Variable case depth powder metal gear and method thereof

A surface carburizing, powder metal technology, applied in gear transmissions, belts/chains/gears, elements with teeth, etc., which can solve problems such as no indication or hint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

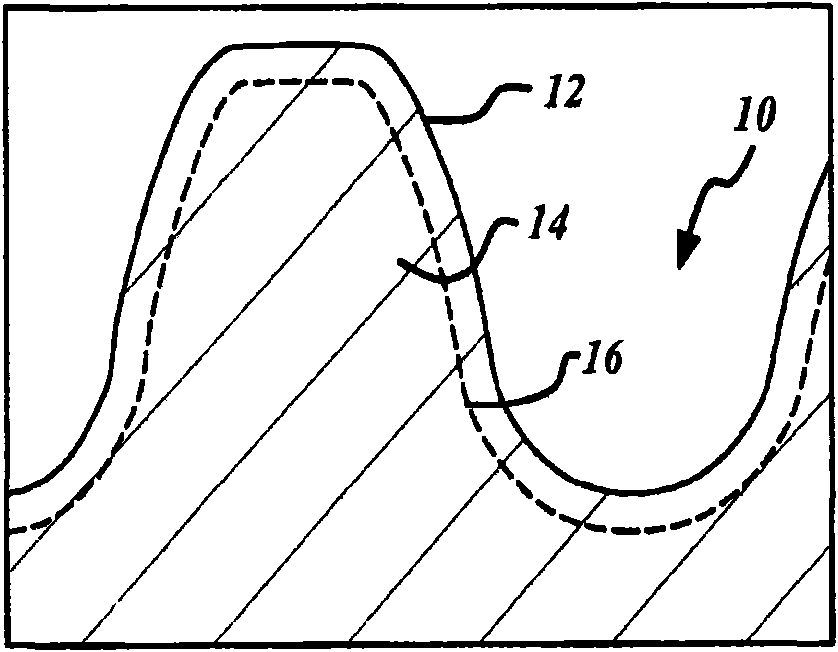

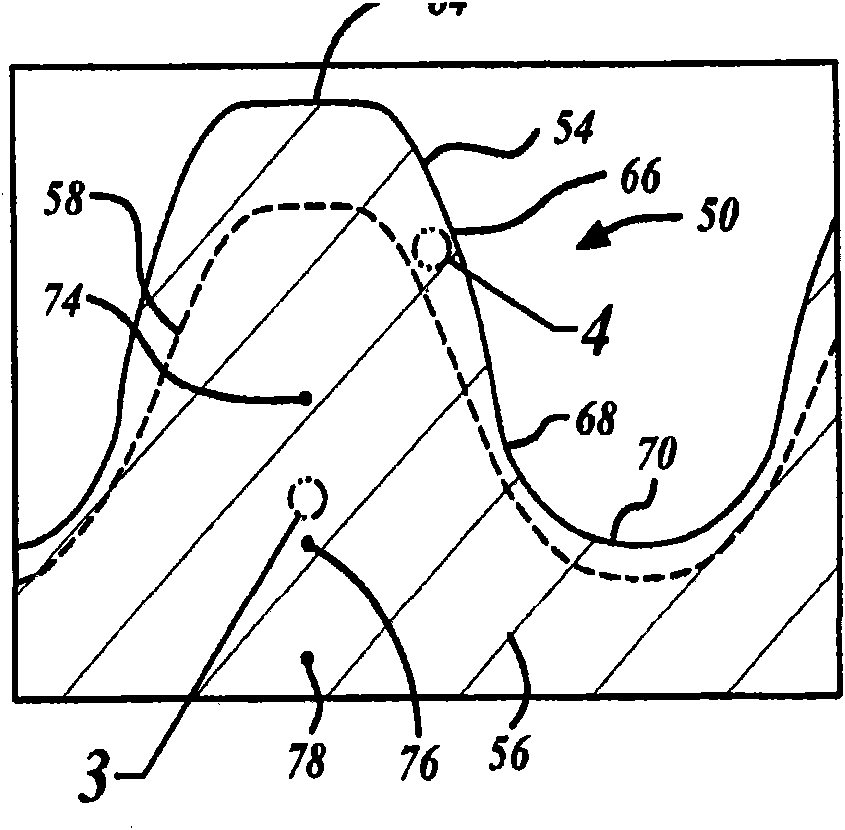

[0017] In all figures, the same reference numerals are used to designate the same parts in each figure. Therefore, it is appropriate to refer to the respective figures at the same time. In some instances, equivalent parts in different figures may have different reference numerals for clarity.

[0018] figure 2 A partial cross-sectional view of the first differential side gear 50 having a variable case depth profile 58 is shown in accordance with an embodiment of the present invention. Figure 7 It shows that according to an embodiment of the present invention, by Figure 6 made of preform 85, figure 2 A perspective view of the first differential side gear 50 of FIG.

[0019] The first differential side gear 50 includes a plurality of teeth 52 and a variable case depth profile 58 . Each tooth of the plurality of teeth 52 has a first surface 54 and a tooth core or root 56 . The first differential side gear 50 has an axis of rotation 60 wherein the teeth 52 extend radially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com