Shearing clutch type hammering Brinell hardness tester for applying test force through impact hammer

A Brinell hardness tester and impact hammer technology, which is applied in the field of shear pin hammer Brinell hardness testers, can solve the problems of large error in measurement results, narrow application range, cost loss, etc., achieve good consistency and reduce labor intensity And operation difficulty, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

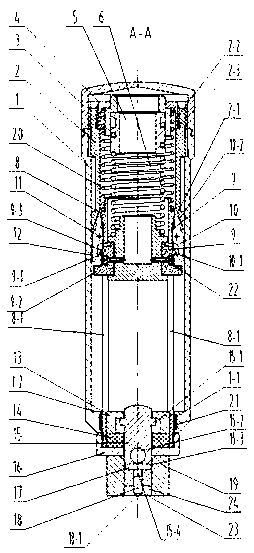

[0052] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

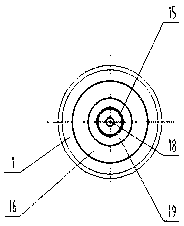

[0053] as attached Figure 1~5 As shown, the technical solution adopted by the present invention includes an outer cylinder 1 with upper and lower ends open, the diameter of the lower opening of the outer cylinder 1 is smaller than the diameter of the upper opening, and an inward annular limit step 1-2 is provided at the lower opening. , the inner wall of the annular limit step 1-2 is provided with an annular groove 1-1, and a wear-resistant ring 21 of a wear-resistant material is installed inside the annular groove 1-1; Connect and install the trigger cylinder 2 with upper and lower openings, the inner side of the lower end of the trigger cylinder 2 is a conical surface 2-1, and the inner and outer sides of the upper end of the trigger cylinder 2 are respectively processed with internal threads 2-2 and external threads 2-3, an upper cover 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com