Preparation method of polyester fiber fire retardant

A flame retardant and chemical fiber technology, applied in the field of polyester chemical fiber flame retardant preparation, can solve the problems of reducing the mechanical strength of polymers, waste of processing costs and resources, uneven product melting, etc., to reduce mold residues, excellent oxidation resistance, Easy coloring and molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

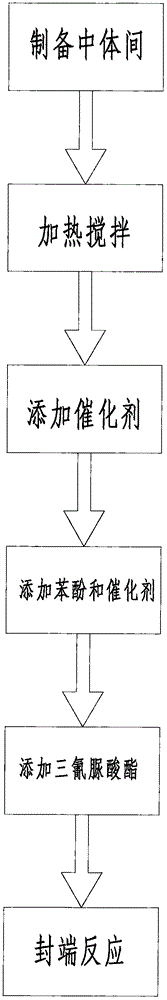

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a preparation method of flame retardant for polyester chemical fiber, the preparation method comprises the following steps: adding tripolyphosphine oxide and uv stabilizer to tetraphenyl diphosphonate, reacting for a certain period of time, and preparing an intermediate; The body is put into the mixer, and after a certain period of time, the temperature is stirred at a constant speed, so that the ratio of the tripolyphosphine oxide, tetraphenyl diphosphonate and uv stabilizer in the intermediate is 4.5: 1: 0.05, and the stirring is stopped; after heating After stirring, add a certain amount of catalyst to the intermediate, and then stir it at a constant speed for a certain time and temperature; when the temperature is adjusted to 160-180 degrees Celsius, add a certain amount of phenol and catalyst, and react for a certain period of time; Add a certain am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com