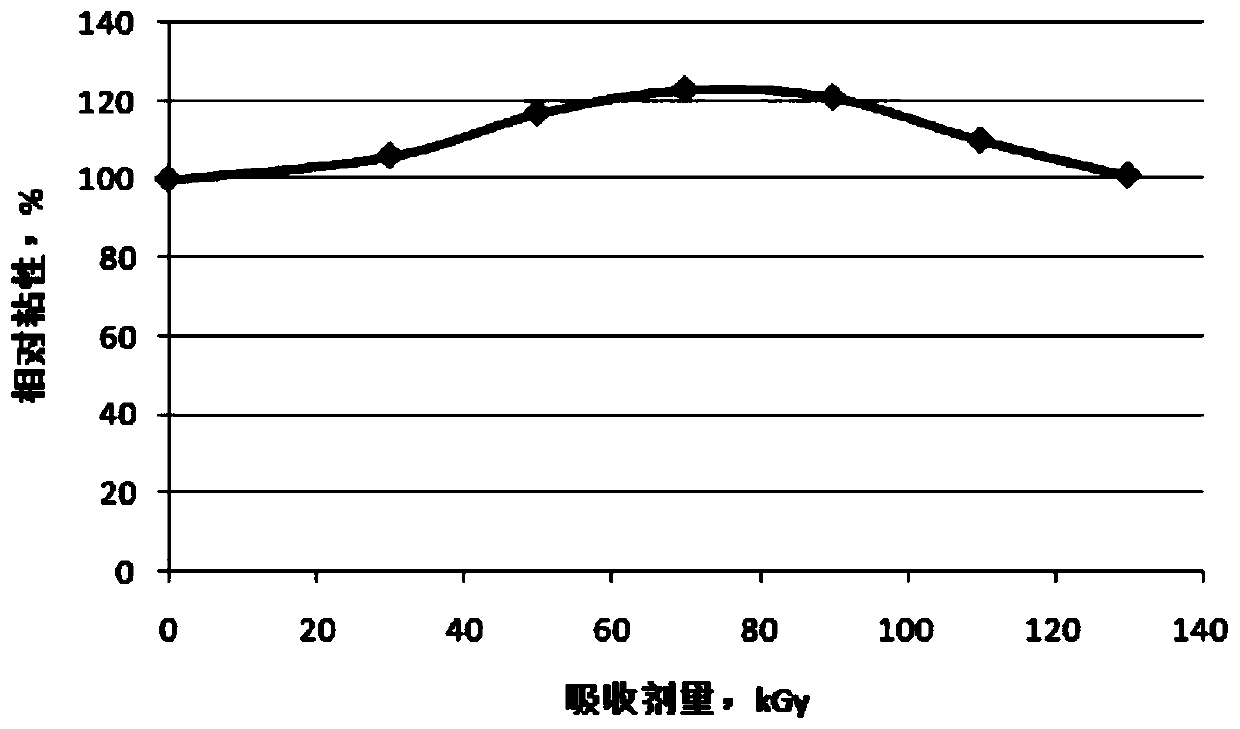

The invention provides a self-adhered type anti-neutron composite shielding material as well as a preparation method and application thereof. The shielding material is prepared from the following raw materials in parts by weight through radiation pre-crosslinking treatment: 100 parts of a rubber susbtrate, 5-50 parts of a tackifying agent polymer, 10-100 parts of a reinforcing agent, 20-200 parts of an anti-neutron additive, 0-50 parts of a softening agent, 0.5-10 parts of a vulcanizing agent, 0.5-5.0 parts of a vulcanization promoter, 0.5-10 parts of a vulcanization activator and 0-5.0 parts of an anti-aging agent. The invention further provides a preparation method of the shielding material and application of the shielding material in complex equipment or irregular parts. The self-adhered type anti-neutron composite shielding material provided by the invention has certain initial crosslinking degrees and self adhesion properties, is good in shape flow property, can be cured by self after being shaped, and has appropriate mechanical strength.

Owner:BEIJING RADIATION APPL RES CENT

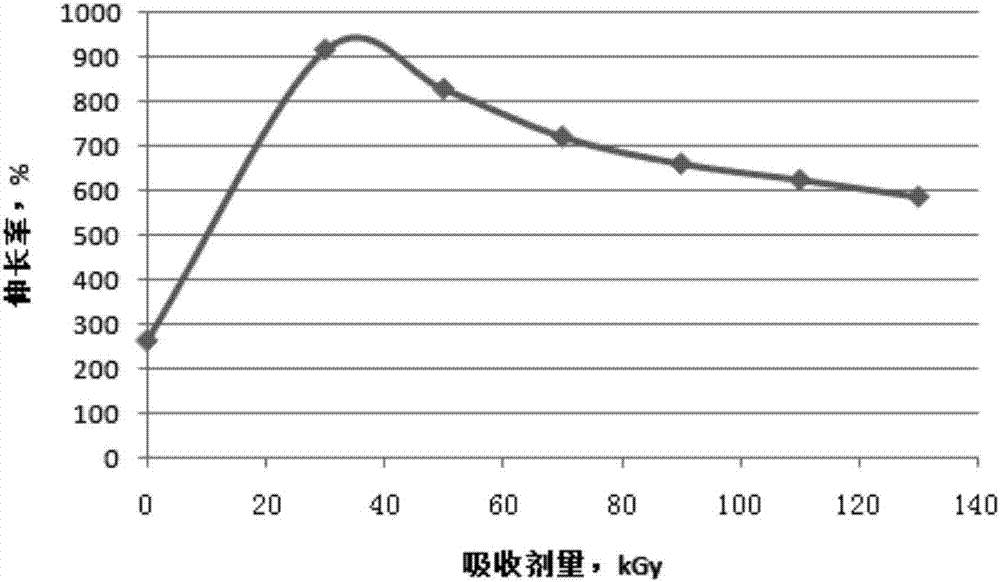

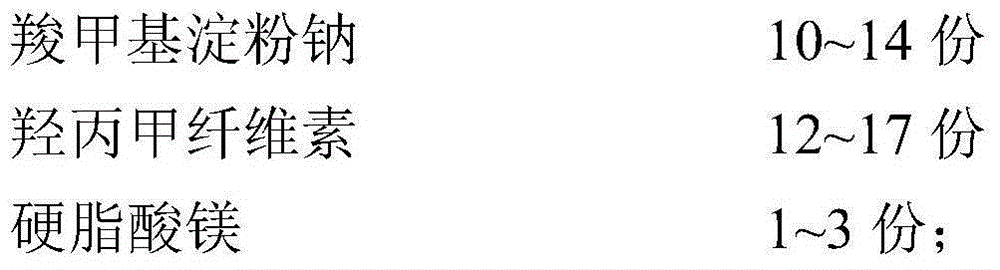

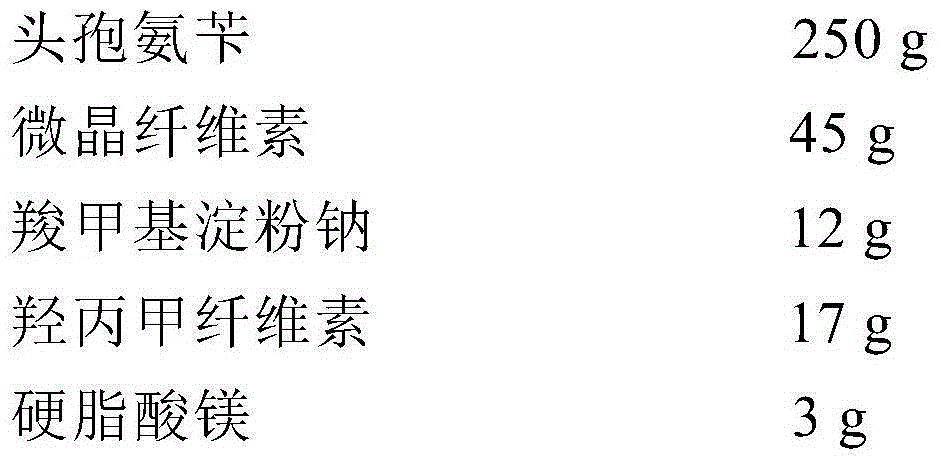

Cefalexin tablet and preparation method thereof

ActiveCN105106166AStable in natureEasy molding processAntibacterial agentsOrganic active ingredientsCefalexinReference product

The invention discloses a cefalexin tablet and a preparation method thereof. A dry granulating process is adopted, and not only is the degradation of beta-lactam rings achieved, but also the problem of low dissolution of products produced through conventional wet granulation is solved. The product is high in stability, a dissolution curve is similar to that of a reference product, and a production process is simple.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

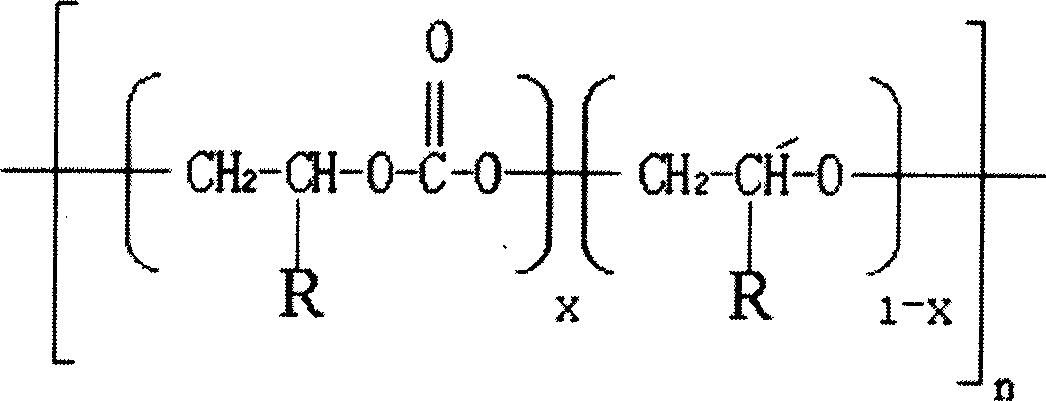

Polyester type biodegradable shape memory polymeric compounds and methods of formulating same

InactiveCN101508772ALarge deformationHigh deformation recovery ratePolyesterBiocompatibility Testing

The invention relates to a polyester type biodegradable shape memory polymer and a preparation method thereof. The product is essentially formed by the copolymerization and the cross linking of sebacic acid, propanetriol and diol. The method is as follows: a. the sebacic acid and the diol are copolymerized, and the propanetriol is added for copolymerizing; and b. the product is obtained by moulding, cross linking and solidifying. The product has the advantages of large deformation, the high restoration ratio of deformation and good biocompatibility. The shape restoration temperature is 0 DEG C to 45 DEG C; the tensile strength is 0.5-10MPa; and the degradation time is 30 to 300 days. The polyester type biodegradable shape memory polymer can be used as material for repairing human body soft tissue injury, such as cornea, retina, skin, blood vessel, connective tissue, islet tissue, musculature, nervous tissue, etc. The method has simple technology and convenient operation.

Owner:HARBIN INST OF TECH

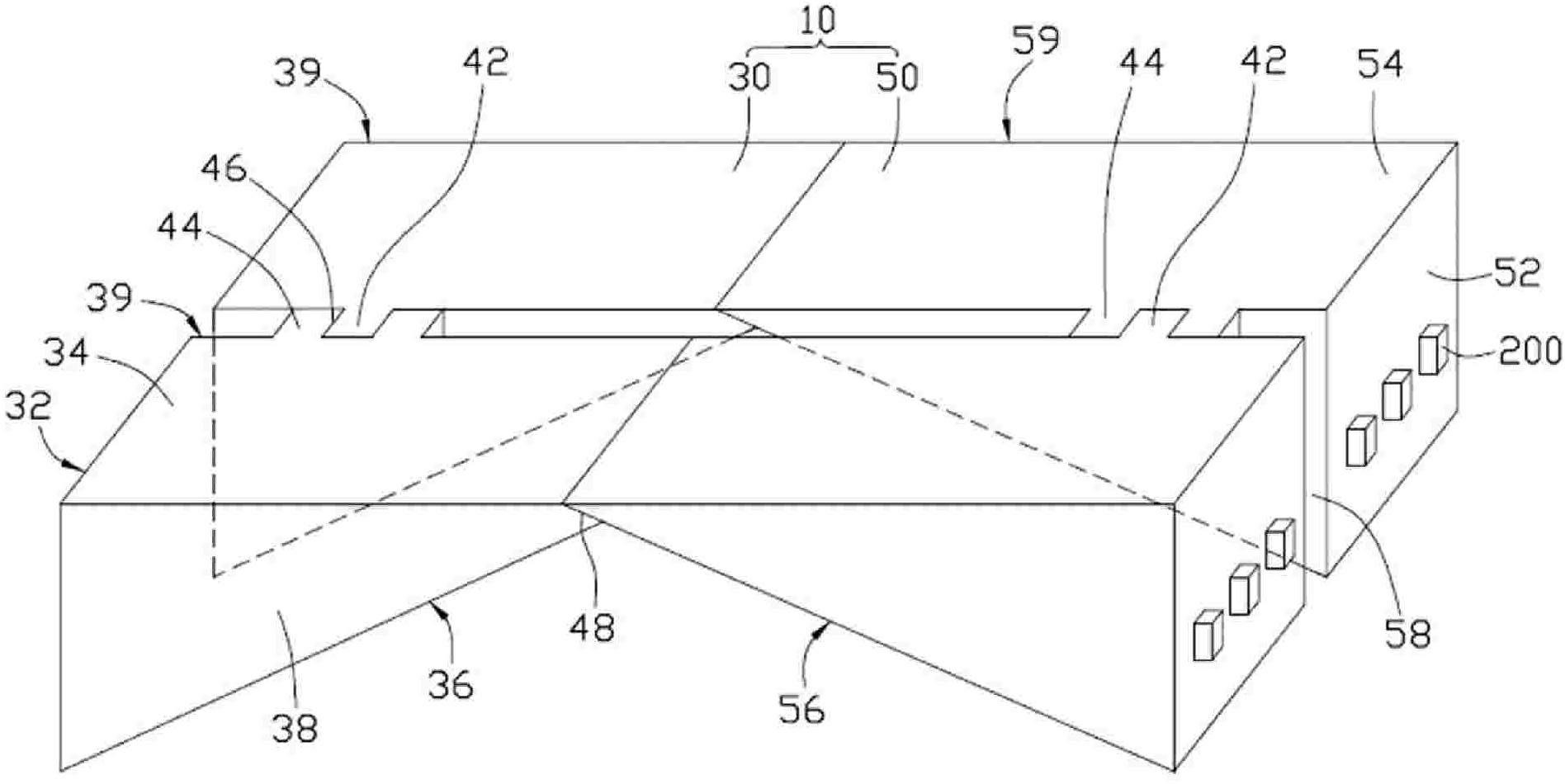

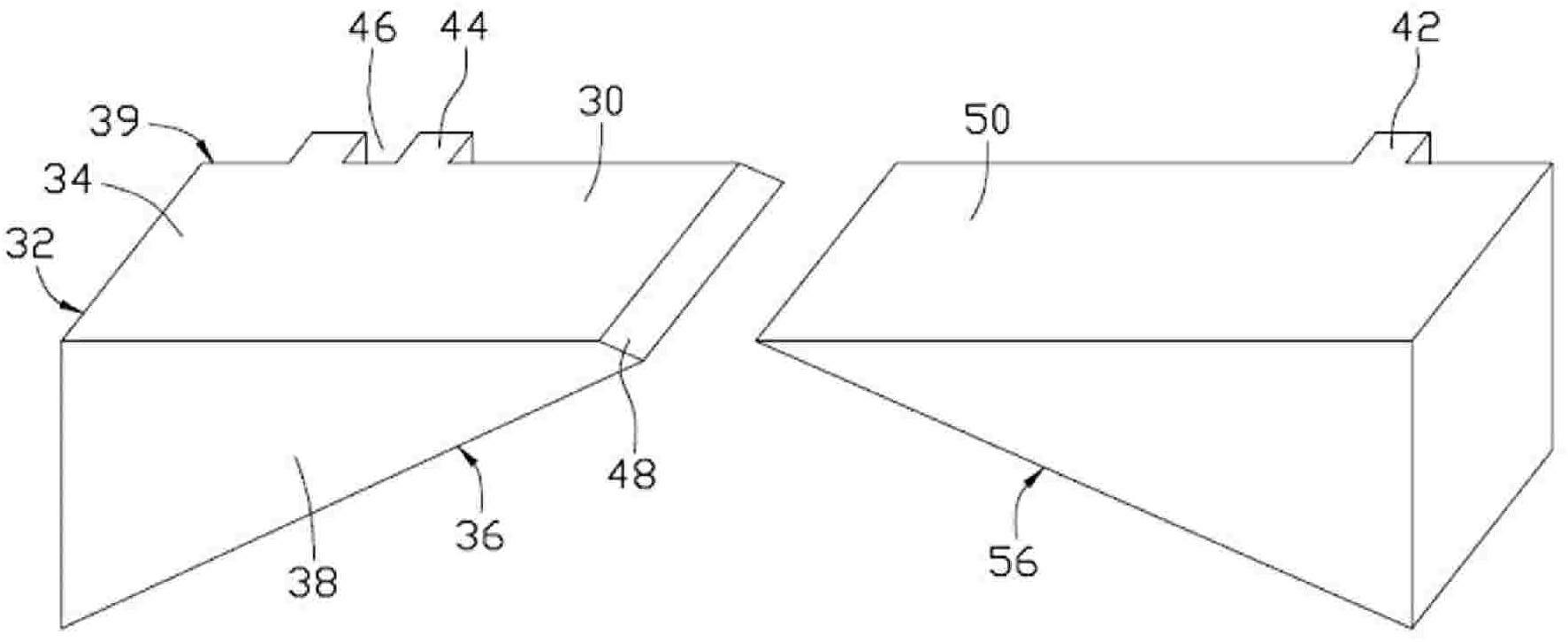

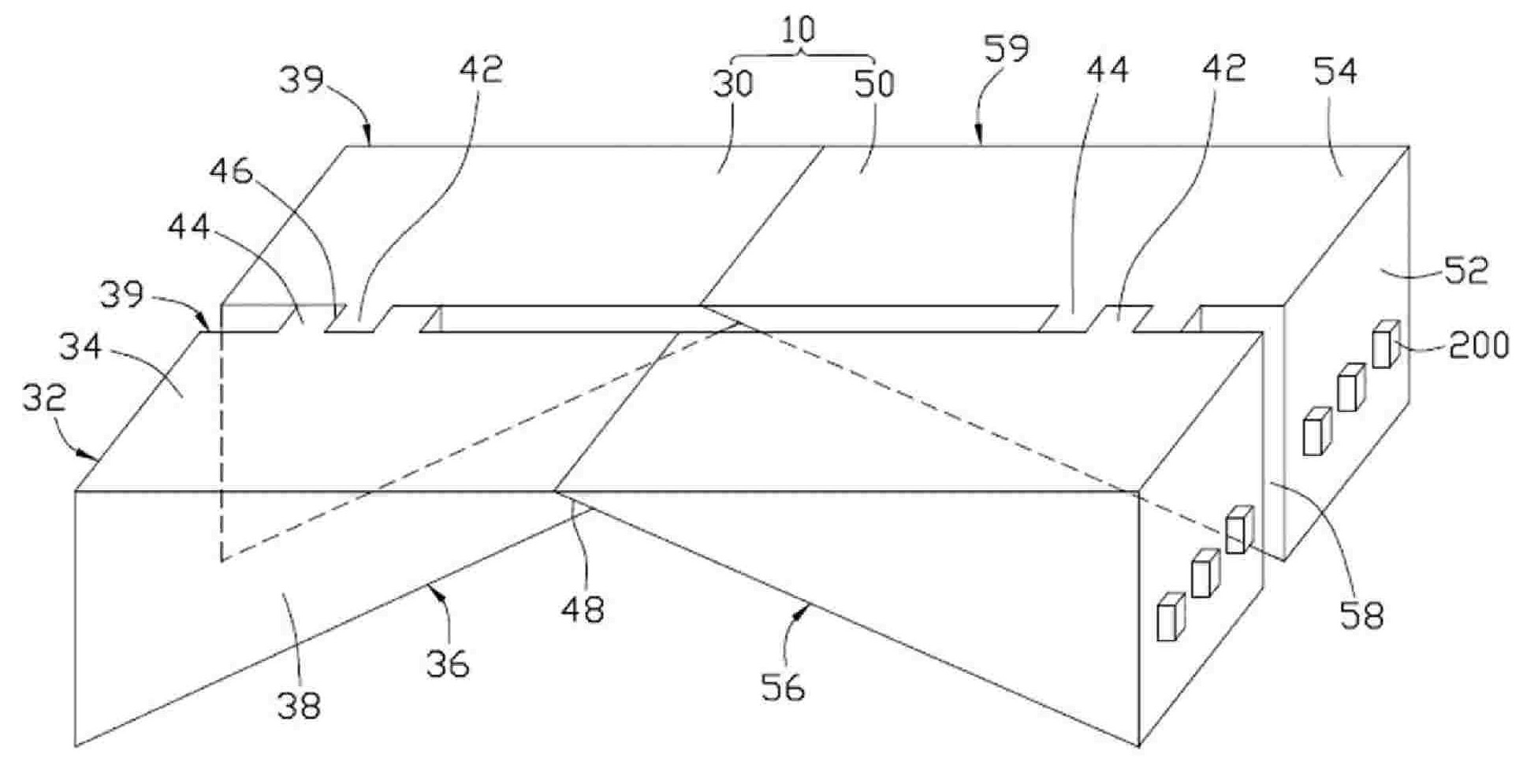

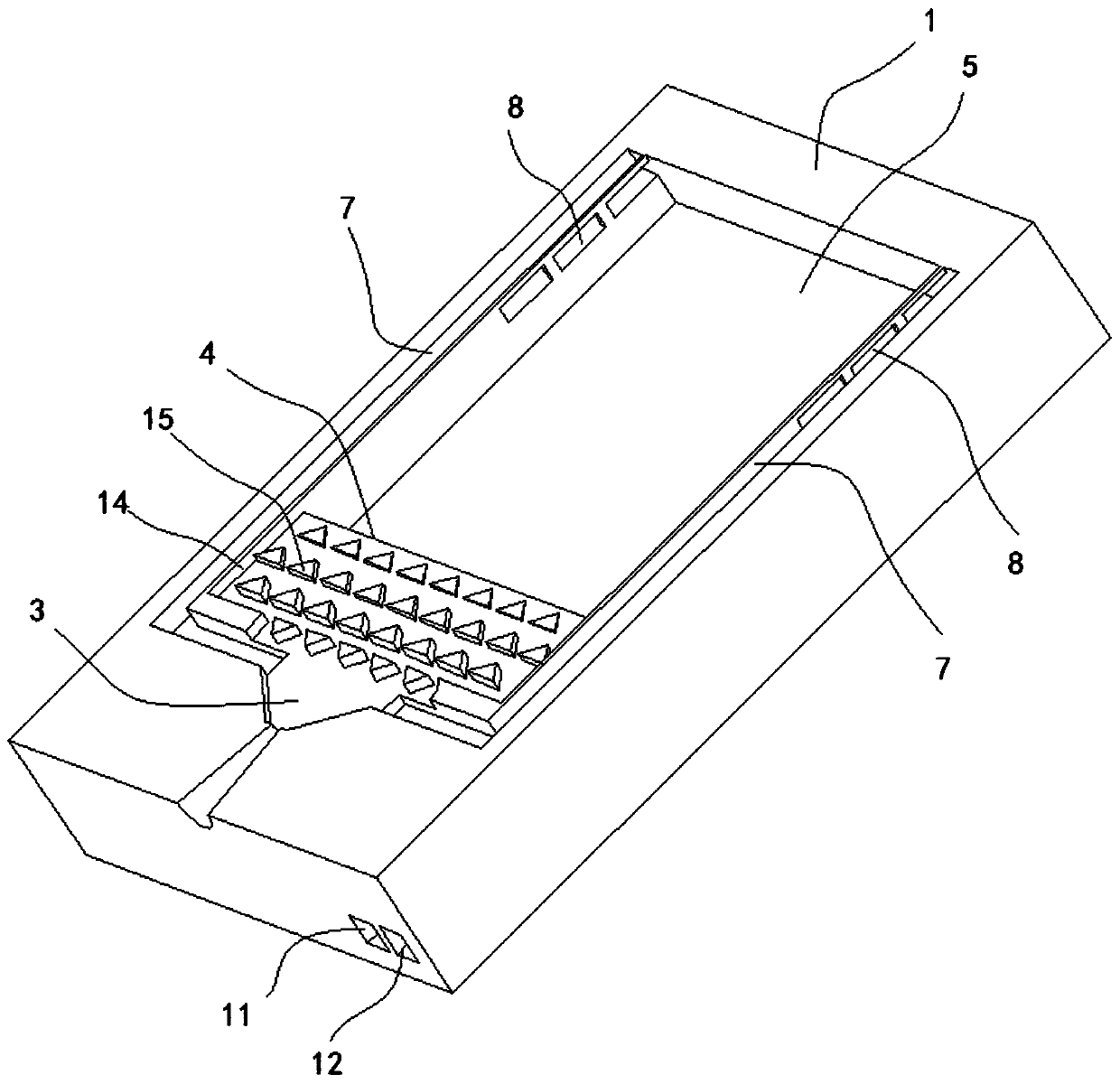

Backlight module and light guide plate thereof

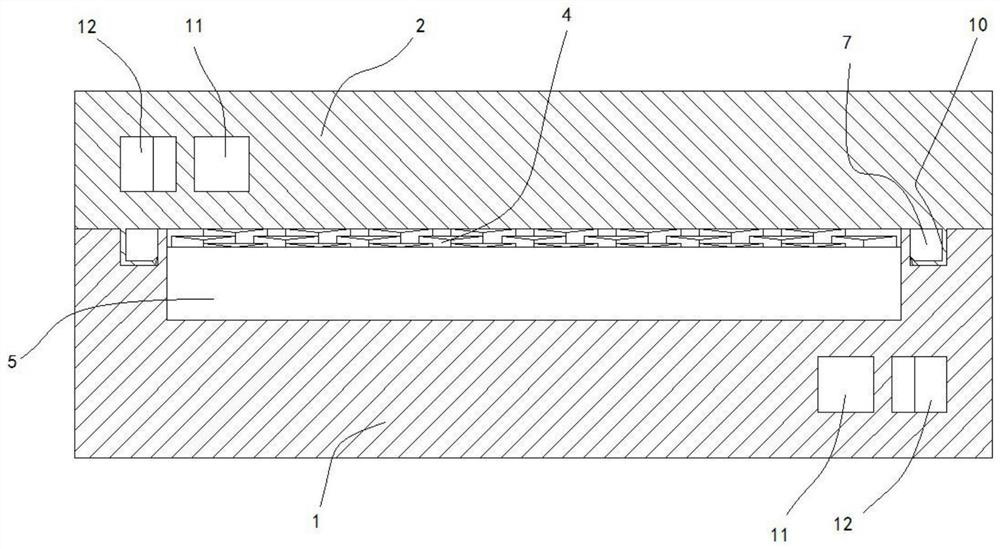

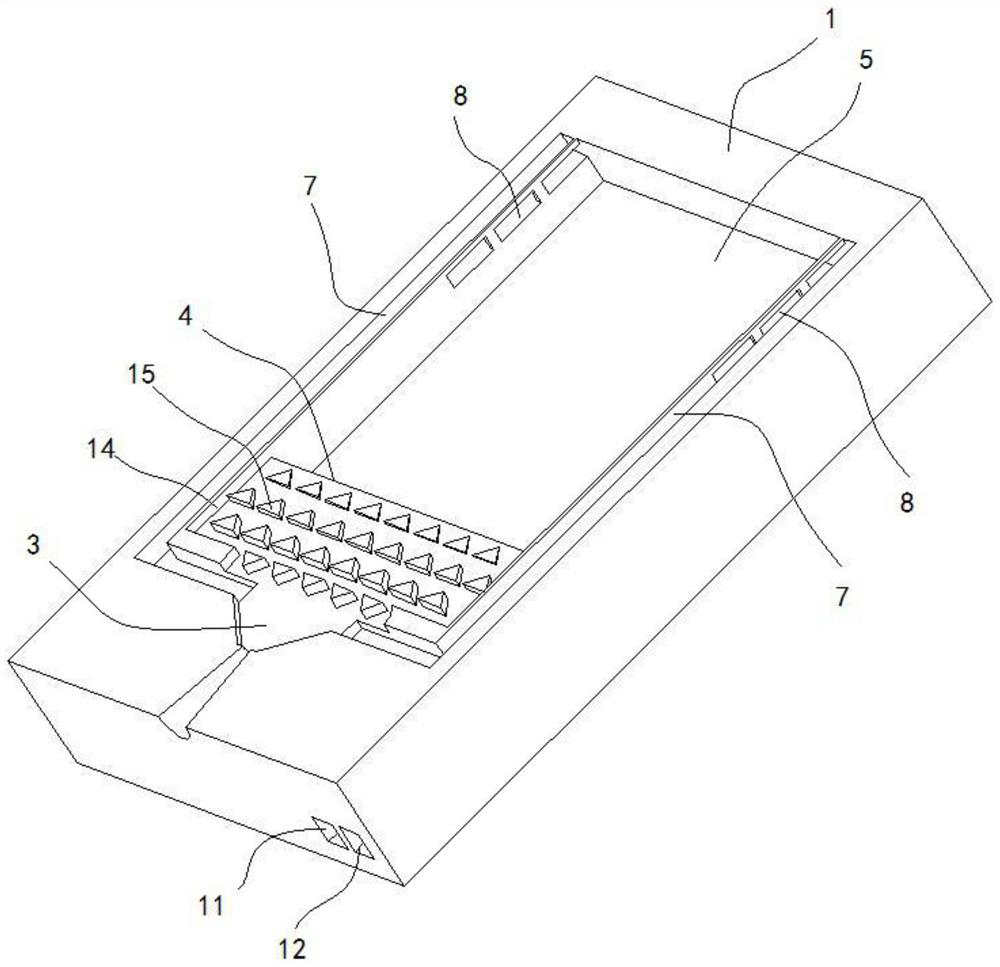

InactiveCN102095168AImprove uniformityEasy molding processMechanical apparatusLighting device detailsStress distributionLight guide

The invention relates to a backlight module which comprises a light source and a light guide plate, wherein the light guide plate comprises a first wedge-shaped block and a second wedge-shaped block which are opposite; the first wedge-shaped block and the second wedge-shaped block respectively comprise an incident surface as well as an emergent surface and a reflecting surface which respectively extend out of two opposite sides of the incident surface; the reflecting surface and the emergent surface of the second wedge-shaped block are intersected; the first wedge-shaped block also comprises a combined surface which is formed between the reflecting surface and the emergent surface of the first wedge-shaped block; the combined surface is inclined relative to the emergent surface of the first wedge-shaped block and connected with the reflecting surface of the second wedge-shaped block; and the light source is opposite to the incident surfaces of the first wedge-shaped block and the second wedge-shaped block. Because each light guide plate is formed by combining a plurality of wedge-shaped blocks with smaller size, the design and moulding are easier, and the cost is lower; in addition, because the sizes of the wedge-shaped blocks are smaller, and the stress distribution of the wedge-shaped blocks are uniform, bending deformation can be prevented, and the light guide uniformity is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Self-adhesion gamma-ray rubber composited shielding material and preparation method and application thereof

ActiveCN107033472AControl the degree of pre-crosslinkingWith degreeShieldingFlat articlesVulcanizationAgricultural engineering

The invention provides a self-adhesion gamma-ray rubber composited shielding material and a preparation method and application thereof. The shielding material is prepared from, by weight, 100 parts of rubber base material, 5-50 parts of tackifying polymer, 10-100 parts of reinforcing agent, 10-200 parts of anti-gamma function assistant, 0-50 parts of softener, 0.5-10 parts of vulcanizing agent, 0.5-5.0 parts of vulcanization accelerator, 0.5-10 parts of vulcanizing activator and 0-5.0 parts of anti-aging agent. The invention also provides a preparation method of the shielding material and application of the shielding material in complex equipment or irregular parts. The prepared gamma-ray rubber composited shielding material has a certain degree of initial crosslinking and self-adhesion, has good shape-following property and can be self-curing after forming.

Owner:BEIJING RADIATION APPL RES CENT

PVC foaming plate extrusion die

The invention discloses a PVC foaming plate extrusion die, and relates to the technical field of foaming plate extrusion dies. The PVC foaming plate extrusion die comprises a lower die plate and an upper die plate matched with the lower die plate, a flow-division buffer zone, a flow equalization zone and a forming die groove are arranged at the upper surface of the lower die plate in a mode of sequentially communicating with a feeding port, wherein the flow-division buffer zone comprises a buffer groove, a pair of L-shaped guide grooves communicating with the buffer groove are symmetrically formed at the positions, located on the two sides of the buffer groove, of the upper surface of the lower die plate, rectangular flow guide holes are linearly arranged on the opposite side surfaces of the pair of L-shaped guide grooves and at the ends, away from the flow-division buffer zone, of the pair of L-shaped guide grooves, a T-shaped flow guide groove communicating with the feeding port is formed in the lower surface of the upper die plate, the T-shaped flow guide groove communicates with the buffer groove and the pair of L-shaped guide grooves correspondingly, and a pair of L-shaped connection guide grooves are symmetrically fixed on the lower surface of the upper die plate. According to the PVC foaming plate extrusion die, through the lower die plate and the upper die plate which are designed, a foaming material enters the forming die groove in three directions, a PVC foaming plate is easier to form rapidly, so that the problem that the efficiency is low when an existing die isused for forming the PVC foaming plate is solved.

Owner:合肥帝品数码科技有限公司

Degradation type composite material

The invention discloses a decomposable composite material, which comprises the following parts: carbon dioxide polymer, 10-30% polysuccinic polybutanediol ester (PBS), 0-10% plasticizer and 1-5% capping agent.

Owner:吉林金源北方科技发展有限公司

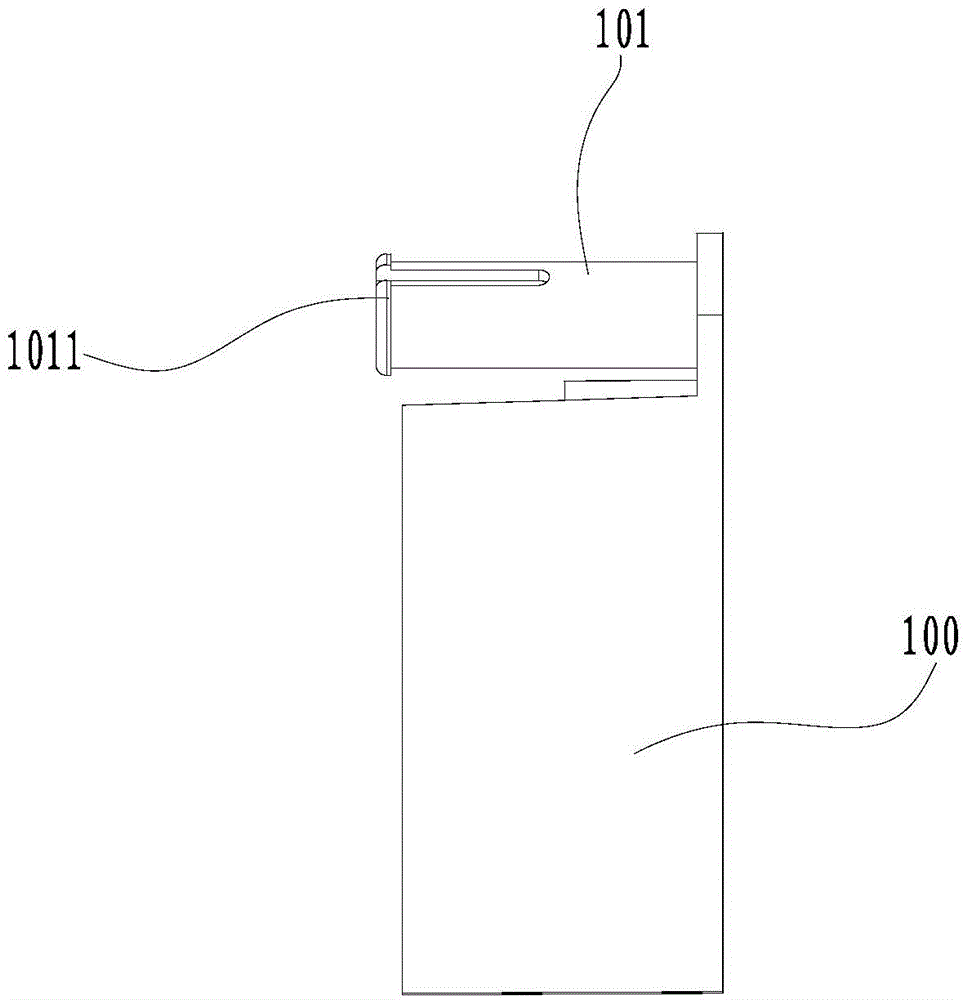

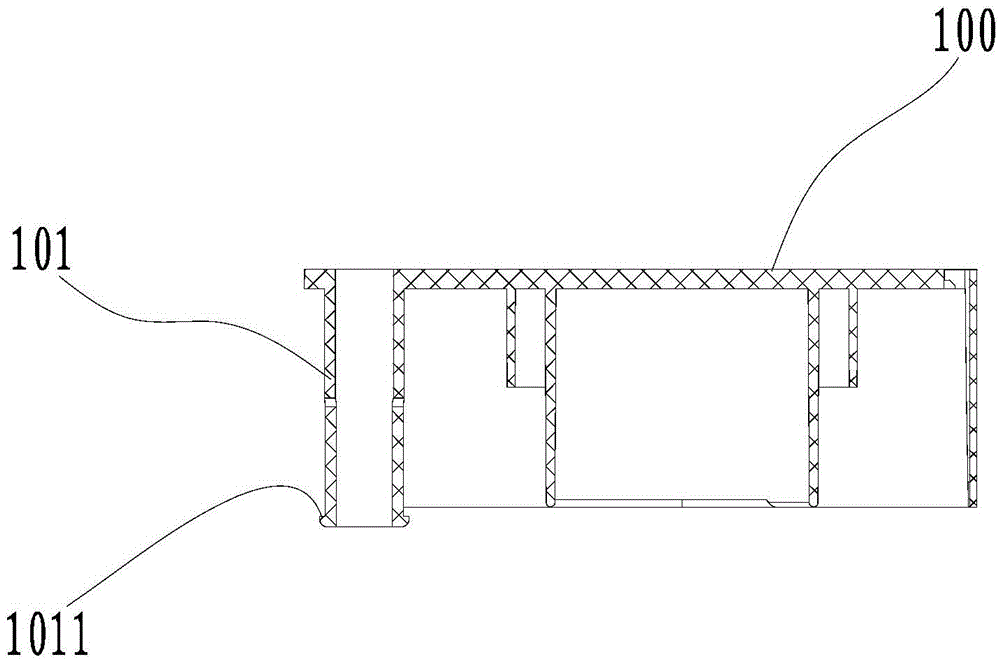

Hanging type power cable and optical cable

InactiveCN111403101AHigh densityStable structureInsulated cablesCommunication cablesPower cableBeam tube

The invention belongs to the technical field of photoelectricity, and particularly relates to a hanging type power cable. The power cable is provided with a central beam tube, a plurality of electricconductors located outside the central beam tube, and an outer sheath located outside the electric conductors. A plurality of sequentially stacked optical fiber ribbons are arranged in the central beam tube, and light transmission components are arranged in the optical fiber ribbons. The hanging type power cable is characterized in that four hanging components are further arranged in the hanging type power cable, each hanging component is composed of a first hanging body, a second hanging body, a third hanging body, a hanging connecting part and a hanging body, and the hanging components are of an integrated structure. The invention further discloses a hanging type optical cable. The power cable and the optical cable have the advantages of being more stable in structure, higher in opticalcommunication density, lower in laying cost, easier to form and replace, better in heat dissipation effect and higher in current-carrying capacity.

Owner:CHANGSHU YUTONG PHOTOELECTRIC TECH CO LTD

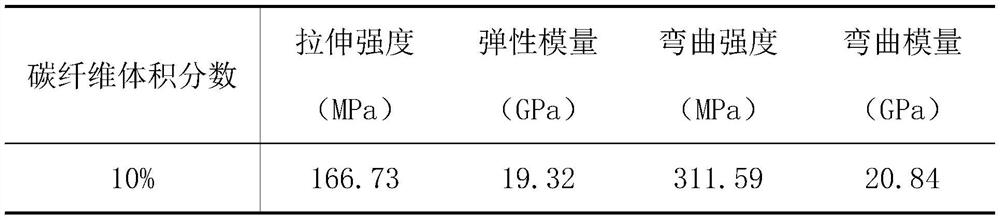

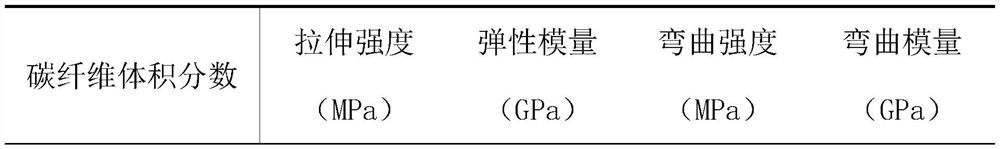

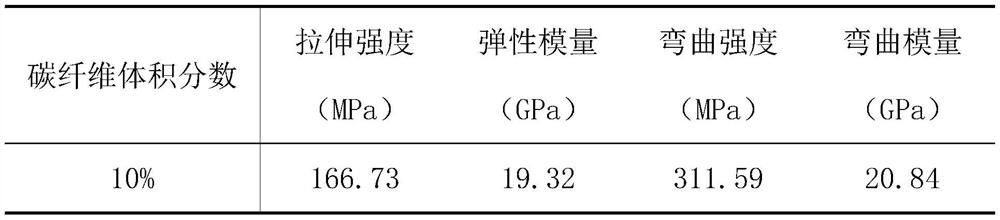

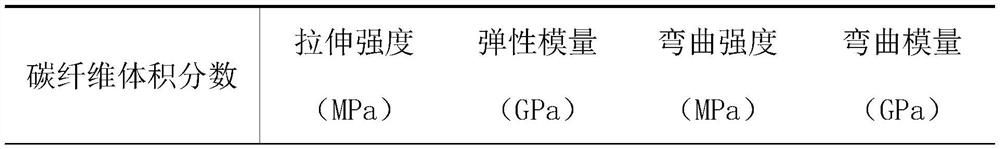

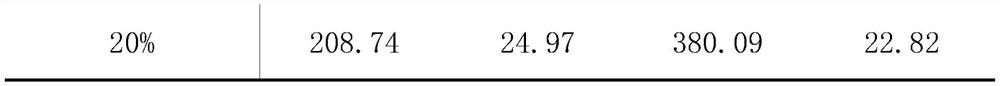

Carbon fiber reinforced thermosetting resin-based composite material and preparation method thereof

The invention discloses a carbon fiber reinforced thermosetting resin-based composite material and a preparation method thereof, and belongs to the technical field of advanced composite materials. The preparation method comprises the following steps: sampling matrix resin, a low-shrinkage agent, a curing agent, a polymerization inhibitor, an internal release agent, a thickening agent and a dispersing aid according to the mass ratio, and conducting stirring and uniform mixing to prepare resin paste; preparing flaky carbon fiber prepreg from the resin paste and the carbon fiber non-woven fabric through a flaky molding compound process; flatly laying and overlaying the sheet-shaped carbon fiber prepreg, and conducting vacuum hot pressing and die assembly molding; and after the vacuum hot pressing die pressing is finished, and conducting cooling and demolding to obtain the carbon fiber reinforced thermosetting resin-based composite material. The preparation method has the characteristics of simple process, short production period, low energy consumption, designable strength and modulus, easiness in large-area forming, capability of meeting the forming requirements of products with complex shapes and structures and the like; and the prepared composite material has the excellent performances of high strength, high modulus, light weight, isotropy and the like.

Owner:WUHAN UNIV OF SCI & TECH

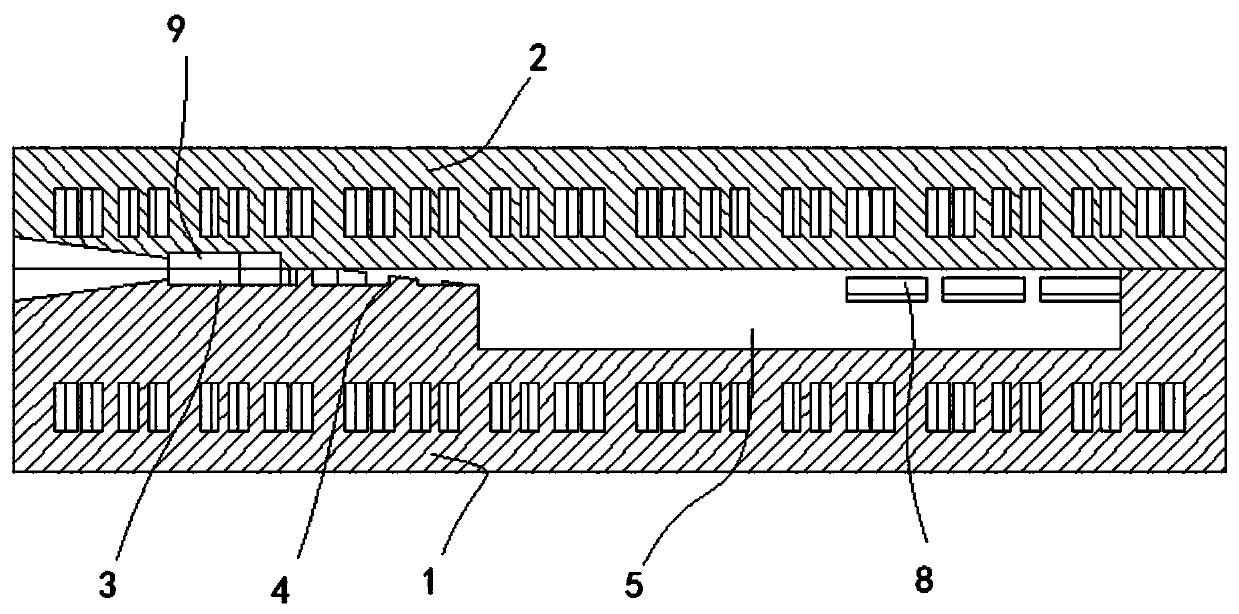

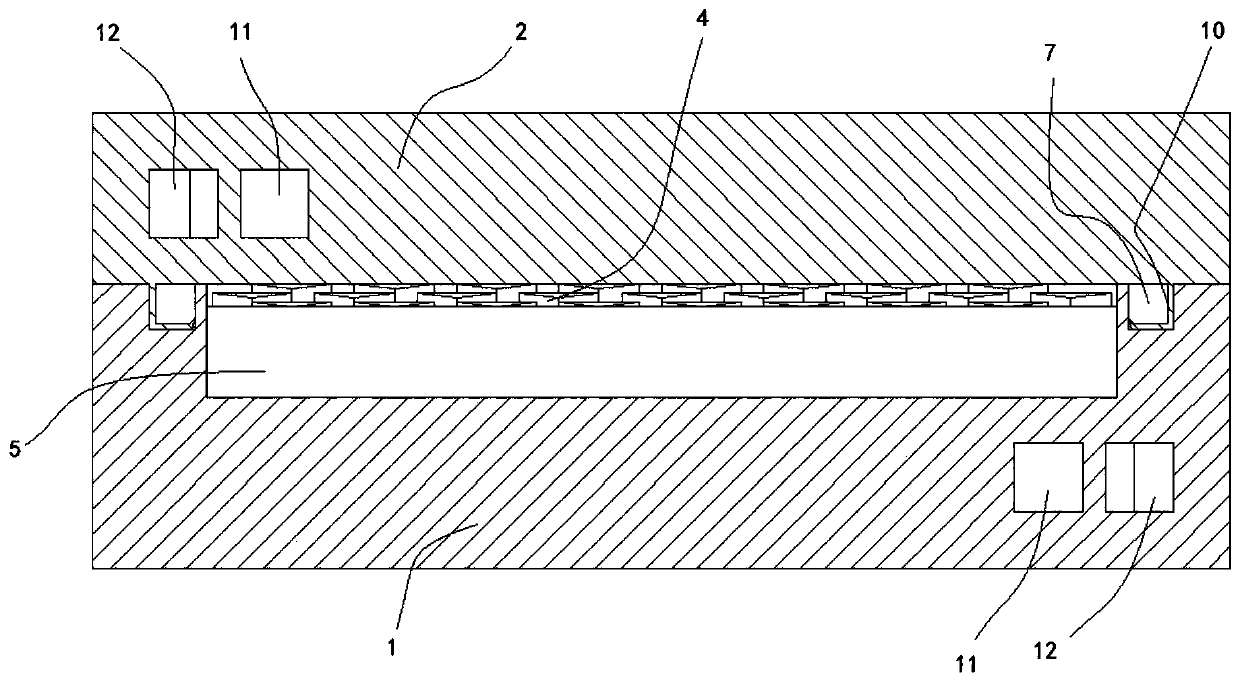

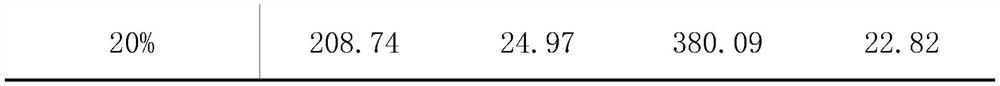

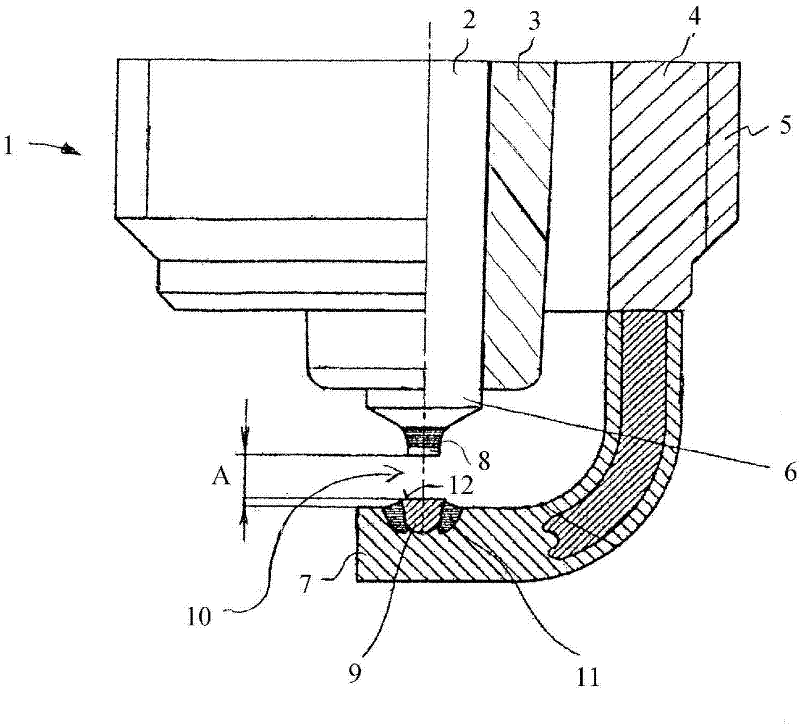

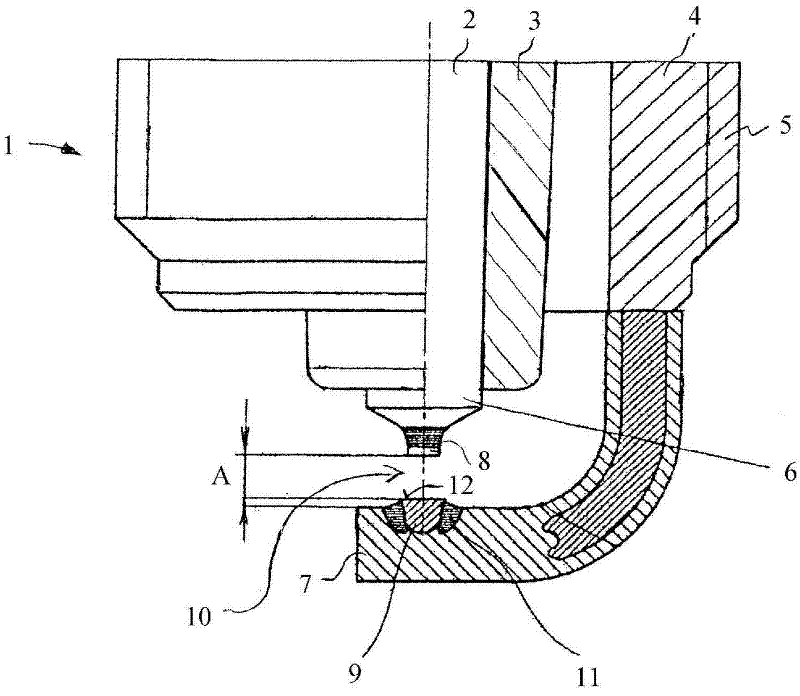

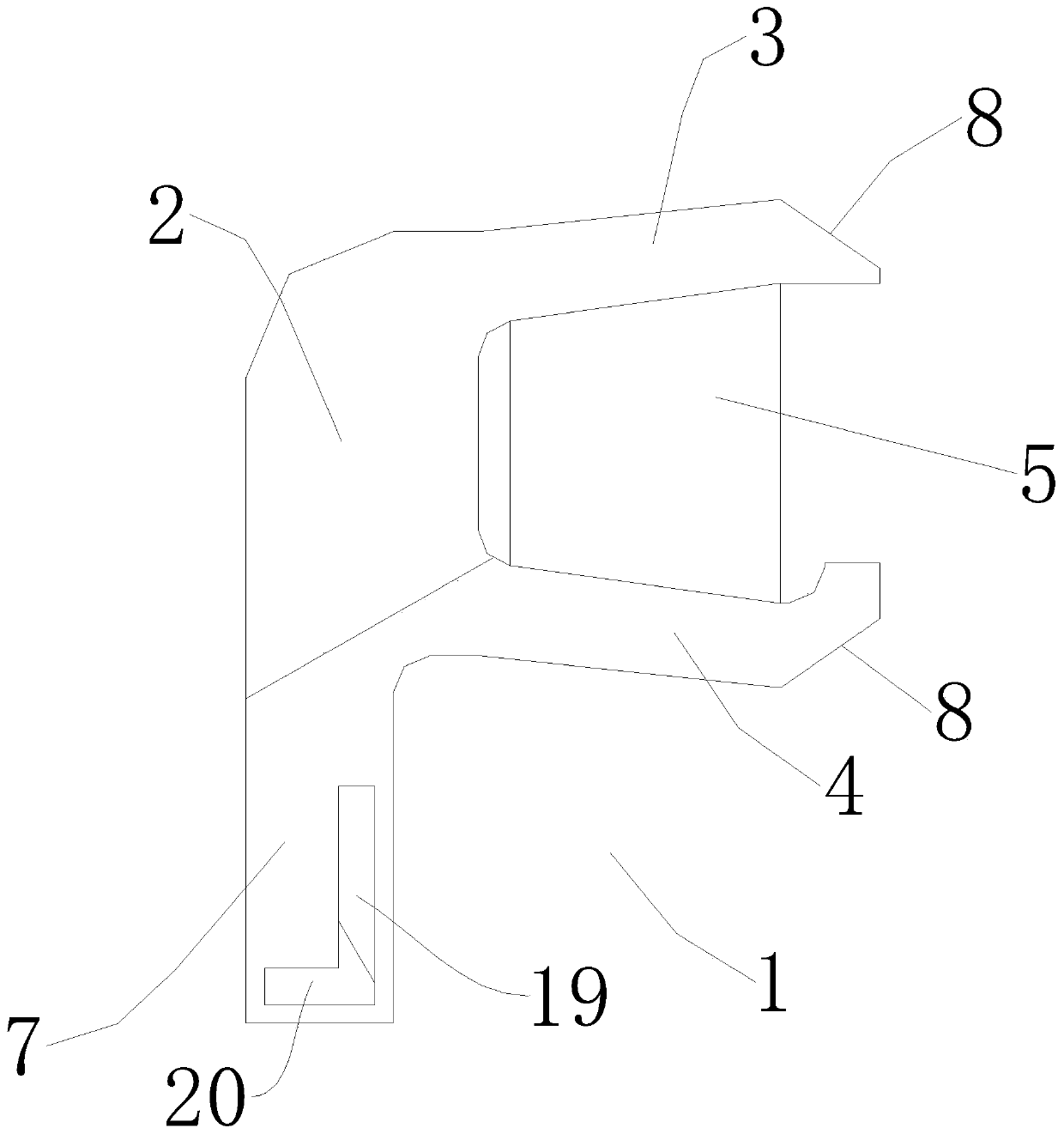

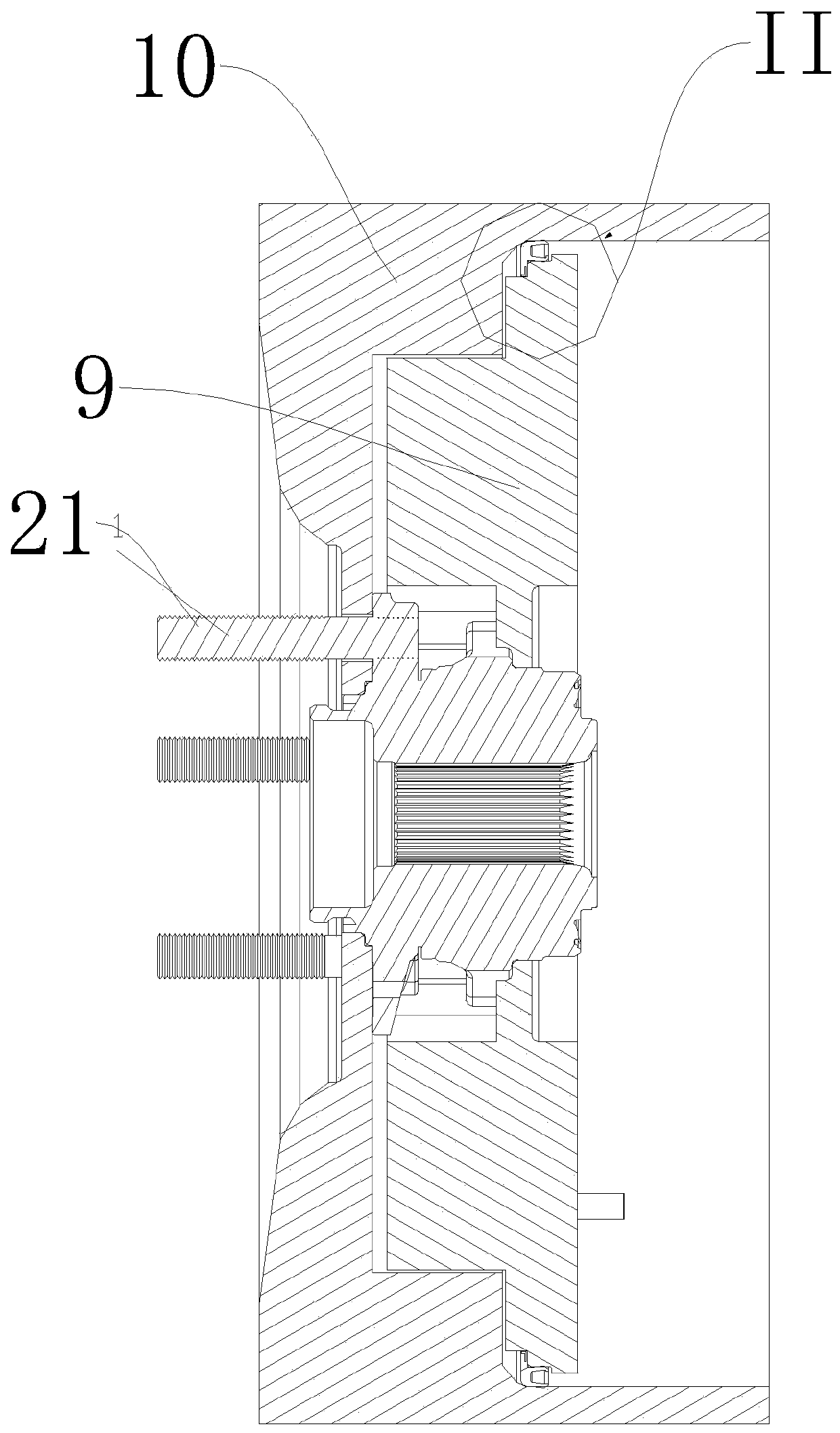

End face sealing structure for motor and stator of hub motor

InactiveCN110289720AExtended service lifeAchieve positioningSupports/enclosures/casingsEngineeringFace seal

The invention relates to the field of hub motor sealing and discloses an end face sealing structure for the motor and the stator of a hub motor. The end face sealing structure comprises a rotor, a stator and a sealing member disposed between the rotor and the stator, wherein the sealing member comprises a mounting portion and a sealing lip; a support skeleton is arranged inside or outside the mounting portion; the sealing lip is in seal fit with the end face of the rotor or the stator; the sealing member can be installed with the rotor and the stator in two ways in one of which the mounting portion is mounted on the rotor and the sealing lip is in sealed against the end face of the stator and in the other of which the mounting portion is mounted on the stator and the sealing lip is in sealed against with the end face of the rotor. The solution in the present invention is designed for solving the technical problem that the conventional hub motor has no reliable sealing member between the stator and the rotor. The sealing member designed by the invention is a separate component, is liable to form and prone to standardized production so as to be convenient in later maintenance.

Owner:ZHEJIANG VIE SCI & TECH

Spark plug and its method of production

InactiveCN102394474AEasy molding processEasy to manufactureSparking plugs manufactureElectrical conductorAlloy

The invention describes a spark plug, which comprises an inner conductor, an insulator enclosing the inner conductor, a spark plug body enclosing the insulator and two electrodes forming a spark gap. The first electrode is a center electrode connected to the inner conductor in an electrically conductive manner and the second electrode is a ground electrode connected to the spark plug body in an electrically conductive manner. At least one of the electrodes has a precious metal region, adjoining the spark gap and consisting predominantly of platinum, iridium or an alloy of both and containing additionally at least one brittle metal. The precious metal region consists of a base material predominantly containing platinum and / or iridium, which comprises a coating with a brittle metal, which is more brittle than the base material.

Owner:BORGWARNER BERU SYST

High-molecular polymer composite suitable for bioreactor and method for manufacturing high-molecular polymer composite

ActiveCN103421262AGood anti-friction performanceMeets and complies with all performance requirements for contactPoly ether ether ketonePolyamide

The invention relates to a high-molecular polymer composite suitable for a bioreactor and a method for manufacturing the high-molecular polymer composite, and belongs to the technical field of biological pharmacy. The composite comprises, by weight, 55-70 parts of polytetrafluoroethylene, 10-15 parts of polyether-ether-ketone, 8-12 parts of polyphenyl ester, 3-5 parts of polyphenyl ether, 3-5 parts of polyethylene, 3-5 parts of polyamide and 3-5 parts of zirconia or silicon nitride. The high-molecular polymer composite and the method have the advantages that problems that parts of existing composites in the prior art are toxic, the existing composites are volatile, are easy to decompose, are poor in temperature resistance and corrosion resistance and are not suitable for bioreactors, or the existing compositions are only suitable for membrane bioreactors and are poor in abrasion resistance are solved; all requirements on the performance of the high-molecular polymer composite which is in contact with biological products in the bioreactor are met, the high-molecular polymer composite has self-lubricating performance, and the abrasion resistance of the high-molecular polymer composite is greatly improved.

Owner:成都英德生物医药设备有限公司

Polylactic acid/carbon dioxide polymer degradation type composite material

This invention relates to a degradation composite material of polylactide / carbon dioxide polymer, composed of 10 to 90 shares(weight) of carbon dioxide polymer, 10 ~ 90 shares of polylactic acid, 10 ~ 20 shares of acetyl Tributyl Citrate plasticizer, 1 ~ 5 of maleic anhydride end blocking agent. This invention has good mechanical properties, degradation, good thermal stability, easy processing and prototyping, good glossiness and transparency, which can apply to the production of medical dressings, packaging materials and others.

Owner:吉林金源北方科技发展有限公司

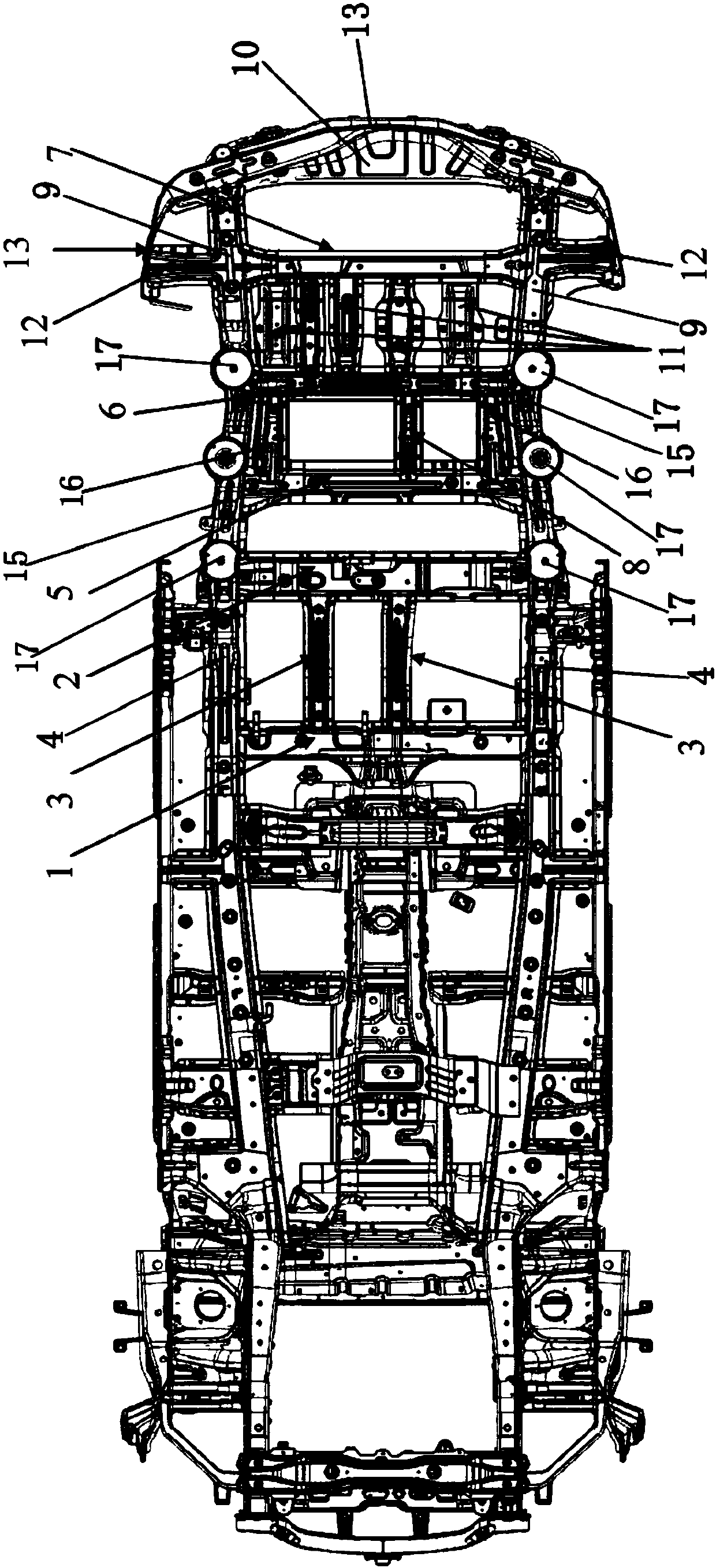

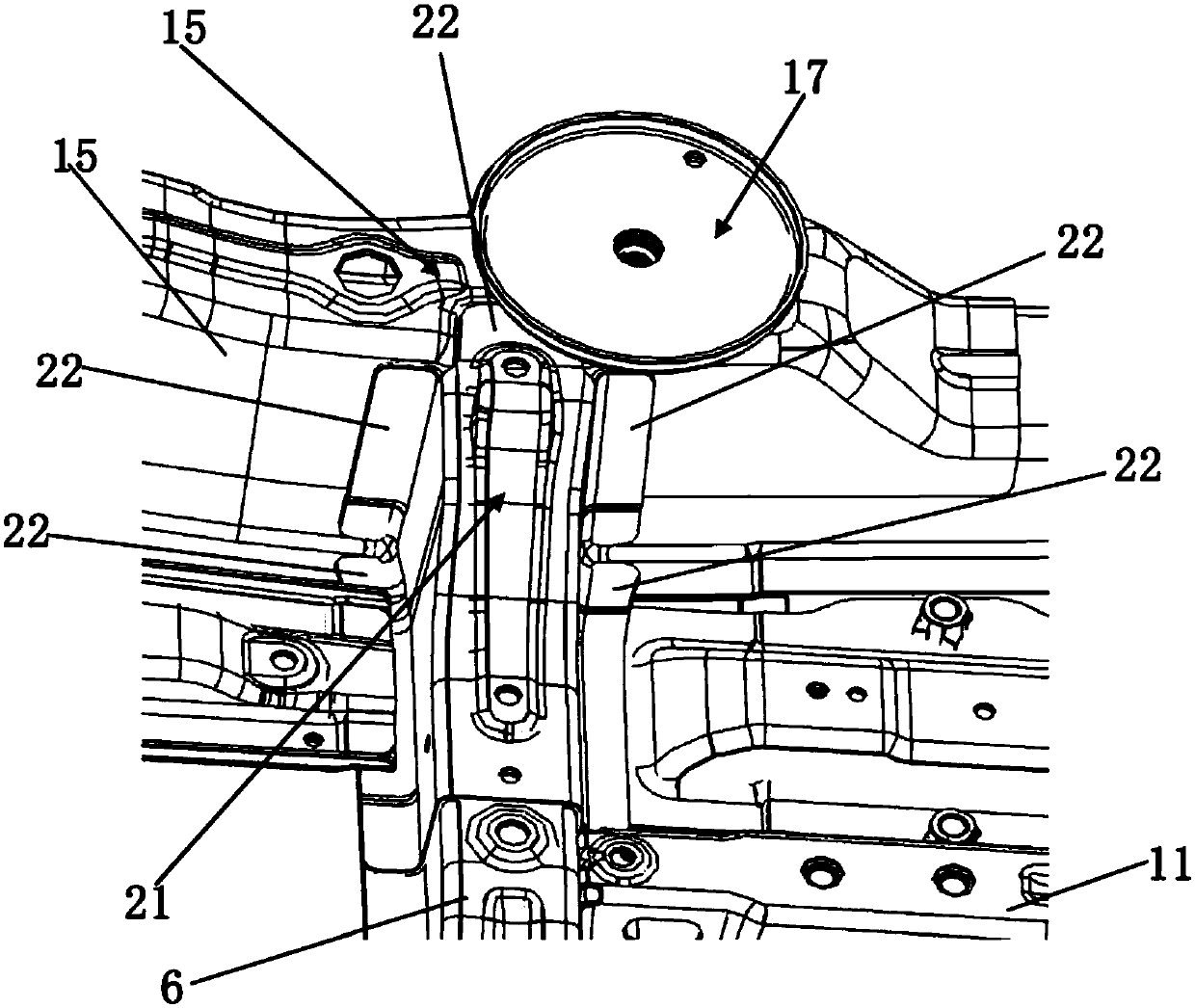

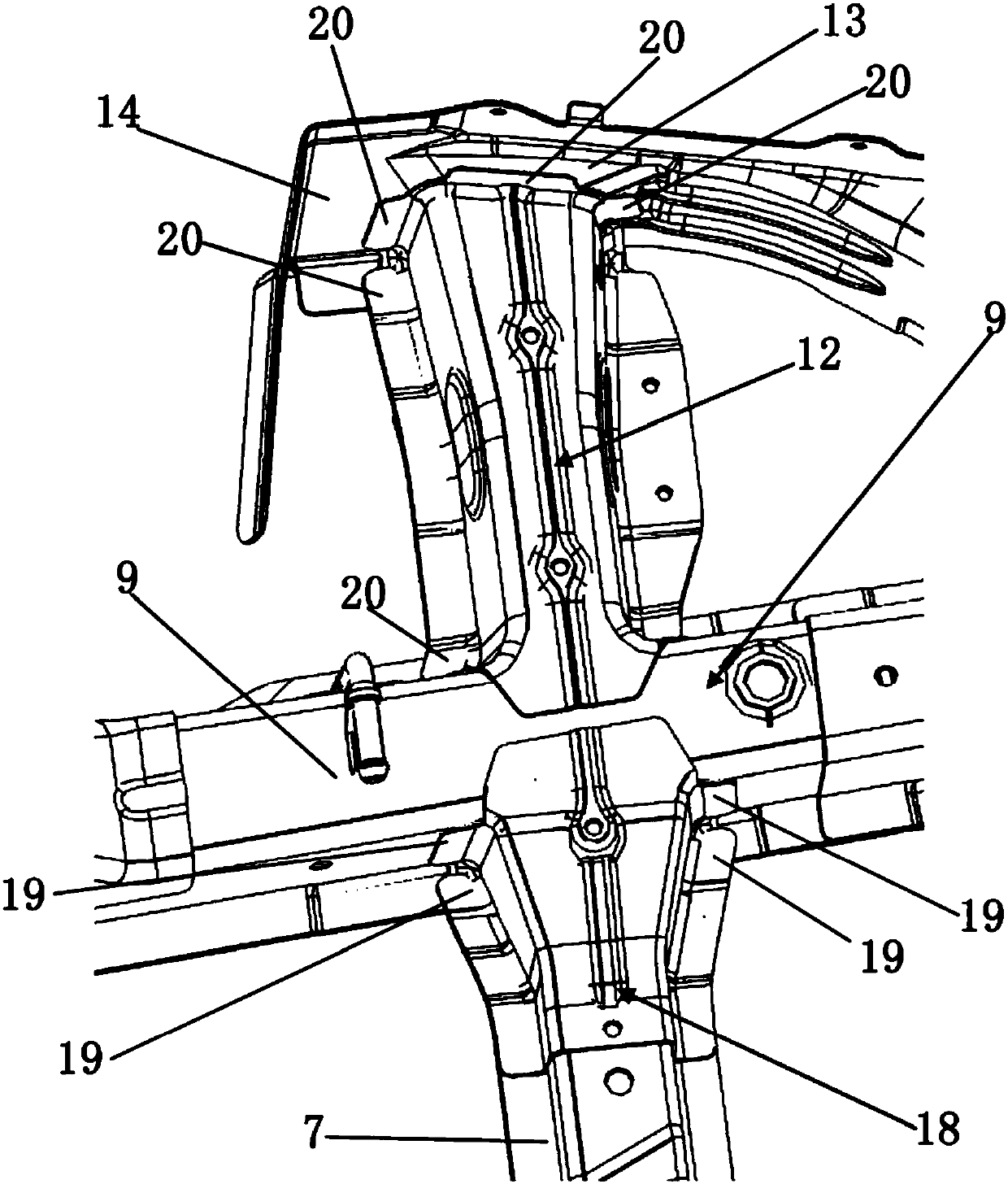

Rear frame assembly of vehicle body chassis

PendingCN109823396AHigh strengthIncrease stiffnessUnderstructuresStress concentrationImpact resistance

The invention discloses a rear frame assembly of a vehicle body chassis, which comprises a vehicle tail longitudinal beam, a vehicle tail cross beam and a vehicle tail frame assembly of a tail cross beam and a vehicle body rear frame assembly which comprises a vehicle rear longitudinal beam, a first cross beam and a second cross beam, wherein a rear protection plate or a rear anti-collision beam is arranged at the rear part of the vehicle tail cross beam; the vehicle tail longitudinal beam and the rear end part of the vehicle rear longitudinal beam are fixed through a rear connecting longitudinal beam; a third cross beam and a fourth cross beam are transversely arranged between the rear connecting longitudinal beams; a rear floor is fixed on the first cross beam, the second cross beam, thethird cross beam and the fourth cross beam; a rear seat longitudinal beam is arranged between the third beam and the fourth beam and the front and rear end are fixed to the third beam and the fourthbeam; the rear seat of the vehicle is fixed to the third beam, the fourth beam and the rear seat longitudinal beam. The rear frame assembly of the chassis of the vehicle body is simple in structure, the riding comfort and the torsional rigidity and impact resistance of a rear floor area are improved, stress concentration is avoided, the running stability is improved, and the safety performance ofthe vehicle body is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Dual-inclined ejecting split type ejection mechanism for injection mold

The invention discloses a dual-inclined ejecting split type ejection mechanism for an injection mold. The ejection mechanism is formed by the cooperation of an inclined ejecting mechanism, an inclined ejecting anti-wear block, an inclined ejecting seat, a mold cavity, a movable mold fixing plate, an ejector pin cover plate, an ejector pin push plate, a lower mold seat plate and a mold core. The dual-inclined ejecting split type ejection mechanism provided by the invention has the superior benefits that during the injection molding process, a first ejecting rod and a second ejecting rod approach each other; during the mold separation process, the first ejecting rod and the second ejecting rod move far away from each other, so as to realize separation from the flange of the plastic product, and the phenomenon of reverse hanging of the plastic product on the first ejecting rod and the second ejecting rod is avoided; the ejection mechanism is simple in structure, easy to form and separate, and capable of molding plastic products with complex structures, and has a good market application prospect.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

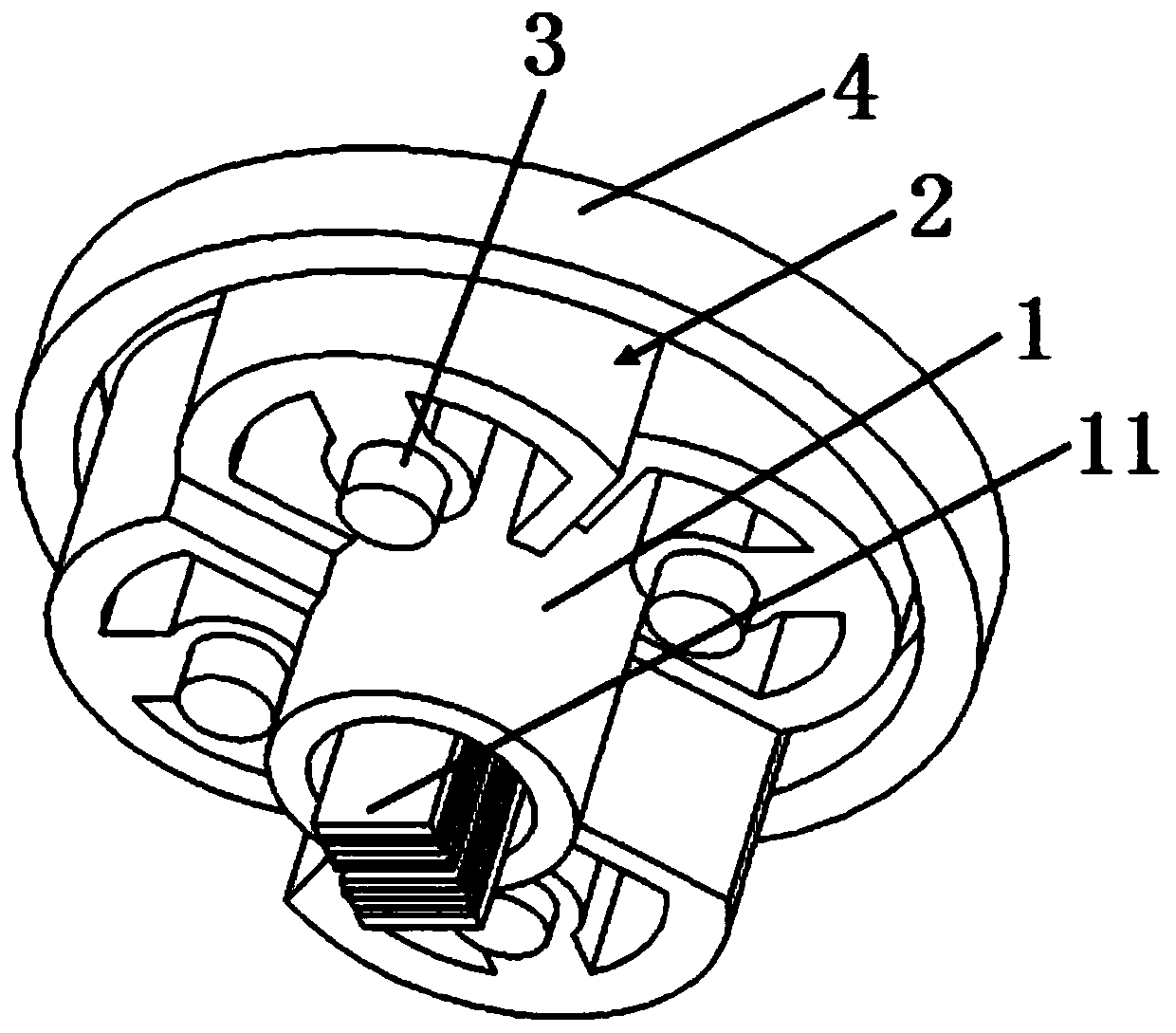

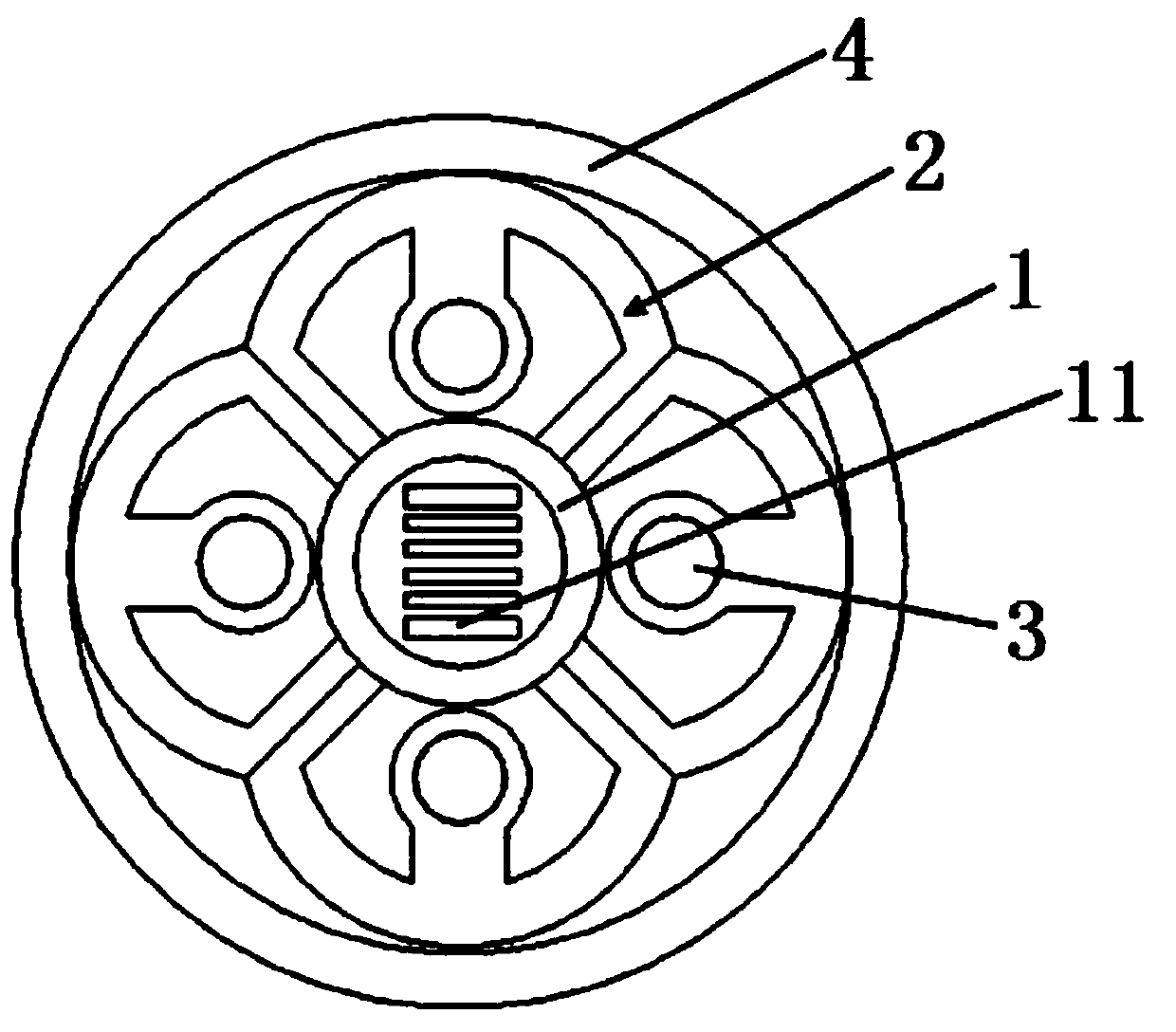

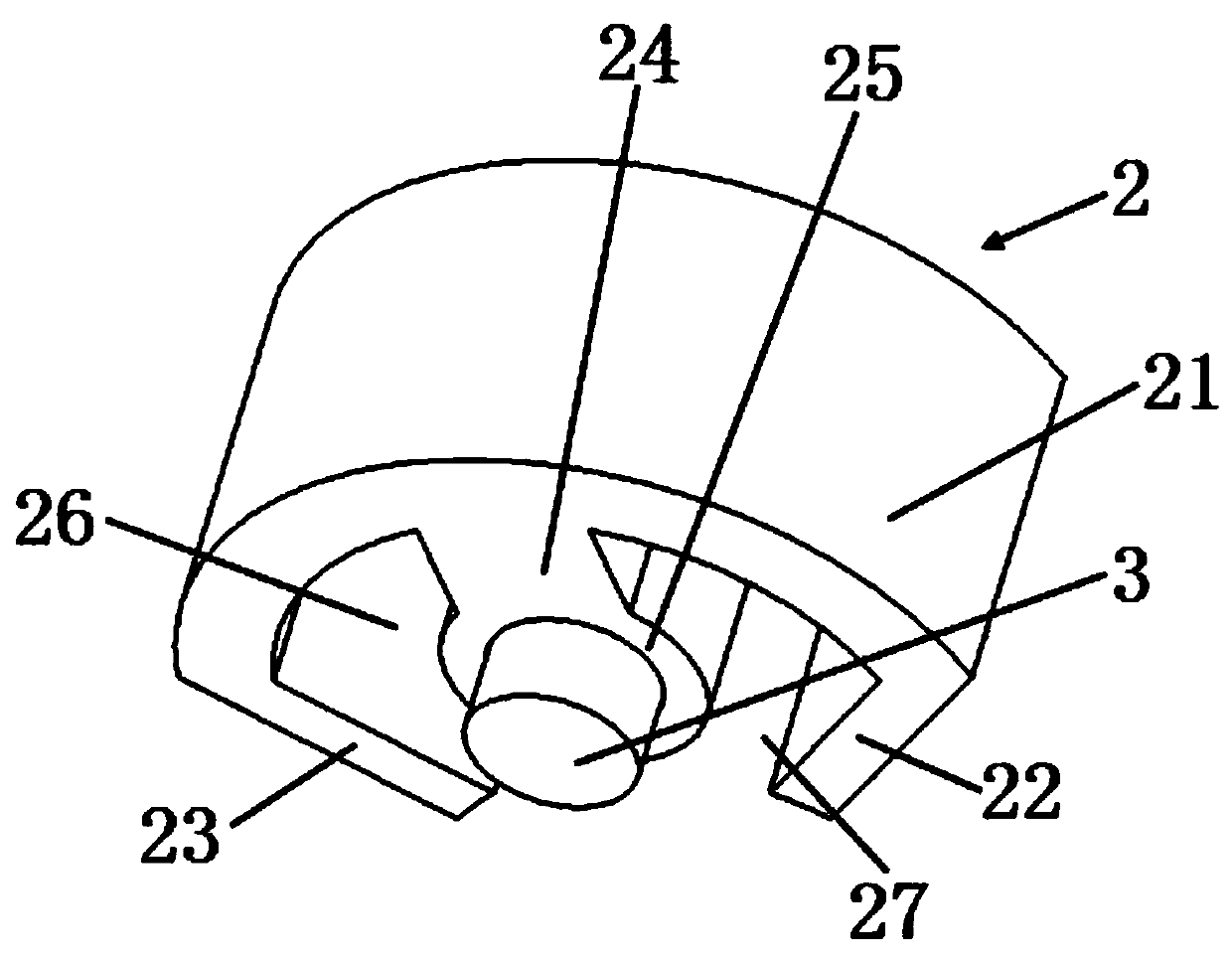

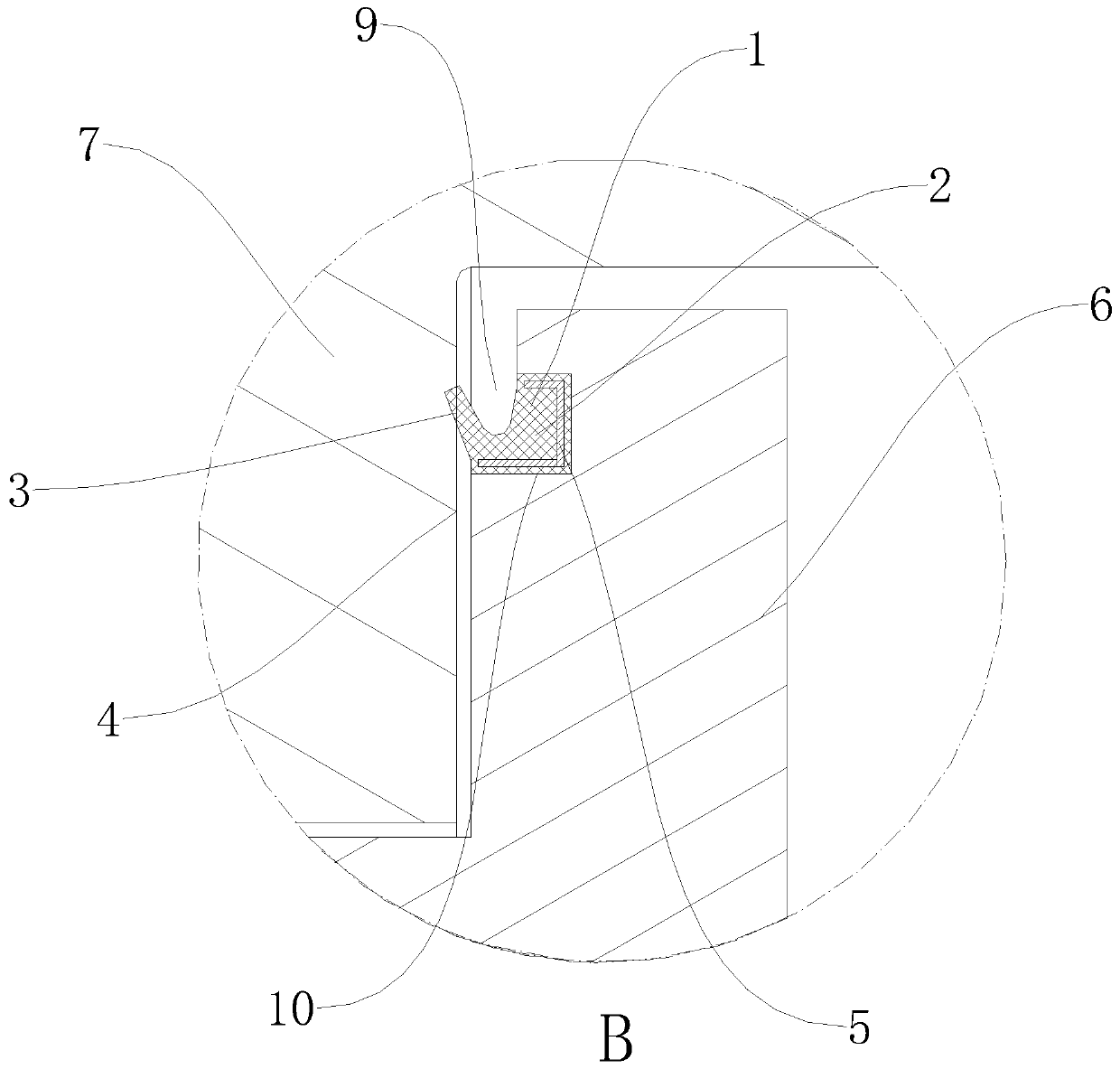

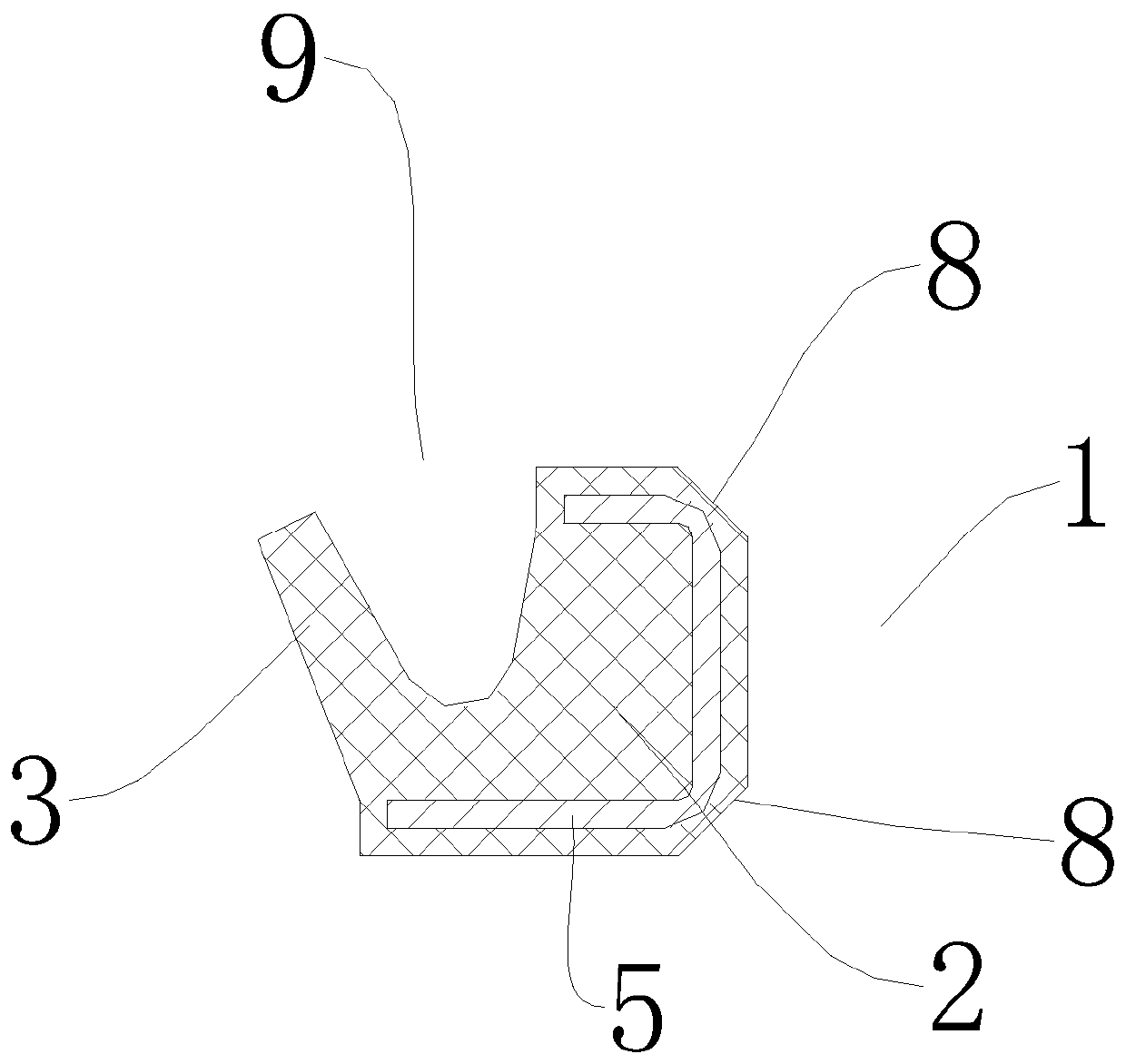

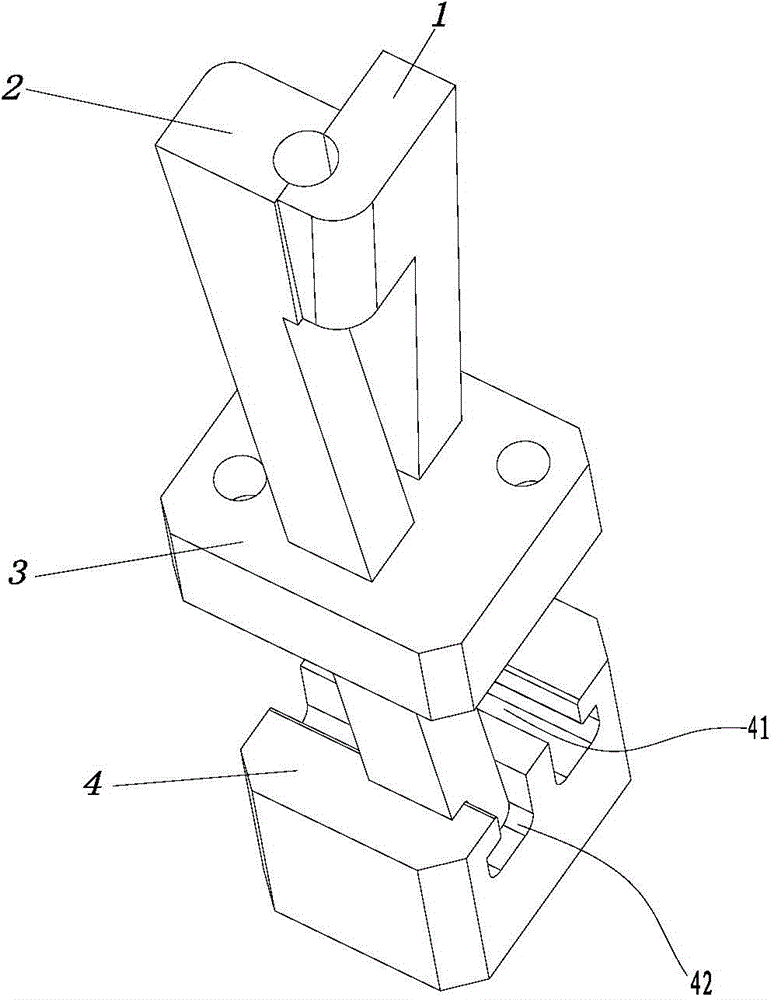

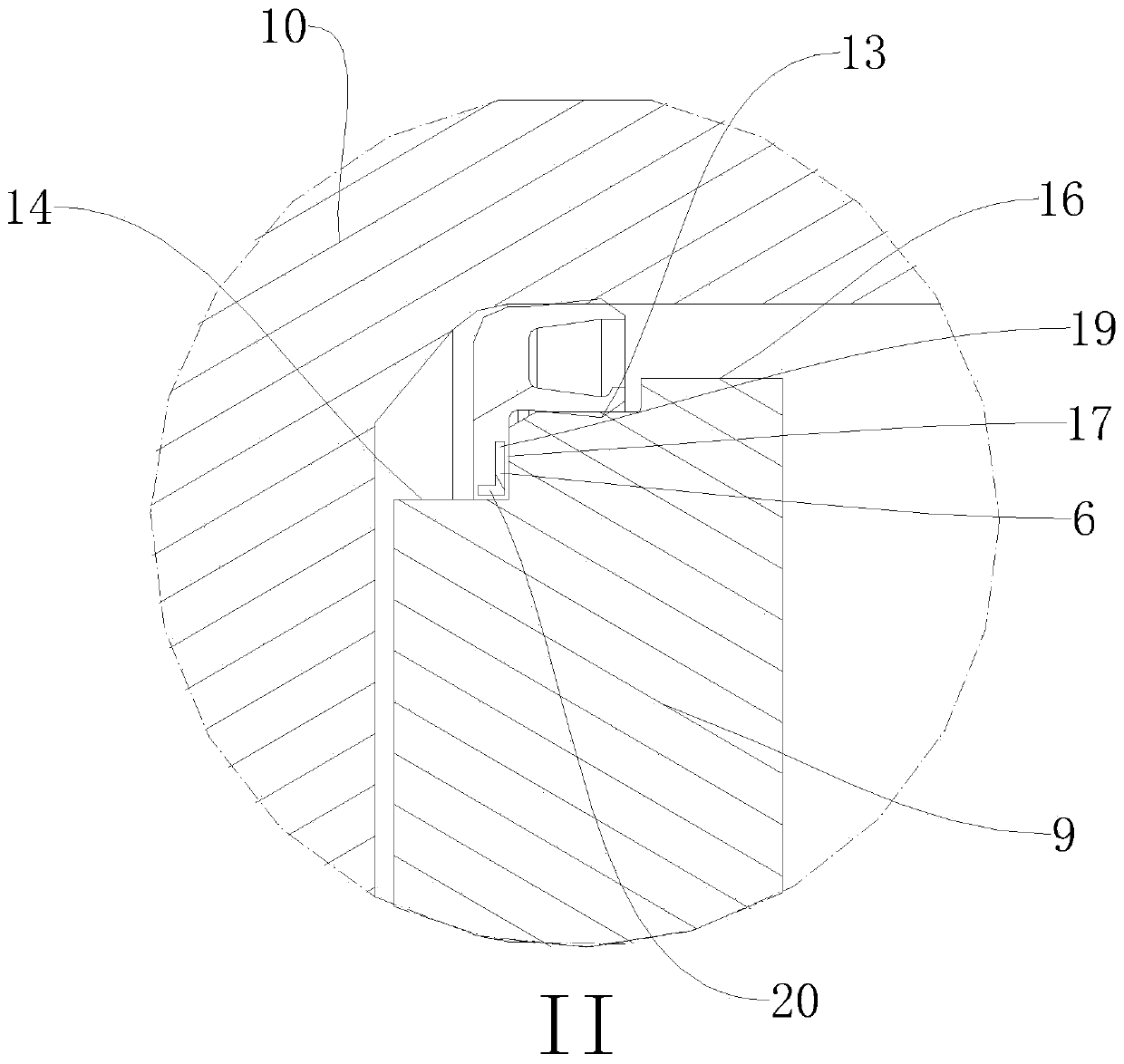

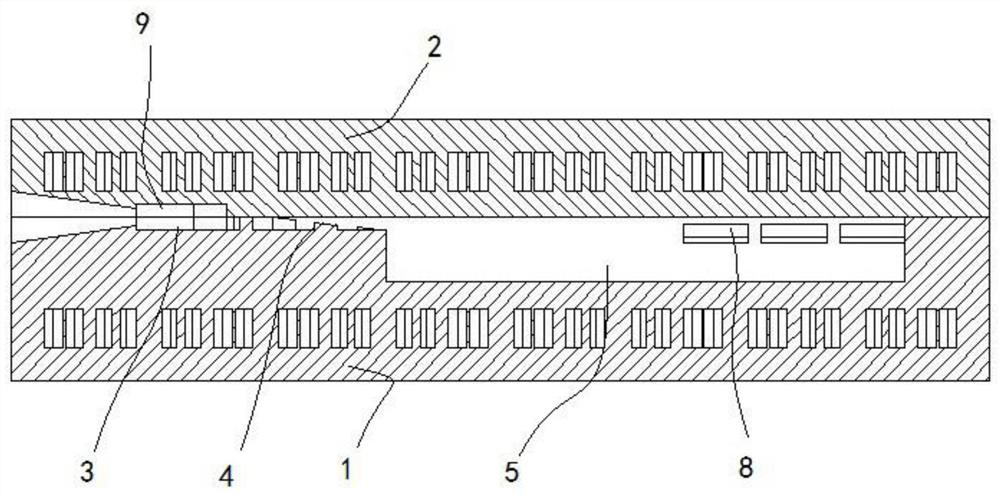

For seals between the stator and rotor of electric motors and hub motors

ActiveCN110165794BEasy molding processEasy maintenanceMagnetic circuit shape/form/constructionElectric machineEngineering

The invention relates to the field of hub motor sealing and discloses a sealing member for use between the stator and the rotor of a motor and a hub motor. The sealing member (1) is used for line sealing, surface sealing, or multi-lip sealing a portion. The sealing member (1) comprises an annular support body (2). A first sealing lip (3) and a second sealing lip (4) are integrally formed on the support body (2). The first sealing lip (3), the second sealing lip (4) and the support body define a storage opening (5). The inside or outside of the support body (2), the inside or outside of the first sealing lip, or the inside or outside of the second sealing lip is provided with a metal skeleton (6) for improving the assembly strength of the sealing member (1). The sealing member can achieve reliable sealing and automatic compensation.

Owner:ZHEJIANG VIE SCI & TECH

A pvc foam board extrusion die

The invention discloses a PVC foam board extrusion die and relates to the technical field of foam board extrusion dies. The present invention includes a lower template and an upper template matched with the lower template. The upper surface of the lower template is connected with the feeding port in sequence with a diversion buffer zone, a flow equalization zone, and a molding groove; the diversion buffer zone includes a buffer tank; the upper surface of the lower template is located at A pair of L-shaped guide grooves connected with the buffer groove are arranged symmetrically on both sides of the buffer tank; a pair of L-shaped guide grooves are arranged linearly on the opposite side and away from the diversion buffer zone, and a rectangular diversion hole is arranged; the lower surface of the upper template is provided with a feeding The T-shaped diversion groove connected to the mouth; the T-shaped diversion groove communicates with the buffer groove and a pair of L-shaped guide grooves respectively; a pair of L-shaped connecting guide grooves are symmetrically fixed on the lower surface of the upper template. In the present invention, the designed lower template and the upper template are foamed into the molding cavity in three directions, and the PVC foam board is easier to be quickly formed, and the problem of low efficiency of the existing mold in molding the PVC foam board is solved.

Owner:合肥帝品数码科技有限公司

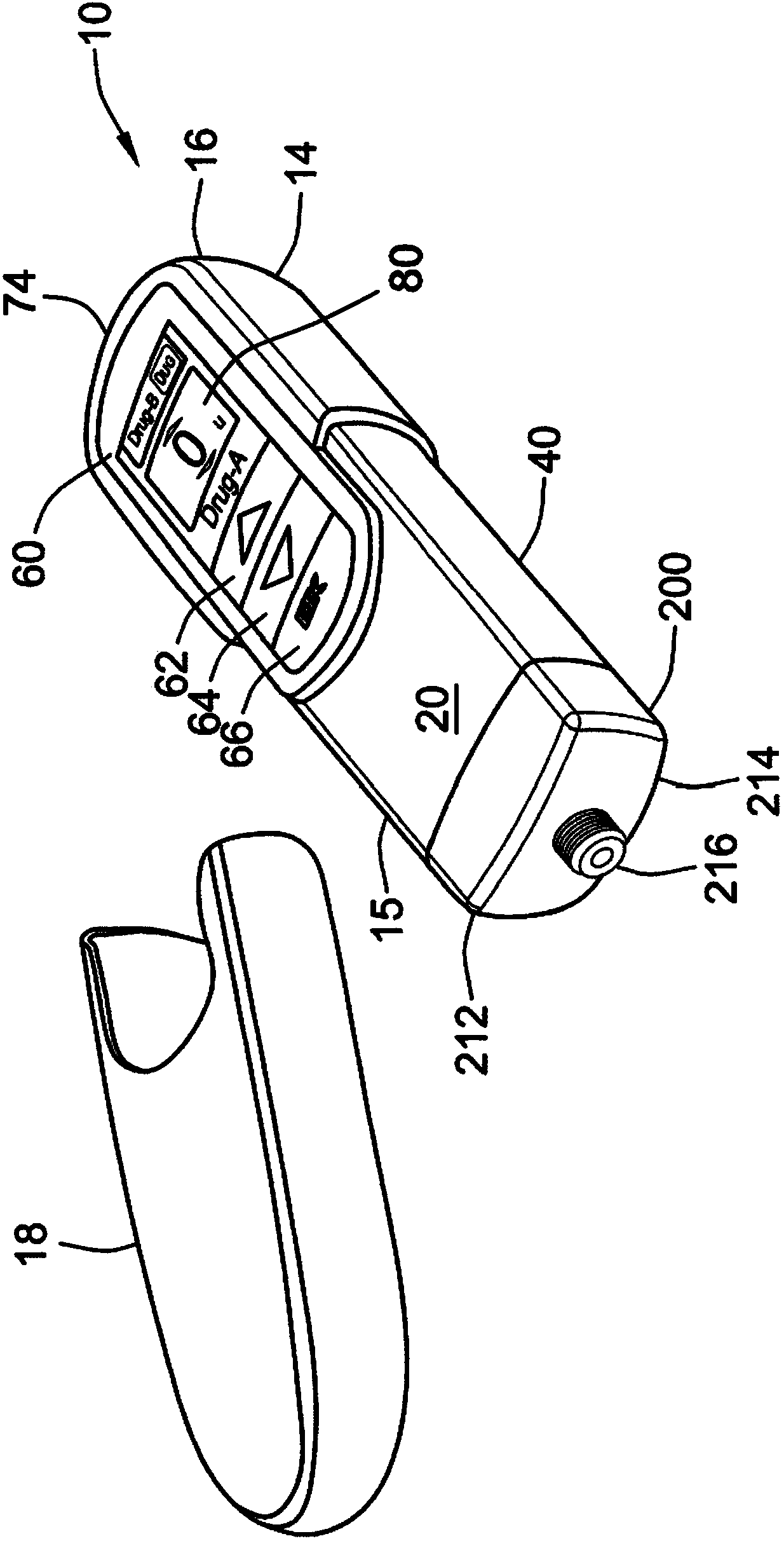

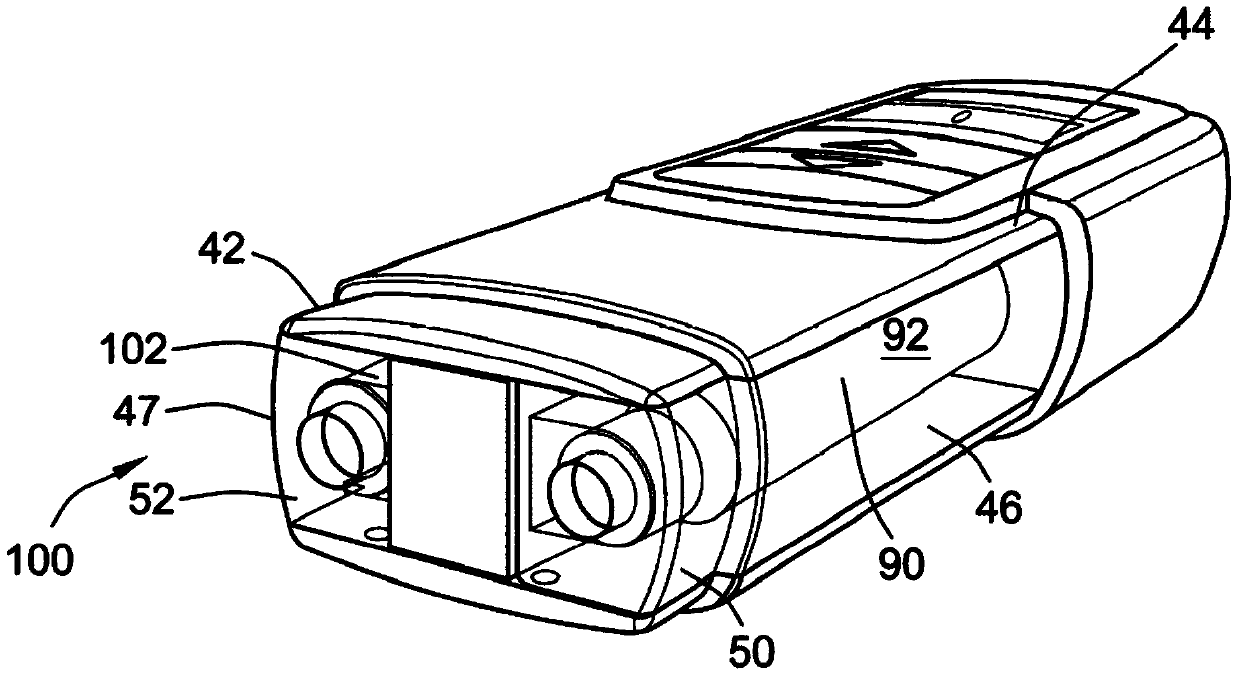

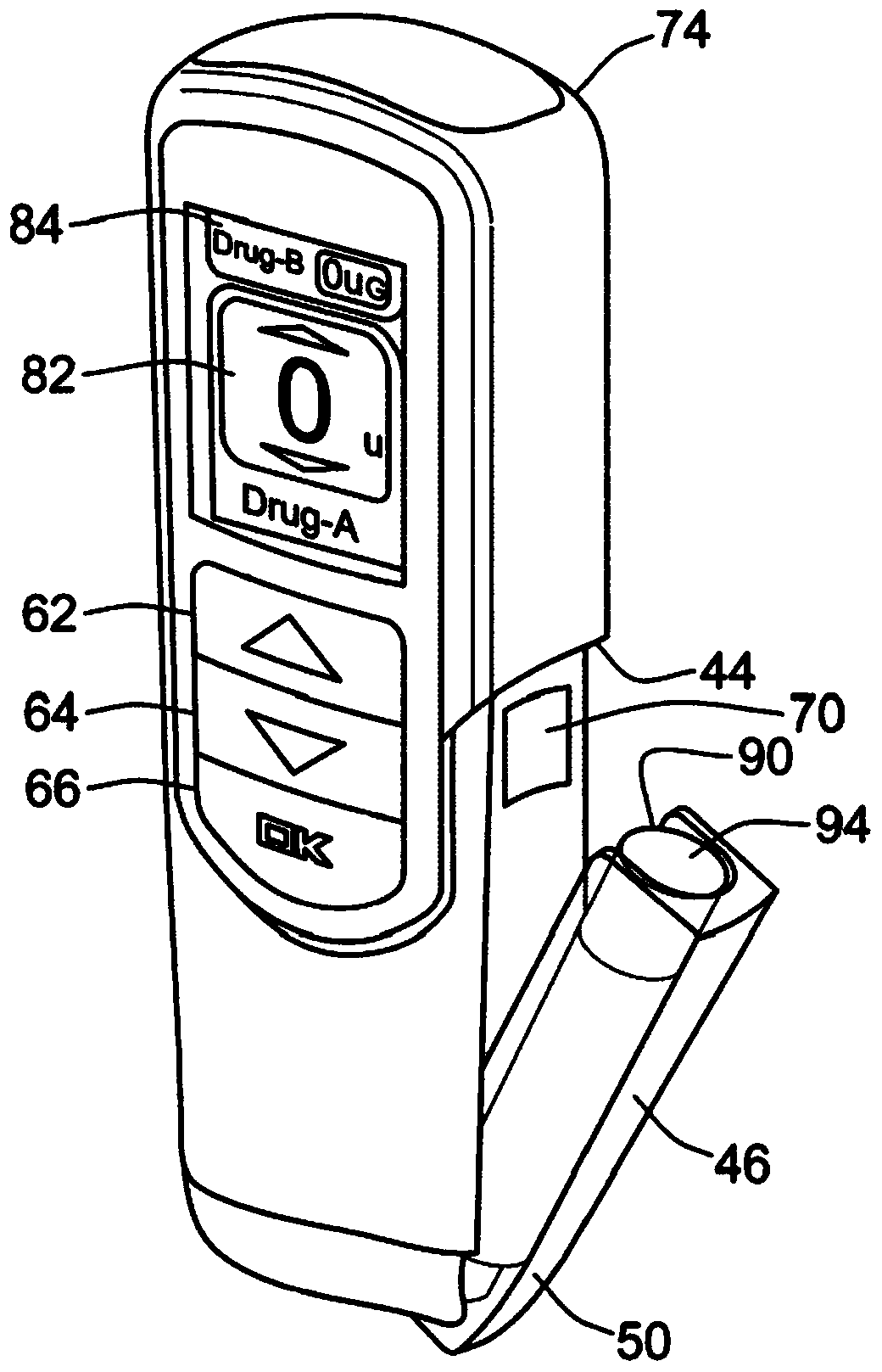

Dispense interface

InactiveCN104271182AWell formedEasy to makeAmpoule syringesAutomatic syringesInlet channelComputer science

The present application relates to a dispense interface (500, 600, 700) comprising at least a first flat part (502, 602) tightly connected with a second flat part (504, 604), wherein at least one of the at least two flat parts (502, 504, 602, 604) comprises at least one deepening (508, 510, 512, 513, 608', 608'', 610', 610'', 612', 612'', 613', 613'') configured for forming at least one part of a channel profile (506, 606), wherein the at least one deepening (508, 510, 512, 513, 608', 608'', 610', 610'', 612', 612'', 613', 613'') is formed by embossing, wherein the channel profile (506, 606) comprises at least a first inlet channel (508, 608) and a second inlet channel (510, 610) and at least one outlet channel (512, 612), wherein each of the at least two inlet channels (508, 510, 608, 610) is configured for fluid communication with a respective reservoir (90, 100, 708, 710) of at least two reservoirs (90, 100, 708, 710).

Owner:SANOFI AVENTIS DEUT GMBH

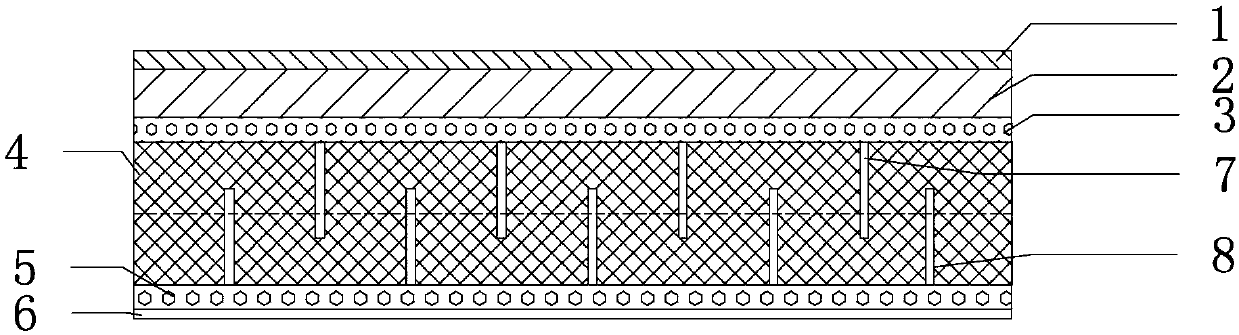

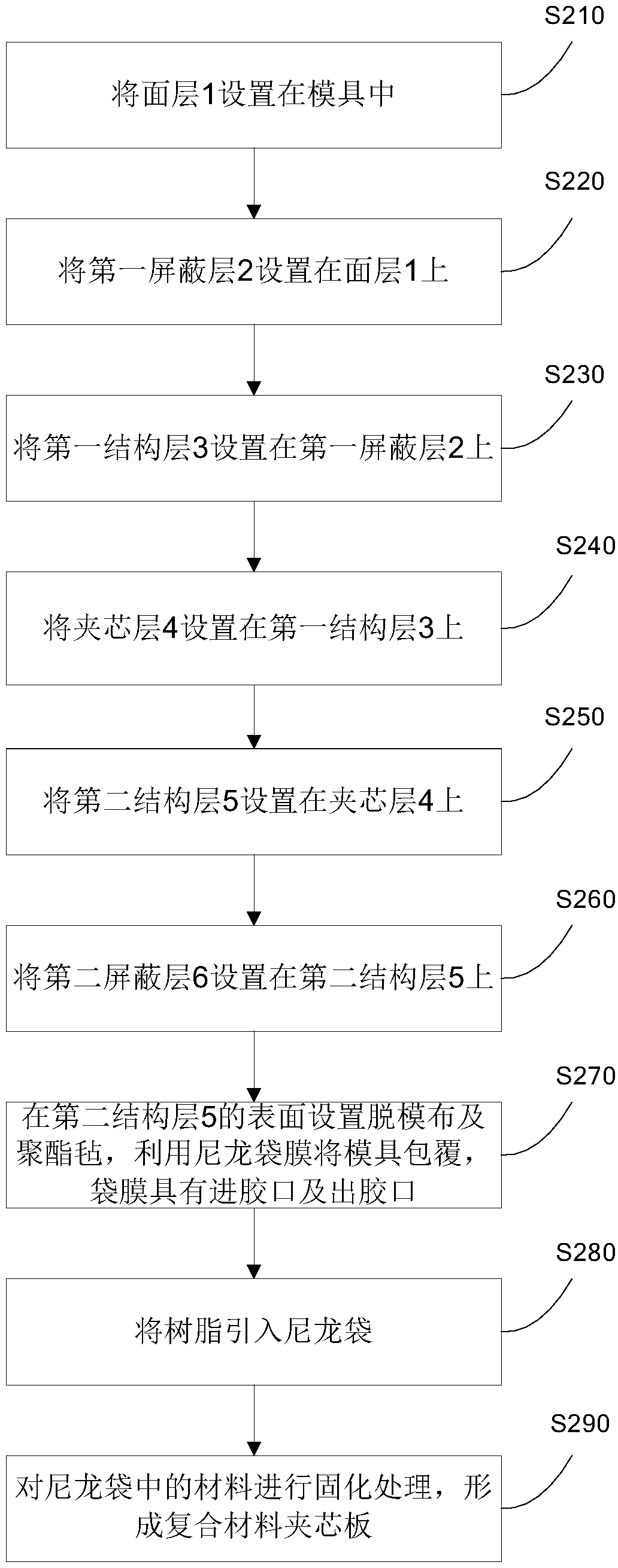

Composite sandwich structure and making method thereof

InactiveCN109648963ALight in massLow densitySynthetic resin layered productsLaminationSurface layerPetroleum engineering

The invention discloses a composite sandwich structure and a making method thereof. By setting a multi-layer structure consisting of a surface layer, a first shielding layer, a first structural layer,a sandwich layer, a second structural layer and a second shielding layer, the composite sandwich structure can adapt ship housing manufacturing, and also can meet the requirements of corrosion resistance, light weight, easy shaping and impact resistance for ship housings at the same time.

Owner:HUBEI SANJIANG BOATS SCI & TECH +1

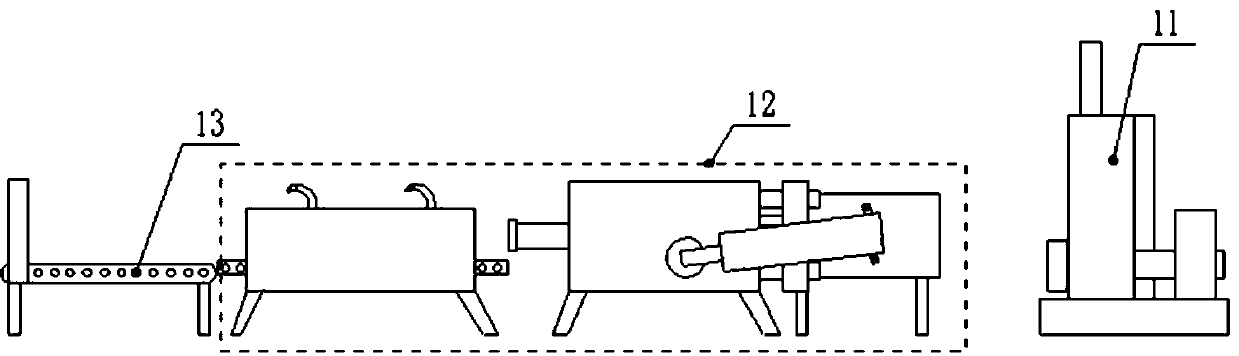

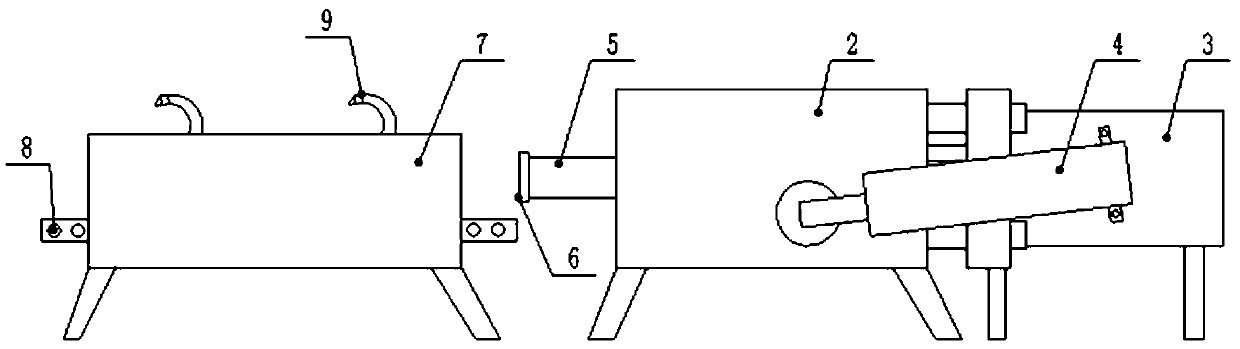

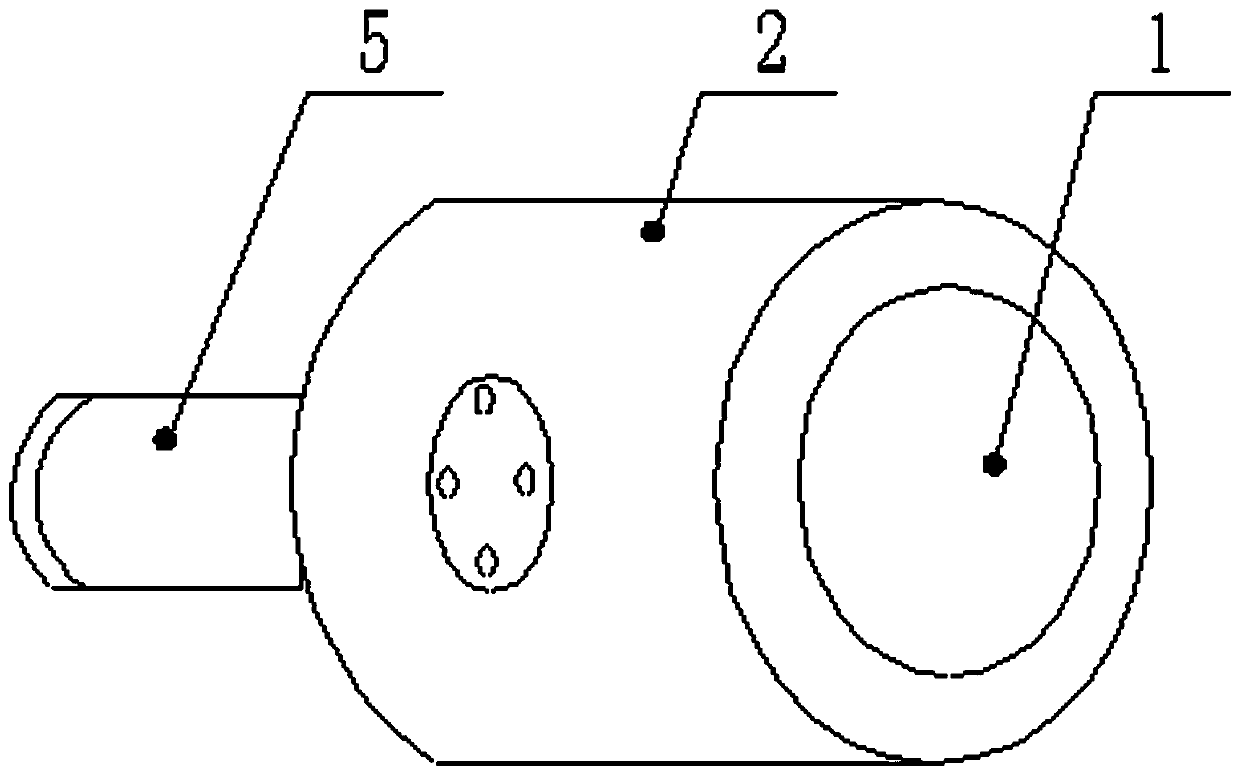

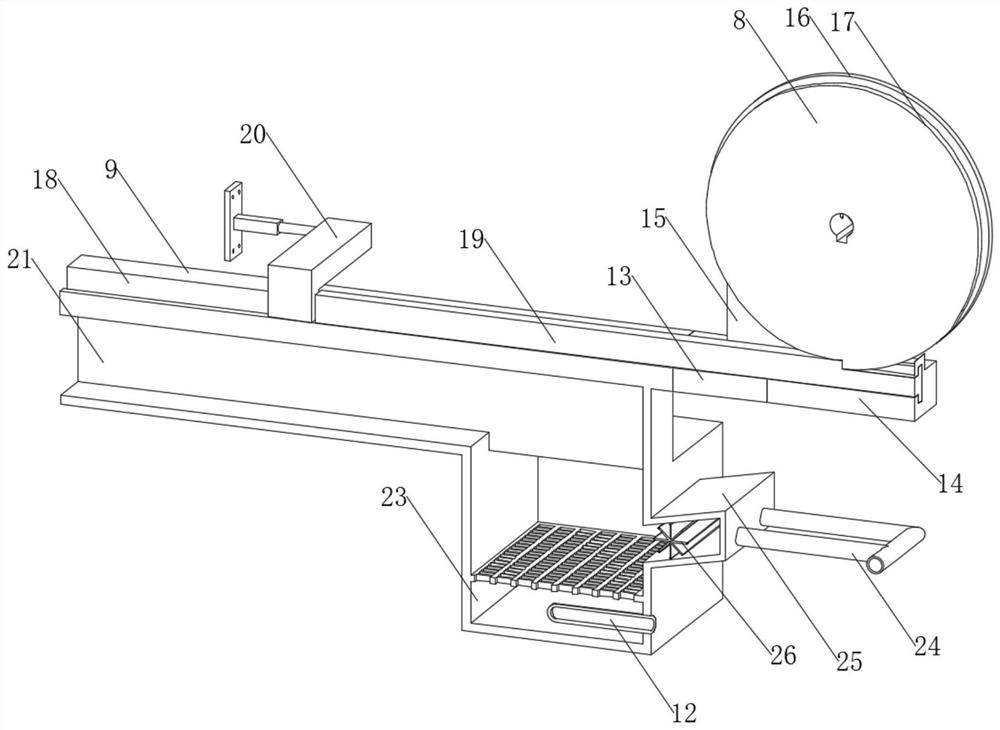

Quickly-formed rubber strip production method and device

The invention provides a quickly-formed rubber strip production method and device, in particular a rubber strip production method and a rubber strip production device. The quickly-formed rubber stripproduction method comprises the steps of mixing, rubber extrusion, cooling and cutting. The quickly-formed rubber strip production device comprises an internal mixer, a rubber extrusion device and a cutting machine, wherein the internal mixer is adjacent to the rubber extrusion device; and a discharging port of the rubber extrusion device is connected with the cutting machine. The quickly-formed rubber strip production method and device provided by the invention have the main characteristics that by the adoption of hot-extrusion forming and longitudinal cutting methods, the error is smaller than that generated in a conventional process, the forming is quicker, and the efficiency is higher.

Owner:广西新三达橡胶科技有限公司

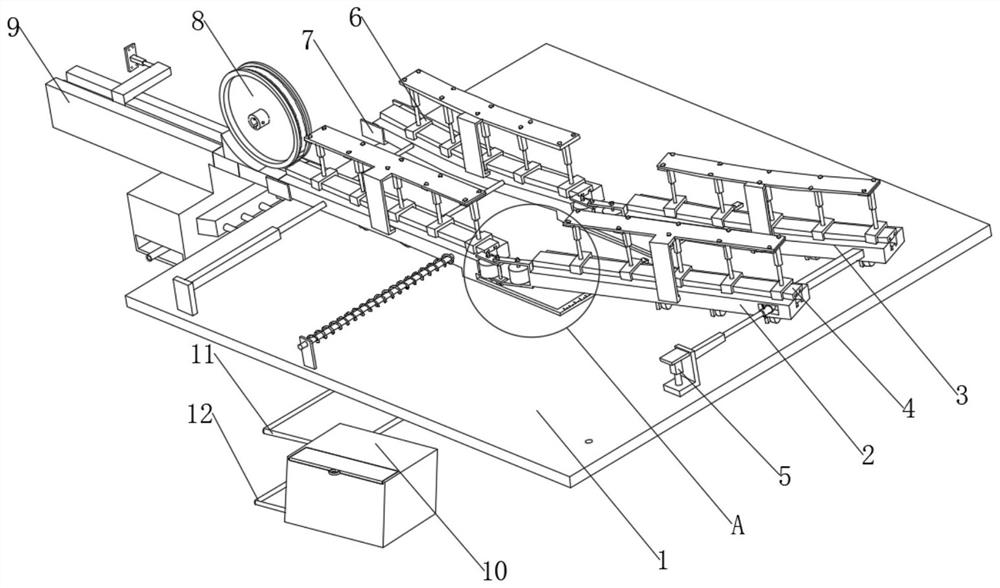

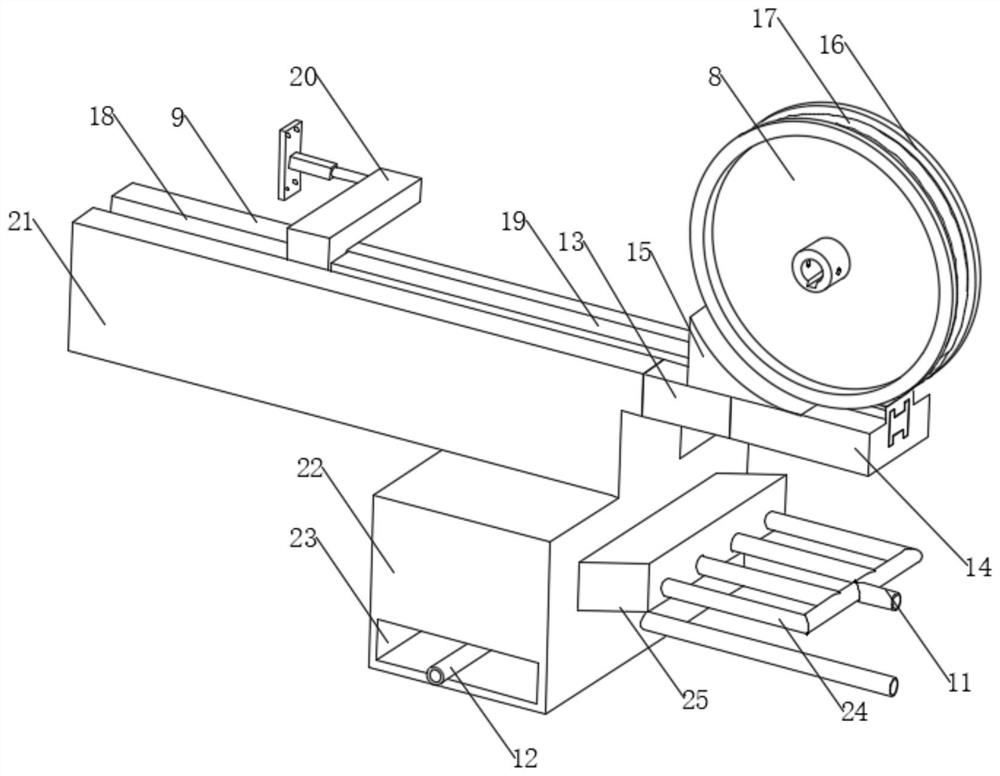

Forging Mechanism for Continuous Forging Point Rail and Preparation Technology of Forging Point Rail

ActiveCN111570691BQuality improvementReduce stressForging/hammering/pressing machinesIndustrial engineeringFlange

The invention discloses a forging mechanism for continuous forging point rails and a preparation process for forging point rails, comprising: a preheating rail for accommodating the point rails to be forged, the preheating rails can maintain the temperature of the forging point rails during the forging process Hot forging is carried out at a temperature above 800°C, and there is also a forging wheel for forging the point rail to be forged. The way of flange extrusion makes the force-bearing area of the point rail to be forged large, and the force is uniform, continuous extrusion molding, easy to quickly form , the equipment loss is small, and the forging time is reduced. The invention also discloses a preparation process for a forging point rail, which includes the following steps: S1: heat treatment; S2: forging; S3: shaping; S4: unloading; S5: cooling; S6: Straightening; S7: Grinding. The invention can forge V-shaped, curved, straight forging materials, one end is bent and the other end is straight, and has a wide range of applications.

Owner:ANHUI ZHONGZHI RAIL TRANSPORTATION EQUIP MFG CO LTD

Ceramic blank rubber base consolidation forming method

The invention relates to a ceramic blank rubber base consolidation forming method. The method comprises the following steps of: adding 5 grams of ammonium polyacrylate of which the pH is 7 to 8, 1 gram of 0.8 mass percent diammonium sulfate, 1 gram of 0.15 to 0.25 mass percent ethyl ammonium acrylate and 3 grams of composition of acrylamide monomer (AM) and aluminum sulfate cross linker in a mass ratio of 1: 20 into 1 kilogram of powder of ceramic slurry, adding water, stirring to form the ceramic slurry, performing injection molding on the ceramic slurry, solidifying at 60-70 DEG C, stripping, firing at the temperature of 1,580 DEG C, thus obtaining a ceramic finished product. According to the method, because the AM and the cross linker are added in the ceramic blank powder, so that the ceramic slurry has cohesiveness and is easily formed and early solidified, and the strength and the quality of the ceramic blank can be improved. The ceramic slurry is applied to preparation of ceramic blanks.

Owner:LIAONING YIFEI TECH

A self-adhesive anti-neutron composite shielding material and its preparation method and application

ActiveCN107082965BImprove shielding effectProper initial stressShieldingFlat articlesVulcanizationActive agent

The invention provides a self-adhered type anti-neutron composite shielding material as well as a preparation method and application thereof. The shielding material is prepared from the following raw materials in parts by weight through radiation pre-crosslinking treatment: 100 parts of a rubber susbtrate, 5-50 parts of a tackifying agent polymer, 10-100 parts of a reinforcing agent, 20-200 parts of an anti-neutron additive, 0-50 parts of a softening agent, 0.5-10 parts of a vulcanizing agent, 0.5-5.0 parts of a vulcanization promoter, 0.5-10 parts of a vulcanization activator and 0-5.0 parts of an anti-aging agent. The invention further provides a preparation method of the shielding material and application of the shielding material in complex equipment or irregular parts. The self-adhered type anti-neutron composite shielding material provided by the invention has certain initial crosslinking degrees and self adhesion properties, is good in shape flow property, can be cured by self after being shaped, and has appropriate mechanical strength.

Owner:BEIJING RADIATION APPL RES CENT

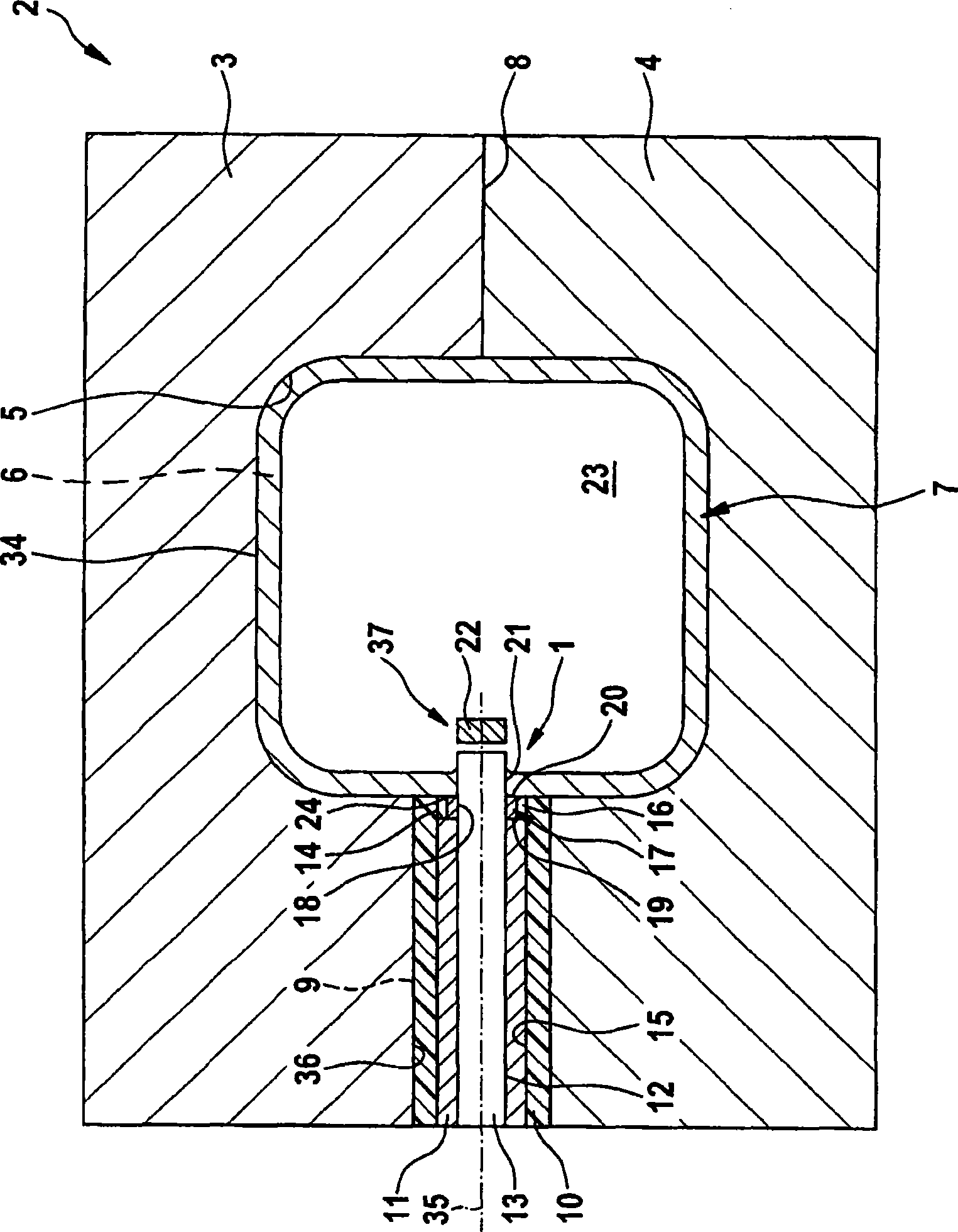

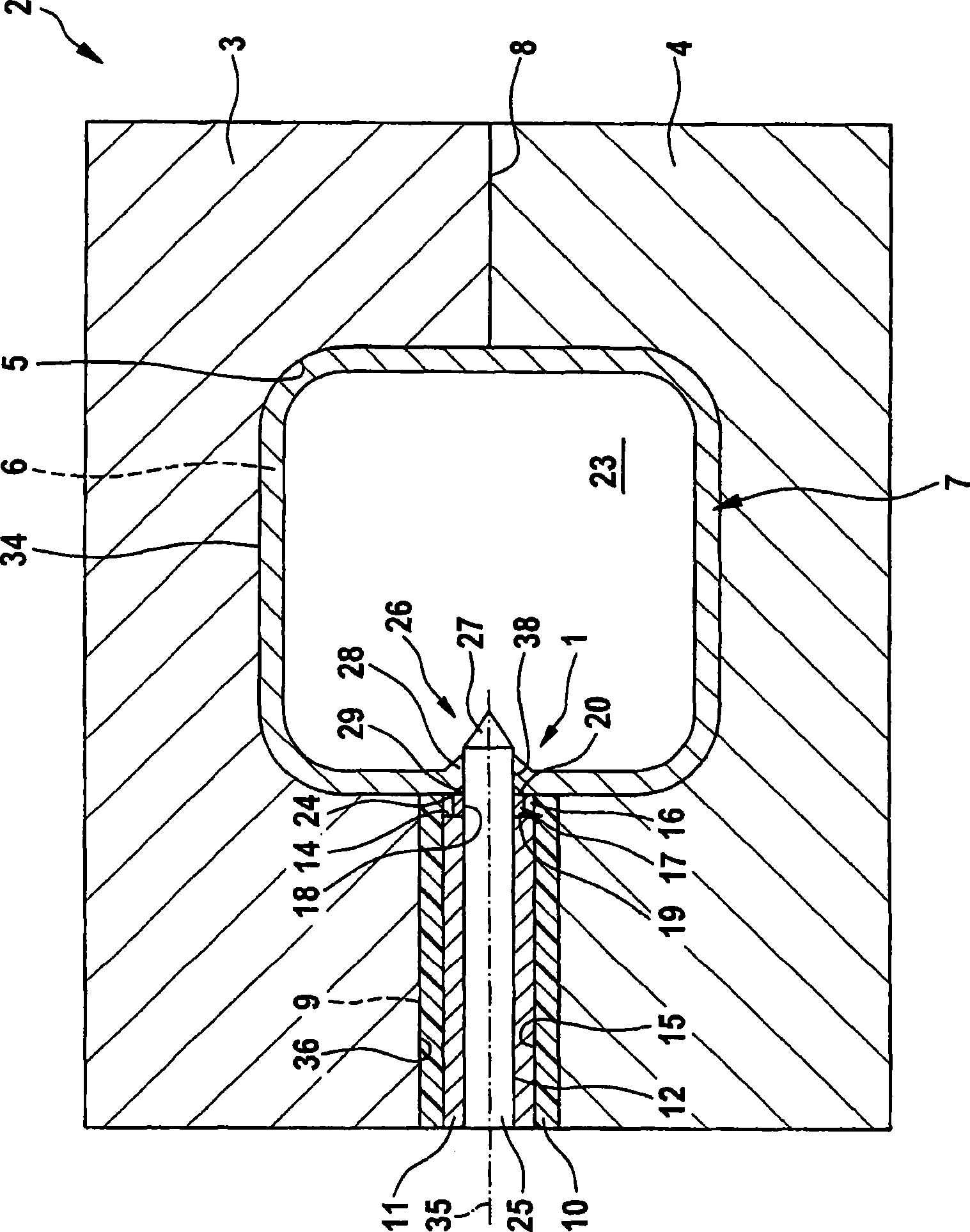

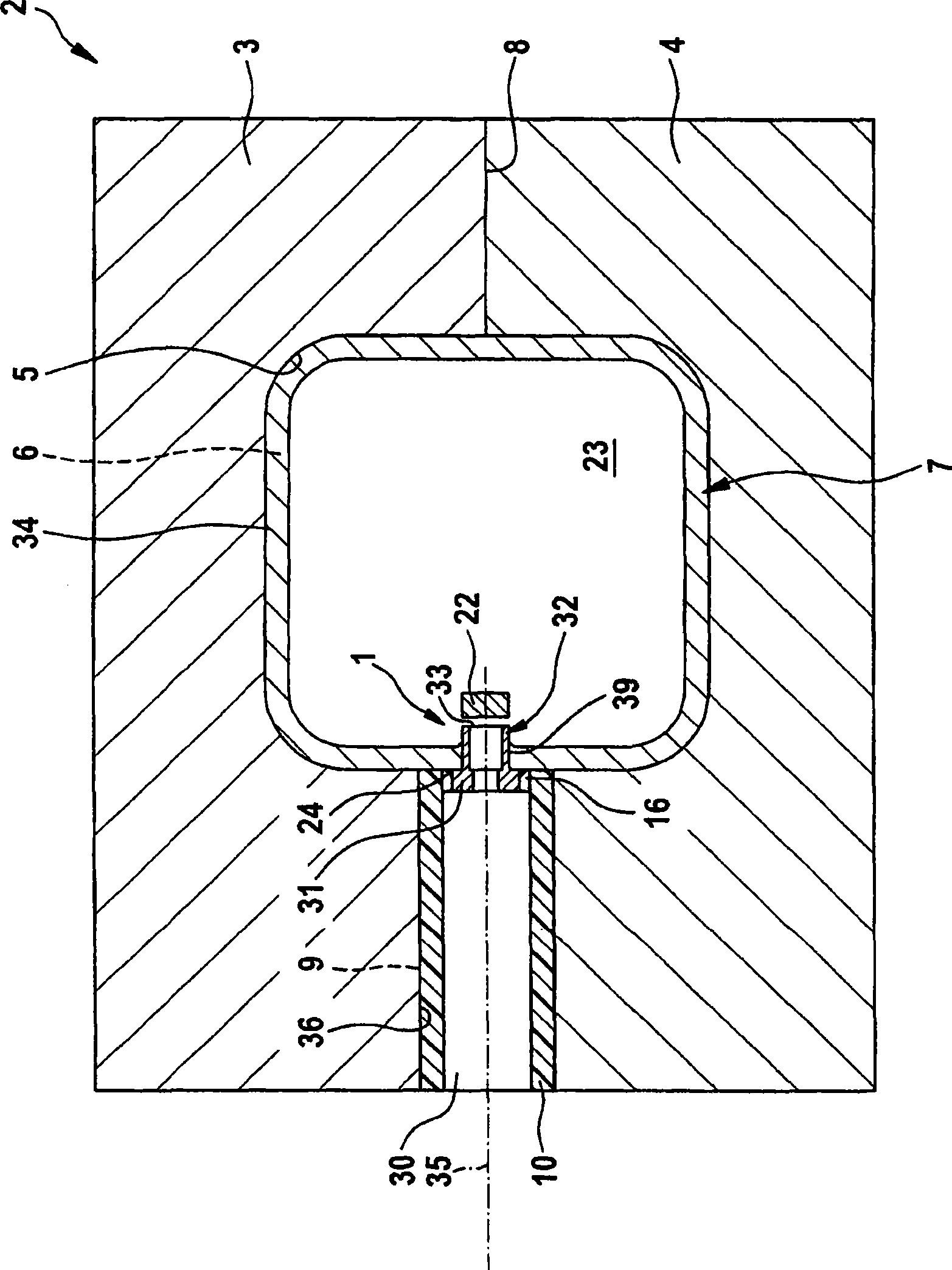

Method and device for producing a screw connection point

InactiveCN101479056ASimplify processing stepsAvoid welding qualityResistance welding apparatusEngineeringHigh pressure

The invention relates to a method and a device for producing a screw connection point (1) on the periphery (34) of a hollow section (7), that is expanded by a high-pressure fluid. An attachment (17, 31) comprising a bore (18) with an inner thread is mounted on the hollow section (7) in the hydroforming mould (2) and a hole is then made in the hollow section (7) in alignment with the bore (18). The aim of the invention is to produce a durable screw connection point (1) on the periphery (34) of a hollow section (7) in a simple and reliable process. To achieve this, the attachment (17, 31) is advanced towards the hollow section (7) with the aid of an electrode (11, 30) that is integrated into the hydroforming mould (2). The attachment (17, 31) is resistance welded to the hollow section (7) by means of the electrode (11, 30), once said attachment has been placed on the mould relief (5) in the vicinity of the screw connection point (1) to be created.

Owner:DAIMLER AG

Macromolecular polymer colored clay and preparation method thereof

The invention discloses amacromolecular polymer colored clay and a preparation method thereof, and relates to the technical field of colored clay. The macromolecular polymer colored clay is prepared from the following components in percentage by weight: 1 to 35 percent of a macromolecular dihydric alcohol, 15 to 50 percent of diisocyanate, 1.5 to 15 percent of a chain extender, 0.1 to 2 percent ofa colored micromolecular dihydric alcohol, 0.1 to 5 percent of a cross-linking agent, 0.1 to 1 percent of a wetting agent and 1 to 20 percent of water. The macromolecular polymer colored clay prepared by the invention belongs to a high polymer material, and has the properties of safety, no toxicity, high ductility, high elasticity, low viscosity and the like. Meanwhile, the micromolecular structures are grafted to the polymer, so that the macromolecular polymer colored clay has the characteristics of rich colors, good permeability and the like. As the wetting agent is added into the macromolecular polymer colored clay, the water retention effect is good, and the macromolecular polymer colored clay can be repeatedly used.

Owner:浙江材华科技有限公司

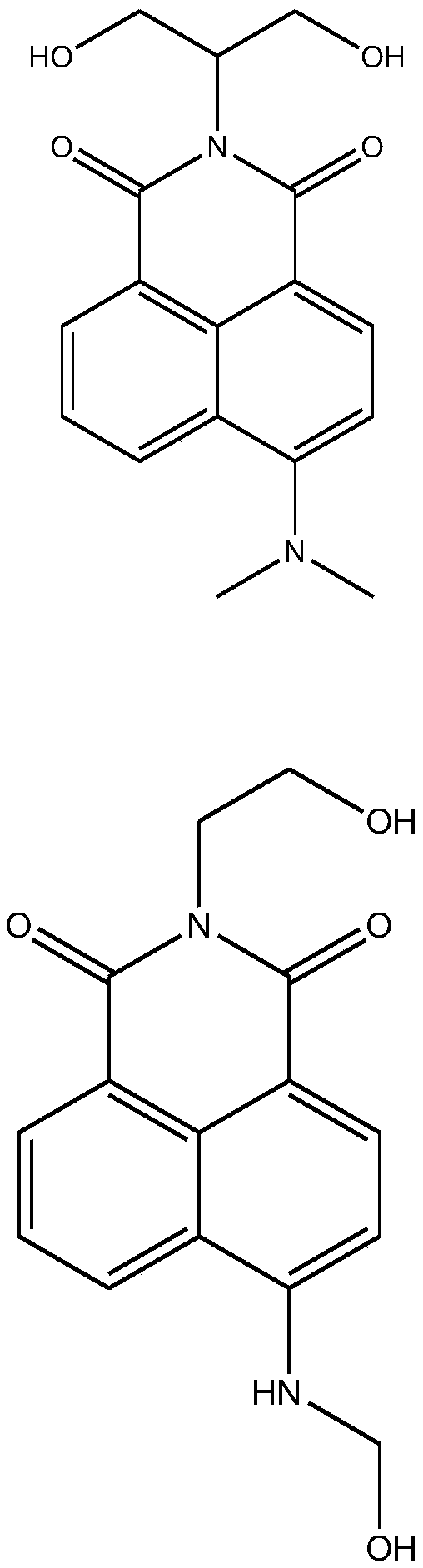

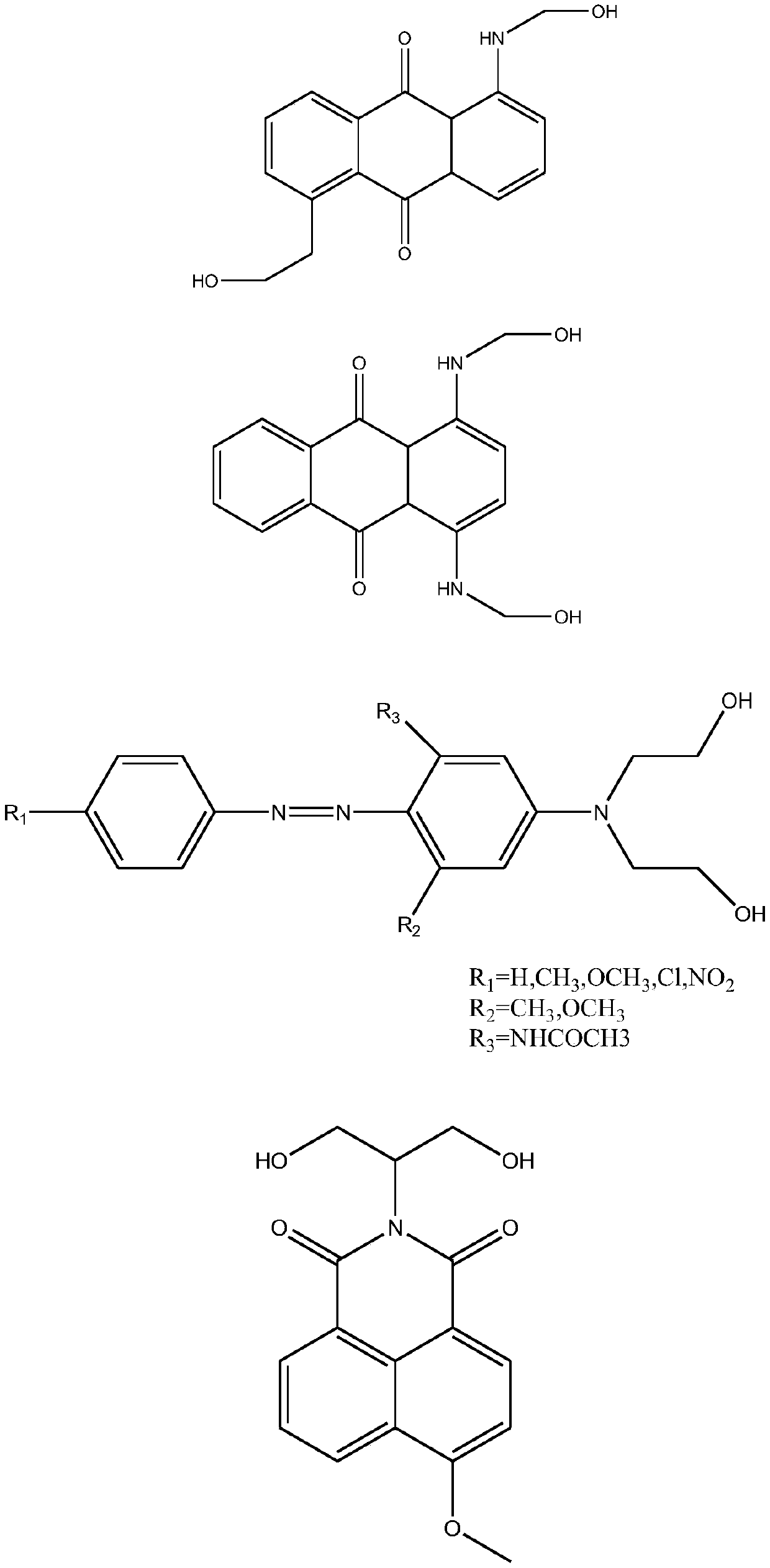

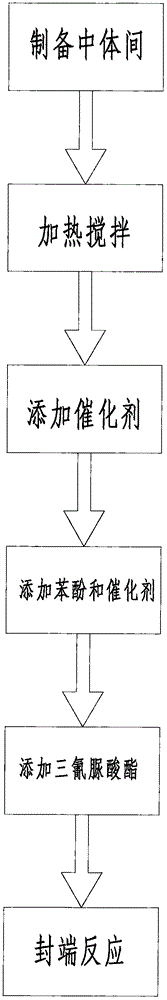

Preparation method of polyester fiber fire retardant

InactiveCN106222770AImprove stabilityStrong antioxidantFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterFire retardant

The invention discloses a preparation method of a polyester fiber fire retardant. The preparation method comprises the following steps: adding tri(phosphine oxide) and a UV stabilizing agent into tetraphenyl diphosphonate, carrying out reactions for a while to prepare an intermediate; adding the intermediate into a stirring machine, stirring the intermediate at a constant speed and a certain temperature for a while, when the ratio of tri(phosphine oxide): tetraphenyl diphosphonate: the UV stabilizing agent of the intermediate reaches 4.5:1:0.05, stopping stirring; adding a certain amount of catalyst into the heated and stirred intermediate, stirring at a constant speed and a certain temperature for a while; adjusting the temperature to 160 to 180 DEG C, adding a certain amount of phenol and catalyst, carrying out reactions for a while; adding a certain amount of tricyanurate into the formed solution; controlling a certain reaction temperature to make the formed solution carry out end capping reactions to prepare the polyester fiber fire retardant. The fire retardant has the advantages of simple structure and practicality.

Owner:孙中志

A kind of carbon fiber reinforced thermosetting resin matrix composite material and preparation method thereof

The invention discloses a carbon fiber reinforced thermosetting resin-based composite material and a preparation method thereof, belonging to the technical field of advanced composite materials. The preparation method of the invention is as follows: firstly, a matrix resin, a low shrinkage agent, a curing agent, a polymerization inhibitor, an internal mold release agent, a thickening agent and a dispersing aid are sampled and mixed uniformly according to the mass ratio to obtain a resin paste; The carbon fiber non-woven fabric is prepared into a sheet-like carbon fiber prepreg by a sheet-like molding compound process; the sheet-like carbon fiber prepreg is laid flat and superimposed, vacuum hot-pressed, and the mold is closed; That is, the carbon fiber reinforced thermosetting resin matrix composite material is obtained. The invention has the characteristics of simple process, short production cycle, low energy consumption, designable strength and modulus, easy large-area molding, and can meet the molding requirements of products with complex shapes and structures, and the like, and the prepared composite material has high strength and modulus. High, light weight, isotropic and other excellent properties.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com