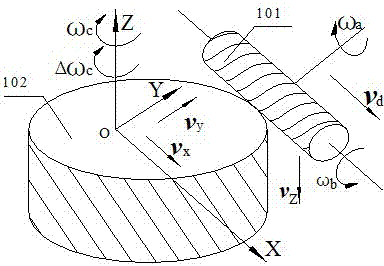

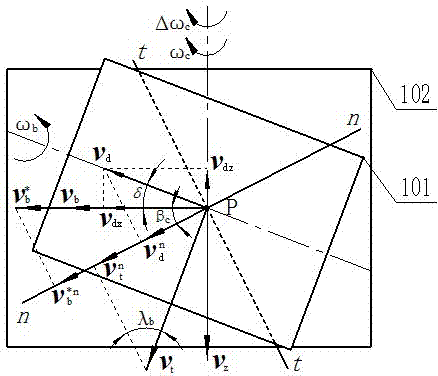

Seven-shaft and six-linkage opposite angle roll cutting method for non-circular gear

A technology of non-circular gear and hobbing method, applied in the direction of belt/chain/gear, gear teeth, elements with teeth, etc., can solve the problem of non-circular gear hobbing and other problems that have not been seen, achieve low labor intensity, The effect of improving tool durability and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is the working condition of AIi, direction of It complies with the right-handed spiral rule, hobbing non-circular left-handed helical gears, using left-handed hobs. The linkage mathematical model in this example is:

[0025] .

Embodiment 2

[0027] This embodiment is the working condition of AIⅡ, direction of It complies with the right-handed spiral rule, hobbing non-circular right-handed helical gears, using left-handed hobs. The linkage mathematical model is:

[0028] .

Embodiment 3

[0030] This embodiment is the AIIi working condition, direction of In accordance with the left-handed spiral rule, the non-circular left-handed helical gear is hobbed and left-handed, and the left-handed hob is used. The linkage mathematical model is:

[0031] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com