Three-cone drill bit for particle impact drilling

A particle impact, tri-cone technology, applied in drill bits, drilling equipment, earth-moving drilling and other directions, can solve the problems of long drilling cycle, high development cost, lowering the development benefit of deep oil and gas resources, etc., to avoid direct impact on the cone. It has the effect of low cost of processing and production of teeth and avoiding operation risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

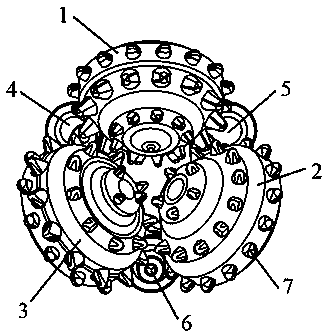

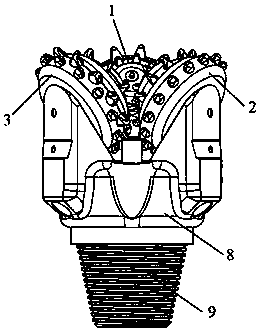

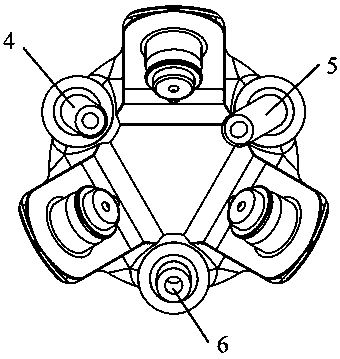

[0023] As a preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0024] A three-cone drill bit for particle impact drilling, comprising a bit body 8, a joint 9, a first claw 10, a second claw 11, a third claw 12, a first cone 1, a second cone 2, a third No. 3 cone 3, No. 1 particle jet modulation nozzle 4, No. 2 particle jet modulation nozzle 5 and No. 3 particle jet modulation nozzle 6, the No. 1 cone 1, No. 2 cone 2 and No. 3 cone 3 pass through the bearing The mechanism is respectively connected and assembled with the No. 1 jaw 10, the No. 2 jaw 11 and the No. 3 jaw 12. The No. 1 particle jet modulation nozzle 4 is located between the No. 1 cone 1 and the No. 3 cone 3, and the No. 2 particle jet modulates The nozzle 5 is located between the No. 1 cone 1 and the No. 2 cone 2, and the No. 3 particle jet modulation nozzle 6 is located between the No. 2 cone 2 and the No. 3 cone 3; the No. 1 particle jet modulati...

Embodiment 2

[0026] As another preferred embodiment of the present invention, with reference to the attached Figure 1-5 , this example discloses:

[0027] A three-cone drill bit for particle impact drilling, comprising a bit body 8, a joint 9, a first claw 10, a second claw 11, a third claw 12, a first cone 1, a second cone 2, a third No. 3 cone 3, No. 1 particle jet modulation nozzle 4, No. 2 particle jet modulation nozzle 5 and No. 3 particle jet modulation nozzle 6, the No. 1 cone 1, No. 2 cone 2 and No. 3 cone 3 pass through the bearing The mechanism is respectively connected and assembled with the No. 1 jaw 10, the No. 2 jaw 11 and the No. 3 jaw 12. The No. 1 particle jet modulation nozzle 4 is located between the No. 1 cone 1 and the No. 3 cone 3, and the No. 2 particle jet modulates The nozzle 5 is located between the No. 1 cone 1 and the No. 2 cone 2, and the No. 3 particle jet modulation nozzle 6 is located between the No. 2 cone 2 and the No. 3 cone 3; the No. 1 particle jet mo...

Embodiment 3

[0030] As another preferred embodiment of the present invention, with reference to the attached Figure 1-5 , this example discloses:

[0031]A three-cone drill bit for particle impact drilling, comprising a bit body 8, a joint 9, a first claw 10, a second claw 11, a third claw 12, a first cone 1, a second cone 2, a third No. 3 cone 3, No. 1 particle jet modulation nozzle 4, No. 2 particle jet modulation nozzle 5 and No. 3 particle jet modulation nozzle 6, the No. 1 cone 1, No. 2 cone 2 and No. 3 cone 3 pass through the bearing The mechanism is respectively connected and assembled with the No. 1 jaw 10, the No. 2 jaw 11 and the No. 3 jaw 12. The No. 1 particle jet modulation nozzle 4 is located between the No. 1 cone 1 and the No. 3 cone 3, and the No. 2 particle jet modulates The nozzle 5 is located between the No. 1 cone 1 and the No. 2 cone 2, and the No. 3 particle jet modulation nozzle 6 is located between the No. 2 cone 2 and the No. 3 cone 3; the No. 1 particle jet mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inlet diameter | aaaaa | aaaaa |

| Inlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com