Spark plug and its method of production

A technology for ignition plugs and manufacturing methods, which is applied in the field of ignition plugs, can solve problems such as complex processing and complex mold production processes, and achieve the effects of easy production and molding, easy production, and high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

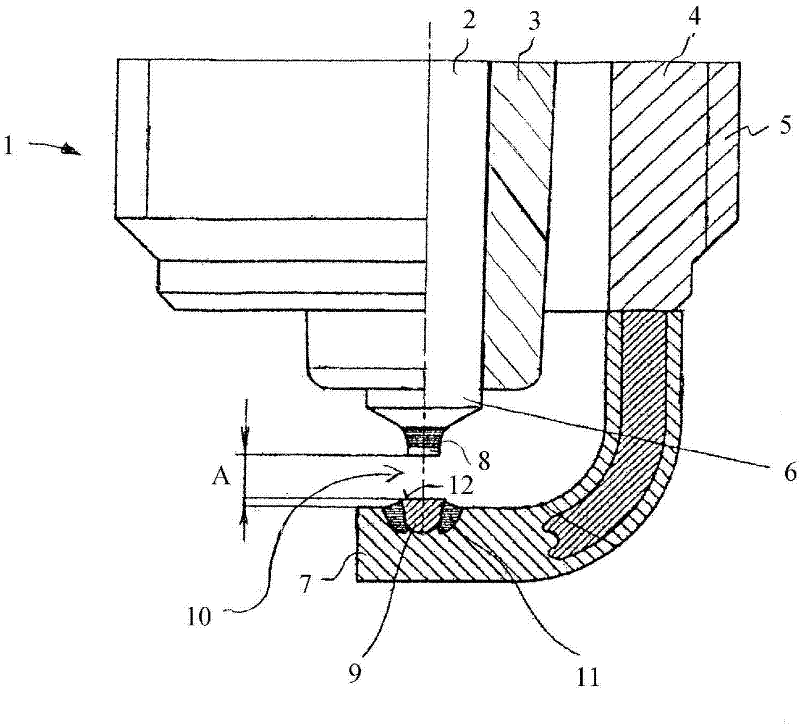

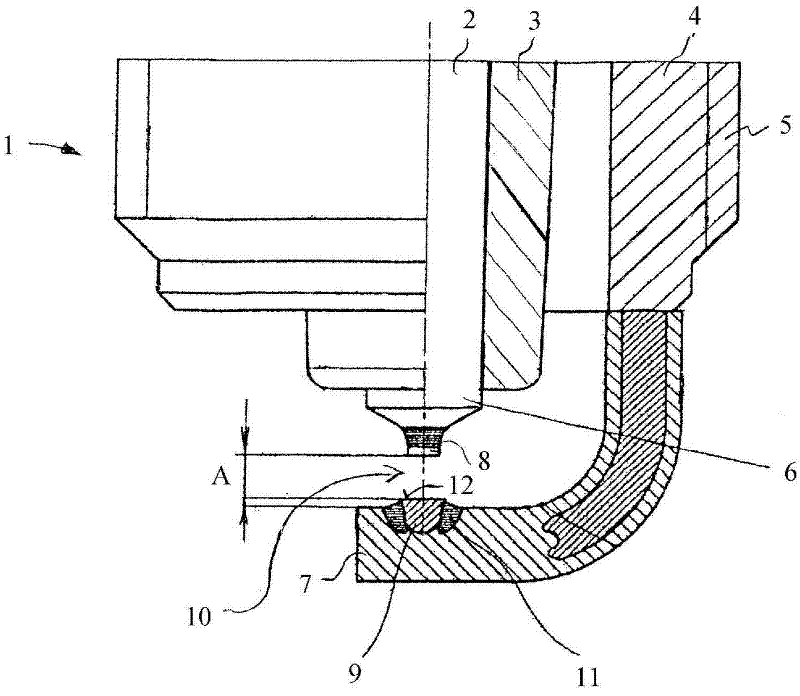

[0022] refer to figure 1 , the ignition plug 1 of the present invention comprises an inner conductor 2, an insulating sheath 3 wrapping said inner conductor 2, the exterior of the insulating sheath 3 is provided with a glow plug body 4 wrapping the insulating sheath 3, and the outer surface of the ignition plug body 4 is A screw thread 5 is provided. The glow plug includes two electrodes, a first electrode 6 and a second electrode 7 , the first electrode 6 is the center electrode, electrically connected to the inner conductor 2 , and the second electrode 7 is a ground electrode, electrically connected to the glow plug body 4 . A noble metal region 8 is attached to the first electrode 6 , and a noble metal region 9 is attached to the second electrode 7 . The second electrode 7 is installed above the first electrode 6 in the form of a front electrode, so that the noble metal region 8 and the noble metal region 9 face each other at a distance A and form an ignition gap 10 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com