Patents

Literature

175 results about "Brinelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brinelling /ˈbrɪnəlɪŋ/ is the permanent indentation of a hard surface. It is named after the Brinell scale of hardness, in which a small ball is pushed against a hard surface at a preset level of force, and the depth and diameter of the mark indicates the Brinell hardness of the surface. Brinelling is a process of wear in which similar marks are pressed into the surface of a moving part, such as bearings or hydraulic pistons. The brinelling is usually undesirable, as the parts often mate with other parts in very close proximity. The very small indentations can quickly lead to improper operation, like chattering or excess vibration, which in turn can accelerate other forms of wear, such as spalling and galling.

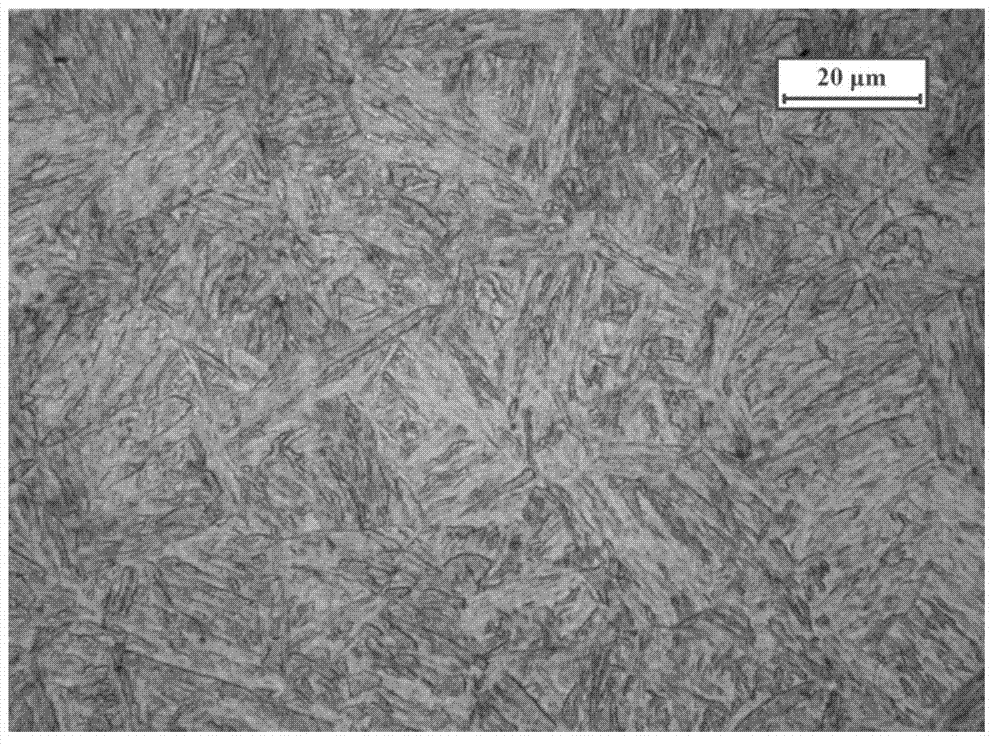

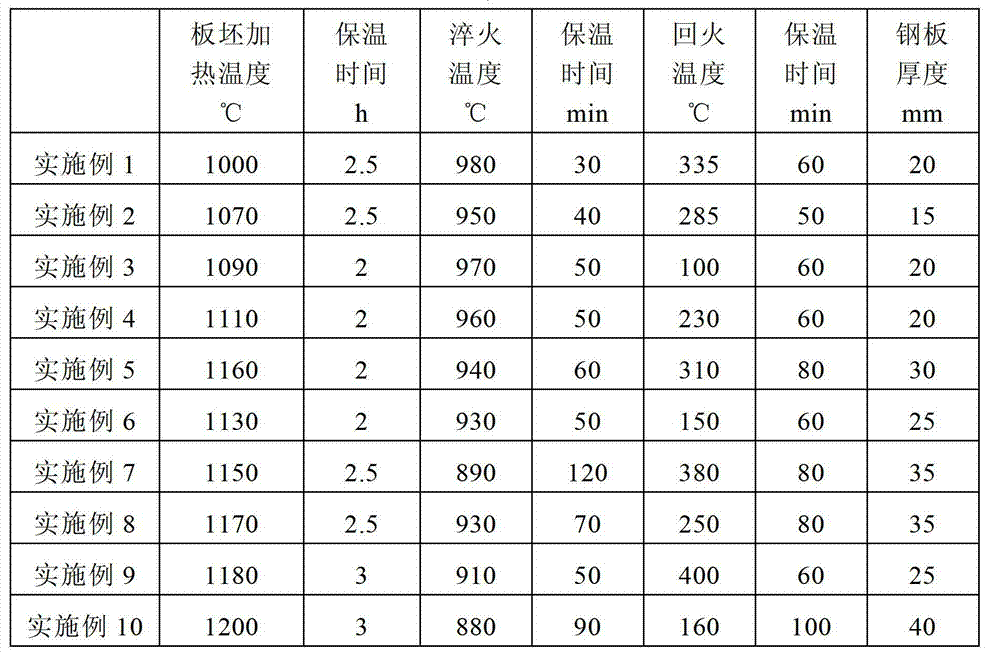

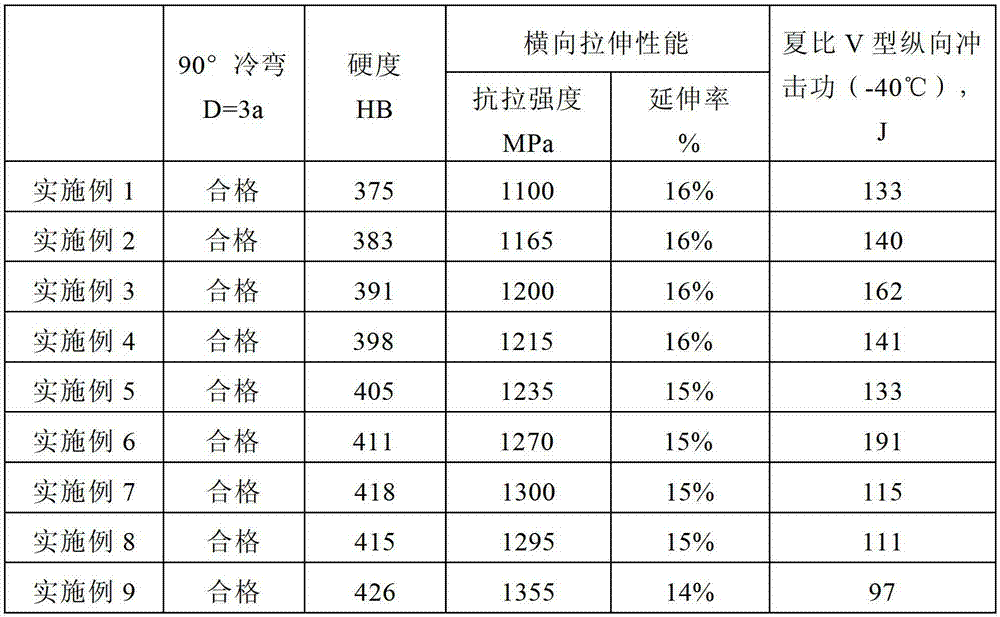

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

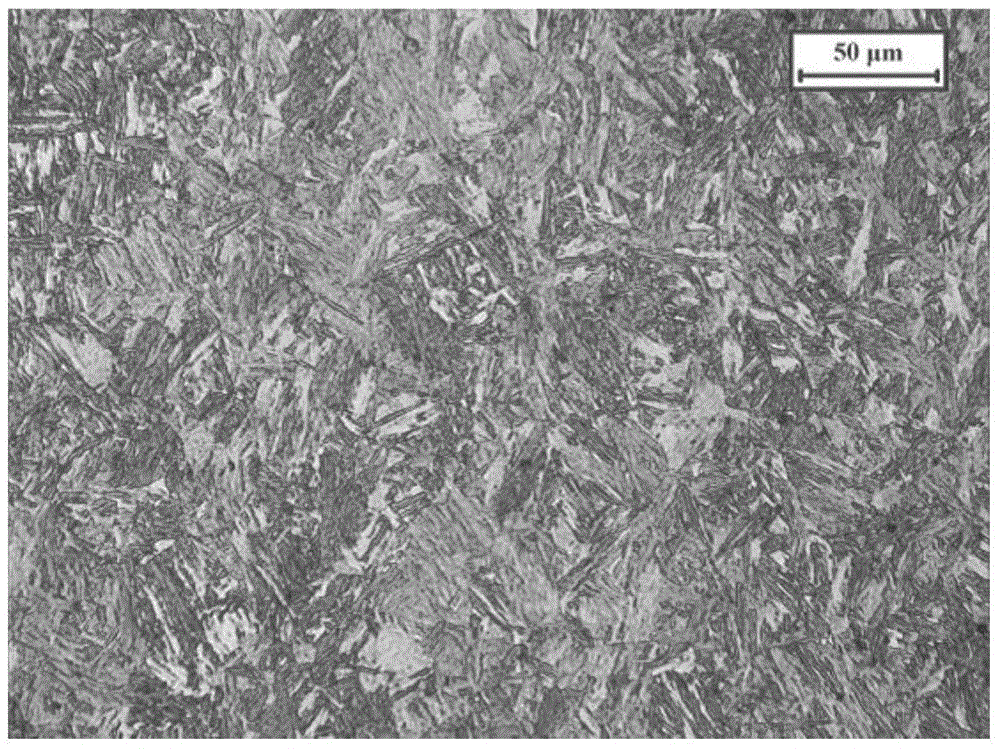

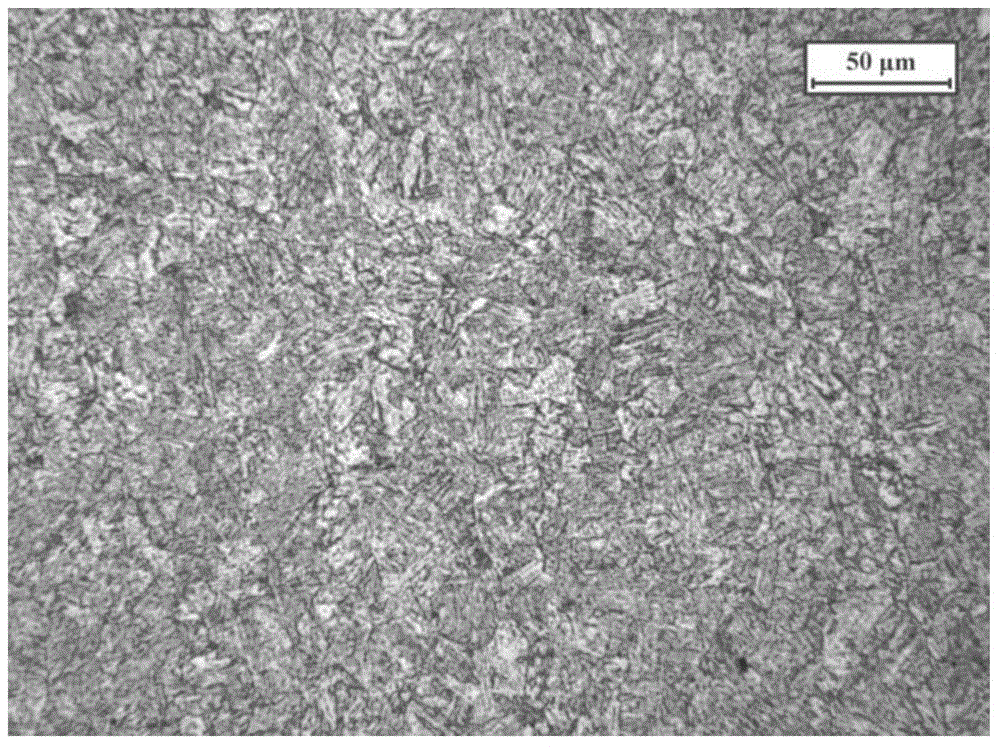

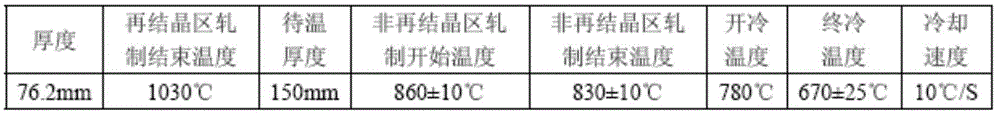

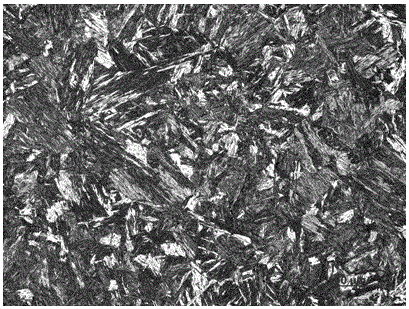

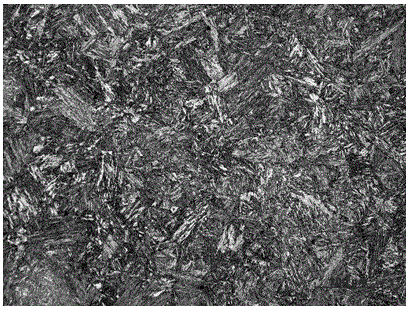

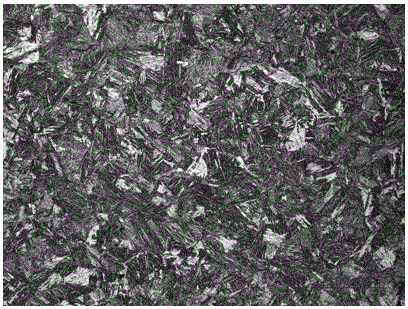

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

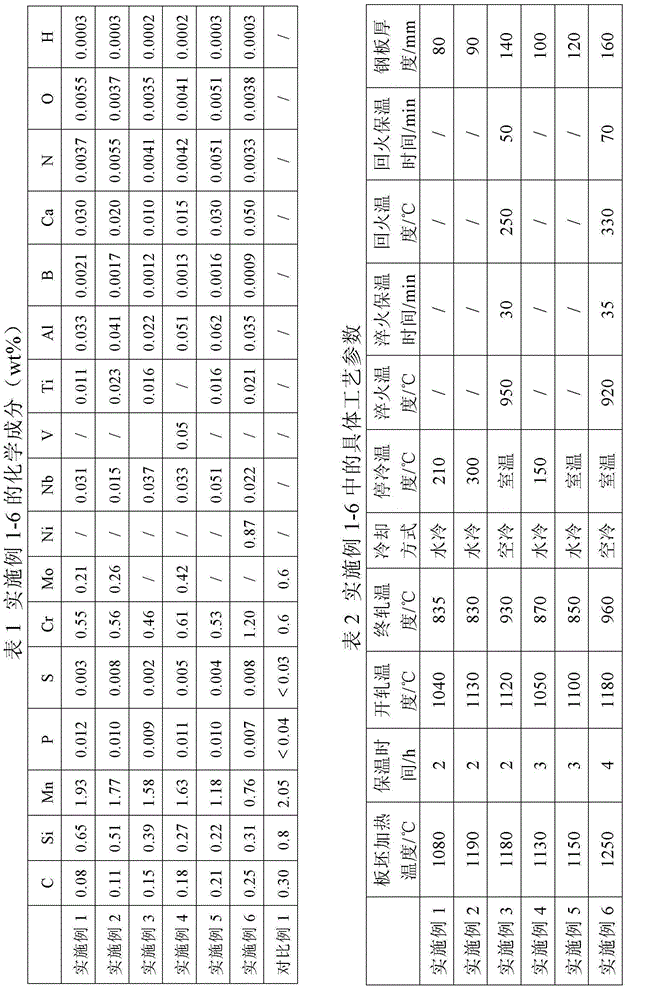

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

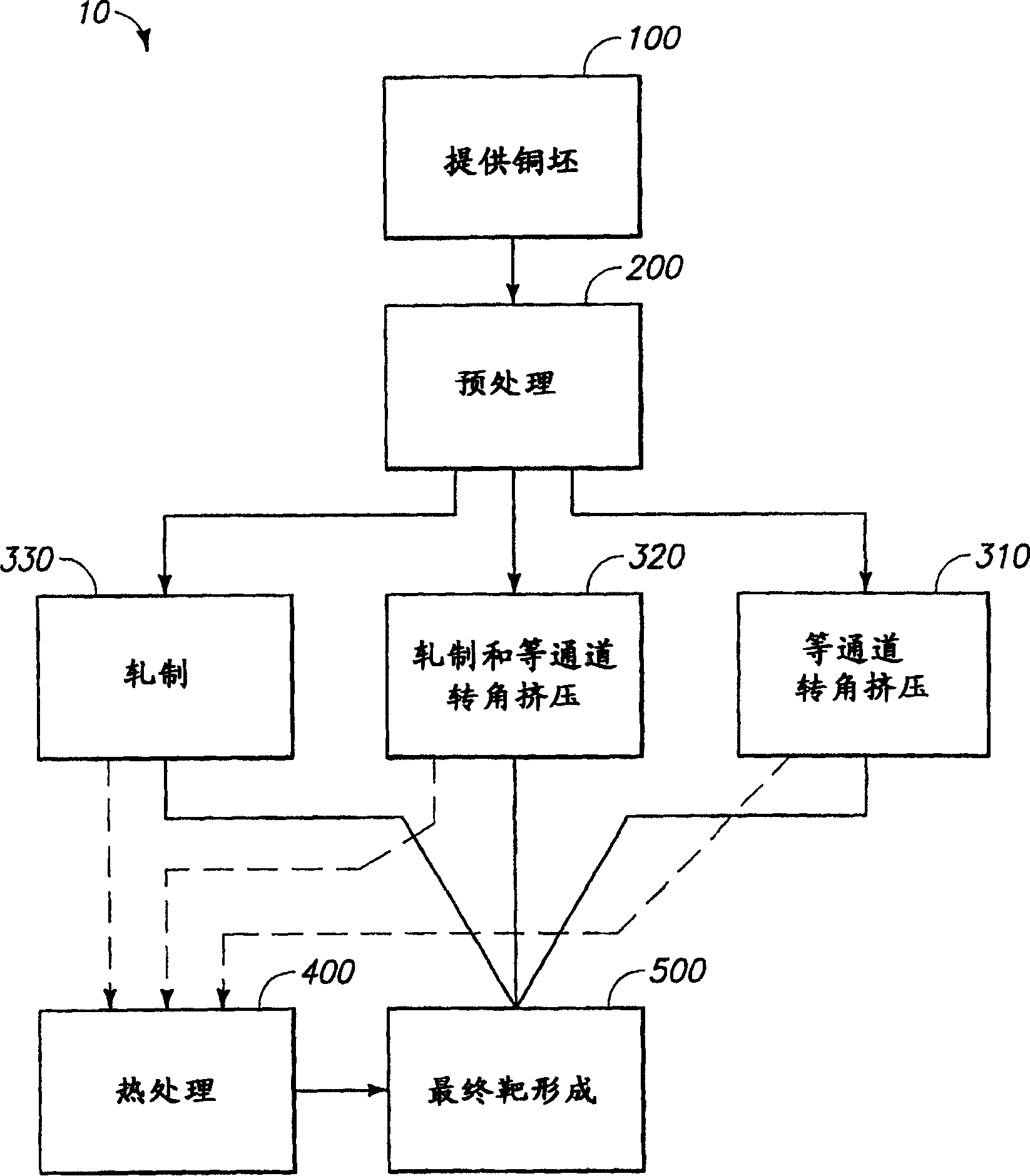

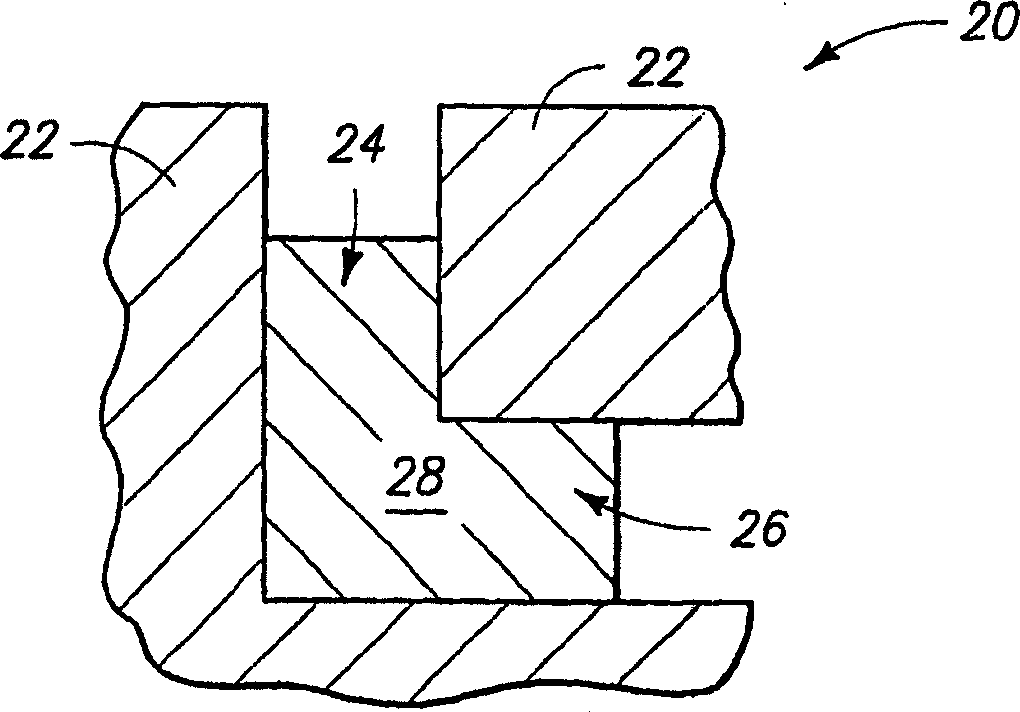

Copper sputtering targets and methods of forming copper sputtering targets

The invention includes a copper-comprising sputtering target. The target is monolithic or bonded and contains at least 99.99% copper by weight and has an average grain size of from 1 micron to 50 microns. The copper-comprising target has a yield strength of greater than or equal to about 15 ksi and a Brinell hardness (HB) of greater than about 40. The invention includes copper alloy monolithic and bonded sputtering targets consisting essentially of less than or equal to about 99.99% copper by weight and a total amount of alloying element(s) of at least 100 ppm and less than 10% by weight. The targets have an average grain size of from less than 1 micron to 50 microns and have a grain size non-uniformity of less than about 15% standard deviation (1-sigma) throughout the target. The invention additionally includes methods of producing bonded and monolithic copper and copper alloy targets.

Owner:HONEYWELL INT INC

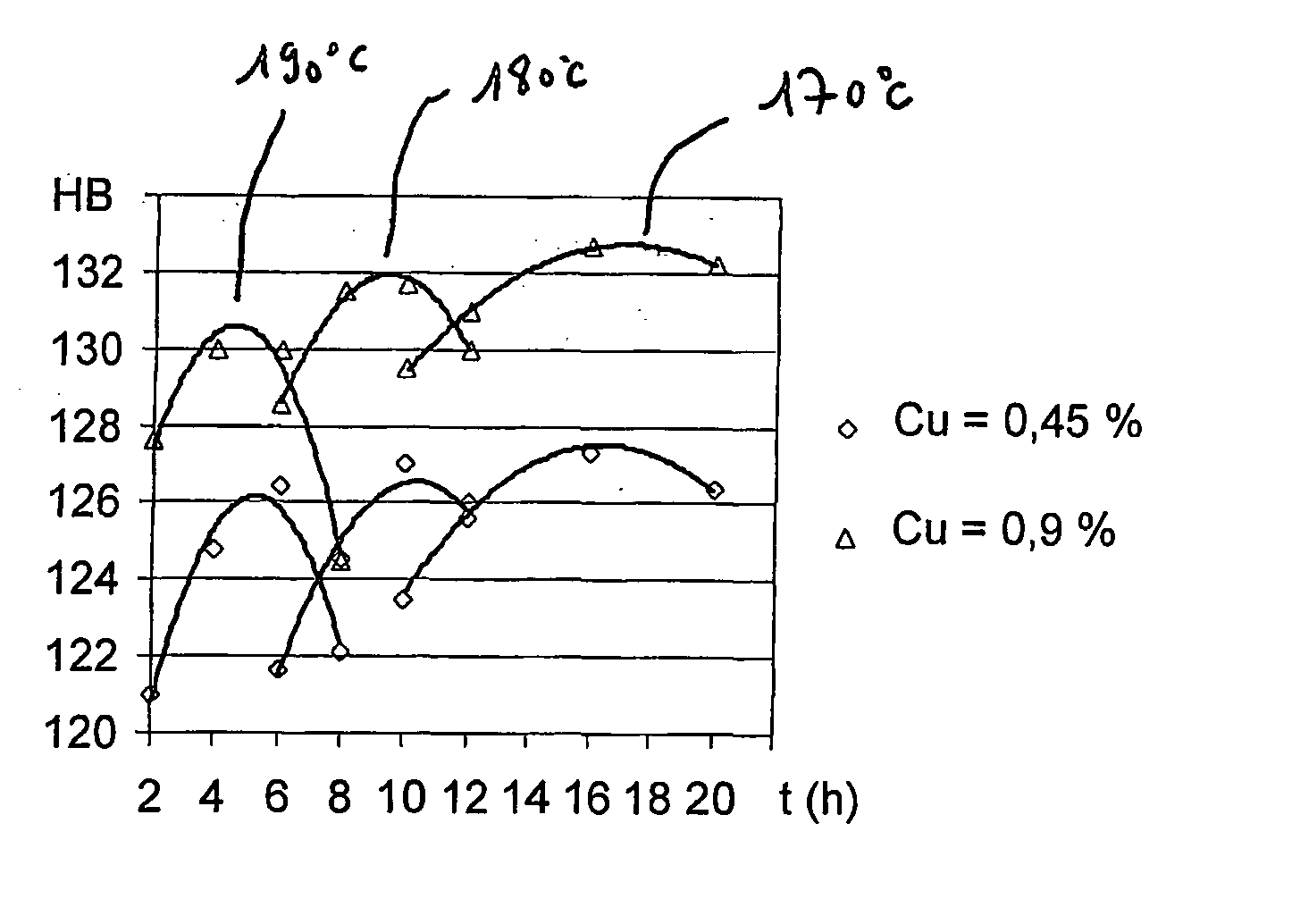

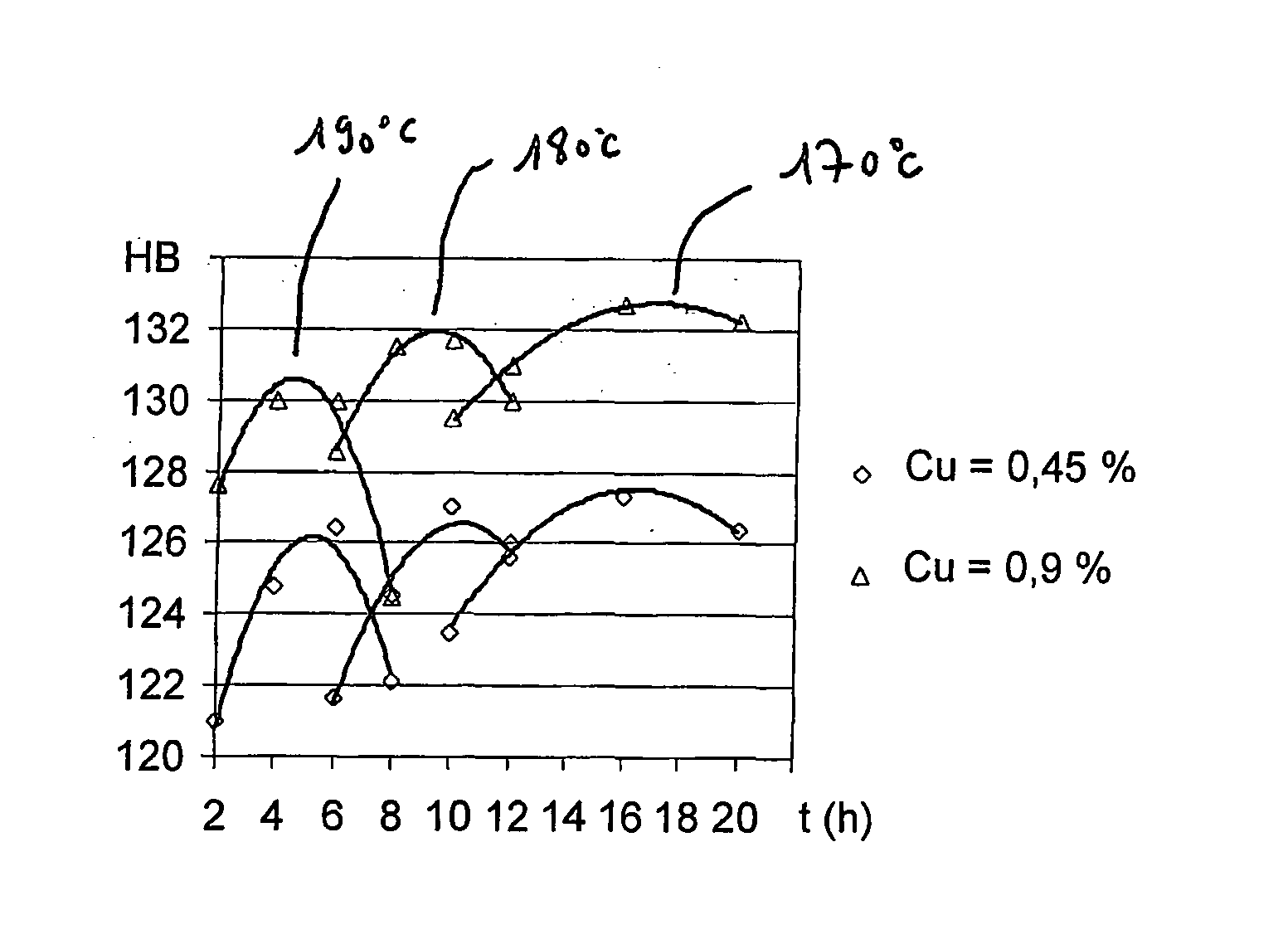

Safety component moulded in a1-si alloy

The invention concerns a safety component with high mechanical strength and good ductility, moulded in Al-Si alloy consisting (in wt. %) of: Si: 2-11; Mg: 0.3-0.7; Cu: 0.3 0.9; other elements <1 each and <2 in total, the rest being aluminium, and solution heat treated, tempered and hardened resulting in Brinell hardness of more than 125. The invention also concerns a safety component with high mechanical resistance and good ductility, moulded in Al-Si alloy consisting (in wt. %) of: Si: 2-6; Mg: 0.3-0.7; Fe <0.20; other elements <0.3 each and <1 in total; the rest being aluminium; solution heat treated, hardened and tempered resulting in a quality index Q=Rm+log A>485 MPa.

Owner:ALUMINUM PECHINEY

Universal testing machine

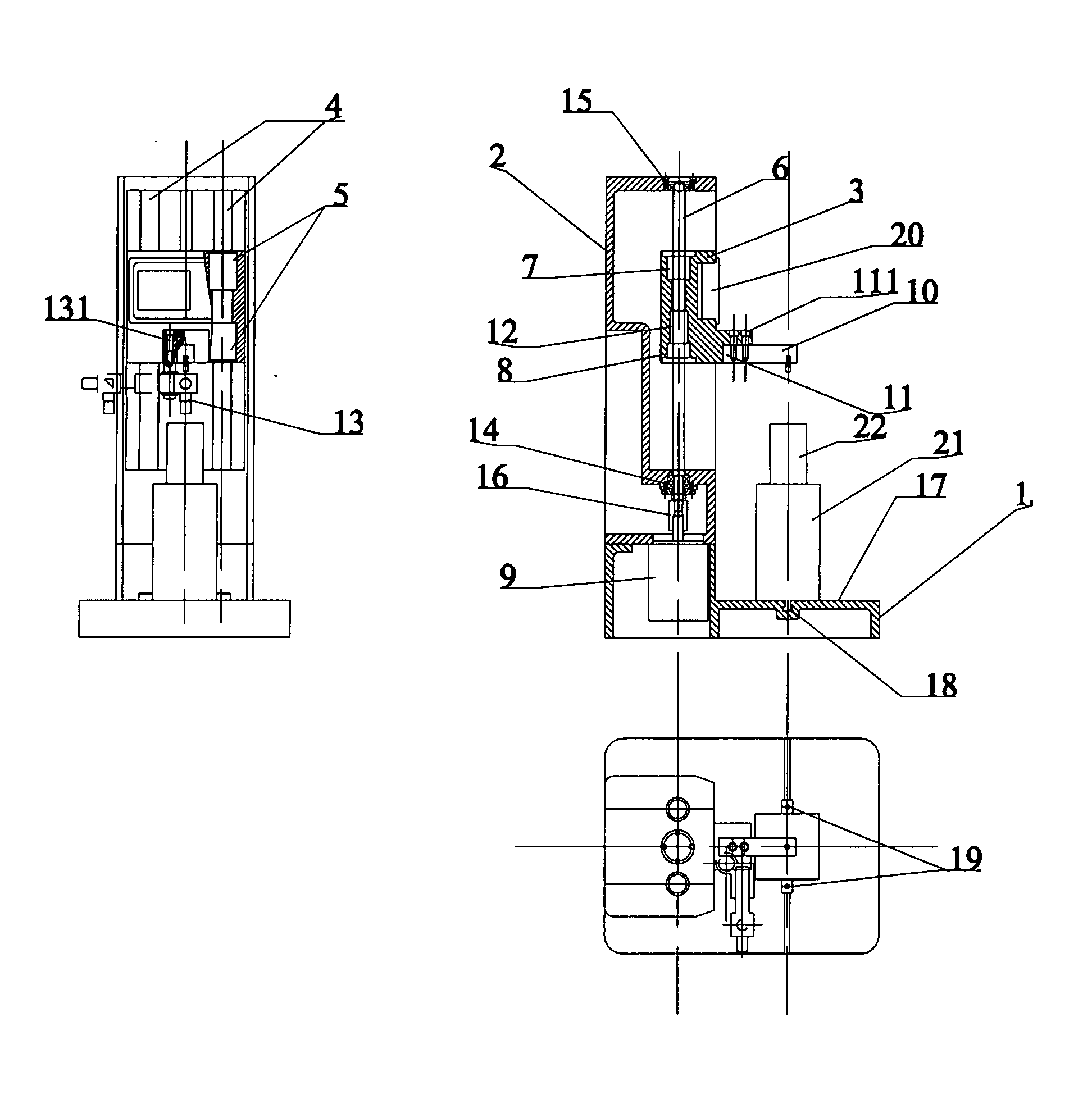

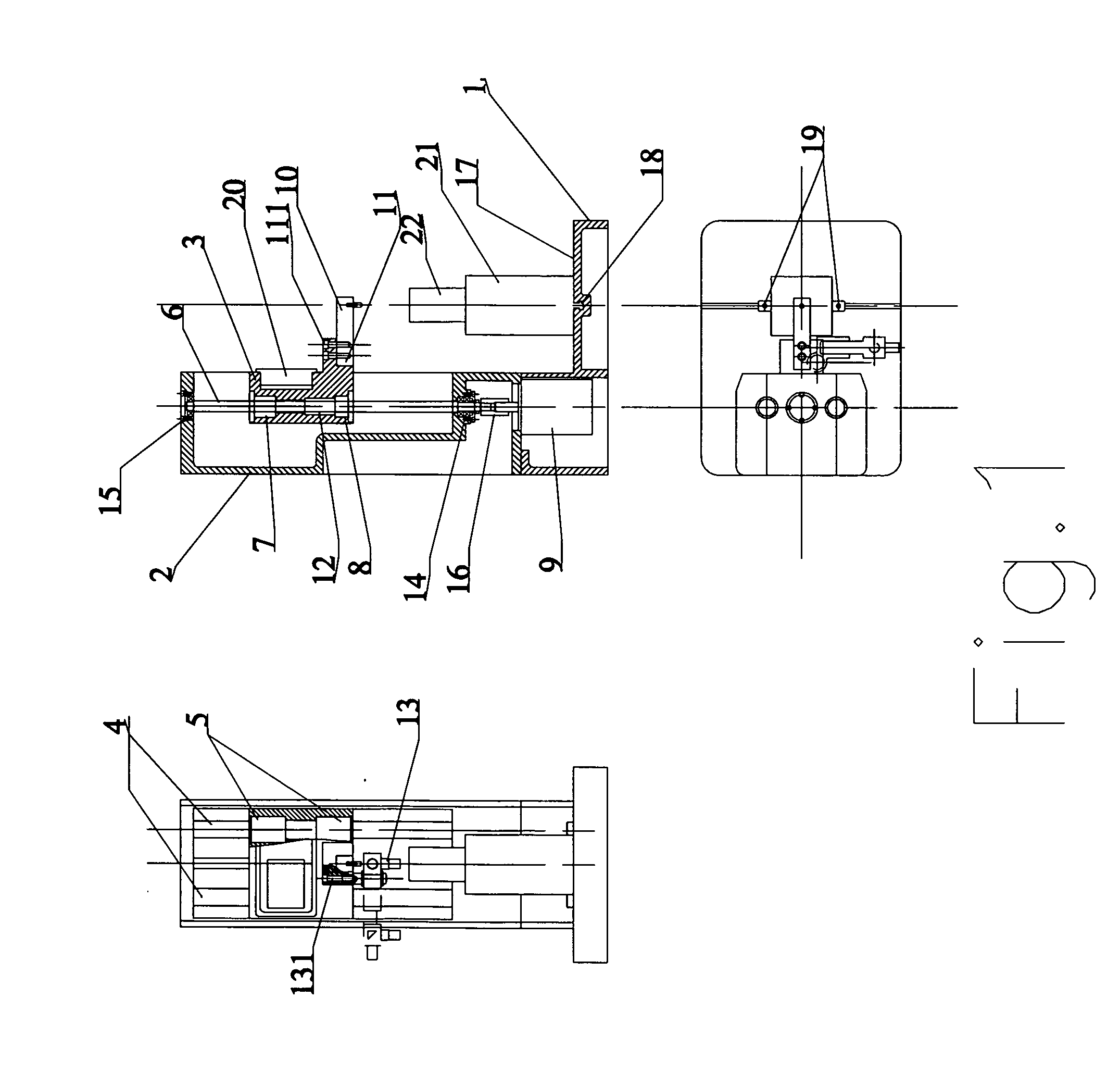

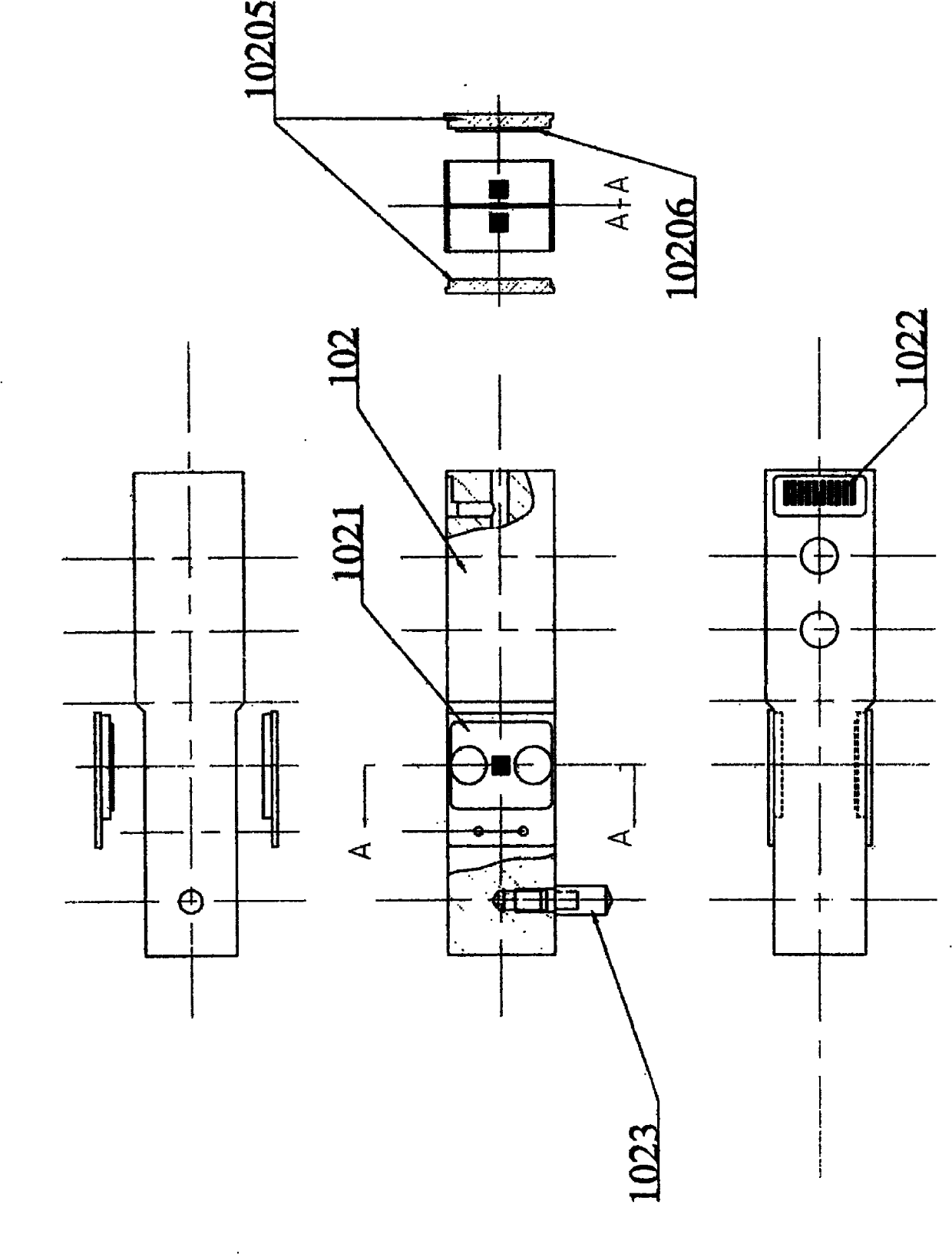

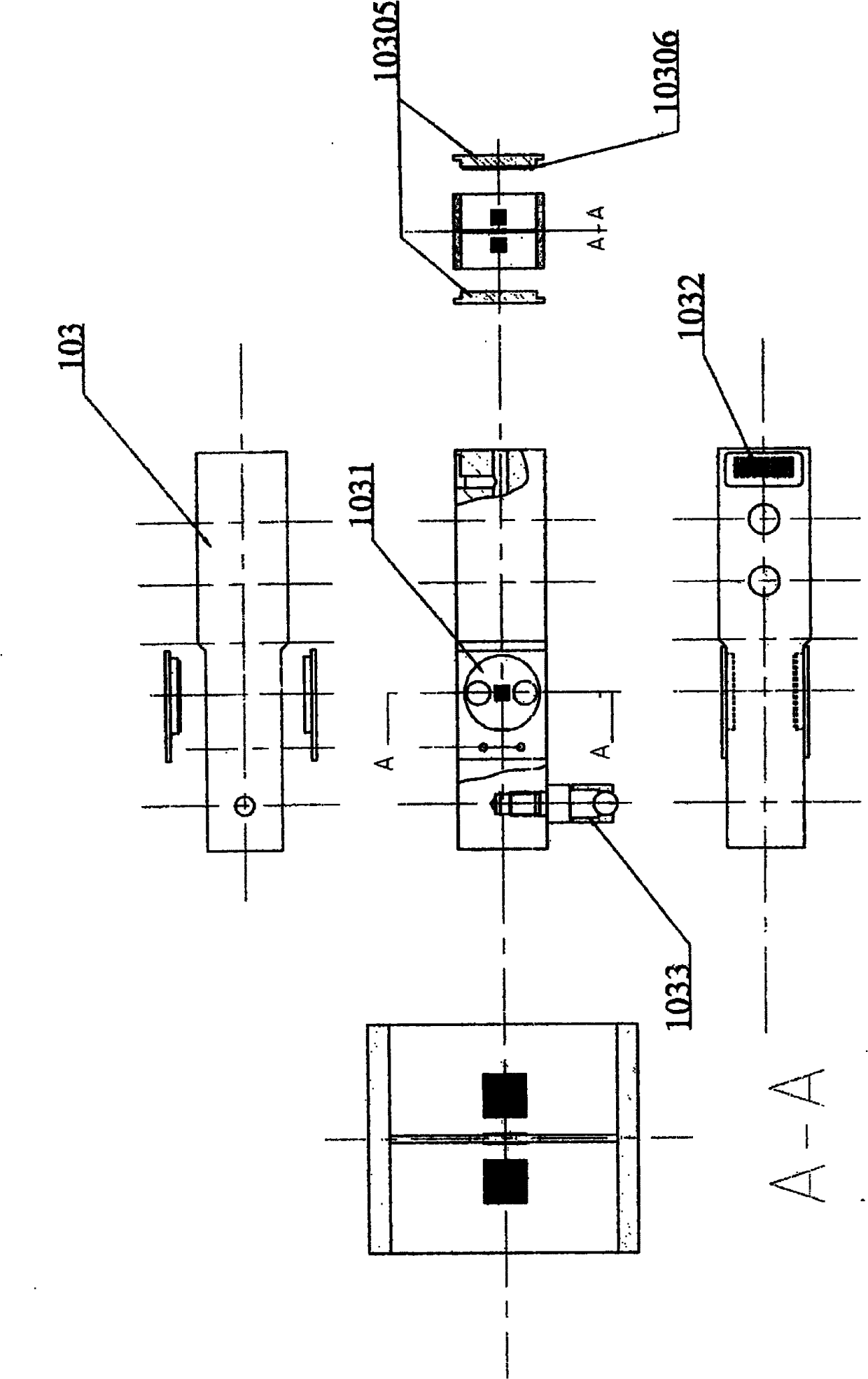

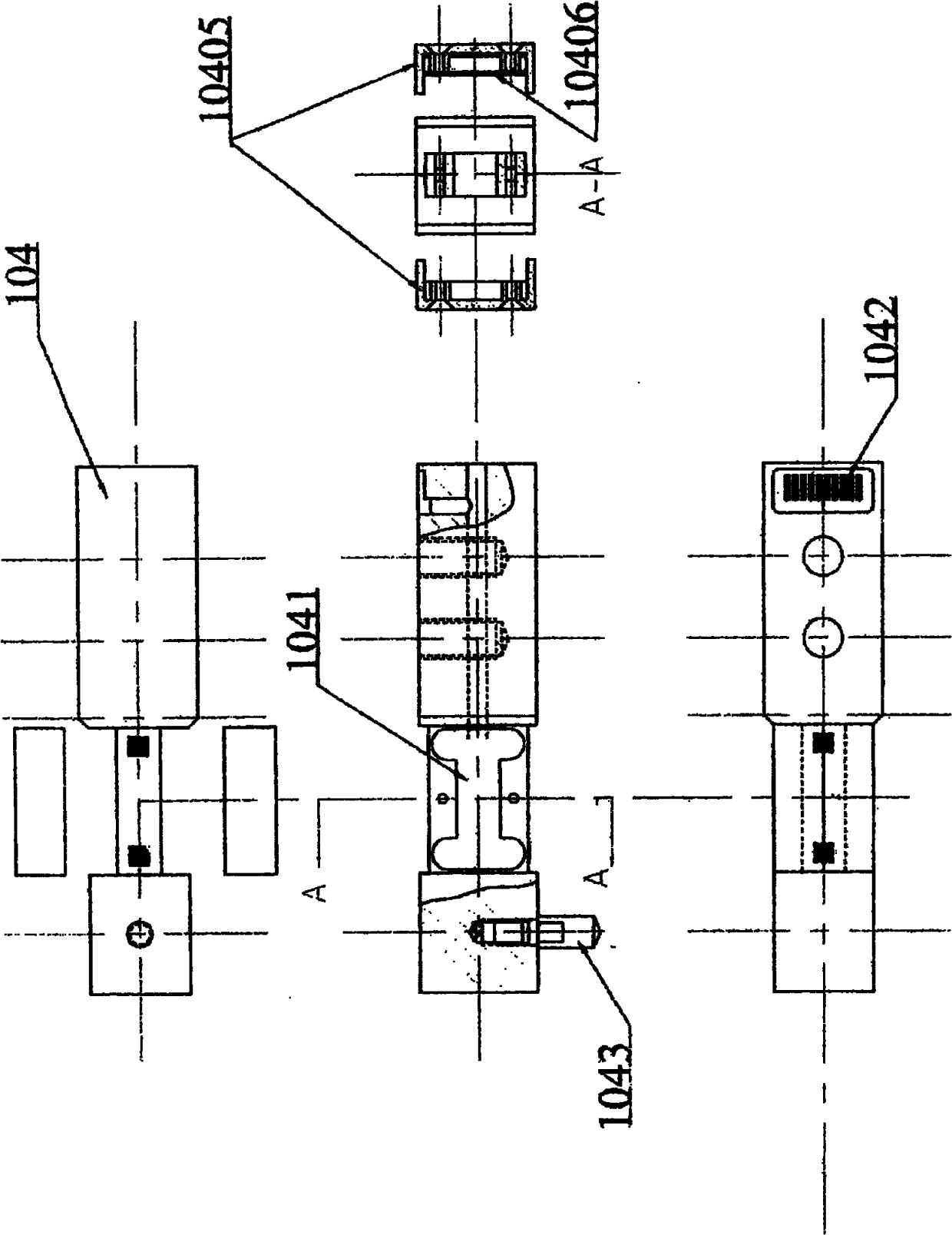

ActiveUS20110132078A1Easy to switchEasy to mountMaterial strength using tensile/compressive forcesInvestigating material hardnessDigital dataEngineering

A testing machine includes a stand and a test device. The stand includes a base, box frame, a slide device driven to slide by a motor, and a control system controls the force applied on the test specimen. The test device is coupled at the slide device for performing various hardness tests consisting of Rockwell hardness test, Vickers hardness test, Brinell hardness test, micro-hardness test, and tension-compression test. The test device includes a force sensor and a data processing circuit converting an analog signal of the force sensor into digital data to interface with the control system.

Owner:WUSOMING +1

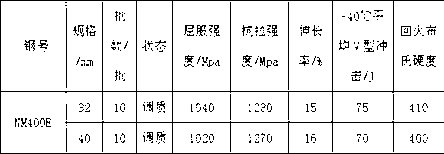

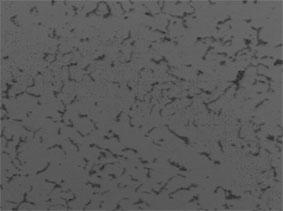

Production process of wear-resistant steel NM400E medium plate

The invention discloses a production process of a wear-resistant steel NM400E medium plate. The production method disclosed by the invention comprises the steps of converter smelting, LF (Ladle Furnace) refining, vacuum refining, pouring, casting blank heating, rolling, slow cooling, heat treatment and the like. According to the invention, the cleanliness of the steel is guaranteed through reasonable chemical component design and processes of LF and VD (vacuum degassing); and high-strength NM400E steel with the thickness of 30-40 mm is successfully developed through the effective implementation of processes such as heating, rolling and thermal refining, wherein the yield strength of the steel is controlled at 1000-1100MPa, the tensile strength is controlled at 1200-1300MPa, the elongation is controlled at 13-17%, the V type impact energy at the temperature of minus 40 DEG C is controlled at 60-80J and the brinell hardness in a high-temperature tempering state is 380-420.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Universal testing machine

ActiveCN102213661AMaterial strength using tensile/compressive forcesInvestigating material hardnessKnoop hardness testDigital data

A testing machine includes a stand and a test device. The stand includes a base, box frame, a slide device driven to slide by a motor, and a control system controls the force applied on the test specimen. The test device is coupled at the slide device for performing various hardness tests consisting of Rockwell hardness test, Vickers hardness test, Brinell hardness test, micro-hardness test, and tension-compression test. The test device includes a force sensor and a data processing circuit converting an analog signal of the force sensor into digital data to interface with the control system.

Owner:吴绍明 +1

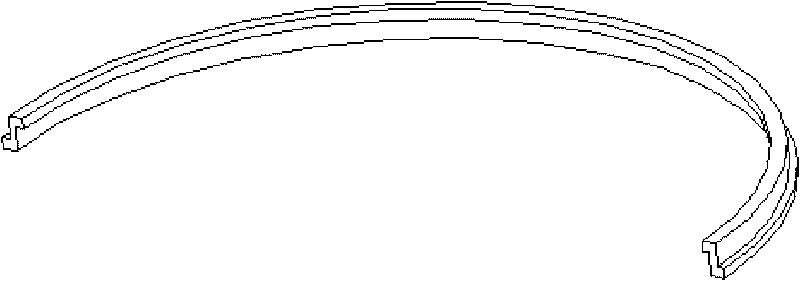

Aluminum alloy semi-ring for fairing of launch vehicle and preparation method thereof

ActiveCN101760682AGuaranteed performanceLess metallurgical defectsExtrusion control devicesHardnessHigh intensity

The invention discloses an aluminum alloy semi-ring for a fairing of a launch vehicle and a preparation method thereof, relating to an alloy semi-ring and a preparation method thereof. The invention solves a problem that the traditional aluminum alloy semi-ring for the fairing of the launch vehicle has a low intensity and cannot satisfy the application requirements of large-scale launch vehicles. The aluminum alloy semi-ring for a fairing of a launch vehicle is made of Si, Fe, Cu, Mn, Mg, Ni, Zn, Ti and Al. The tensile strength of the semi-ring is 380-450MPa, the percentage elongation after fracture is 6.0-10% and the Brinell hardness is 110N / sq.m-150N / sq.m. The preparation method comprises the following steps of: preparing the raw material, melting, casting, homogenizing annealing, forging, extruding, bending, quenching, coldly compressing to deform, flattening and ageing the raw materials to obtain the aluminum alloy semi-ring for the fairing of the launch vehicle. The aluminum alloy semi-ring for the fairing of the launch vehicle has a high intensity and can be applied to the large-scale launch vehicle.

Owner:NORTHEAST LIGHT ALLOY CO LTD

HB360-level wear-resistant steel plate and preparation method thereof

The invention discloses an HB360-level wear-resistant steel plate and a preparation method thereof. The HB360-level wear-resistant steel plate comprises the following components in percentage by weight: 0.08%-0.20% of C, 0.10%-1.00% of Si, 1.00%-2.00% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 1.20% of Cr, not more than 0.80% of Mo, not more than 1.00% of Ni, not more than 0.080% of Nb, 0.010%-0.100% of Al, 0.0005%-0.0040% of B, 0.005%-0.050% of Ti, 0.0010%-0.0080% of Ca, not more than 0.080% of N, not more than 0.0080% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein (Cr / 5+Mn / 6+50B) is not less than 0.20% and not more than 0.55%, (Mo / 3+Ni / 5+2Nb) is not less than 0.02% and not more than 0.45%, (Al+Ti) is not less than 0.01% and not more than 0.13%. The tensile strength of the steel plate is 1100MPa-1400MPa, the elongation of the steel plate is 14%-16%, the Brinell hardness of the steel plate is 360HB-440HB, the Charpy longitudinalV-shaped longidutional impact power at -40 DEG C is 80J-120J. The steel plate obtained by the components through each thermal treatment process is high in strength hardness, good in flexibility, easy to weld, excellent in mechanical machining performances and suitable for easy-wearing components in various mechanical devices.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength cast aluminum-silicon alloy for engine body and preparation method thereof

The invention relates to a high-strength cast aluminum-silicon alloy for an engine body and a preparation method thereof, belonging to the field of metal materials. The alloy comprises the following components in percentage by weight: 12.0-14.0% of Si, less than 0.3% of Ni, 3.0-5.0% of Cu, 0.3-0.8% of Fe, 0.4-0.8% of Mn, less than 0.4% of Mg, 0.1-0.2% of Ti, less than 0.27wt% of Zr and balance of Al. Heat treatment parameters are as follows: the solution treatment is carried out at 510+ / -5 DEG C for 5-8h and then water quenching is carried out at room temperature; and the aging treatment is carried out at 160+ / -5 DEG C for 6-10h and then air cooling is carried out. The tensile strength and the yield strength of the alloy at room temperature after heat treatment respectively reach 316-336MPa and 245-263MPa, the elongation of the broken alloy reaches 0.72-0.83%, and the Brinell hardness reaches 155-166HBW to the maximum. Compared with the similar alloys, the alloy of the invention has the advantages of high mechanical properties, low content of Ni elements, reduction of content of noble elements in the alloy, wider allowed fluctuation range of content of Fe elements, good cast ingot quality, simple processes and strong operability.

Owner:UNIV OF SCI & TECH BEIJING

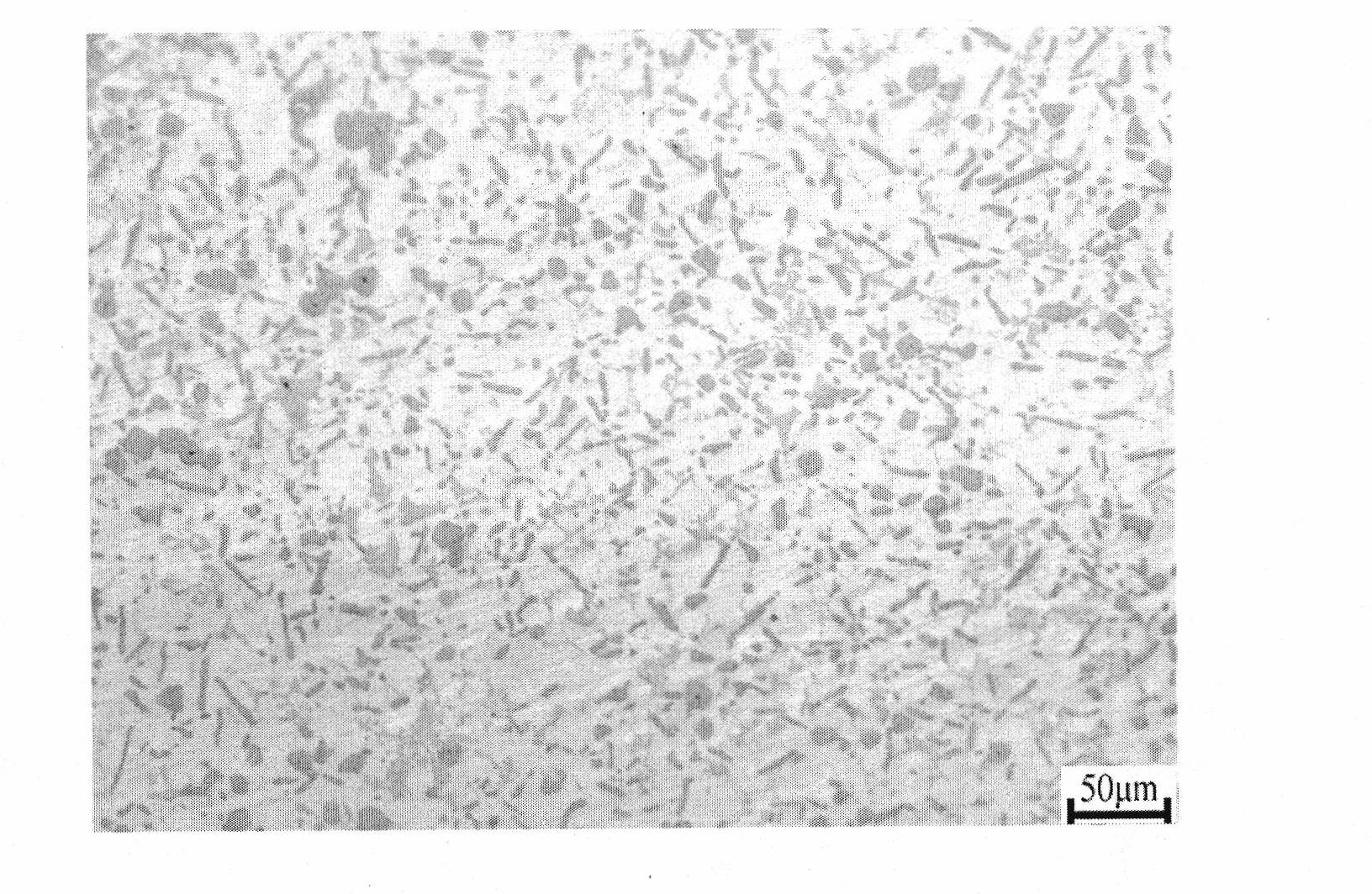

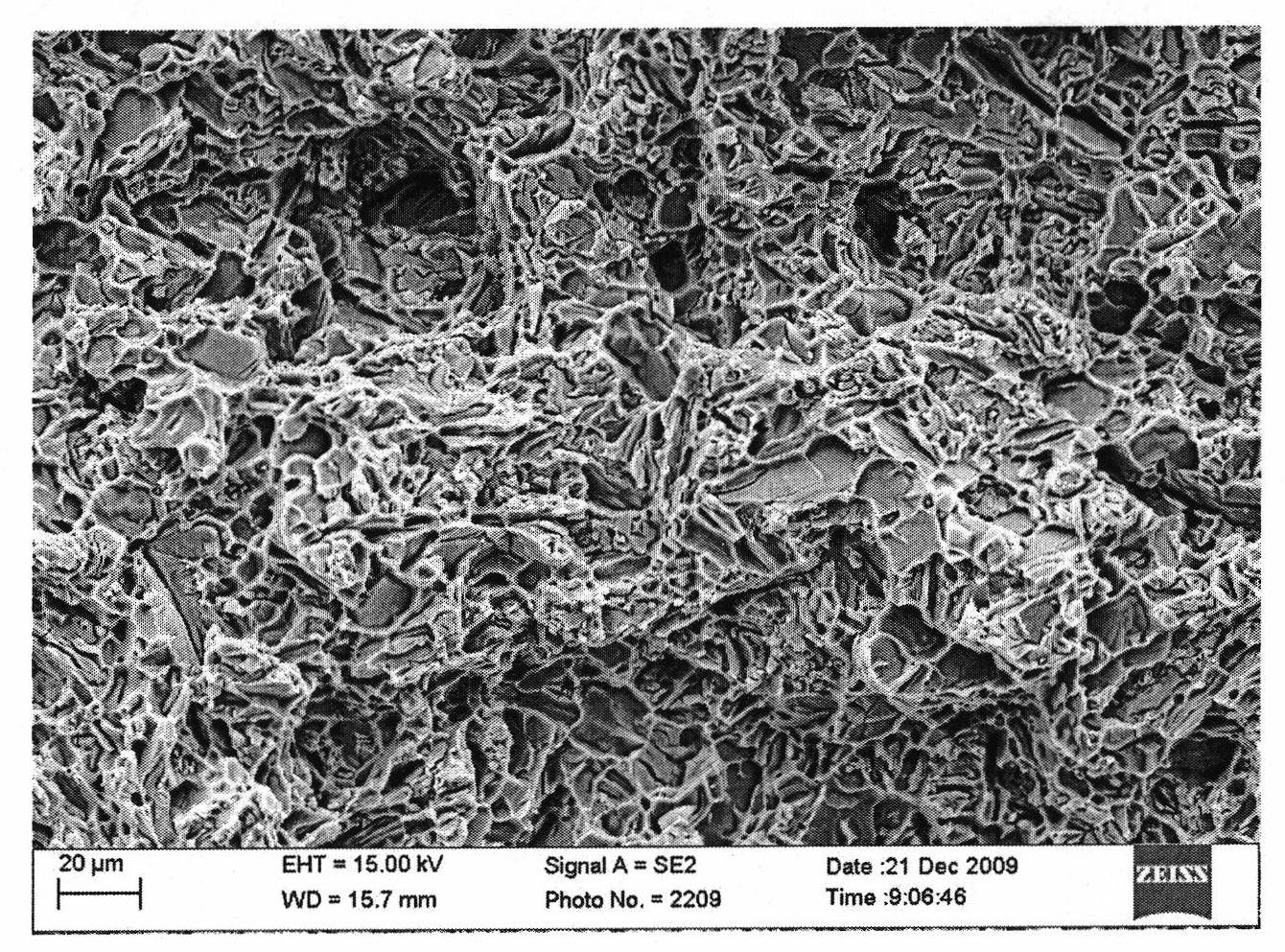

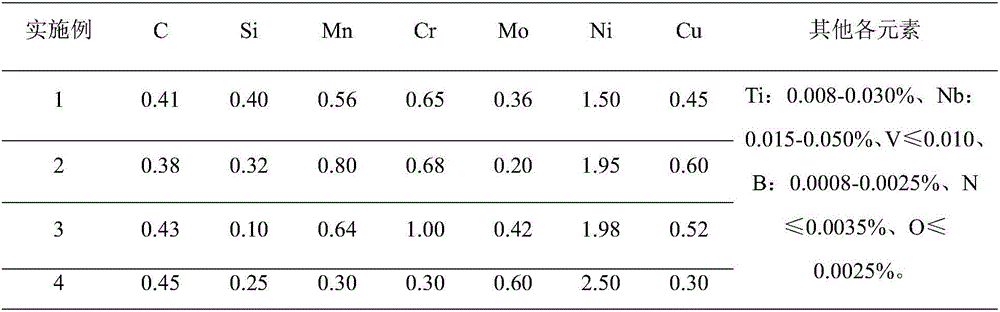

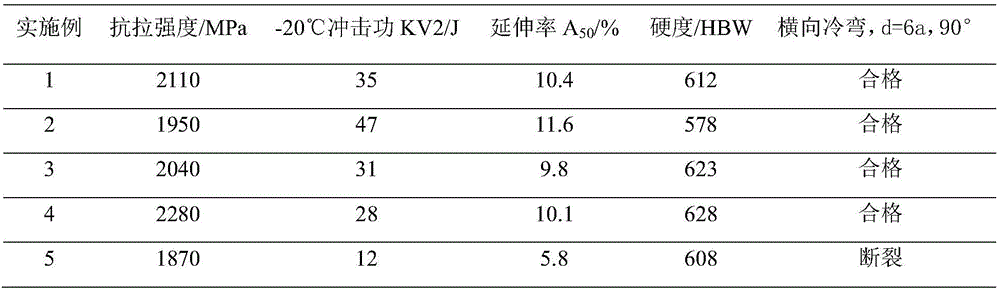

NM600 high-grade low-alloy wear-resistant steel and application thereof

The invention provides NM600 high-grade low-alloy wear-resistant steel and a manufacturing method thereof. The steel is prepared from, by weight, 0.38%-0.45% of C, 0.10%-0.40% of Si, 0.30%-0.80% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.003% of S, 0.30%-1.00% of Cr, 0.20%-0.60% of Mo, 1.50%-2.50% of Ni, 0.30%-0.60% of Cu, 0.008%-0.030% of Ti, 0.015%-0.050% of Nb, smaller than or equal to 0.010% of V, 0.0008%-0.0025% of B, smaller than or equal to 0.0035% of N and smaller than or equal to 0.0025% of O. The invention further provides a steel plate prepared from the NM600 high-grade low-alloy wear-resistant steel. The Brinell hardness of the steel plate ranges from 570 HBW to 630 HBW, and low temperature impact toughness at -20 DEG C is larger than or equal to 27.

Owner:NORTHEASTERN UNIV LIAONING +1

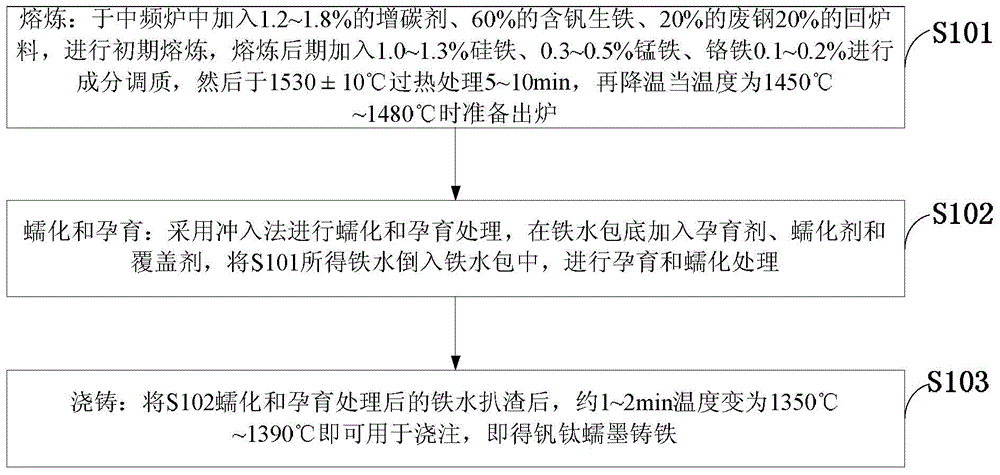

As-cast bainite vermicular graphite cast iron cylinder jacket and its preparation method

The invention provides an as-cast bainite vermicular graphite cast iron cylinder jacket, and the as-cast bainite vermicular graphite cast iron comprises the following chemical components by weight percent: 3.4-3.9% of carbon, 2.2-2.8% of silicon, greater than 0 and smaller than or equal to 0.6% of manganese, greater than 0 and smaller than or equal to 0.4% of phosphorus, greater than 0 and smaller than or equal to 0.03% of sulfur, 0.8-1.2% of copper, 0.5-1.2% of molybdenum, 0.08-0.2% of titanium, 0.04-0.13% of rare earth element, 0.005-0.011% of magnesium, and the balance Fe. With Brinell hardness of 280-340HB and tensile strength over 700MPa, the cylinder jacket of the invention has better wear resistance than traditional cylinder jackets, and is suitable to be used in high-end engines.

Owner:ZYNP GRP

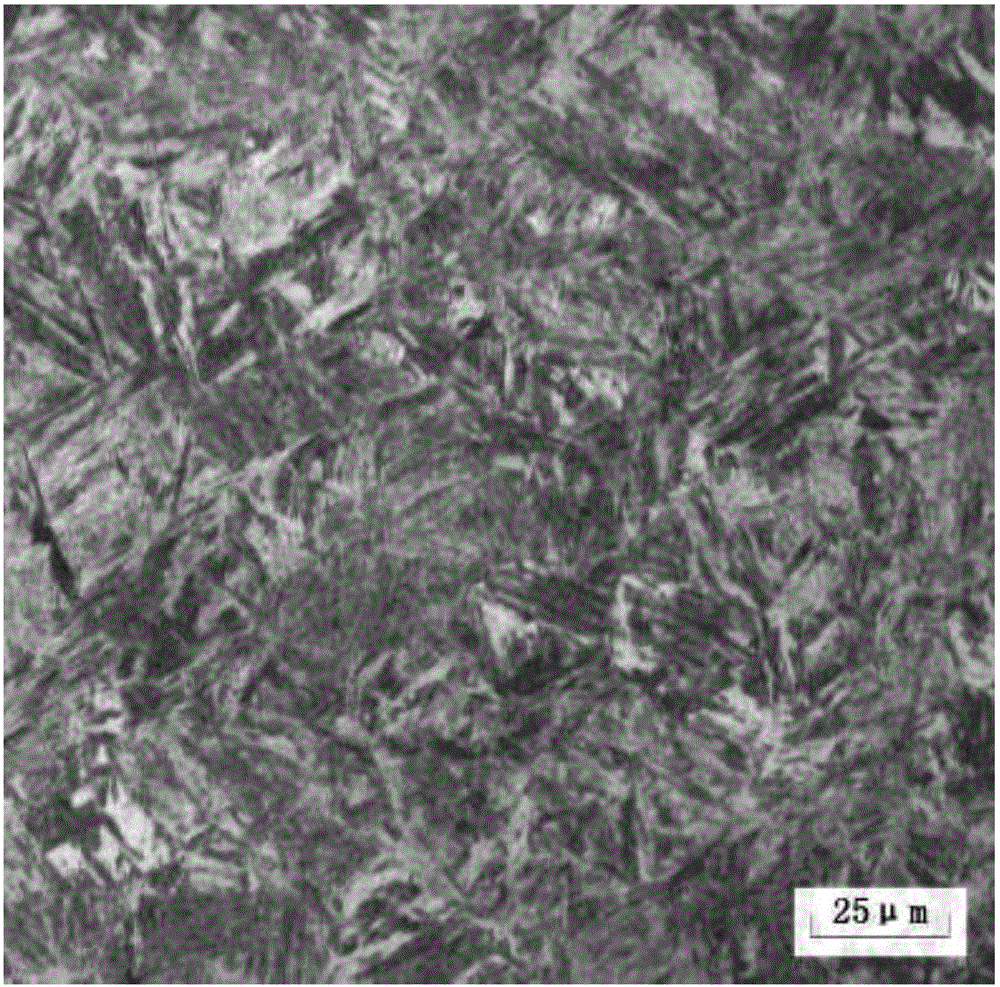

1400 MPa super-high strength alloy steel and manufacturing method thereof

The invention belongs to the technical field of smelting and particularly relates to 1400 MPa super-high strength alloy steel and a manufacturing method thereof. The 1400 MPa super-high strength alloy steel is characterized by comprising 0.18-0.25% of C, 0.40-0.65% of Si, 1.10-1.40% of Mn, not greater than 0.009% of P, not greater than 0.002% of S, 0.30-0.80% of Cr, 0.20-0.60% of Ni, 0.20-0.60% of Mo, 0.008-0.0025% of B, 0.020-0.035% of Ti and balance Fe and inevitable impurities. The 6-60 mm super-high strength alloy steel plates produced through the method is great in strength and toughness matching and good in impact toughness at the low temperature of -40 DEG C. By controlling rolling, quenching and temper heat treatment, the metallographic phase mainly is tempered martensite organizations, the strength of extension is higher than 1400 Mpa, the yield strength is higher than 1170 Mpa, the transverse low temperature ballistic work at -40 DEG C is larger than 50 J, the surface brinell hardness is larger than 430 HBW, and the surface residual magnetization is less than 15 GS.

Owner:SHANDONG IRON & STEEL CO LTD

Anti-bullet steel with ultrahigh-strength being 1760 MPa and manufacturing method thereof

The invention discloses a manufacturing method for ultrahigh-strength alloy steel with the tensile strength being more than 1760 MPa or applied to protection. The method comprises the following main steps of KR molten iron pre-treatment, converter smelting, refining outside an LF converter, RH vacuum degassing secondary refining outside the converter, plate blank continuous casting, plate blank reheating, rough rolling through a roughing mill, finish rolling through a finishing mill and quenching and tempering test. By adoption of the manufacturing method for poduction, an obtained ultrahigh-strength alloy steel plate with the thickness being 6-25 mm achieves excellent high-toughness matching and good low-temperature impact toughness at the temperature being minus 40 DEG C. By controlling rolling, quenching and tempering heat treatment, the metallurgical structure is mainly a tempered martensite, the tensile strength is equal to or more than 1760 MPa, the yield strength is equal to or more than 1270 MPa, the transverse low-temperature impact work at the temperature being minus 40 DEG C is equal to or more than 20 J, and the surface Brinell hardness is equal to or more than 490 HBW.

Owner:SHANDONG IRON & STEEL CO LTD

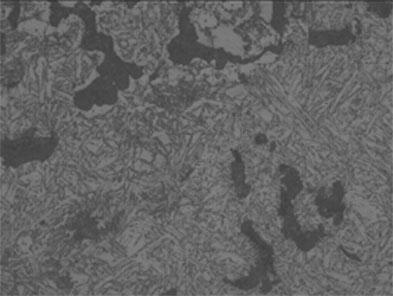

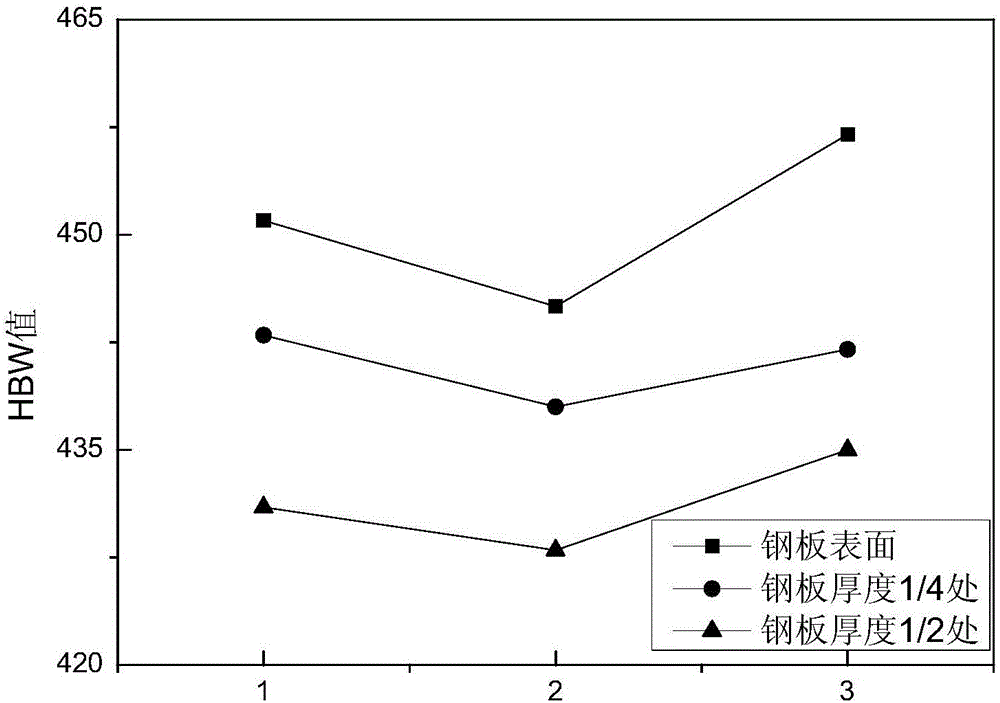

High-toughness stable-brinell-hardness extra-thick abrasion-resistant steel and preparation method thereof

The invention provides high-toughness stable-brinell-hardness extra-thick abrasion-resistant steel and a preparation method thereof, and belongs to the technical field of metal material manufacturing. The abrasion-resistant steel comprises, by weight, 0.18% to 0.22% of C, 0.10% to 0.30% of Si, 0.90% to 1.10% of Mn, 0.40% to 0.60% of Cr, 0.30% to 0.50% of Mo, 0.10% to 0.30% of Ni, 0.01% to 0.03% of Nb, 0.010% to 0.020% of Ti, 0.010% to 0.030% of Alt, 0.0015% to 0.0025% of B, smaller than or equal to 0.012% of P, smaller than or equal to 0.005% of S and the balance Fe and inevitable impurities. The preparation method includes the steps of casting blank smelting, casting blank casting, casting blank heating, steel plate rolling and heat treatment. The high-toughness stable-brinell-hardness extra-thick abrasion-resistant steel and the preparation method have the advantages that through the reasonable component design and technology improvement, a steel plate is excellent in comprehensive mechanical property, good in impact toughness and stable in abrasion resistance index-brinell hardness value, and the high-toughness stable-brinell-hardness extra-thick abrasion-resistant steel can be massively applied to coal mine machinery and engineering machinery industries and has the high application prospect.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Completely-hardened high-toughness ultra-thick wear-resistant steel plate which is easy to weld, and production method thereof

The invention relates to a steel plate. Fe is taken as the base element of the steel plate; and the steel plate comprises, by mass, 0.11 to 0.15% if C, 0.20 to 0.40% of Si, 0.9 to 1.3% of Mn, P<=0.010%, S<=0.002%, 0.4 to 0.8% of Cr, 0.4 to 0.7% of Mo, 1.0 to 2.6% of Ni, 0.2 to 0.5% of Cu, 0.06 to 0.1% of Al, 0.03 to 0.06% of V, Nb<=0.04%, N<=0.006%, 0.001 to 0.002% of B, 0.0005 to 0.005 of Ca, Ca / S>=1, and Al>=(Mn / C)*(%N). A production method comprises following steps: KR molten iron pretreatment, converter steel making, LF refining, RH refining, continuous casting, covered slow cooling, control rolling, straightening, slow cooling, quenching, and tempering. The thickness of the obtained steel plate ranges from 110 to 180mm, carbon equivalent CEV is equal to or lower than 0.75%, Brinell hardness of the thickness cross section of the steel plate ranges from HBW320 to HBW400, and Charpy impact energy of the parts at 1 / 4 thickness and 1 / 2 thickness is larger than 60J at -40 DEG C.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

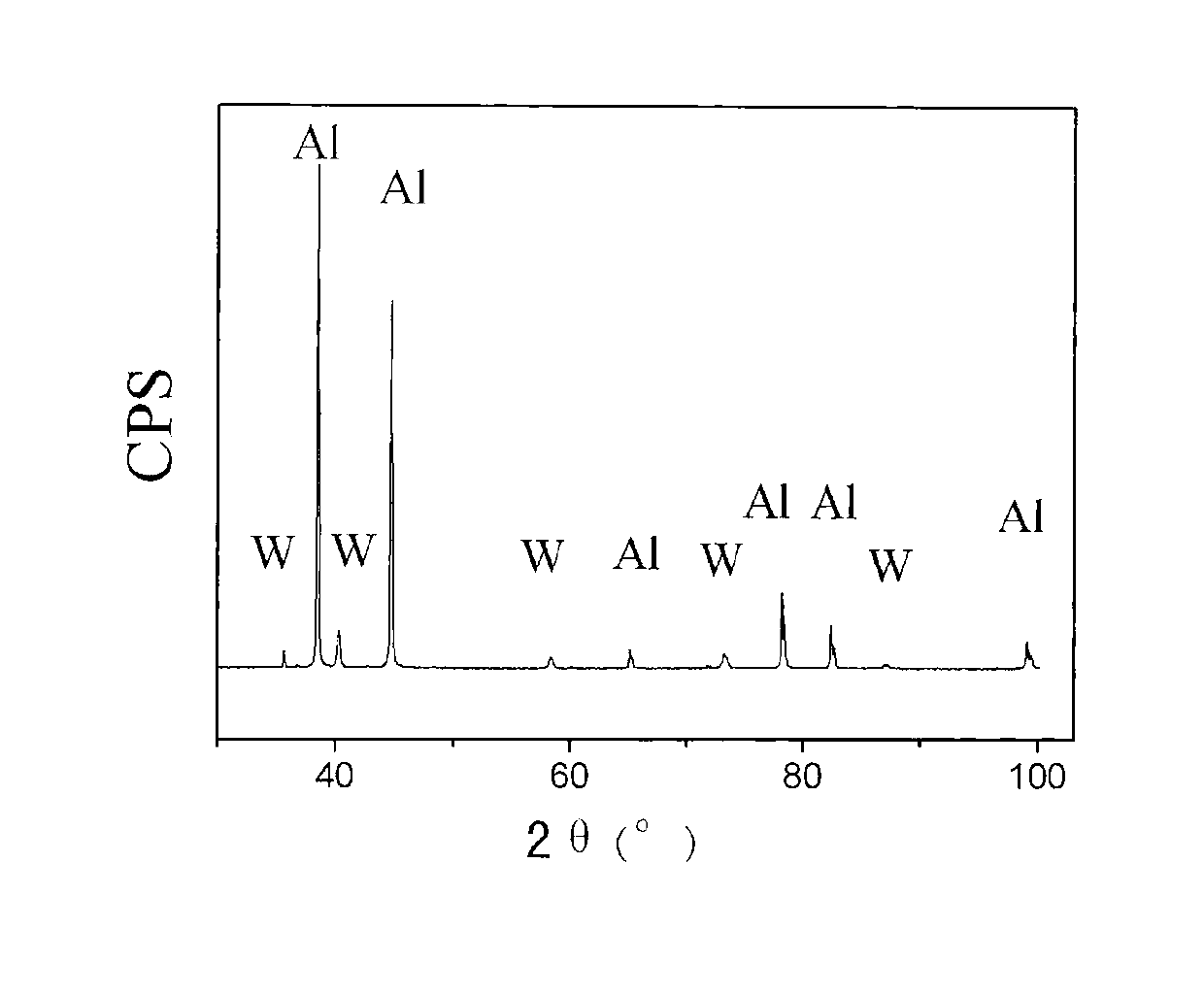

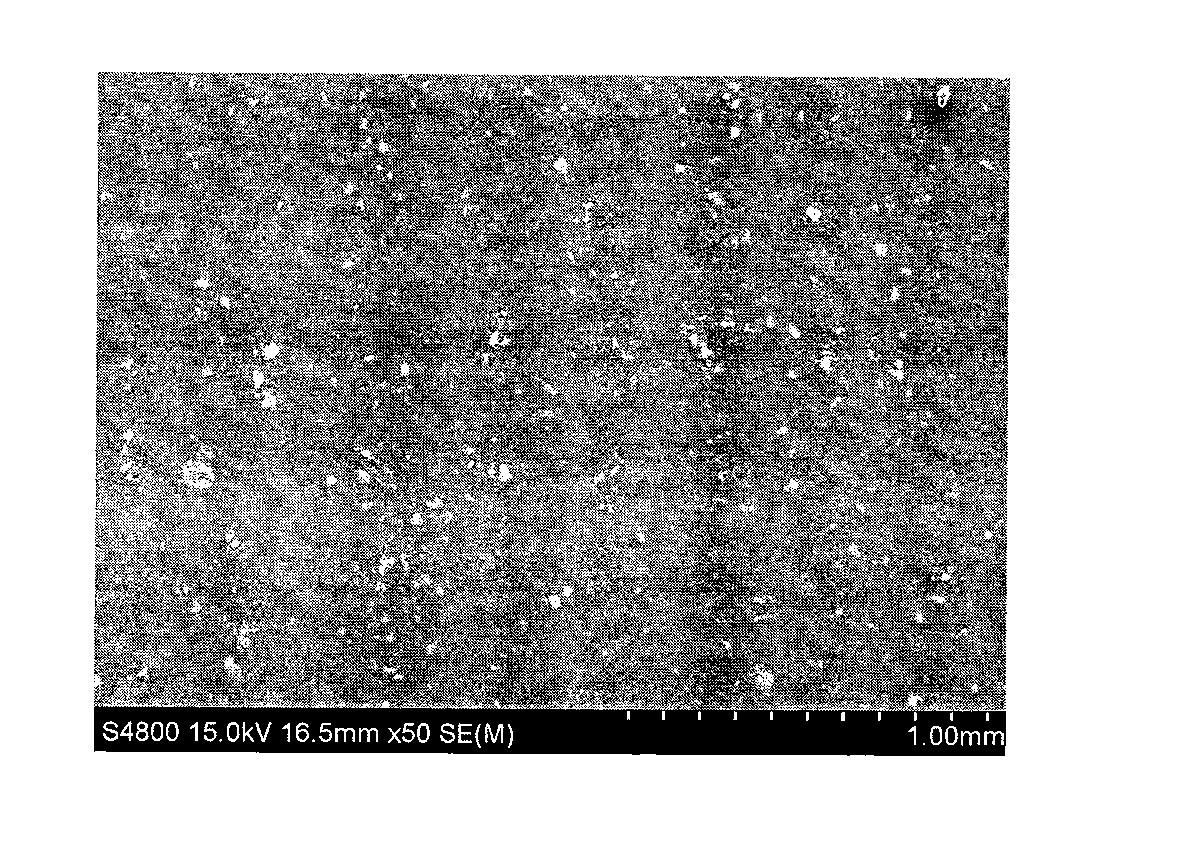

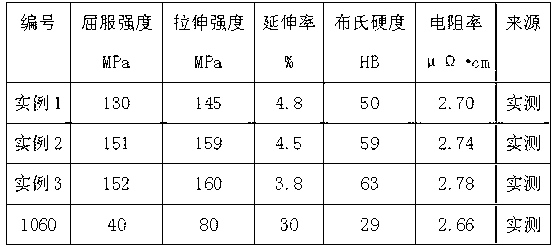

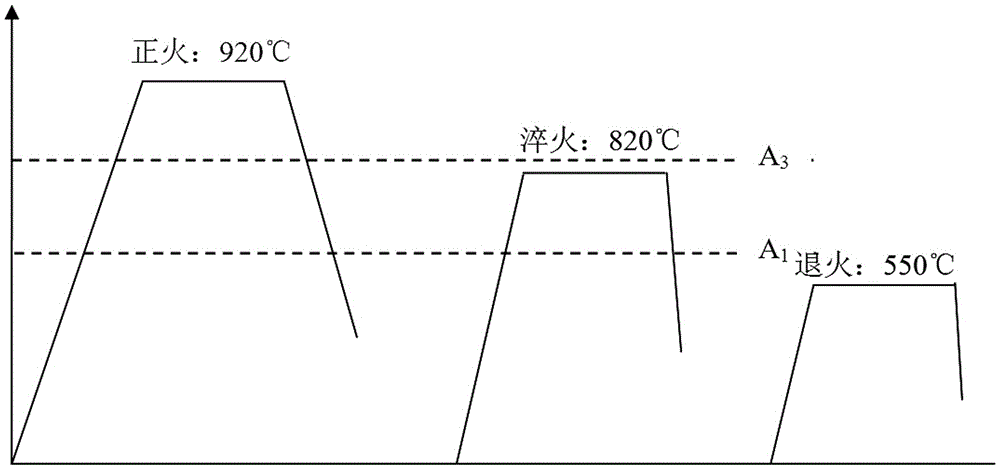

Aluminum-tungsten composite and production method thereof

Disclosed is aluminum-tungsten composite. Tungsten accounts for 1.4%-4.2% of aluminum in volume ratio. A production method of the aluminum-tungsten composite mainly includes spreading particles of pure tungsten between two aluminum plates, heating to 280-350 DEG C, rolling the particles on a mill at the rolling speed of 0.4-0.8m / s with rolling reduction of 50% after heating continues for 5-20 minutes, air-cooling to room temperature after rolling, repeatedly heating for four times, and cyclically processing combined composite plates by shearing, grinding, cleaning, heating and rolling for 11 times by the method. The aluminum-tungsten composite has the advantages of high strength, high rigidity and high conductivity and has yield strength of 130-152MPa, tensile strength of 145-160MPa, Brinell hardness of 50-63HB, and electric conductivity of 2.70-2.83 Mu omega / cm.

Owner:YANSHAN UNIV

High-strength high-toughness abrasion-resistant cast steel material and preparation method thereof

The invention relates to a high-strength high-toughness abrasion-resistant cast steel material and a preparation method thereof. The novel high-strength high-toughness abrasion-resistant cast steel material is pertinently designed and developed for the severe working conditions that in the operation process, a trough side not only bears violent friction of coal, a scraper blade and a chain, but also bears operation load of a coal cutter, lateral force and longitudinal force used for pushing and pulling a hydraulic support, extrusion force and impact force generated when large sized coal and rock get stuck in a trough and the like. According to the mechanical performance indexes the cast steel material can reach, the tensile strength Rm>=900 MPa, the fracture elongation A>=16%, the impact absorbing energy Aku>=32J, and the Brinell hardness HB is 270-310. According to the abrasion resistance, weightlessness is 1.55+ / -0.03 g, and the weight loss ratio is 15.5+ / -0.3 mg / m. According to the preparation method, production is easy, the cost is low, and the performance is high. Quantity production and application can be achieved in the industries such as mines, energy, transportation, agricultural machinery and engineering machinery.

Owner:SHANXI ZHONGTIAOSHAN MECHANICAL & ELECTRONICS EQUIP

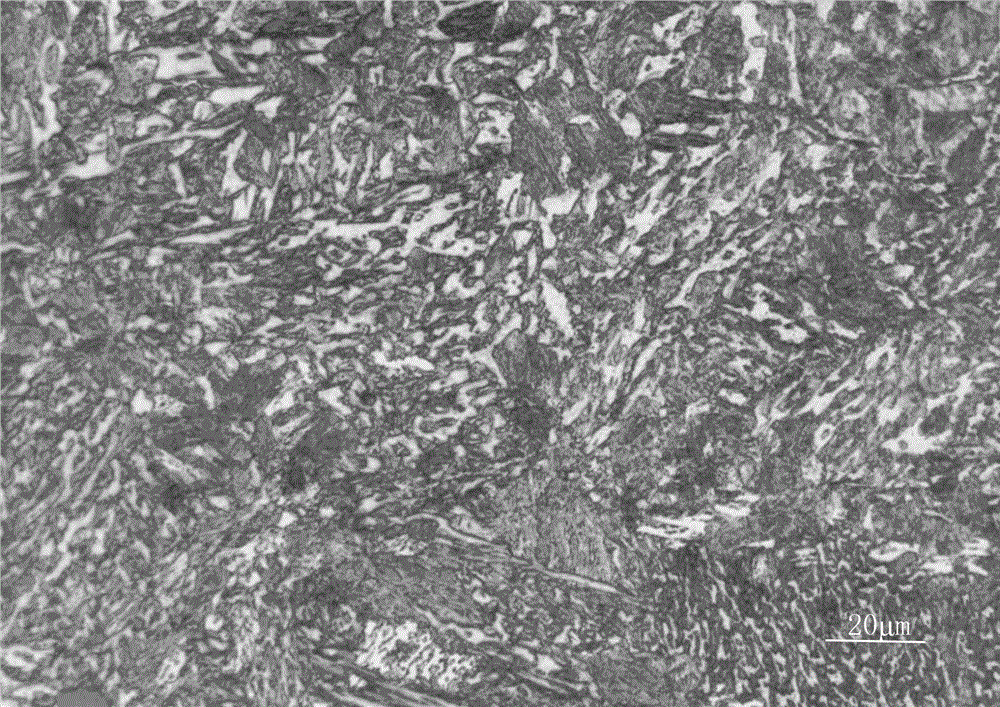

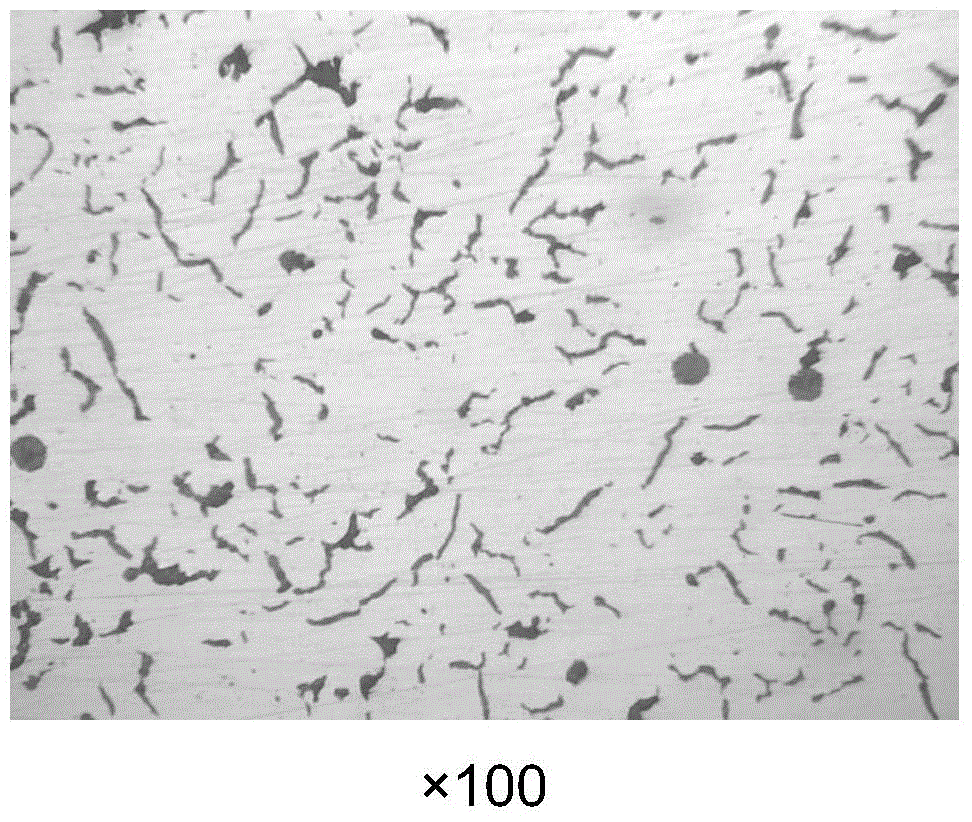

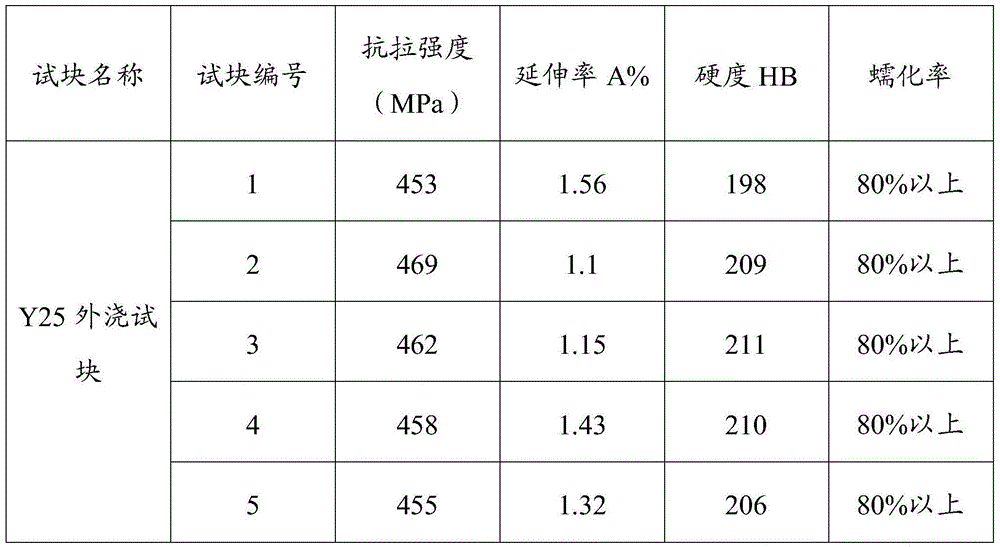

Vanadium-titanium vermicular cast iron and production method thereof

The invention discloses vanadium-titanium vermicular cast iron and a production method thereof. The vanadium-titanium vermicular cast iron comprises the following compositios in percent by weight: 3.8-4.2% of carbon, 1.8-2.2% of silicon, 0.4-0.7% of manganese, 0.15-0.34% of vanadium, 0.05-0.08% of titanium, 0.1-0.3% of chromium, 0.03-0.06% of sulfur, 0.05-0.09% of phosphorus, 0.01-0.03% of residual magnesium, and the balance iron. The vanadium-titanium vermicular cast iron employs vanadium-containing pig iron as a raw material, and is not added with other precious metal elements. The produced vanadium-titanium vermicular cast iron possesses the characteristics of excellent mechanical properties, good wear resistant, thermal fatigue resistance, low production cost and the like. The pearlite content in the vanadium-titanium vermicular cast iron microstructure is 70% or more, the vermicular graphite rate is 70% or more, and on the aspect of mechanical properties, the tensile strength is 400 MPa-460 MPa, and the Brinell hardness is 200 HBS-240 HBS. The vanadium-titanium vermicular cast iron utilizes vanadium-containing pig iron as the raw material and is not added with other precious metal elements, therefore the production cost is reduced and the performances reach RuT450A requirements. The vanadium-titanium vermicular cast iron possesses good mechanical properties, wear resistance and thermal conductivity, is applicable to produce automobile brake drums, brake discs and other parts, and has wide market application prospect.

Owner:四川西南钒钛科技有限公司

Wear-resistant copper alloy material and casting method thereof

The invention relates to a wear-resistant copper alloy material and a casting method thereof, wherein total seven raw materials, including an aluminum-copper alloy, a nickel plate, pure iron, electrolytic copper, metal manganese, hexachloroethane and cullet, are employed; the CuAl10Ni wear-resistant copper alloy material is obtained through the steps of stove charging, melting, sodium fluoroaluminate doping and sand mold test sample casting, casting molding and the like; and the mechanical properties of the obtained wear-resistant copper alloy material reach the following standards: yield strength B0.2: more than or equal to 270N / mm<2>; tensile strength Bb: more than or equal to 600N / mm<2>; elongation sigma5: more than or equal to 12%; and Brinell hardness HBW: more than or equal to 140; the wear-resistant copper alloy material is specially used for manufacture of the positioning guide sleeve of the air spring of a rail transit vehicle, and has excellent comprehensive mechanical properties, and extremely high abrasive resistance and corrosion resistance; and the service life of the wear-resistant copper alloy material is twice as long as that the service life of the traditional ZCuAl9Mn2(S) material.

Owner:株洲联诚集团铸业有限责任公司

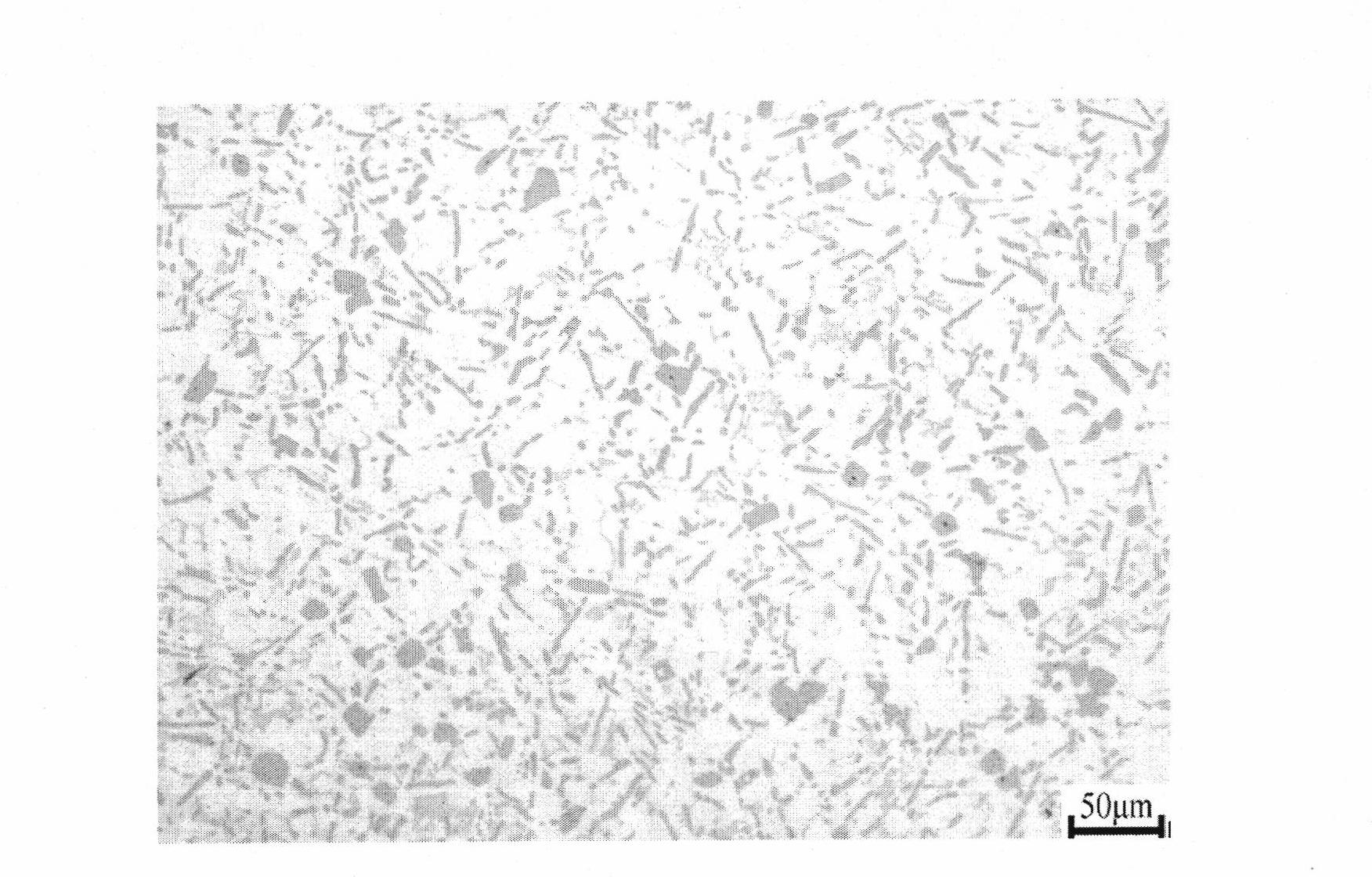

On-line quenching complex-phase structure hot-rolled wear-resistant steel and preparation method thereof

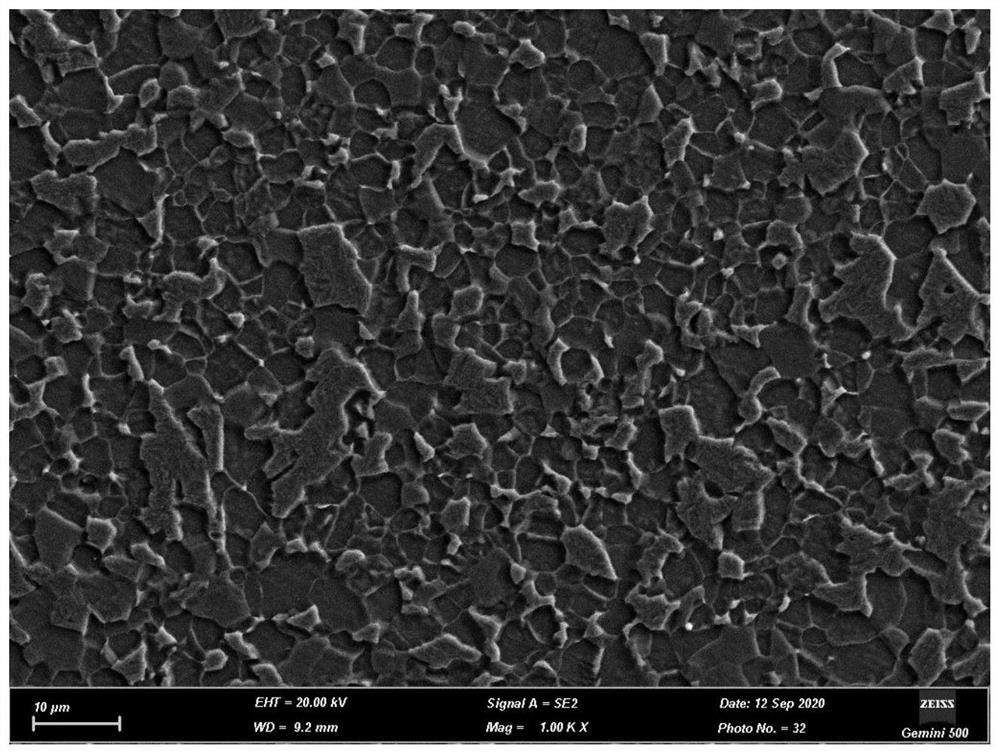

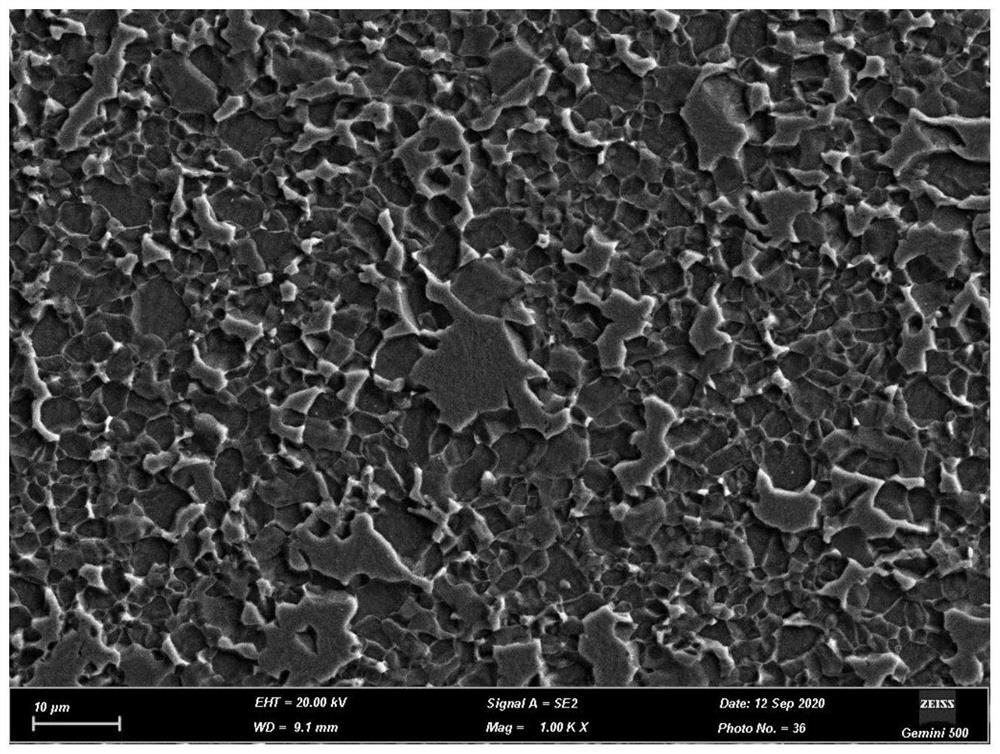

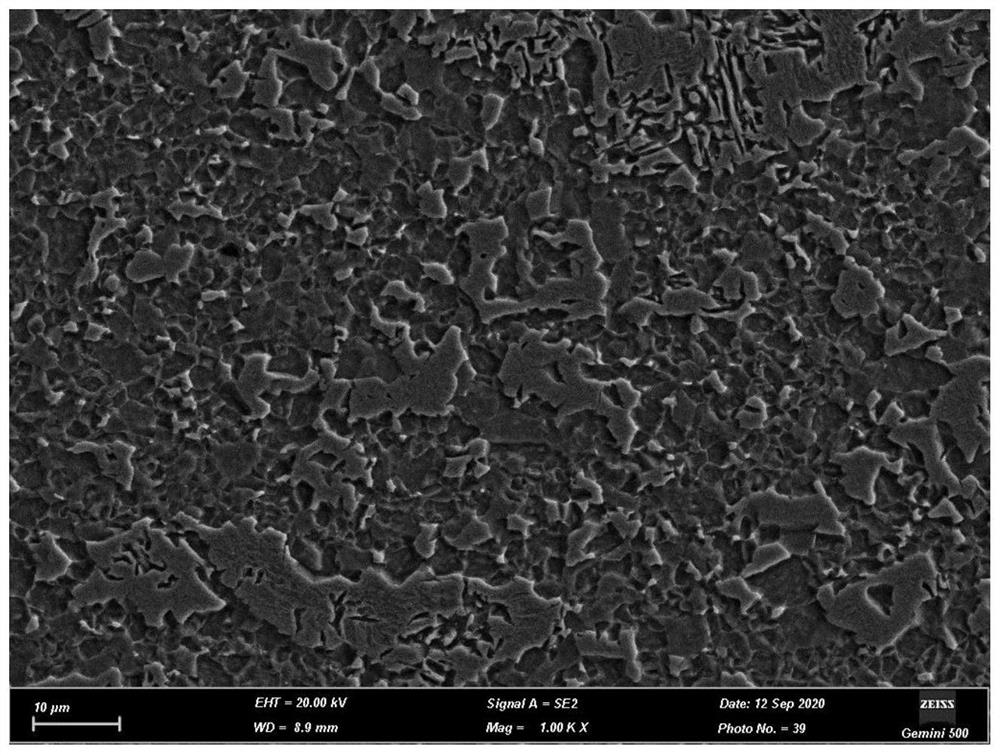

InactiveCN112831731AMeeting Industrial Performance RequirementsSimple processBrinellingHeat conservation

The invention relates to on-line quenching complex-phase structure hot-rolled wear-resistant steel. The on-line quenching complex-phase structure hot-rolled wear-resistant steel comprises the following chemical components in percentage by weight: 0.14-0.18% of C, 1.5-2.0% of Mn, 0.20-0.35% of Cr, 1.0-1.3% of Si, 0.02-0.04% of Nb and the balance Fe and inevitable impurities. The preparation method comprises the working procedures of converter smelting, slab continuous casting, slab heating, controlled rolling, controlled cooling and coiling. In the slab heating process, a steel billet is heated to 1,200-1,280 DEG C, heat preservation is conducted for 3-4 h, the furnace discharging temperature is 1,150-1,200 DEG C, and the homogenization quality of the steel billet is guaranteed; and in the controlled cooling process, a sectional cooling process is adopted, namely, firstly, a hot-rolled plate is subjected to water cooling to 600-700 DEG C for intercooling for 5-8 s, then, a steel plate is subjected to water cooling to 100-200 DEG C, and finally, coiling is carried out. The Brinell hardness of the produced hot-rolled wear-resistant steel is larger than or equal to 400 HBW, the tensile strength is larger than or equal to 1300 MPa, the yield strength is larger than or equal to 900 MPa, the ductility is 10-15%, the cold bending performance meets the condition that D is equal to 3a, 120-degree qualification is achieved, and the impact energy at the temperature of-40 DEG C is larger than or equal to 65 J; a microstructure is an austenite + ferrite + martensite three-phase structure, and the ferrite content is 12%-18%; and the technological process is simple and the production cost is low.

Owner:HANDAN IRON & STEEL GROUP +2

High-conductivity oxygen-free copper silver alloy rod and production technology thereof

The invention relates to a high-conductivity oxygen-free copper silver alloy rod and a production technology thereof. The alloy rod comprises the following components of silver, copper and oxygen, wherein the content of the silver is 0.03%-0.10%, a fluctuation range of the content of the silver is 10ppm, the content of the copper and the silver is higher than 99.99%, and the content of the oxygen is lower than 5ppm. The conductivity of the alloy rod is higher than 100%IACS, the tensile strength of the alloy rod is higher than 190MPa, the extension rate of the alloy rod is higher than 37%, the Brinell hardness of the alloy rod is HB66-75, and the dimensional tolerance of the alloy rod is smaller than 0.1mm. The production technology of the high-conductivity oxygen-free copper silver alloy rod disclosed by the invention adopts a high-efficiency energy-saving continuous production method, and properties are excellent.

Owner:浙江力博实业股份有限公司

High-carbon medium-chromium medium-manganese multicomponent alloy steel ball mill lining plate and thermal treatment process thereof

The invention relates to a high-carbon medium-chromium medium-manganese multicomponent alloy steel ball mill lining plate and a thermal treatment process thereof. The high-carbon medium-chromium medium-manganese multicomponent alloy steel ball mill lining plate comprises the following chemical components in percentage by weight: 0.7-1.5% of C, 1.8-2.5% of Cr, 0.5-0.8% of Ni, 1.0-1.6% of Mn, 0.2-0.5% of Si, 0.4-0.9% of Mo, 0.4-1% of Cu, 0.05-0.1% of V, 0.03-0.06% of Ti, 0.002-0.005% of B, not more than 0.03% of P, not more than 0.025% of S and the balance of Fe. Steel is prepared according to the content of the chemical components, and then the lining plate is cast; after being subjected to thermal treatment, the lining plate can achieve good mechanical performances and good wear resistance and corrosion resistance, has brinell hardness of 390-450, impact toughness (without a notch) of 110-150J / cm<2>, and the service life of the lining plate is one year and a half.

Owner:ANSTEEL GRP MINING CO LTD

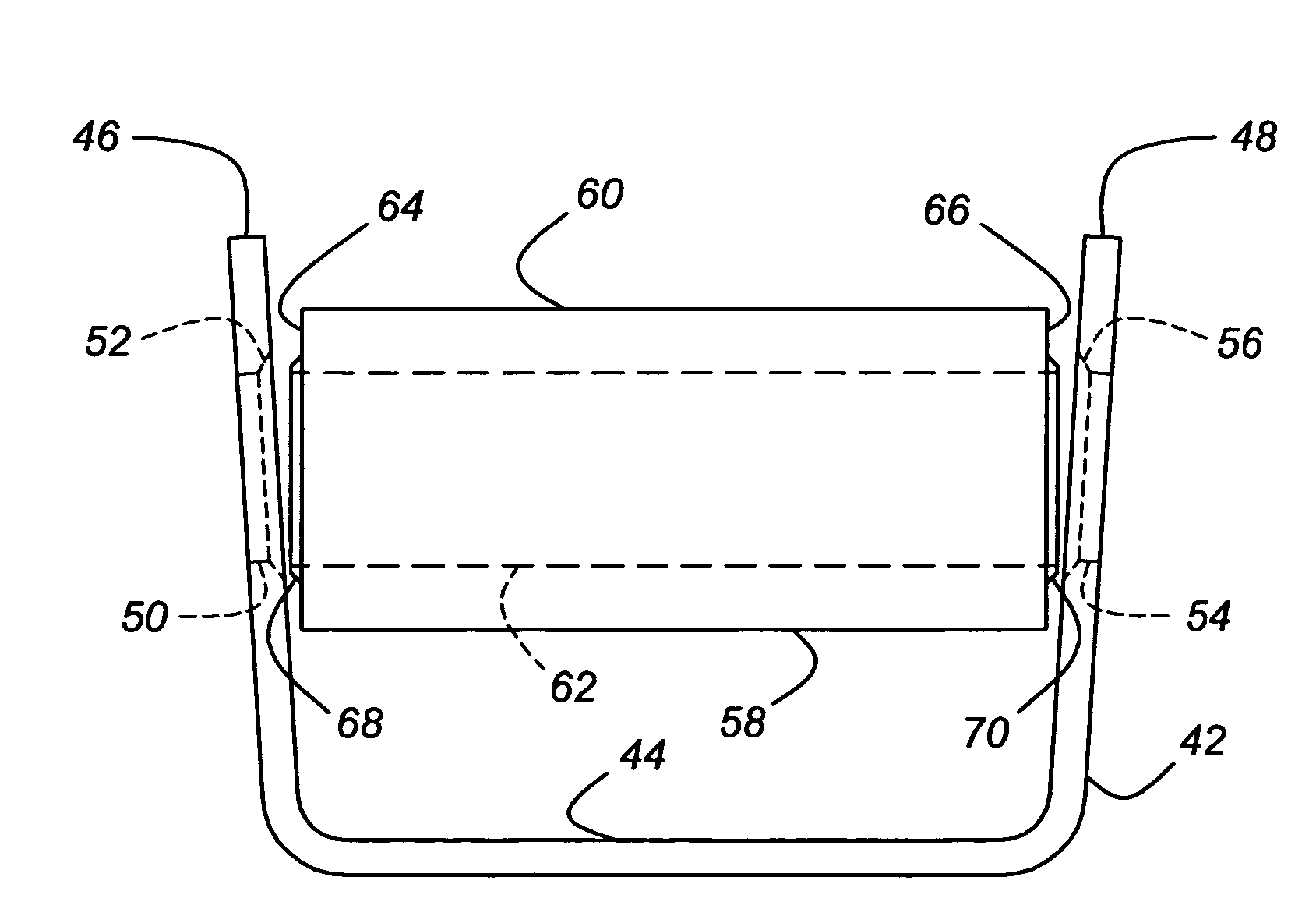

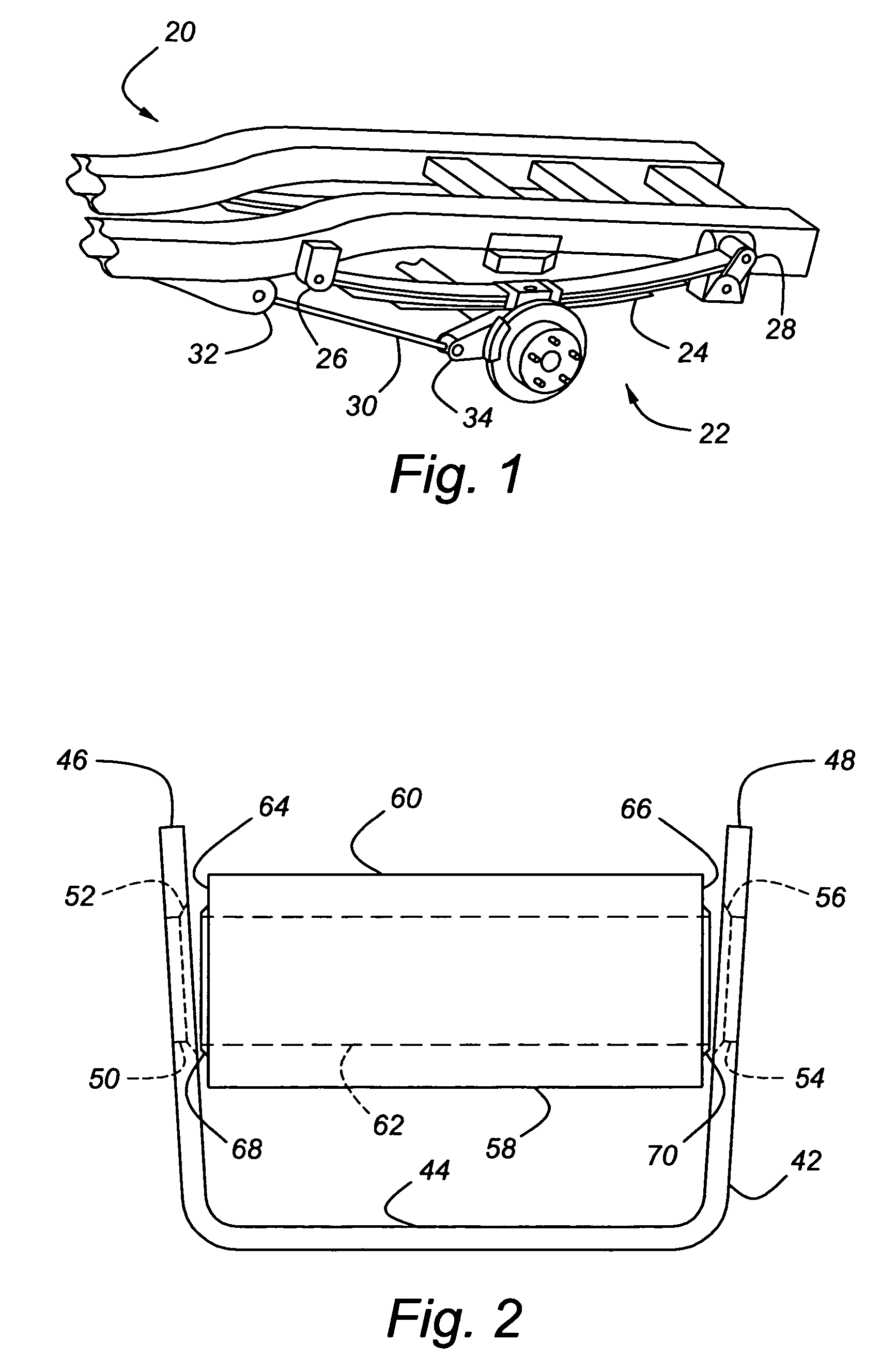

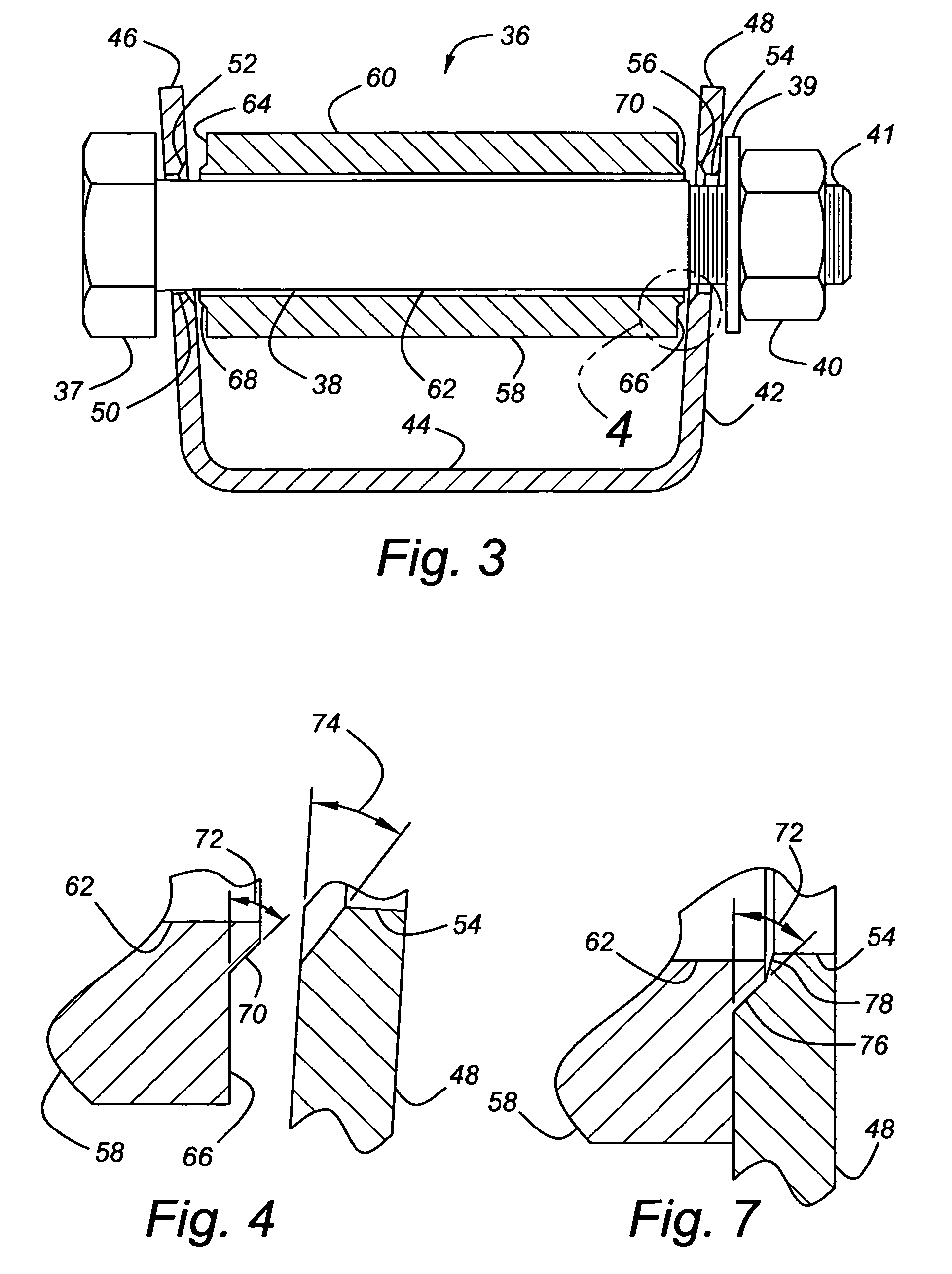

Brinelling bushing joint assembly

The invention concerns a brinelling bushing joint assembly having a brinelling bushing sleeve with a brinelling feature that mates with a bracket. This joint assembly may be particularly advantageous when employed to connect a vehicle frame to a vehicle suspension.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-level low-alloy wear-resisting steel plate with Brinell hardness larger than 550 HB and manufacturing method

The invention discloses a high-level low-alloy wear-resisting steel plate with Brinell hardness larger than 550 HB. The high-level low-alloy wear-resisting steel plate comprises following components including, by weight percent, 0.33 to 0.41% of C, 0.50 to 0.60% of Si, 0.30 to 0.80% of Mn, not larger than 0.012% of P, not larger than 0.003% of S, 0.30 to 1.00% of Cr, 0.20 to 0.60% of Mo, 0.80 to 1.20% of Ni, 0.008 to 0.030% of Ti, 0.015 to 0.050% of Nb, 0.080 to 0.150% of V, 0.0008 to 0.0025% of B, not larger than 0.0040% of N, not larger than 0.0025% of O and the balance Fe and inevitable impurities. High carbon and alloy component design is adopted, through cooperative effect of carbon, manganese, chromium, nickel, molybdenum, copper and other alloy elements, and micro alloy elements ofniobium, titanium, vanadium and the like, through the auxiliary controlled rolling and offline heat treatment method, the obtained steel plate has the high level with the Brinell hardness larger than550 HB, and -20 DEG C low-temperature impact toughness is larger than or equal to 20J.

Owner:NANJING IRON & STEEL CO LTD

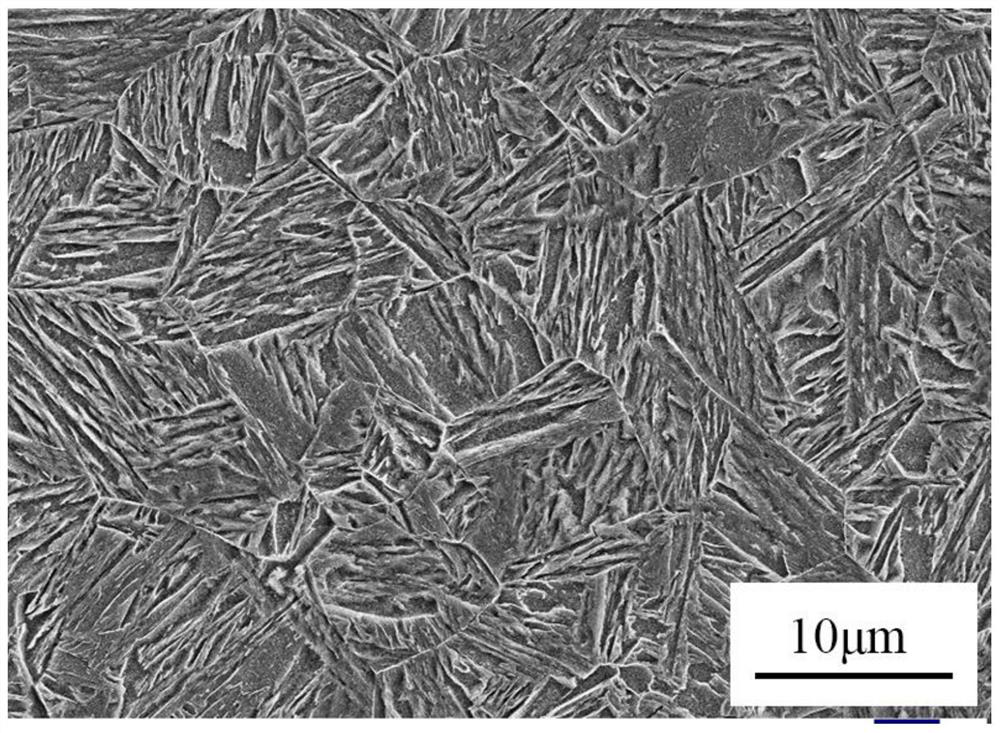

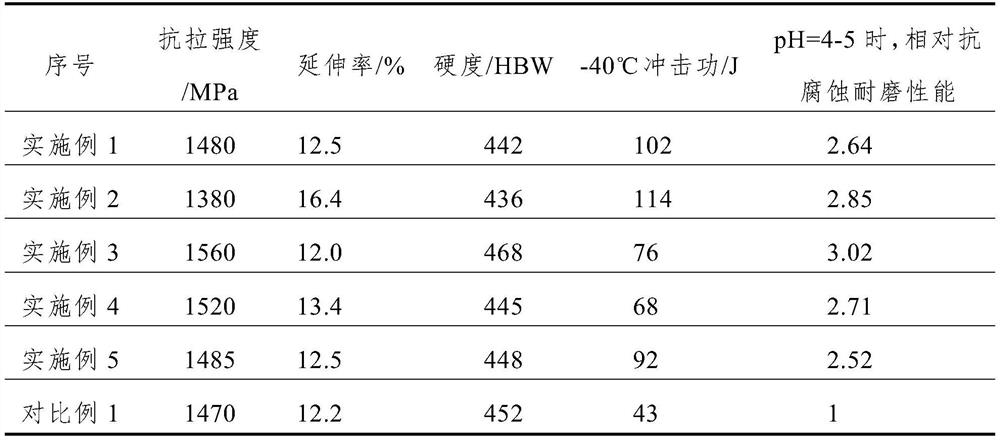

Corrosion-resistant wear-resistant steel plate and preparation method thereof

InactiveCN112159934AExcellent resistance to corrosion and wearGood wear resistance and corrosion resistanceBrinellingPapermaking

The invention relates to a corrosion-resistant wear-resistant steel plate and a preparation method thereof. The corrosion-resistant wear-resistant steel plate comprises the following chemical components in percentage by mass: 0.14-0.22% of C, 0.10-1.00% of Si, 0.1-1.0% of Mn, less than 0.015% of P, less than 0.005% of S, 3.00-6.00% of Cr, 0.00-1.50% of Ni, 0.00-0.80% of Mo, 0.02-0.06% of Als, 0.0008-0.005% of B, 0.0015-0.0040% of Ca and the balance of Fe and inevitable impurity elements, wherein Ca / S> / =1, and the volume fraction of a lath martensite structure in the steel plate is larger thanor equal to 95%. The novel steel plate with excellent corrosion and wear resistance in an acid environment is prepared through an alloy component design and the combination of a heat treatment process, the corrosion and wear resistance of the novel steel plate is 2.5-3.0 times that of existing Brinell hardness martensite wear-resistant steel under the acid working condition with a pH value of 4-5,the corrosion-resistant wear-resistant steel plate can be widely applied to manufacturing of equipment for garbage storage and transportation, papermaking and chemical engineering, ore sand transportation, coal mining and transportation and the like.

Owner:NORTHEASTERN UNIV

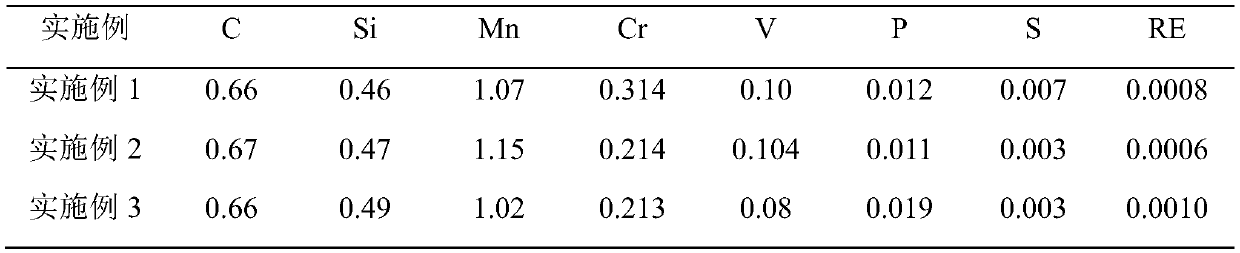

Rolled steel rail with high low-temperature impact performance and production method thereof

InactiveCN111041350AIncrease productivityHigh yieldFurnace typesHeat treatment furnacesBrinellingAlloy

The invention discloses a rolled steel rail with high low-temperature impact performance. The raw material of the rolled steel rail contains the following chemical components of, in percentage by mass, 0.60%-0.75% of C, 0.45%-0.80% of Si, 0.85%-1.20% of Mn, 0.15%-1.0% of Cr, 0.02%-0.10% of V, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 0.002%-0.01% of the adding amount ofthe RE alloy, and the balance Fe and inevitable impurities. The mechanical properties of the rolled steel rail with the high low-temperature impact property are as follows, the yield strength is greater than or equal to 580 MPa, the tensile strength is greater than or equal to 1029 MPa, the yield ratio is less than or equal to 0.58, the elongation is greater than or equal to 14.5%, the Brinell hardness is greater than or equal to 302 HB, and the impact energy at minus 40 DEG C is greater than or equal to 13.5 J; and the rolled steel rail has good tensile strength, tread hardness, low-temperature toughness and impact energy.

Owner:BAOTOU IRON & STEEL GRP

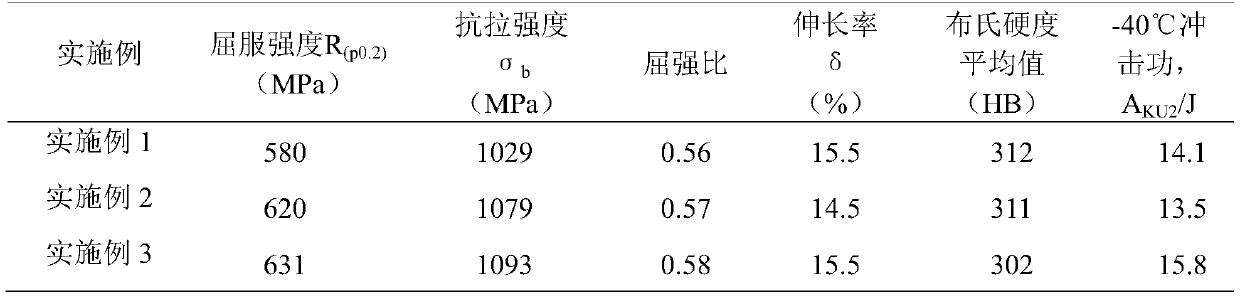

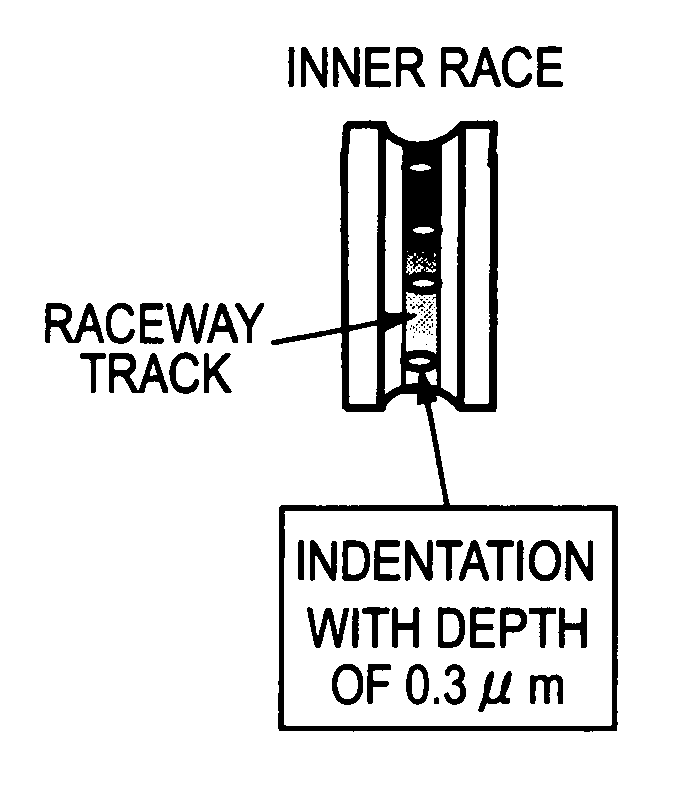

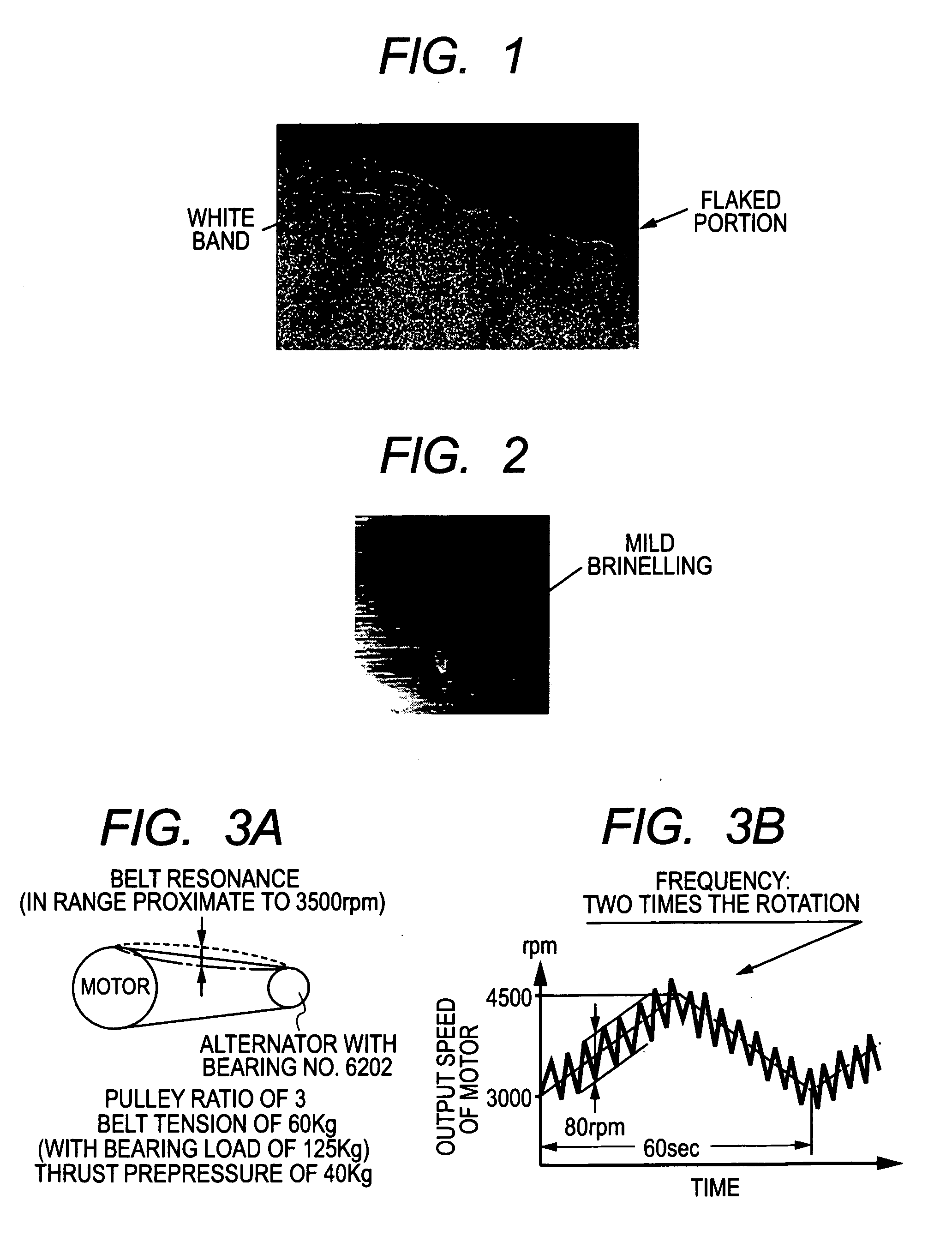

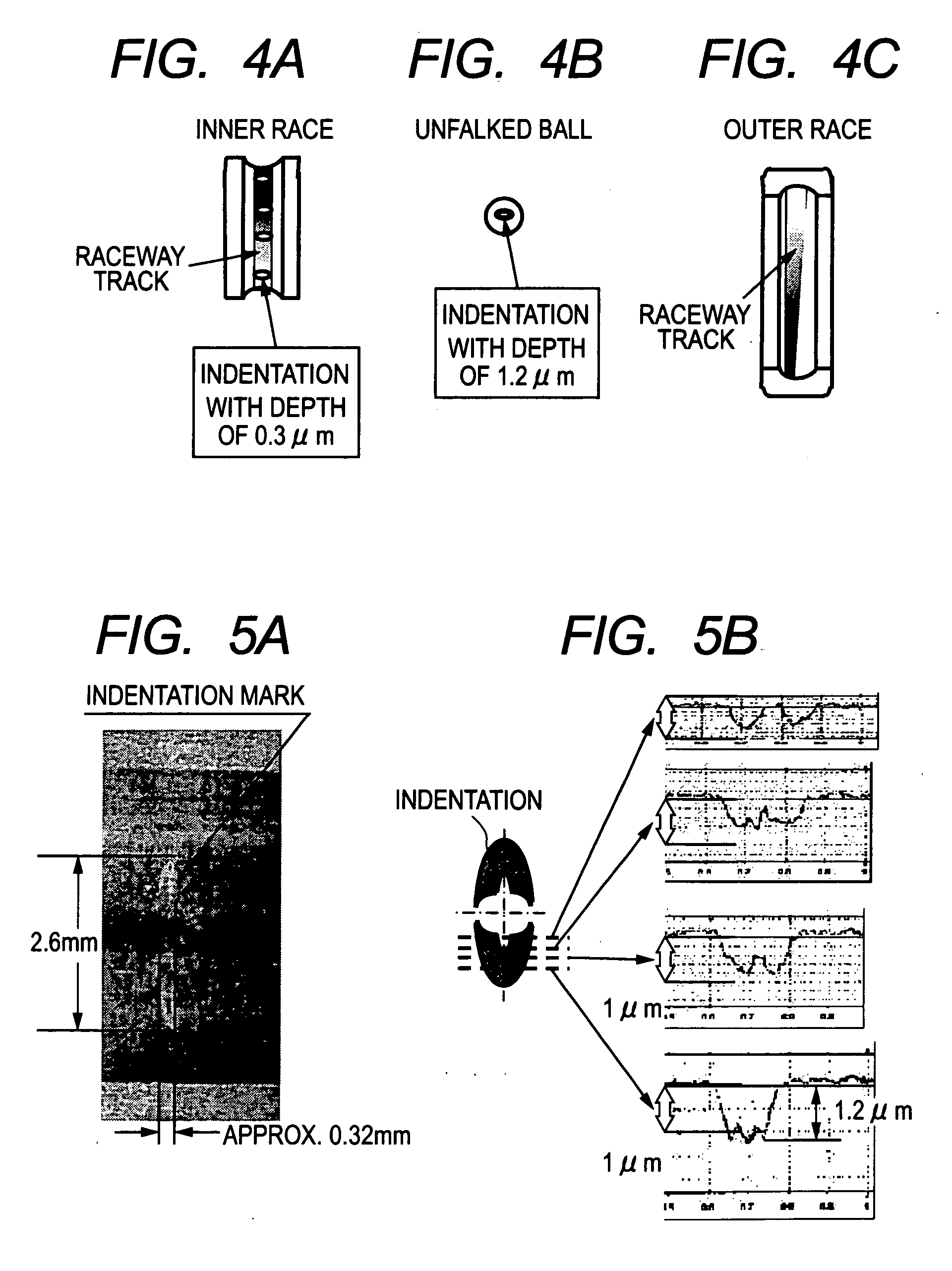

Apparatus and method for determining patterns of damage being caused in rolling contact element

InactiveUS20070044543A1Simple fashionAvoid damagePlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

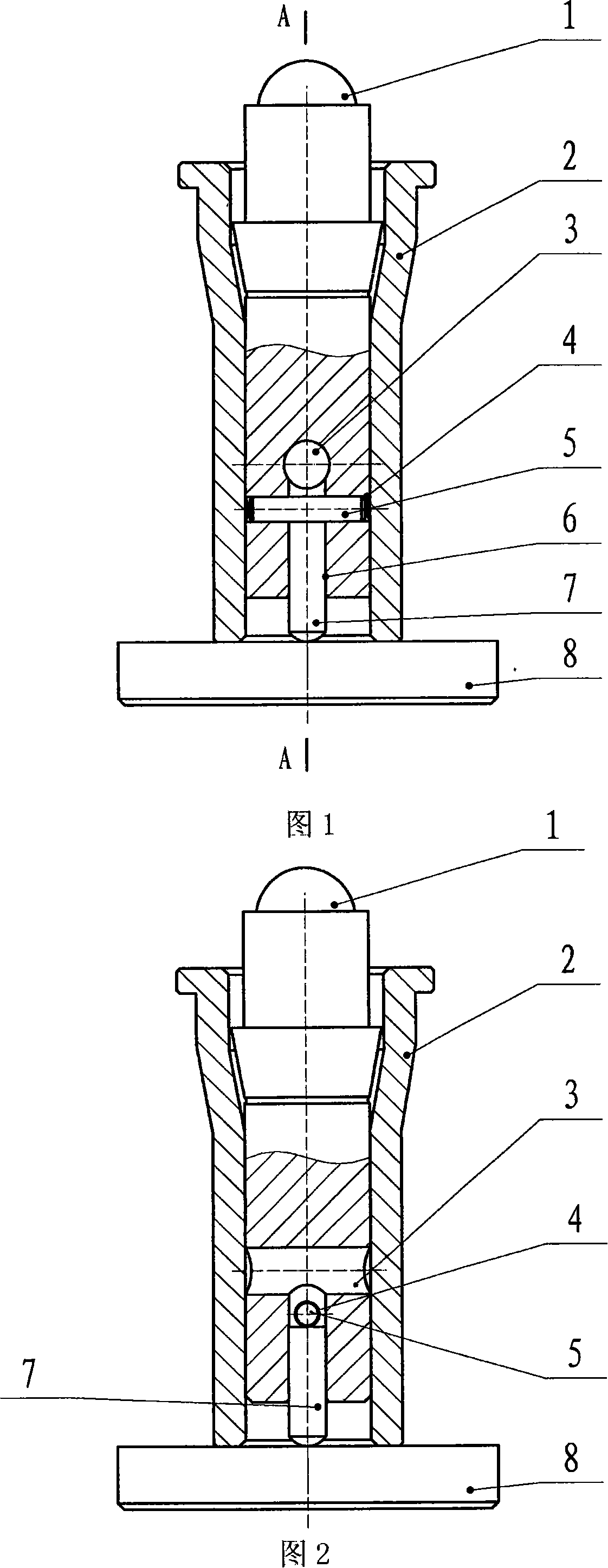

Portable Brinell hardness tester

The invention portable type brinell tester, the characteristic is that it includes pressure head strut, cut forelock and pressure head; setting the pressure head hole on the axes place of the bottom of pressure head strut, setting the cut forelock hole on the vertical cross place of the axes place of the bottom of pressure head strut; pressure head hole and cut forelock hole interpenetrate each other; setting the cut forelock in the cut forelock hole, setting the pressure head in the pressure head hole, superior extremity face touches with the middle of cut forelock, the bottom of pressure head comes out from pressure head hole. When doing the rigidity detection, throwing the pressure on the top of pressure head strut by the augmentor of dynamic or static state, when the test force reach cut forelock scissor broken, the cut forelock is cut three parts by pressure head strut and the top brink of pressure head. The advantage is easy operation, convenient carry,not need sample, it can test large scale work piece unable centre gripping on site testing and removing discommodityly.

Owner:SHENJAN TJANSIN TESTING INSTR KO LTD

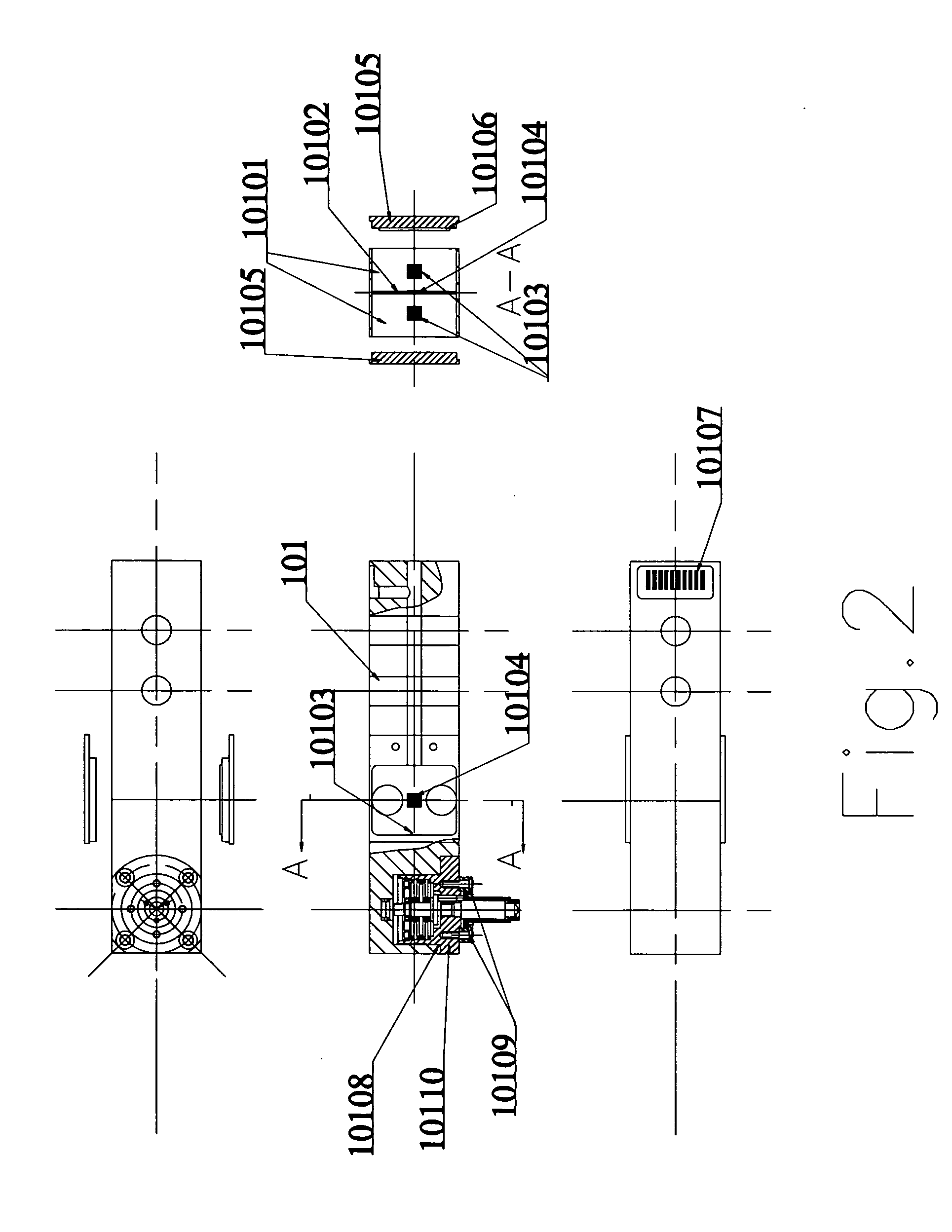

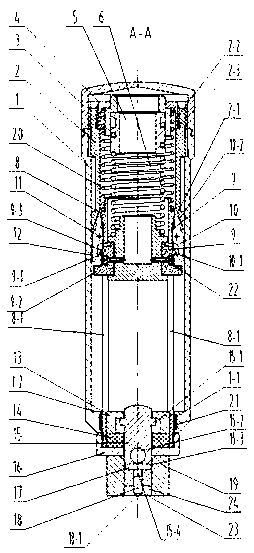

Shearing clutch type hammering Brinell hardness tester for applying test force through impact hammer

PendingCN110208121AConsistent test forceReduce labor intensityInvestigating material hardnessBrinellingHardness

The invention discloses a shearing clutch type hammering Brinell hardness tester for applying test force through an impact hammer. The problems that each operation impact force is inconsistent, the measurement result is large in error and the applicable range is narrow since the impact force on a spherical pressure head is produced by the knocking of a hammer or the knocking of the knocking part;the hardness tester is characterized in that a trigger cylinder and a telescopic cylinder are arranged in an outer cylinder, an impact hammer is arranged in the telescopic cylinder; after a circular conical surface at a lower end of the trigger cylinder contacts an arc bevel of a trigger, the trigger rotates around a trigger shaft, a trigger hook head of the trigger breaks away from a low boss ofa trigger pothook, the impact hammer downwardly popups under the expansion force effect of a main spring to strike a spherical head of a pressure head seat; the pressure head produces a counter-actingforce for the impact force produced by the impact hammer to break the shearing clutch into three sections. The hardness tester disclosed by the invention reduces the labor intensity and the operationdifficulty, so that the operation is easier and safer, the impact force is consistent, the measurement precision is high, the measurement is more stable, and the applicable range is wide.

Owner:SHENJAN TJANSIN TESTING INSTR KO LTD

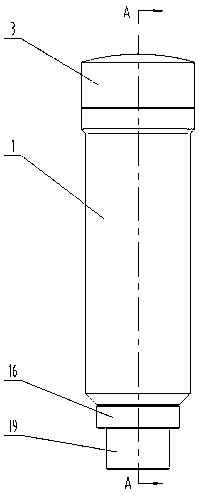

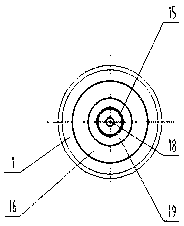

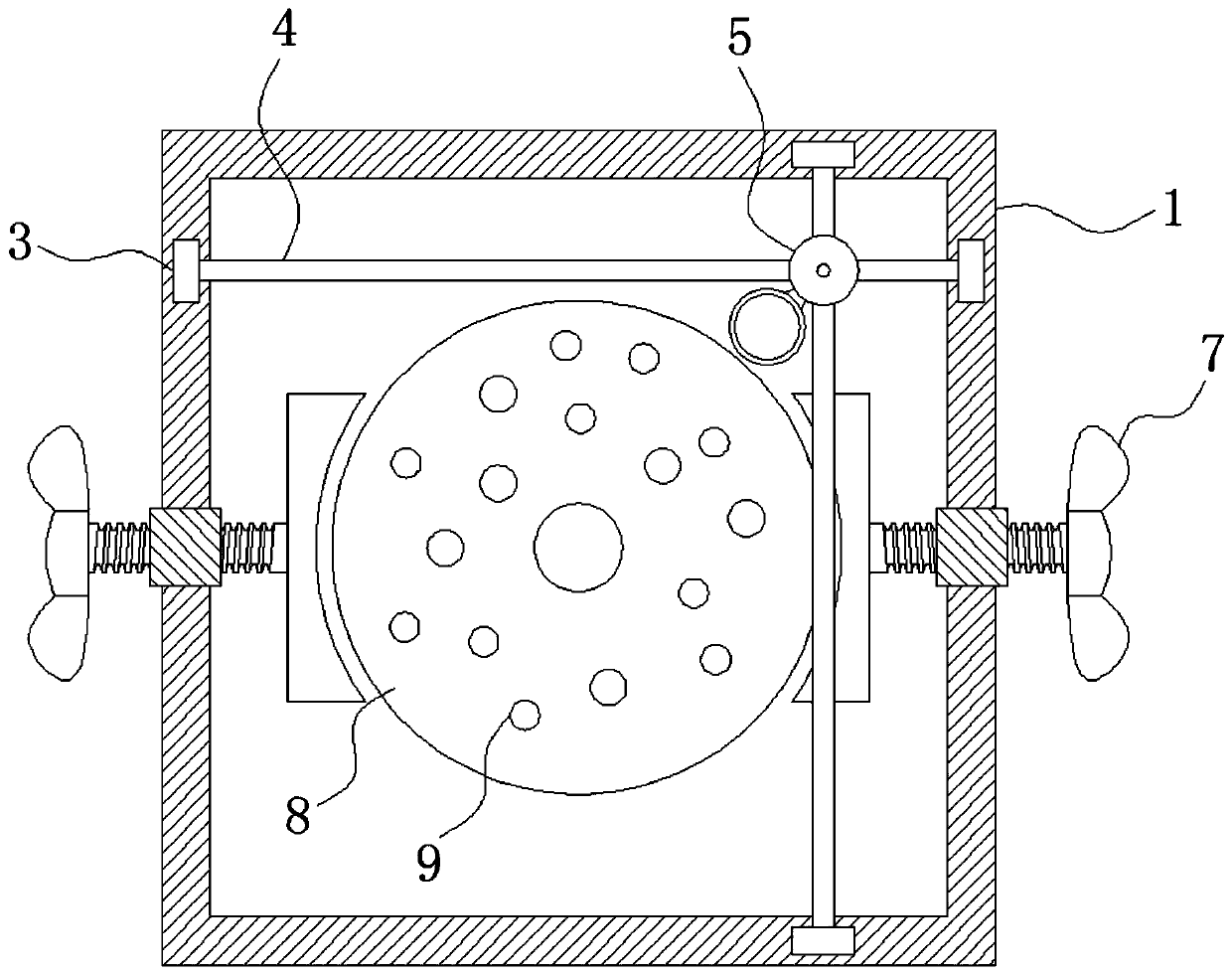

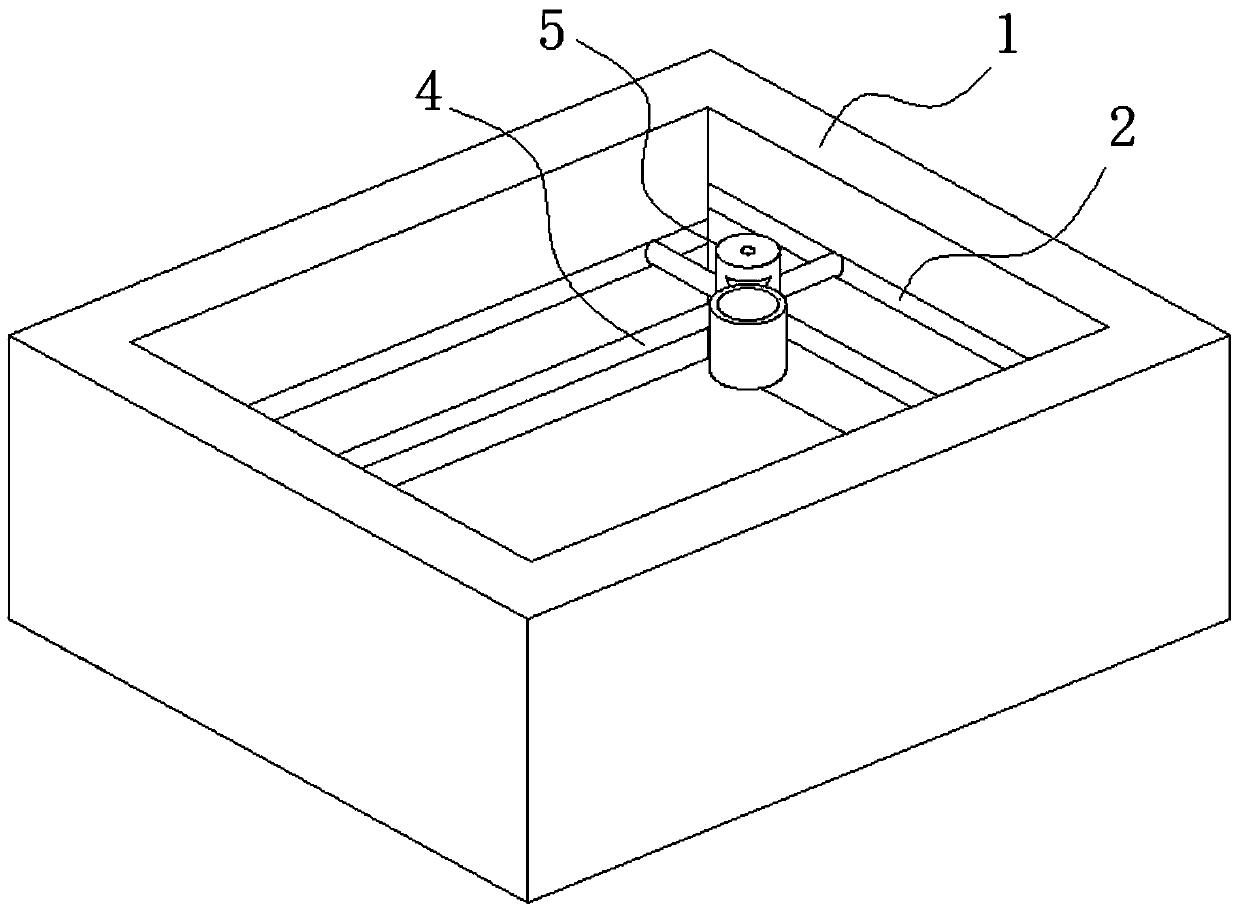

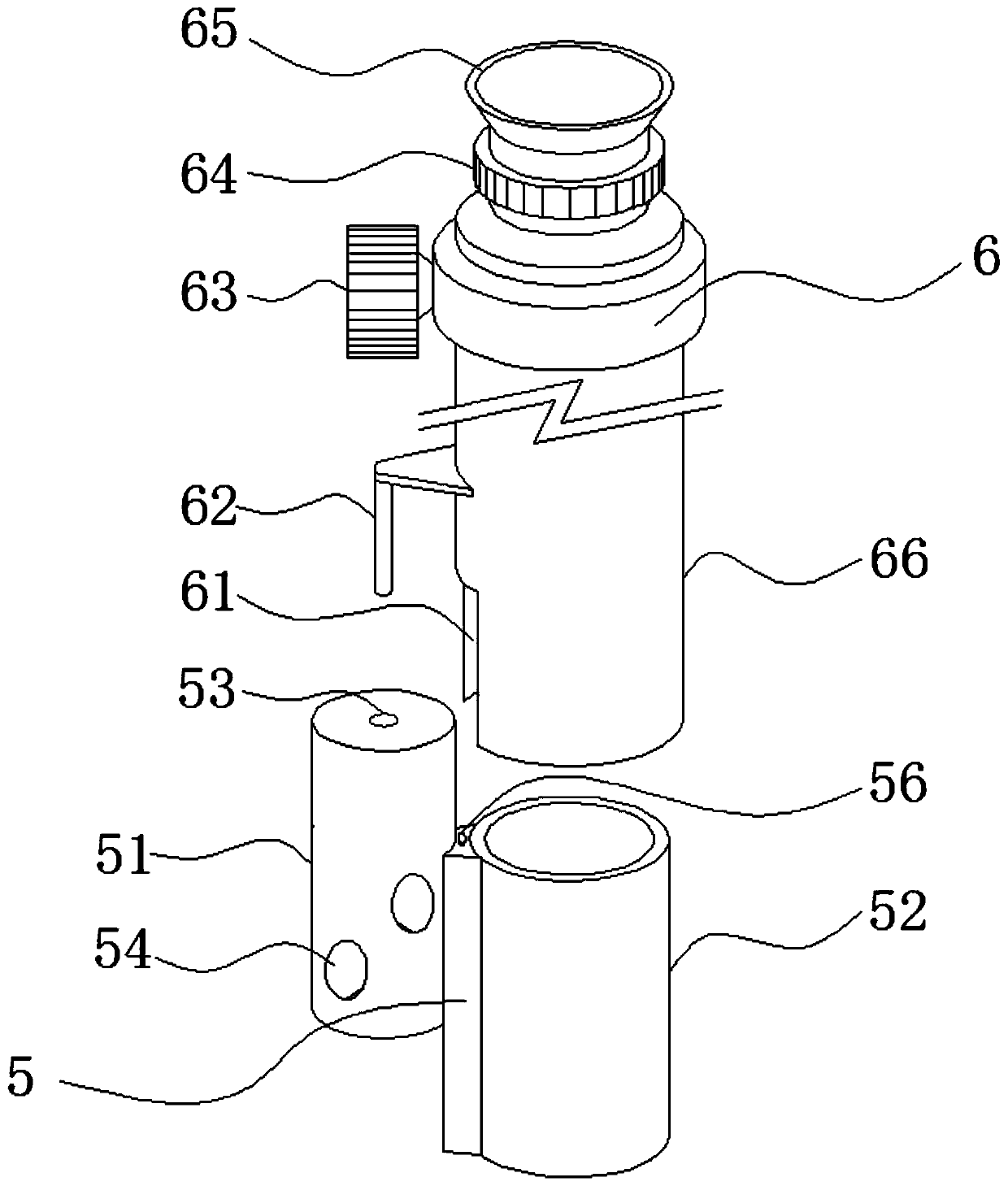

Brinell hardness circular groove indentation diameter measuring device

InactiveCN111189697AImprove practicalityGuaranteed levelMechanical diameter measurementsInvestigating material hardnessBrinellingMeasurement device

The invention provides a Brinell hardness circular groove indentation diameter measuring device, and relates to the technical field of metal hardness measuring instruments. The Brinell hardness circular groove indentation diameter measuring device comprises a frame body, and is characterized in that a guide rail groove is inwards formed in the inner wall of the frame body; the interior of the guide rail groove is slidably connected with a connecting rod through a roller, the connecting rod is slidably connected with a positioning device, the upper portion of the positioning device is sleeved with an observation and measurement device, the two sides of the frame body are fixedly connected with fixing devices, a metal sample plate is fixedly placed between the fixing devices, and an indentation groove is formed in the metal sample plate in an extruded mode. According to the invention, the measuring device can still measure the diameter of the indentation in a complex environment, the practicability is improved, the precision during measurement is improved, the indentation circular groove can be singly positioned and aligned before measurement, missing measurement or excessive measurement of the indentation circular groove is avoided, and the authenticity of multiple groups of data is improved.

Owner:林丽洁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com