Hanging type power cable and optical cable

A hanging and hanging technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of slow production speed, cable untwisting, stripping, expensive, etc., to achieve easier molding and replacement, and high optical communication density. , good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

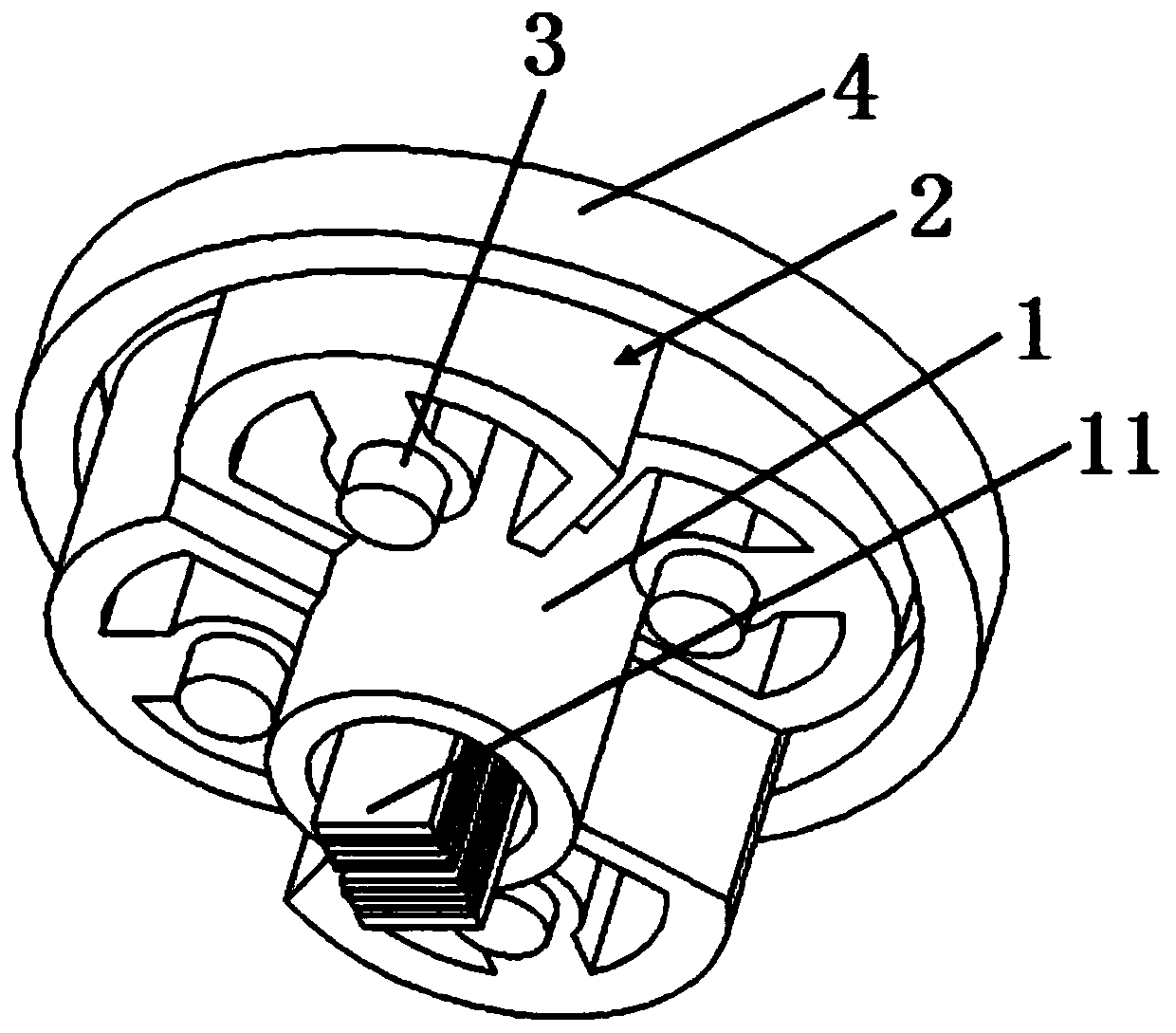

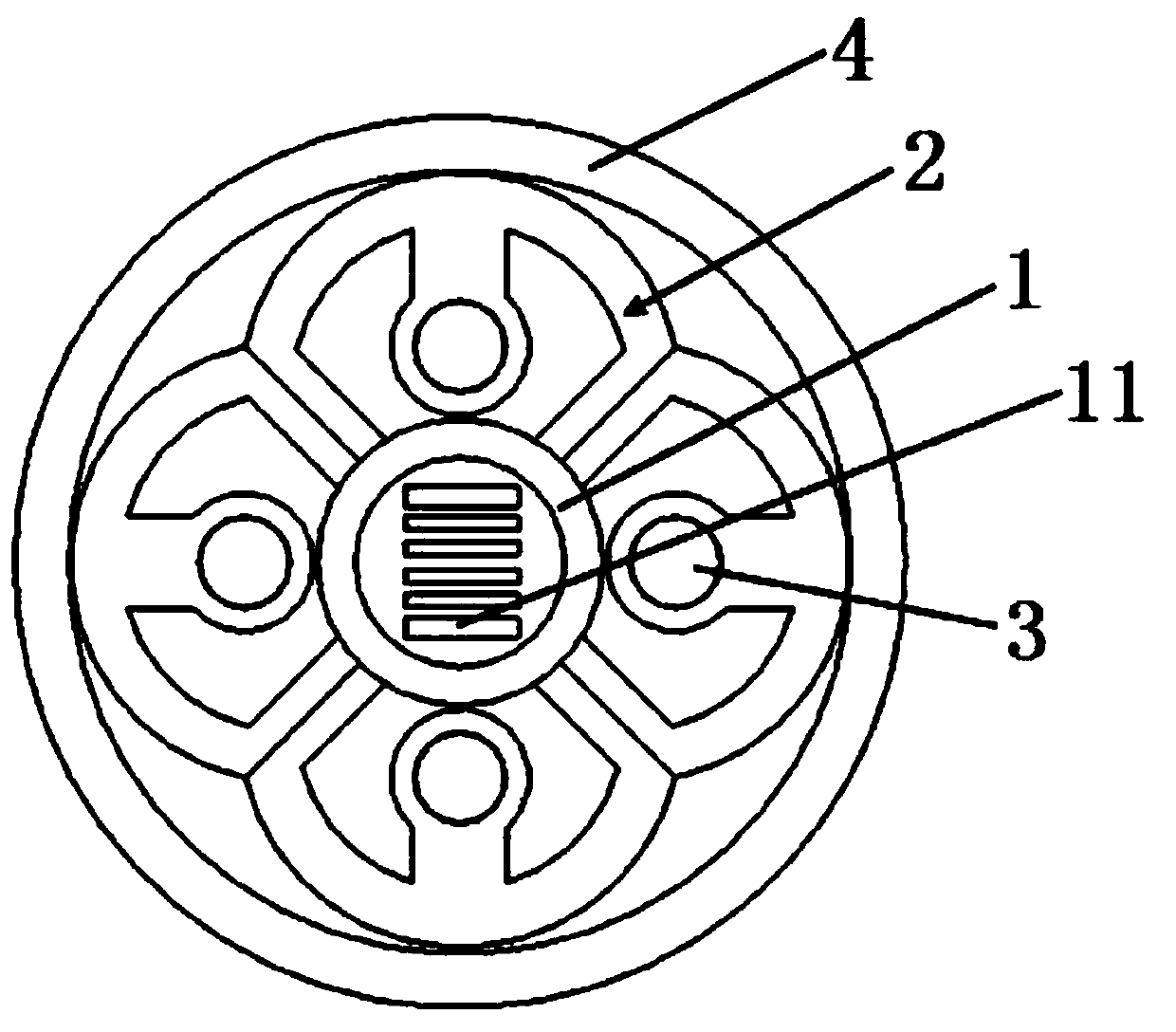

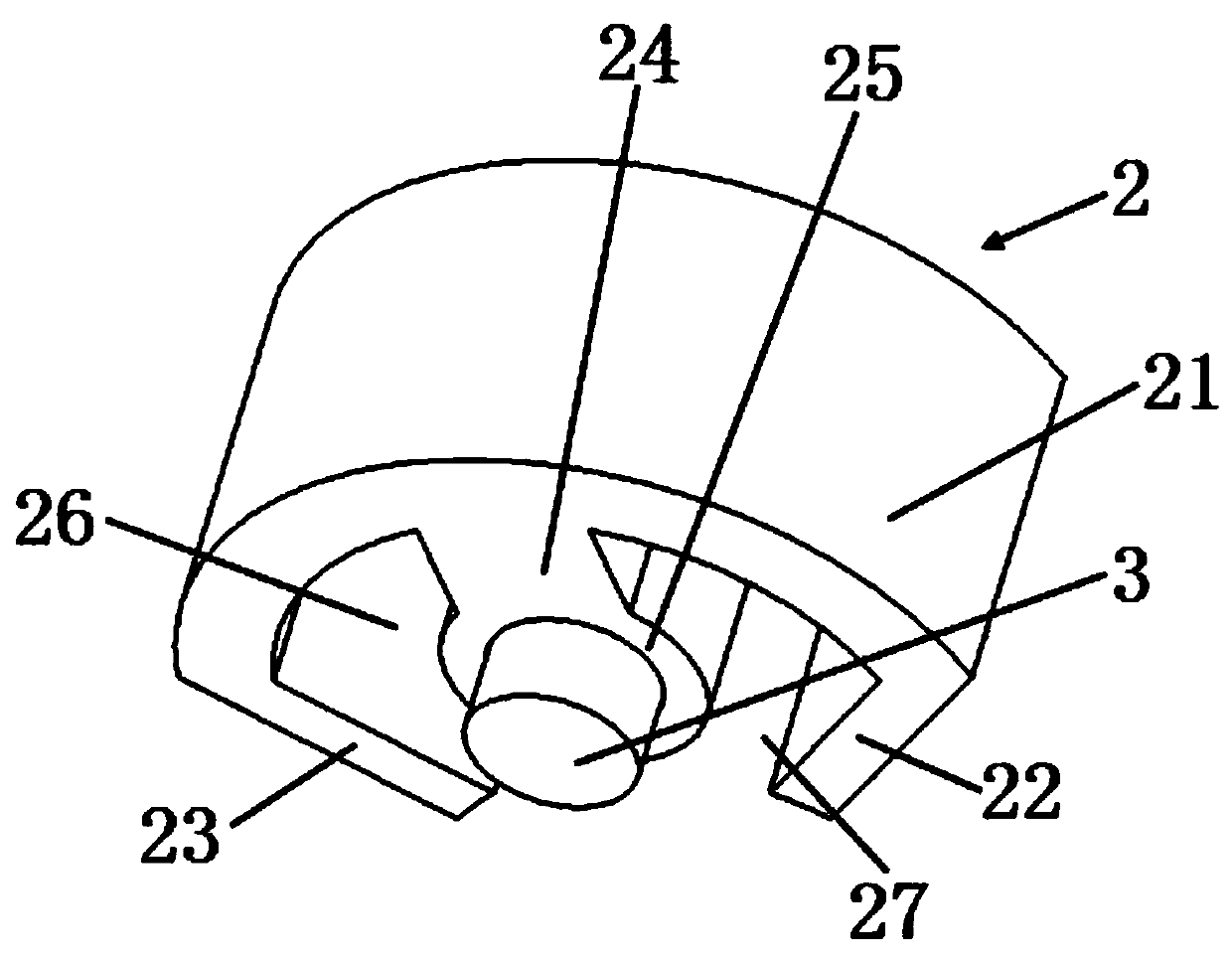

[0026] please see Figure 1 to Figure 4 , a kind of suspension type cable, has central bundle tube 1, four electrical conductors 3 outside the central bundle tube, outer sheath 4 outside the electrical conductors, inside the central bundle tube there are a plurality of optical fiber ribbons 11 stacked in sequence, There are light-transmitting parts in the optical fiber ribbon, and it is characterized in that there are four hanging parts 2 in the hanging cable, and each hanging part consists of a first hanging body 21, a second hanging body 22, a third hanging body The hanging body 23, the hanging connecting part 24, and the hanging body 25 are composed of the hanging parts. The third hanging body 23 is approximately cuboid, the first hanging body 21 is bent downward, one end of the first hanging body 21 is connected to one end of the third hanging body 23, and the other end of the first hanging body 21 is connected to the second hanging body 21. One end of the second suspensi...

Embodiment 2

[0028] please see Figure 5 , and refer to Figure 1 to Figure 4 , a suspension type optical cable, has a central beam tube 1, a plurality of photoconductors 12 located outside the central beam tube, an outer sheath 4 located outside the photoconductor 12, and a plurality of optical fiber ribbons stacked in sequence inside the central beam tube 11. There are light-transmitting components in the optical fiber ribbon, which is characterized in that there are four hanging components 2 in the hanging optical cable, and each hanging component consists of a first hanging body 21, a second hanging body 22, The third hanging body 23, the hanging connecting part 24, and the hanging body 25 are composed of the hanging parts in an integrated structure, the first hanging body 21 is a part of a circular cylinder, and the second hanging body 22 is approximately cuboid shape, the third hanging body 23 is approximately cuboid, the first hanging body 21 is bent downward, one end of the first ...

Embodiment 3

[0030] please see Image 6 , and refer to Figure 1 to Figure 5 , a suspension type optical cable, has a central beam tube 1, a plurality of photoconductors 12 positioned outside the central beam tube, an outer sheath 4 positioned outside the photoconductor 12, and a plurality of optical fibers 13 inside the central beam tube, characterized in that There are also four hanging parts 2 in the hanging optical cable, and each hanging part is composed of a first hanging body 21, a second hanging body 22, a third hanging body 23, a hanging connecting part 24, Suspension body 25 is formed, the suspension parts are integrated structure, the first suspension body 21 is a part of circular cylinder, the second suspension body 22 is approximately cuboid shape, the third suspension body 23 is approximately cuboid shape, The first hanging body 21 is bent downward, one end of the first hanging body 21 is connected to one end of the third hanging body 23, the other end of the first hanging b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com