End face sealing structure for motor and stator of hub motor

A technology of end face sealing and wheel hub motors, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of shortening the service life of hub motors, lack of stable sealing supports, and unreliable positions of seals, etc., to achieve easy standardized production, Favorable effect of sealing and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

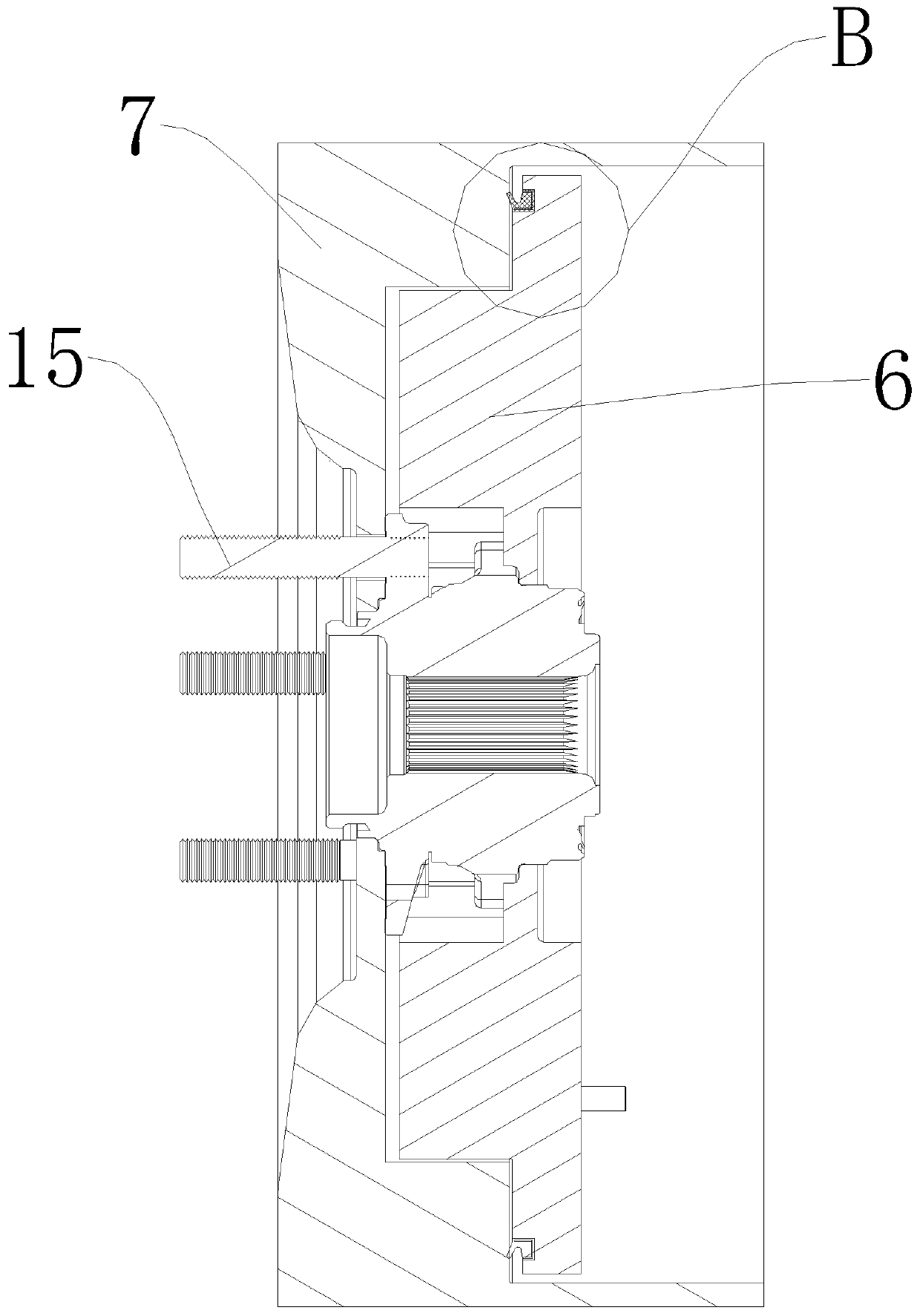

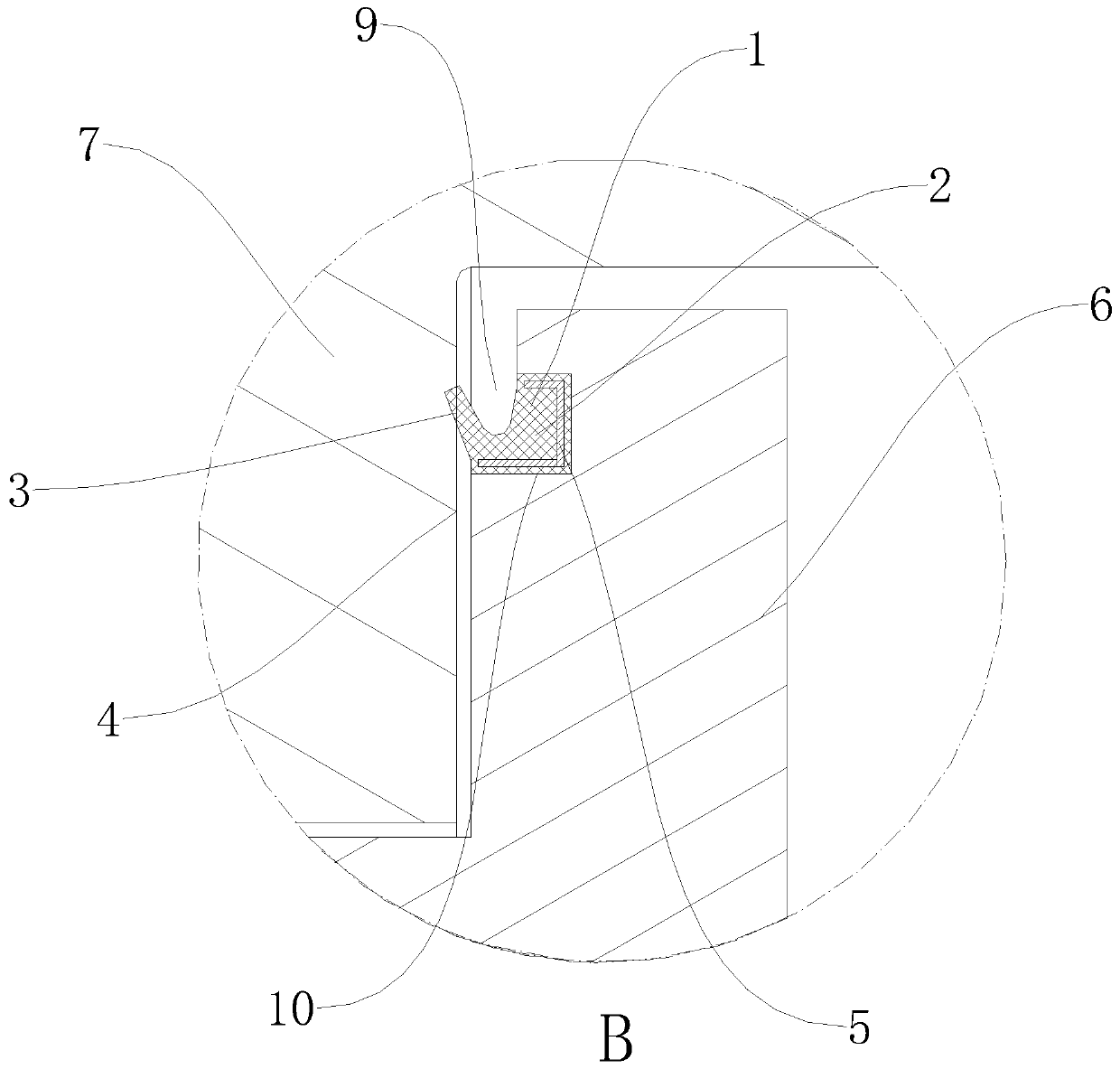

[0032] Such as Figure 1 to Figure 3 As shown, this embodiment provides an end face sealing structure for the rotor and the stator of the in-wheel motor. For ease of understanding, the installation of the in-wheel motor is first described. The rotating part of the bearing 15 of the in-wheel motor is installed with the wheel, and the rotor 7 of the in-wheel motor is connected to the rotating part of the bearing 15 by bolts, so as to be fixed with the wheel. The rotor 7 It can drive the wheels to realize synchronous rotation. The stator 6 is connected with the non-rotating part of the bearing 15 through bolts and does not rotate. The coil of the stator 6 is energized to drive the rotor 7 to rotate, and the rotor 7 drives the wheels to rotate. This is the basic principle of the hub motor. Since there is a gap between the rotor 7 and the stator 6, external impurities will enter the interior of the hub motor and affect the hub motor. Therefore, this embodiment provides a seal 1 to ...

Embodiment 2

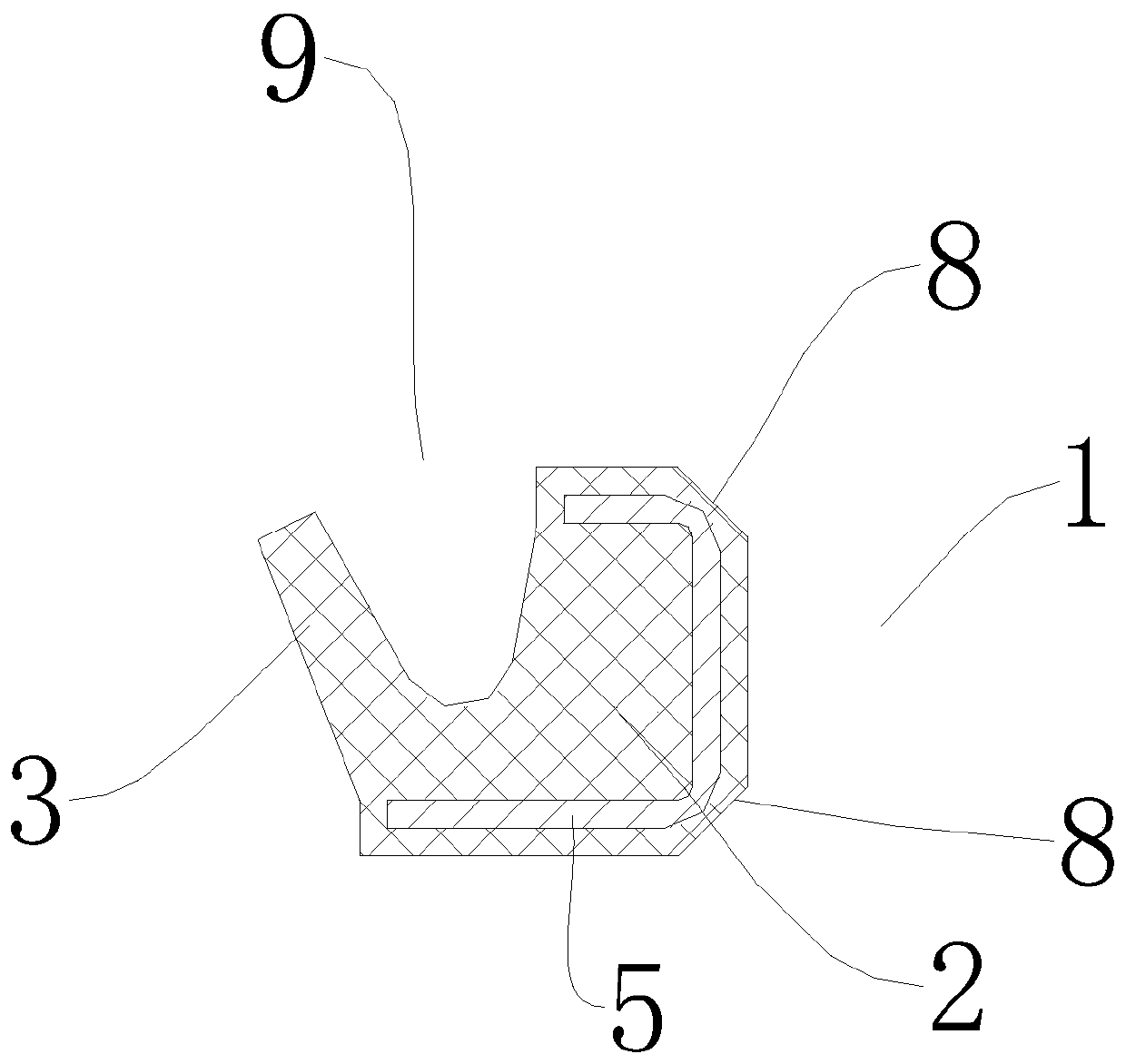

[0038] Such as Figure 4 As shown, this embodiment provides an end face sealing structure for the hub motor rotor and stator. The difference between this embodiment and Embodiment 1 is that the support frame 5 is covered on the outside of the installation part 2, and the cross section of the support frame 5 is "U" shape.

Embodiment 3

[0040] Such as Figure 5 As shown, this embodiment provides an end face sealing structure for the rotor and stator of an in-wheel motor. The difference between this embodiment and Embodiment 1 is that the cross-sectional shape of the support frame 5 is "L" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com