Patents

Literature

56results about How to "Low processing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

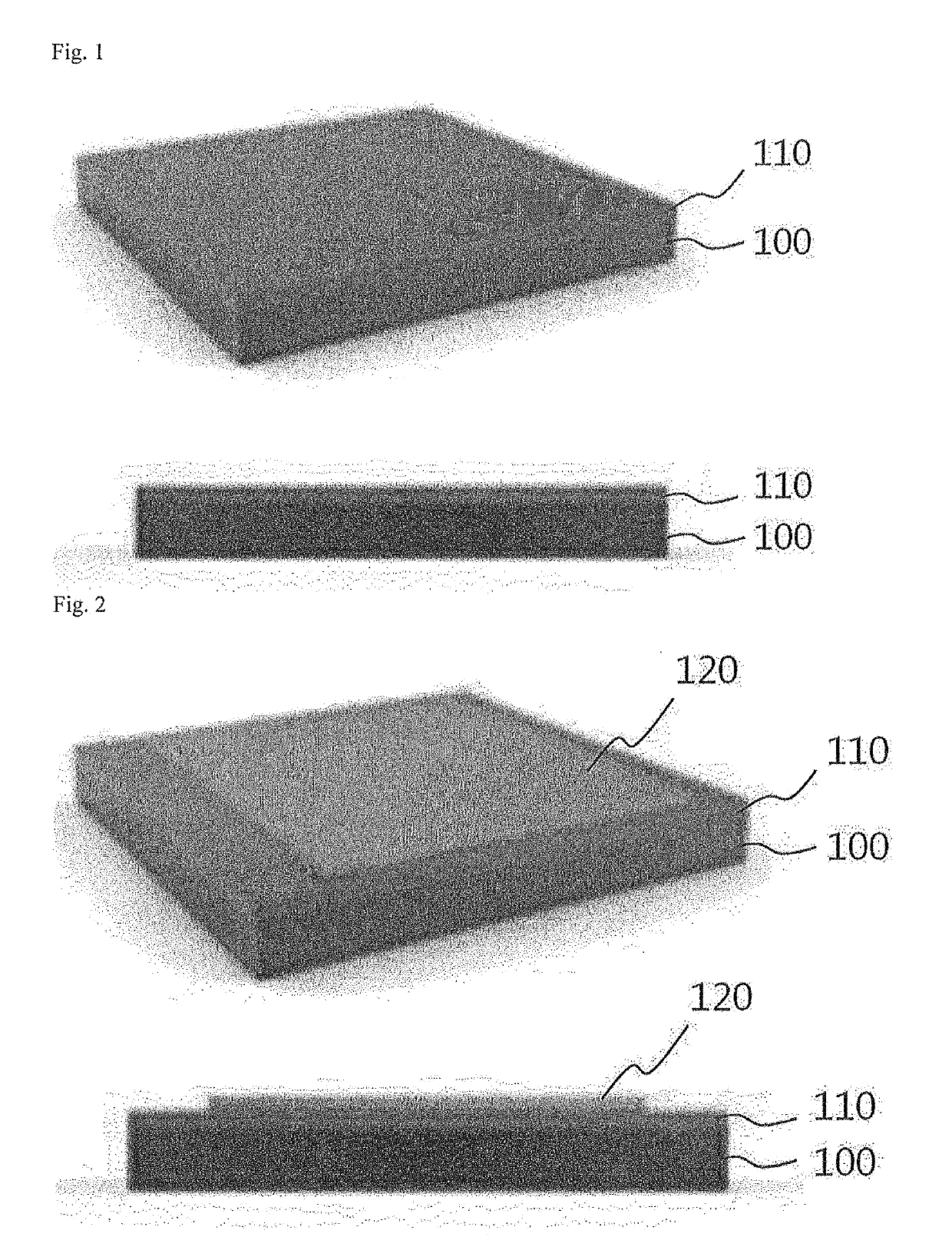

Ceramic microwave absorbing material and preparation method and application thereof

InactiveCN101665350AHigh surface hardnessScratch resistantScreening apparatusCooking vesselsMicrowaveUtilization rate

The invention discloses a ceramic microwave absorbing material and a preparation method and an application thereof. The ceramic microwave absorbing material comprises ceramic material powder and microwave absorbing powder, and the weight percentage of the components is as follows: 40 to 80 percent of ceramic material powder and 20 to 60 percent of microwave absorbing powder. The preparation methodof the ceramic microwave absorbing material comprises the following steps: 1) respectively weighing the ceramic material powder and the microwave absorbing powder according to weight percentage; 2) evenly mixing the ceramic material powder with the microwave absorbing powder to obtain compound wave-absorbing powder; 3) evenly mixing the compound wave-absorbing powder with methylcellulose and water to obtain the pulp of the ceramic microwave absorbing material; 4) forming the pulp to obtain a green body; and 5) drying the green body, and then sintering at high temperature to obtain the ceramicmicrowave absorbing material. The ceramic microwave absorbing material can be used for manufacturing ceramic microwave absorbing cooking equipment. The cooking equipment has high microwave utilization rate and heating efficiency; and food is not easy to be coked and is heated more uniformly. The preparation method of the ceramic microwave absorbing material has simple technique and low cost of raw material and processing.

Owner:MIDEA GRP CO LTD

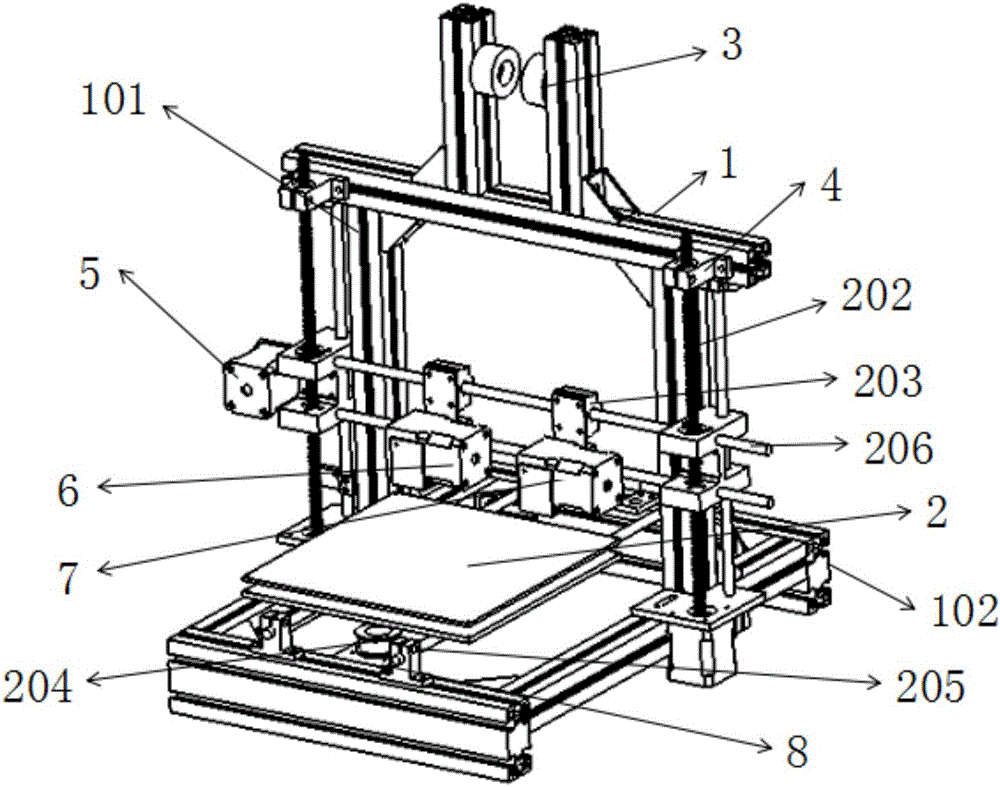

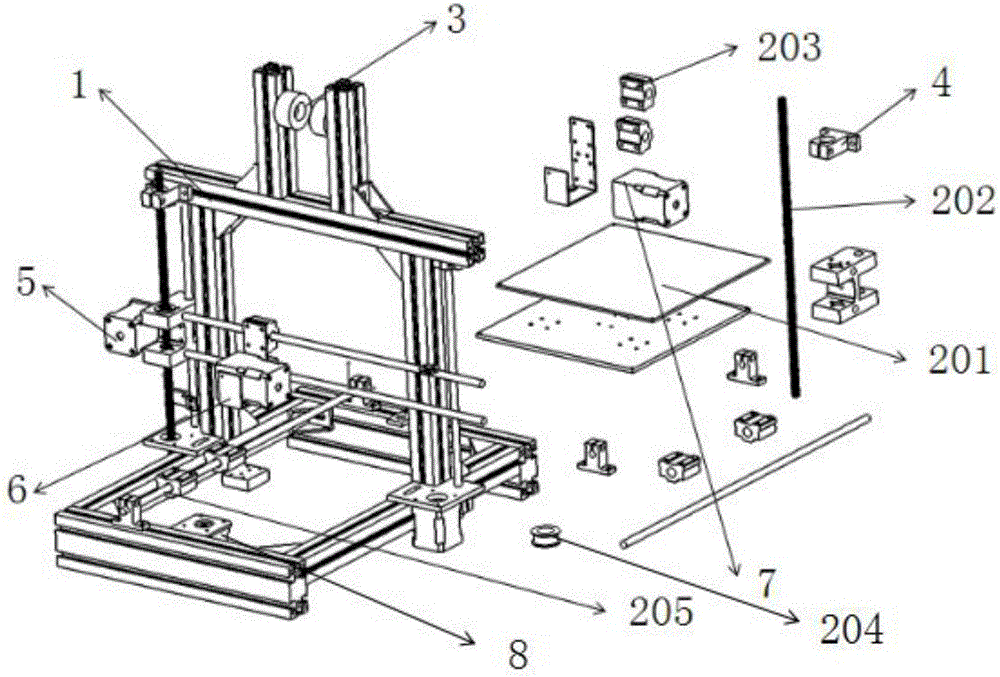

Double-sprayer and dual-mode 3D printer and operation method thereof

The invention discloses a double-sprayer and dual-mode 3D printer and an operation method thereof, and belongs to the technical field of 3D printing equipment. The printer comprises a bracket, a bottom platform device, a printed material fixing device, a driving motor I, a sprayer I, a sprayer II, a driving motor II and a central control unit, wherein the sprayer II is provide with two nozzles, and the two nozzles are respectively loaded with liquid A and liquid B in PU resin AB adhesive. The printer adopts a technology for constructing an object by replacing the mode of printing layer by layer through a mode of printing a casing and spraying the filler (PU resin AB adhesive), ensures that the strength of parts is improved, and reduces the part scrapping ratio. The weight mixing ratio of the liquid A to the liquid B in the PU resin AB adhesive is 1:1, as the liquid A and the liquid B can be cured in 1.5 to 2 minutes after being mixed, the curing speed is high, and the purpose of saving printing time is achieved. The printer adds new structure improvement design on traditional 3D printer equipment, and is low in improvement machining cost, and good in inheritability of manufacturing process and technical process.

Owner:CHANGCHUN UNIV OF TECH

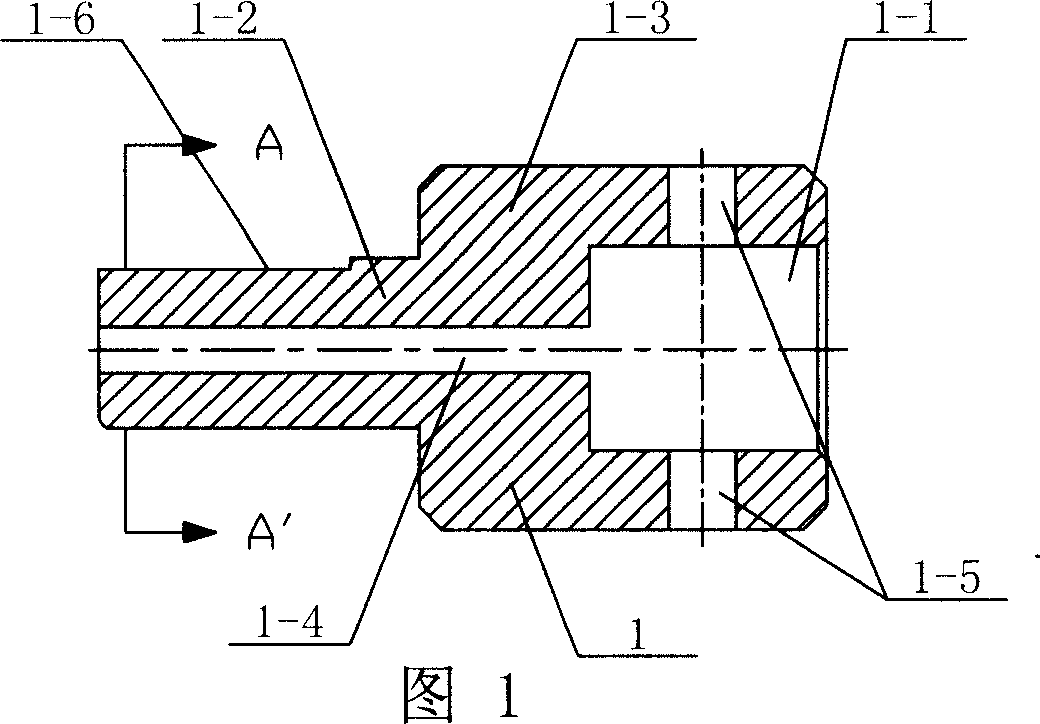

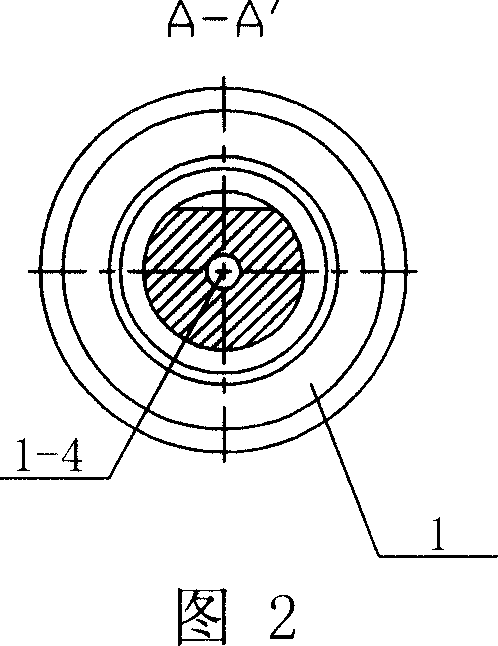

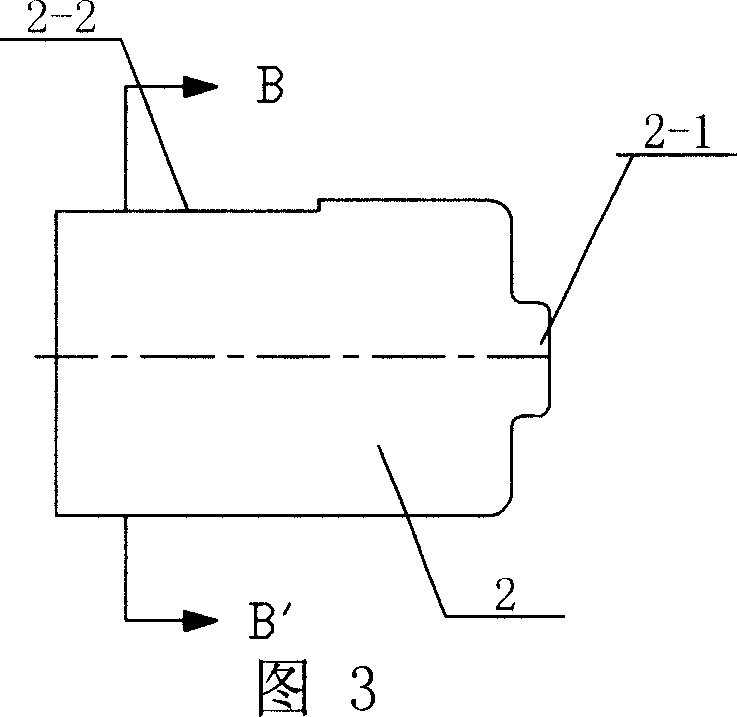

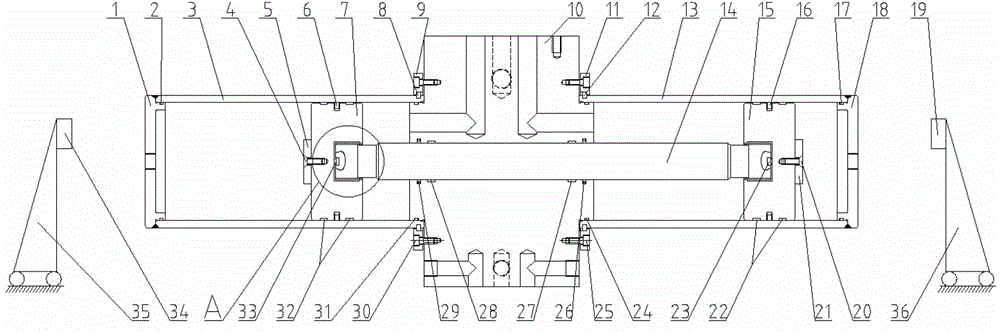

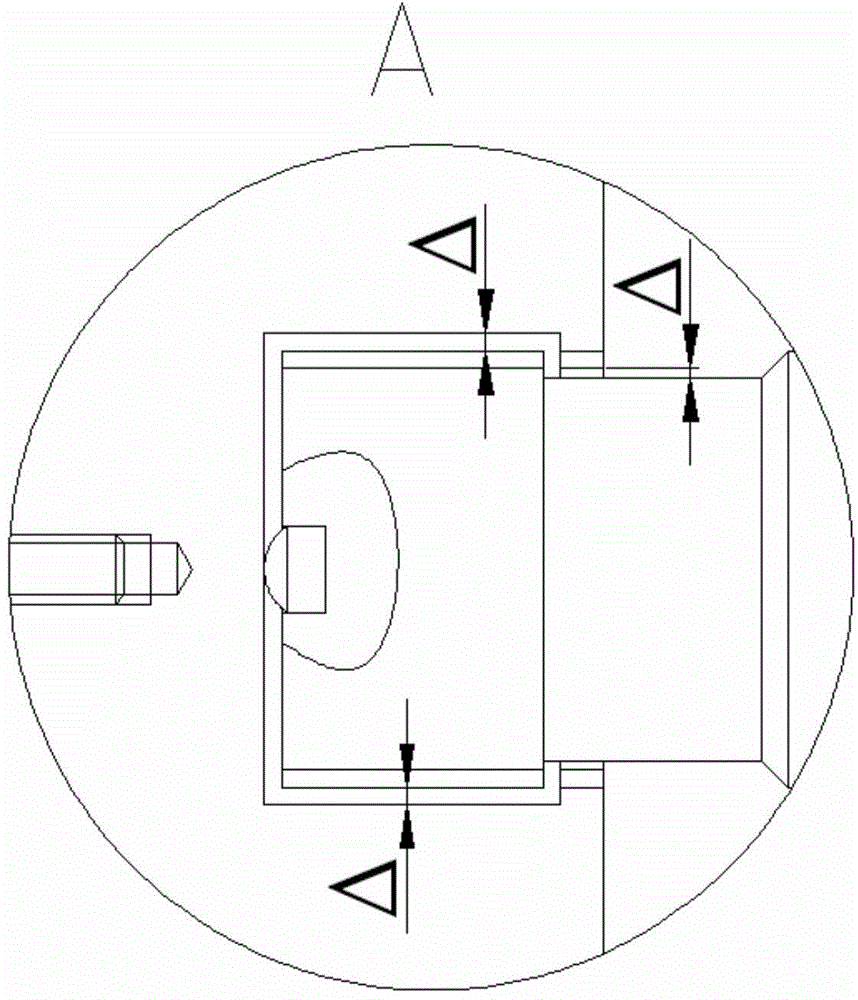

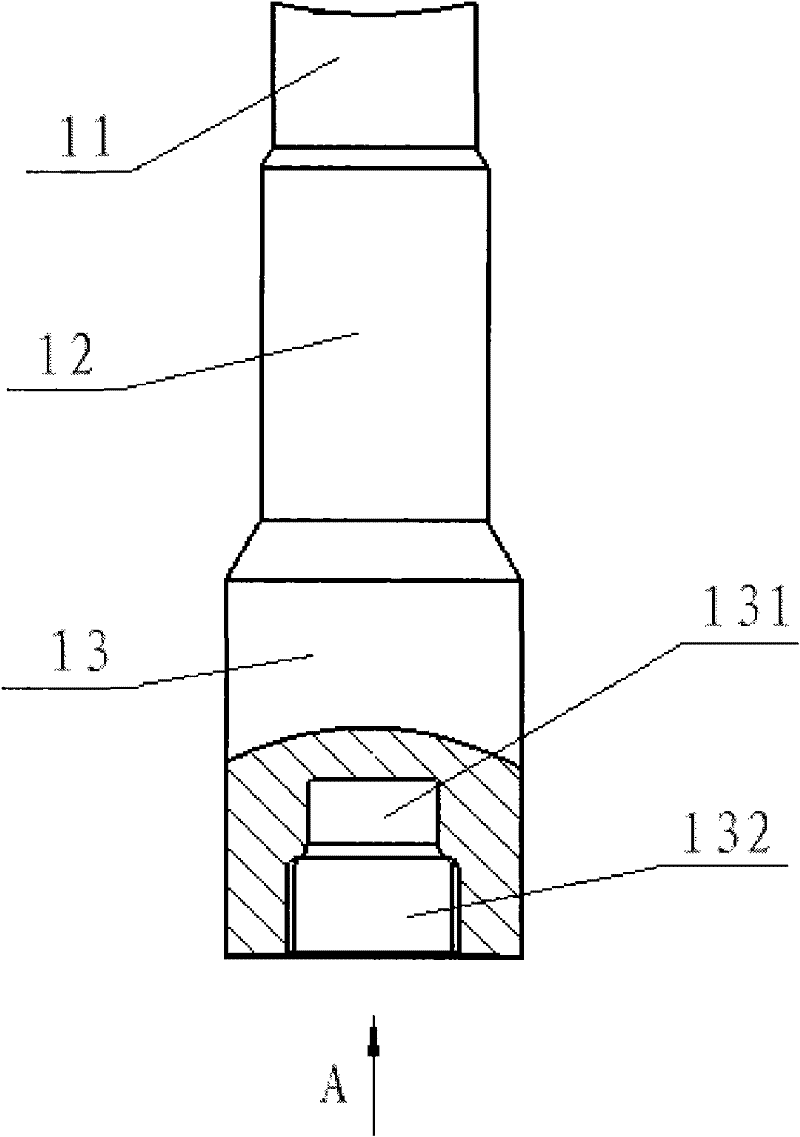

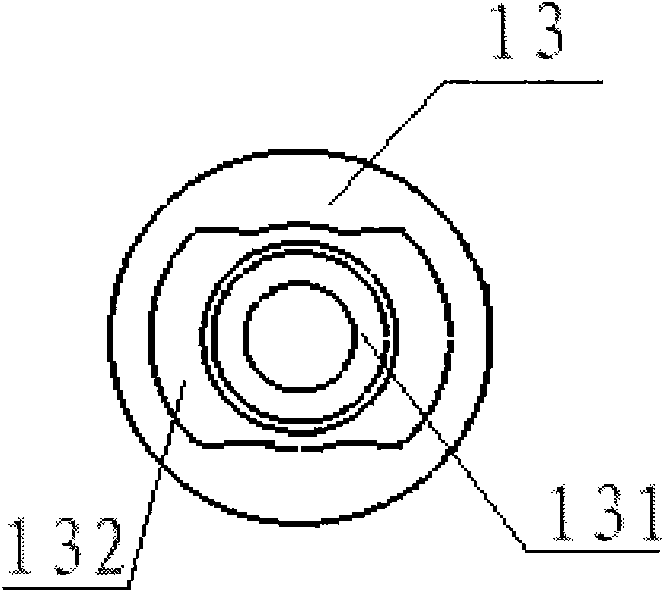

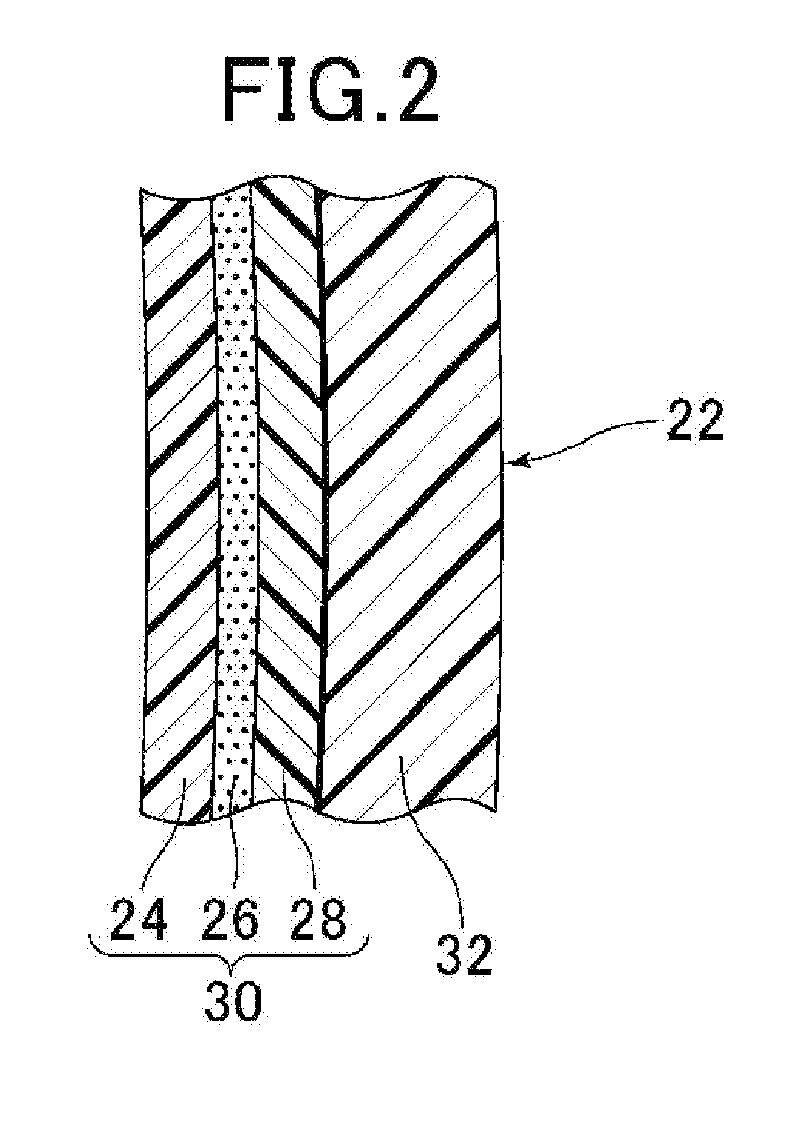

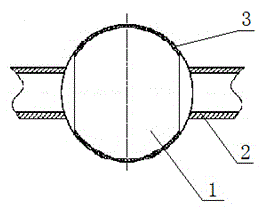

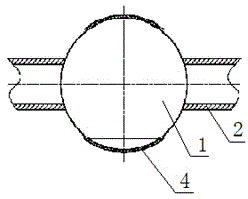

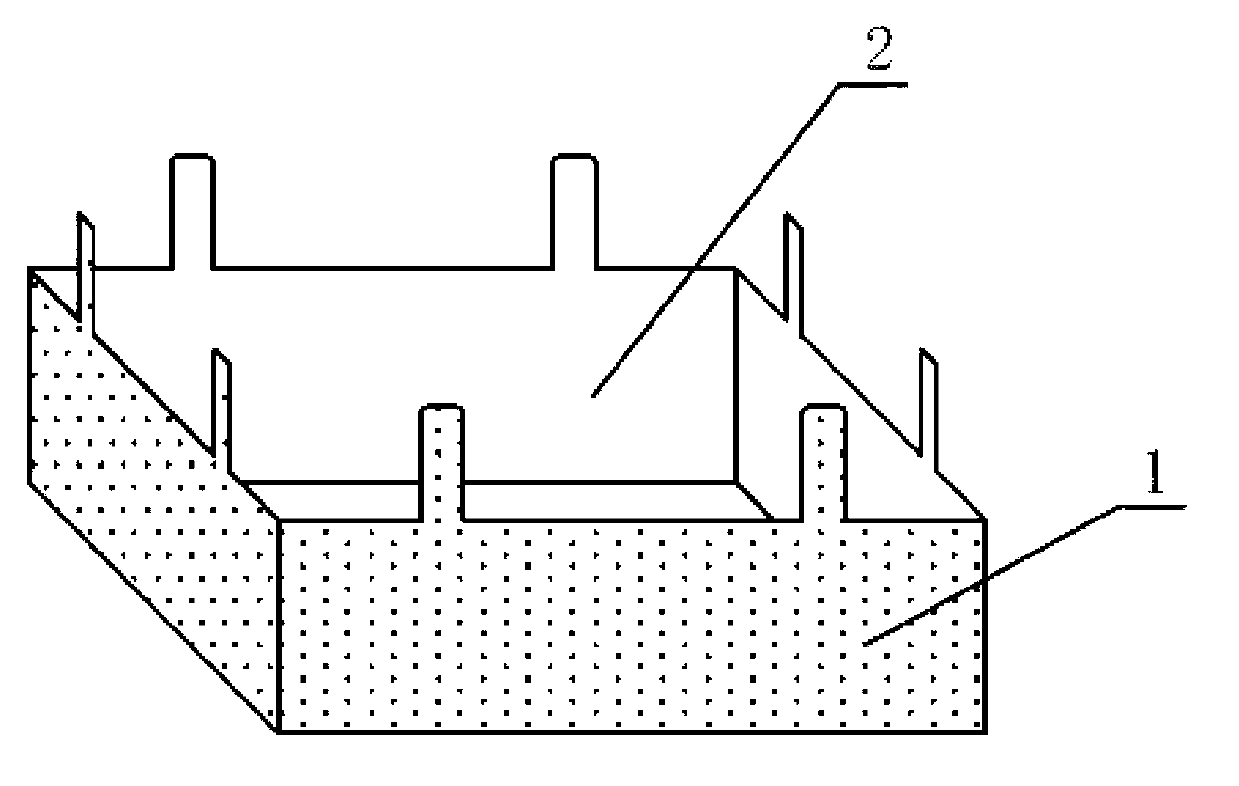

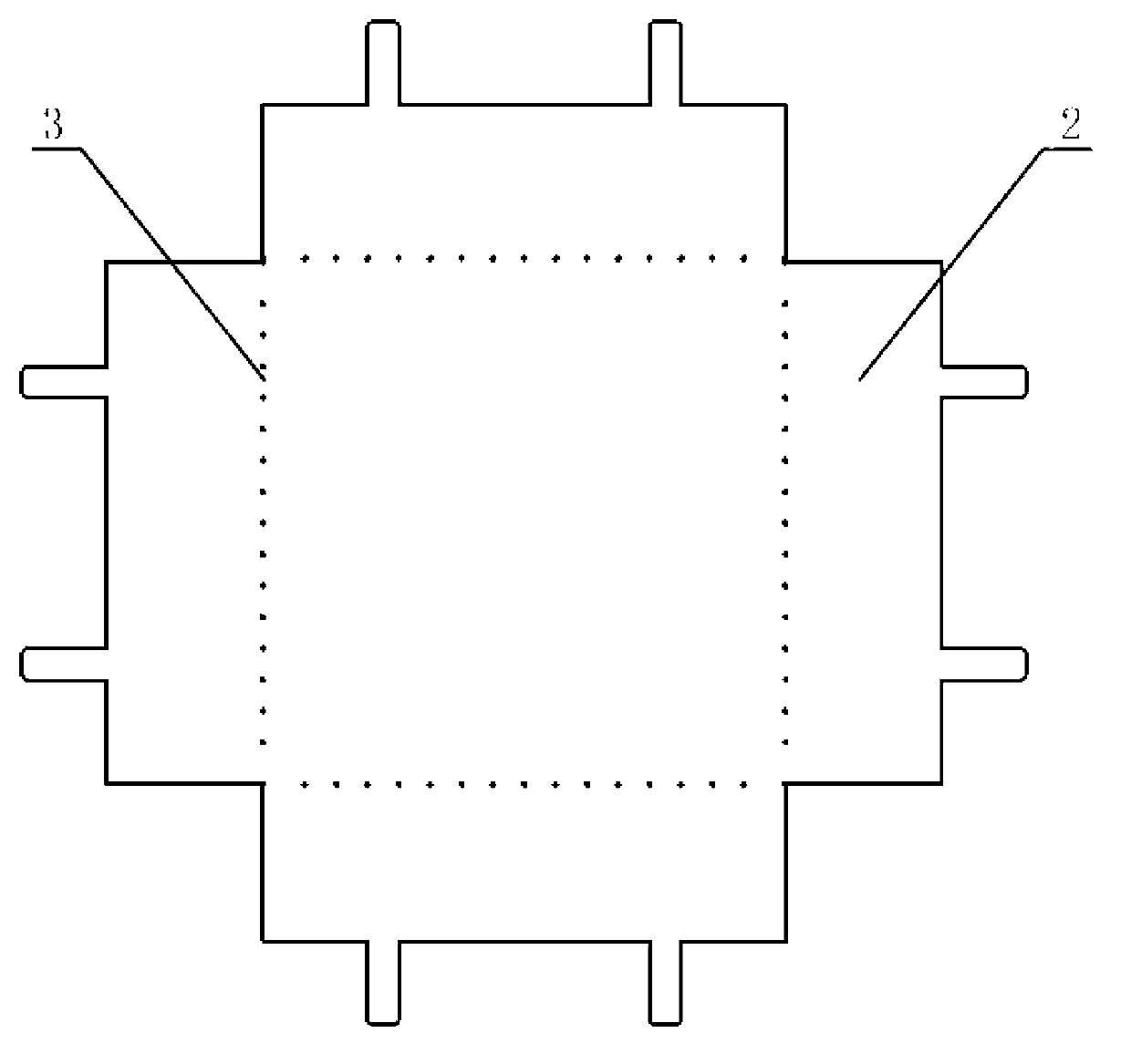

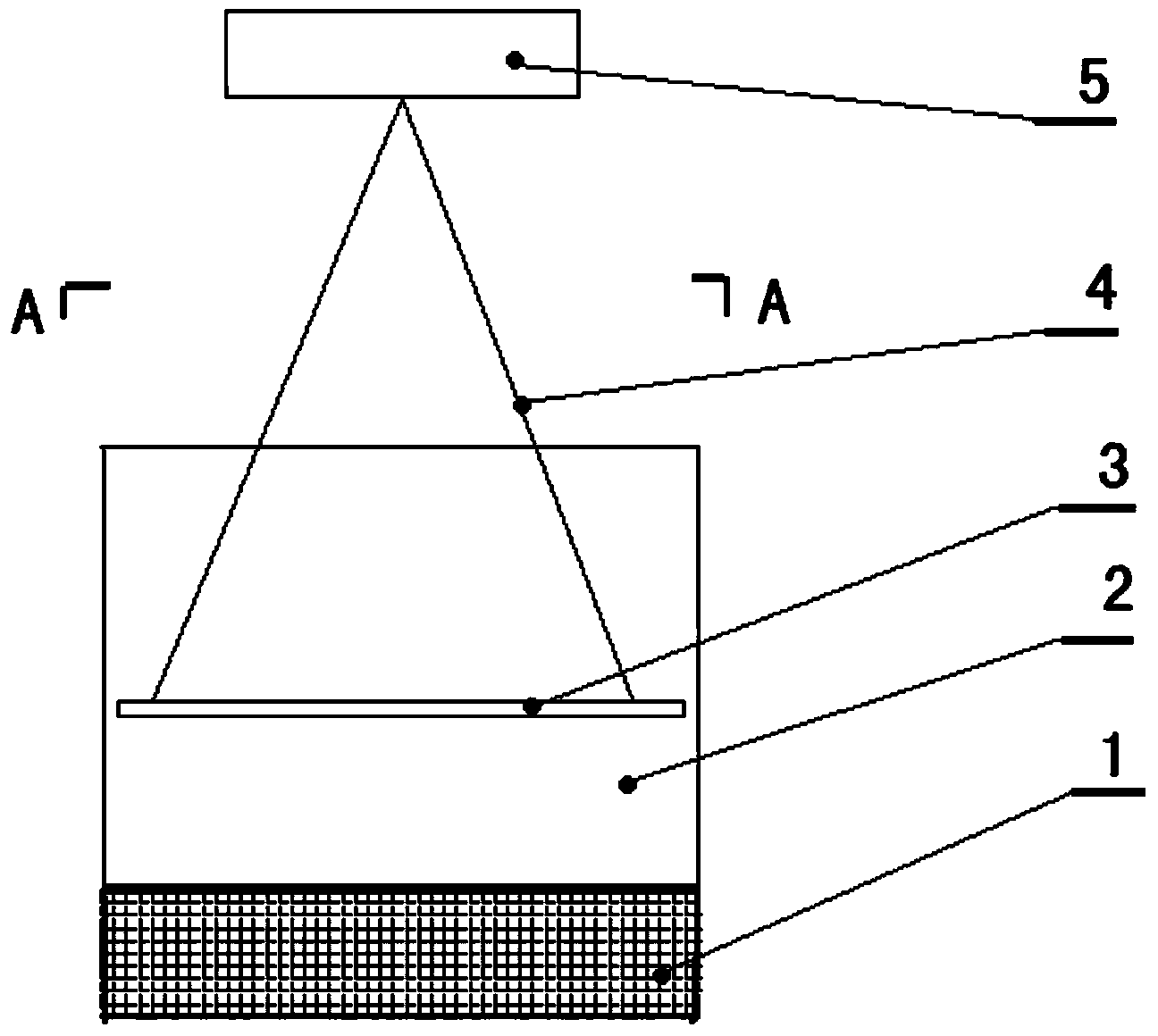

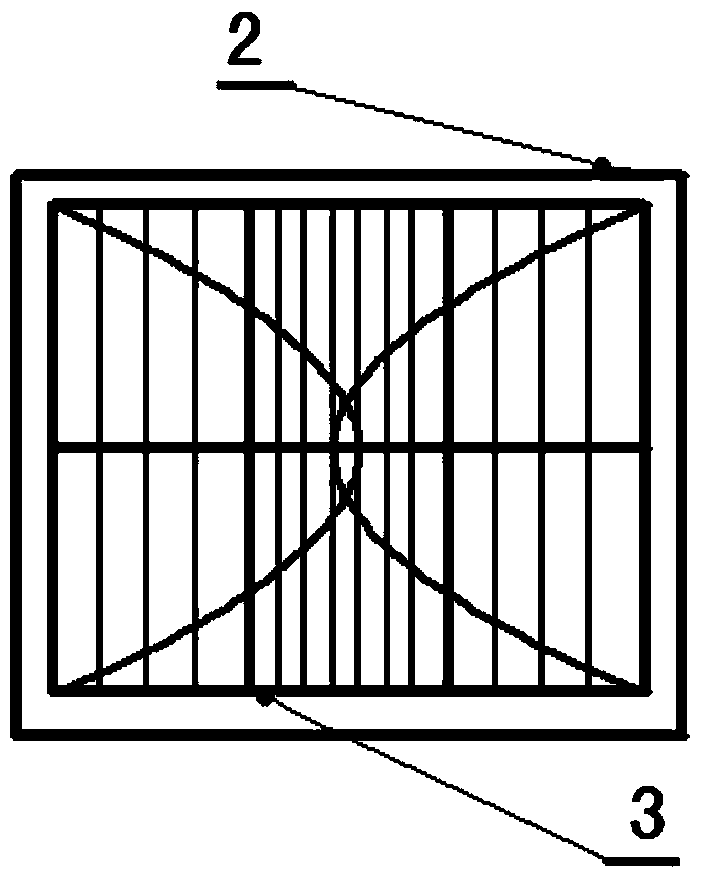

Welding tool for copper and copper alloy stirring friction welding

InactiveCN1927517ASave high melting point materialsLow processing costNon-electric welding apparatusEngineeringFriction stir welding

The invention relates to a welding device used to mixing and welding copper and copper alloy. Wherein, it is separated structure, which is formed by clamper (1), mixing head (2) and screw (3); the clamper is formed by left and right coaxial cylinders; the diameter of left cylinder (1-2) is smaller than the right one (1-3); the right cylinder has chamber (1-1) for arranging mixing head; the upper and lower walls of chamber of right cylinder has screw through hole (1-5) vertical to the axis of right cylinder; the mixing head is cylinder while the middle of its right end has protruded mixing needle (2-1); the right of mixing head is inserted into the chamber; the screw is screwed into the screw through hole; and the mixing head is fixed inside the clamper. The invention can save high-fusion material and reduce cost.

Owner:HARBIN INST OF TECH

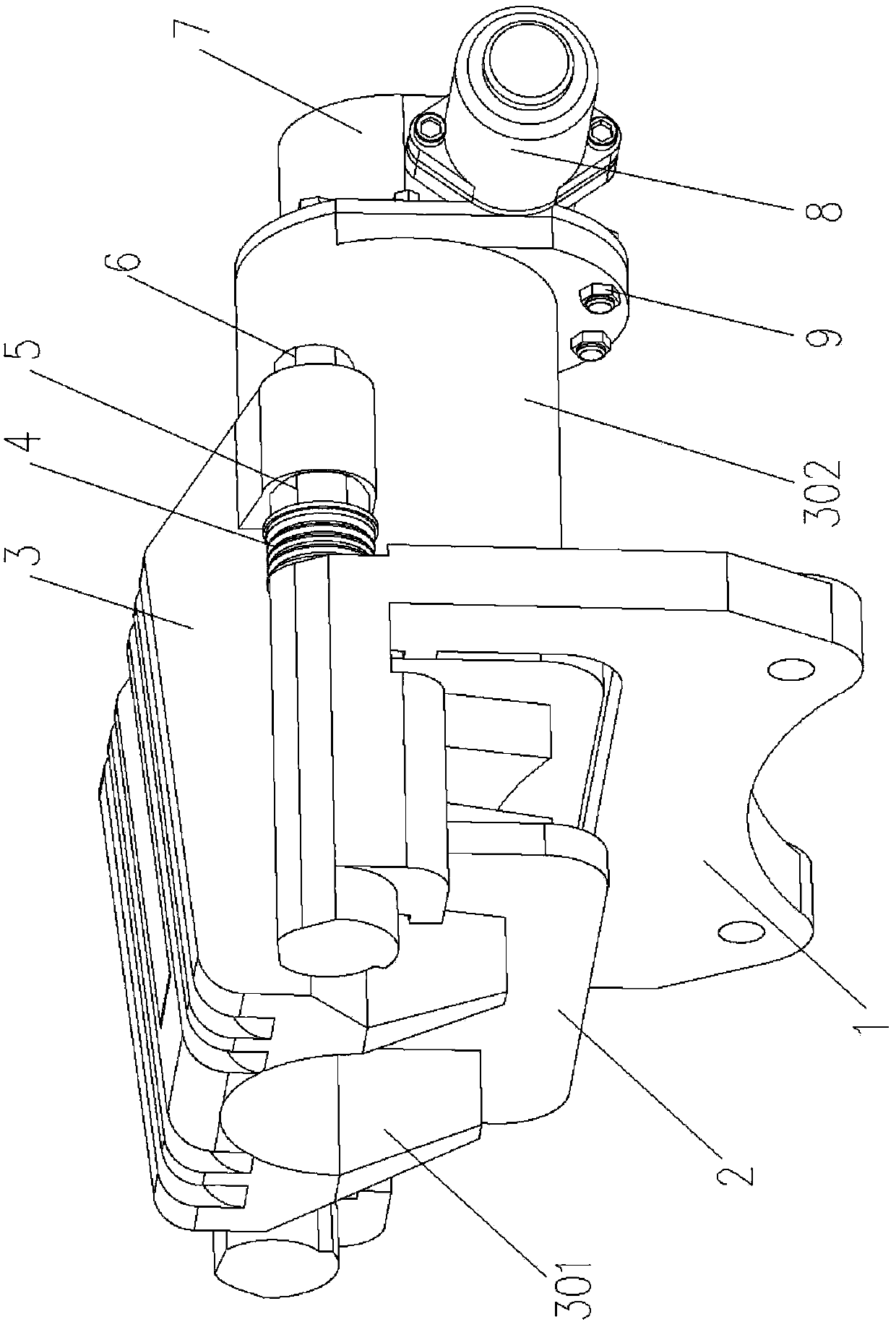

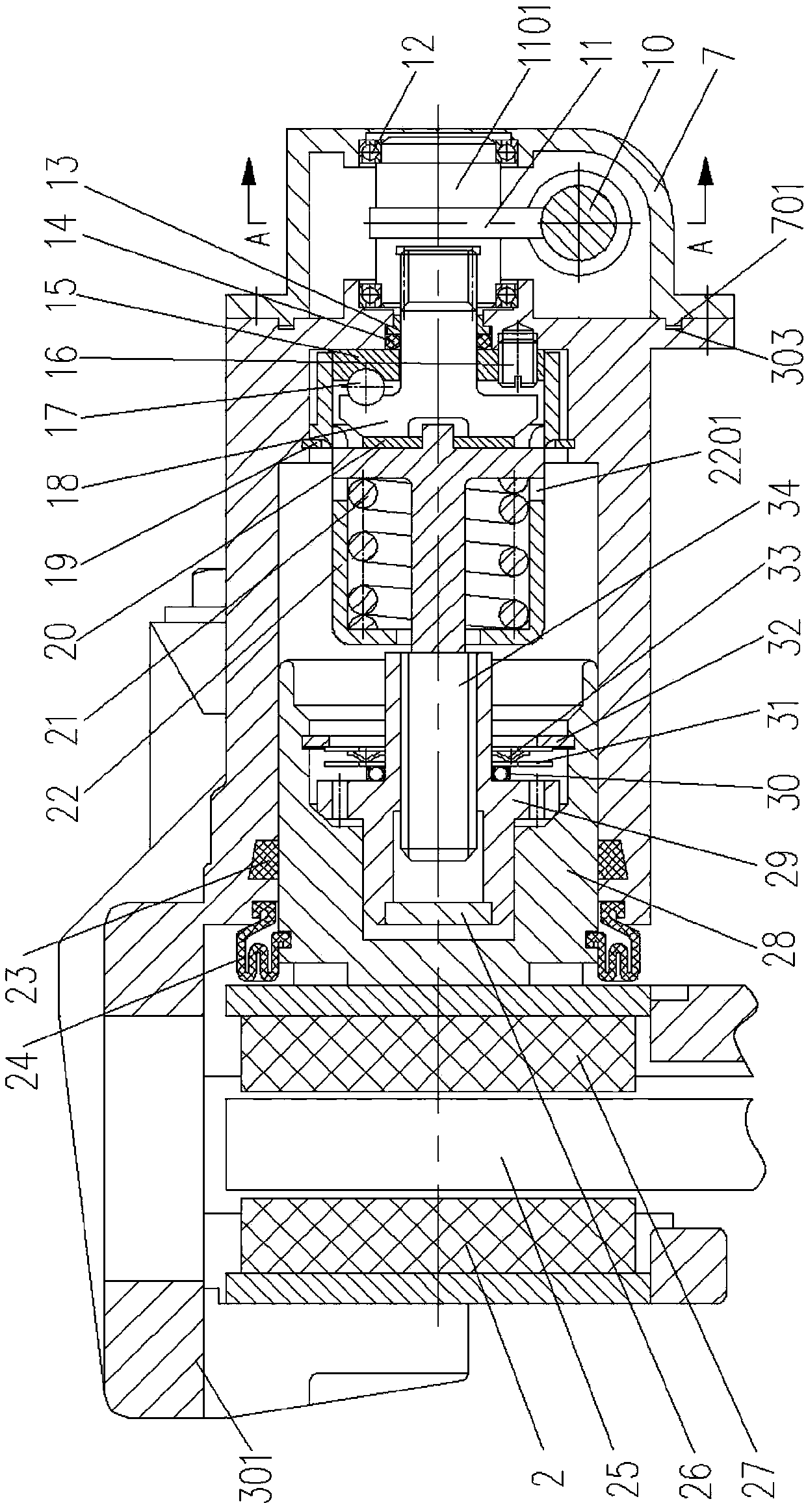

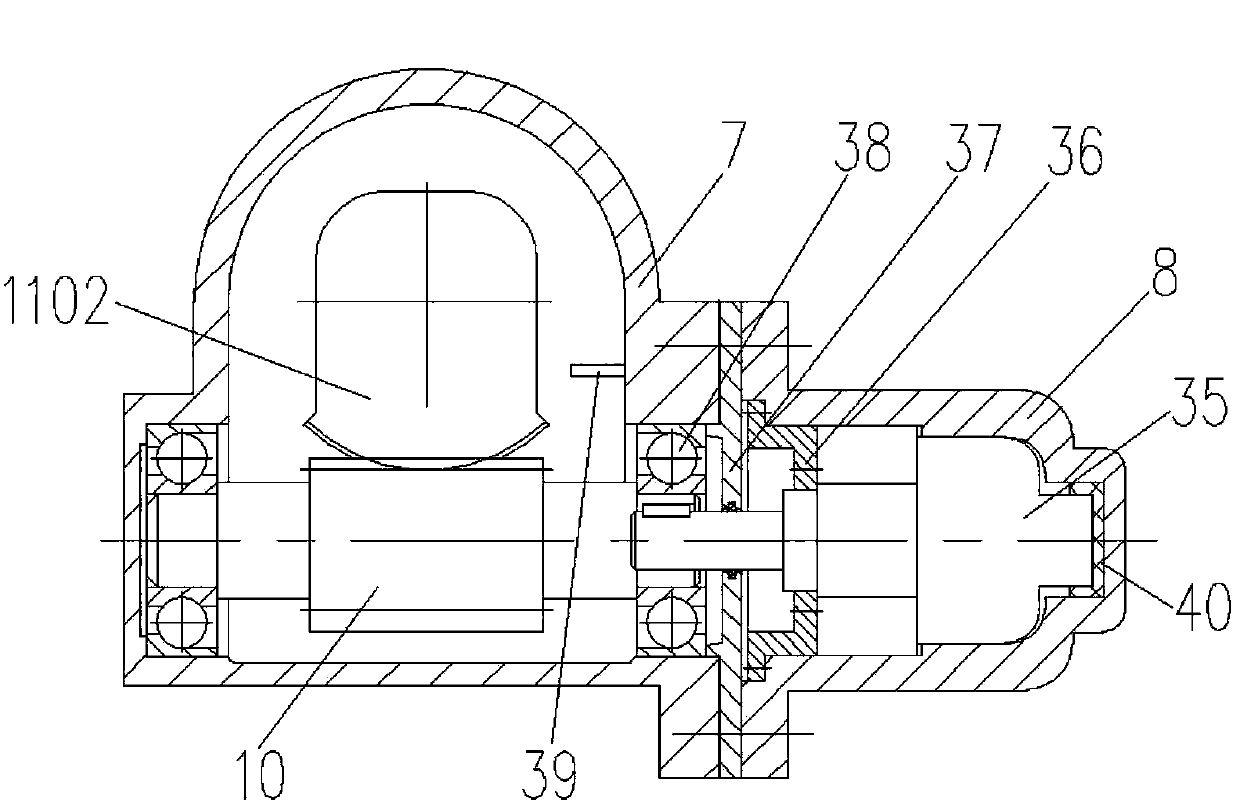

Worm gear, worm, ball and wedge-disc type electronic parking brake

InactiveCN104196922ASave spaceReduce physical exertionAxially engaging brakesBrake actuating mechanismsDrive motorSelf locking

The invention discloses a worm gear, worm, ball and wedge-disc type electronic parking brake which comprises an actuating device and a brake caliper assembly. The brake caliper assembly comprises a push rod assembly and a piston assembly which are arranged in a cavity of a brake caliper. The push rod assembly comprises a wedge disc, balls, a push rod shaft, a self-regulation screw, a pressure spring and a spring limiting sleeve. The push rod shaft extends out of the cavity and is connected with a transmission mechanism of the actuating device. The multiple balls are evenly distributed between the push rod shaft and the wedge disc in a clamped mode and used for generating axial push force. The self-regulation screw is connected with the self-regulation screw of the piston assembly in a threaded mode. The actuating device comprises a shell, the transmission mechanism and a driving motor. The worm gear, worm, ball and wedge-disc type electronic parking brake has the advantages that physical output of a driver can be reduced, a vehicle parking brake system can be simplified, the gap self-regulation function, the speed-reduction and torque-increasing functions, the movement conversion function and the mechanical reverse self-locking function can be conveniently achieved, and electric power consumed during long-time parking can be reduced; in addition, the transformation machining cost is low, and the manufacturing-process succession performance and the technological-process succession performance are good.

Owner:JILIN UNIV

Production process for bamboo fiber

InactiveCN102433593AReduce pollutionImprove folding resistanceVegetable materialMechanical fibre separationFiberPulp and paper industry

The invention relates to a production process for bamboo fiber, which comprises steps of material selection, fiber splitting, classification, digestion, reduction, acid pickling, cleaning, dehydration, curing and the like. According to the production process, the whole piece of bamboo is directly processed after being flatten by a special tool under the condition of no cutting and splitting, a mode of bamboo eaten and fiber spit is realized, the production process is free from the limitation of bamboo varieties, bamboo age, bamboo joint and bamboo diameter, a heat-force-chemical multi-field coupling principle is adopted in a bamboo fiber splitting separator to make the machined bamboo fiber longer, finer and more uniform than original fiber, edges and unprocessed bamboo are a few, and an additive is added, so that a product has high folding resistance and flame retardance. The production process is reliable, the resource utilization rate is high, the processing cost is low, environmental pollution is low, the product quality is stable, and the problem of high-efficiency mass production of fine and long bamboo pure fiber is effectively solved.

Owner:常熟市佳懿针纺织品有限公司

Modified formulation for high surface hardness PC-ABS resin

The present invention relates to one kind of modified PC-ABS resin with high surface hardness. The recipe of the modified PC-ABS resin consists of PC-ABS resin 60-85 weight portions, PMMA 12-25 weight portions, CPE 1-5 weight portions, graft copolymer 1-5 weight portions, and toughener 1-7 weight portions. The modified PC-ABS resin has high surface hardness, mechanical performance basically the same as that of PC-ABS resin, lowered processing cost, and expanded application fields.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Desulphurization method of cracked C5 fraction

ActiveCN105112093AGood desulfurization effectLow processing costTreatment with plural serial refining stagesChemistryBenzene

The invention relates to a desulphurization method of cracked C5 fraction. The desulphurization method of cracked C5 fraction comprises the following steps: firstly adding a desulfurizer into a cracked C5 fraction raw material, and carrying out a reaction at a certain pressure and a certain temperature for a while; separating a cracked C5 fraction which is free of sulfur from the top of a tower by a filtering and a distillation method; after reaction, obtaining a sulfur compound in a column bottom; the desulfurizer comprises the following components: 3-8% of triethanolamine, 3-8% of acetonitrile, 3-8% of toluene, 3-8% of acetone, 8-12% of benzene, 25-35% of saturated ammoniacal liquor, 8-12% of butyronityile, 8-12% of cyclohexane, 10-20% of aniline, and 3-8% of diethyltoluenediamine. According to the method, a proper amount of desulfurizer is added into the cracked C5 fraction raw material, and the purpose for desulphurization of cracked C5 fraction is realized by the methods of filtering and distillation. The method provided by the invention has a good desulphurization effect, by-products are not introduced into the desulphurized product, and the composition of the cracked C5 fraction is not changed; the desulfurizer has little toxicity and is not volatile and inflammable.

Owner:濮阳市联众兴业化工有限公司

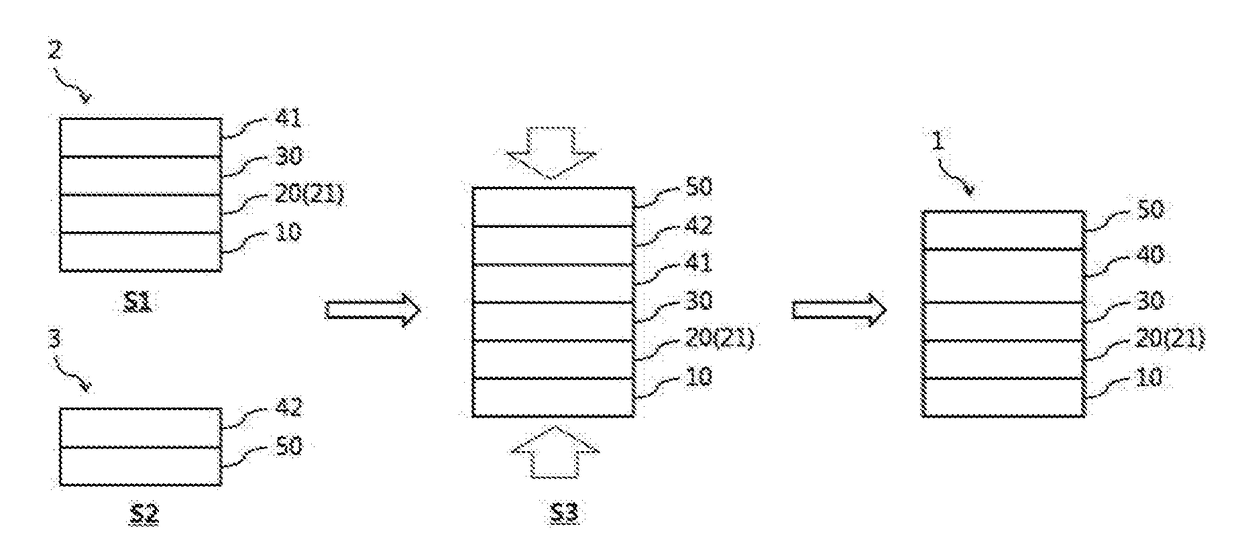

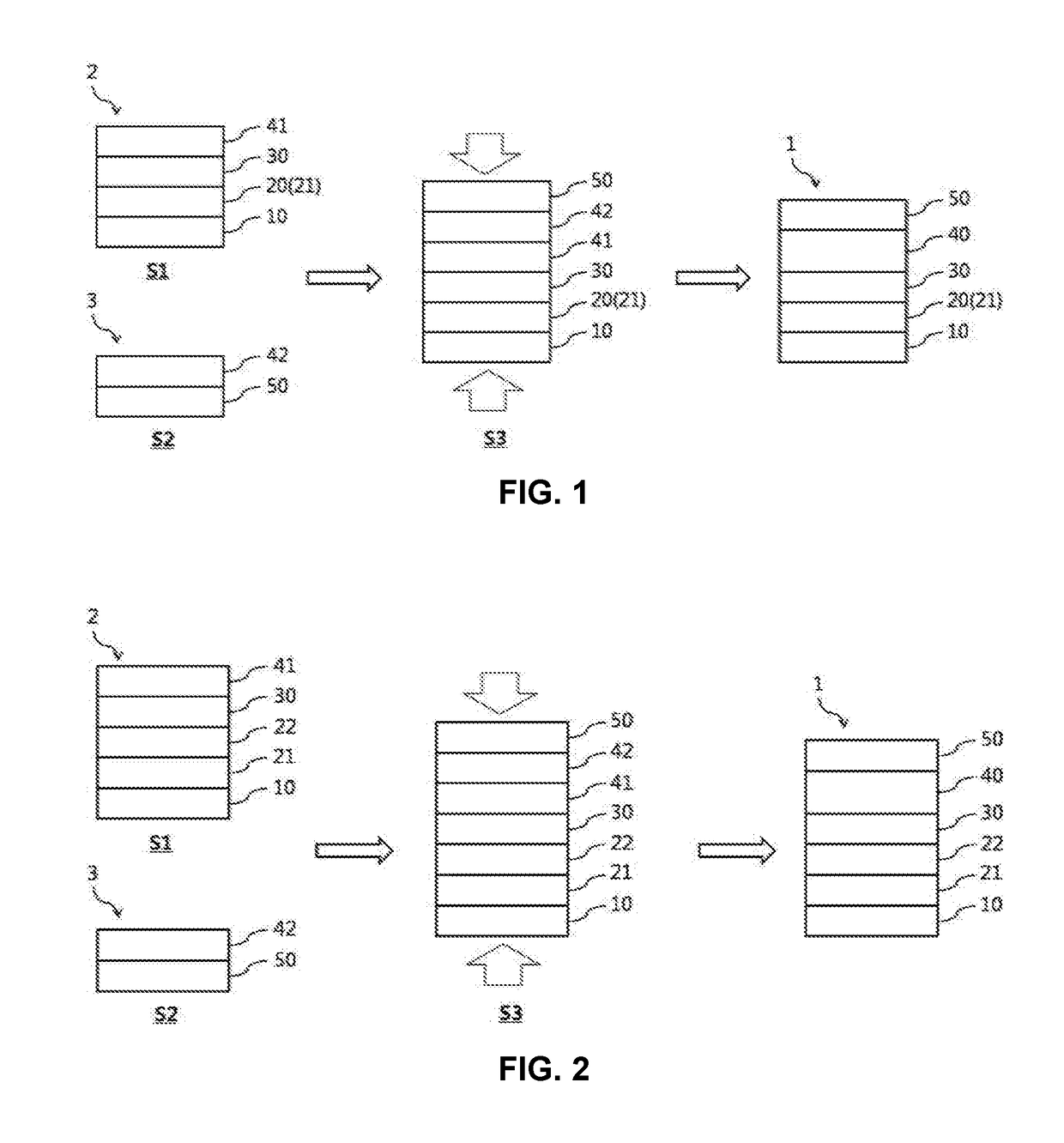

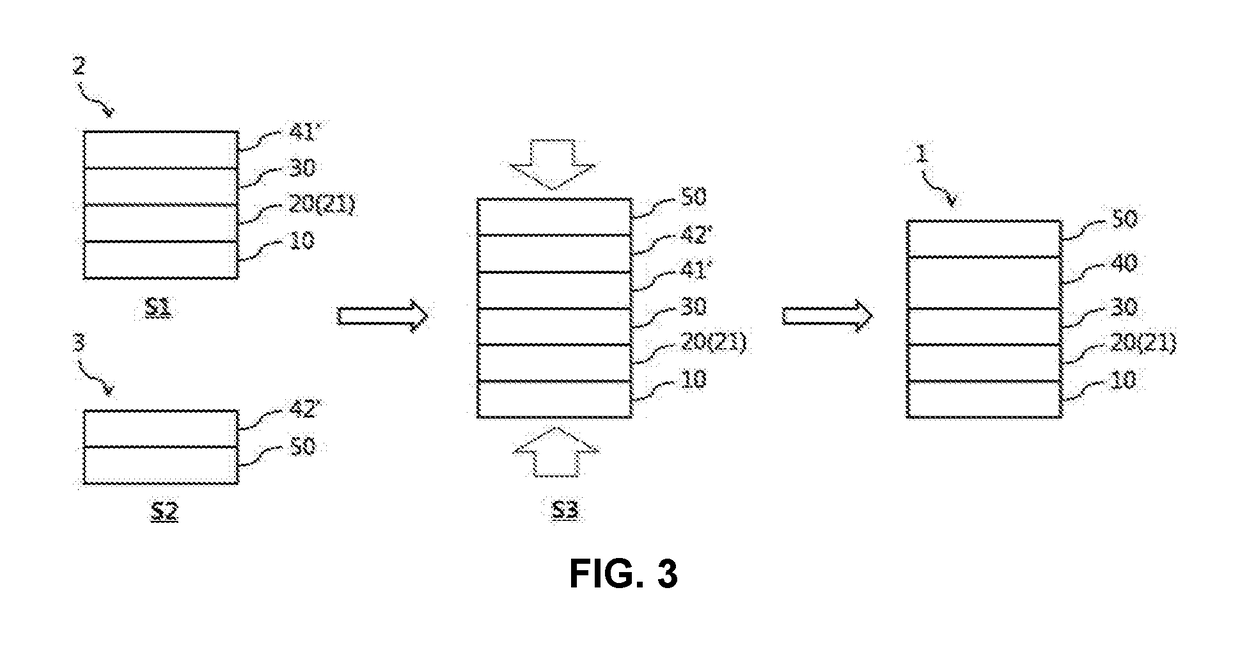

Method for preparing a bonded type perovskite solar cell

ActiveUS20180122584A1Low processing costEnhance price competitivenessLight-sensitive devicesSolid-state devicesPerovskite solar cellOptoelectronics

A method for preparing a perovskite solar cell by a non-deposition method is provided. Particularly, the method includes preparing a first substrate by forming a hole transport layer on a light absorbing layer in a semi-dried state and pressurizing and drying a second substrate including an opposing electrode to the first substrate.

Owner:HYUNDAI MOTOR CO LTD +1

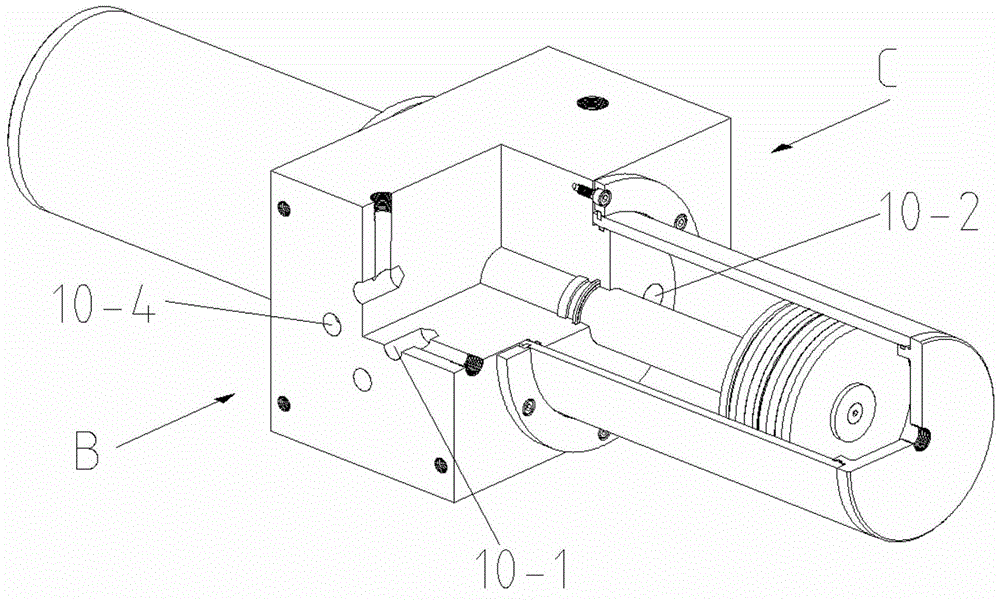

Pressure exchanger energy recovery cylinder

ActiveCN104061205ASimple structureLow processing costSeawater treatmentWater/sewage treatment bu osmosis/dialysisMagnetEngineering

The invention discloses a pressure exchanger energy recovery cylinder. The pressure exchanger energy recovery cylinder adopts the structure that a left cylinder barrel and a right cylinder barrel are respectively mounted on the two sides of a central block; a piston rod is mounted on the central block; the two ends of the piston rod respectively extend into the left cylinder barrel and the right cylinder barrel to be connected with a left piston and a right piston; rare earth permanent magnets are mounted on the outer side ends of the left piston and the right piston; a left end cover and a right end cover are mounted on the outer side ends of the left cylinder barrel and the right cylinder barrel; magnetic approach switches mounted on a rack are respectively close to a left end cover and a right end cover; holes are formed in the left end cover and the right end cover; four aperture passages are formed in each of the top and the bottom of the central block; the four aperture passages in the top are in one-to-one correspondence with and connection with four connectors of a four-way rectifying valve; the four aperture passages in the bottom are in one-to-one correspondence with and connection with four connectors of a two-position four-way rectifying valve. The pressure exchanger energy recovery cylinder can automatically adapt to different shaft errors between the left and right cylinder barrels and the central block through a radial clearance between a piston counter bore and the piston rod, and has the advantages of compact structure, reliable operation, convenience in maintenance and the like.

Owner:GUANGXI UNIV

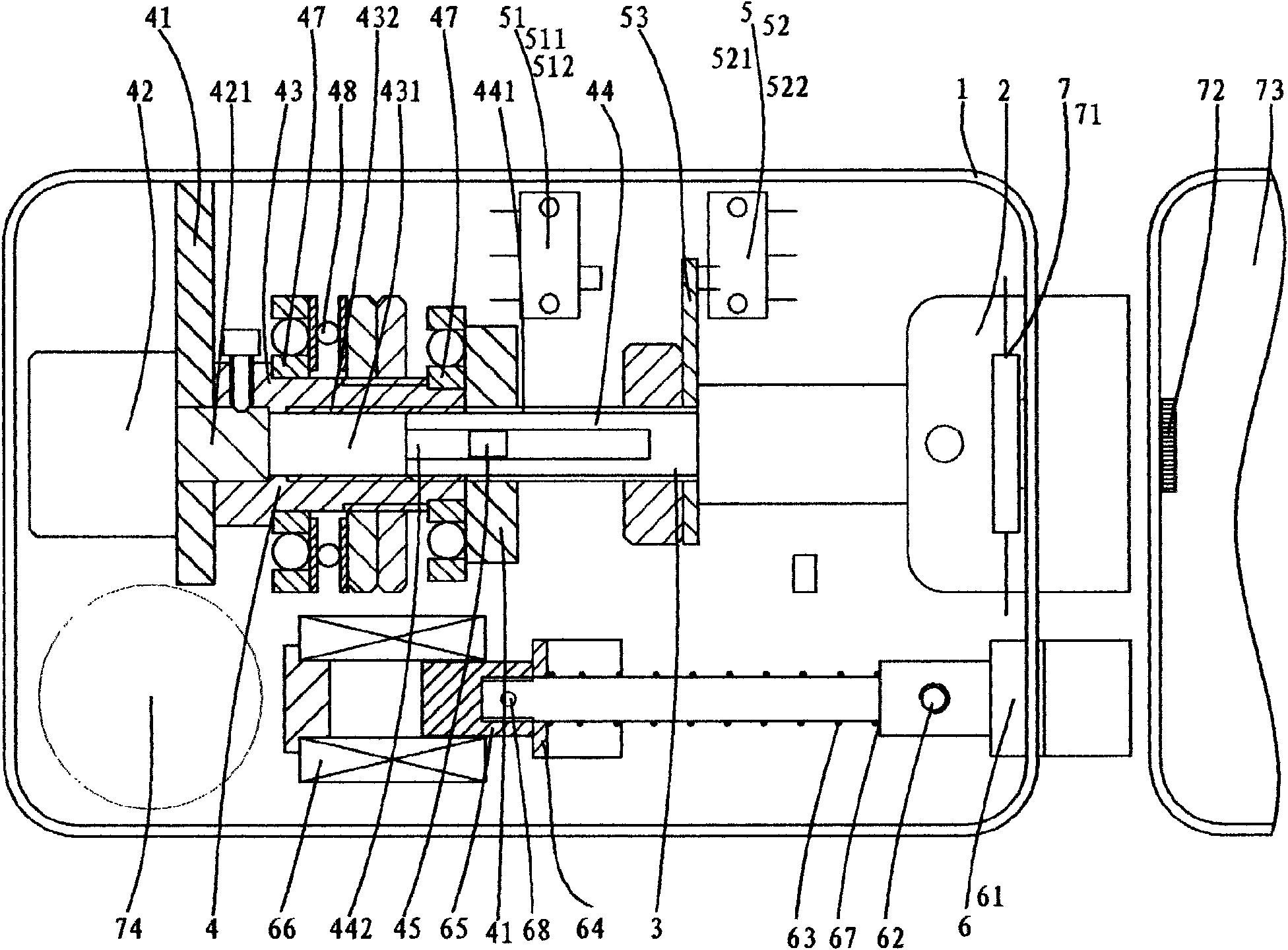

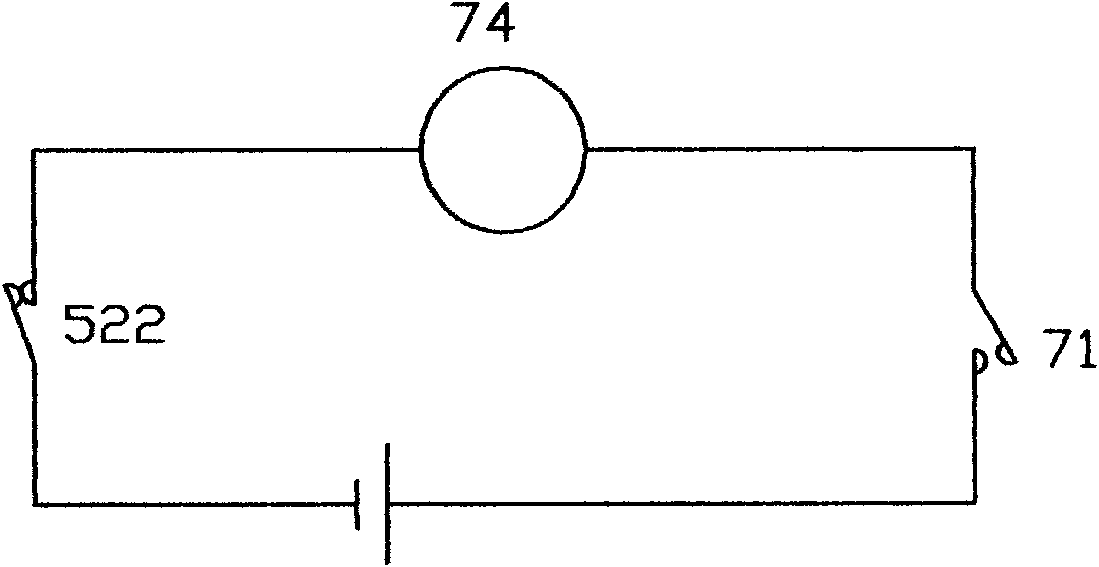

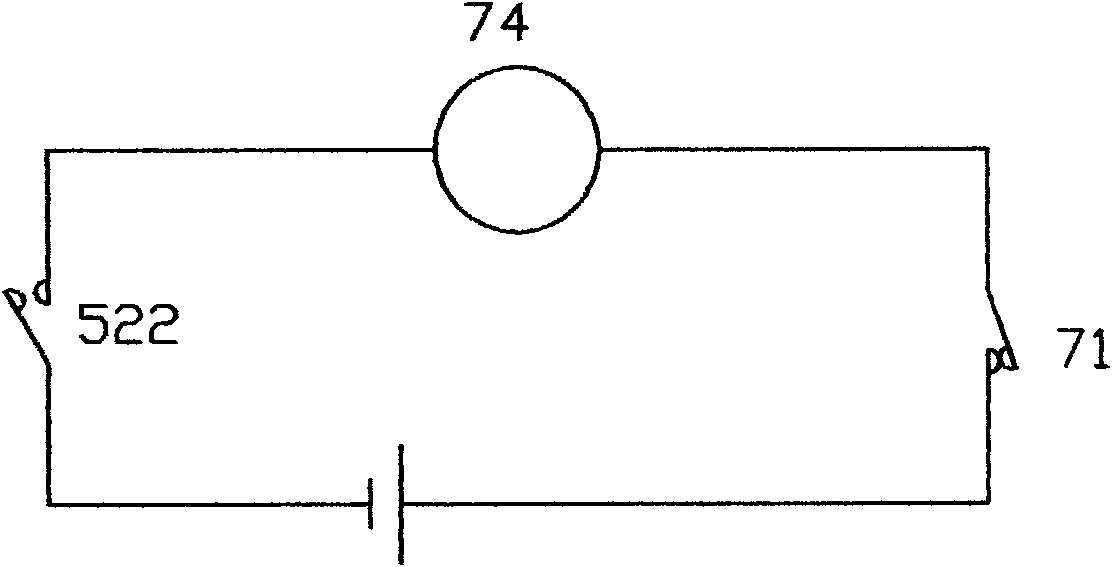

Pickproof alarm door lock

ActiveCN101603386ASimple structureLow processing costNon-mechanical controlsAlarm locksMotor driveElectric machinery

The invention discloses a pickproof alarm door lock, which comprises a lock shell, a large lock bolt, a piston driving device, a motor, a small lock bolt device and a pickproof alarm device, wherein the piston driving device is provided with a rigid telescopic piston; the motor drives the piston driving device; and the small lock bolt device has manual or electric double opening. The pickproof alarm door lock has a simple structure and low cost, is controlled by a remote signal transmitter and locked on a door to be flexibly and lightly locked or opened; and once locking, the pickproof alarm door lock cannot be picked by a thin iron sheet and alarms at the same time.

Owner:JIANGSU GAOSHIDA ELECTRIC TOOL CO LTD

Shielding case and manufacturing method thereof

InactiveCN103889198ASimple and light structureSimple processMagnetic/electric field screeningProcess efficiencyEngineering

The invention discloses a shielding case and a manufacturing method of the shielding case. The shielding case comprises an insulating case body and a metal conducting layer arranged on the outer side of the insulating case body. The thickness of the metal conducting layer is 0.001mm-0.003mm. The shielding case and the manufacturing method of the shielding case have the advantages that the shielding case is formed by arranging the metal conducting layer on the insulating case body, the structure is light and simple, working procedures are simple, processing efficiency is high, and assembly cost is low.

Owner:领胜科技(苏州)有限公司

Laser drilling method of FPC

InactiveCN103659001ALow costLow processing costWelding/soldering/cutting articlesLaser beam welding apparatusLaser pulse widthLaser drilling

The invention discloses a laser drilling method of an FPC. The laser drilling method of the FPC adopts a CO2 laser drilling machine and comprises the following steps of S1, starting the laser drilling machine and confirming the size of a mask; S2, setting laser parameters, wherein the output power is 5100-5900W, the laser frequency is 90-110Hz, the laser pulse width is 67-107ms, and the CO2 laser drilling machine automatically adjusts the position of a condenser according to the mask and the laser parameters; S3, debugging a laser transmitting device to perform laser drilling, wherein the laser drilling mode is a front and back side drilling mode, the front and back sides are consistent in laser parameter, and the front and back side laser transmitting times is set to be 2. By adopting the laser drilling method of the FPC, the cost can be reduced, and the efficiency can be improved. The laser drilling method is applicable to special materials, such as a Teflon material.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

Cold Extrusion Forming Technology of Pinion Shaft in Power Steering Gear

The invention discloses a cold extrusion molding process of a pinion shaft in a power steering gear, which comprises the following steps: step 1, sawing a cylindrical blank with a required length on a disc according to product requirements; step 2, grinding The outer circle of the cylindrical blank; Step 3, carry out the first phosphorus saponification treatment to the cylindrical blank according to the conventional phosphorus saponification process; Step 4, put the blank into a cold extrusion molding die for forward extrusion process , be pressed into the preform of pinion shaft; step five, carry out spheroidizing annealing treatment to preform; step six, carry out the second phosphorus saponification process to blank according to conventional phosphorus saponification process; step seven, pass through The blank in step 6 is then put into a cold extrusion molding die for a reverse extrusion process to be pressed into a cold extrusion of the pinion shaft. The cold extrusion molding process of the pinion shaft in the power steering gear of the present invention realizes one-time molding of the pinion gear shaft in the power steering gear, and realizes less cutting or no cutting processing of complex cavity parts.

Owner:上海久丰汽车零件有限公司

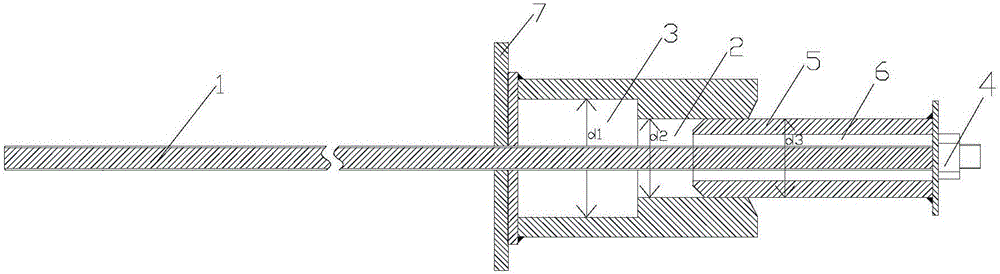

Metal anchor rod with yielding function and using method thereof

ActiveCN106401627ASimple structureLow processing costAnchoring boltsStructural engineeringYield function

The invention discloses a metal anchor rod with a yielding function. Based on the prior art, a yielding base is additionally arranged. A left base body of the yielding base is of an integrated structure and comprises a base plate, a lower cylinder and an upper cylinder, wherein the inner diameter of the lower cylinder is d1, the inner diameter of the upper cylinder is d2, the length of the upper cylinder is 20-25 mm, and the length of the lower cylinder is 25-30 mm. A plurality of through notches are evenly formed in the cylinder wall of a cylinder body of a right base body in the axial direction, and a plurality of ribs are formed on the cylinder wall, so that the right base body has the high elastic deformation capacity after being pressed; the length of the cylinder body is 45-50 mm, the wall thickness of the cylinder body is 5-8 mm, and the outer diameter of the cylinder body is d3; and d1>=d3, and d3=d2+1 mm. The using method of the metal anchor rod with the yielding function is basically the same as a using method of an ordinary anchor rod, and has the beneficial effects that the structure is simple, using is convenient, the machining and manufacturing cost is low, supporting is safe, worry is avoided, and labor is saved.

Owner:SHANDONG UNIV OF SCI & TECH

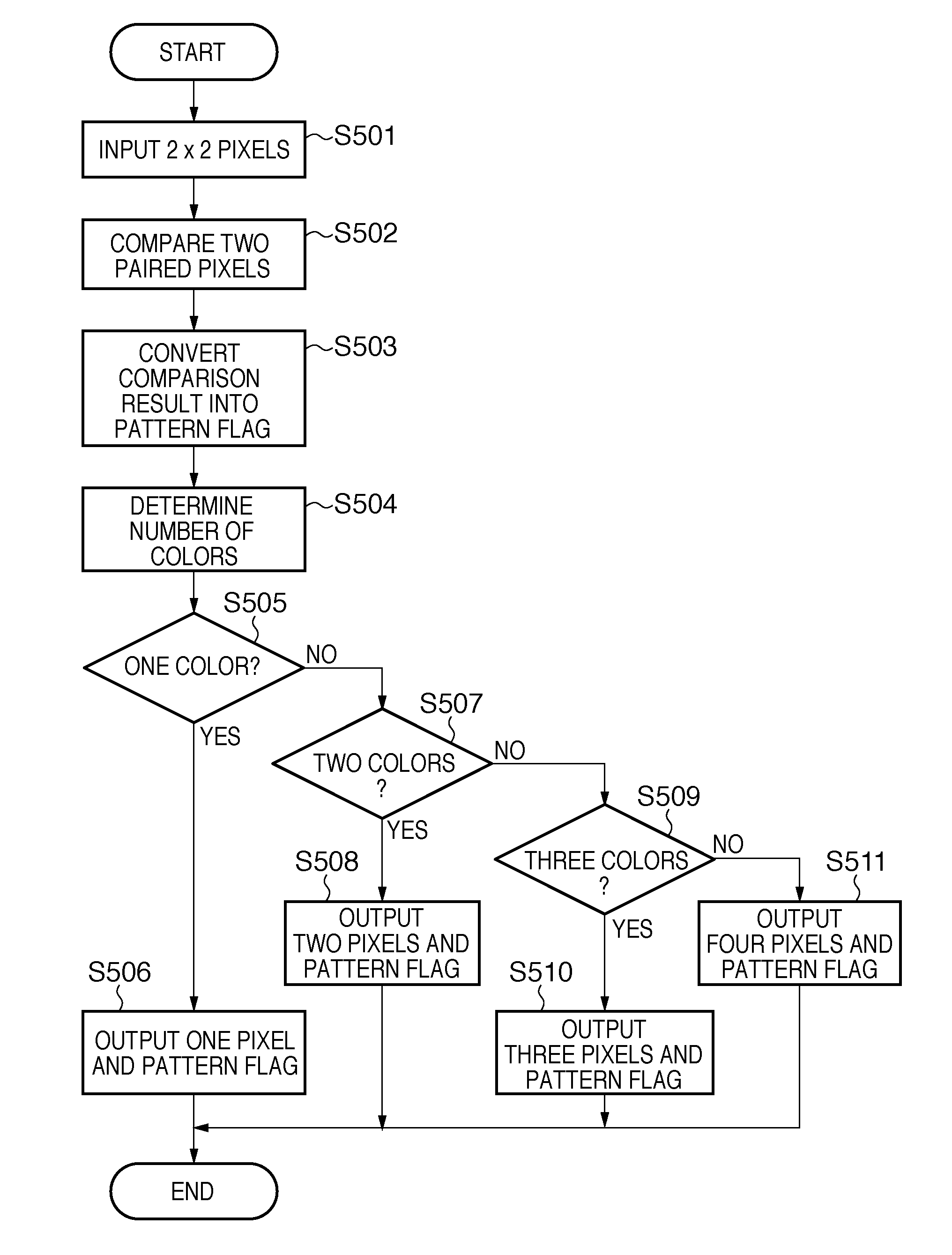

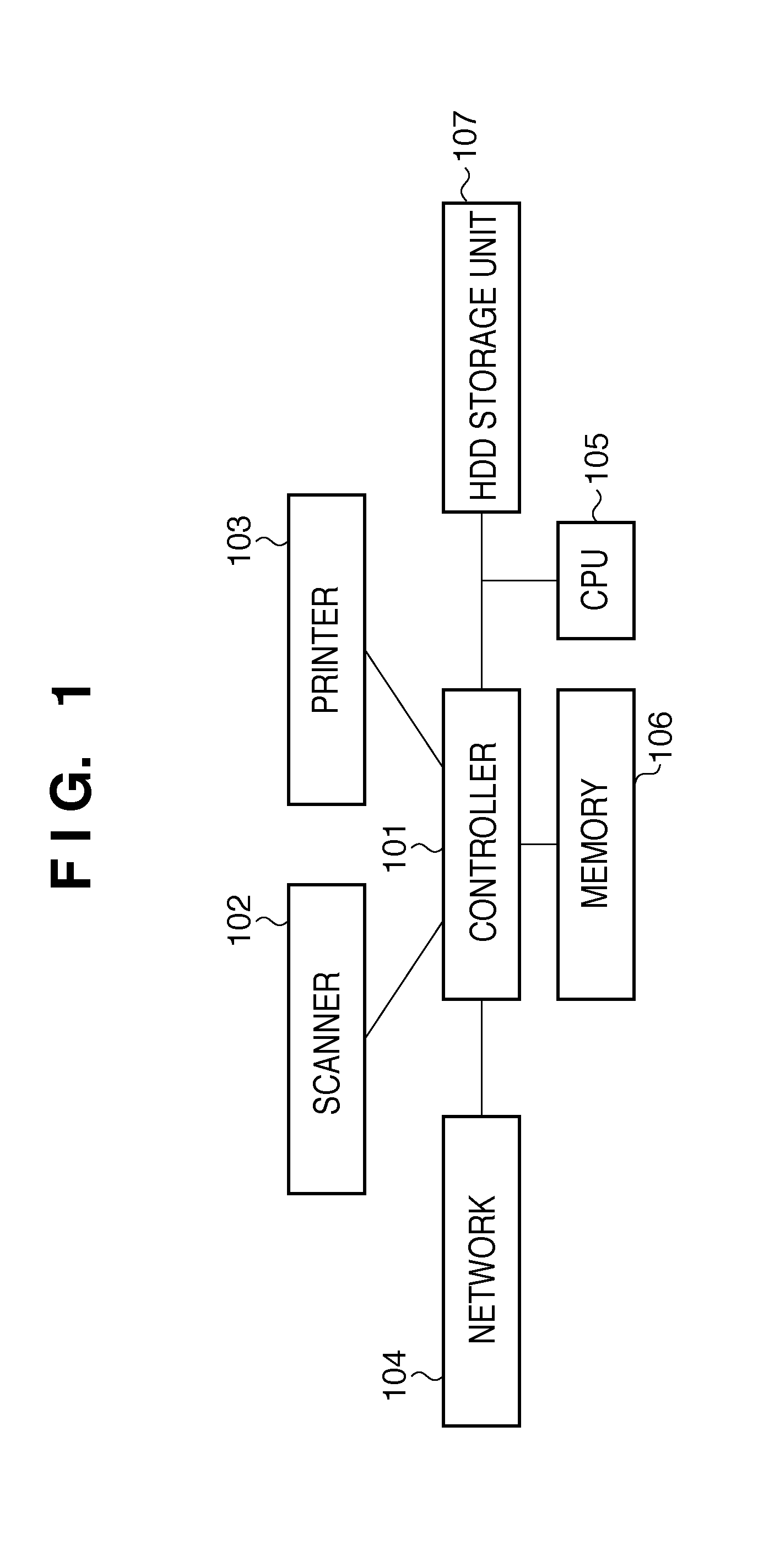

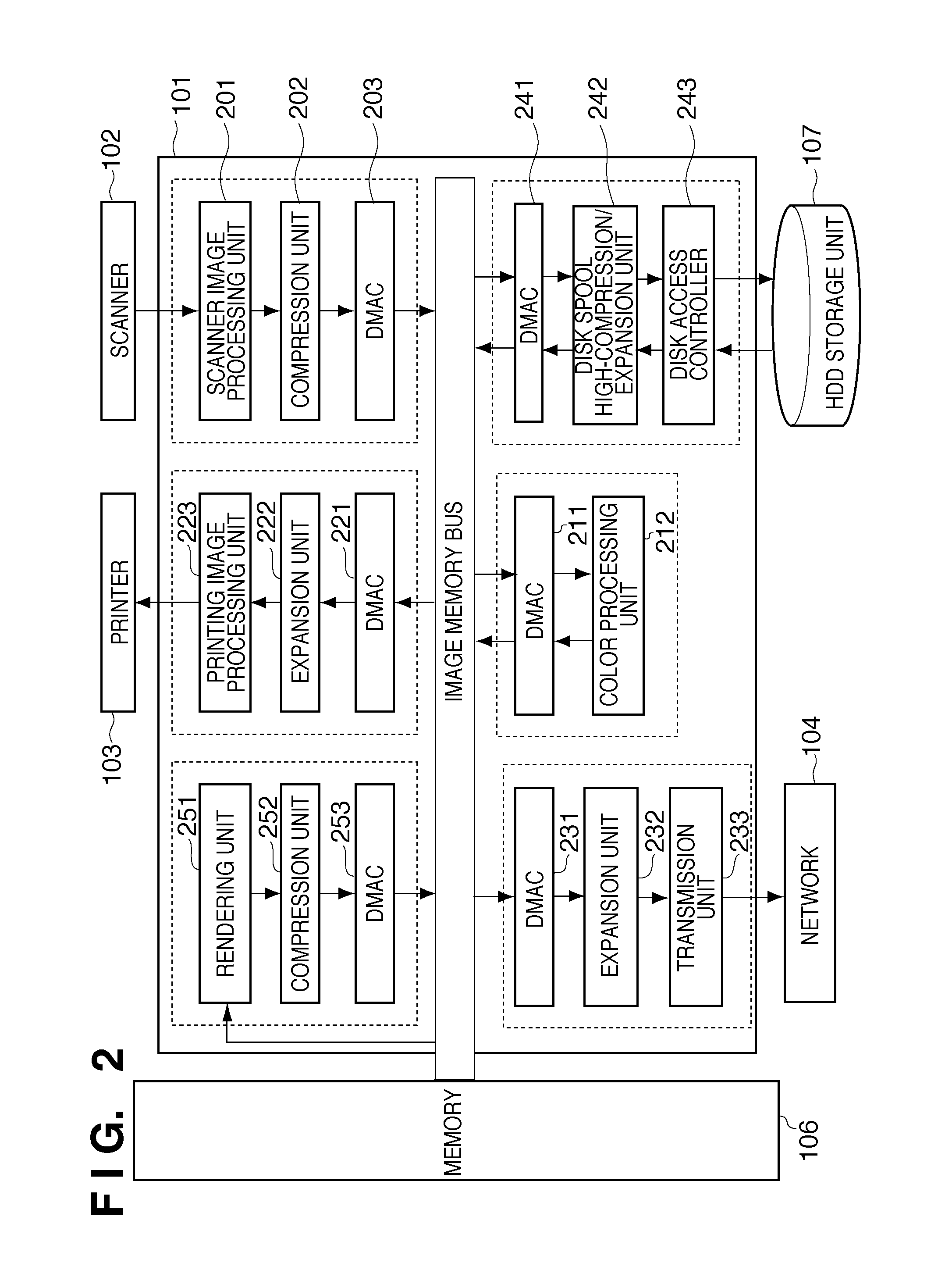

Image processing apparatus, image processing method, and program

InactiveUS20120262738A1Minimize deteriorationLow processing costDigitally marking record carriersVisual presentation using printersImaging dataPattern recognition

An image processing apparatus comprises: means for performing color-reduction processing for a block; means for comparing color data of respective pixels in the block, thereby specifying a placement pattern of the color data included in the block; means for extracting, as first color data, color data corresponding to a pixel at a predefined position in the block, and further extracting color data other than the first color data included in the block; means for outputting the placement pattern specified, and the first color data and the color data other than the first color data, which are extracted; and means for controlling to execute color-reduction processing, for second image data formed from the first color data output, upon determining blocks each including a predetermined number of pixels as blocks to be processed, thereby further controlling to re-execute, for the block having undergone the color-reduction processing, processing by each means.

Owner:CANON KK

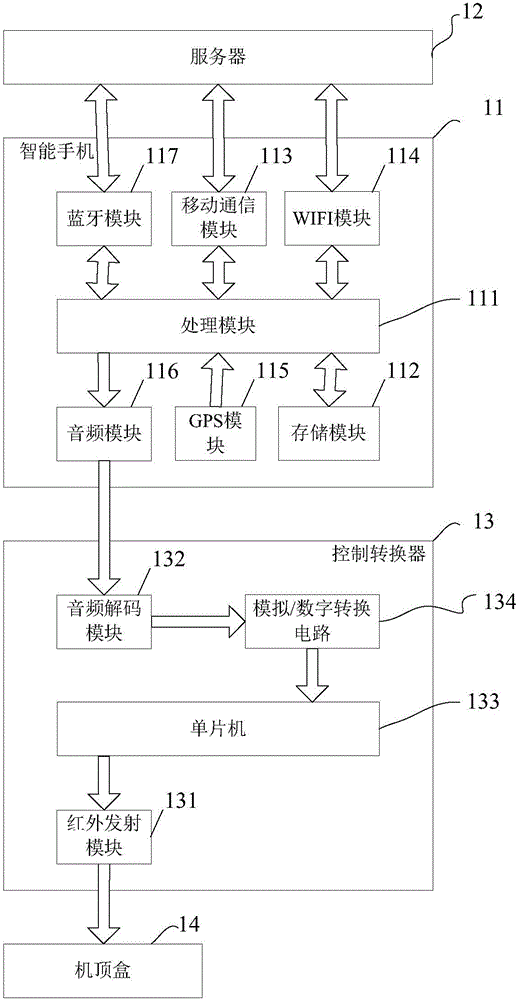

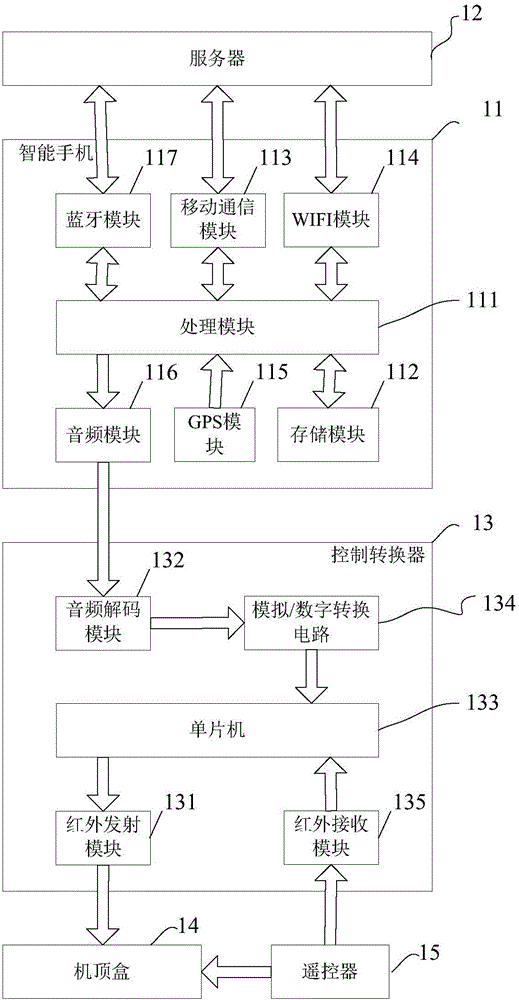

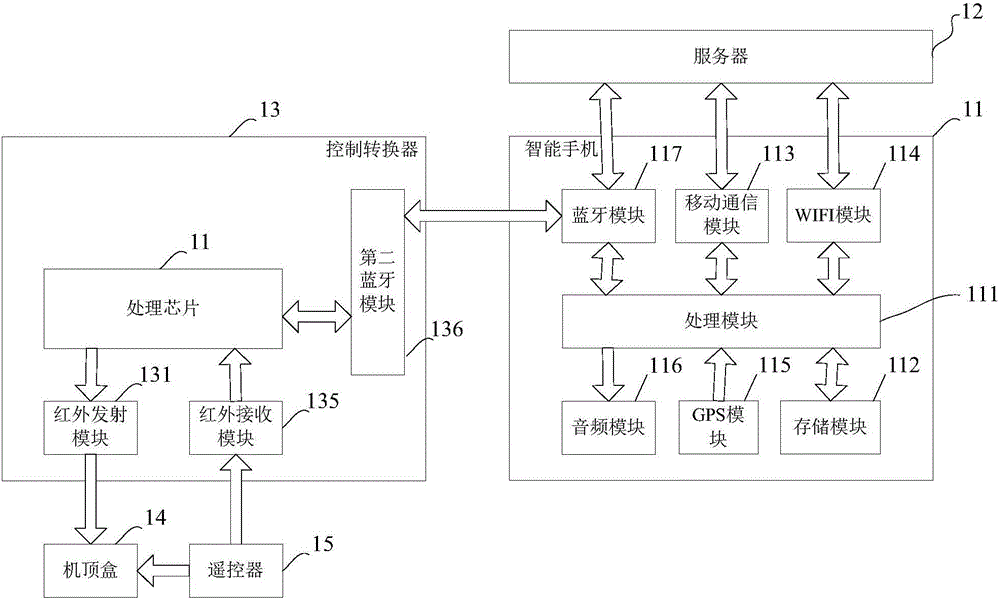

Television advertisement automatic switching system based on intelligent mobile phone

Provided is a television advertisement automatic switching system based on an intelligent mobile phone. The intelligent mobile phone comprises a mobile phone processing module, a storage module and a network module. A machine code of a set top box is stored in the storage module. The system further comprises a control convertor and a server. The control convertor comprises an infrared emission module. The network module sends a television station selected by a user to the server. The server obtains time information of the television advertisement inserted in the television station. When the television station begins to insert the television advertisement, a television station switching instruction will be sent to the network module. The mobile phone processing module analyzes the television station switching instruction and forms a control signal of television channel switching according to the machine code of the set top box, and the control signal of the television channel switching is sent to the set top box through the infrared emission module. When the television station stops inserting the television advertisement, a television station return instruction is sent to the network module. The mobile phone processing module analyzes the television station return instruction and forms a control signal of television channel return according to the machine code of the set top box, and the control signal of the television channel return is sent to the set top box.

Owner:绍兴市亿跃智能科技有限公司

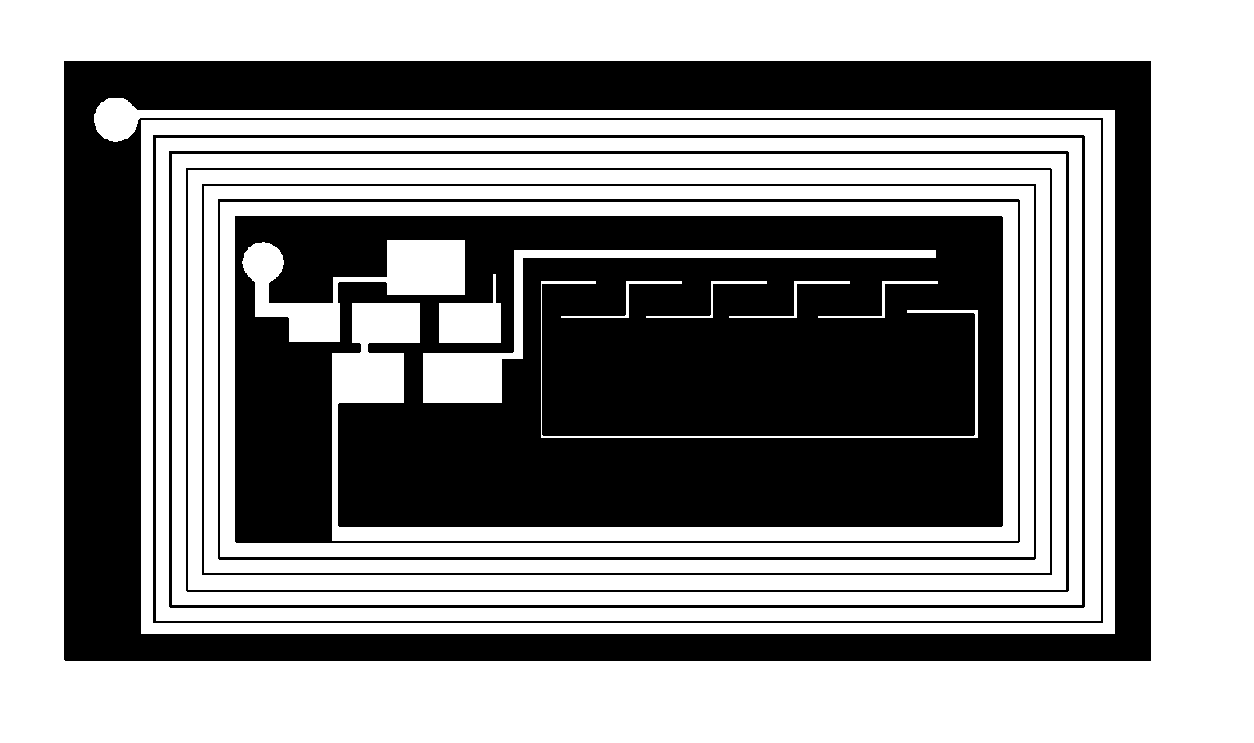

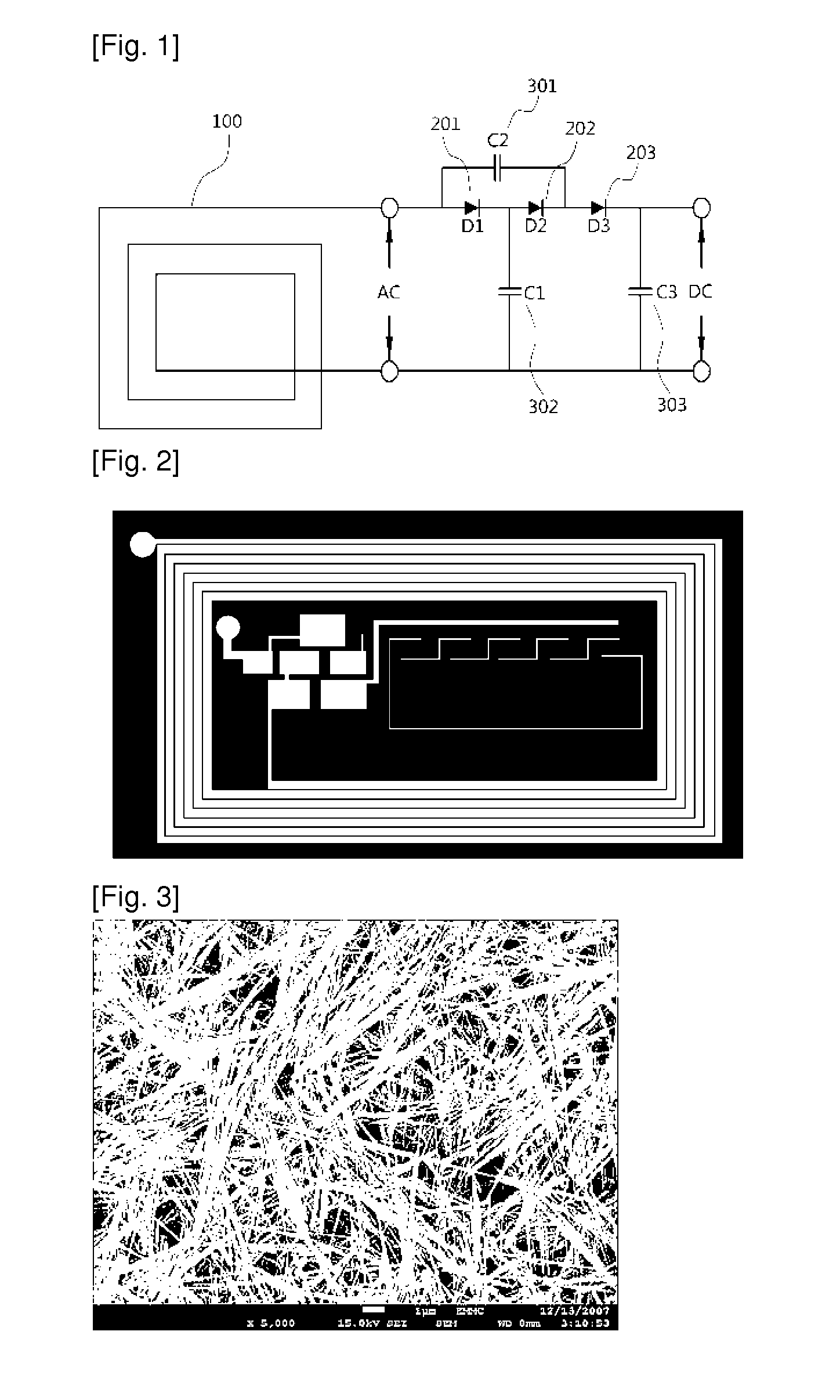

RF printing rectifier using roll to roll printing method

InactiveUS20110012809A1Low processing costHigh processing efficiencyMaterial nanotechnologyPrinted electric component incorporationDc currentCapacitor

Disclosed herein is an RF printed rectifier manufactured using a roll to roll printing process, comprising: a printed antenna manufactured using conductive ink through the roll to roll printing process; a printed diode manufactured using the conductive ink through the roll to roll printing process; and a printed capacitor manufactured using the conductive ink through the roll to roll printing process, wherein an alternating current is input through the printed antenna, and a direct current is output through the printed diode and capacitor.

Owner:PARU

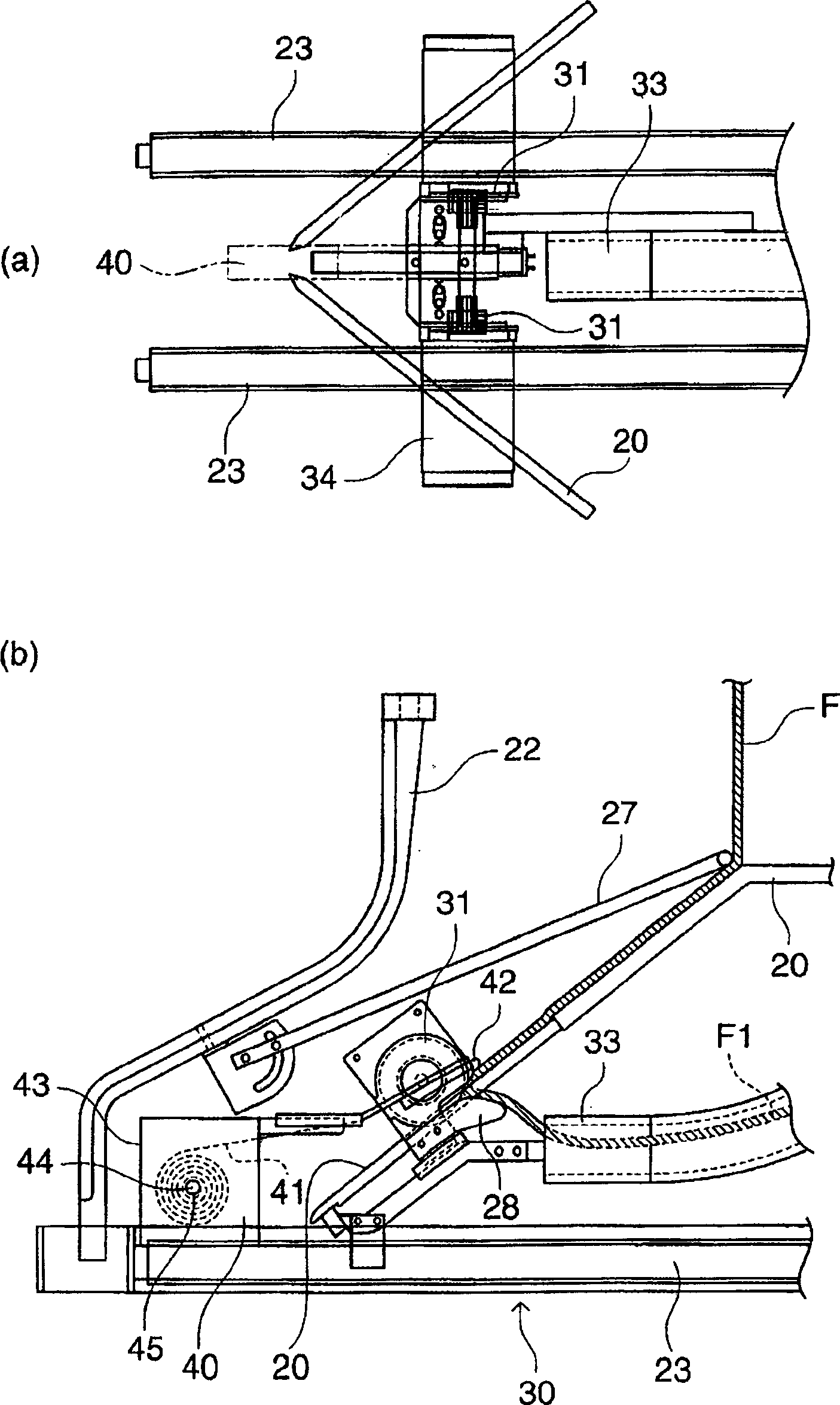

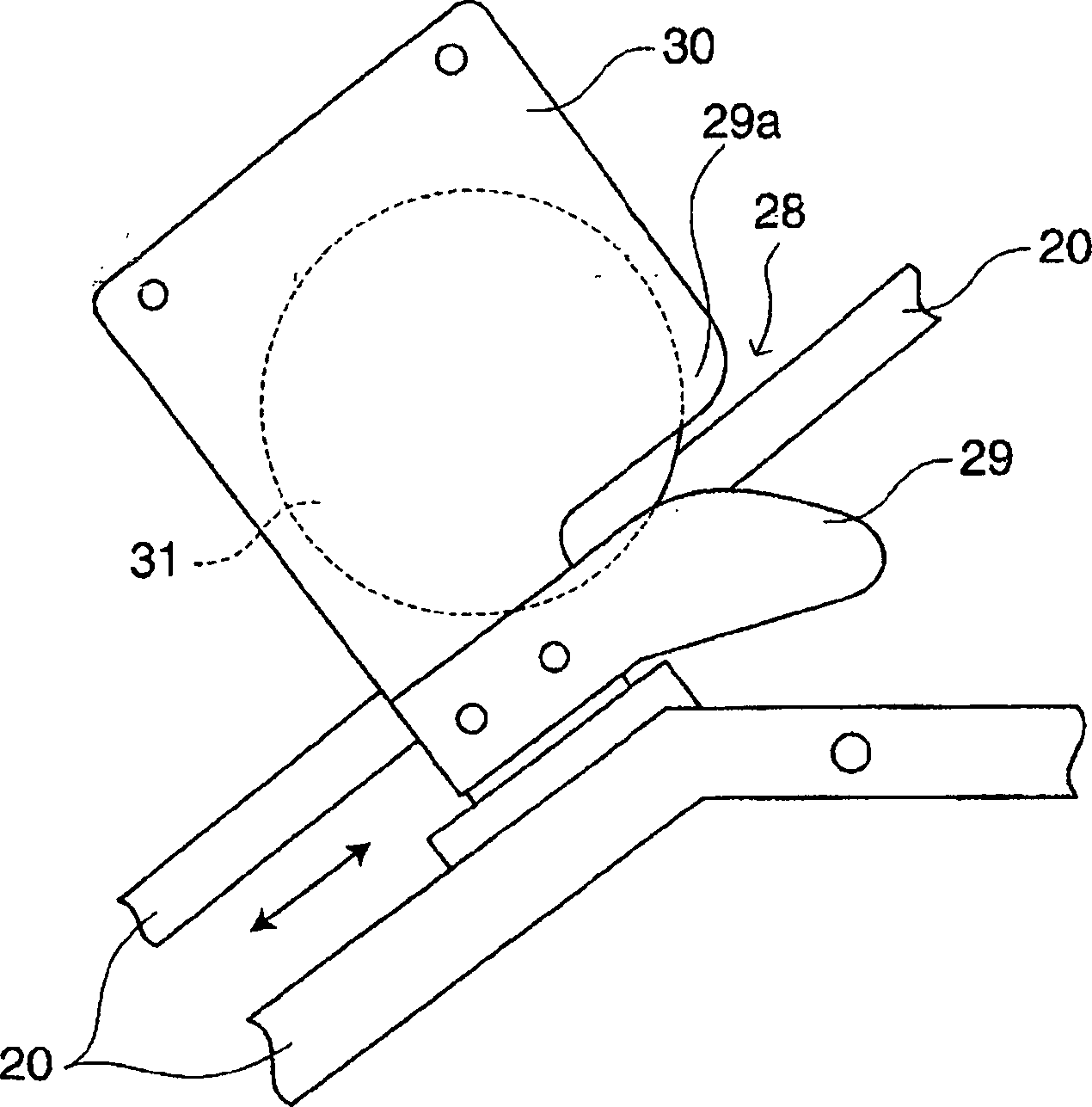

Apparatus for removing terminals of fabrics and circular loom therewith

The invention discloses a knitted fabric end removal device (30) in a circular knitting machine equipped with a switching device (16). This device (30) has an opening device ( 20) at least two cutting mechanisms (31) at one end, and a removing mechanism for separating the cut knitted fabric end (F1) from the knitted fabric main body. The above-mentioned removing mechanism may be a device (32, 33) that sucks and discharges the end of the knitted fabric outside the knitting machine, or a device that stores the end of the knitted fabric separated from the main body of the knitted fabric inside the knitting machine. The above-mentioned cutting mechanism may be a rotary cutting device (31) or a scissors type cutting device.

Owner:PRECISION FUKUHARA WORKS

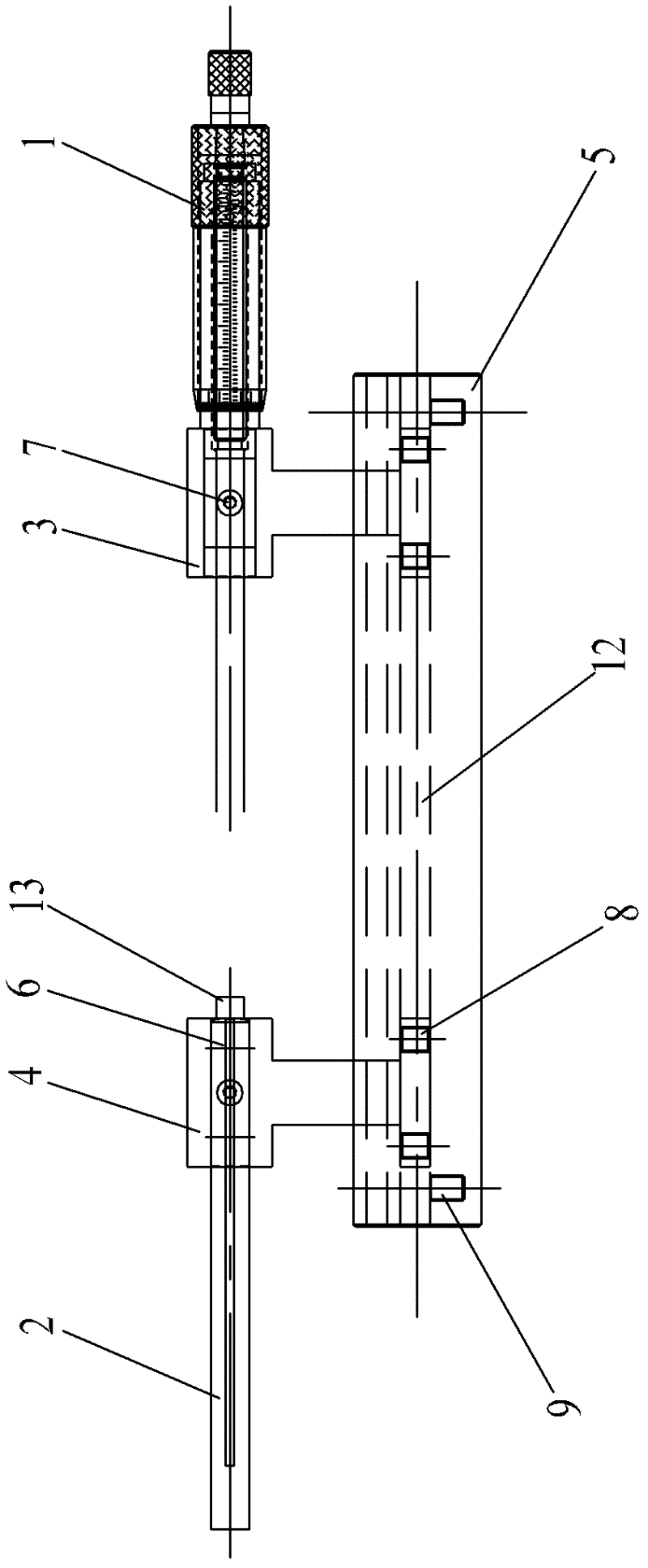

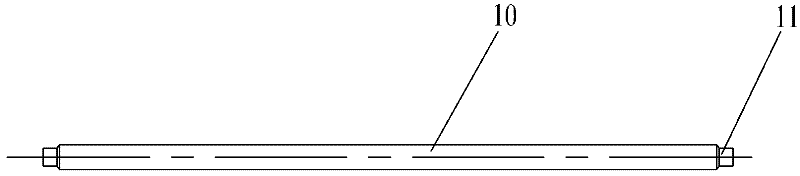

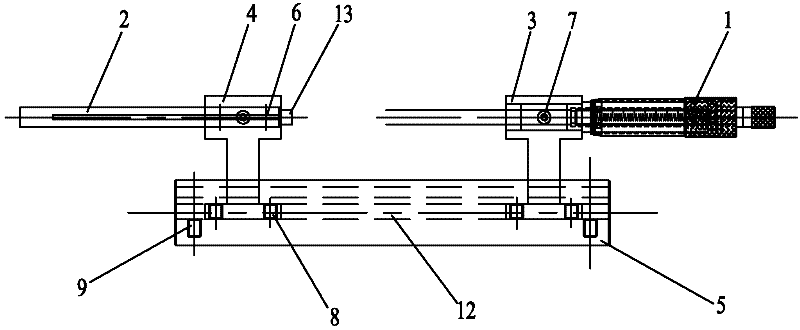

Adjustable calibrating device for measuring intermediate diameter of internal thread of oil casing

InactiveCN102230774AEasy to useLow processing costMechanical diameter measurementsMicrometerAccuracy and precision

The invention relates to an adjustable calibrating device for measuring the intermediate diameter of an internal thread of an oil casing. The adjustable calibrating device comprises a fixing bracket base, wherein one end of the fixing bracket base is provided with a micrometer head fixing bracket, and the other end of the fixing bracket base is provided with a movable measuring rod fixing bracket; the micrometer head fixing bracket is provided with a micrometer head; the movable measuring rod fixing bracket is provided with a movable measuring rod; and the movable measuring rod and the micrometer head are distributed in parallel with the fixing bracket base. The adjustable calibrating device is convenient to use, and the processing cost on various specifications and a single size is greatly saved; the intermediate diameter size can be adjusted optionally between 50 millimeters and 550 millimeters, and the technical requirement is met; the accuracy is high and is almost equal to that of a micrometer, and conversion and adjustment of positive and negative sizes on a dial indicator of the intermediate diameter gauge are not required in the using process of the adjustable calibrating device; and the adjustable calibrating device has a simple and reliable structure, high stability, wide application range and high measuring accuracy, is very convenient to maintain, is easy to operate and is safe and reliable, and the measuring efficiency is increased.

Owner:WUXI SEAMLESS OIL PIPE

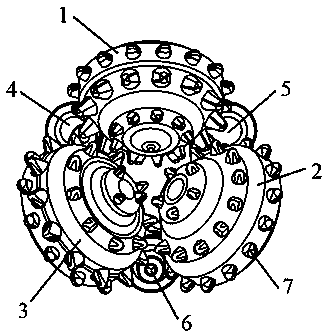

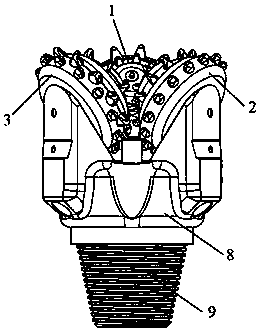

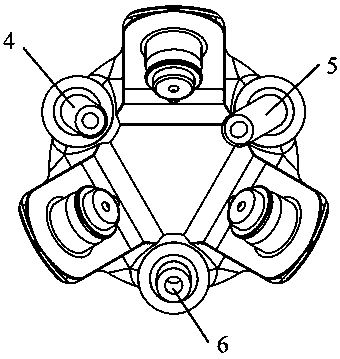

Three-cone drill bit for particle impact drilling

PendingCN107905732ASimple structureLow processing costDrill bitsDrilling machines and methodsRock breakingDrill bit

The invention relates to a three-cone drill bit for particle impact drilling. The three-cone drill bit is composed of jaws, cones, teeth, particle jet flow preparing nozzles, a joint and a drill bit body. The particle jet flow preparing nozzles are made of hard alloys and are connected with the drill bit body in a brazed mode. The outlet positions and inclined angles of the nozzles are all different, and the arrangement positions of the teeth on the three cones are also different. Prepared particle jet flows can completely cover the shaft bottom, meanwhile it can be ensured that the particle jet flows penetrate through gaps of the teeth and the cones, and the situation that the particle jet flows directly impact the cones and the teeth is avoided. Through the main working mode that impactof the particle jet flows is used for rock-breaking drilling and the auxiliary working mode of mechanical rock-breaking drilling of the cones and the teeth, and the drilling efficiency of a hard stratum and a high-grindability stratum is greatly superior to that of an existing cone drill bit; and under the extreme condition, when a ground particle injection system breaks down, the three-cone drillbit can also be used as a common cone drill bit to conduct rock-breaking drilling, and thus operation risks are avoided effectively.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

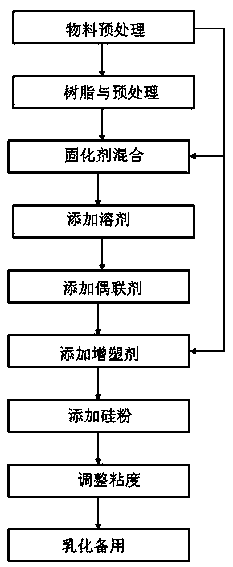

High-performance colloid for aluminum-based copper-clad plate and preparation method of high-performance colloid

InactiveCN108624270AEasy accessIncrease productivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesResin matrixSolvent

The invention relates to high-performance colloid for an aluminum-based copper-clad plate and a preparation method of the high-performance colloid. The high-performance colloid comprises, by mass percentage, 20-30% of resin matrix, 8-19% of curing agent, 9-21% of plasticizer, 1-2.1% of coupling agent, 40-55% of filler and the balance organic solvent. The preparation method includes: preprocessingraw materials, preprocessing resin, performing curing agent mixing, adding the solvent, adding the coupling agent, adding the plasticizer, adding silicon powder, regulating viscosity, and emulsifyingfor standby. The high-performance colloid and the preparation method thereof have the advantages that the high-performance colloid is convenient in raw material acquiring, low in raw material and processing costs, small in toxic and side effects and simple in processing and production process, colloidal liquid production efficiency can be increased effectively, production cost can be lowered, thethermal coefficient, high-temperature resistance and bending resistance of colloidal liquid can be increased effectively, and accordingly the high-temperature resistance and bending resistance of thealuminum-based copper-clad plate can be improved while the production and application costs of the aluminum-based copper-clad plate are lowered greatly.

Owner:焦作市高森建电子科技有限公司

Thermochemical Gas Sensor Using Thermoelectric Thin Film And Method Of Manufacturing The Same

PendingUS20190100851A1Low processing costHigh processing costAnodisationElectrolysis componentsExothermic reactionChalcogenide

The present invention relates to a thermochemical gas sensor including a substrate provided with an insulating layer; a seed layer provided on the insulating layer; a thermoelectric thin film provided on the seed layer; an electrode provided on the thermoelectric thin film; a catalyst layer provided on the electrode and causing exothermic reaction when in contact with gas to be sensed; and an electrode wire electrically connected to the electrode, wherein the thermoelectric thin film is formed of a material including a chalcogenide, wherein the chalcogenide includes one or more chalcogens selected from the group consisting of selenium (Se) and tellurium (Te). The thermochemical gas sensor according to the present invention can be miniaturized and sense gases at various concentrations due to being based on a thermoelectric thin film, does not undergo physical / chemical changes, such as phase change of a thermoelectric thin film, even if repeatedly exposed to gas, and can sense various desired gas types using changes in a catalyst reacting selectively with gases to be sensed.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

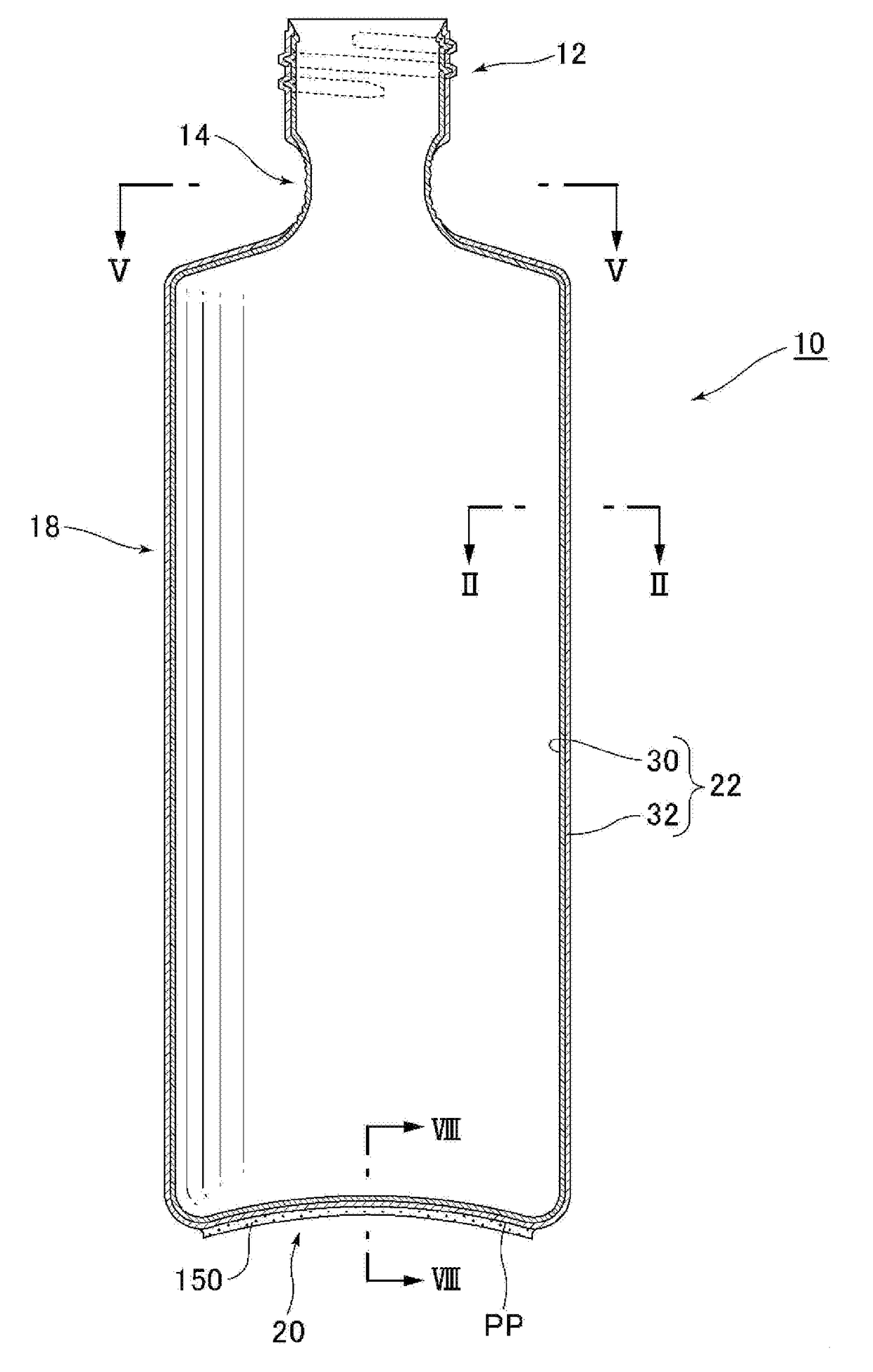

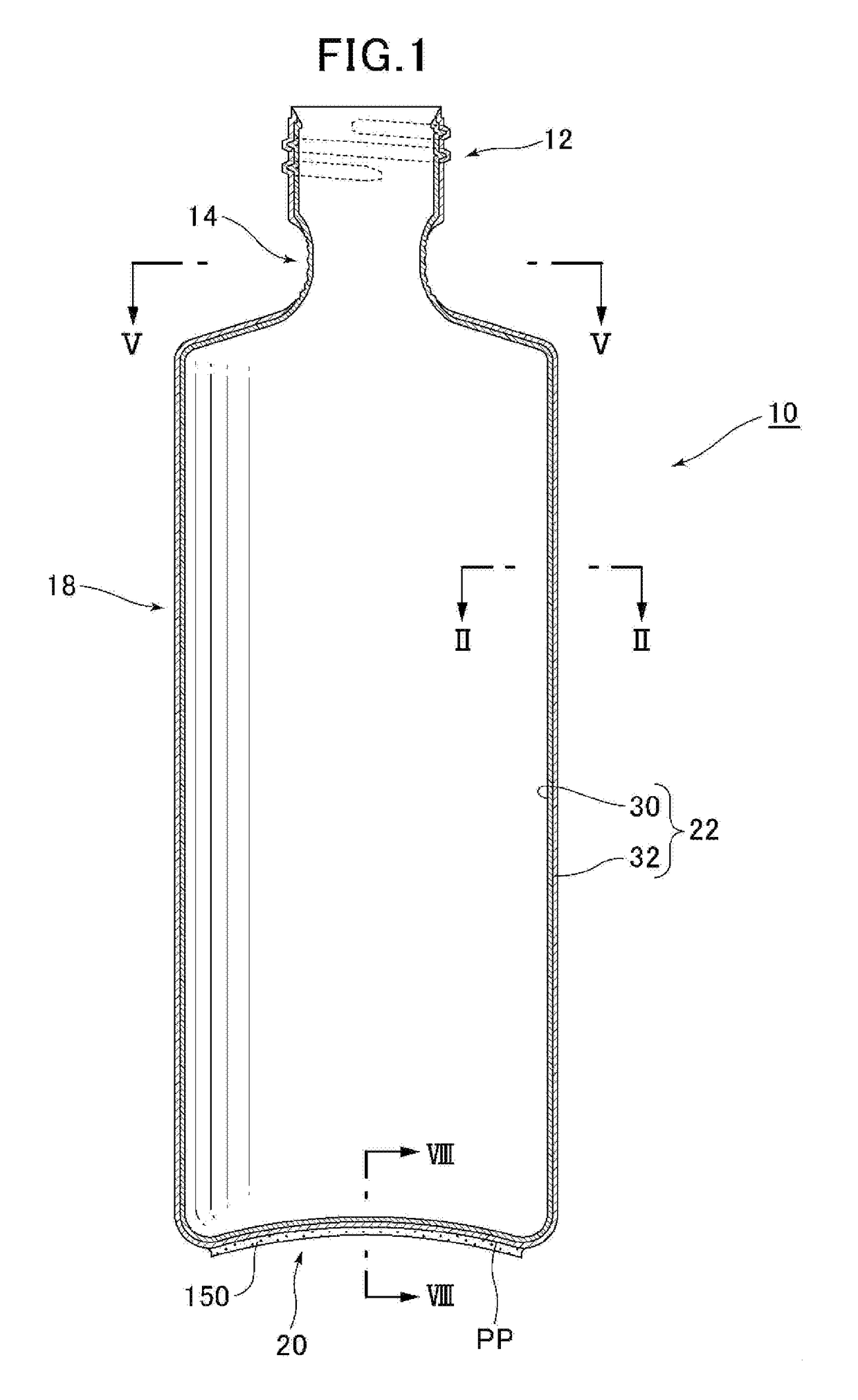

Double-walled container manufacturing method

ActiveUS20170239873A1Low processing costEasily manufactureDispensing apparatusBottlesEngineeringDouble walled

The present invention is a double-walled container manufacturing method in which when a pair of partial molds is brought towards each other to be assembled to form a split mold, at least a portion of the mating surfaces of the pair of partial molds clamp a parison at two side portions that are at horizontal positions facing each other. The method is able to manufacture the container easily with a molding device that does not differ significantly from the past and, in a double-walled container obtained from a relatively rigid outer container and a flexible inner container the volume of which can change according to the amount of contents filled inside said outer container, an opening for introducing outside air can be formed very easily and reliably at a lower cost than the processing cost of prior art.

Owner:HEIWA KAGAKU INDSSHO

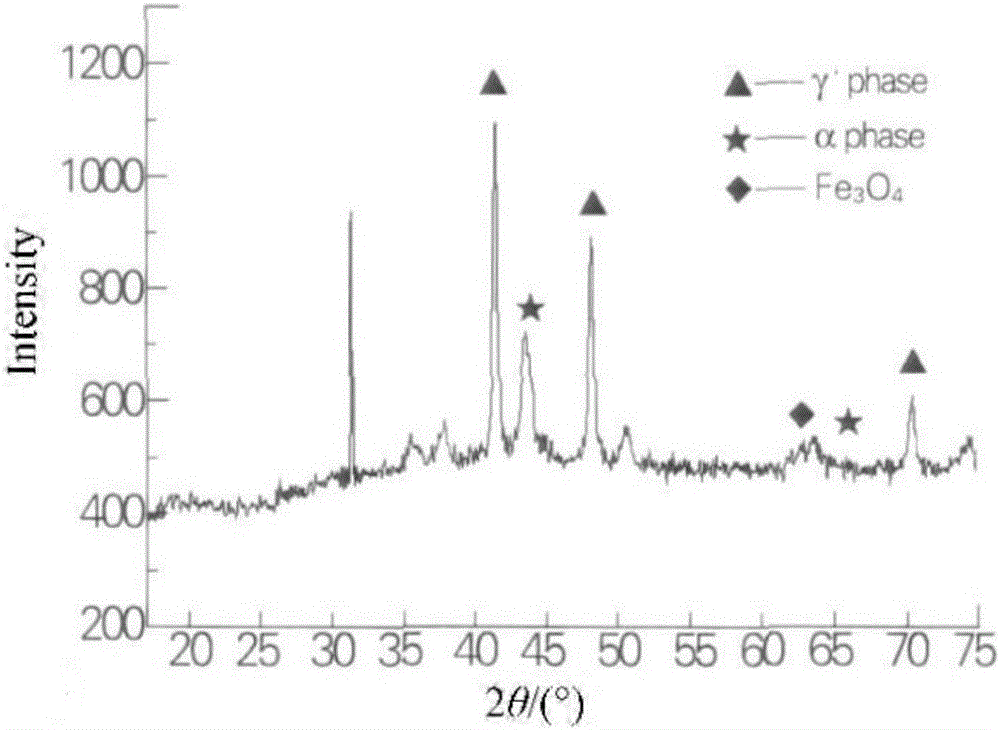

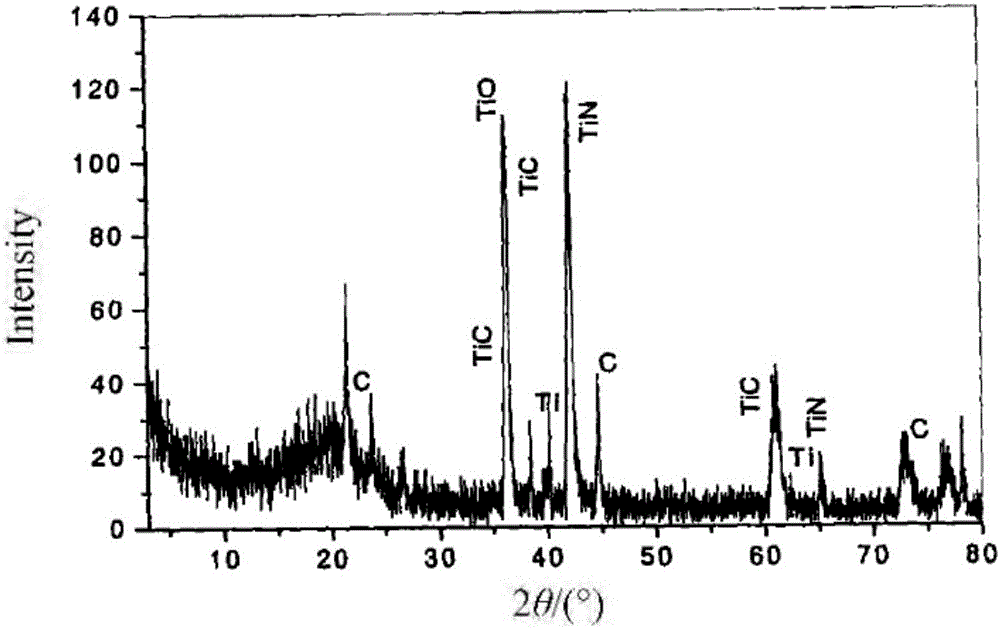

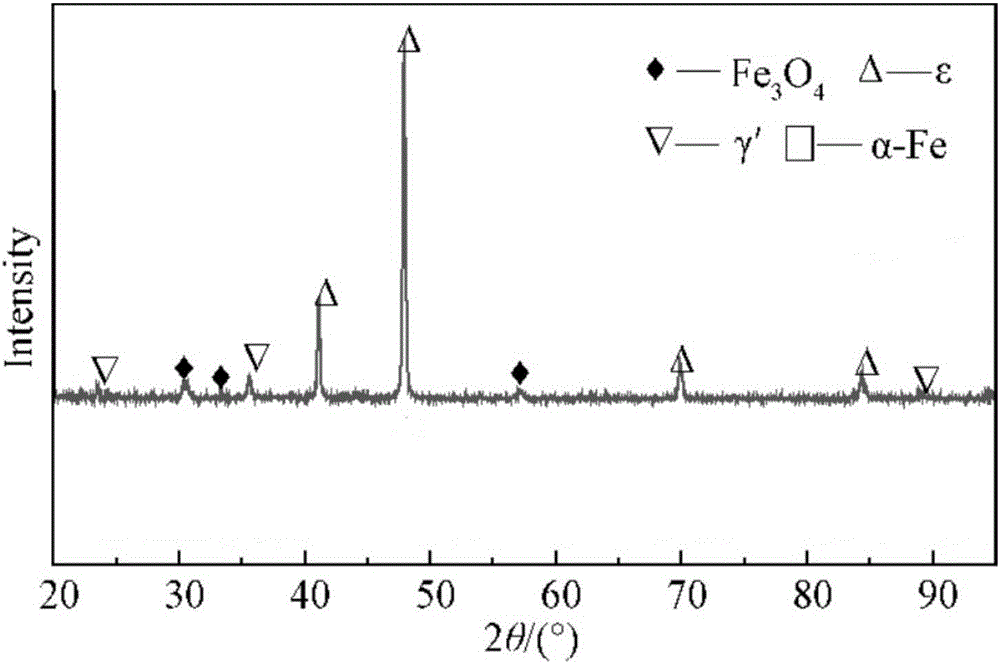

Mechanical-assisted chemical heat treatment method for metal surfaces

ActiveCN106048511ARealize the shapeRealize processingPolishing machinesSolid state diffusion coatingCompound (substance)Surface roughness

The invention relates to a mechanical-assisted chemical heat treatment method for metal surfaces. The method comprises the following steps that 1, a metal workpiece substrate to be subjected to chemical heat treatment is pretreated; 2, a chemical heat treatment electrode is prepared; 3, chemical heat treatment equipment is assembled; 4, chemical heat treatment preparation is conducted; and 5, the metal workpiece substrate to be subjected to chemical heat treatment is ground and polished. The mechanical-assisted chemical heat treatment method for metal surfaces has the advantages of being simple in equipment, low in investment, and low in maintenance and machining cost; a strengthened layer is mainly of a solid solution structure, and is compact, uniform and high in quality; the strengthened layer and the substrate are subjected to metallurgical bonding, and are free of obvious interfaces and high in bonding force; chemical heat treatment and grinding are conducted at the same time, the surface polishing effect of low surface roughness and high smoothness can be achieved, and secondary machining such as polishing and deburring is not needed; no special requirement for the shape and precision of workpieces exists, treatment of thin-walled parts made of composite materials can be achieved, and applicability is high; and operation is easy and feasible, efficiency is high, and the mechanical-assisted chemical heat treatment method can be used for large-scale treatment of the workpieces.

Owner:广东博友制钛科技有限公司

Large-diameter steel ball hard-turning method

The invention provides a large-diameter steel ball hard-turning method. The large-diameter steel ball hard-turning method comprises the following steps of 1 conducting automatic turning on a hollow clamp and enabling the hollow clamp to meet the requirements for rotation accuracy and core portion positioning-clamping accuracy equivalent to the accuracy of a machine tool spindle, 2 selecting an appropriate hard-turning allowance according to the deformation amount and finished product size of a steel ball subjected to heat treatment, and 3 performing clamping and turning in two-time mode, wherein the first-time turning is used for turning and removing most of area except a clamped position and decreasing the area for second-time turning, and a workpiece is needed to rotate at 90 degrees during the first-time turning and the second-time turning. The large-diameter steel ball hard-turning method has the advantages of being high in machining efficiency, reducing machining cost, improving product quality and the like.

Owner:WAFANGDIAN BEARING GRP CO LTD

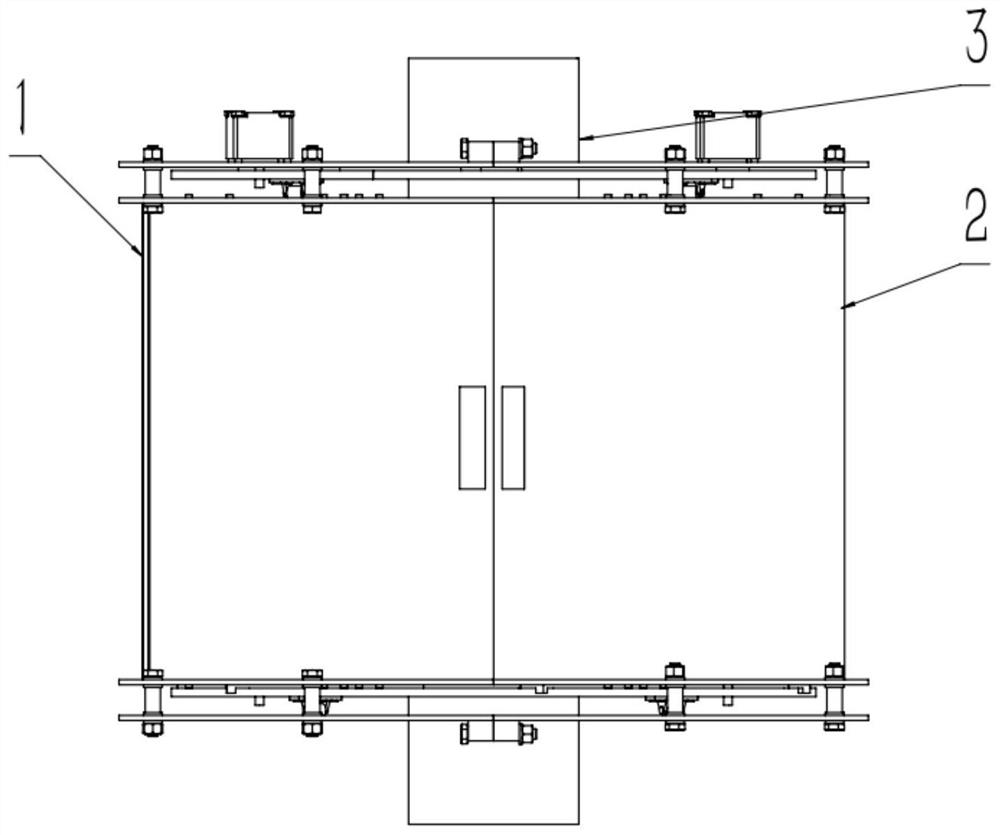

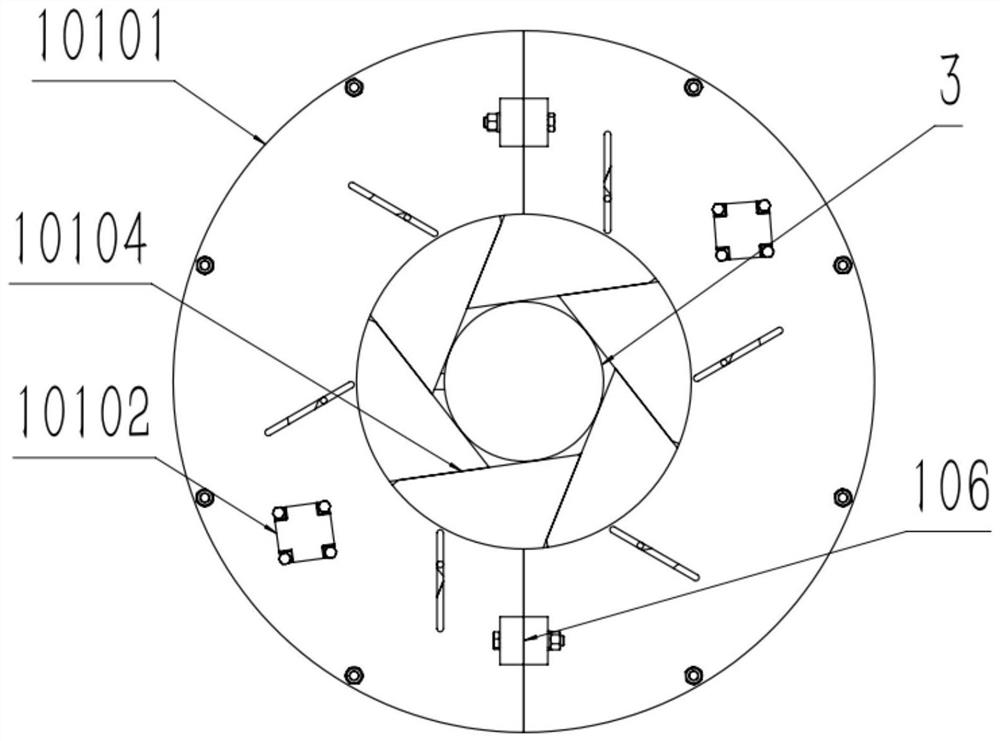

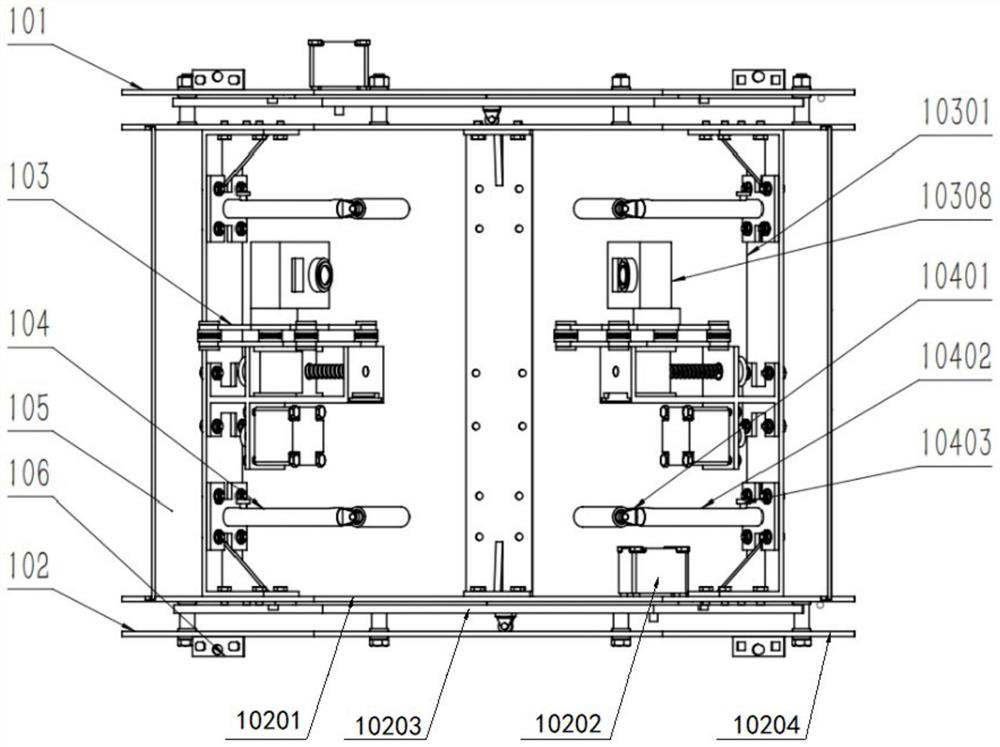

Visual cable detection device with adjustable detection space closed shooting distance

ActiveCN112414942AGuaranteed stabilityGood anti-interference performanceMaterial analysis by optical meansSet screwInterference resistance

The invention relates to the technical field of cable detection, in particular to a visual cable detection device with an adjustable detection space closed shooting distance, which comprises two symmetrical systems, namely a left side system and a right side system; wherein the left side system is provided with an upper rotary opening and closing system and a lower rotary opening and closing system; a distance-adjustable shooting system is arranged between the upper rotary opening and closing system and the lower rotary opening and closing system, pressing mechanisms are arranged between the shooting system and the upper rotary opening and closing system and between the shooting system and the lower rotary opening and closing system respectively, shading structures are arranged on the outer sides of the symmetrical systems, and connecting structures are arranged on the upper sides and the lower sides of the symmetrical systems. The device is built mostly with bolt connection, so that the structure is simple, maintenance is convenient, the production and manufacturing cost is low, and good economic benefits can be brought; the bolts are rigidly connected with the set screws and thelike, so that the stability of the detection device in the detection process is ensured, and the external interference resistance of the detection device is improved.

Owner:上海能莹实业有限公司

Shielding case and preparation method thereof

InactiveCN103108534ALow costLow processing costMagnetic/electric field screeningMetal foilPlastic materials

The invention discloses a shielding case and a preparation method of the shielding case. The shielding case is composed of a supporting layer with certain strength and a conducting layer which is compounded on the outer side of the supporting layer. The supporting layer is non-conducting, and vicat softening temperature of the supporting layer is not lower than 100 DEG C. Metal materials used in a traditional shielding case product and metal stamping forming technology adopted in the process of machining are changed, and ordinary plastic composite metal foil rubber belt materials and plastic die cutting machining technology are adopted. An ordinary cutting die is used for cutting and machining plastic materials and metal foil rubber belt, raw material cost is low, machining technique is easy to control, and die cost and machining cost are low. Obtained products can effectively be shielded from electromagnetism.

Owner:DALIAN SHENGFENG ADHESIVE PROD

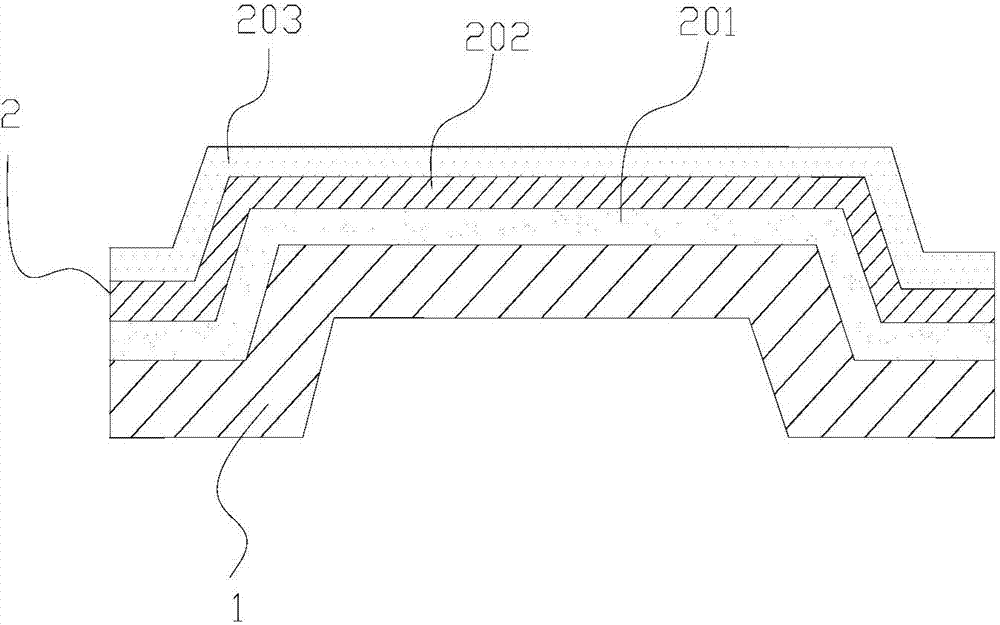

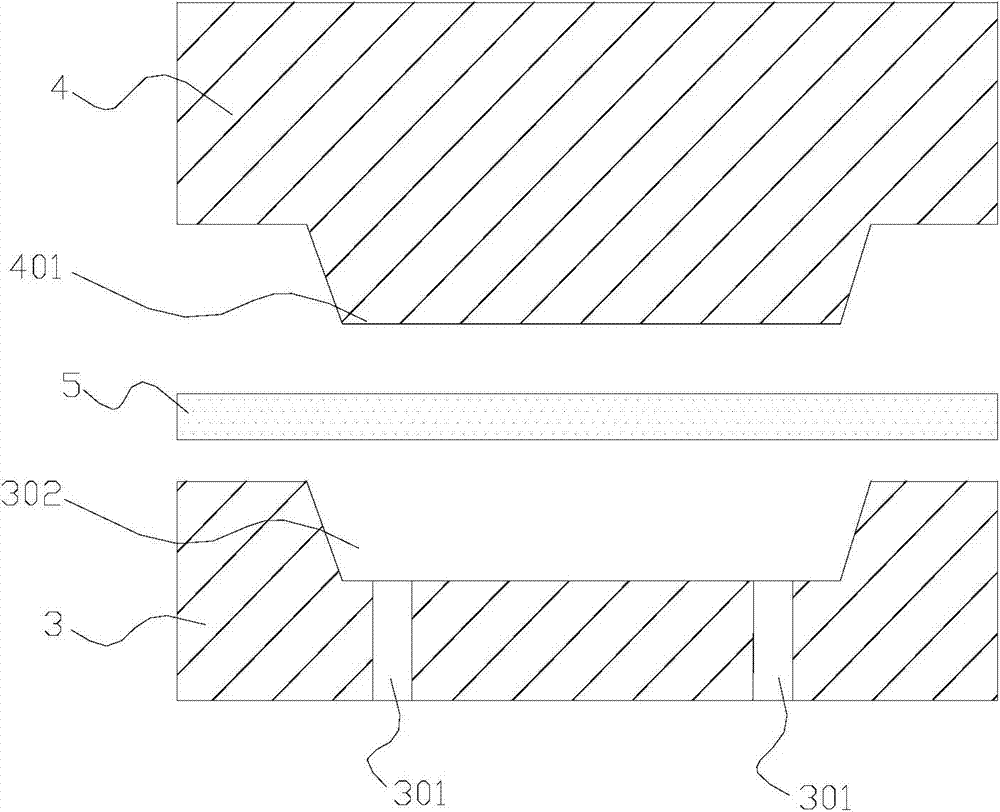

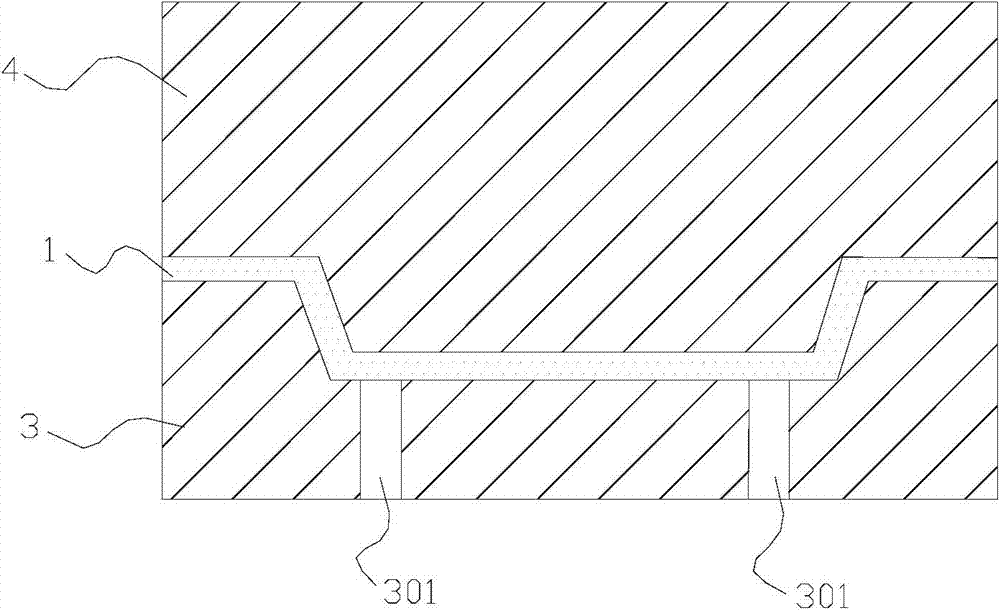

Interposer substrate and method for fabricating the same

ActiveUS20160037634A1Low processing costSimple processSemiconductor/solid-state device detailsSolid-state devicesExternal connectionEngineering

Owner:PHOENIX PIONEER TECH

Aluminum alloy heavy heat treatment method

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

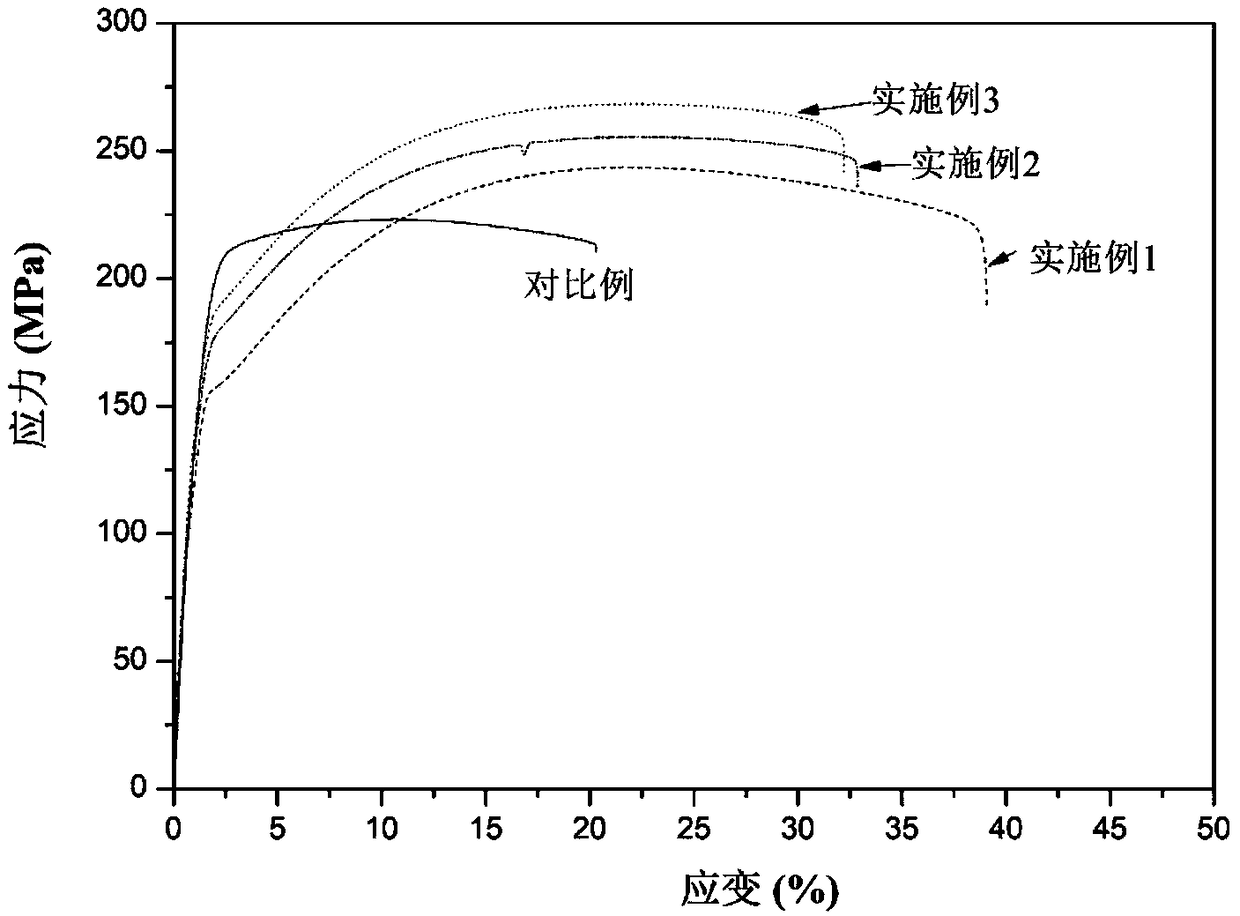

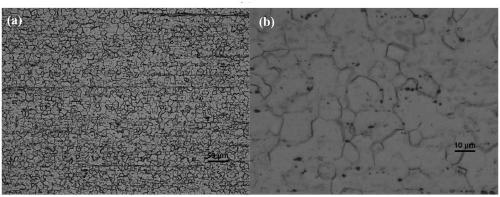

Low-cost high-room temperature plastic deformation magnesium alloy and preparation method thereof

The invention discloses a low-cost high-room temperature plastic deformation magnesium alloy and a preparation method thereof. The low-cost high-room temperature plastic deformation magnesium alloy isan Mg-Bi-Sn-Zr-Ca-Y alloy, and comprises the following chemical components by mass percent: 2 wt% to 5.0 wt% of Bi, 2 wt% to 5.0 wt% of Sn, 0.5 wt% to 1.2 wt% of Zr, 0.1 wt% to 0.8 wt% of Ca and 0.01wt% to 0.08 wt% of Y, and the balance being Mg and unavoidable impurities; and besides, the mass ratio of Bi to Ca is (6 to 7) to 1. According to the low-cost high-room temperature plastic deformation magnesium alloy and the preparation method thereof, the high-room temperature plastic deformation magnesium alloy can be obtained through an extremely simple processing means, the room-temperature extension rate reaches 35% or above, raw materials are cheap, processing cost is low, and mass production is each to achieve.

Owner:北京中安璟润新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com