Patents

Literature

91 results about "Tooth wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tooth wear refers to loss of tooth substance by means other than dental caries. Tooth wear is a very common condition that occurs in approximately 97% of the population. This is a normal physiological process occurring throughout life, but accelerated tooth wear can become a problem. Tooth wear varies substantially between people and groups, with extreme attrition and enamel fractures common in archaeological samples, and erosion more common today.

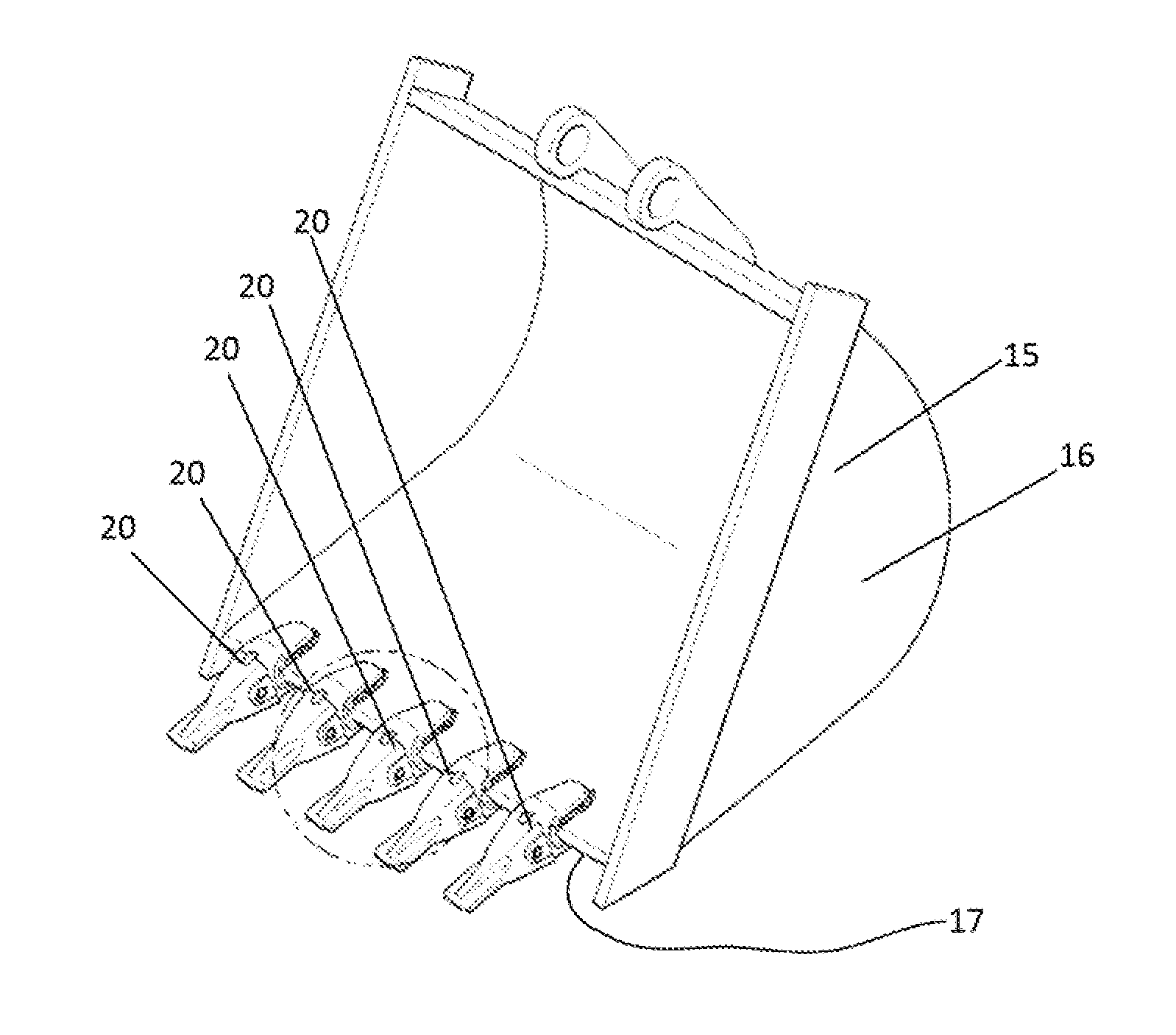

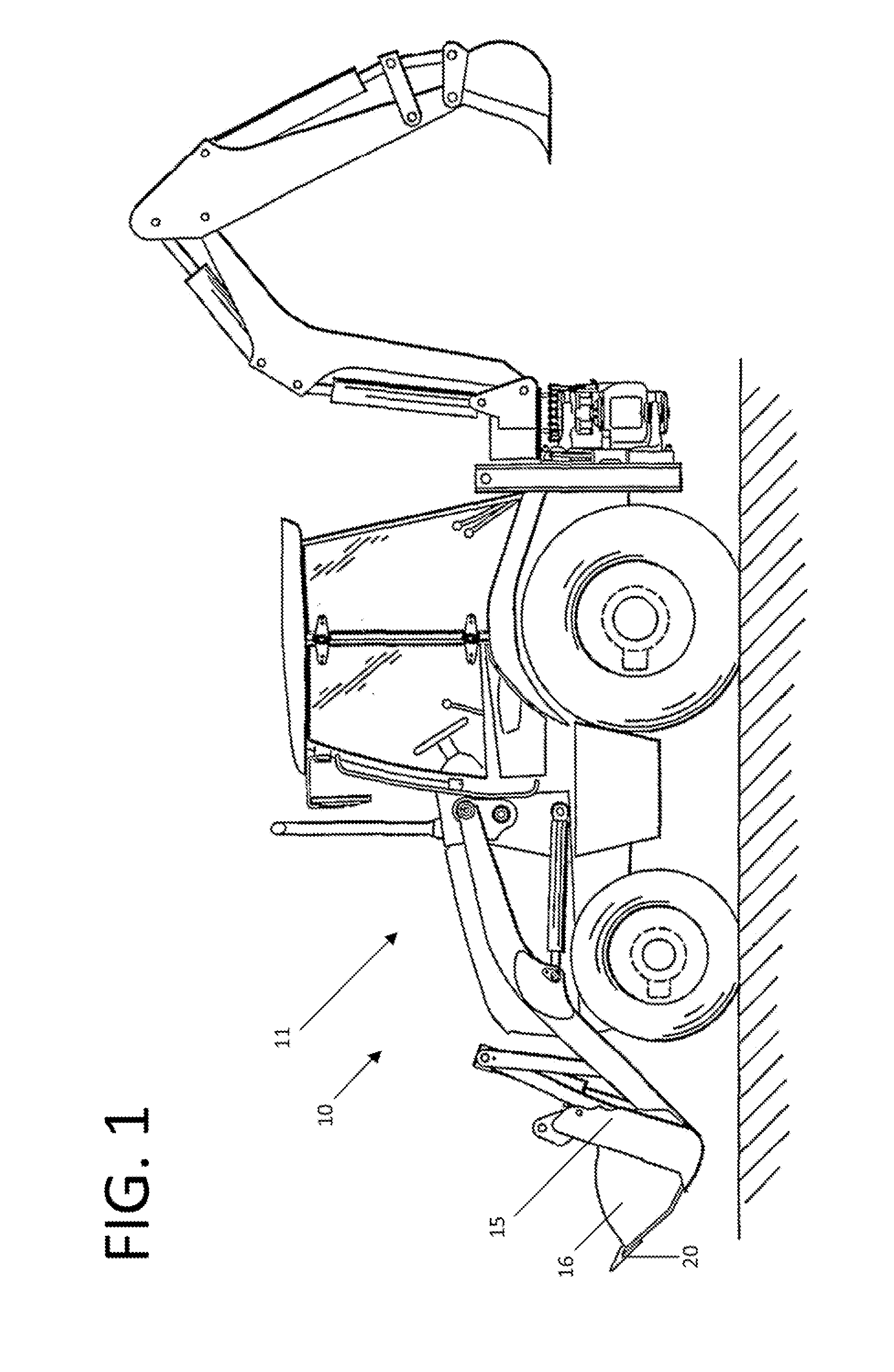

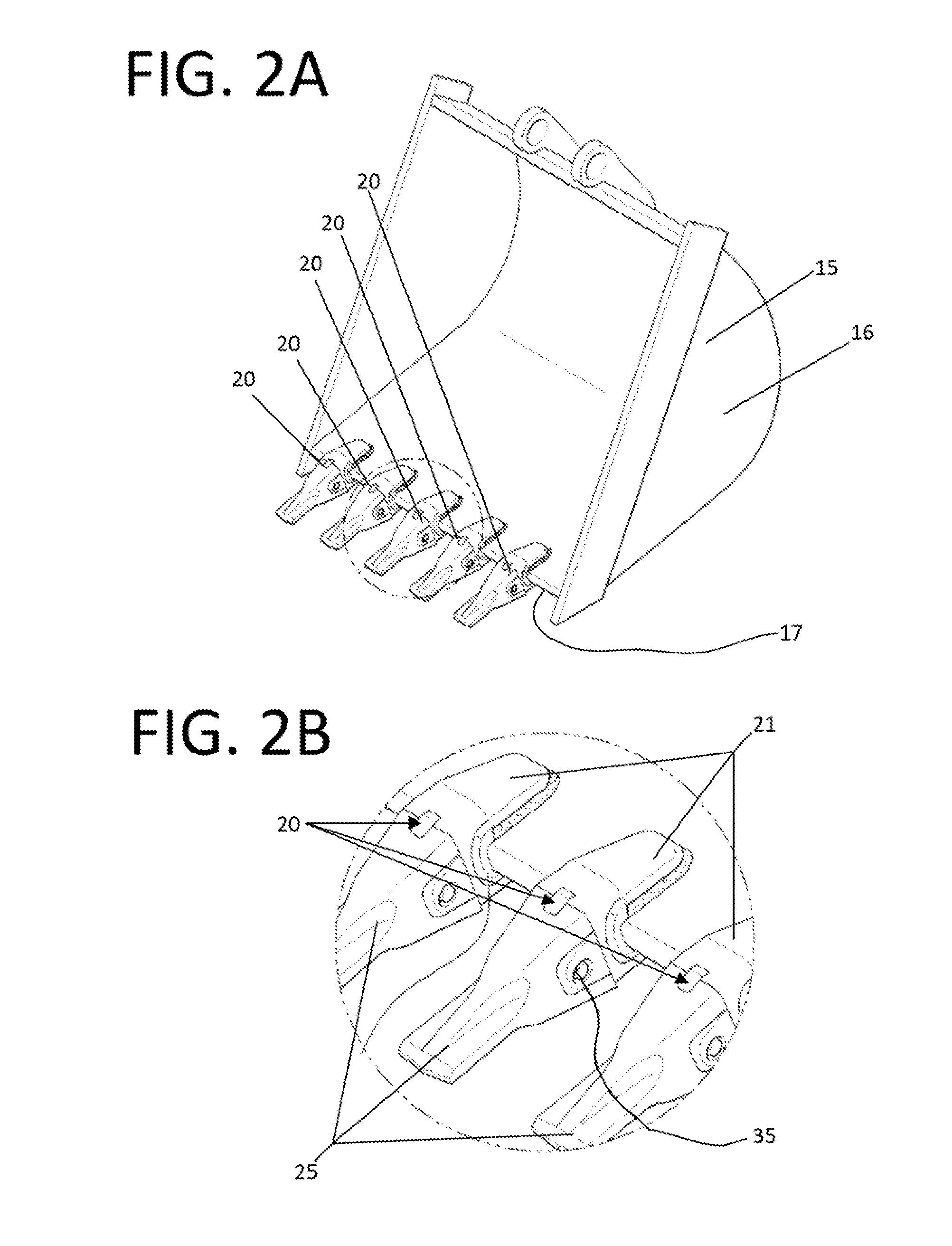

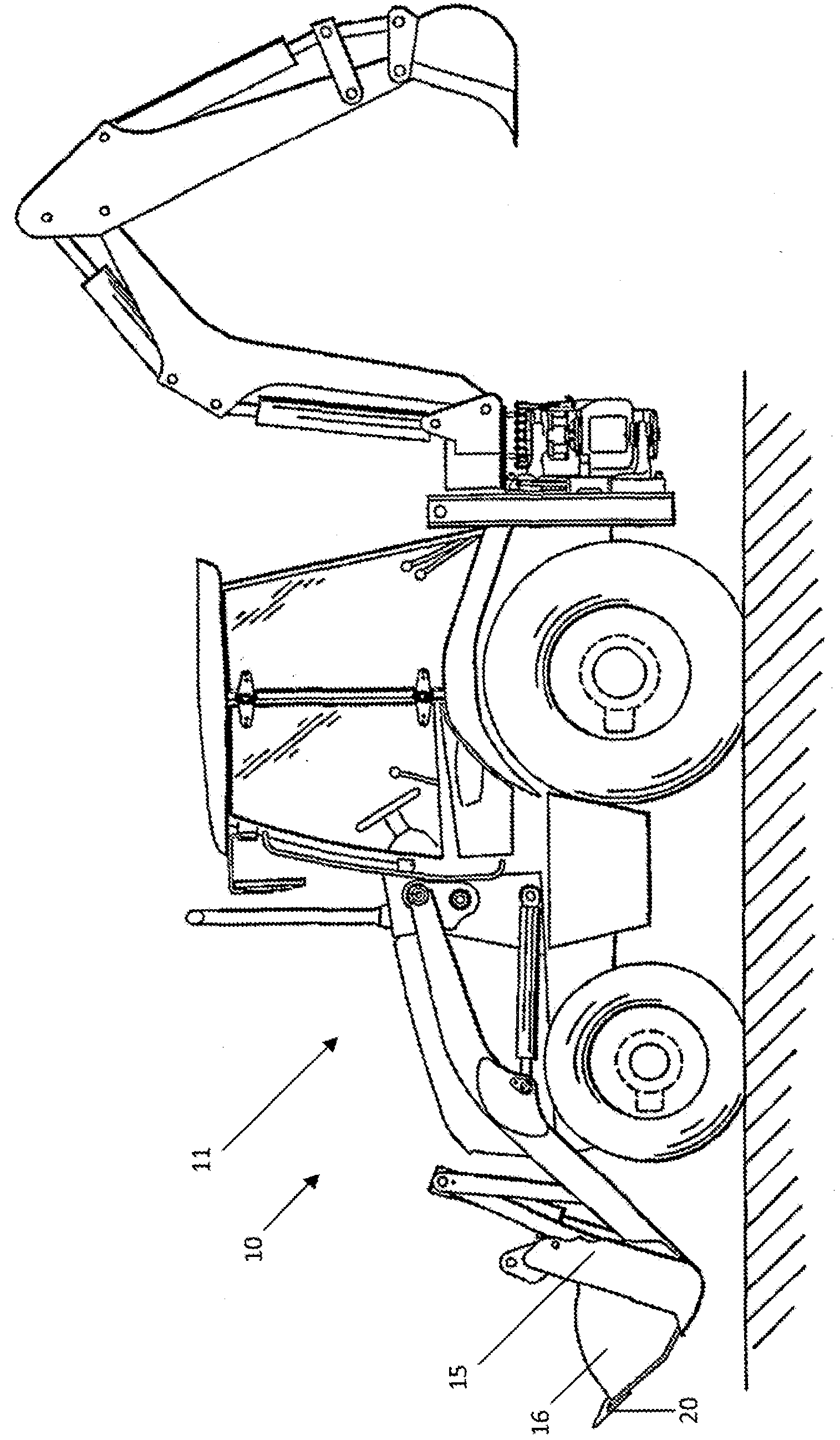

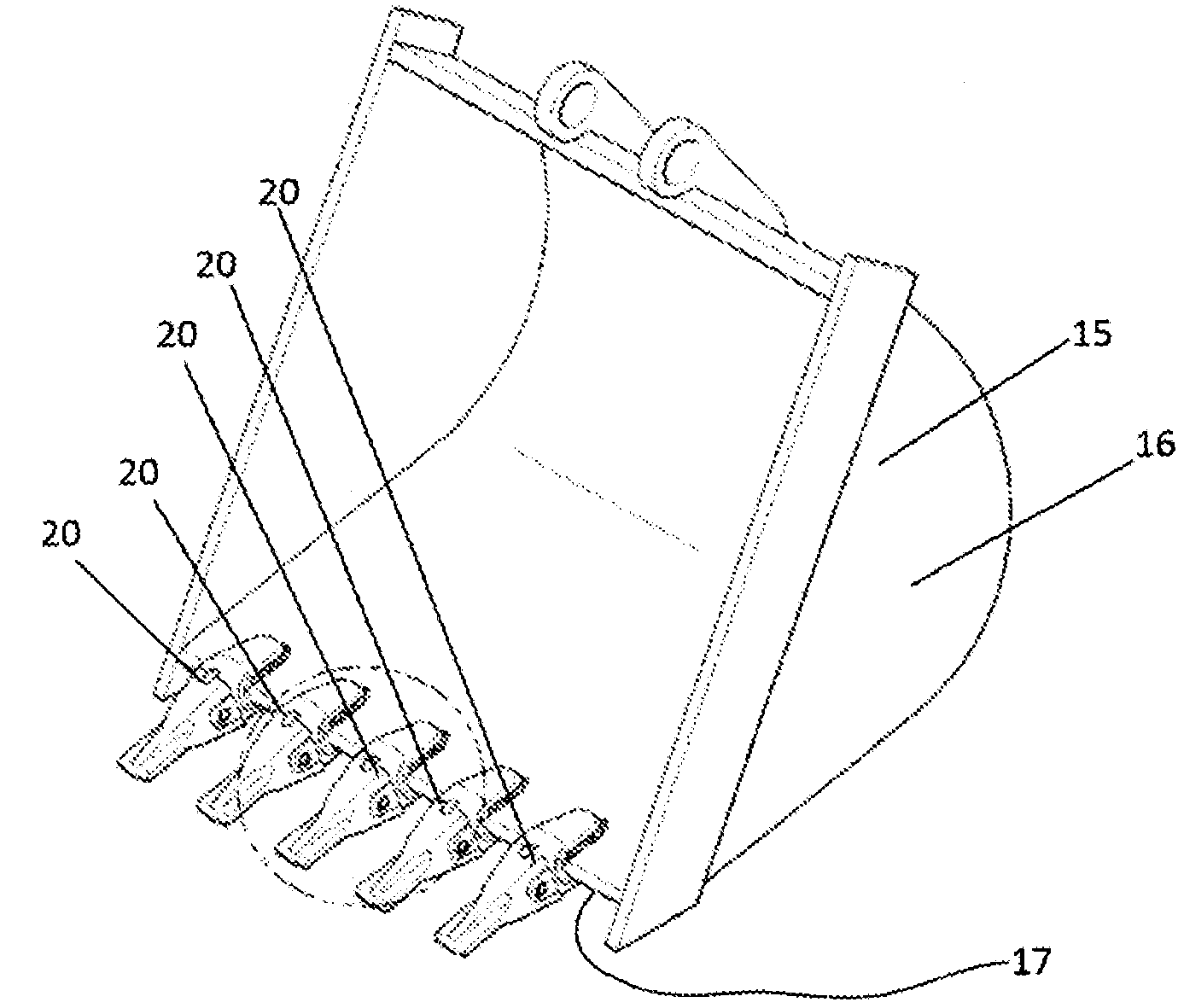

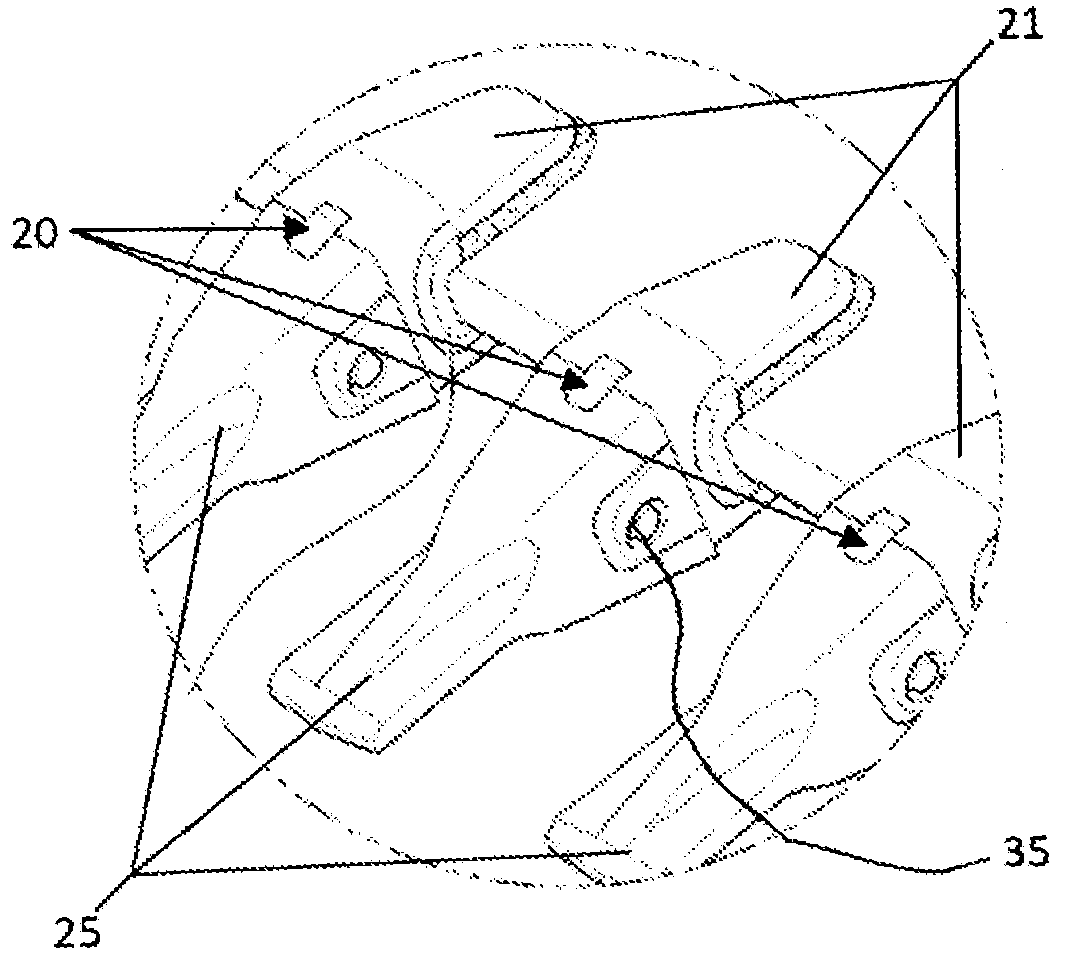

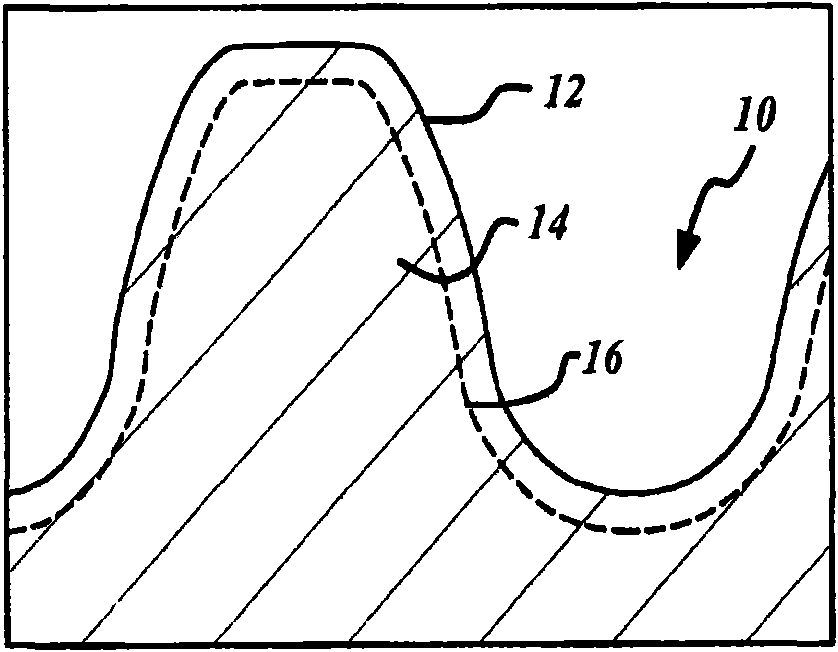

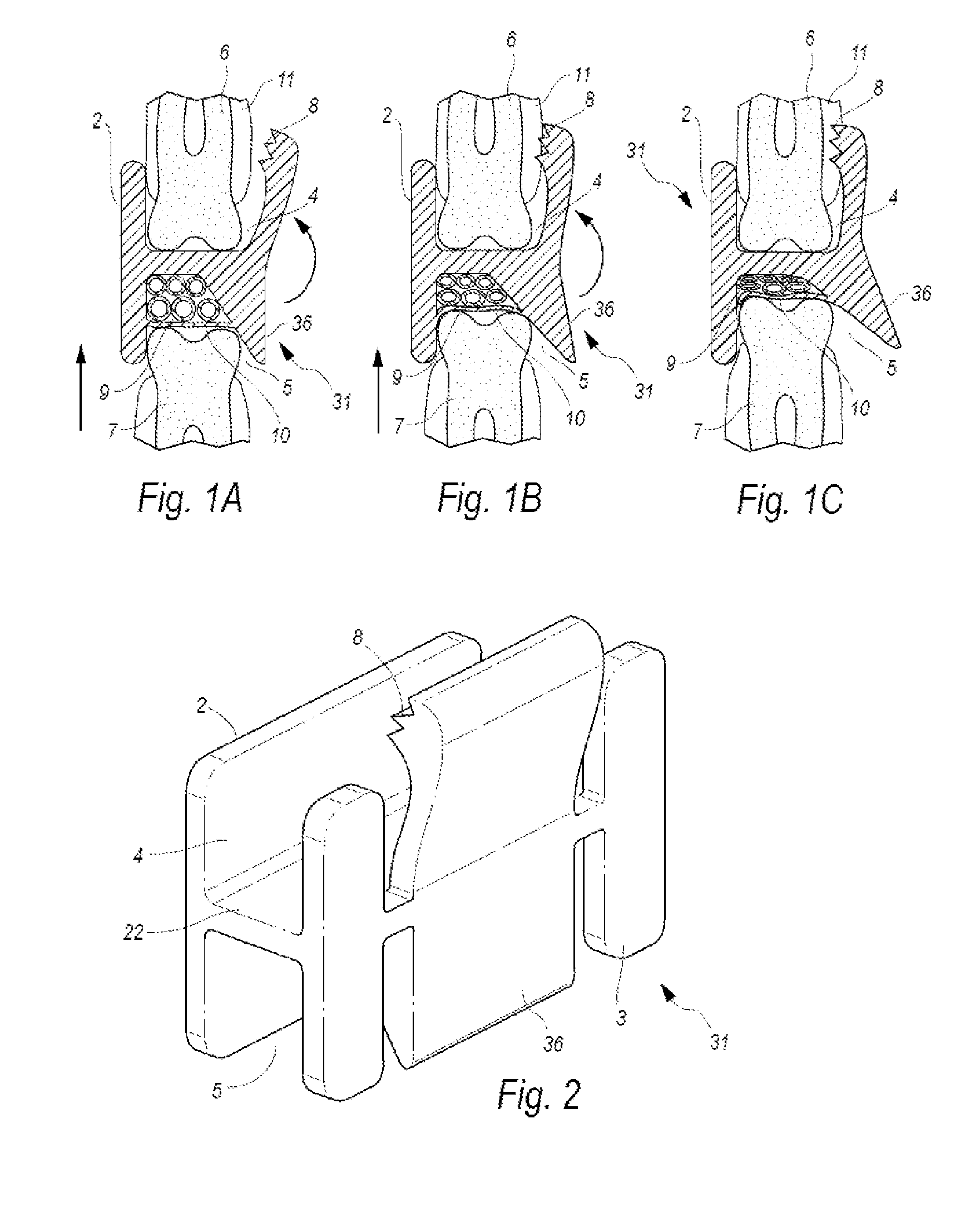

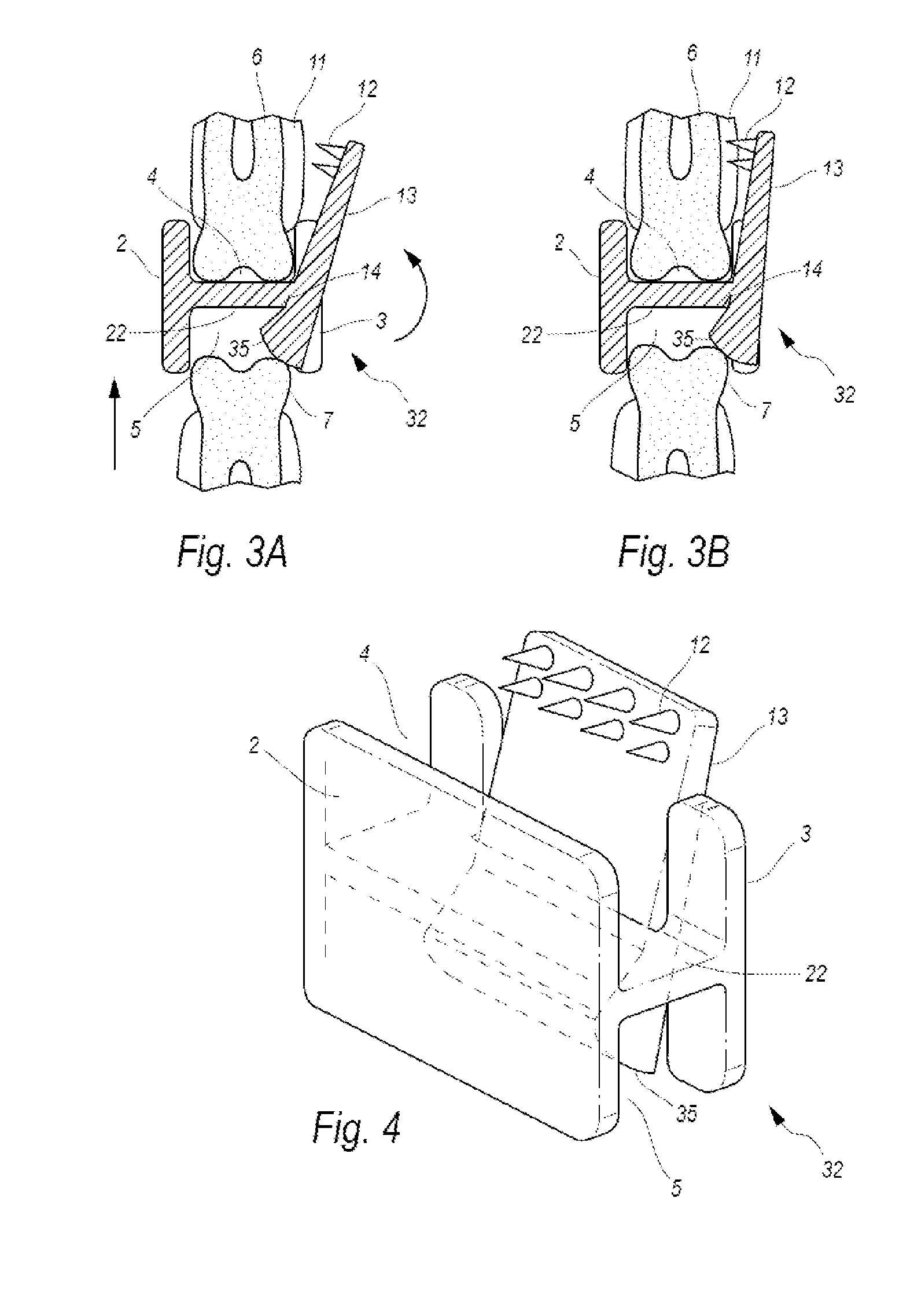

Excavating tooth wear indicator and method

Owner:VOLVO CONSTR EQUIP

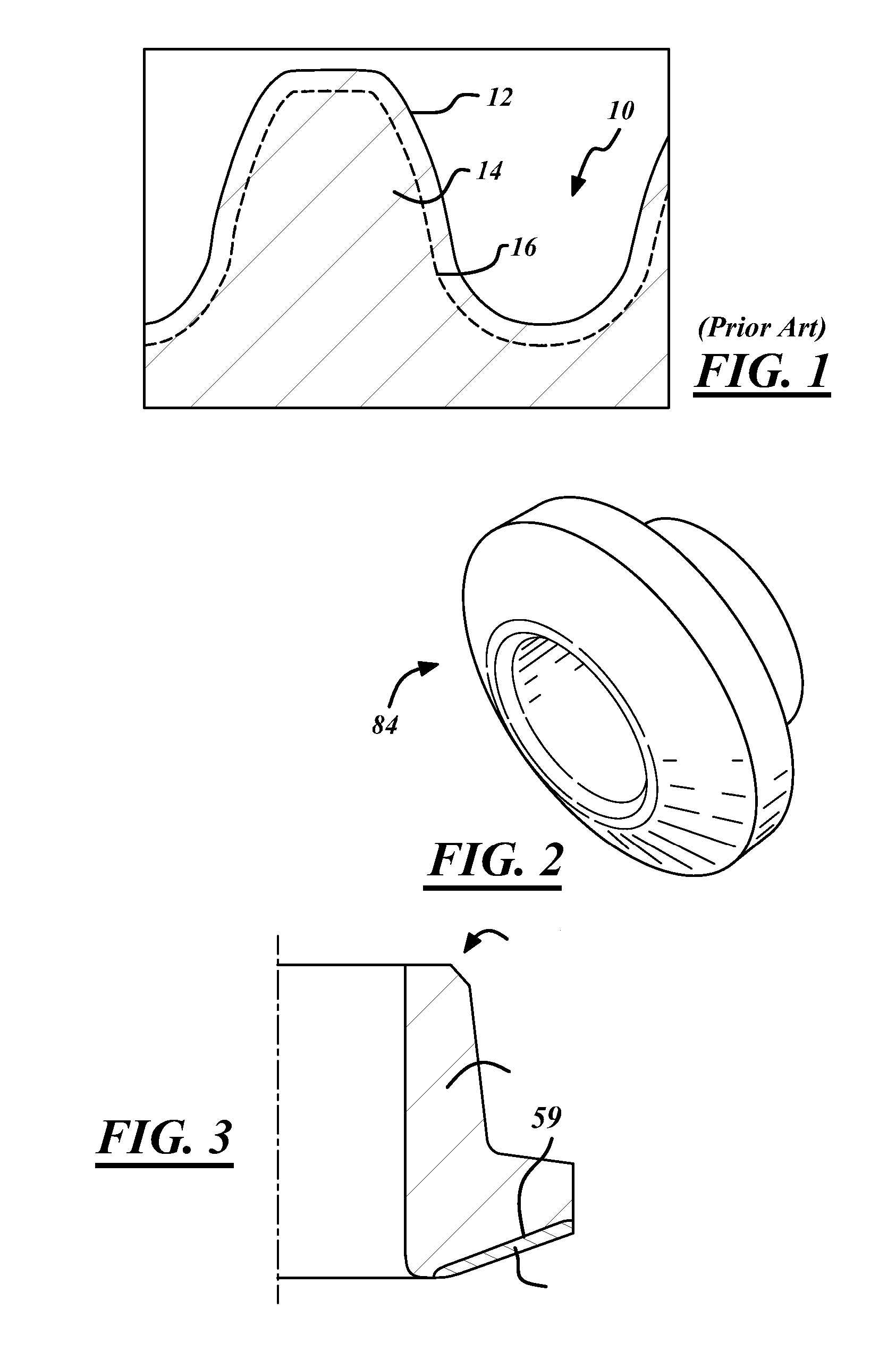

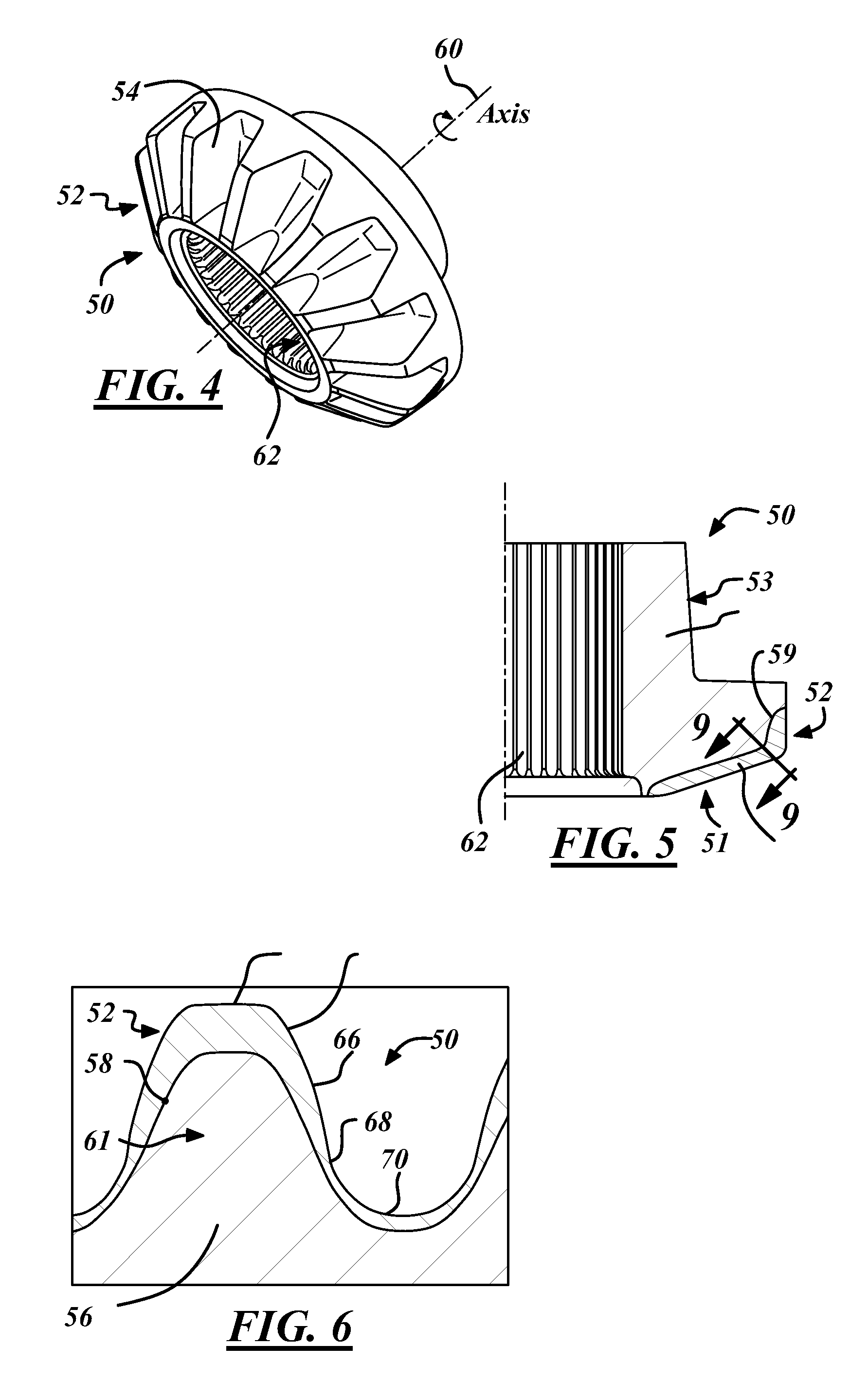

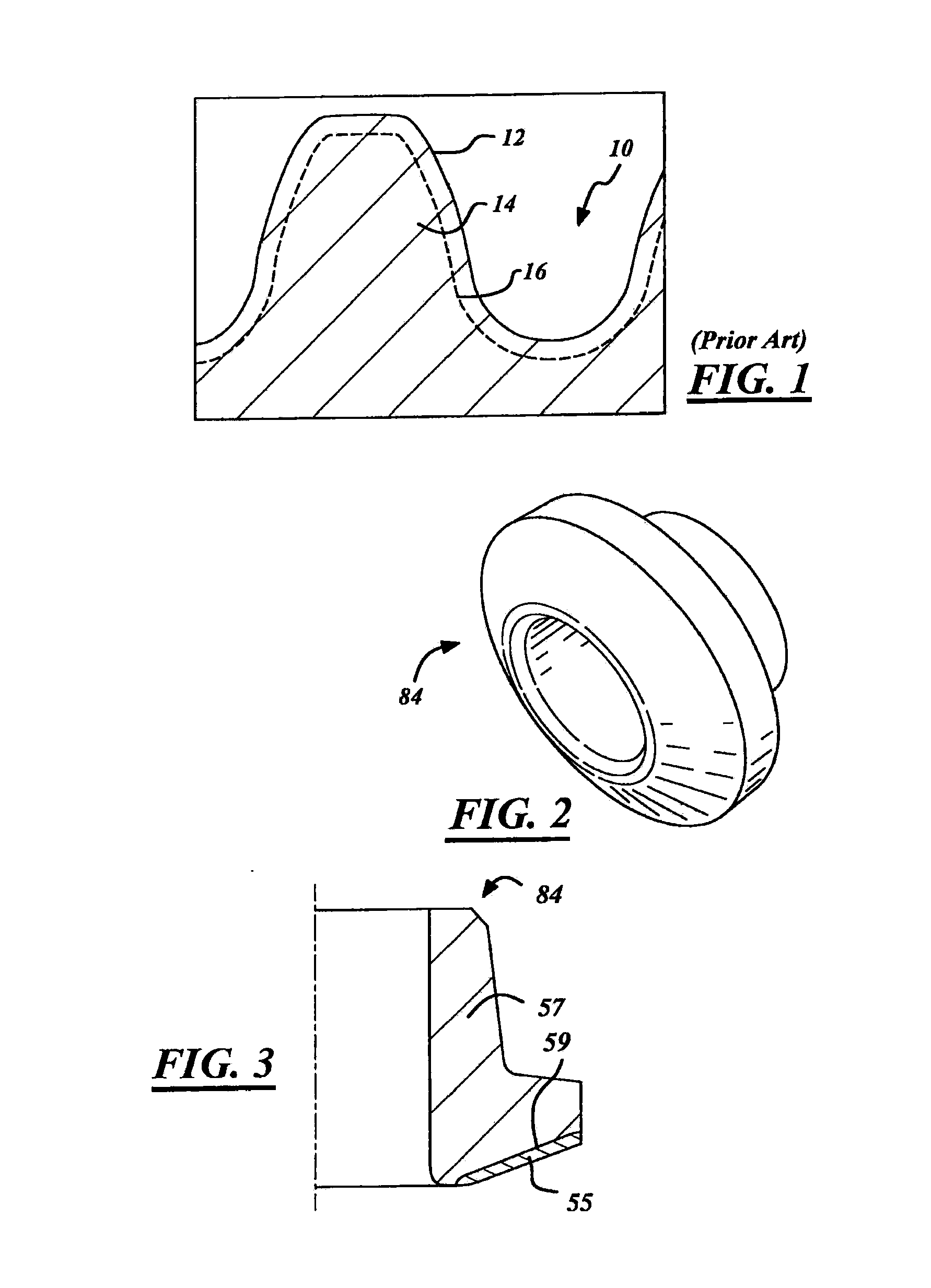

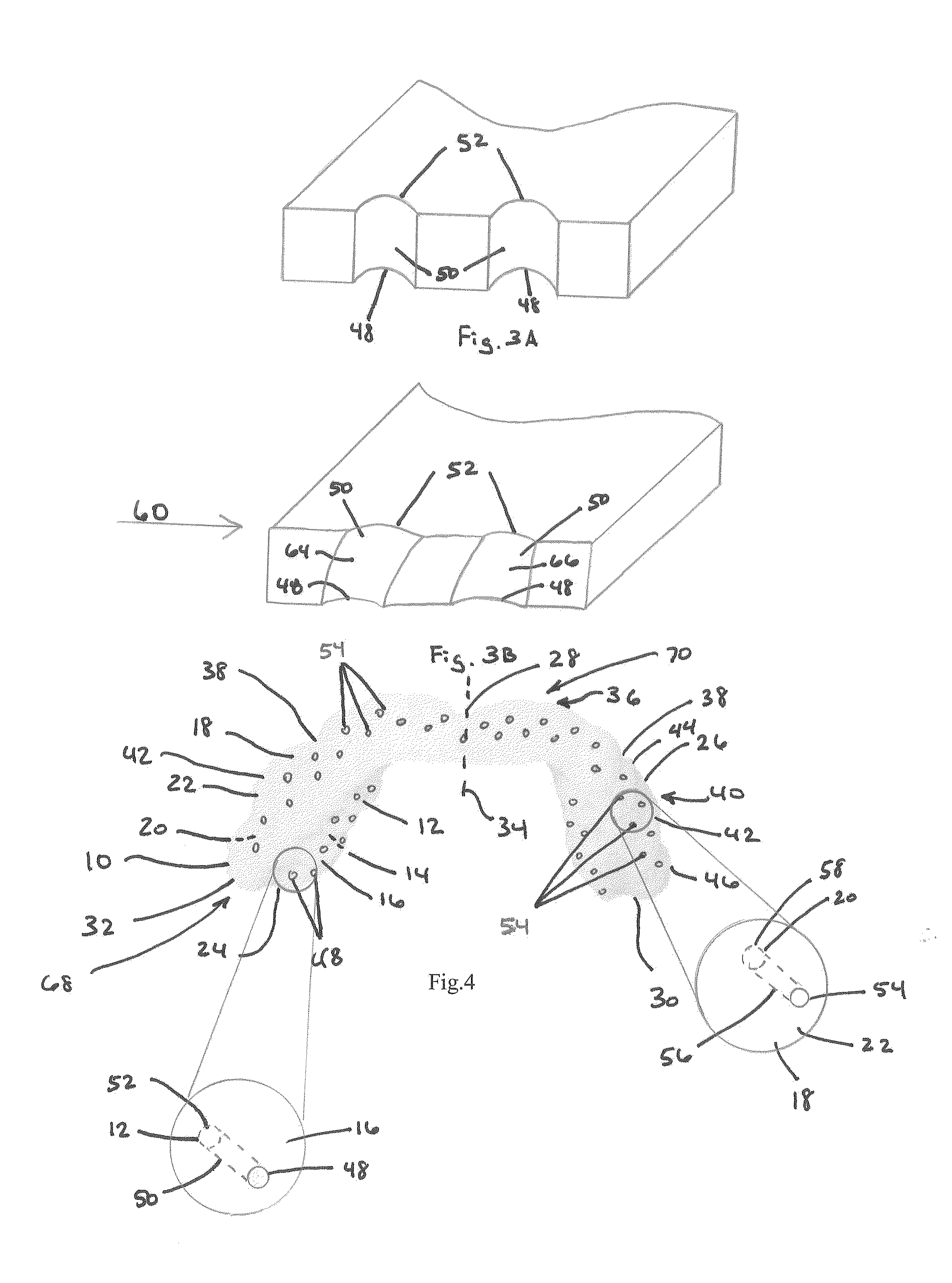

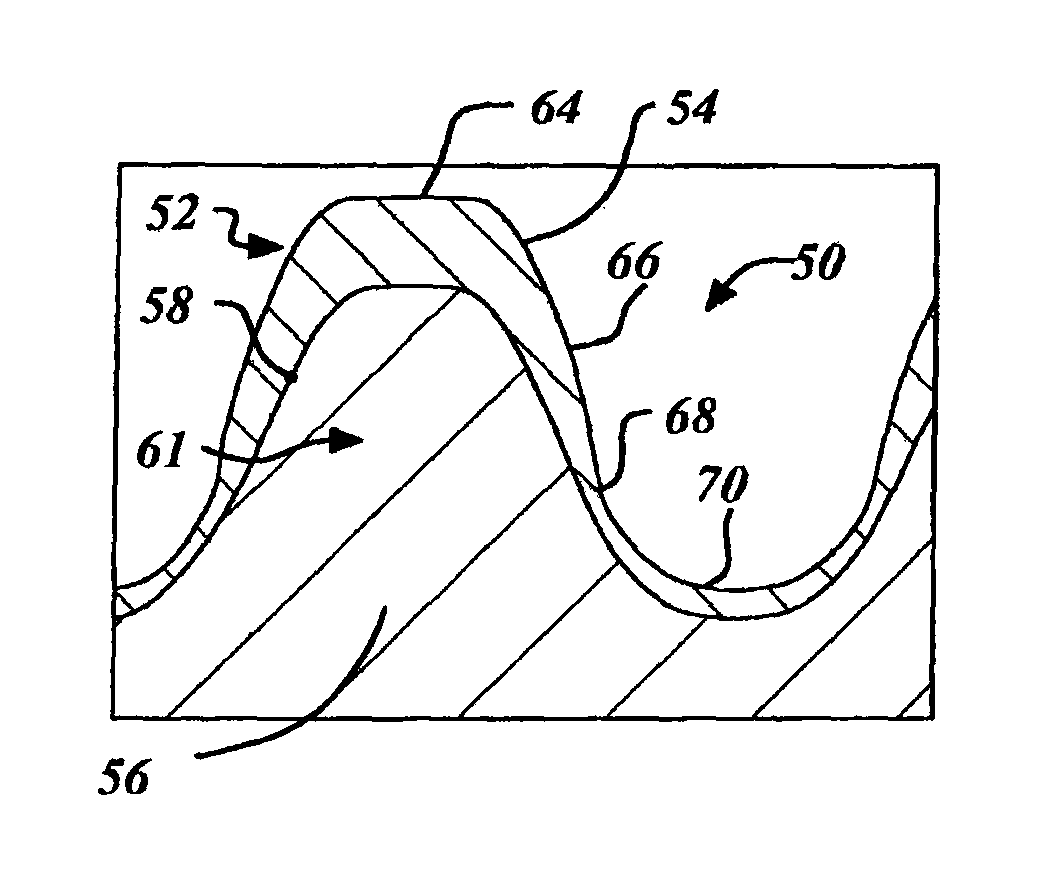

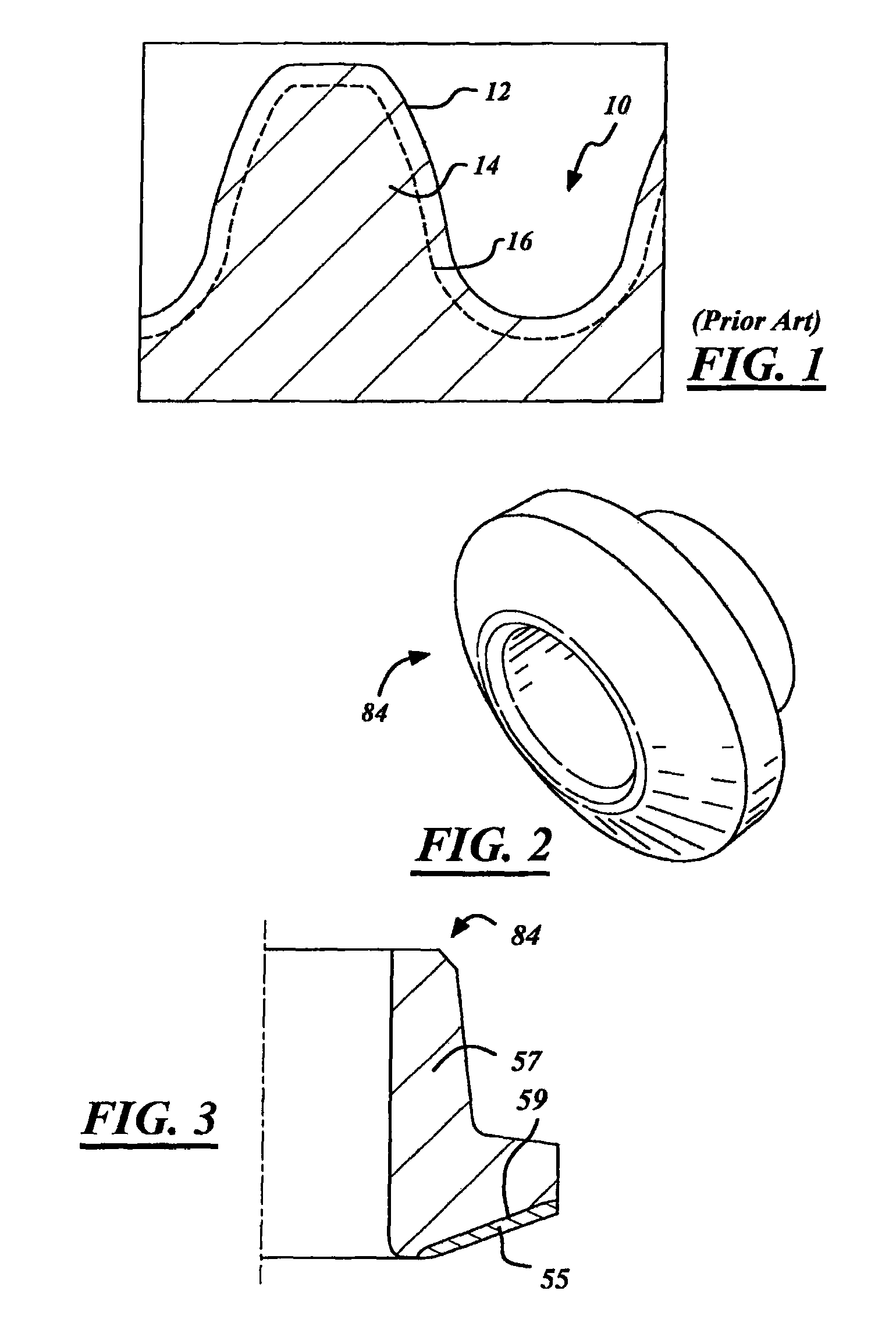

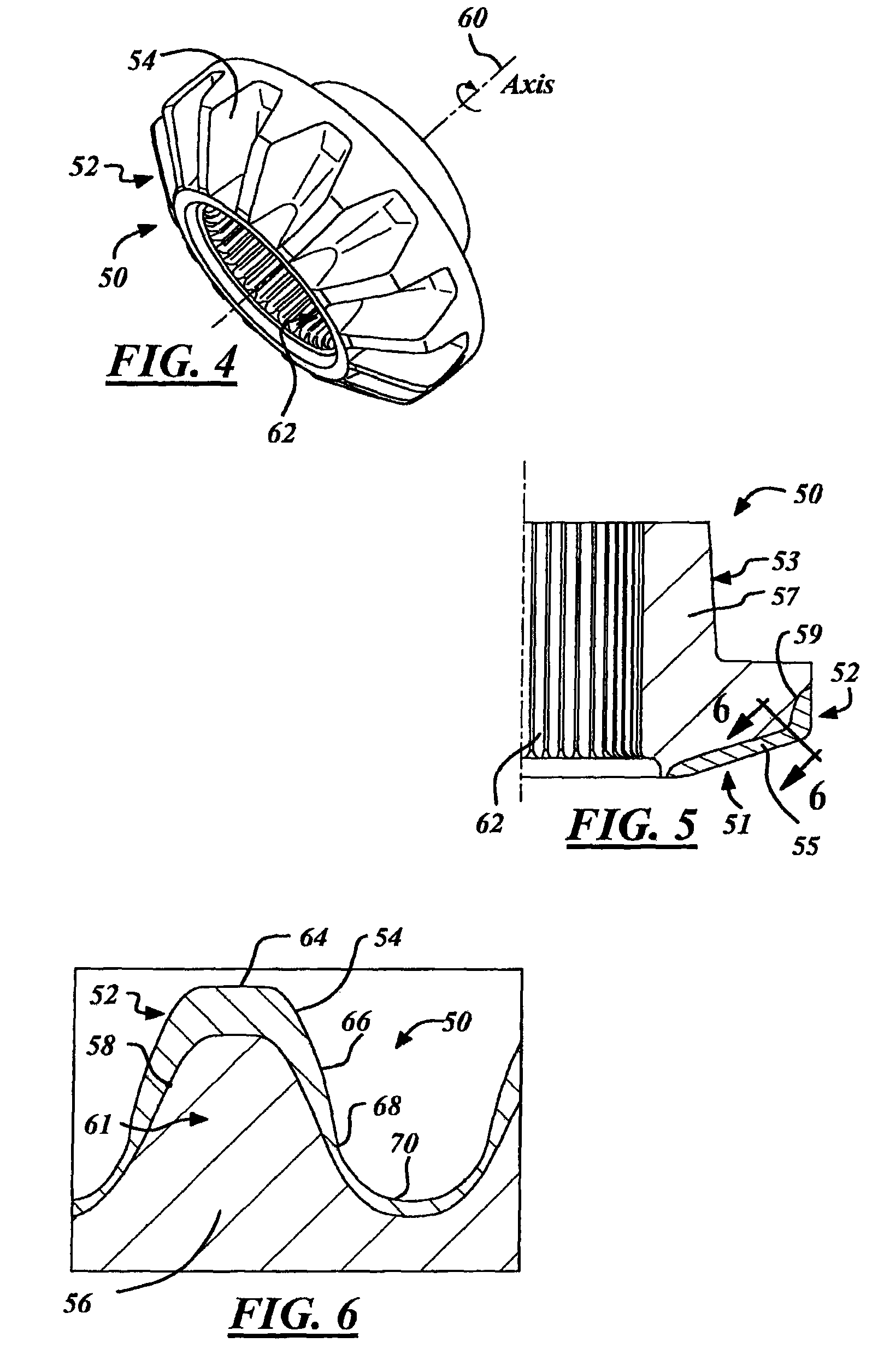

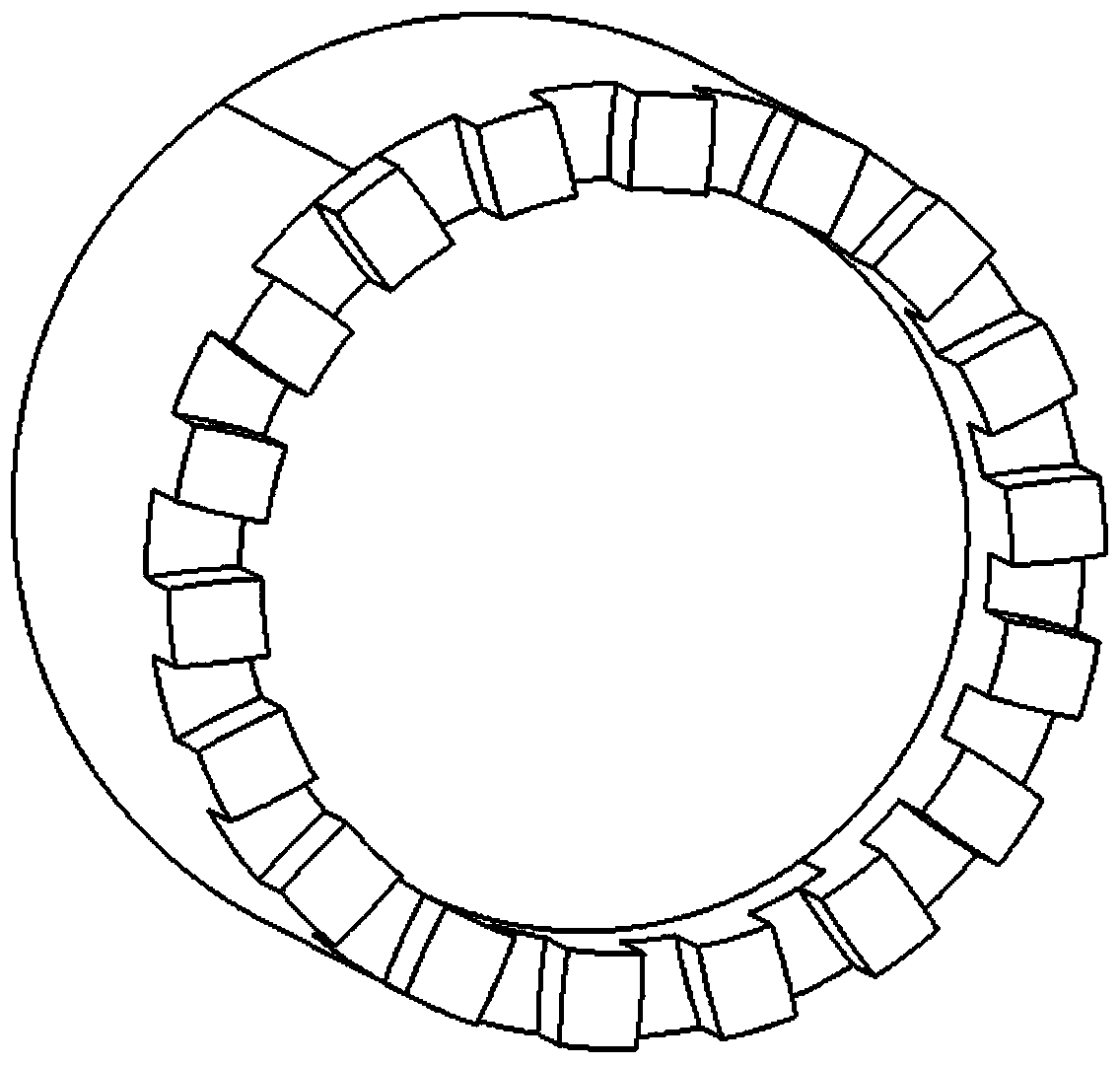

Composite powder metal variable boundary gear and method

InactiveUS20070221005A1Increase resistanceImprove impact resistancePortable liftingWheelsTooth wearMetallic materials

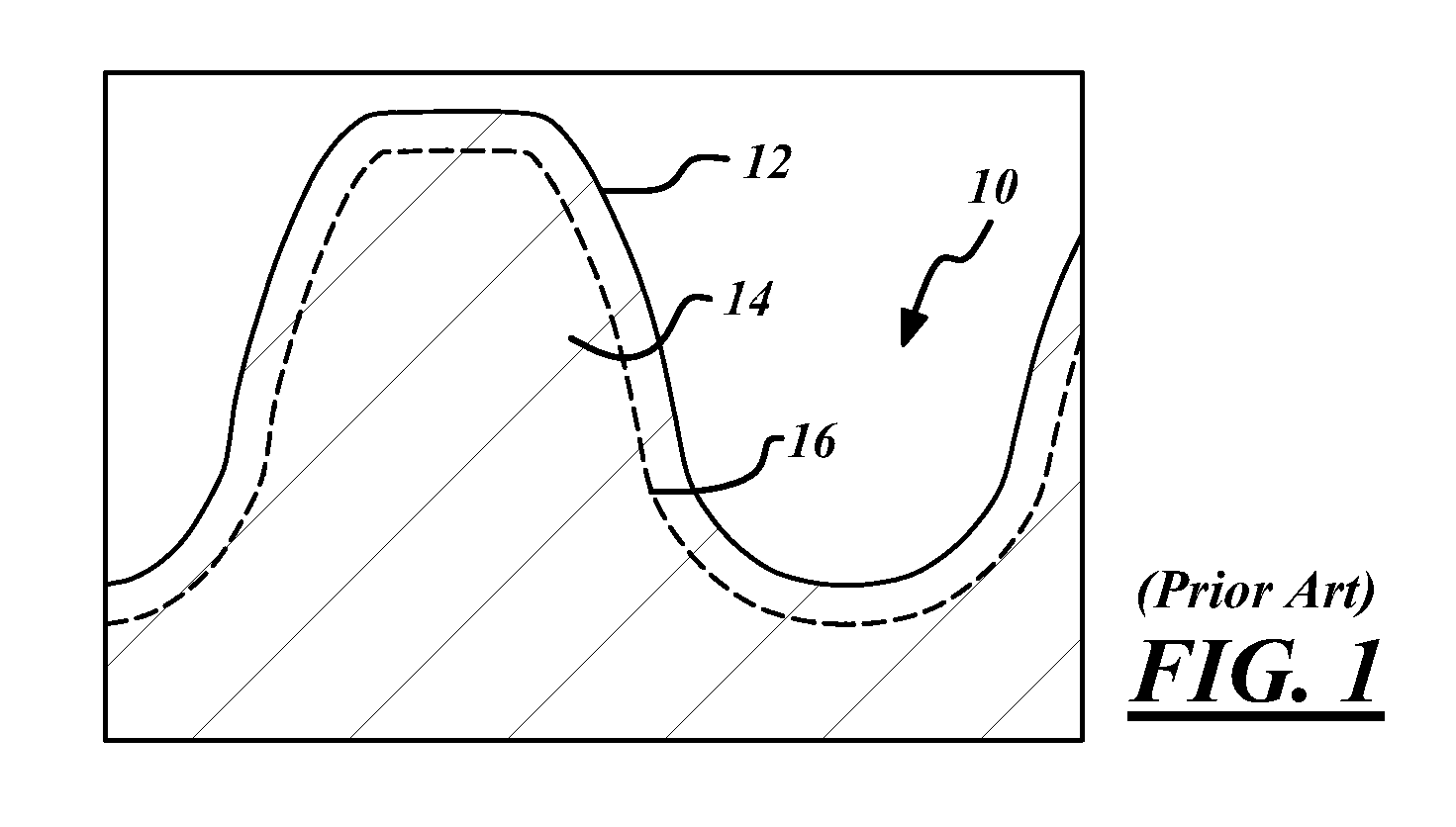

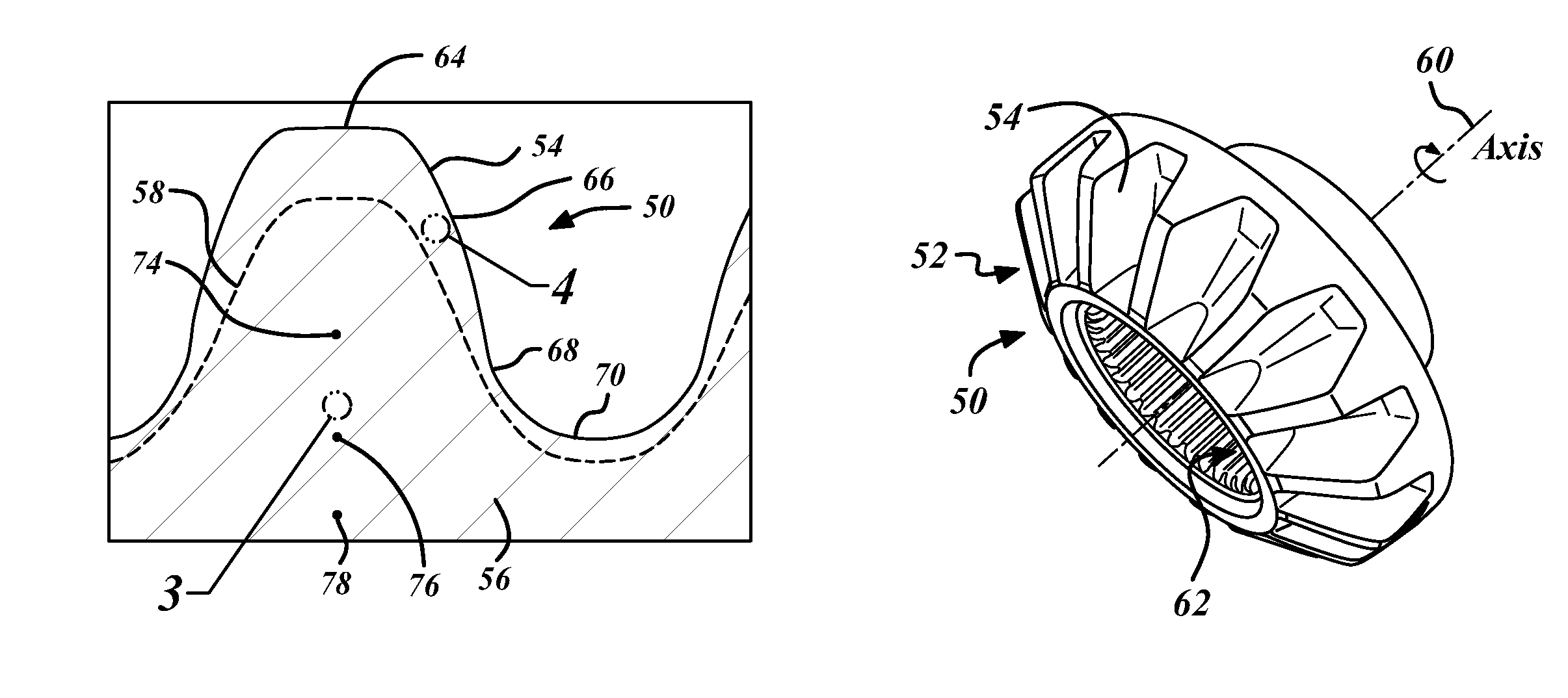

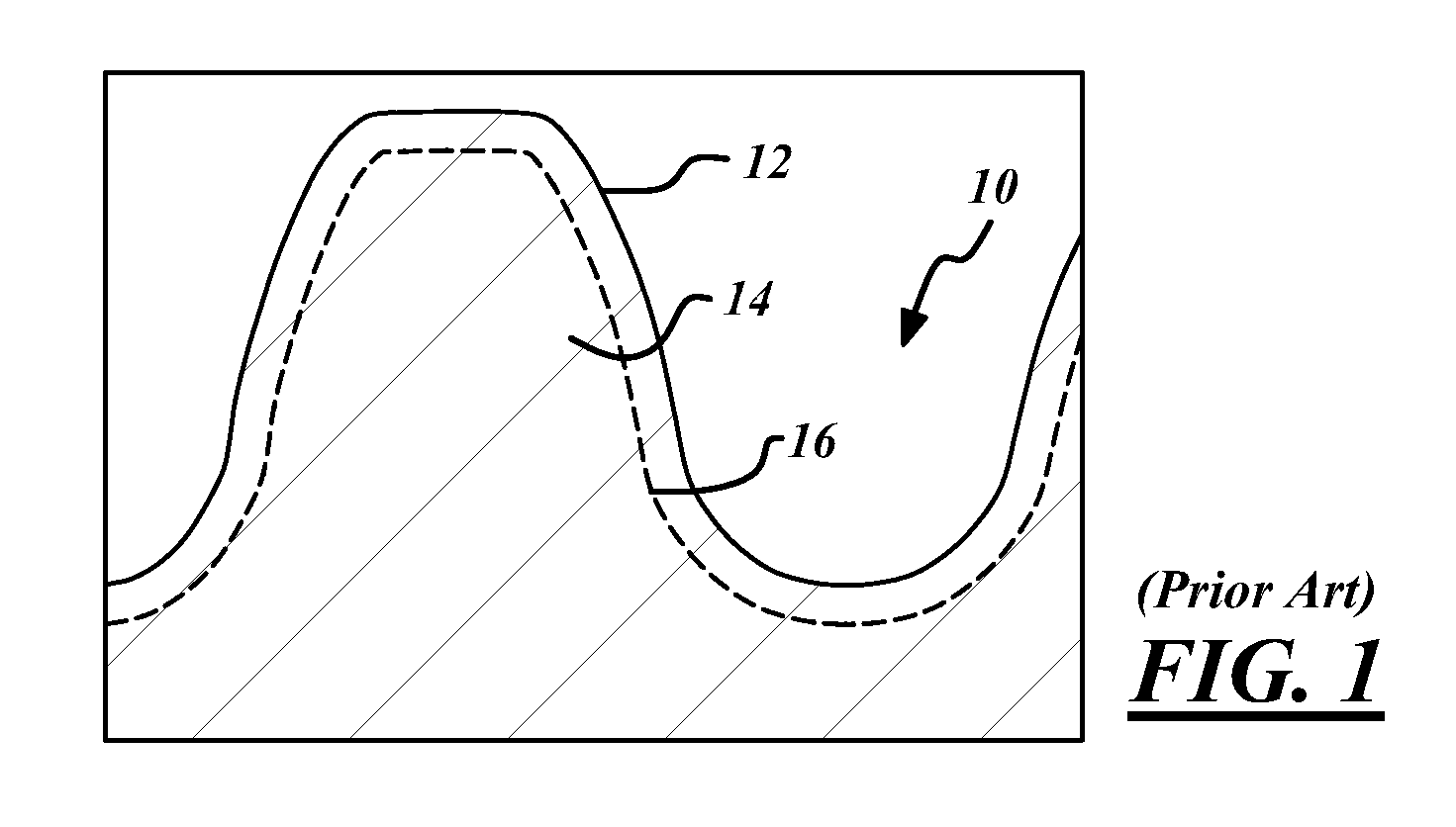

A forged composite gear and a method of making a forged composite powder metal gear. The forged composite gear includes a plurality of teeth extending from a core, a first section having a first powder metal material, a second section having a second powder metal material and a variable boundary profile. The variable boundary profile is formed between the first section and the second section, whereby said variable boundary profile exhibits greater tooth wear resistance on the teeth and greater impact resistance in the core.

Owner:SKN SINTER METALS LLC (US)

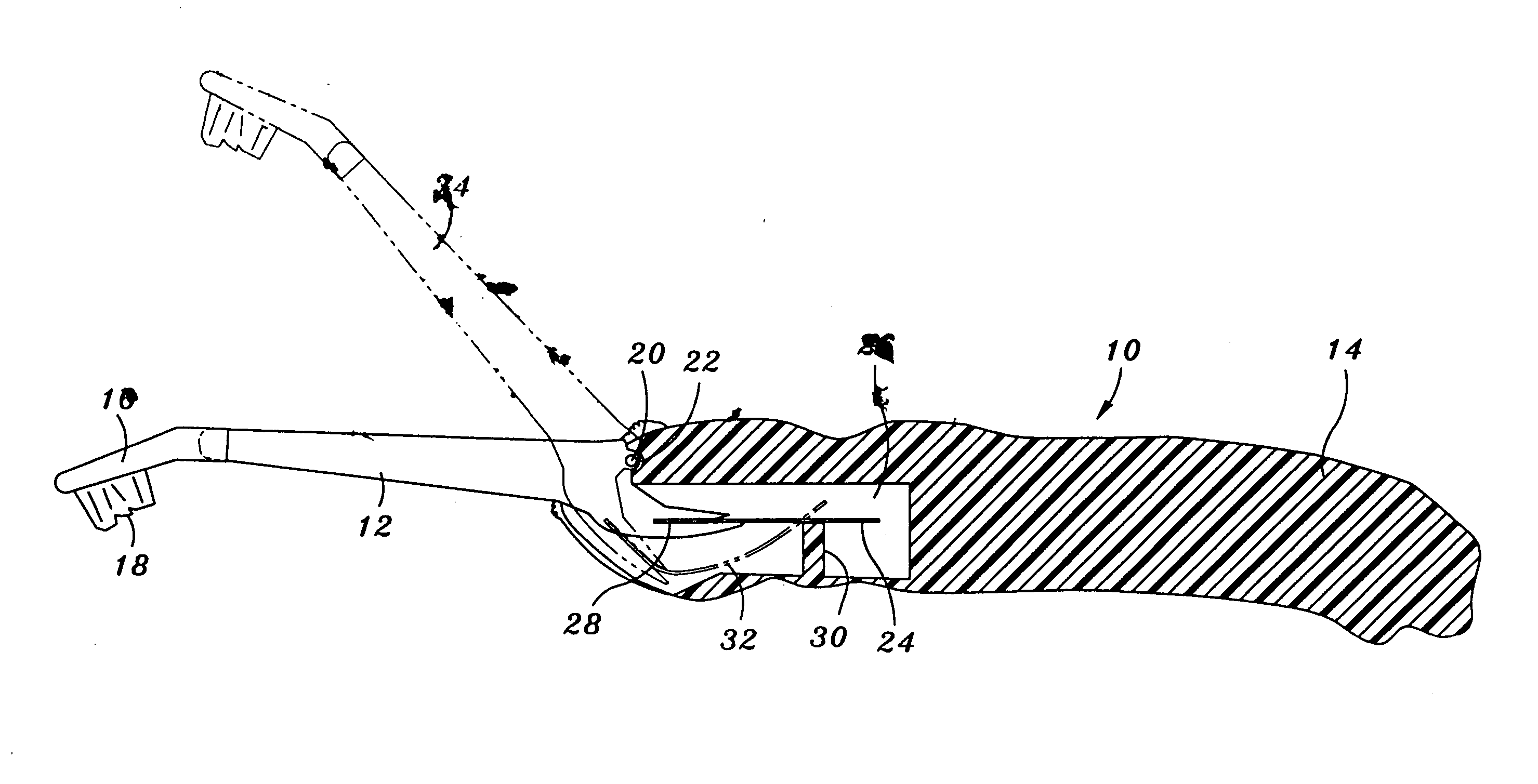

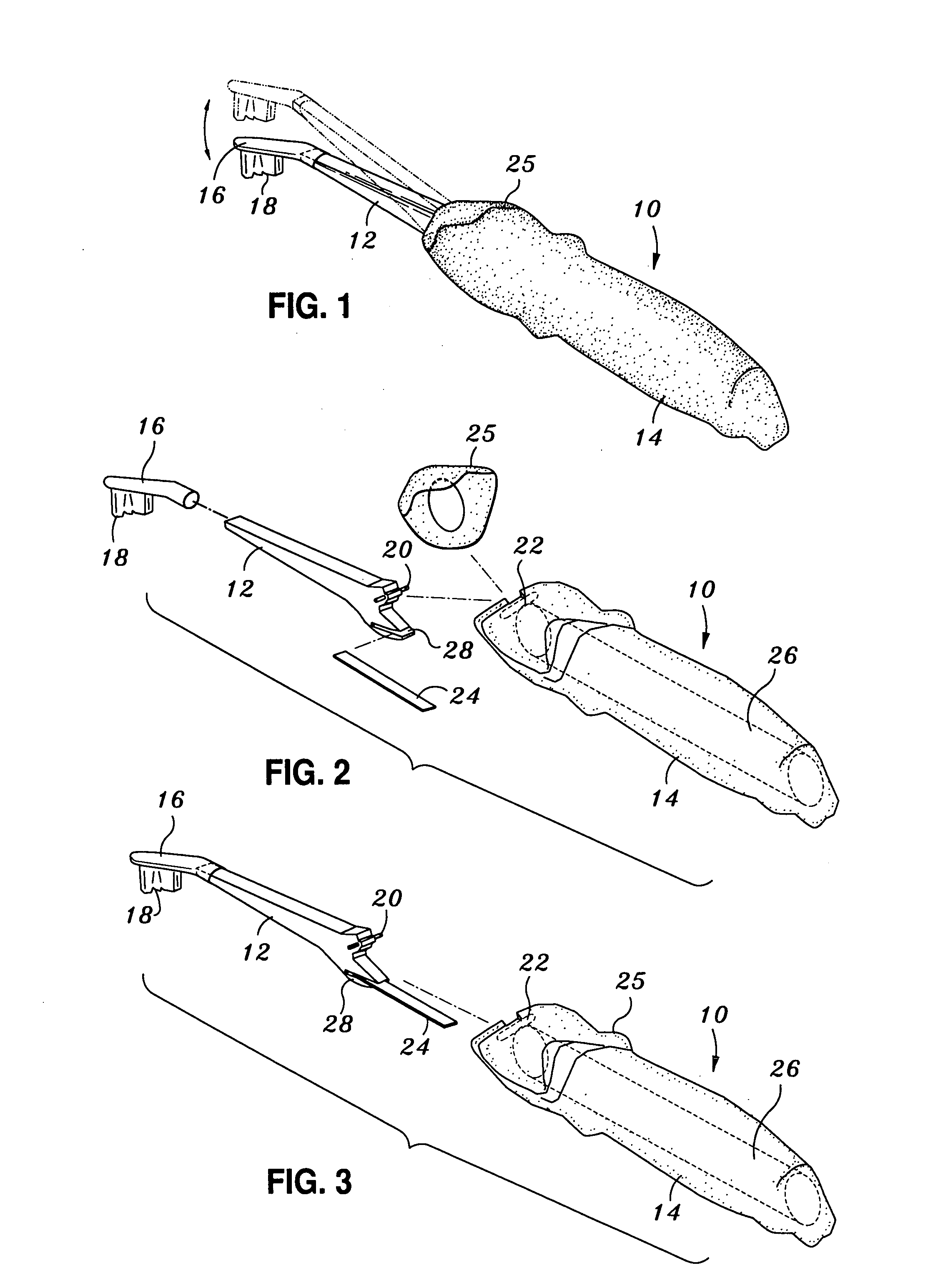

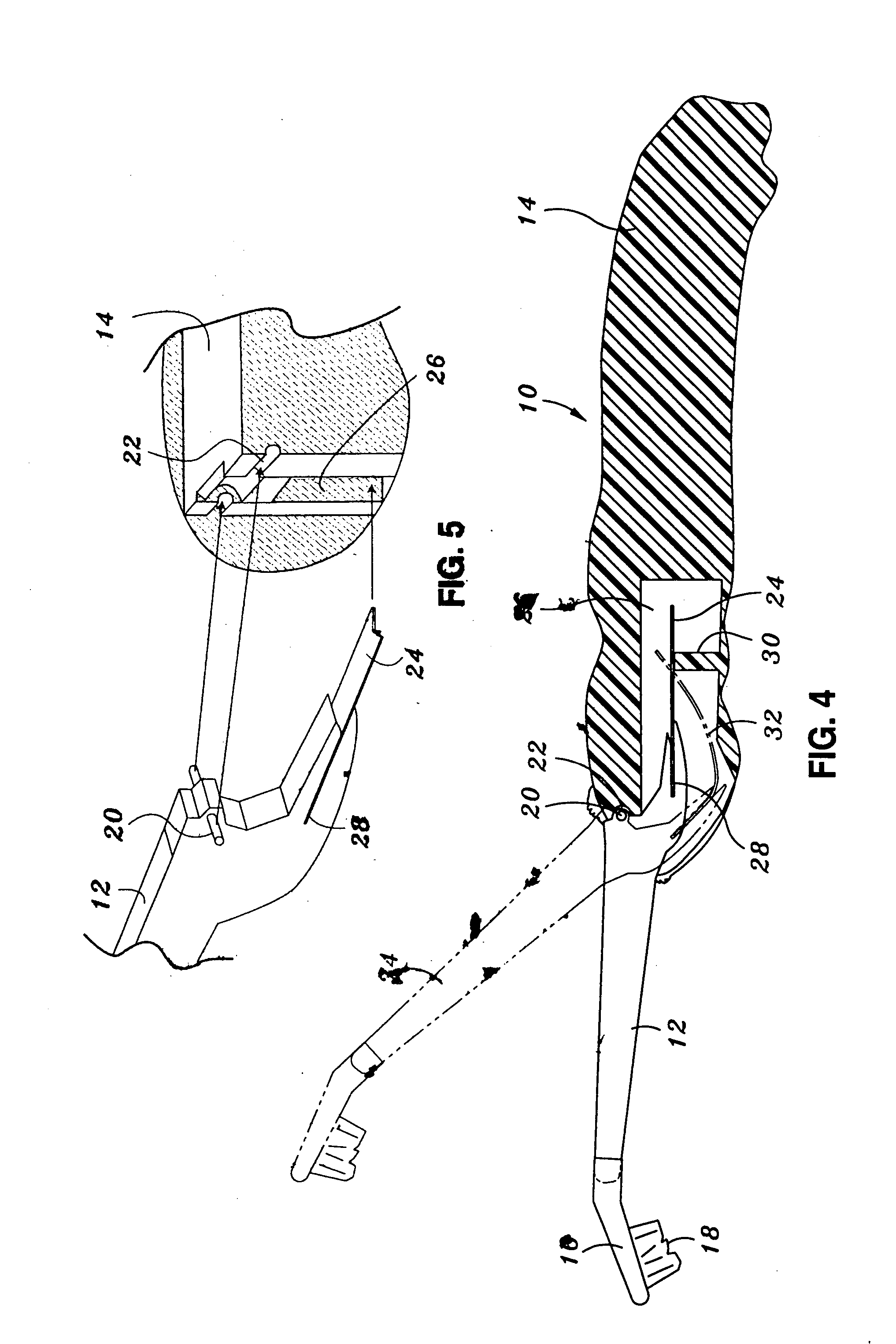

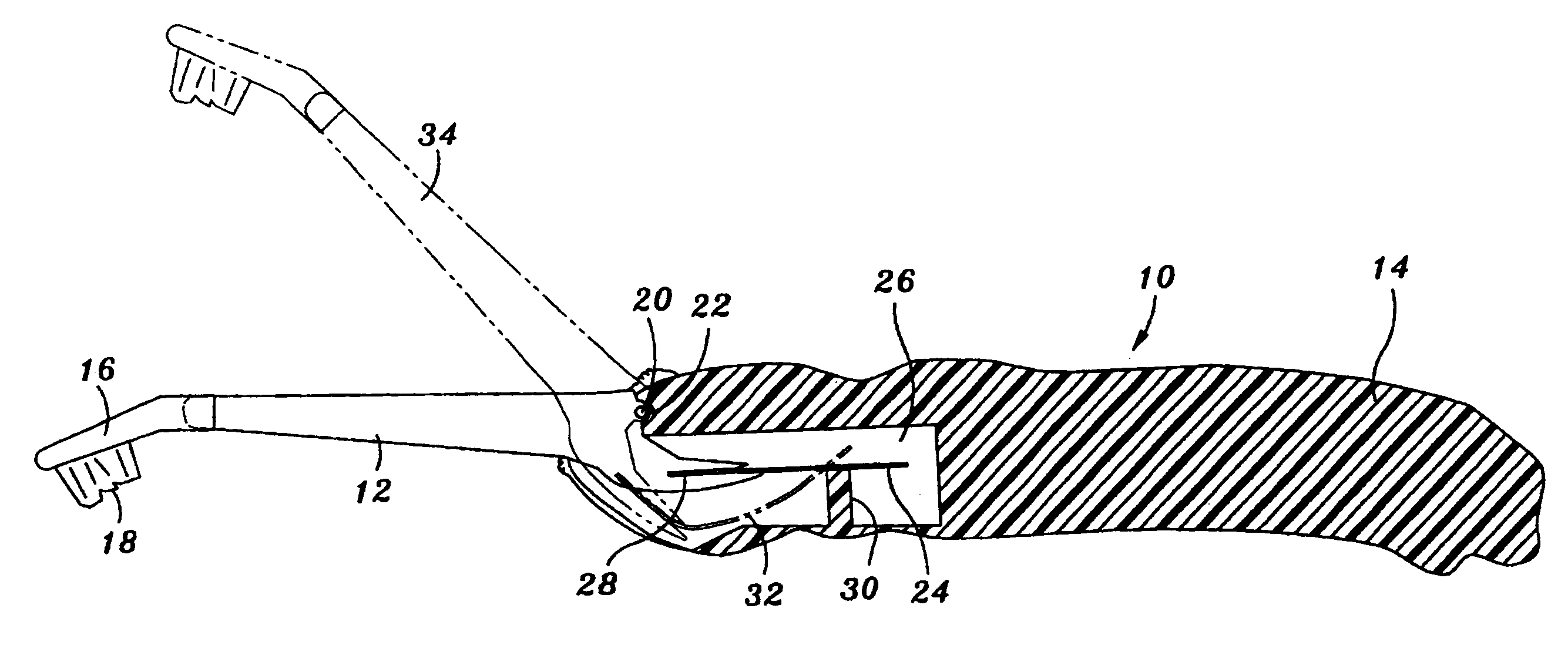

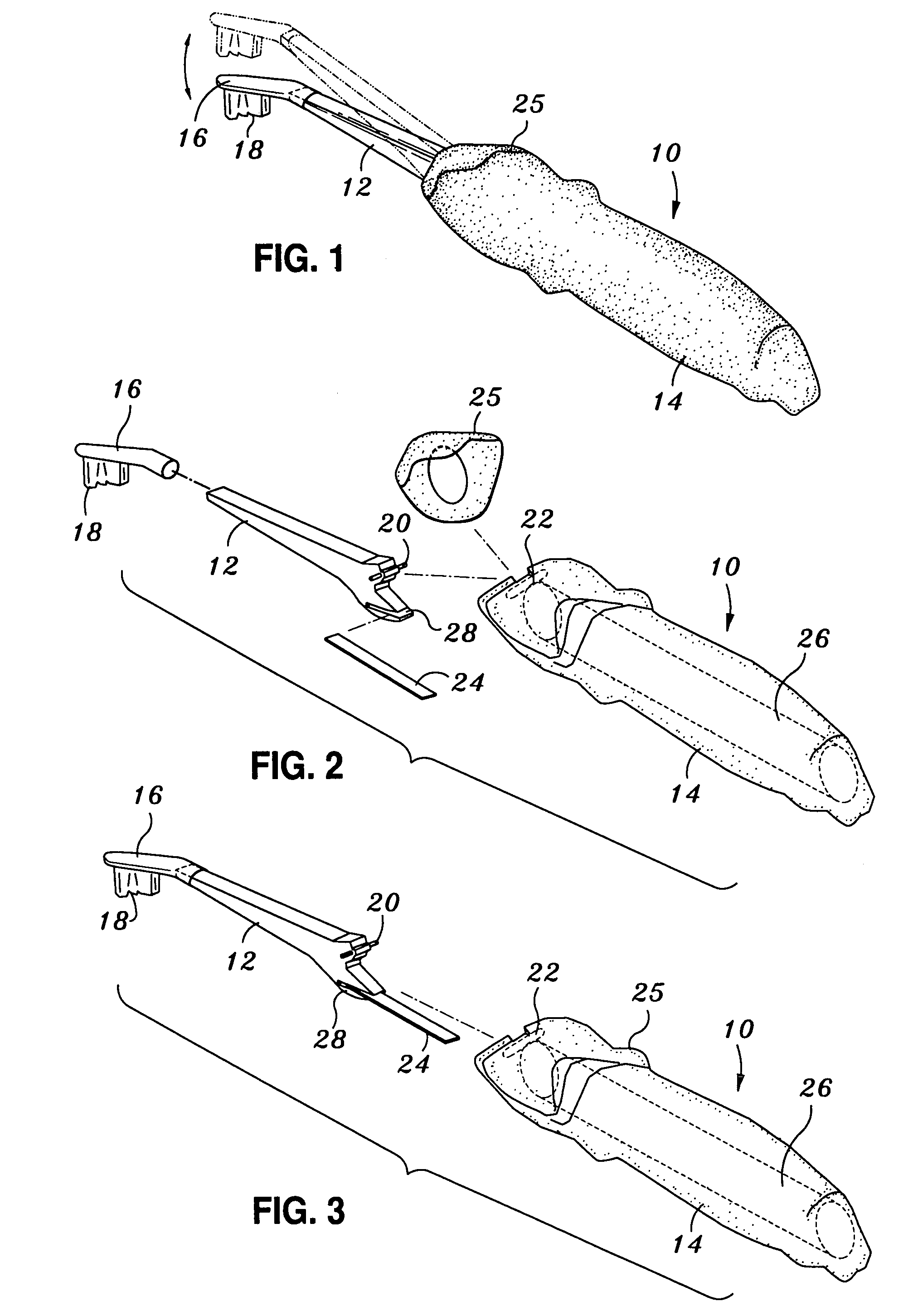

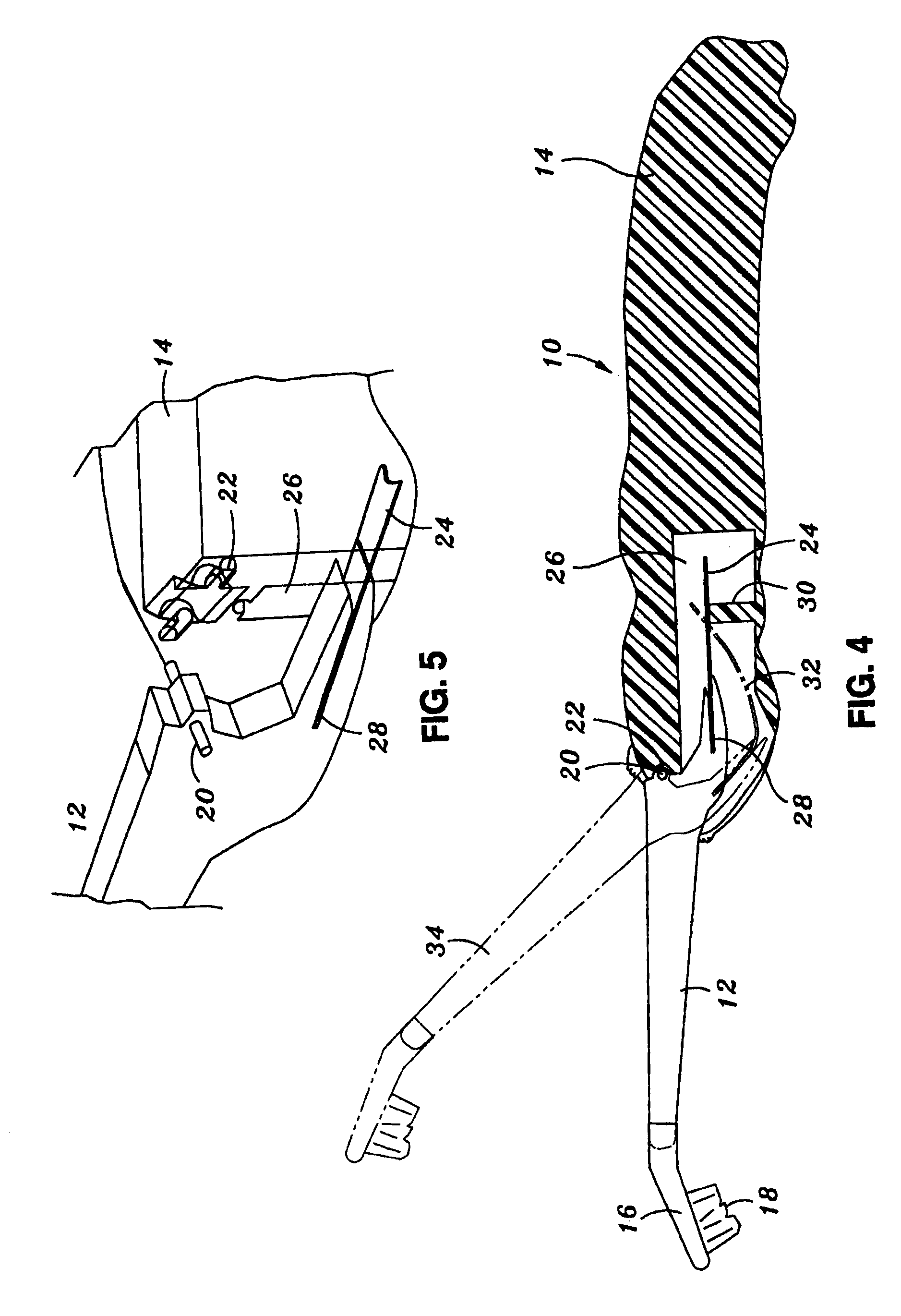

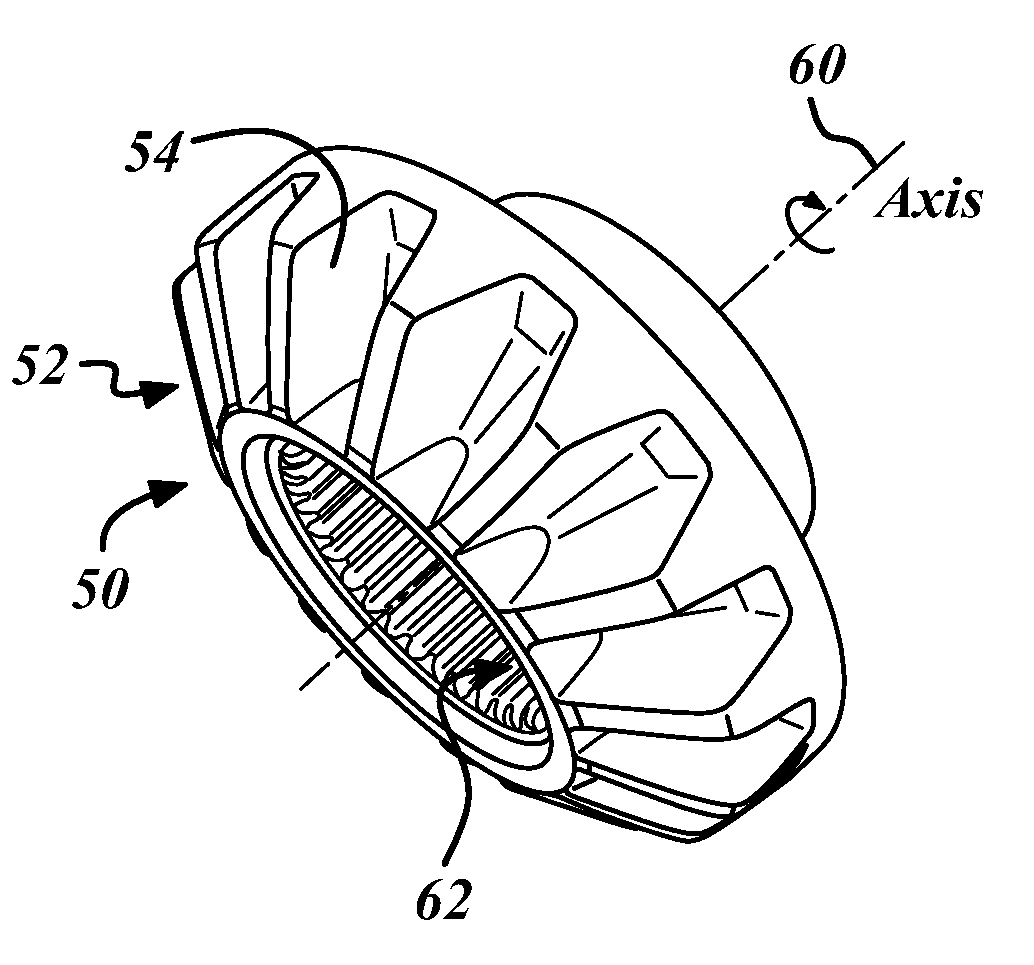

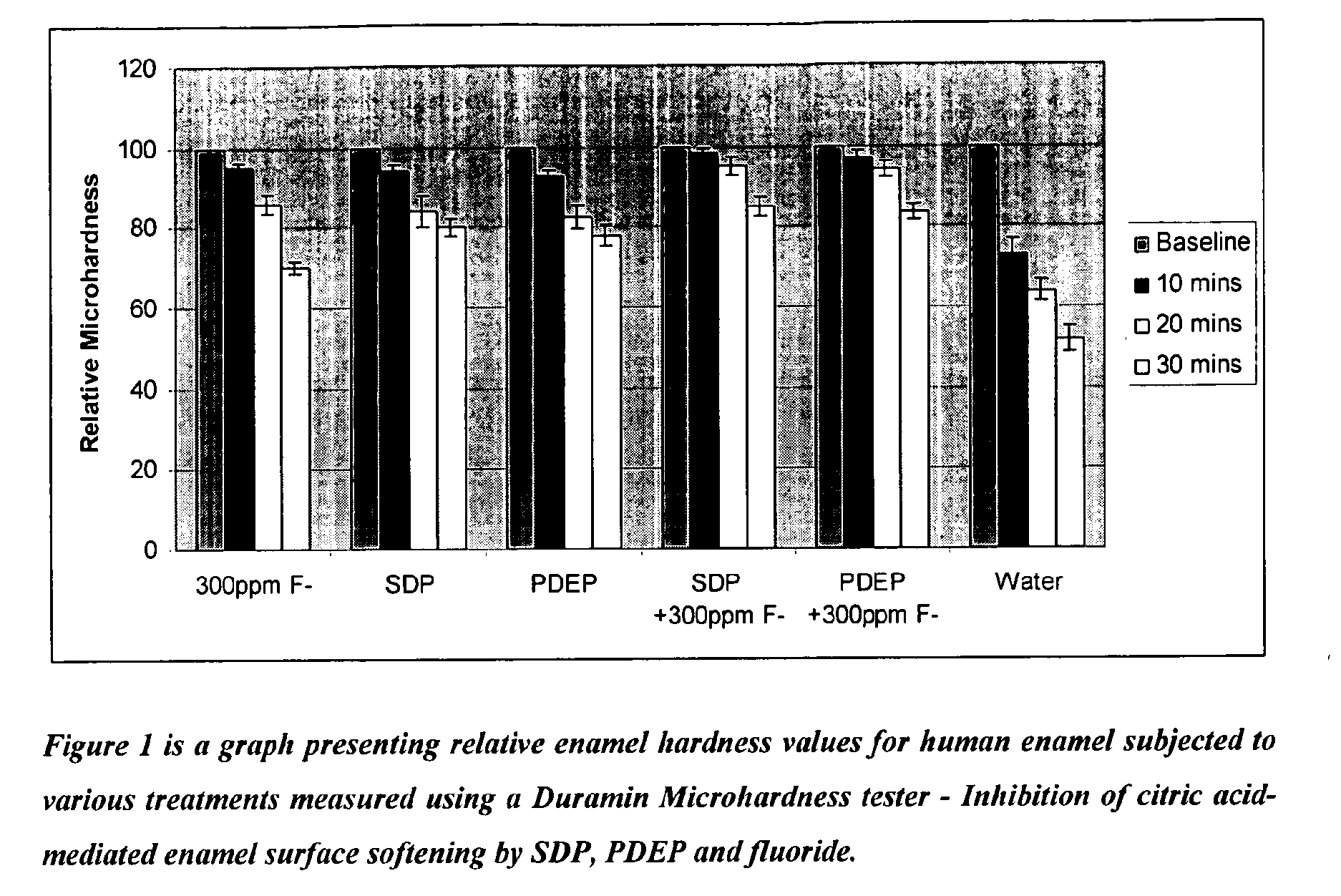

Flexible neck toothbrush

InactiveUS20050108841A1Avoid abrasionsAvoid prolonged useCarpet cleanersBrush bodiesTooth wearEngineering

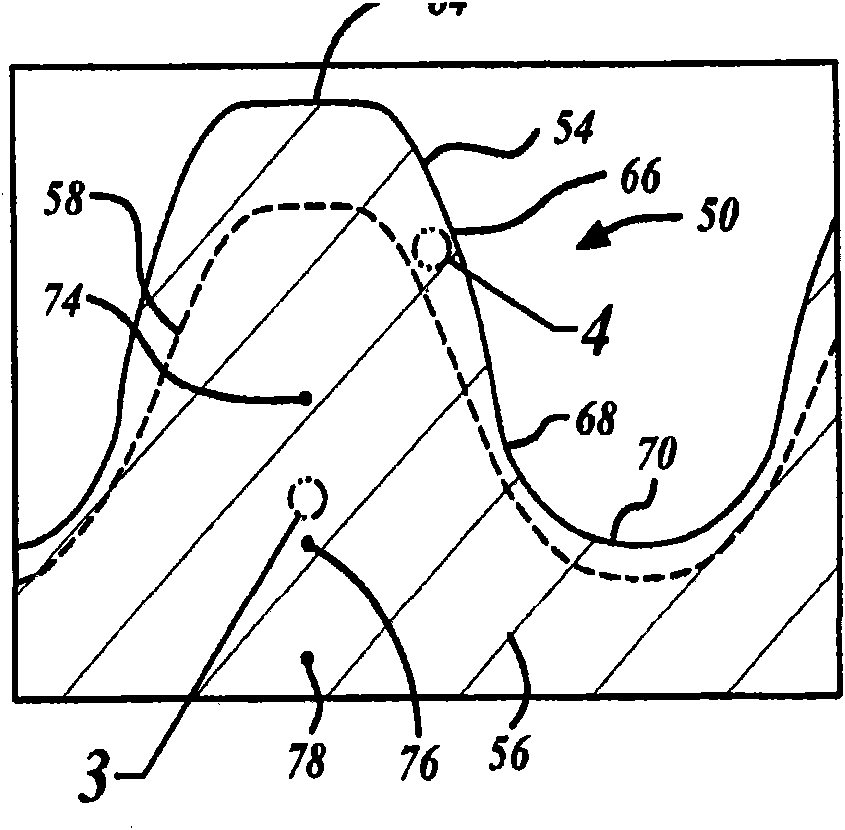

All embodiments of the present invention relate to a toothbrush to prevent tooth abrasion and gum damage during use. A first embodiment of the invention includes a handle including an open cavity and a neck interconnected to the handle by a pivot. The neck is movable between an aligned first position and a second angled position relative to the handle. A leaf spring is bonded to the end of the neck at a first end, and the second end of the leaf spring engages the handle to provide biasing resistance. The leaf spring is configured such that if pressure to the neck exceeds a threshold limit, there is movement of the neck portion from the first position to a second position. The threshold limit is the pressure just below the pressure at the brush that may cause damage to the hard and soft tissue of the mouth. A protective sheath envelops the junction between the handle member and the neck member to prevent accumulation of unwanted material within the cavity of the handle. A second embodiment is equivalent in structure and components to the first embodiment except that it also includes a manual adjustment of the biasing force of the leaf spring to provide variable pressure and a motor for providing mechanical movement of the brush head. Third and fourth embodiments are equivalent in structure and components of the first and second embodiments, respectively, except that the leaf spring is bonded to the handle instead of the neck.

Owner:EDWARDS STEVEN J

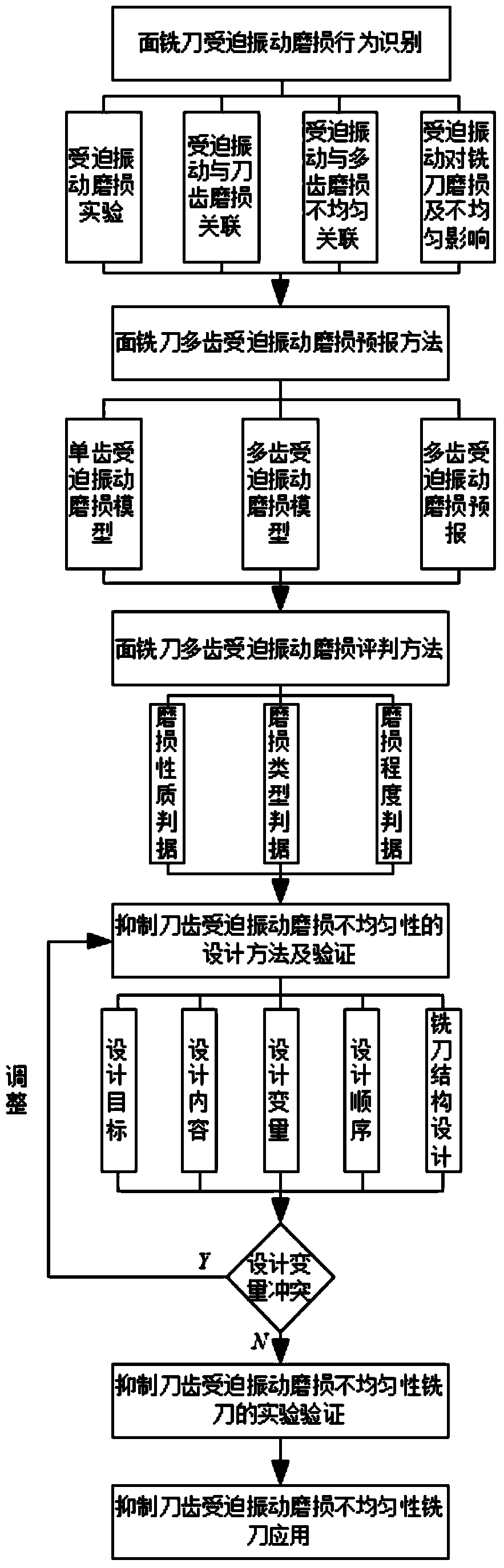

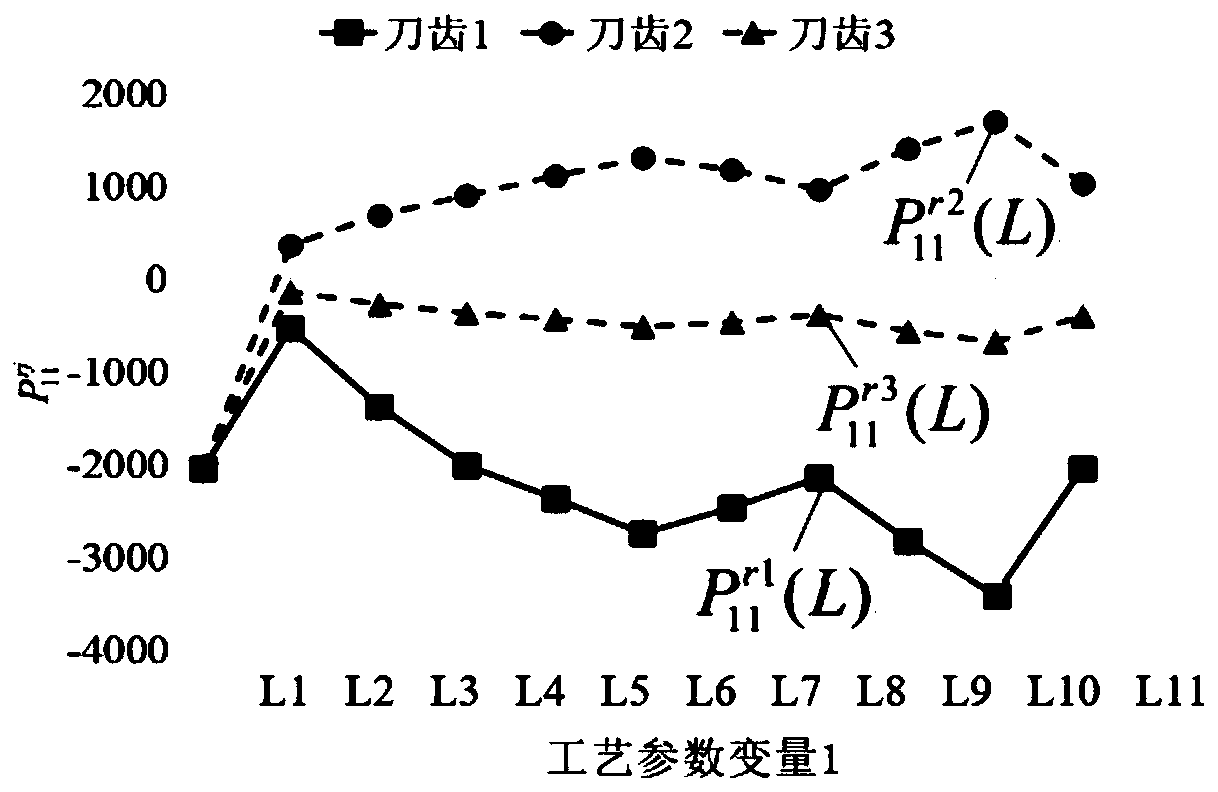

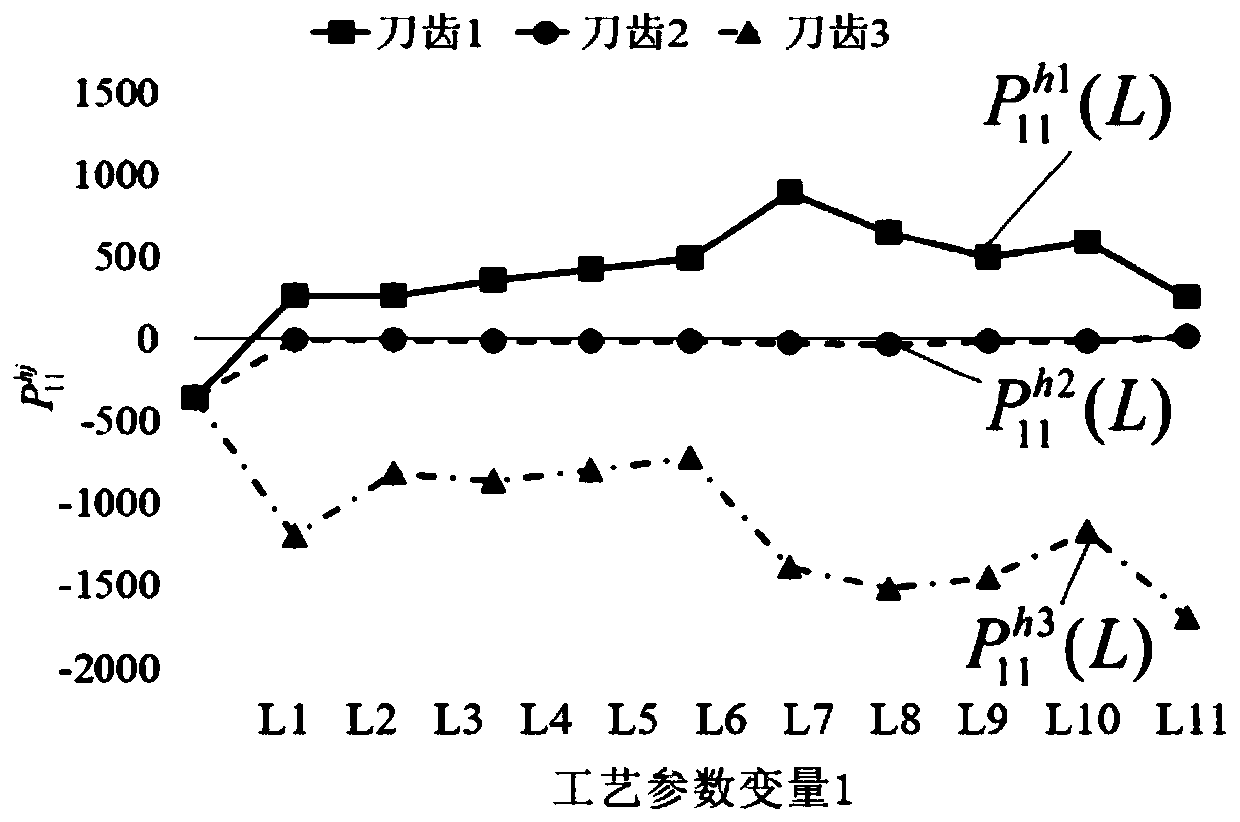

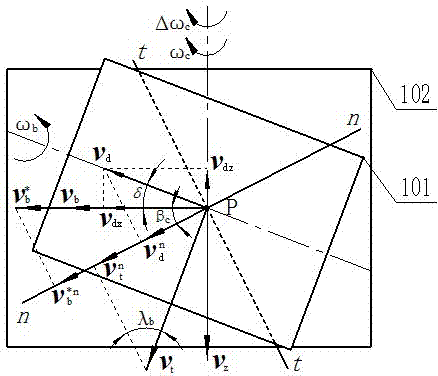

High-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth

ActiveCN103761386AReduce unevennessSolution to short lifeStapling toolsSpecial data processing applicationsTooth wearMilling cutter

The invention discloses a high-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth, and belongs to the technical field of cutters. The high-speed milling cutter designing method particularly includes providing a process for identifying forced vibration wear behavior of a milling cutter by the aid of correlation characteristics of forced vibration of the high-speed face milling cutter and wear behavior of the cutter teeth; building a multi-tooth forced vibration wear model of the milling cutter and providing a process for predicting and judging forced vibration wear and uneven wear of the milling cutter. The high-speed milling cutter designing method has the advantages that a process for controlling the uneven wear of the milling cutter and a process for designing the milling cutter are provided, so that the problem of design conflicts among multi-tooth wear positions, wear areas and wear depth control variables of an existing milling cutter can be solved, the milling cutter with the diameter of 63mm can be designed by the high-speed milling cutter designing method, the unevenness in forced vibration wear of the cutter teeth for cutting No.45 steel at high speeds can be effectively suppressed, and the high-speed milling cutter designing method is used for designing milling cutters.

Owner:HARBIN UNIV OF SCI & TECH

Flexible neck toothbrush

InactiveUS7383603B2Avoid abrasionsAvoid prolonged useCarpet cleanersBrush bodiesTooth wearEngineering

All embodiments of the present invention relate to a toothbrush to prevent tooth abrasion and gum damage during use. A first embodiment of the invention includes a handle including an open cavity and a neck interconnected to the handle by a pivot. The neck is movable between an aligned first position and a second angled position relative to the handle. A leaf spring is bonded to the end of the neck at a first end, and the second end of the leaf spring engages the handle to provide biasing resistance. The leaf spring is configured such that if pressure to the neck exceeds a threshold limit, there is movement of the neck portion from the first position to a second position. The threshold limit is the pressure just below the pressure at the brush that may cause damage to the hard and soft tissue of the mouth. A protective sheath envelops the junction between the handle member and the neck member to prevent accumulation of unwanted material within the cavity of the handle. A second embodiment is equivalent in structure and components to the first embodiment except that it also includes a manual adjustment of the biasing force of the leaf spring to provide variable pressure and a motor for providing mechanical movement of the brush head. Third and fourth embodiments are equivalent in structure and components of the first and second embodiments, respectively, except that the leaf spring is bonded to the handle instead of the neck.

Owner:EDWARDS STEVEN J

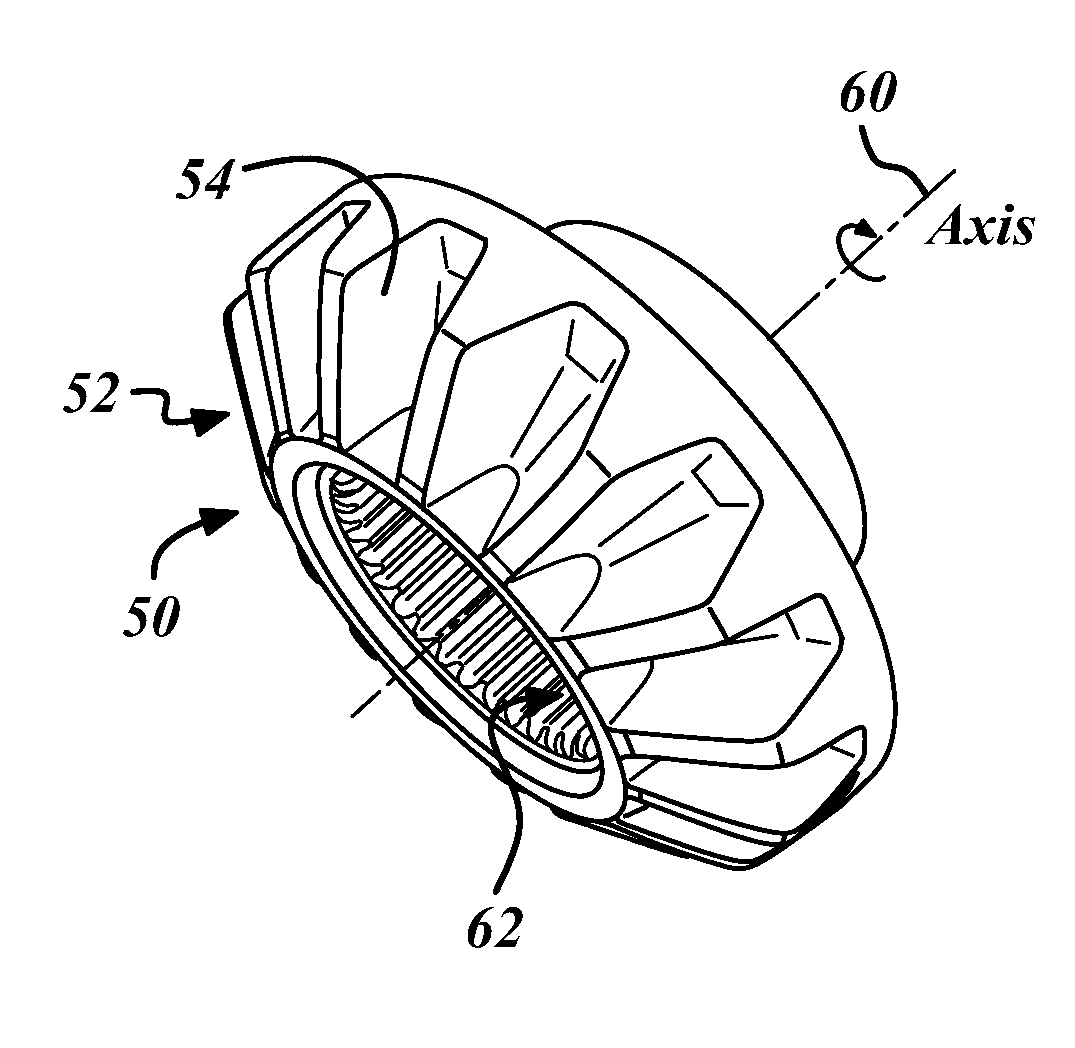

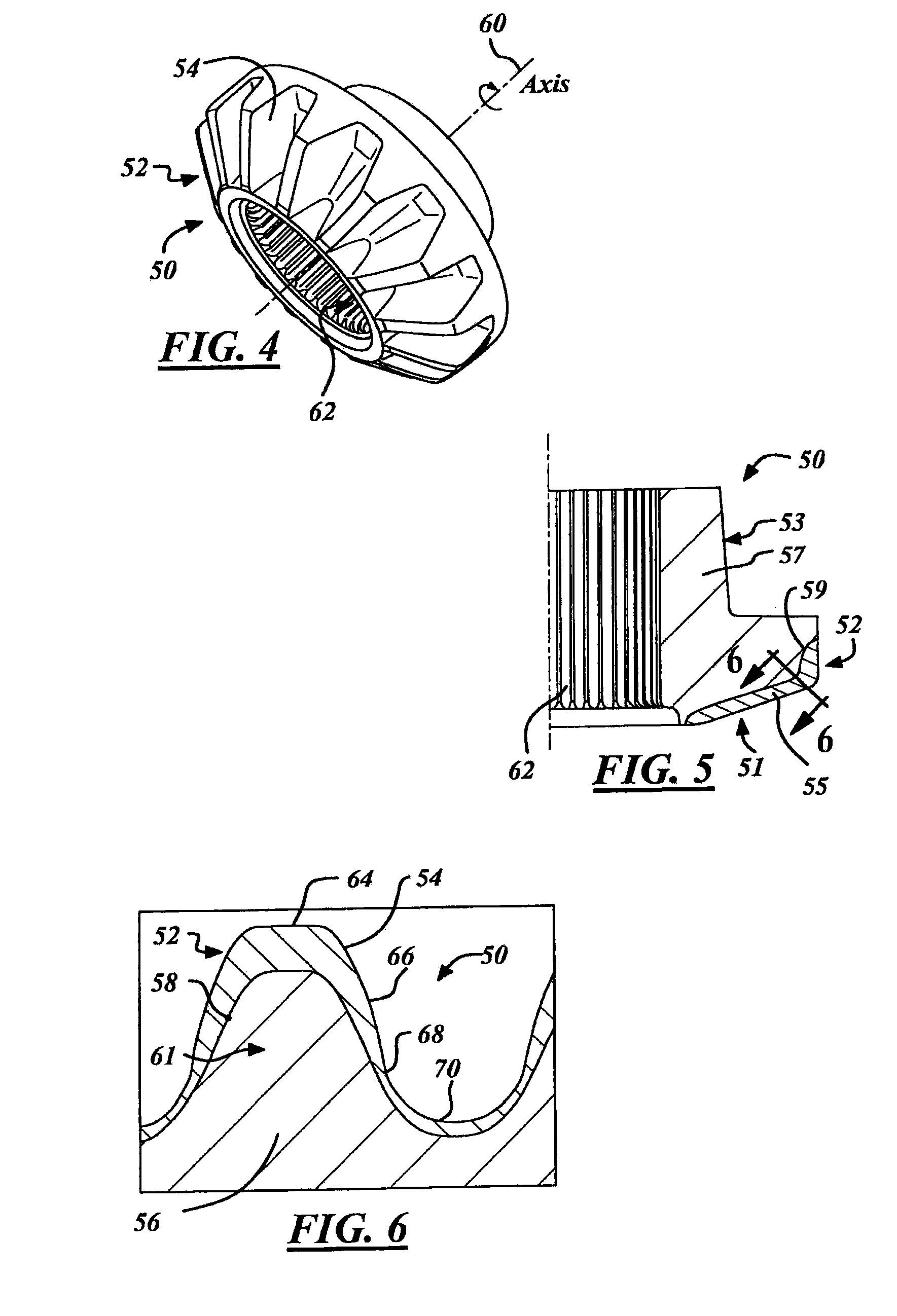

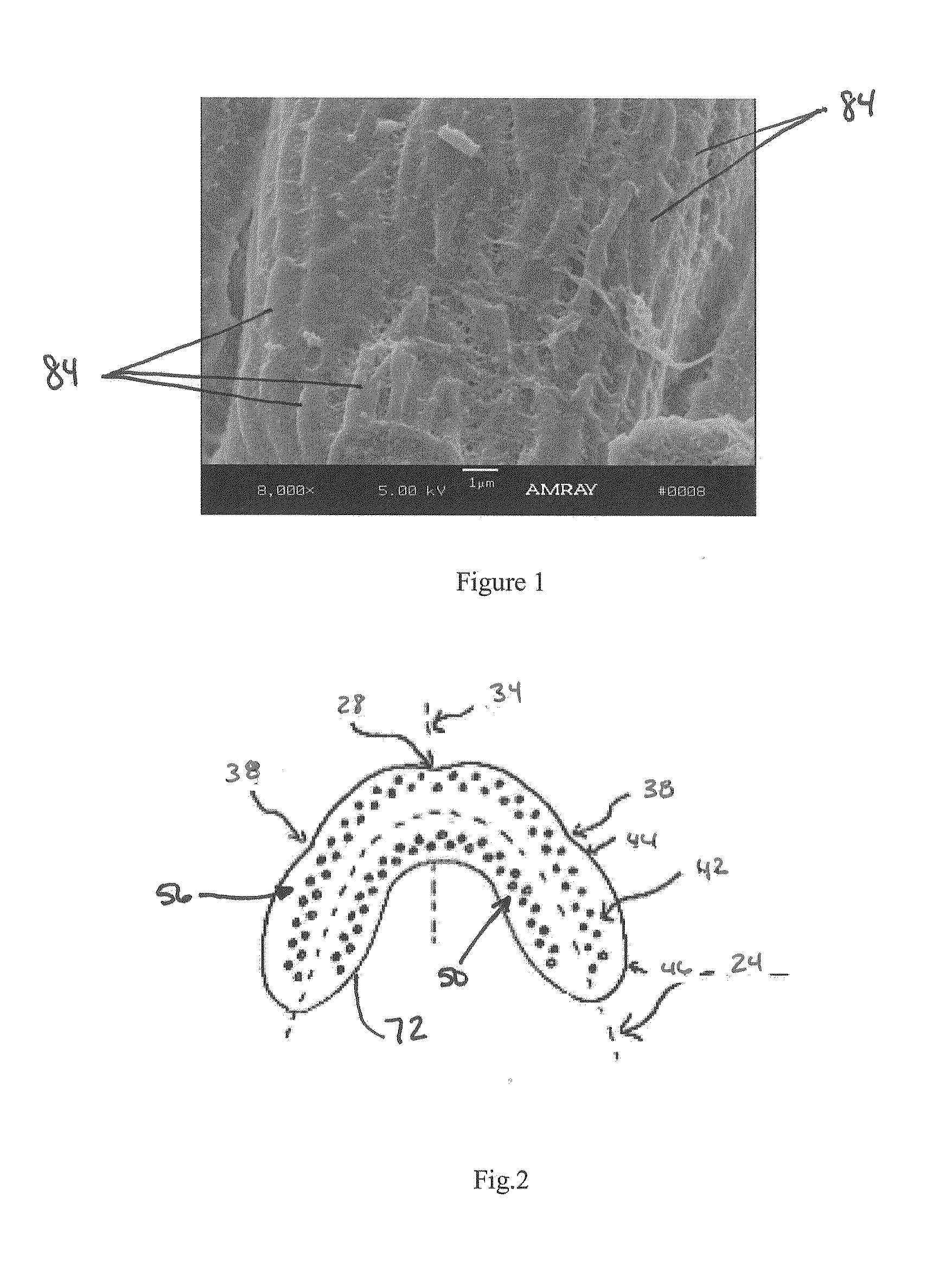

Variable case depth powder metal gear and method thereof

ActiveUS20070221006A1Increase loadImproved tooth wear resistanceMetal-working apparatusPortable liftingEngineeringTooth wear

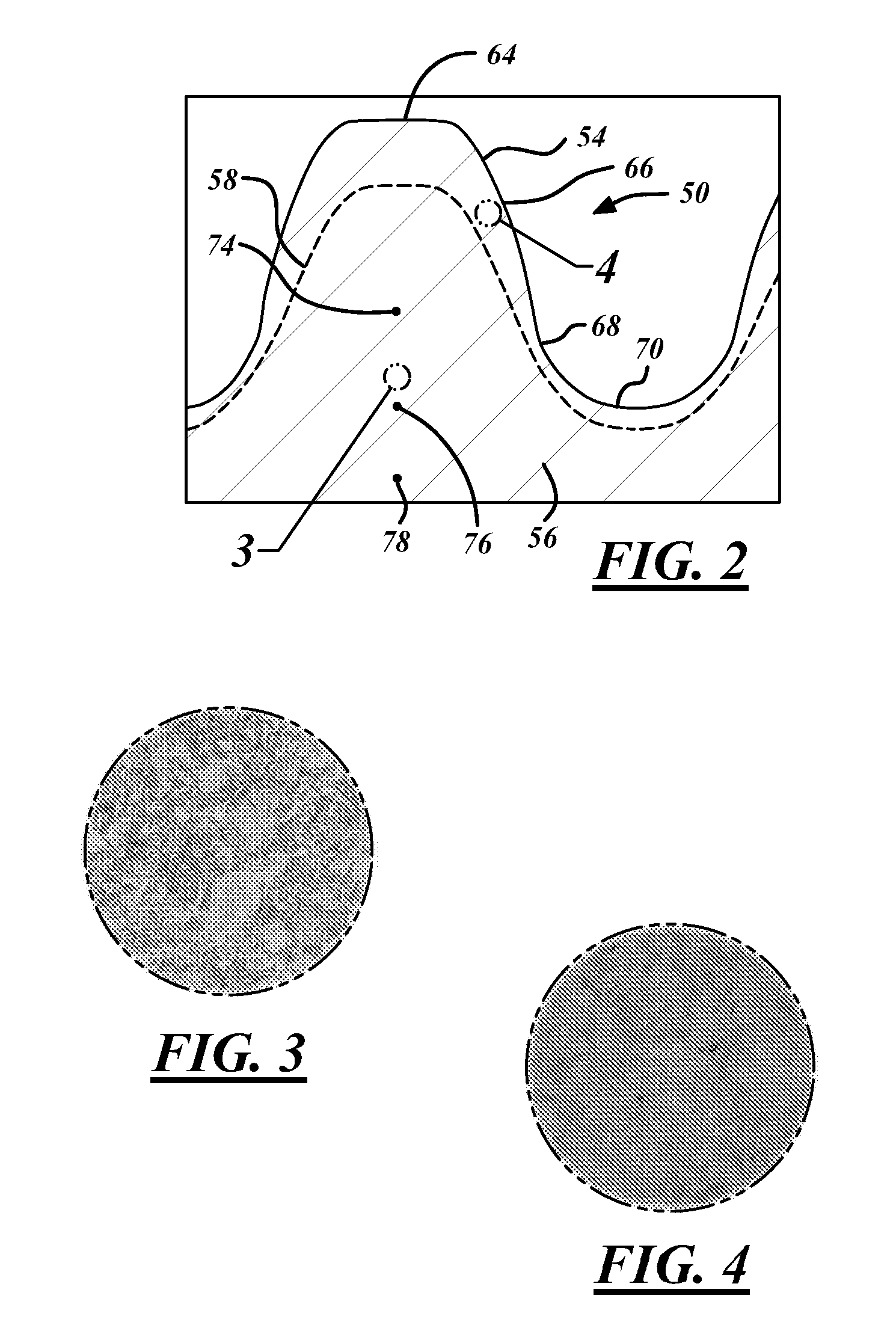

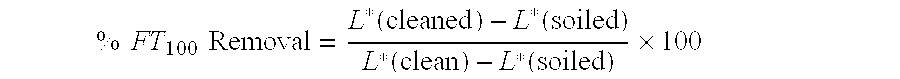

A gear and a method of making a forged powder metal gear having a plurality of teeth and a variable case depth profile forged in the plurality of teeth. Each tooth of the plurality of teeth has a first surface and a tooth root. A variable case depth profile is formed in each tooth of the plurality of teeth, whereby the variable case depth profile exhibits greater tooth wear resistance on the first surface and greater impact resistance in the tooth root.

Owner:SKN SINTER METALS LLC (US)

Dentifrice compositons and abrasive systems

A dentifrice composition comprising an abrasive system comprising at least one abrasive silica which may be selected from a first silica having a Radioactive Dental Abrasion (RDA) in the range 30 to 150 and a second silica an RDA in the range 100 to 300, and a crystalline aluminosilicate having an average crystallite size below 0.2 μm plus an orally acceptable carrier. The content by weight of the first silica being greater than that of the second silica and the RDA of the second silica being greater than that of first silica.

Owner:PQ SILICAS UK

Variable case depth powder metal gear and method thereof

ActiveUS7827692B2Increase loadIncrease resistanceMetal-working apparatusPortable liftingTooth wearEngineering

Owner:SKN SINTER METALS LLC (US)

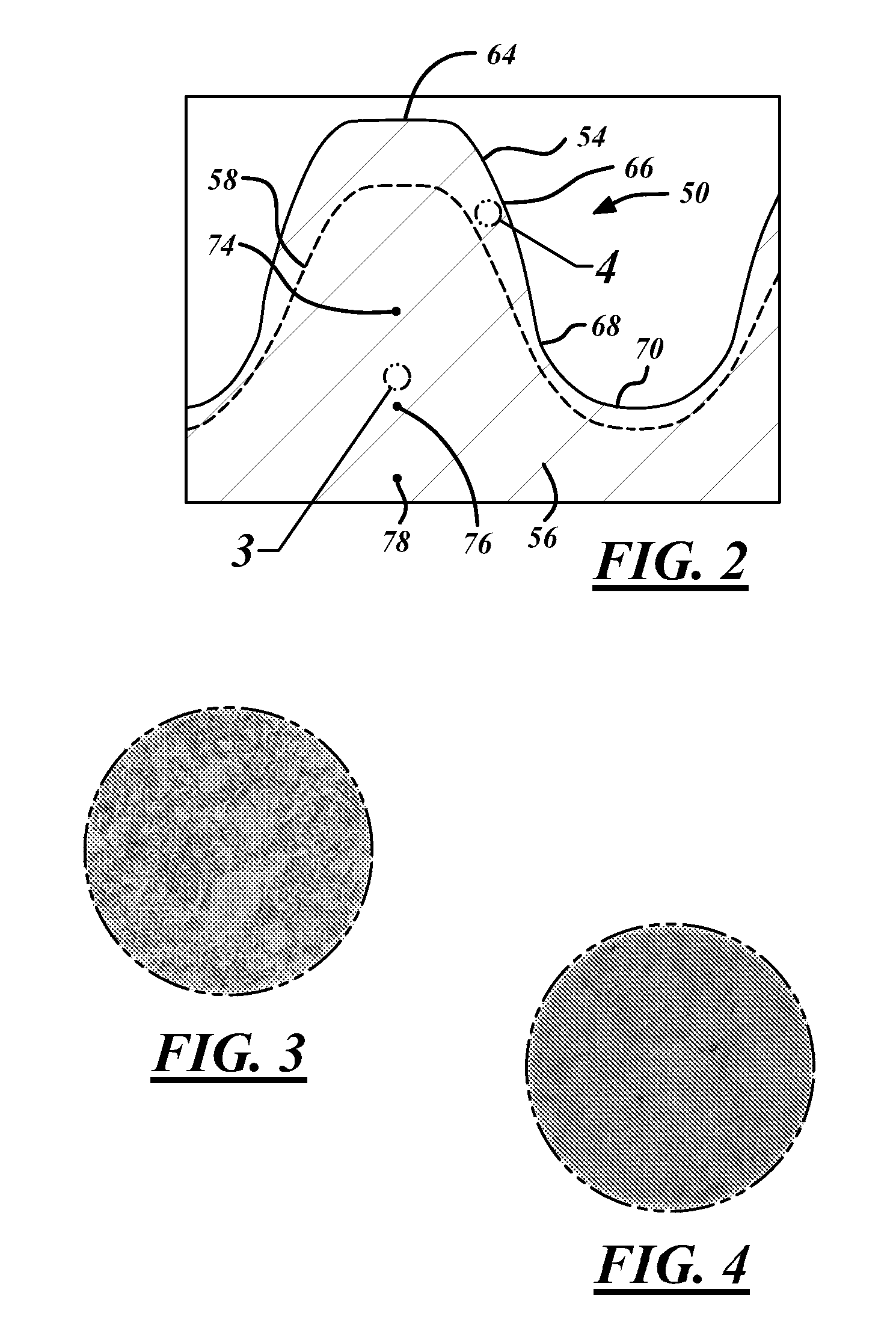

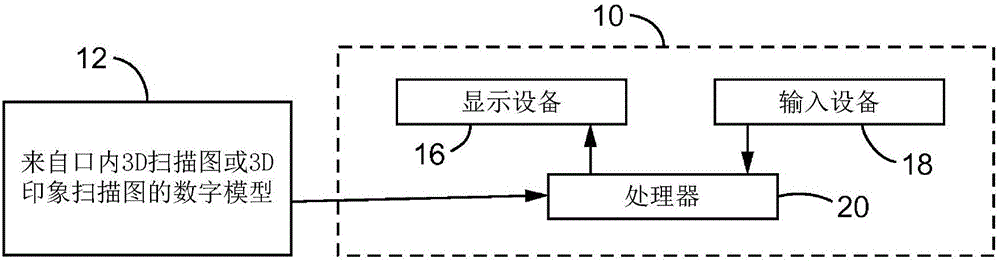

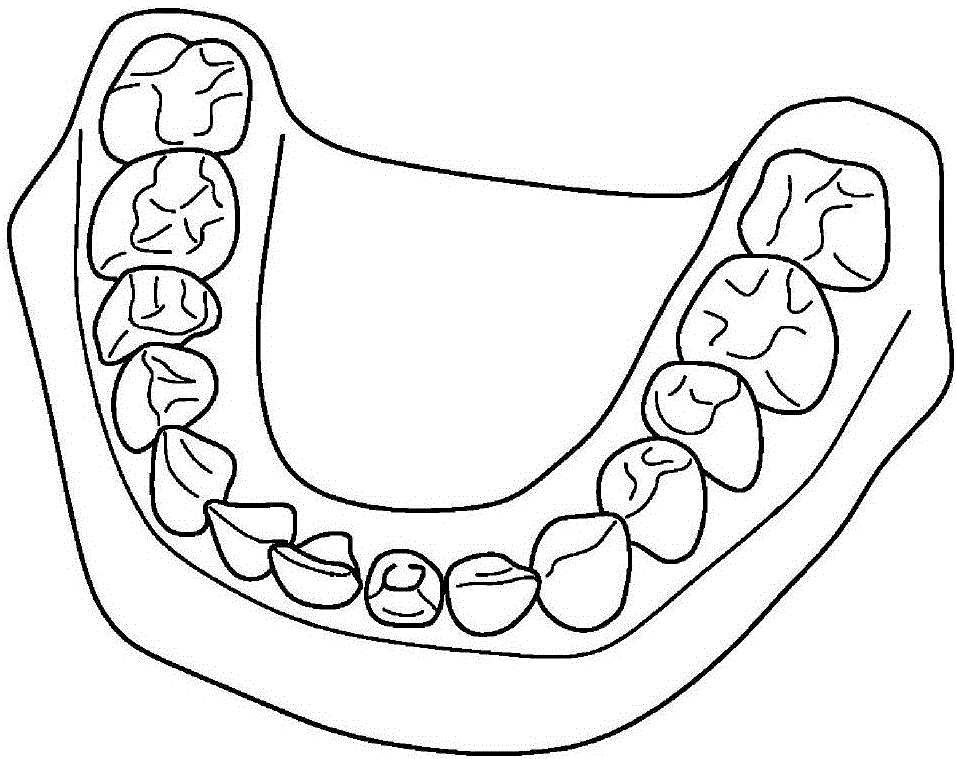

Detecting tooth wear using intra-oral 3D scans

A method for detecting tooth wear using digital 3D models of teeth taken at different times. The digital 3D models of teeth are segmented to identify individual teeth within the digital 3D model. The segmentation includes performing a first segmentation method that over segments at least some of the teeth within the model and a second segmentation method that classifies points within the model as being either on an interior of a tooth or on a boundary between teeth. The results of the first and second segmentation methods are combined to generate segmented digital 3D models. The segmented digital 3D models of teeth are compared to detect tooth wear by determining differences between the segmented models, where the differences relate to the same tooth to detect wear on the tooth over time.

Owner:3M INNOVATIVE PROPERTIES CO

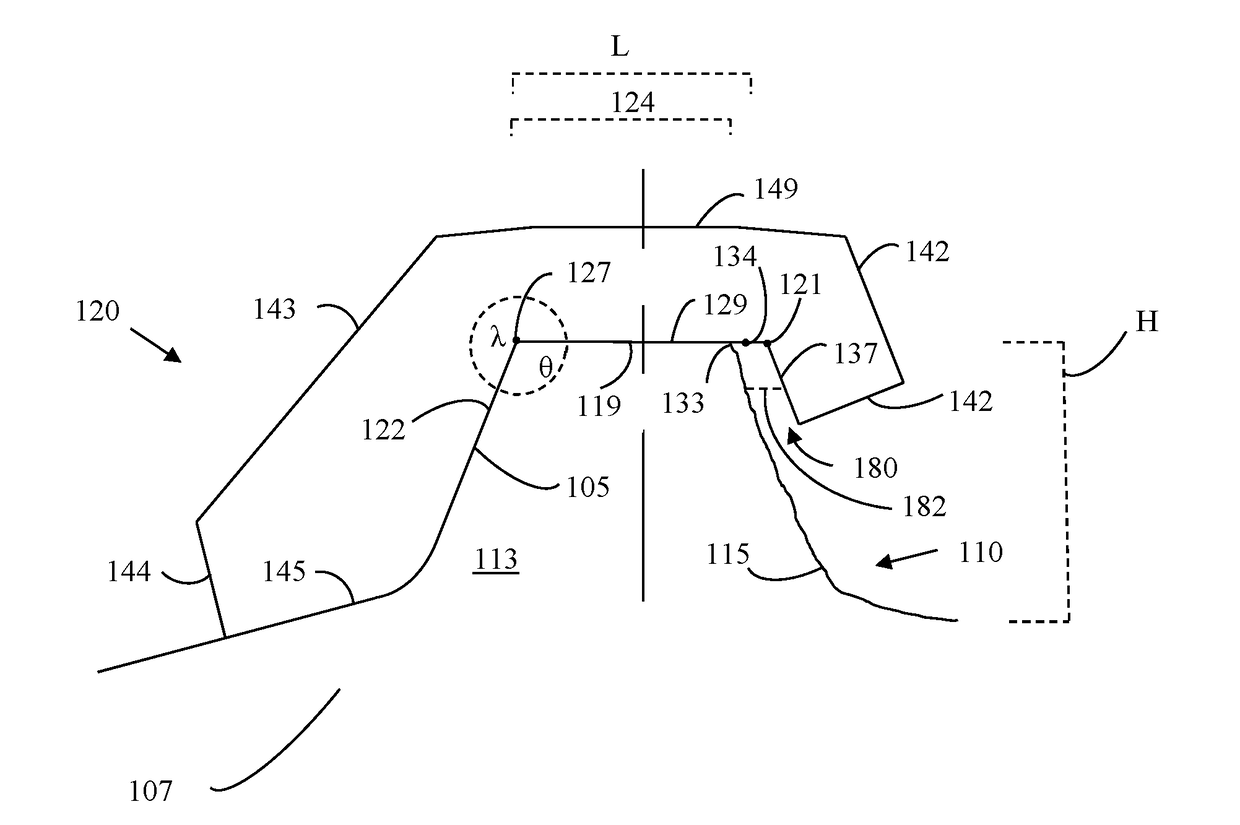

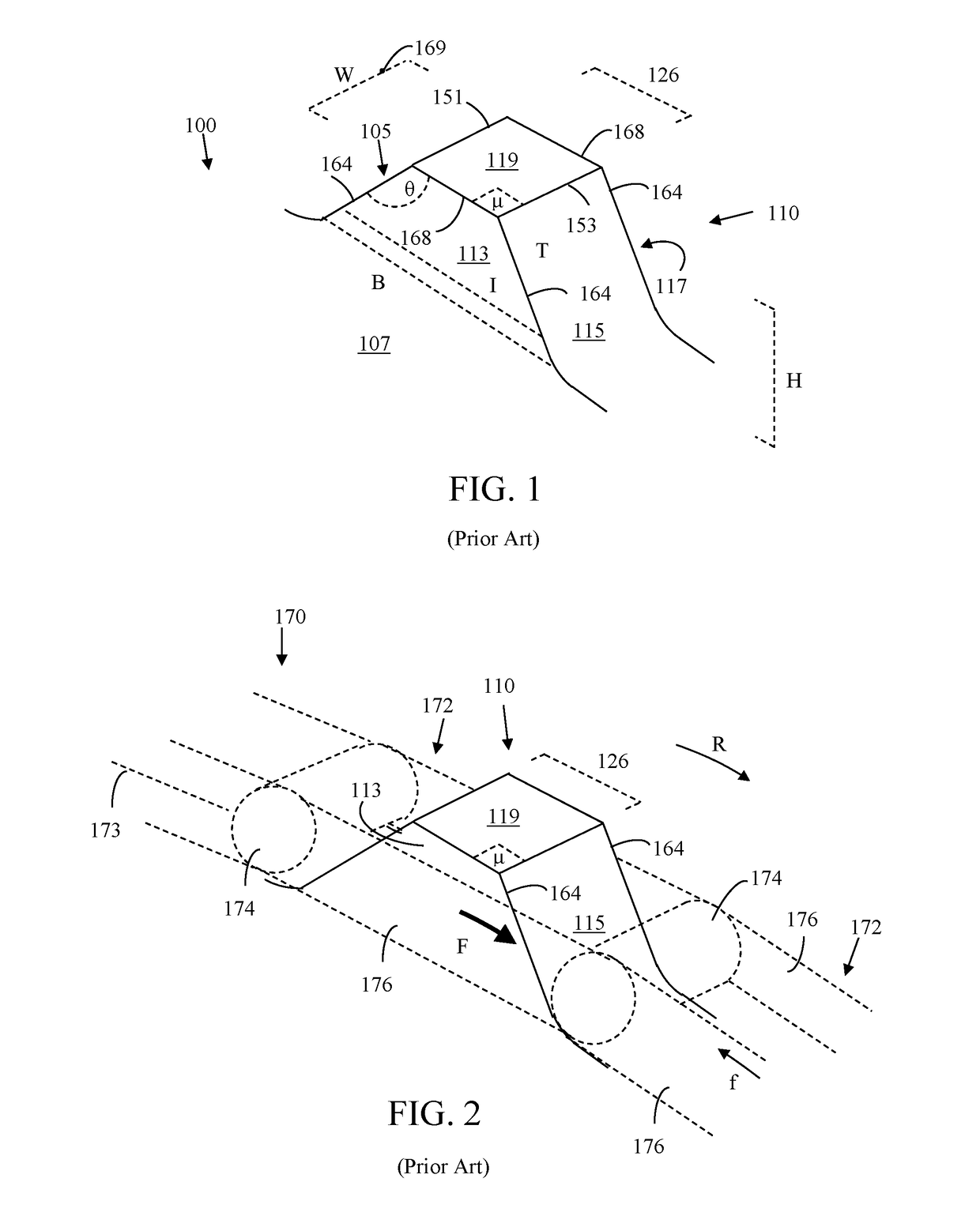

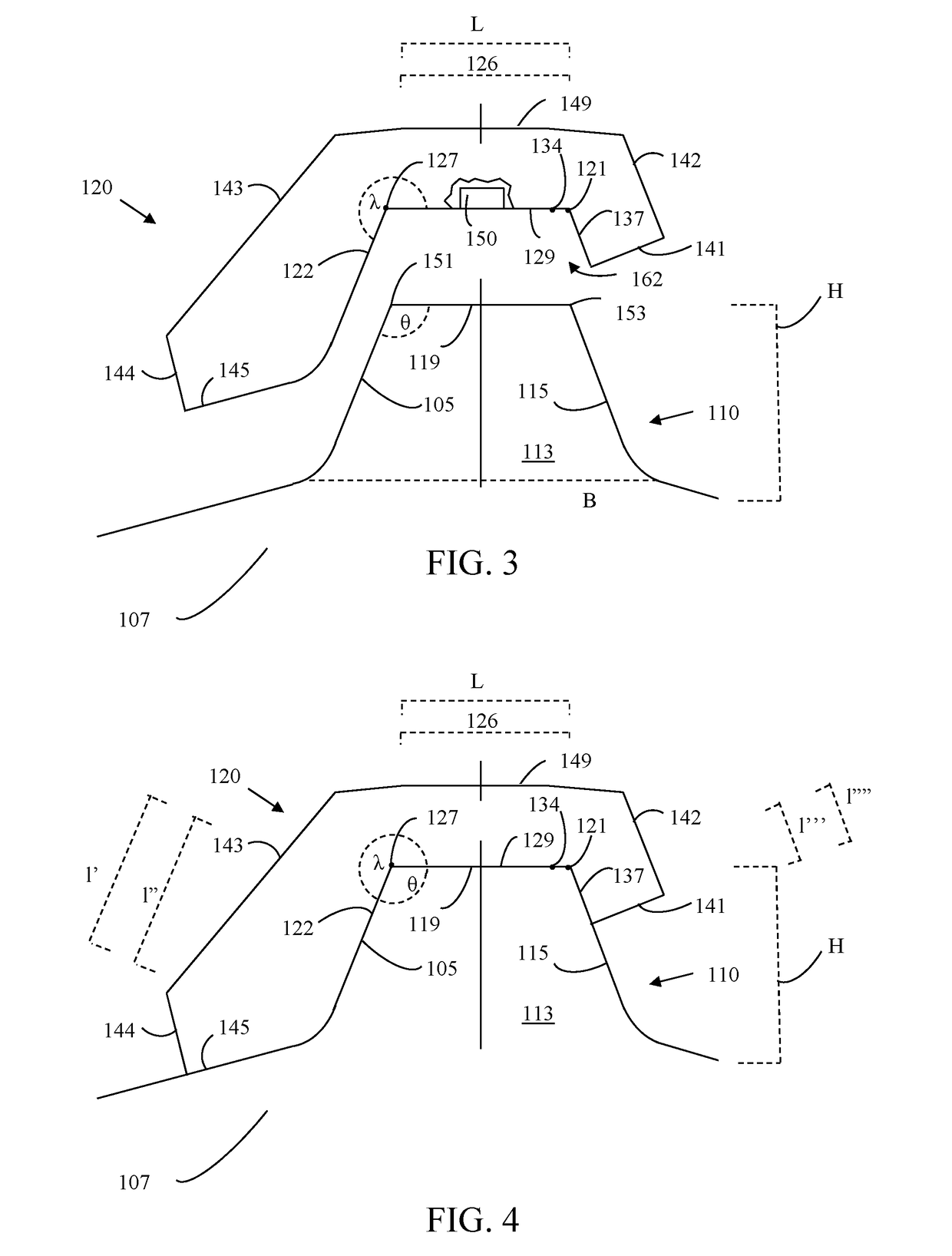

Method and system for evaluating and predicting sprocket tooth wear

An exemplary method may comprise: ascertaining an original distance between a first tooth face and a second tooth face of a sprocket tooth, wherein the sprocket tooth comprises two tooth faces extending from a sprocket core and terminating in a top of the sprocket tooth, wherein an original distance separates the two tooth faces, placing a sprocket gauge on the sprocket tooth, wherein the sprocket gauge comprises: a bottom, and two gauge faces extending from the bottom of the sprocket gauge, wherein the bottom of the sprocket gauge is disposed upon the top of the sprocket tooth and the first gauge face is disposed adjacently on the first tooth; and comparing the original distance defined by the sprocket gauge with an actual distance between the first tooth face and the second tooth face.

Owner:ANDRITZ INC

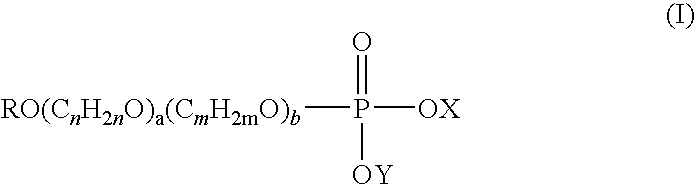

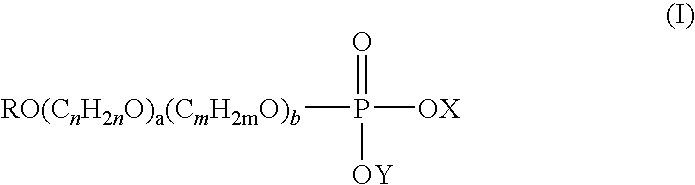

Novel use of alkyl phosphate esters

The use of an oral care composition comprising certain alkyl phosphates is described for combating dental erosion and tooth wear.

Owner:GLAXO GROUP LTD

Method of forming composite powder metal gear

InactiveUS20100322812A1Increase resistanceImprove impact resistanceMetal-working apparatusSolid state diffusion coatingTooth wearGear tooth

Owner:SKN SINTER METALS LLC (US)

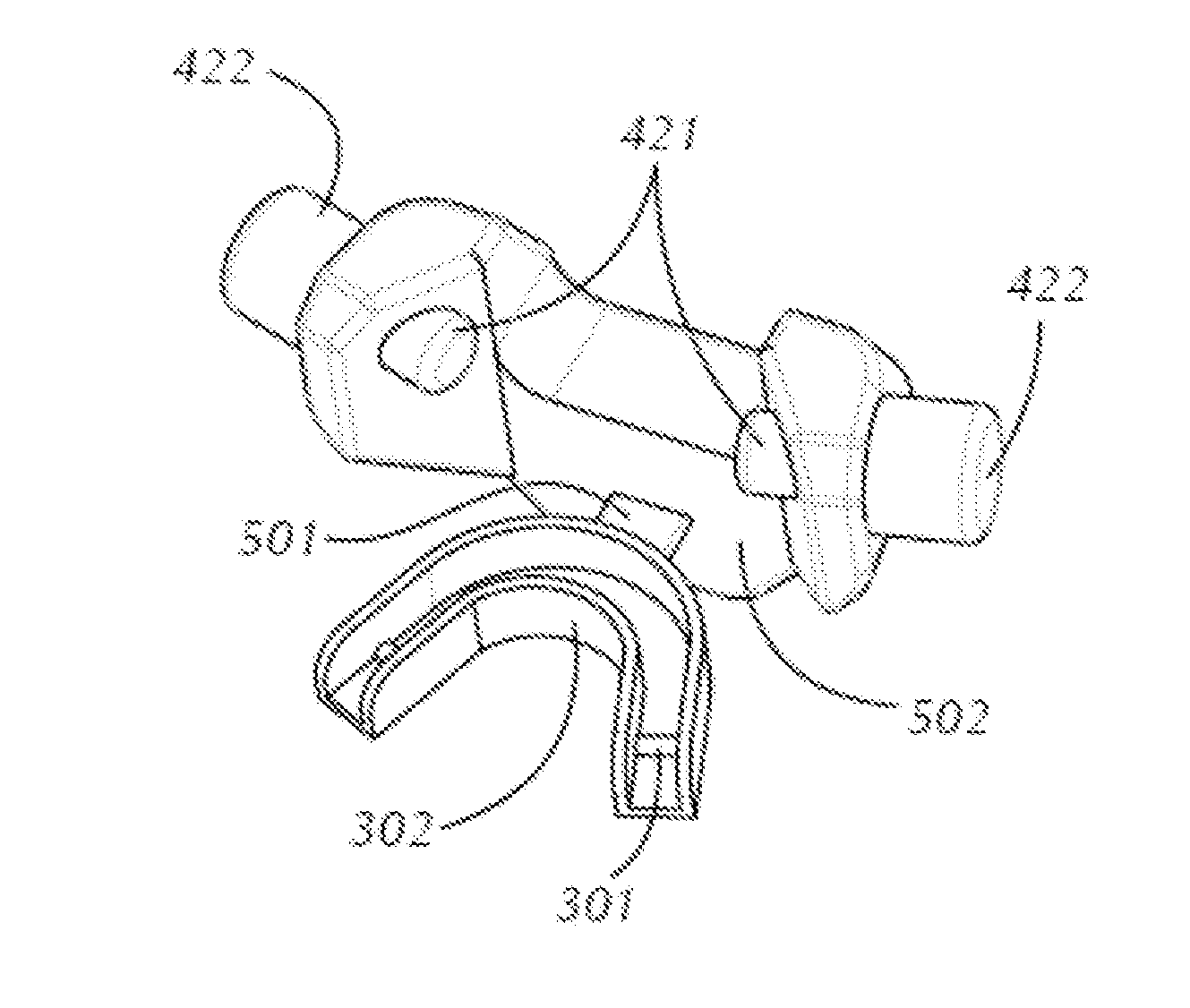

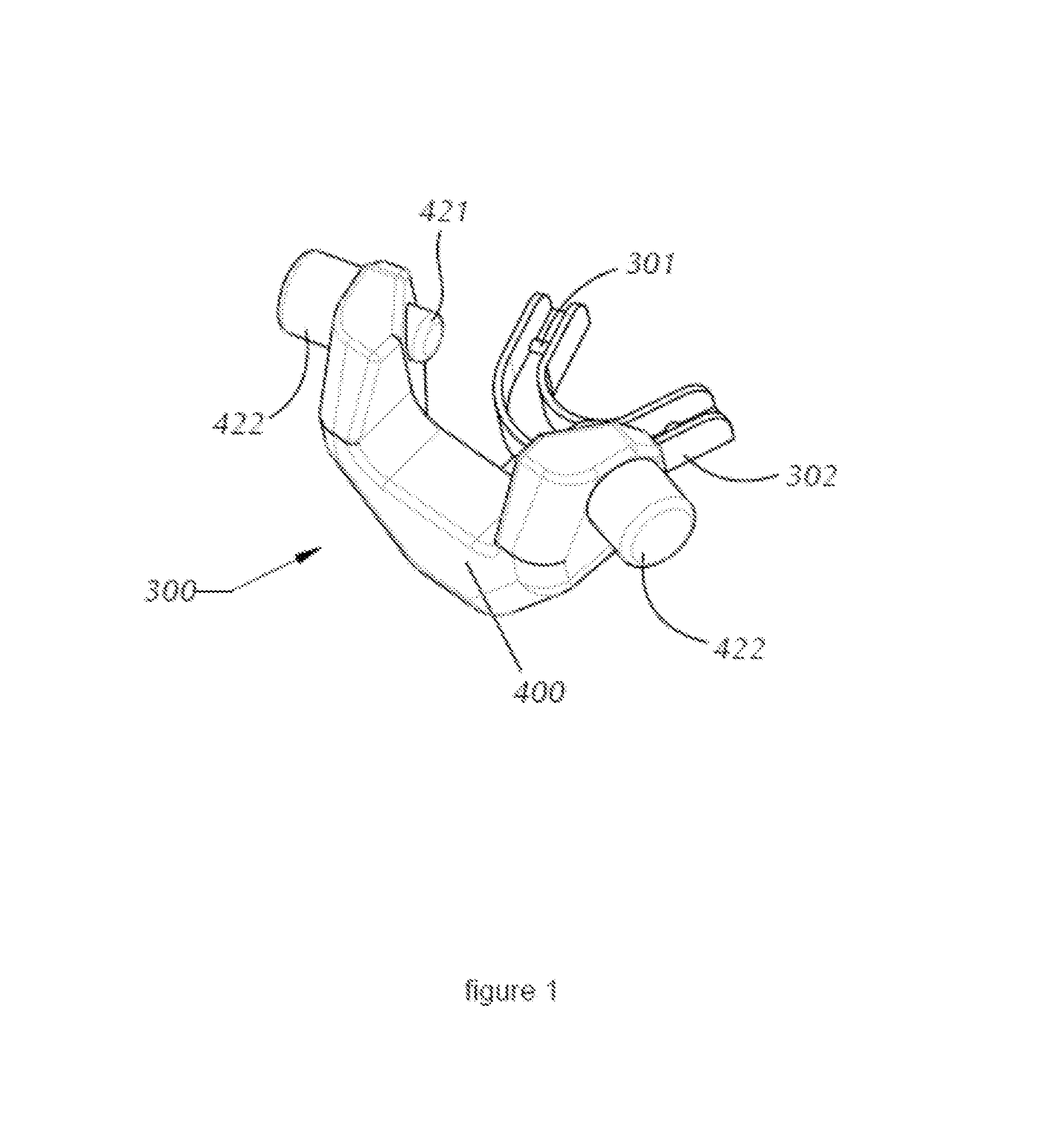

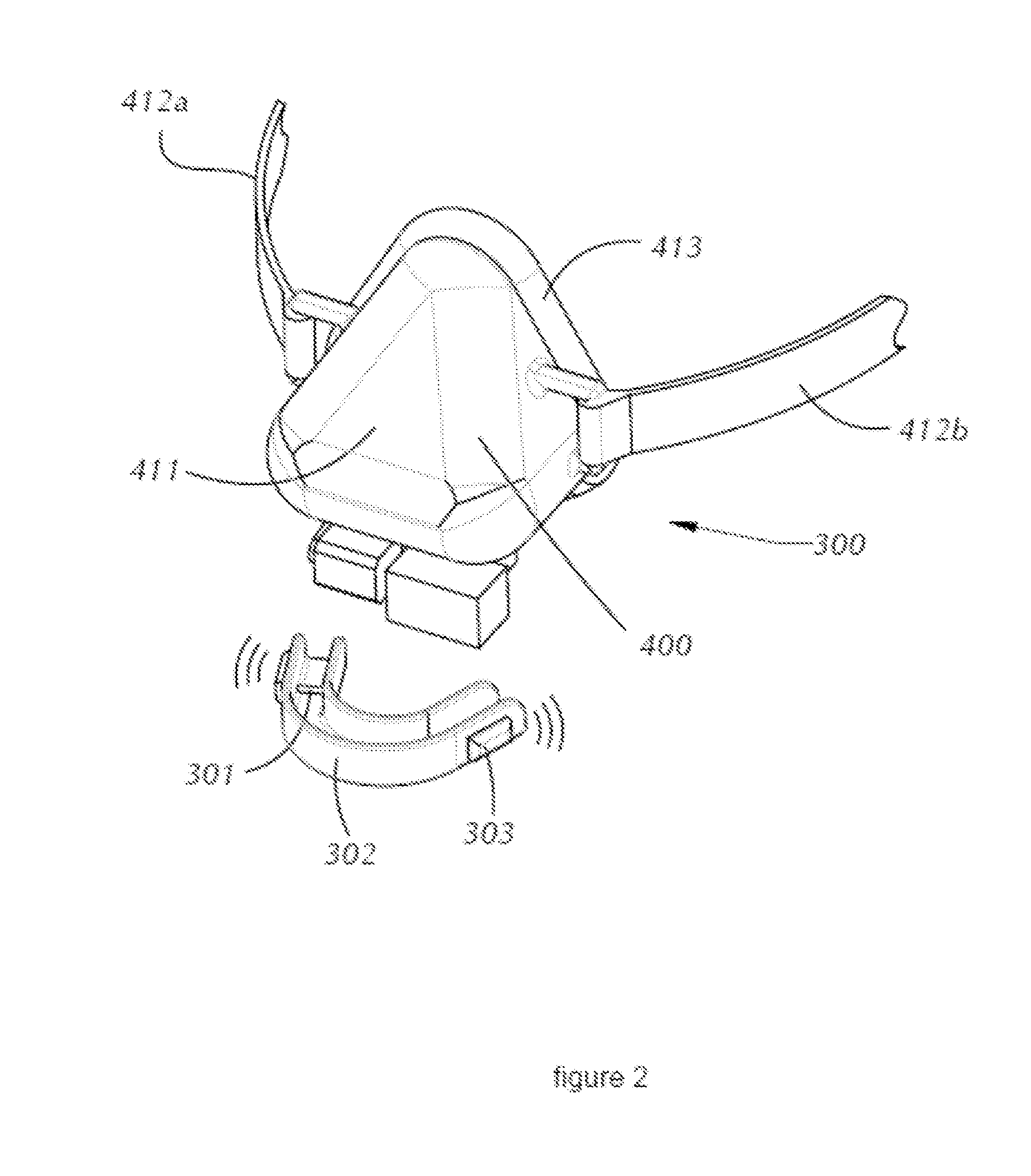

Device and method for the treatment of bruxism

Bruxism, which is a human medical condition characterized by clenching of the jaw and / or grinding of teeth, leads to conditions such as severe tooth wear and Temporomandibular Joint (TMJ) Disorder. Described herein is a biofeedback device that utilizes the human physiological reflex to open the mouth when the nasal airway is obstructed. The device and method blocks the nasal airway while clenching, but allows nasal respiration while not clenching. Clenching of the jaw and breathing through the mouth cannot happen simultaneously while unconscious.

Owner:VEZINA WILLIAM KARL +1

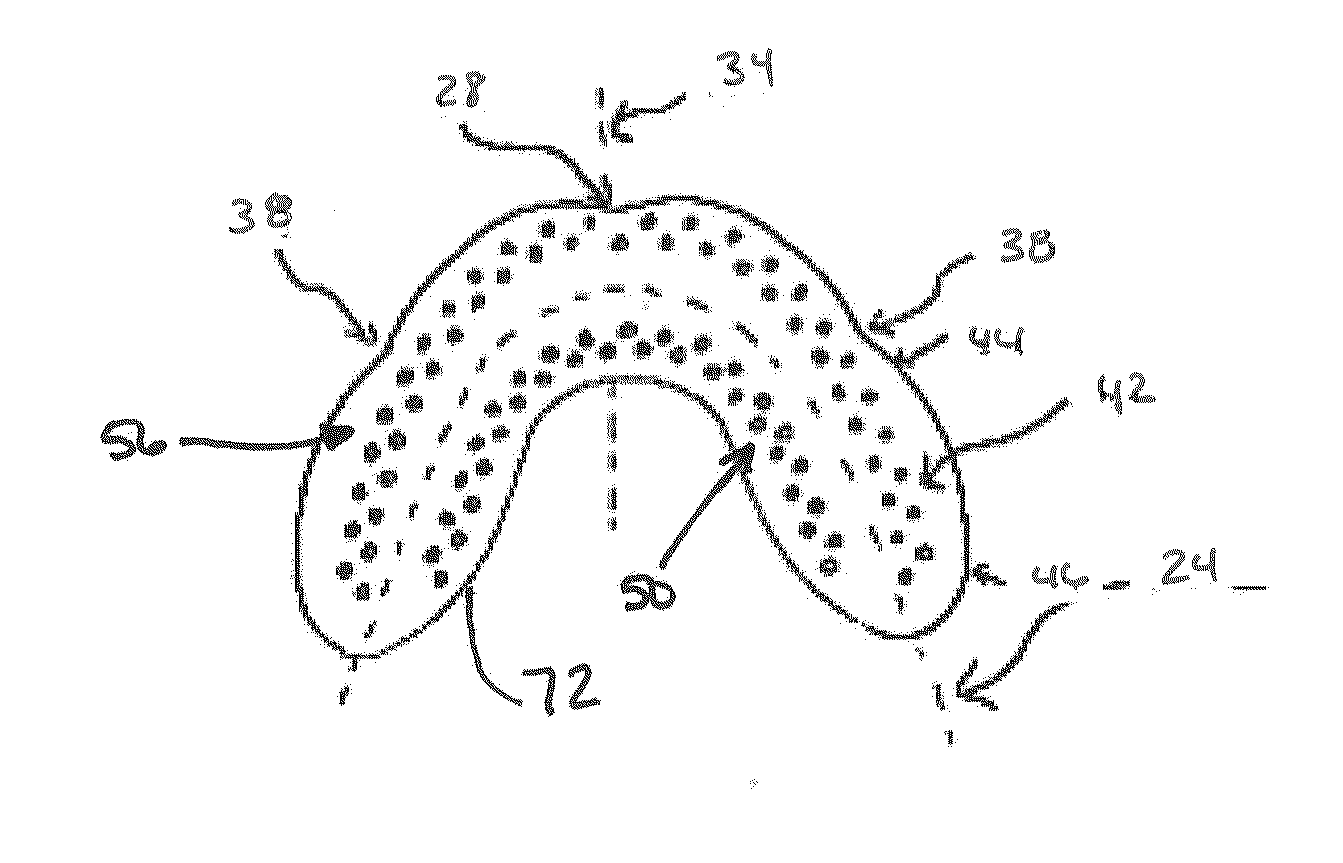

Custom-Formable Night Grinding Appliance and Method of Use

ActiveUS20140338675A1Low softening pointEasy to breatheSnoring preventionNon-surgical orthopedic devicesHealth professionalsBiomechanics

Disclosed is a dental appliance composed of a thermo-plastic polymer with low compressibility, high toughness, and high tensile strength, with a low softening point. The appliance has perforations that enable it to be easily custom-fitted by the user or a health professional. The appliance begins as a generally U-shaped, unformed dental tray that is significantly thinner than existing dental appliances. Once fitted, the dental appliance provides superior protection against damage to the enamel of the teeth and abrasion of the teeth due to bruxism or other mechanism leading to biomechanical wear of dental surfaces. The perforations facilitate the custom-fitting process by allowing the user to suck air through the perforations, thus applying a negative pressure between the material and the teeth while the material is still soft and pliable. This enables a user or health professional to within minutes create a final product that rivals the quality and fit of an appliance made by dental laboratories using dentist made impressions.

Owner:AKERVALL TECH

Excavating tooth wear indicator and method

Owner:VOLVO CONSTR EQUIP AB

Multifunctional liquid toothpaste

The invention discloses multifunctional liquid toothpaste. The multifunctional liquid toothpaste comprises a fluorine ion source, a friction agent, an activating agent and cell messenger enzyme, wherein the fluorine ion source is sodium monofluorophosphate; the friction agent is hydrated colloidal hydroxyapatite; the activating agent is bisabolol; the cell messenger enzyme is coenzyme Q10. The multifunctional liquid toothpaste is specially effective for resisting slow erosion of teeth and preventing related problems of tooth erosion and tooth wear from deteriorating, or can be used for preventing oral ulcer, periodontal disease and gingival bleeding and treating decayed teeth or tooth hypersensitivity; the utilization rate of free fluorine ions and repair of the teeth are improved; micro-sized hydroxyapatit and fluorophosphates are gelatinated to generate a constantly-smooth clean frictional force; with moderate frictional force, RDA of the toothpaste is ensured to be 20 to 30, so thattooth wear is not increased while the toothpaste properly cleans the teeth; the multifunctional liquid toothpaste has a powerful decontaminating effect for teeth subjected to tooth erosion or softening caused by acid attack.

Owner:叶绿芝生物科技(中山)有限公司

Variable case depth powder metal gear and method thereof

ActiveCN101827673AImprove wear resistanceImprove bearing capacityToothed gearingsPortable liftingEngineeringTooth wear

A gear and a method of making a forged powder metal gear having a plurality of teeth and a variable case depth profile forged in the plurality of teeth. Each tooth of the plurality of teeth has a first surface and a tooth root. A variable case depth profile is formed in each tooth of the plurality of teeth, whereby the variable case depth profile exhibits greater tooth wear resistance on the first surface and greater impact resistance in the tooth root.

Owner:GKN SINTER METALS GMBH & CO KG

Laser cladding repairing method for end tooth wear or cracks of general high speed pump gear shafts

ActiveCN107419262AThorough repairSimple processMetallic material coating processesGear pumpWear resistant

The invention belongs to the field of repairing of high speed pump shafts for petrochemical industry and relates to a laser cladding repairing method for end tooth wear or cracks of general high speed pump gear shafts. The method aims at repairing of parts with wear and cracks on end teeth in long-time running process and comprises the steps of firstly removing damaged end teeth and remanufacturing new end teeth, carrying out hot charging by utilizing the part size change caused by temperature difference, selecting stainless steel powder and wear-resistant Co-based alloy powder which have mechanical properties similar to those of a base material, carrying out cladding by adopting laser cladding process parameters, removing residual stress in cladded parts through a hammering method, finally recovering the parts to a design size through a precise mechanical processing method, thereby recovering the operational performance of the high speed pump gear shafts. The method disclosed by the invention has the advantages that in the laser cladding repairing process of the high speed gear pump shafts, the base material is maintained at a low temperature all the time during cladding and the part deformation rate is almost zero; and the obtained cladding layer is metallurgically combined with a matrix, the automatic efficiency is high and the cost is low.

Owner:浙江翰德圣智能再制造技术有限公司

Producing method of attapulgite double fluorine toothpaste

InactiveCN101224172AQuality improvementImprove adsorption capacityCosmetic preparationsToilet preparationsLow speedToothpaste

The invention discloses a production method of attapulgite bifluoride toothpaste; the key points of the technical proposal are that: the production method of the attapulgite bifluoride toothpaste includes preparation of materials, low-speed stirring, grinding, high-speed stirring, vacuum degassing and canning into the finished product of the attapulgite bifluoride toothpaste. The attapulgite bifluoride toothpaste is composed of paste attapulgite clay, sodium fluoride, sodium monofluorophosphate, zinc citrate, sodium dodecyl sulfate, titanium white powder, sodium saccharine and deionized water. The attapulgite bifluoride toothpaste can absorb and remove a plurality of offensive smells in the oral cavity, reduce tooth wear, strengthen and regenerate the enamel on the surface of the teeth; the attapulgite bifluoride toothpaste has clean paste body, soft and delicate texture, normal luster and good stability, the paste body is not overflowed to the outside of a pipe mouth, the water is not separated from the invention, the flavor and the luster are normal, and the glass slide has no scratches. The invention is applicable to the production of attapulgite bifluoride toothpaste, Chinese herbal medicine toothpaste and other medicine toothpastes.

Owner:HUAIAN UNIV SCI PARK MANAGEMENT CO LTD

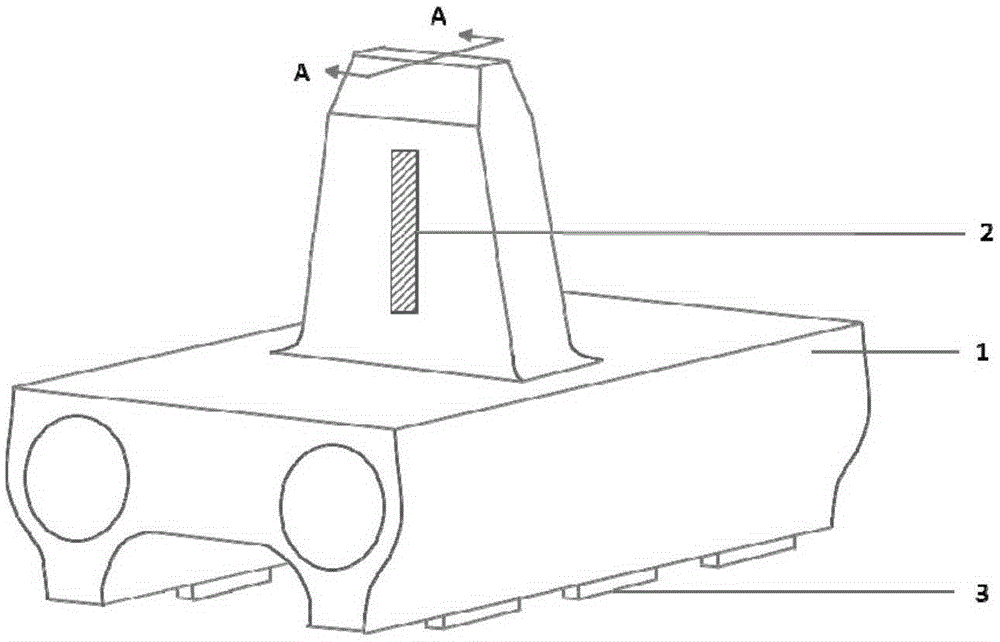

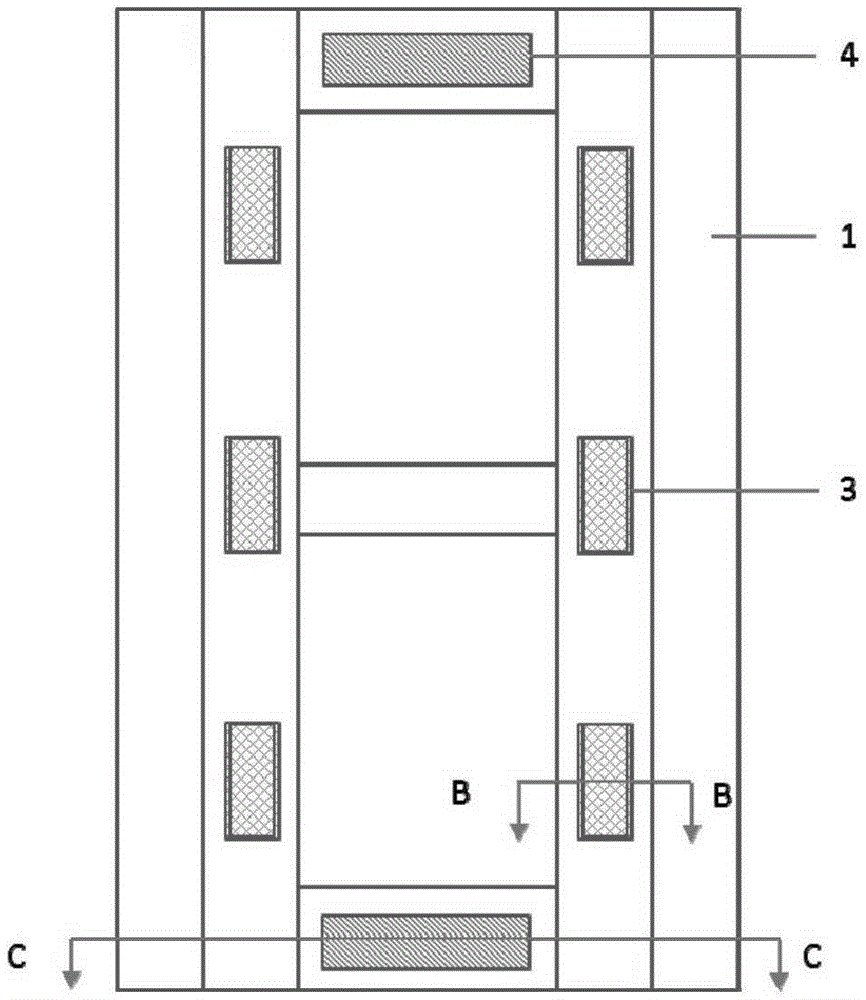

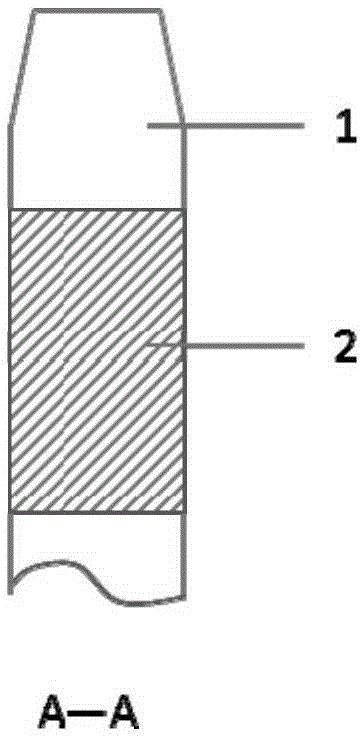

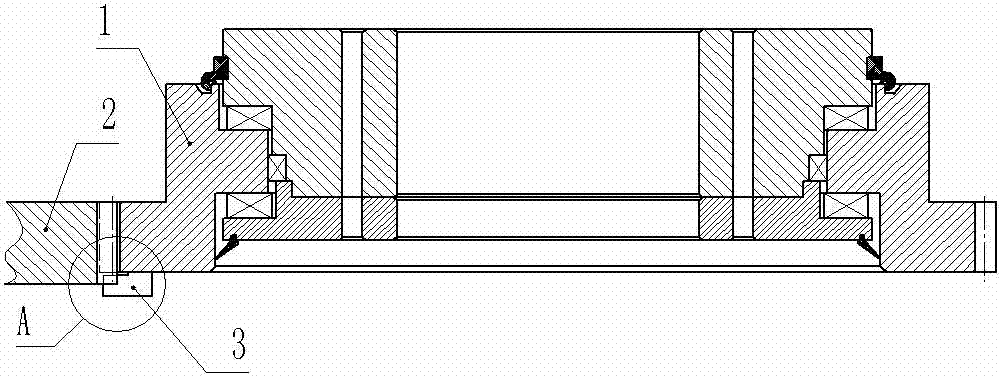

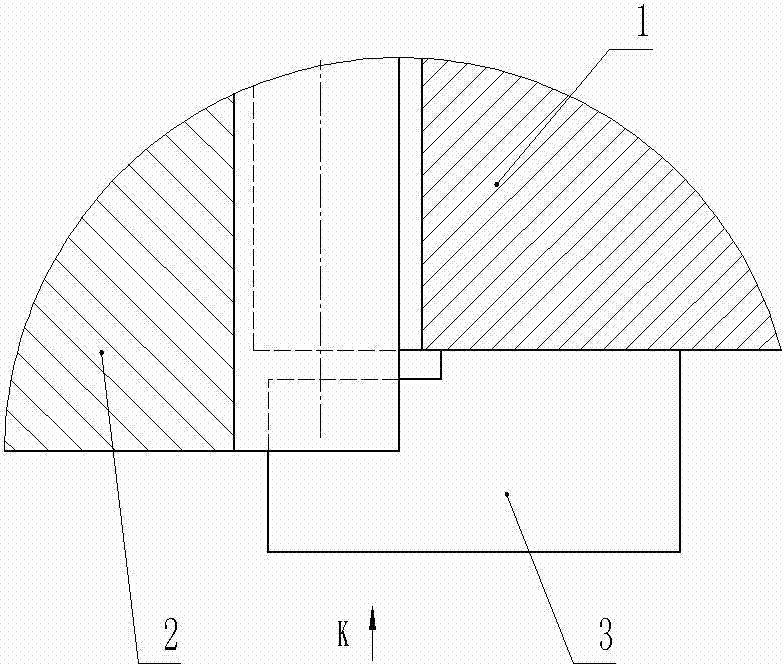

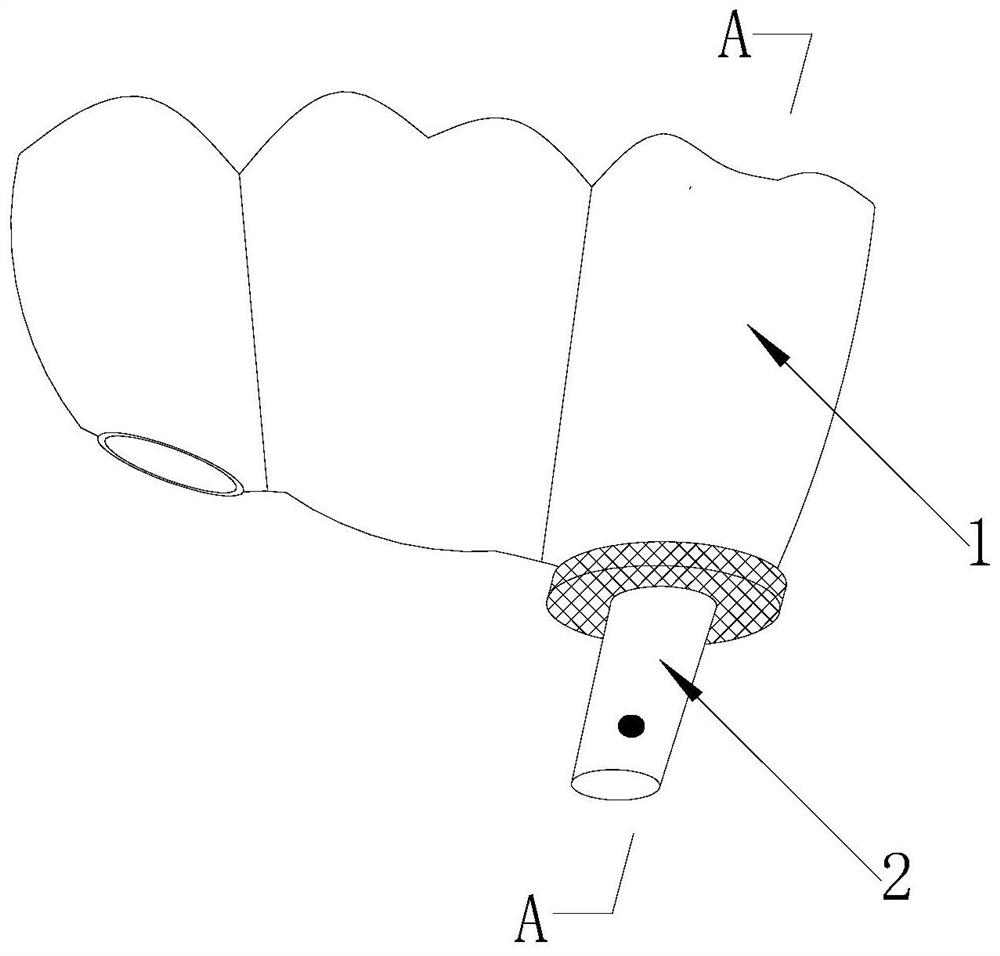

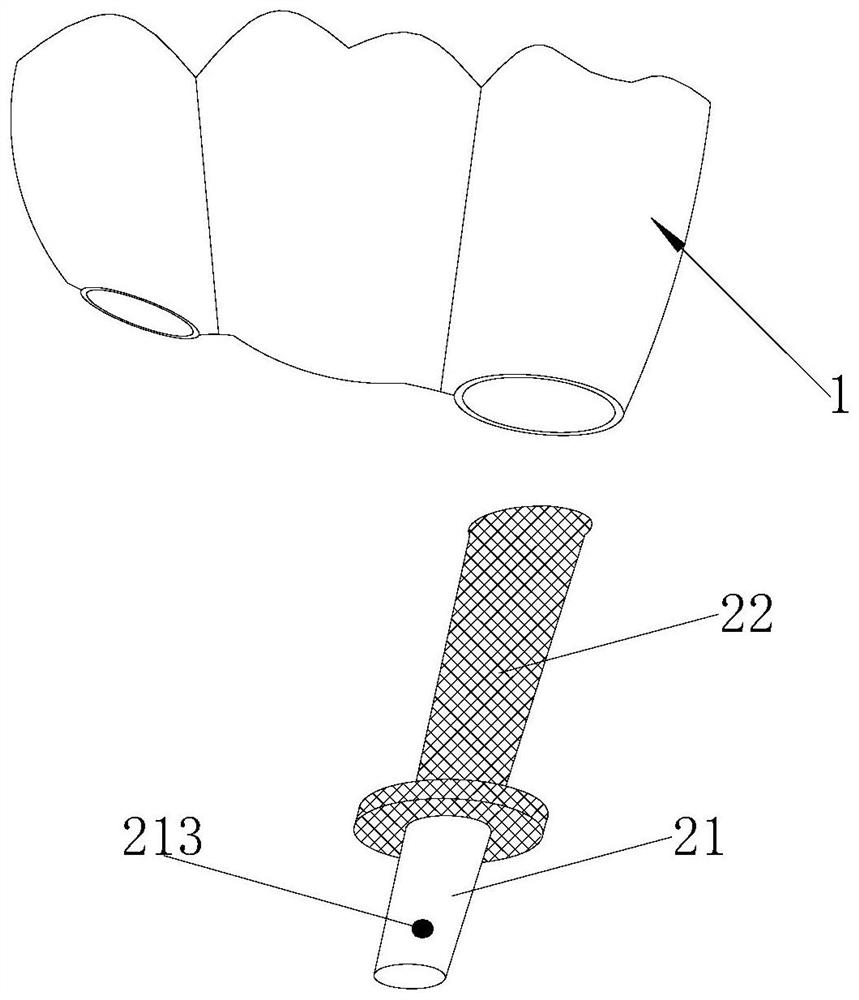

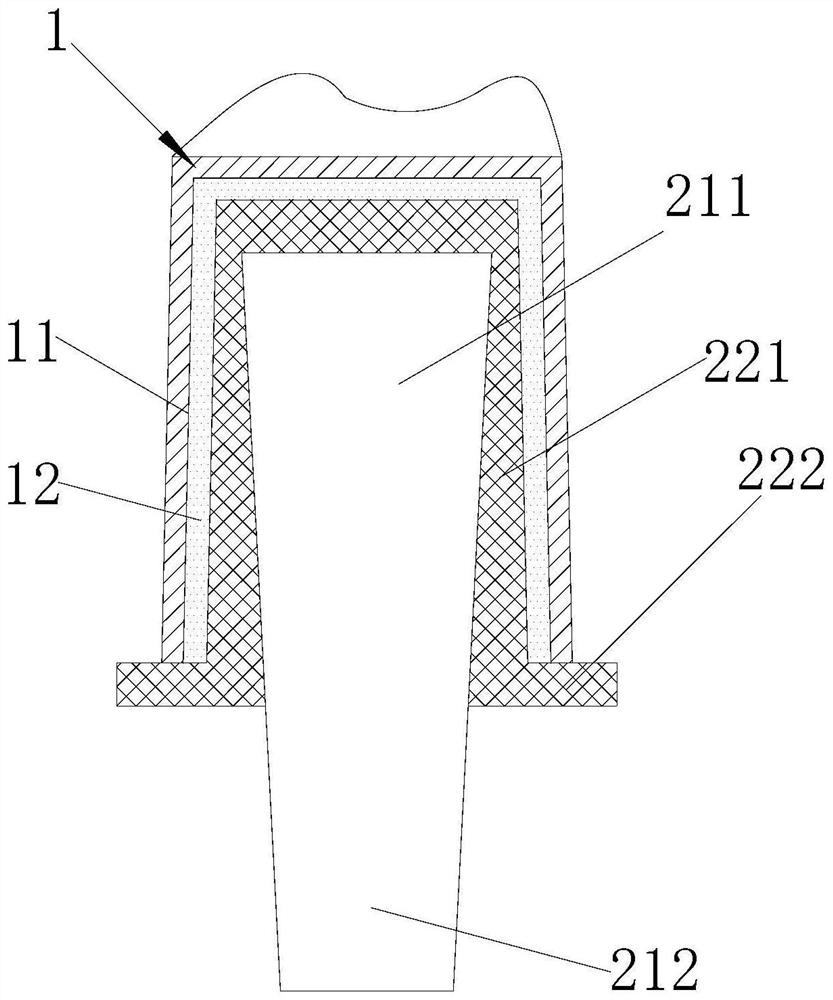

Composite-structure track shoe and forming method thereof

ActiveCN105398502ALow structural strengthImprove structural strengthEndless track vehiclesTooth wearWear resistant

The invention belongs to the field of forming of track shoes, particularly relating to a composite-structure track shoe and a forming method thereof. The composite-structure track shoe is characterized in that an inducing tooth wear-resistant insert (2) is inlaid in an inducing tooth part of the upper part of a track shoe body (1); a grouser wear-resistant insert (3) is inlaid in a landing grouser part of the lower part of the track shoe body; a pin hole reinforcing insert (4) is inlaid in a pin hole part in the middle of the track shoe body; and the lightweight high-strength and high-wear-resistance composite-structure track shoe is prepared by a rheological extrusion casting and inlaying forming method. The composite-structure track shoe is light in weight, an aluminum alloy body is high in structural strength, the strength of the composite-structure track shoe is close to that of a forged aluminum alloy track shoe, requirements on the strength of a tracked vehicle are met, and by a casting and inlaying structure, the problem that the aluminum alloy track shoe is poor in local wear resistance and low in performance is solved. By the forming method, near net shaping of a complicated structure of the composite-structure track shoe can be realized. The composite-structure track shoe has the advantages of convenience in operation, high machining efficiency, long service life of a mold, few followed-up machining and high material utilization.

Owner:有研金属复材技术有限公司

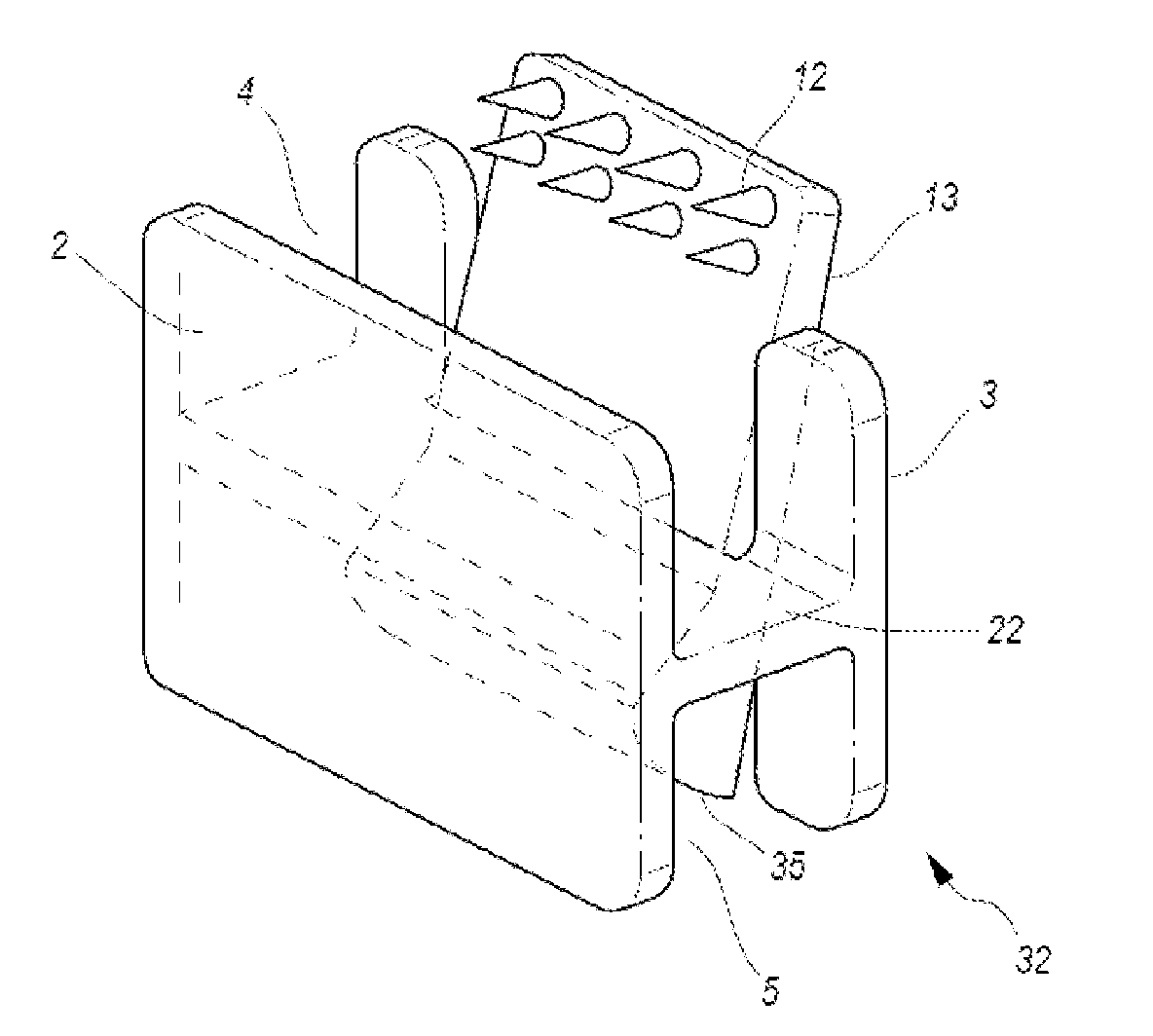

Device and Methods for Treatment of Temporomandibular Joint (TMJ) Disorder

The present invention relates to a mouth guard and methods of use to aid in the treatment of bruxism and temporomandibular joint (TMJ) disorder comprising an adjustable molded thermoplastic outer face plate, an inner face plate and irritation spines, the mouth guard containing a section for placement and fitting to a patient's upper and lower dentition, the molded thermoplastic mouth guard including tooth channels that, upon commencing of tooth grinding, initiate mild irritation to the gums or cheeks of a wearer by the irritation spines wherein, the wearer is alerted to the occurrence of tooth grinding, whether the wearer is sleeping or awake, whereupon the wearer ceases the tooth grinding thereby preventing development of temporomandibular joint (TMJ) disorder and tooth wear.

Owner:GARCIA RENE

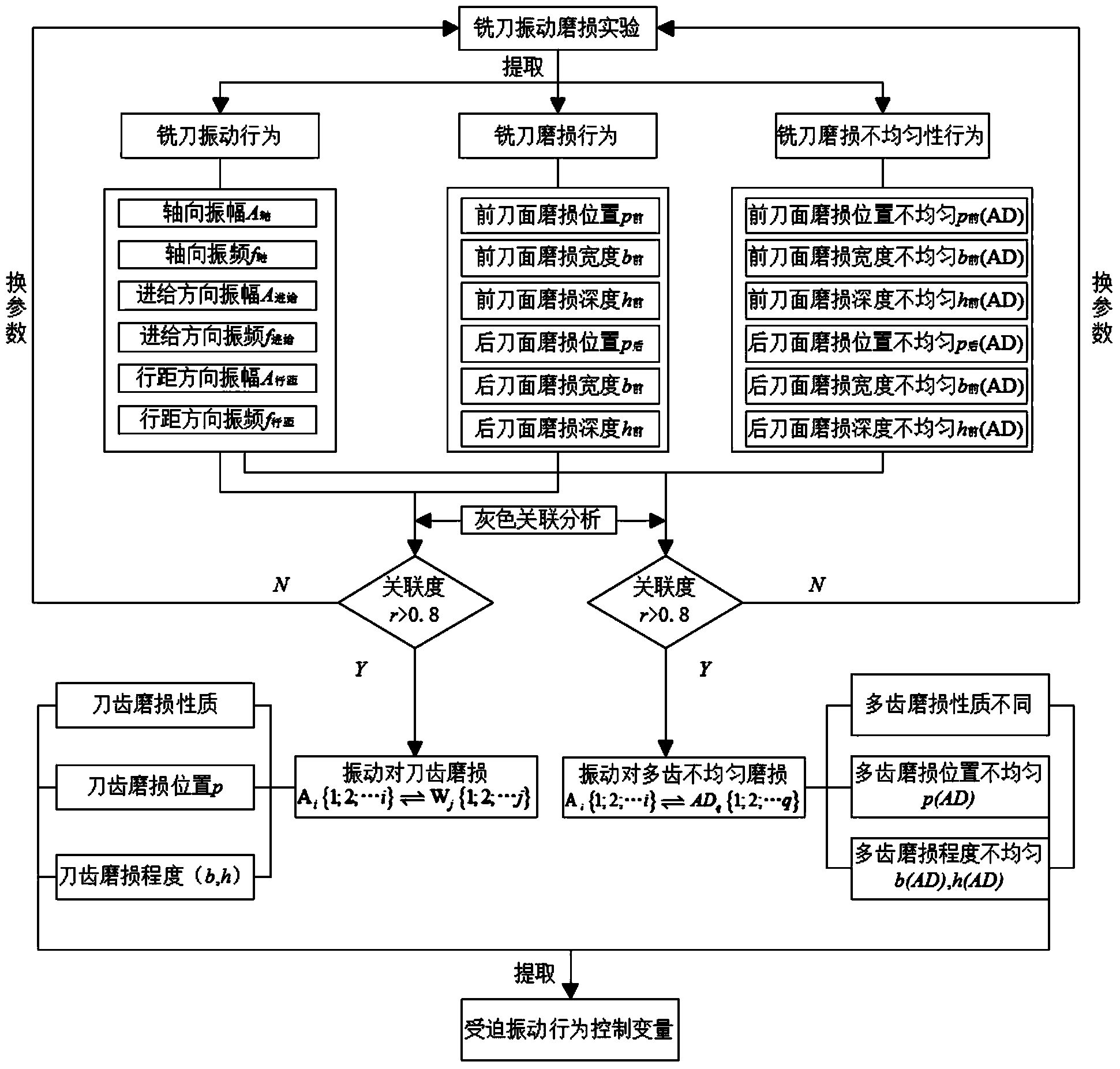

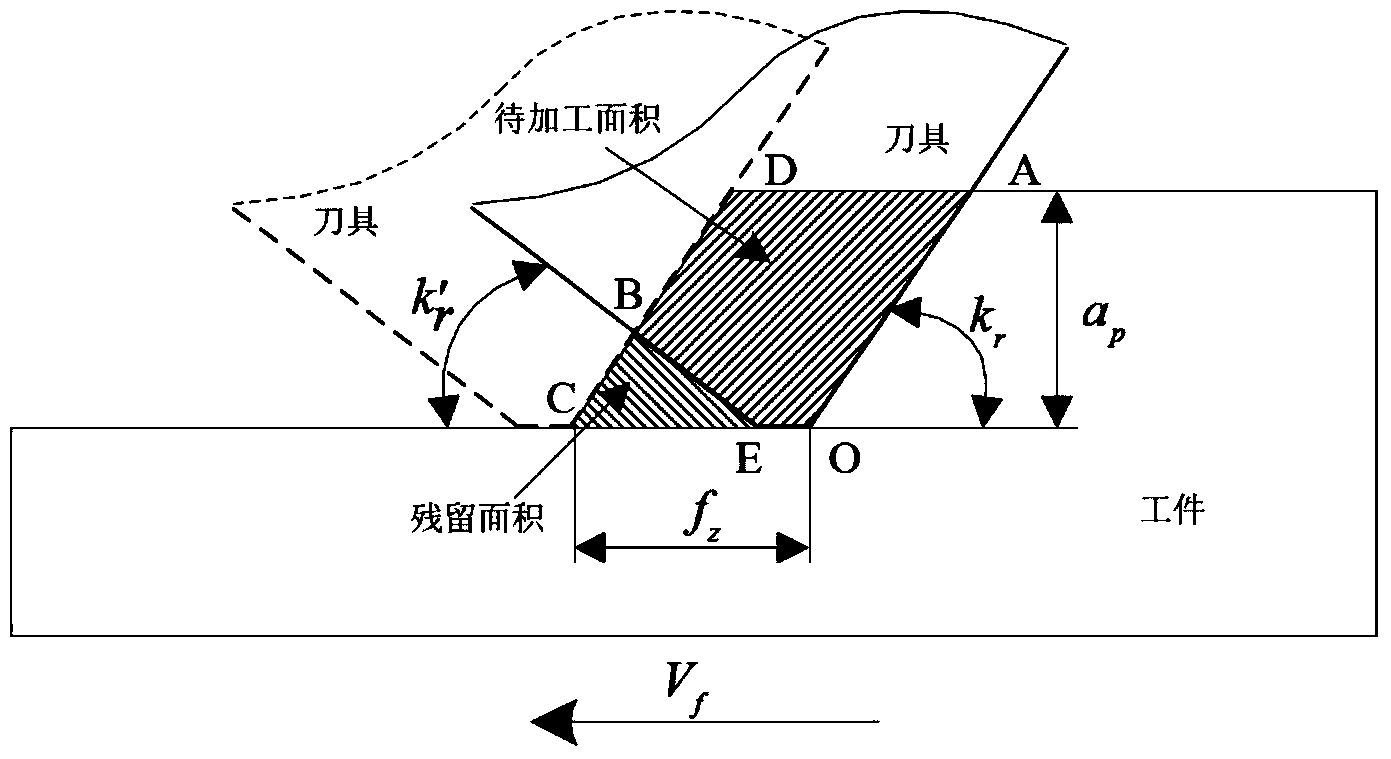

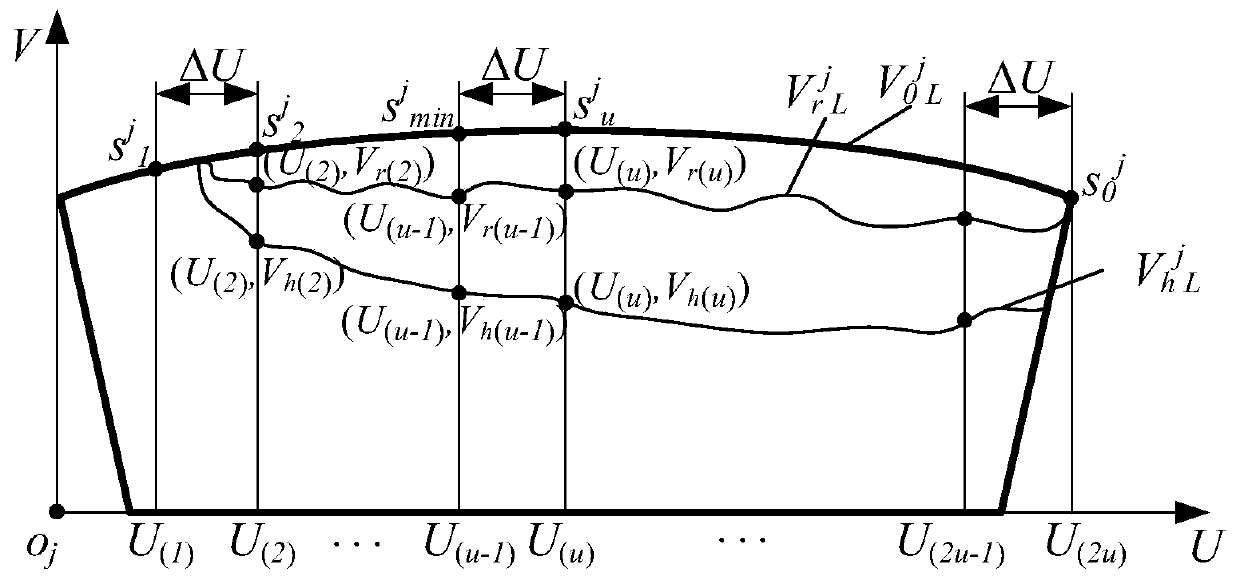

Analysis model construction and verification method for revealing wear difference of cutter teeth of high-feed milling cutter

ActiveCN110704969AAccurate and comprehensive identificationFully and accurately describeGeometric CADTooth wearAnalytic model

The invention discloses an analysis model construction and verification method for revealing wear difference of cutter teeth of a high-feed milling cutter. The invention belongs to the technical fieldof milling cutter teeth. In the prior art, in the milling process of the high-feed milling cutter, the contact length and the contact depth of the cutter teeth are increased nonlinearly, and heat isdissipated rapidly due to idle cutting, and the instantaneous cutting positions and postures of the cutter teeth are changed due to impact and vibration generated by intermittent cutting of a millingcutter, and the abrasion degrees of the cutter teeth of the milling cutter are remarkably different, and difference influence factors of the cutter teeth are difficult to recognize effectively. The analysis model construction and verification method can accurately and effectively identify the influence factors of the wear difference of the cutter teeth of the high-feed milling cutter, constructs acutter tooth wear difference analysis model, accurately describes milling cutter errors, pose changes and workpiece geometric structure characteristic changes in the high-feed milling cutter millingprocess, provides a cutter tooth abrasion area boundary recognition method, accurately recognizes cutter tooth rear cutter face abrasion upper and lower boundary distribution and change characteristics, and finally verifies the effectiveness of the analysis model.

Owner:HARBIN UNIV OF SCI & TECH

Method of forming composite powder metal gear

InactiveUS8424204B2Increase resistanceImprove impact resistanceMetal-working apparatusSolid state diffusion coatingTooth wearMetallic materials

A forged composite gear and a method of making a forged composite powder metal gear. The forged composite gear includes a plurality of teeth extending from a core, a first section having a first powder metal material, a second section having a second powder metal material and a variable boundary profile. The variable boundary profile is formed between the first section and the second section, whereby said variable boundary profile exhibits greater tooth wear resistance on the teeth and greater impact resistance in the core.

Owner:SKN SINTER METALS LLC (US)

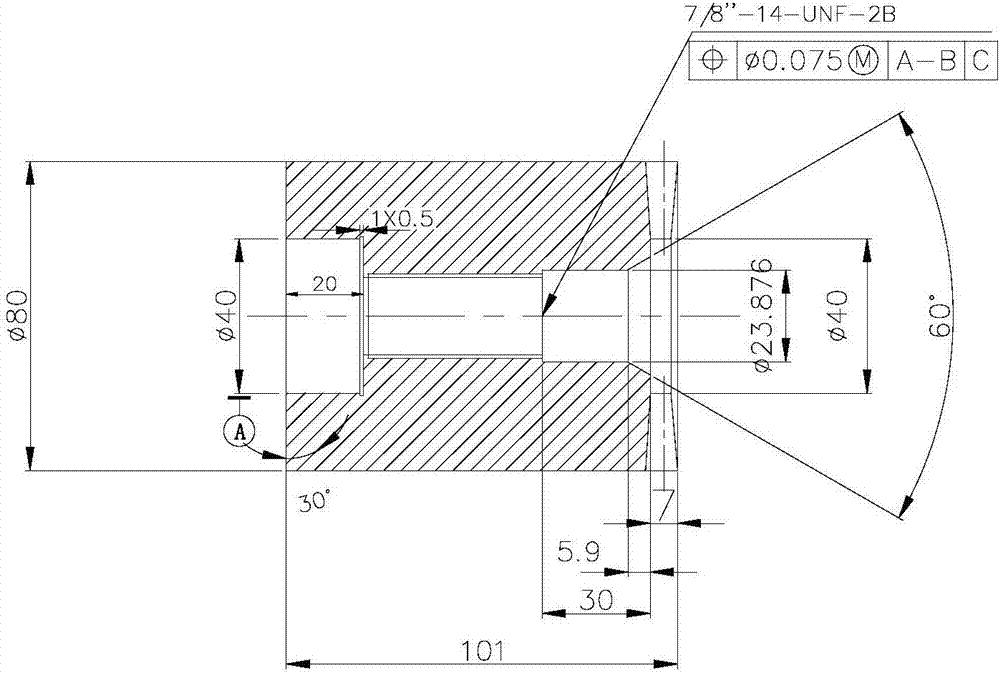

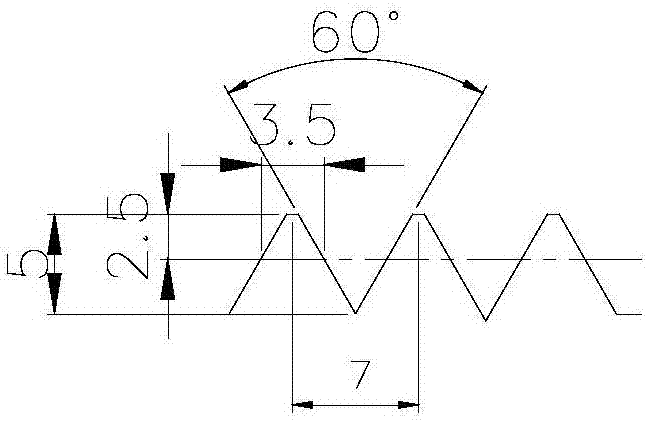

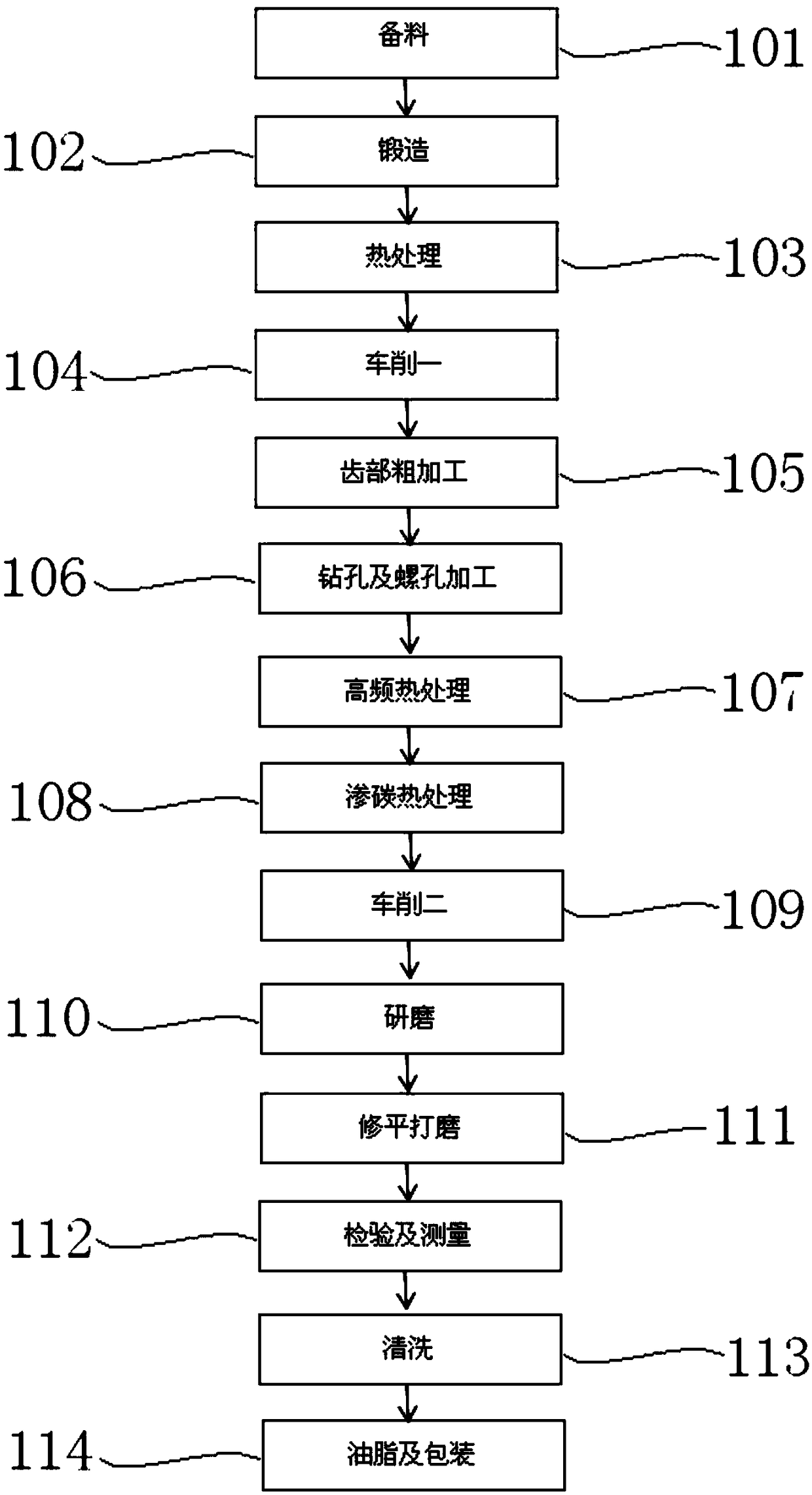

Processing technique of end teeth

The invention discloses a processing technique of end teeth, comprising the steps of 1, preparing a material; 2, forging; 3, carrying out thermal treatment; 4, carrying out turning I; 5, roughly machining teeth; 6, drilling, and machining screw holes; 7, carrying out high-frequency thermal treatment; 8, carrying out carburization thermal treatment; 9, carrying out turning II; 10, grinding; 11, flattening by dressing, and polishing; 12, inspecting, and measuring; 13, cleaning; 14, oiling, and packaging. Modifications are made herein in order to solve the problems that, for instance, end teeth processed by means of existing end tooth processing techniques are low in hardness, poor in wear resistance, prone to rusting, low in surface flatness, prone to causing noise during operating and shortin service life. The processing technique herein has the advantages that, for instance, end tooth hardness is improved, end tooth wear resistance is improved, corrosion resistance of end teeth is improved, surface flatness of end teeth is improved, the end teeth produce less noise during operating, and the end teeth have longer lives.

Owner:雄名航空科工(芜湖)股份有限公司

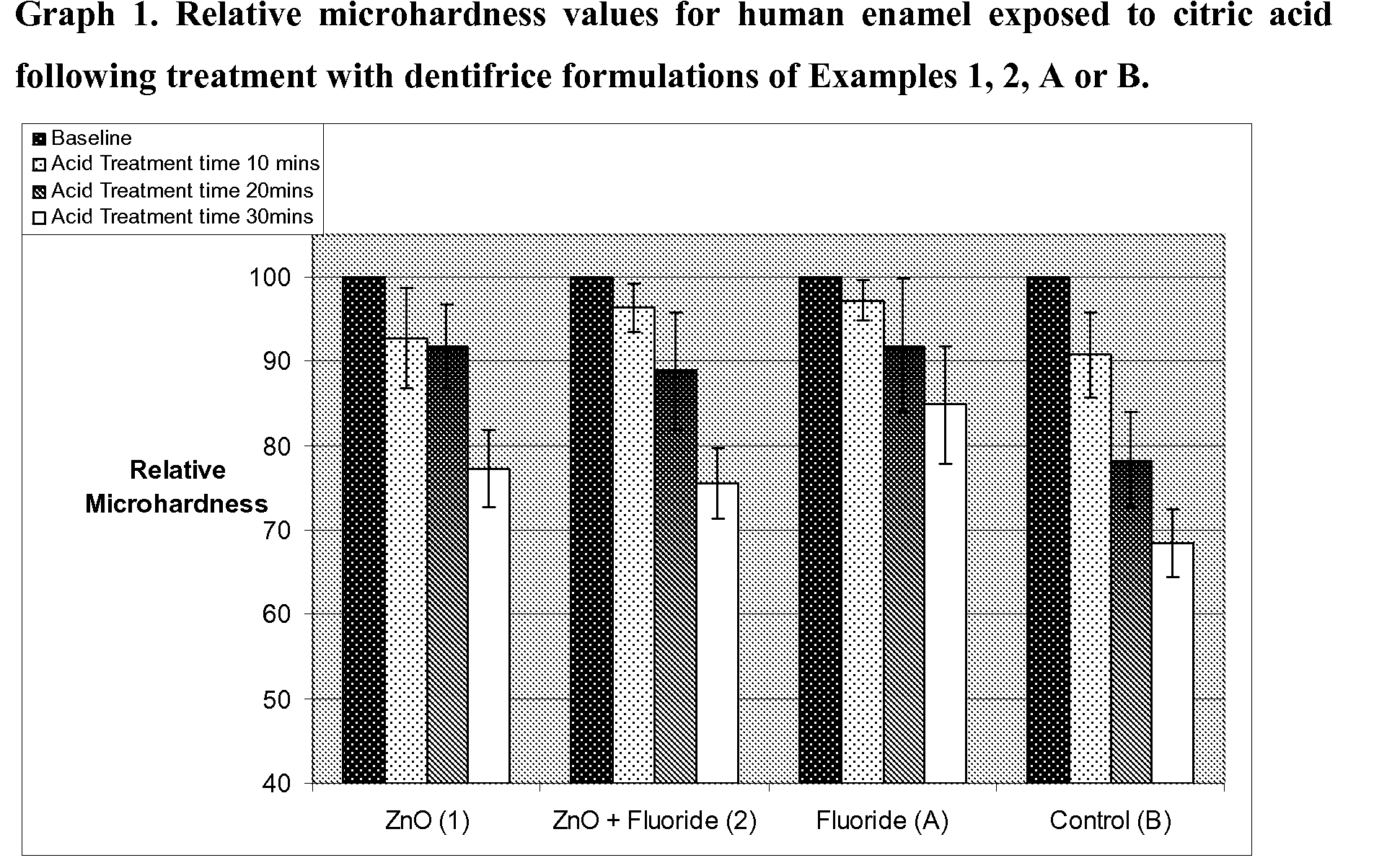

Novel use

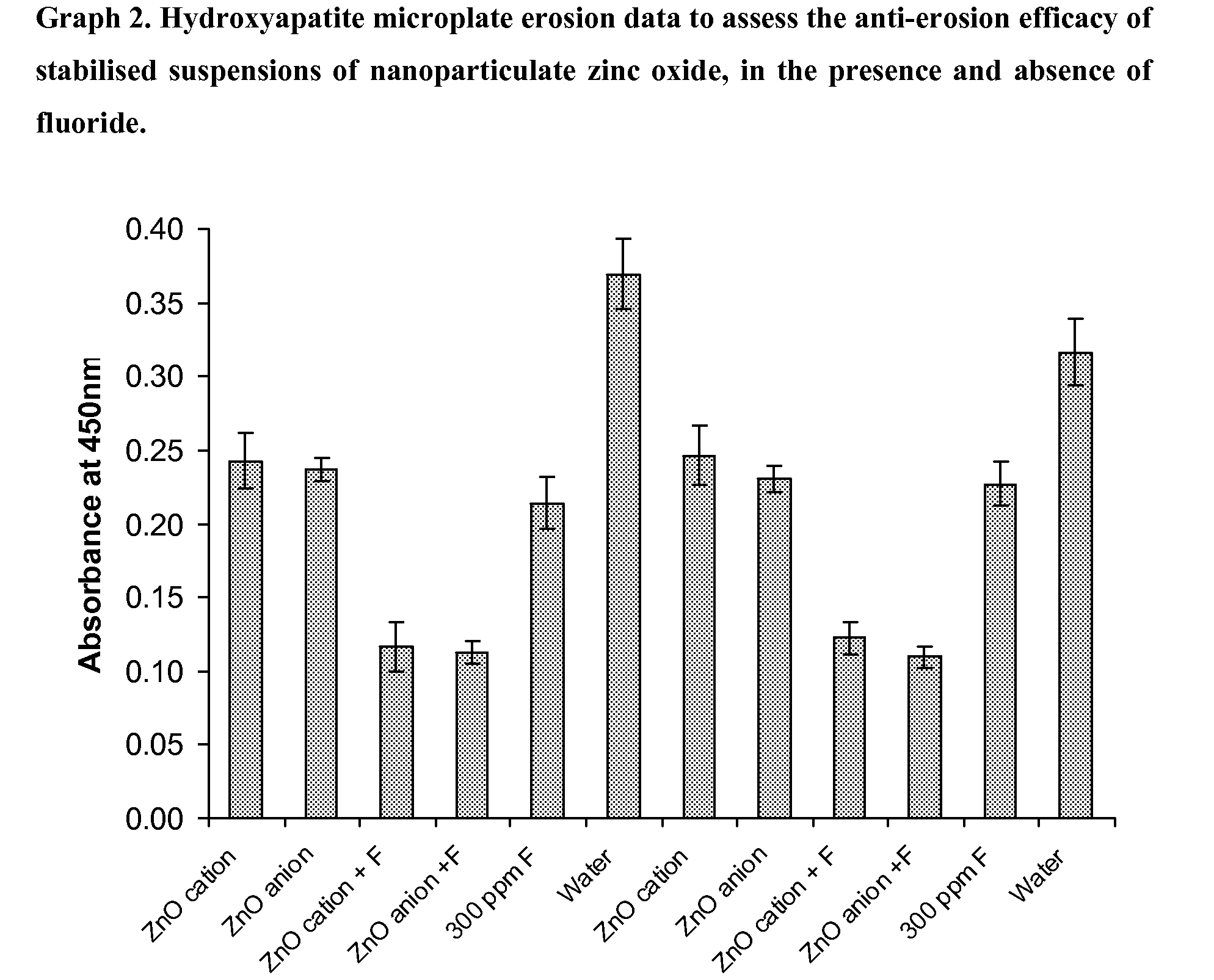

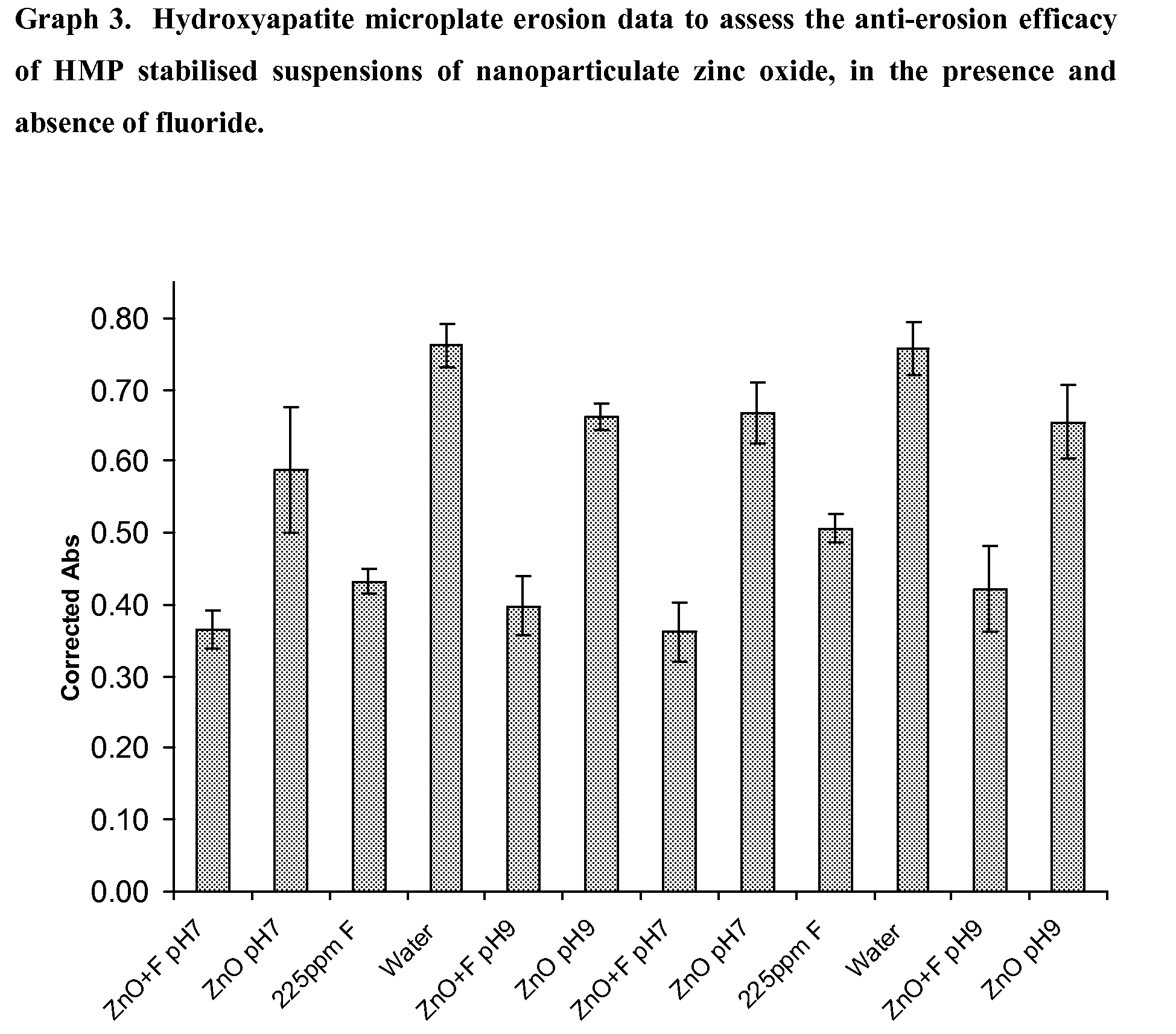

The use of an oral care composition comprising particulate zinc oxide (suitably in nanoparticulate form) optionally in the presence of a source of fluoride ions is described for combating dental erosion and / or tooth wear. Such compositions are also of use in combating dental caries.

Owner:FOWLER CHRISTABEL

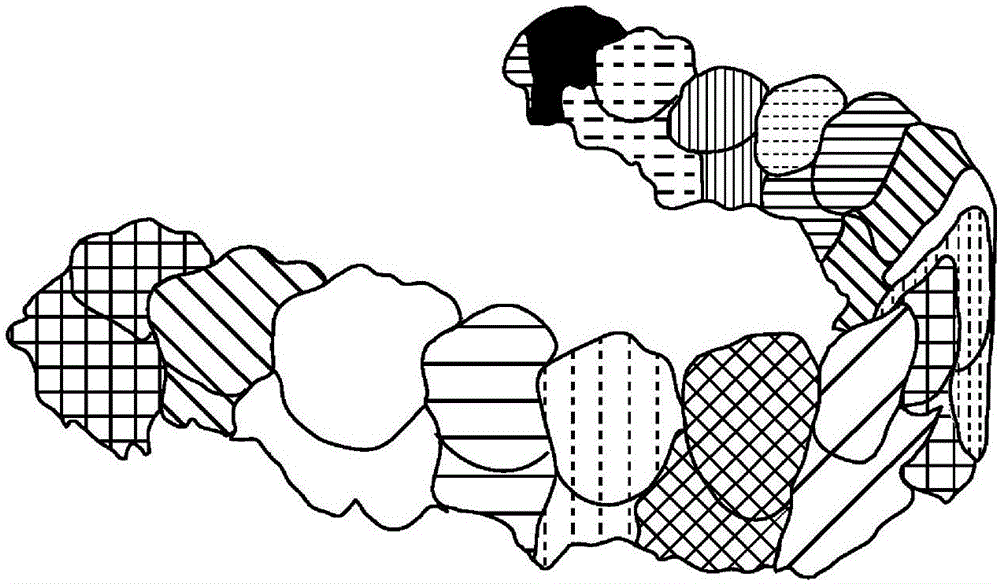

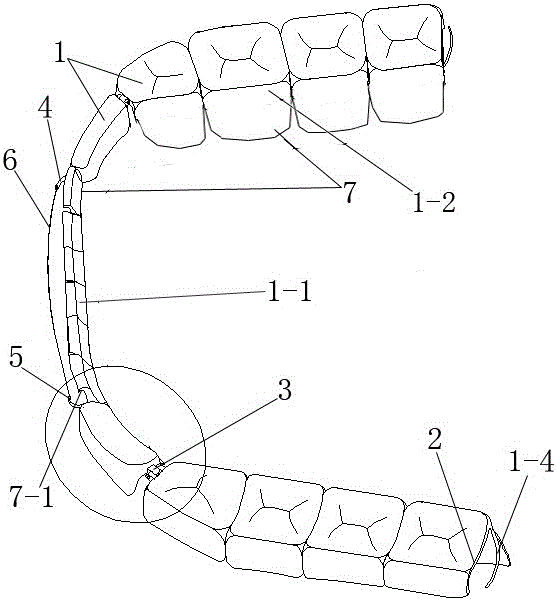

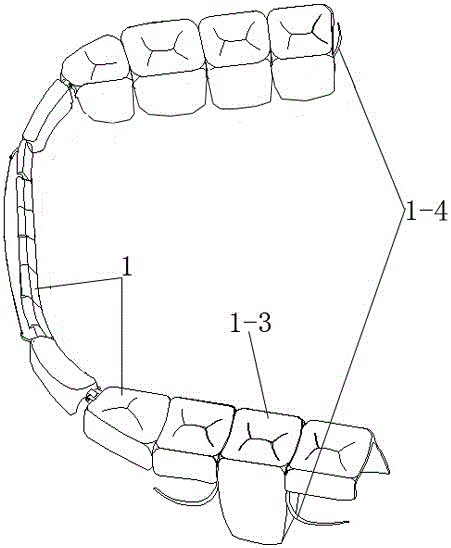

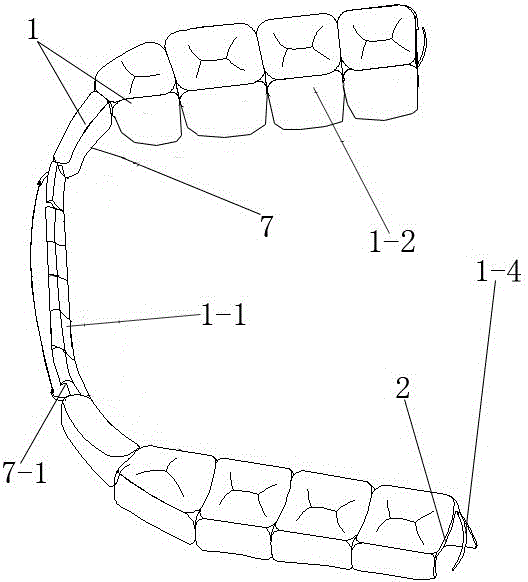

Track-chain type removable denture

The invention relates to track-chain type removable denture. The track-chain type removable denture comprises an upper jaw part and a lower jaw part, wherein the upper jaw part and the lower jaw part adopt the identical overall structure and can be independently used with the single upper jaw and the single lower jaw. The track-chain type removable denture is characterized in that occlusion surfaces of denture bodies of the upper jaw part and the lower jaw part are produced according to tooth occlusion records of a patient, preferably, produced after a therapeutic occlusion pad is used for occlusal reconstruction, the thicknesses of the denture bodies of the upper jaw part and the lower jaw part are increased by 2-4 mm between the upper jaw part and the lower jaw part according to the tooth occlusion records of the patient and increased by 1-2 mm when a single jaw is used. The structure is suitable for short-time wearing, that is, the structure is suitable for being worn during dining for chewing activity and can be cleaned and disinfected for storage after being used, a single person can manufacture the track-chain type removable denture in batches to facilitate use, and the track-chain type removable denture can be worn for a long time like conventional removable denture; the problems of loss of a few teeth, tooth wearing, hemodia, oral impaction and the like can be solved, the overall chewing function is recovered, and occlusal reconstruction is performed.

Owner:冯思田

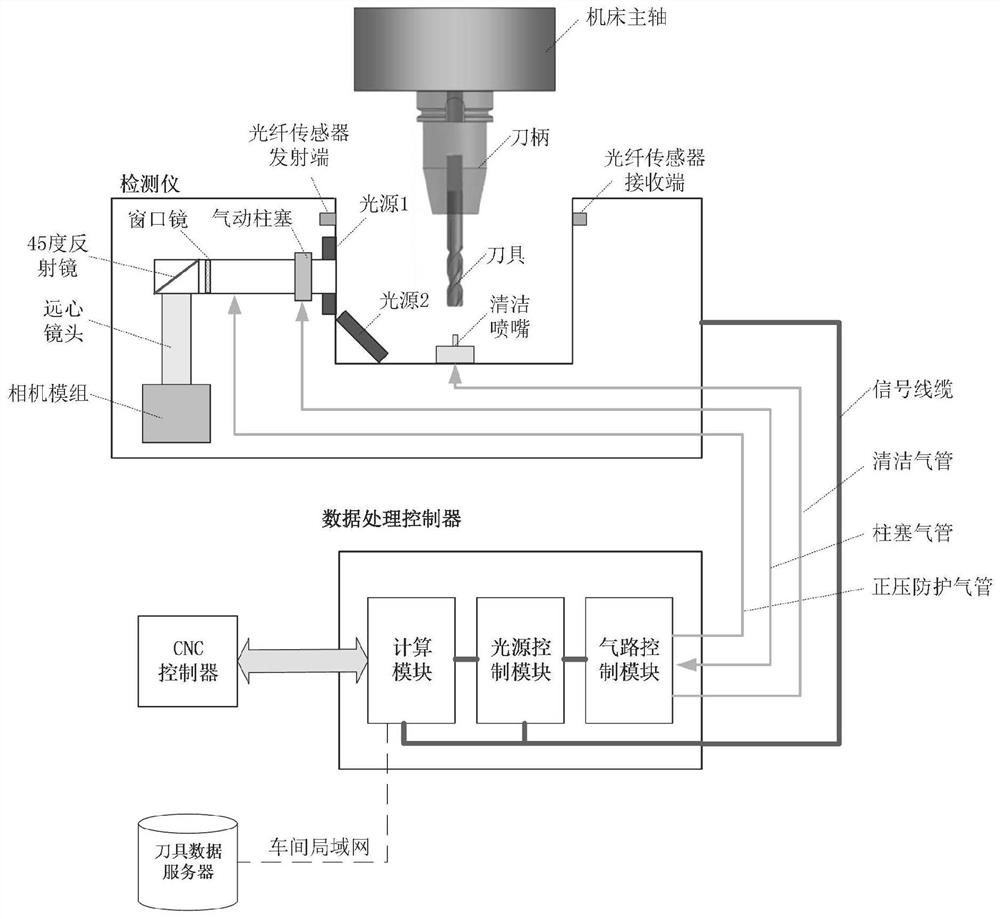

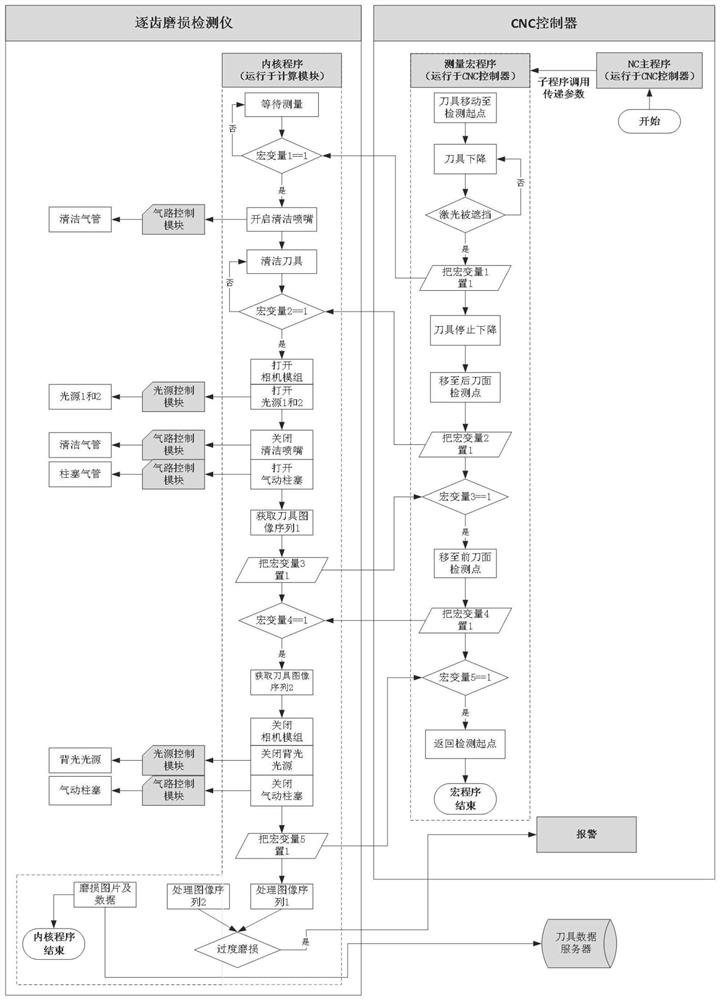

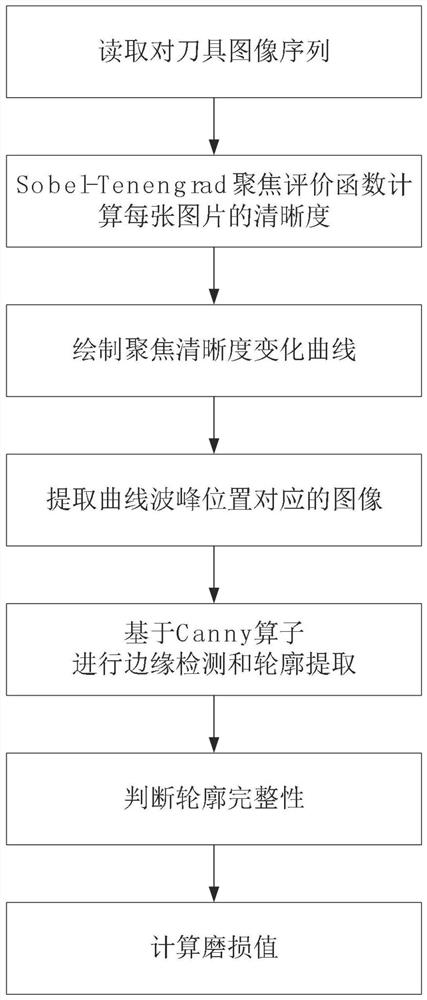

Rotary cutter front-back cutter face tooth-by-tooth wear detector and detection method

ActiveCN111774935AEfficient direct observationPrecise direct observationMeasurement/indication equipmentsNumerical controlTooth wear

The invention relates to a rotary cutter front-back cutter face tooth-by-tooth wear detector and detection method. The rotary cutter front-back cutter face tooth-by-tooth wear detector comprises a detector body, a data processing controller and a cutter data server, wherein the detector body and the data processing controller are connected by means of a signal cable, the data processing controlleris further connected to a CNC controller of a numerical control machine tool and the cutter data server, a 45-degree reflector, a telecentric lens, an inclined light source and a forward light sourceare arranged in the detector, a cutter image sequence is obtained in the rotation process of a cutter, the data processing controller performs 90-degree steering on an imaging optical path by using the 45-degree reflector, based on a gray-scale response detection principle, wear images of a front cutter face and a rear cutter face of the rotary cutter are directly acquired and analyzed directly in an on-machine mode tooth by tooth according to the cutter image sequence. The detector can be adopted to realize efficient and accurate direct observation of wear images of the front and rear cutterfaces of all cutter teeth in the rotating state.

Owner:SHANGHAI WALNUT PRECISION TECH CO LTD

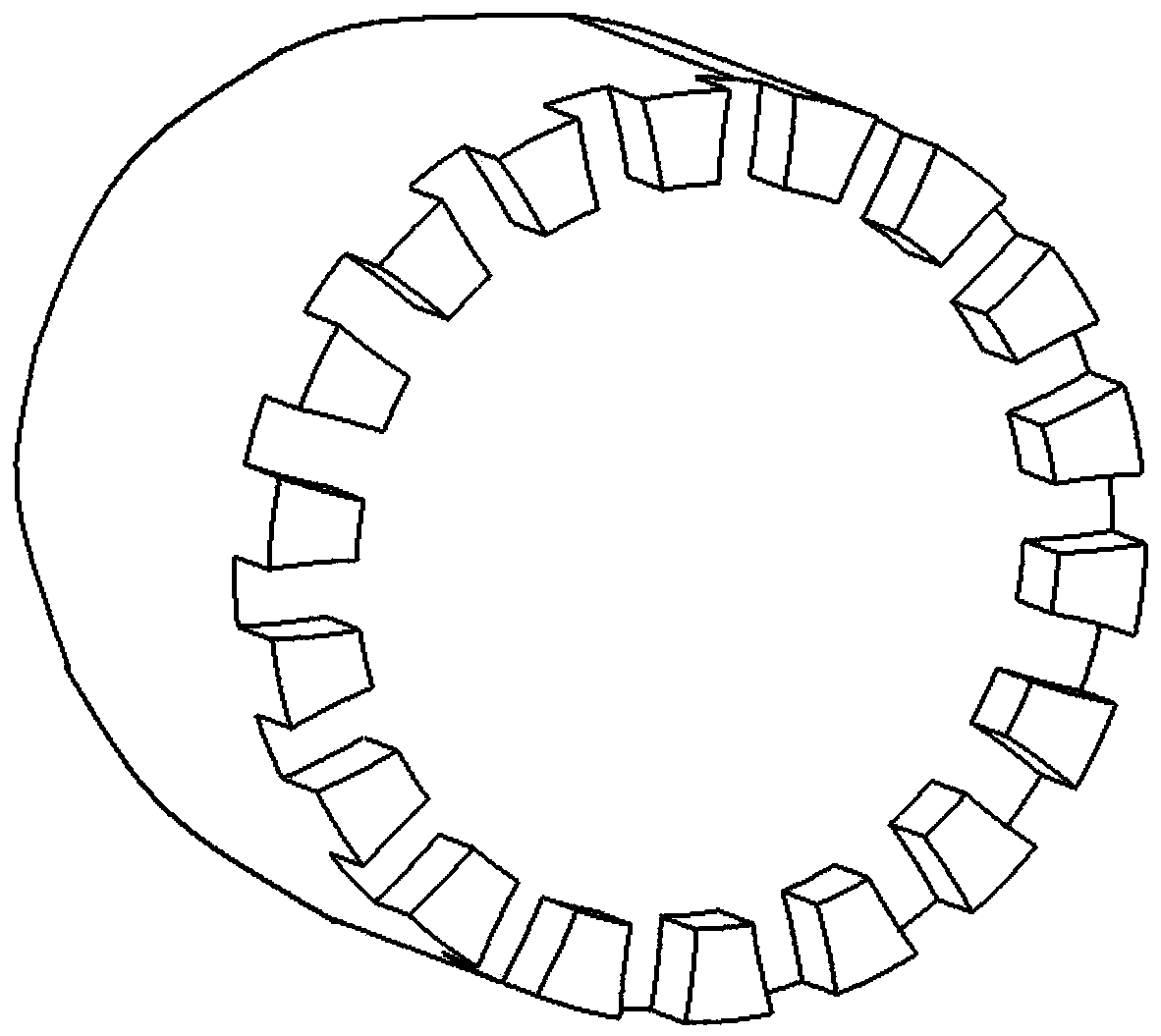

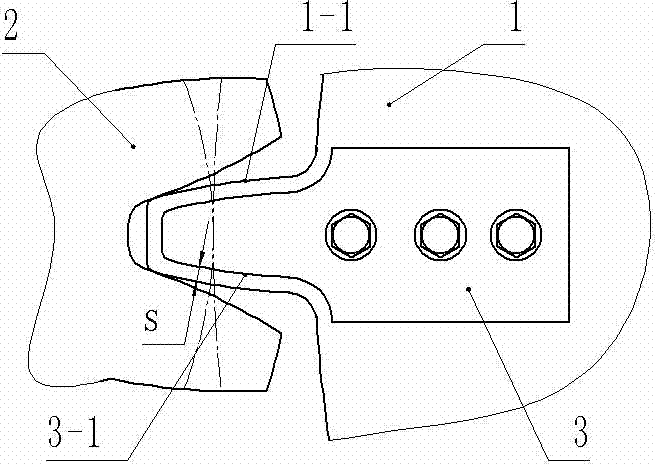

Outer tooth ring wear detection method

The present invention discloses an outer tooth ring wear detection method. An outer tooth ring wear detection device is used. The outer tooth ring wear detection device comprises a driving gear which is engaged with an outer tooth ring. The lower end of the driving gear extends out of the end face of the lower end of the outer tooth ring, and the lower end face of the outer tooth ring is provided with a detection tooth which is corresponding to one tooth of the outer tooth ring and extends into driving gear teeth. The method comprises the steps of (A) fixing the detection tooth to the lower end face of the outer tooth ring through a bolt such that the wear value S of the outer tooth profile surface of the detection tooth is reduced relative to the outer tooth profile surface of one tooth of the outer tooth ring, and (B) checking the outer tooth profile surface of the detection tooth regularly, wherein the outer tooth profile surface of the outer tooth ring reaches an outer tooth ring replacement period when the outer tooth profile surface has a scratch. Compared with the prior art, the problem that the tooth wear on an existing outer tooth ring can not be detected can be solved.

Owner:GUANGXI WUZHOU YUNLONG PORT & SHIP MACHINERY MFG

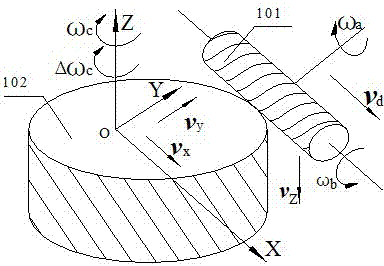

Seven-shaft and six-linkage opposite angle roll cutting method for non-circular gear

The invention belongs to the field of numerical control machining of gears and relates to a seven-shaft and six-linkage opposite angle roll cutting method for a non-circular gear. In the implementation process of the method, three fundamental frequency shafts, another three shafts linked with the three fundamental frequency shafts and an independent numerical control shaft are applied; a hobbing cutter also continuously moves along the axis of the hobbing cutter while vertically feeding; and a linkage mathematical model is disclosed. According to the seven-shaft and six-linkage opposite angle roll cutting method disclosed by the invention, all blades of the hobbing cutter can be fully and effectively utilized; cutter tooth wear is uniformly distributed; the durability of the cutter is improved; the tooth profile shape precision and the surface roughness can be improved; and the independent numerical control shaft can automatically adjust a mounting angel of the hobbing cutter, and compared with a mechanical structure, the independent numerical control shaft has the advantages of higher automatic degree, higher adjustment precision and lower labor intensity of workers. The seven-shaft and six-linkage opposite angle roll cutting method disclosed by the invention can be used for numerical control gear hobbing of non-circular spur gears, non-circular helical gears, elliptical spur gears and elliptical helical gears.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Implant upper part repair pre-bonded abutment replica and preparation method thereof

The invention discloses an implant upper part repair pre-bonded abutment replica and a preparation method thereof. The implant upper part repair pre-bonded abutment replica comprises an implant upperpart repair body and a pre-bonded abutment replica inserted into the implant upper part repair body; the pre-bonded abutment replica comprises a steel nail and a resin abutment replica formed at one end of the steel nail; the end, fixedly provided with the resin abutment replica, of the steel nail is a fixed end, the end, away from the resin abutment replica, of the steel nail is a clamping end, and a mark is arranged at the clamping end; and the resin abutment replica comprises an embedding part and a sealing part. An abutment in the mouth of a patient can be simulated outside the mouth of the patient through the pre-bonded abutment replica, so that redundant adhesive can be effectively cleaned outside the mouth of the patient, cleaning operation of the adhesive is changed from intraoraloperation to extraoral operation, the tooth wearing time of a doctor is shortened, the mouth opening time and pain of the patient are reduced, a series of complications such as inflammation and feverof the oral cavity of the patient due to the fact that the adhesive is not completely cleaned can be avoided, and the health of the patient is protected.

Owner:美尚(广州)医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com