A self-adhesive anti-neutron composite shielding material and its preparation method and application

A composite shielding and self-adhesive technology, which is applied in the field of shielding materials, can solve problems such as poor structural adaptability, limited application occasions, and difficult construction, and achieve the effects of preventing deformation or relaxation, good conformity, and appropriate mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for preparing a self-adhesive anti-neutron composite shielding material, which includes the following steps:

[0062] Raw material formula:

[0063] Rubber matrix: 70 parts by weight of EPDM4045, 30 parts by weight of natural rubber;

[0064] Viscosifying polymer: 25 parts by weight of liquid polyisobutylene rubber;

[0065] Reinforcing agent: 35 parts by weight of white carbon black;

[0066] Anti-neutron additive: B 4 15 parts by weight of C, 5 parts by weight of graphite powder, 5 parts by weight of lithium fluoride;

[0067] Vulcanization activator: 5 parts by weight of zinc oxide, 1 part by weight of stearic acid;

[0068] Softener: 5 parts by weight of epoxy soybean oil;

[0069] Vulcanizing agent: 2.0 parts by weight of S-80;

[0070] Vulcanization accelerator: 1.5 parts by weight of ZBEC80, 0.5 parts by weight of zinc isopropyl xanthate ZIX, 1.5 parts by weight of DPG80;

[0071] Antiaging agent: 3 parts by weight of micr...

Embodiment 2-6

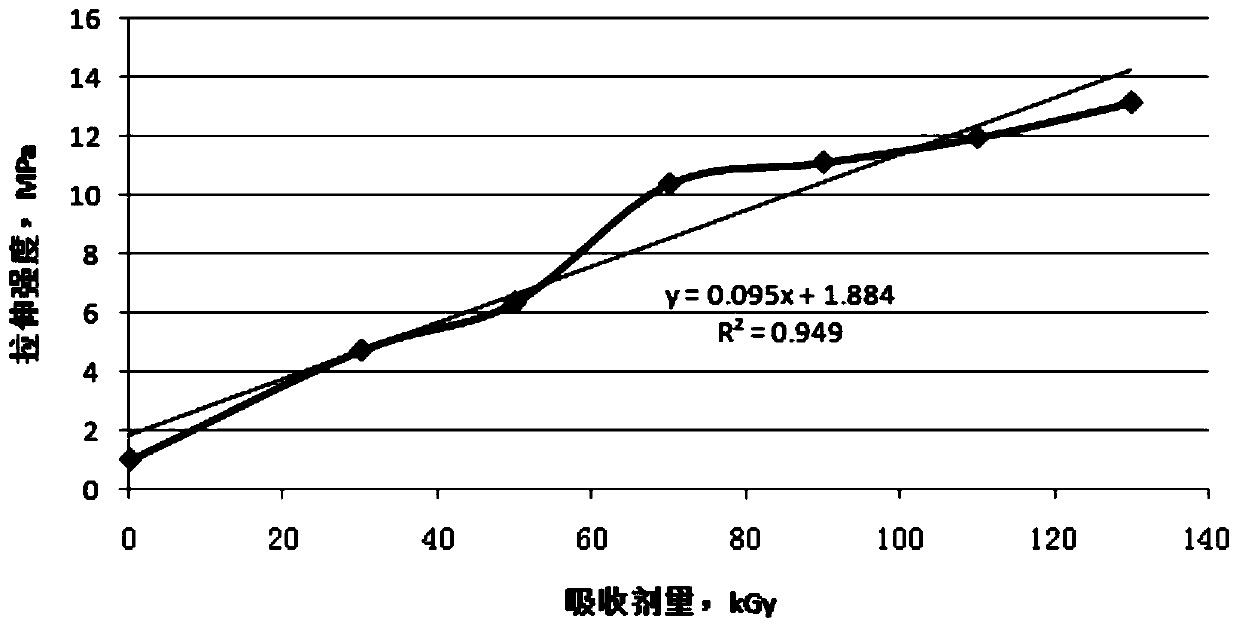

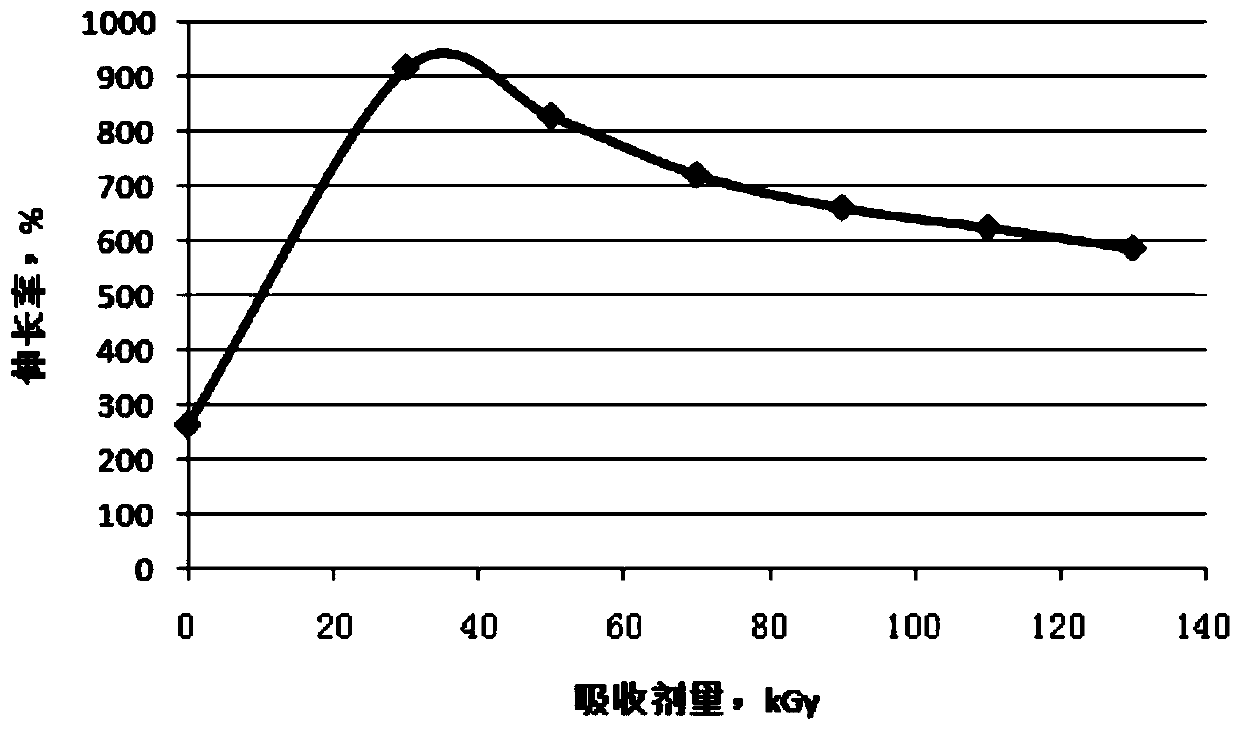

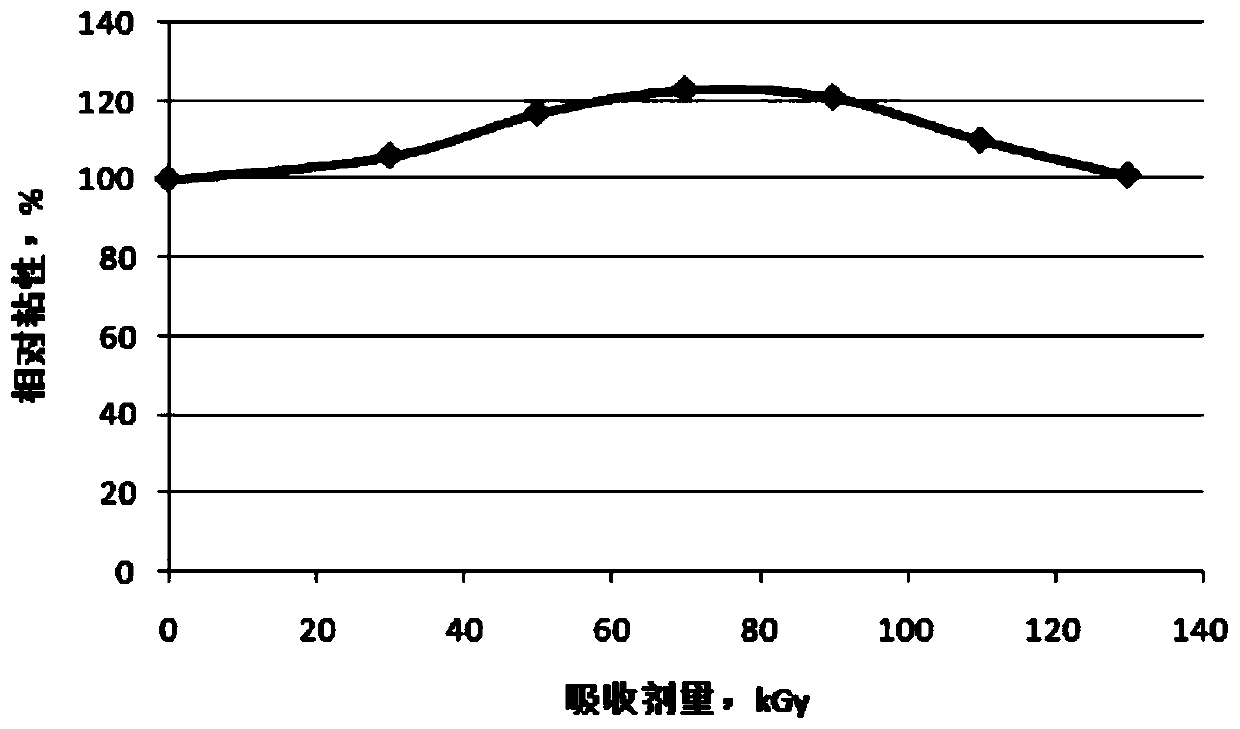

[0078] Embodiment 2-6 respectively provides a kind of preparation method of self-adhesive type anti-neutron composite shielding material, and its difference with embodiment 1 is only that the radiation absorbed dose is different in the pre-crosslinking process, used in embodiment 2-6 The absorbed doses of radiation are: 30kGy, 70kGy, 90kGy, 110kGy and 130kGy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com