Patents

Literature

157 results about "Vertical shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

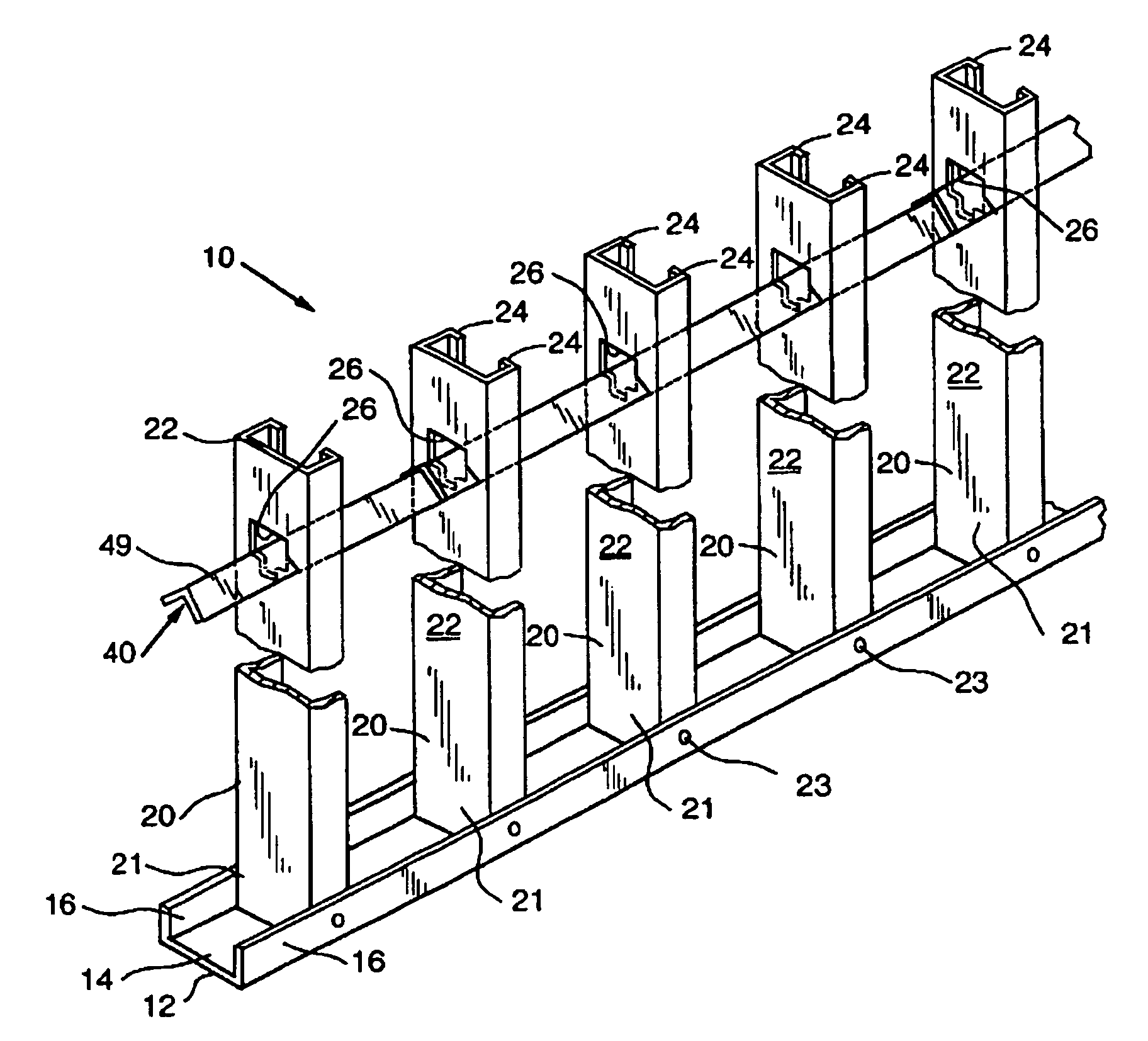

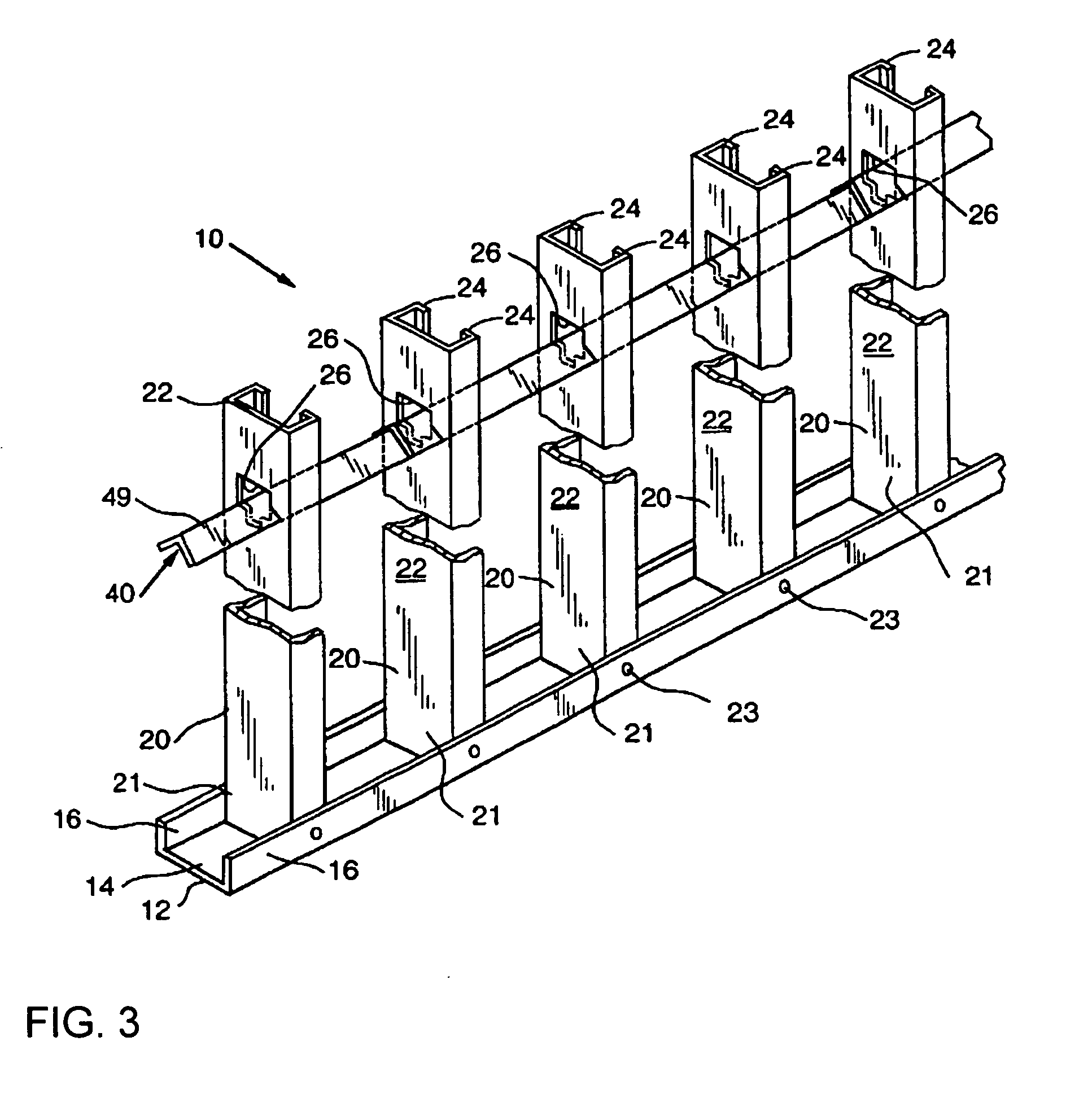

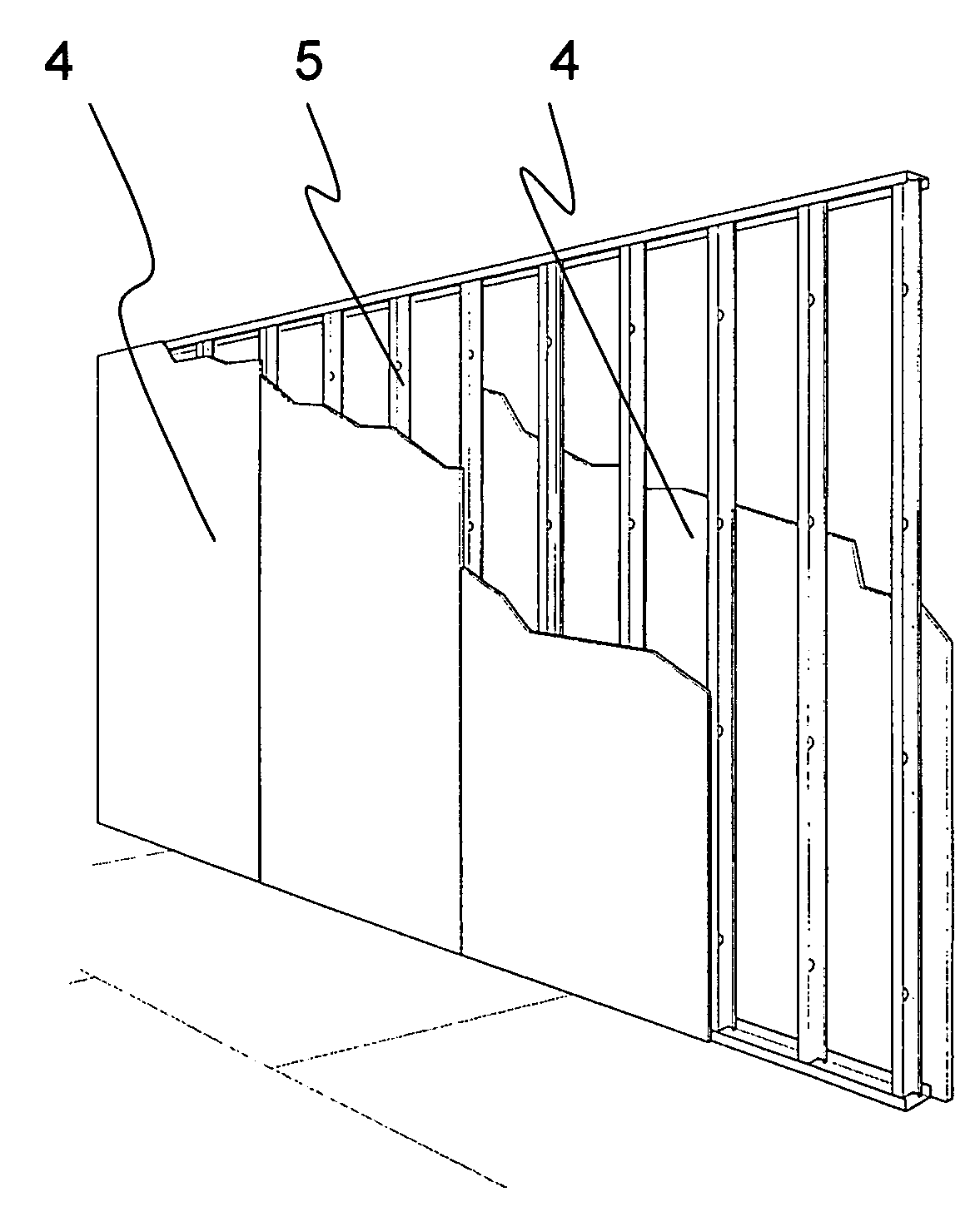

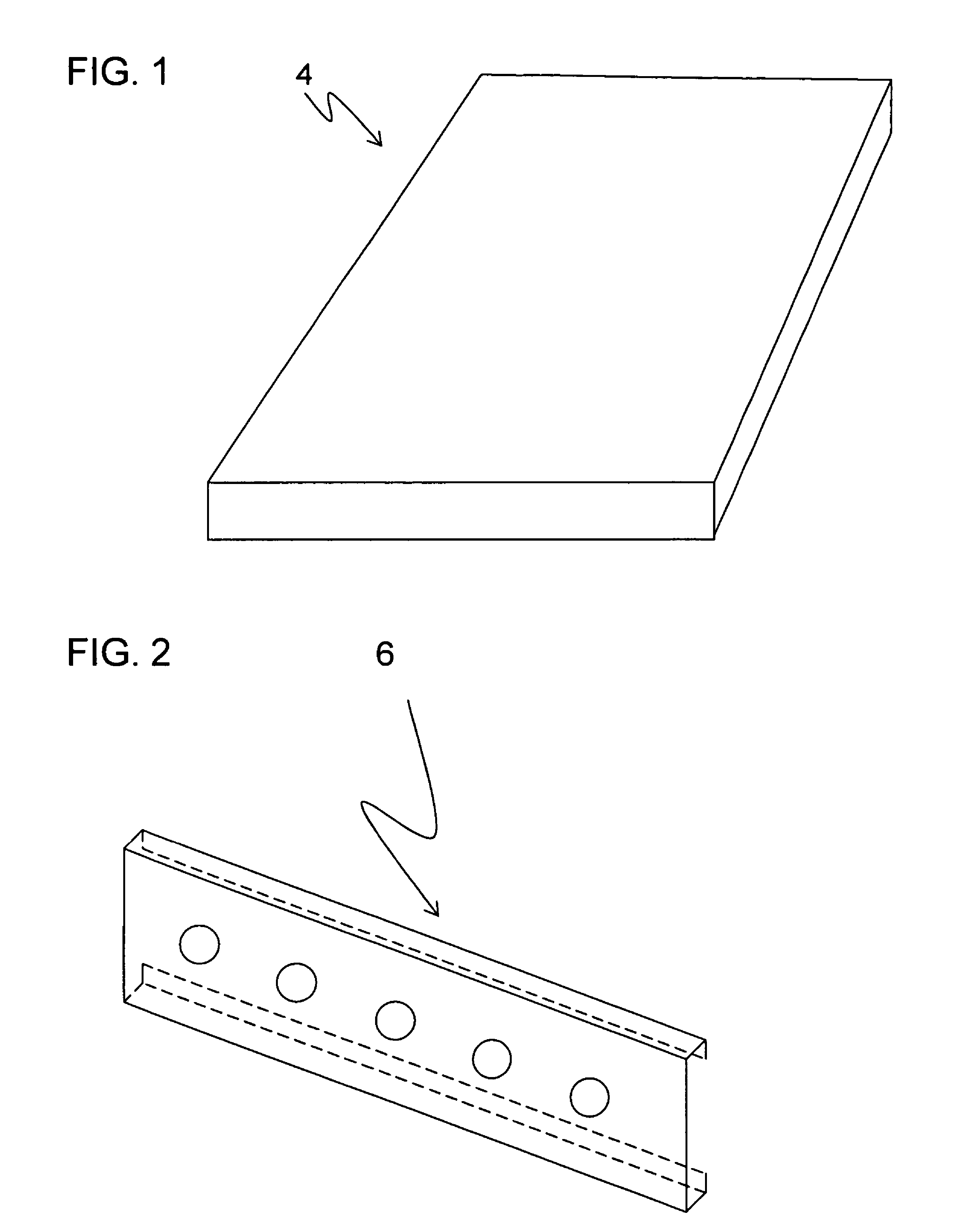

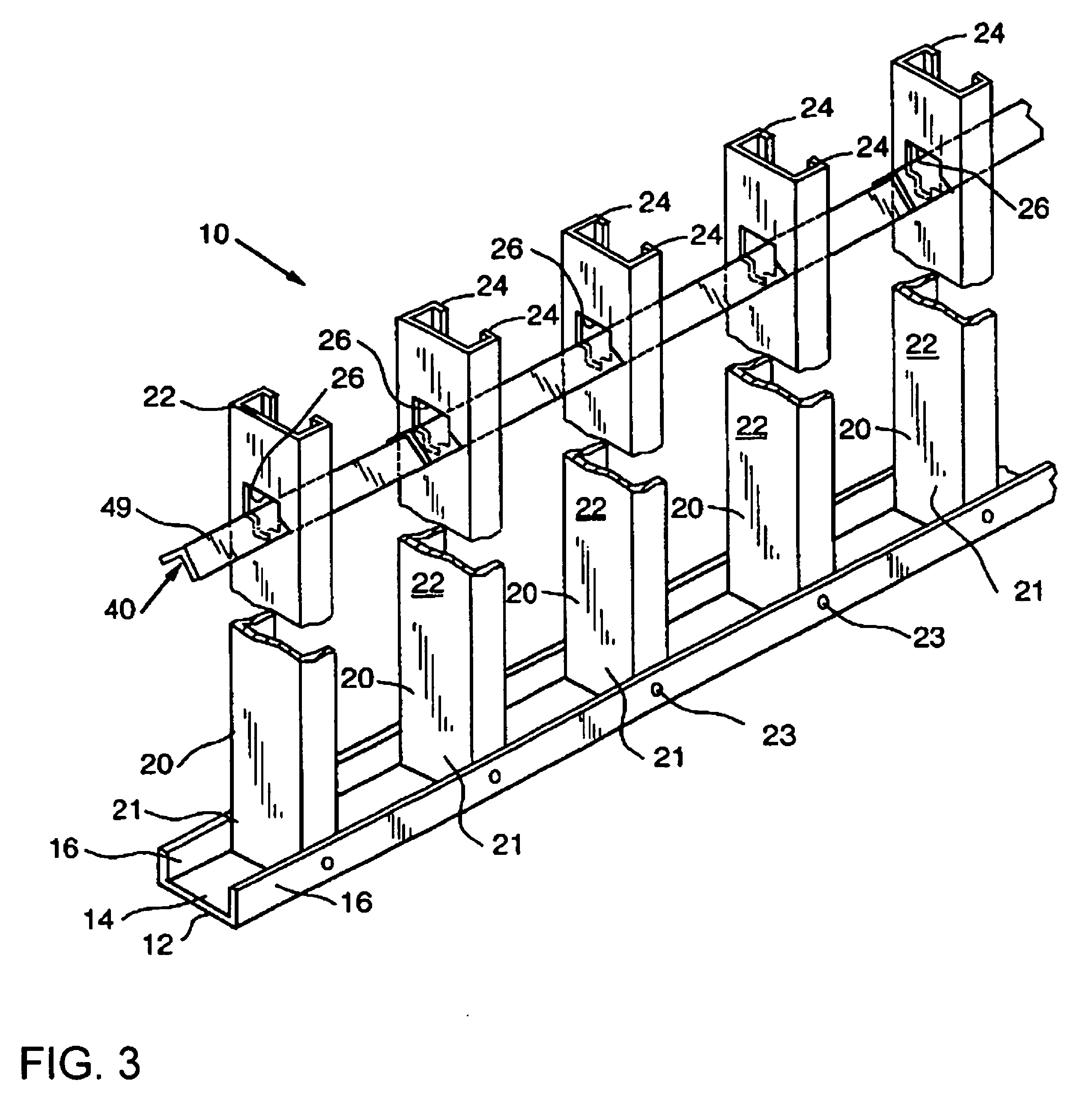

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

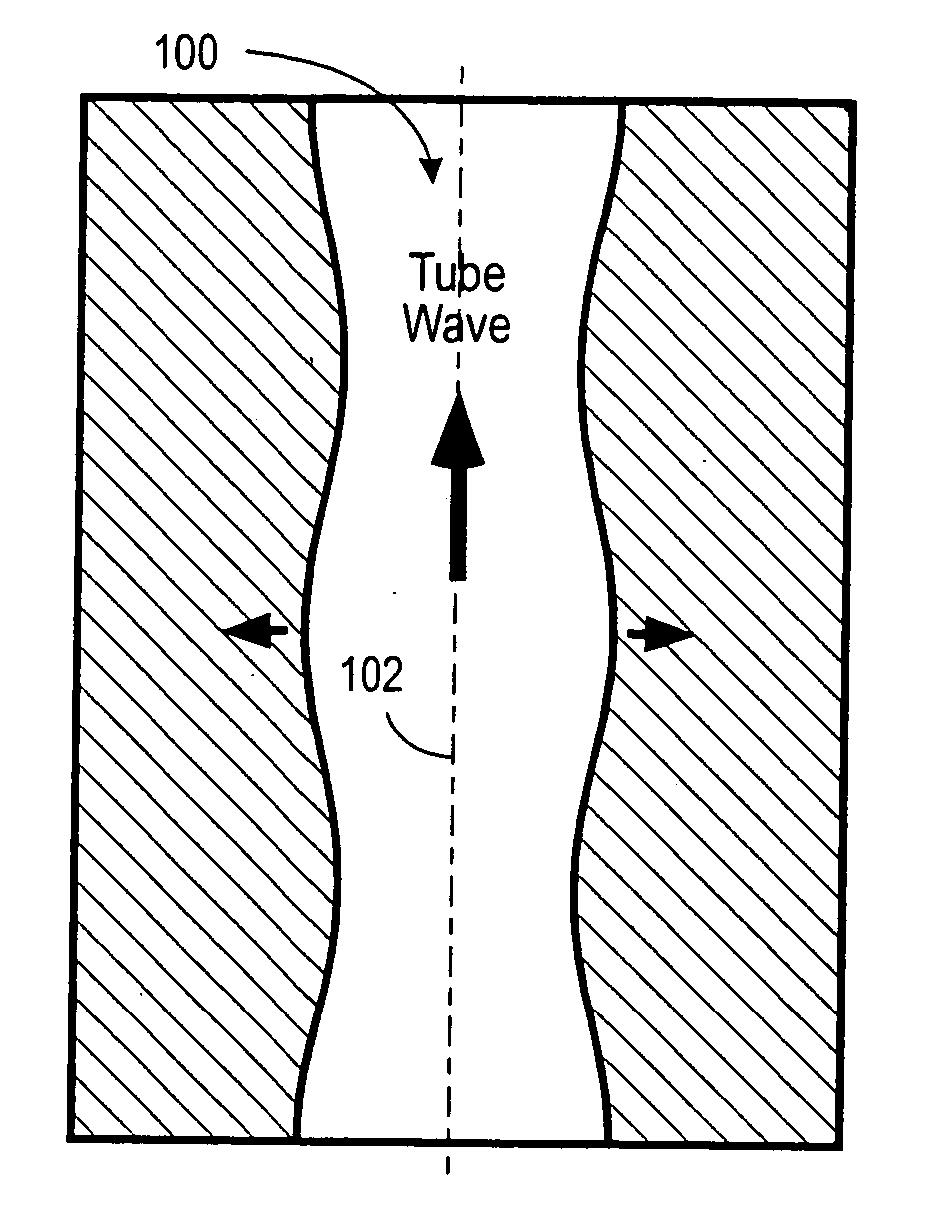

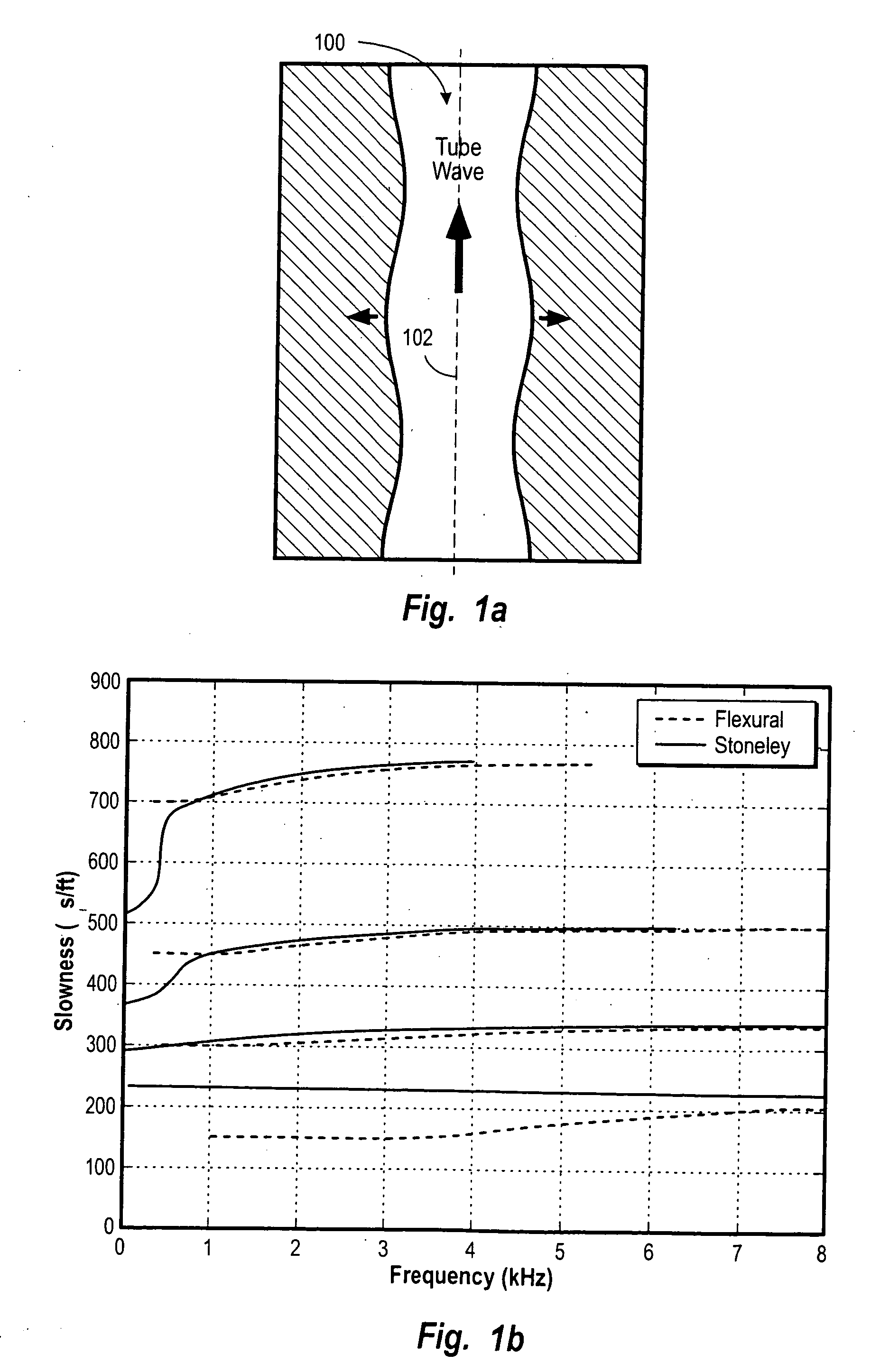

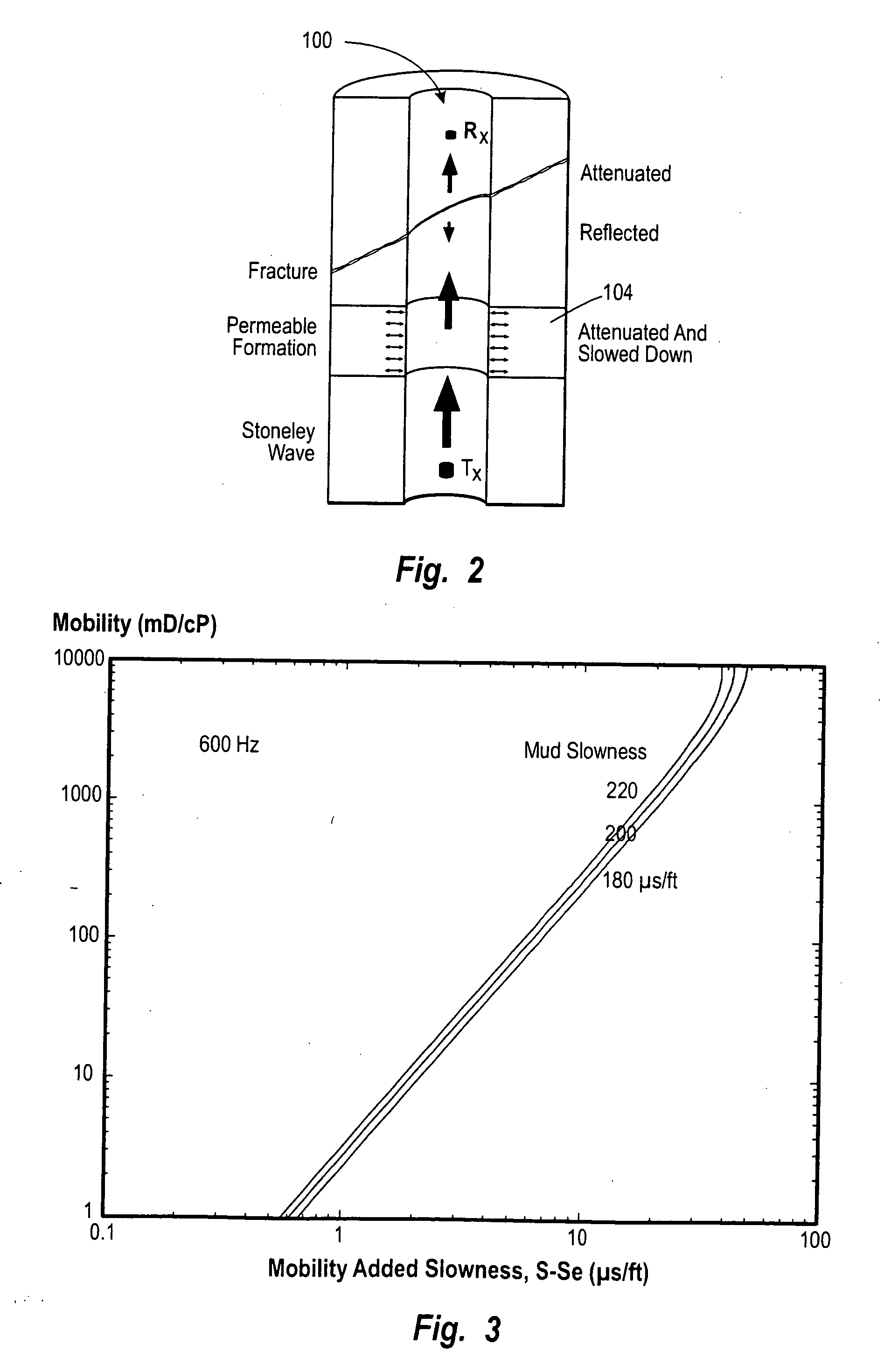

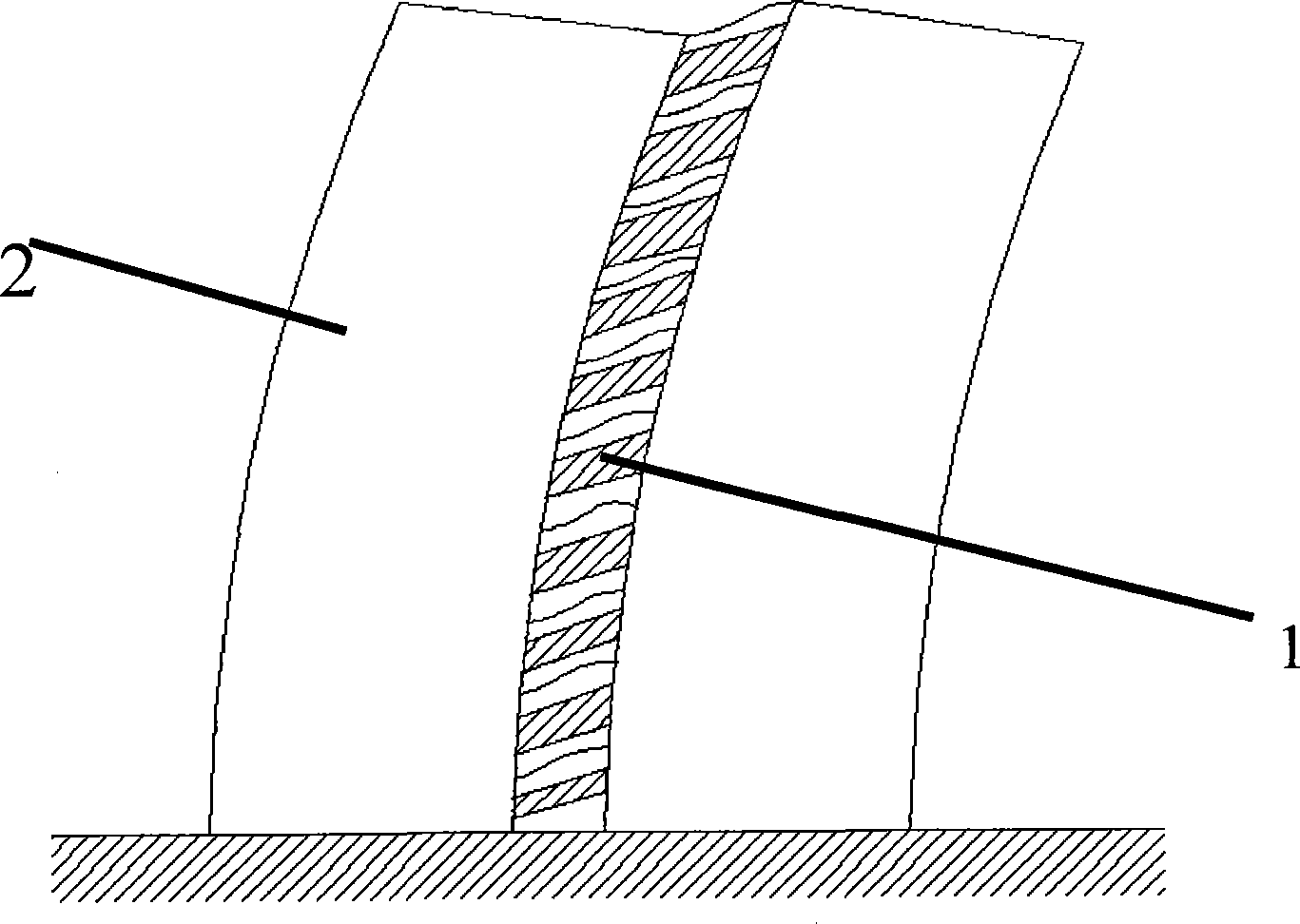

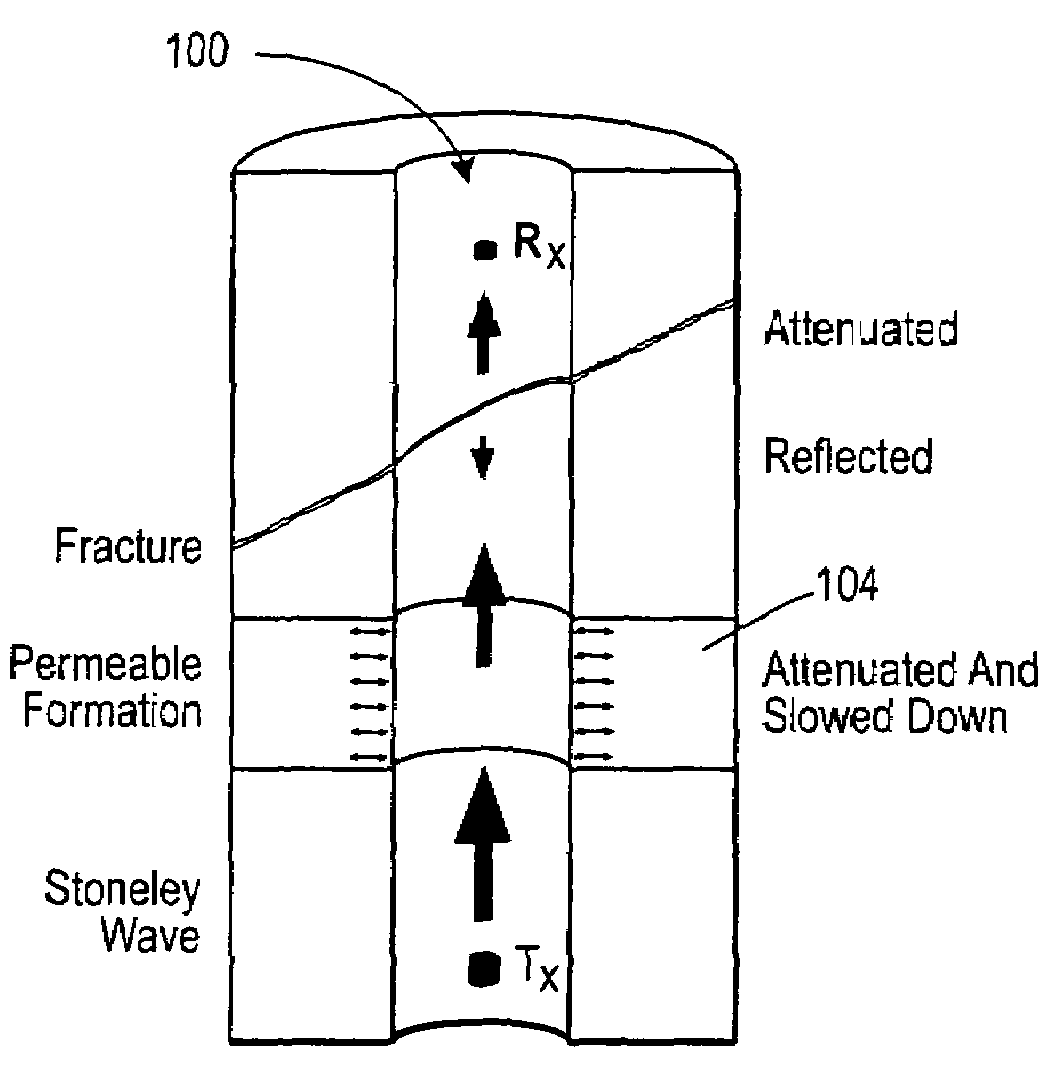

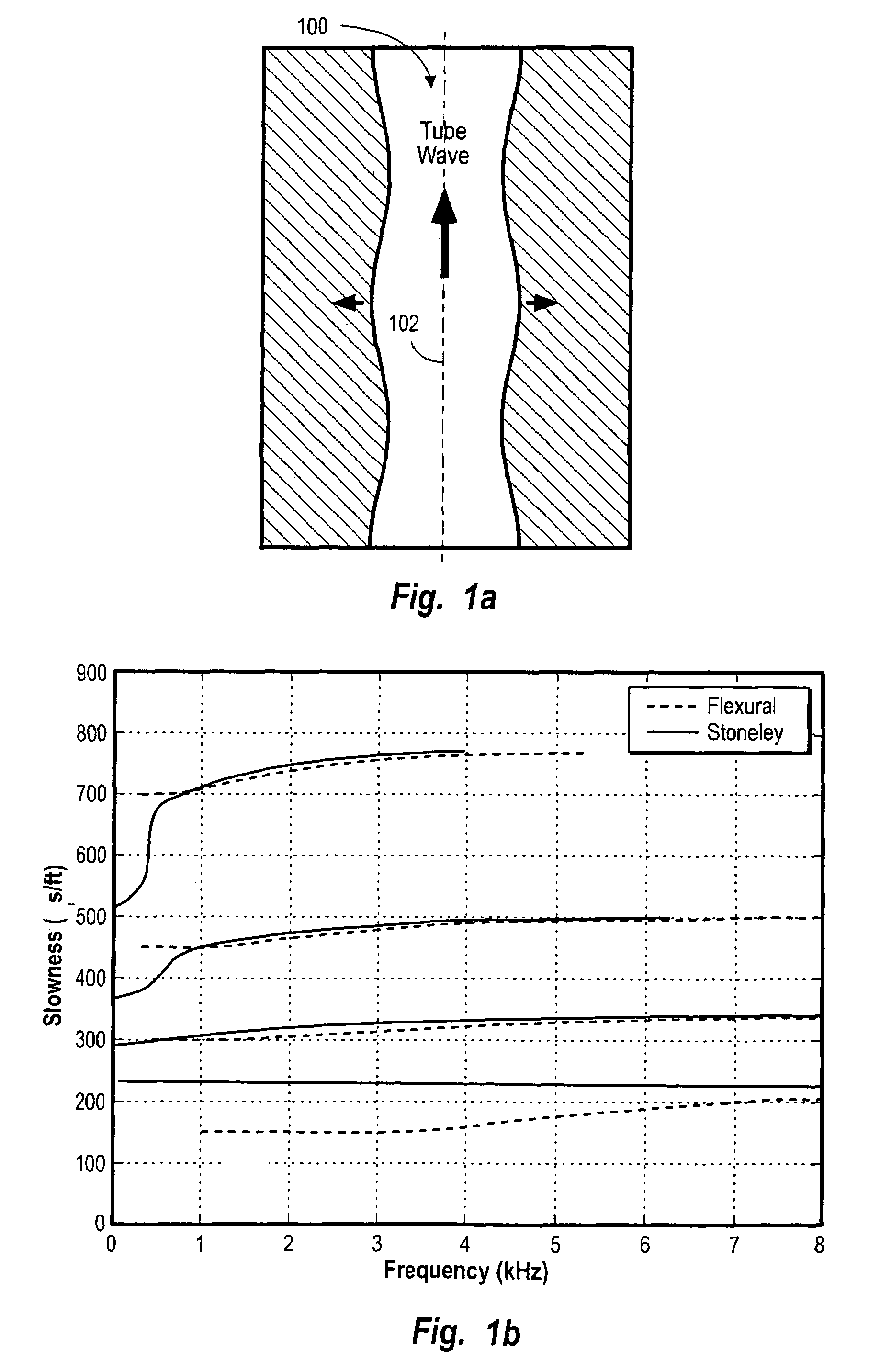

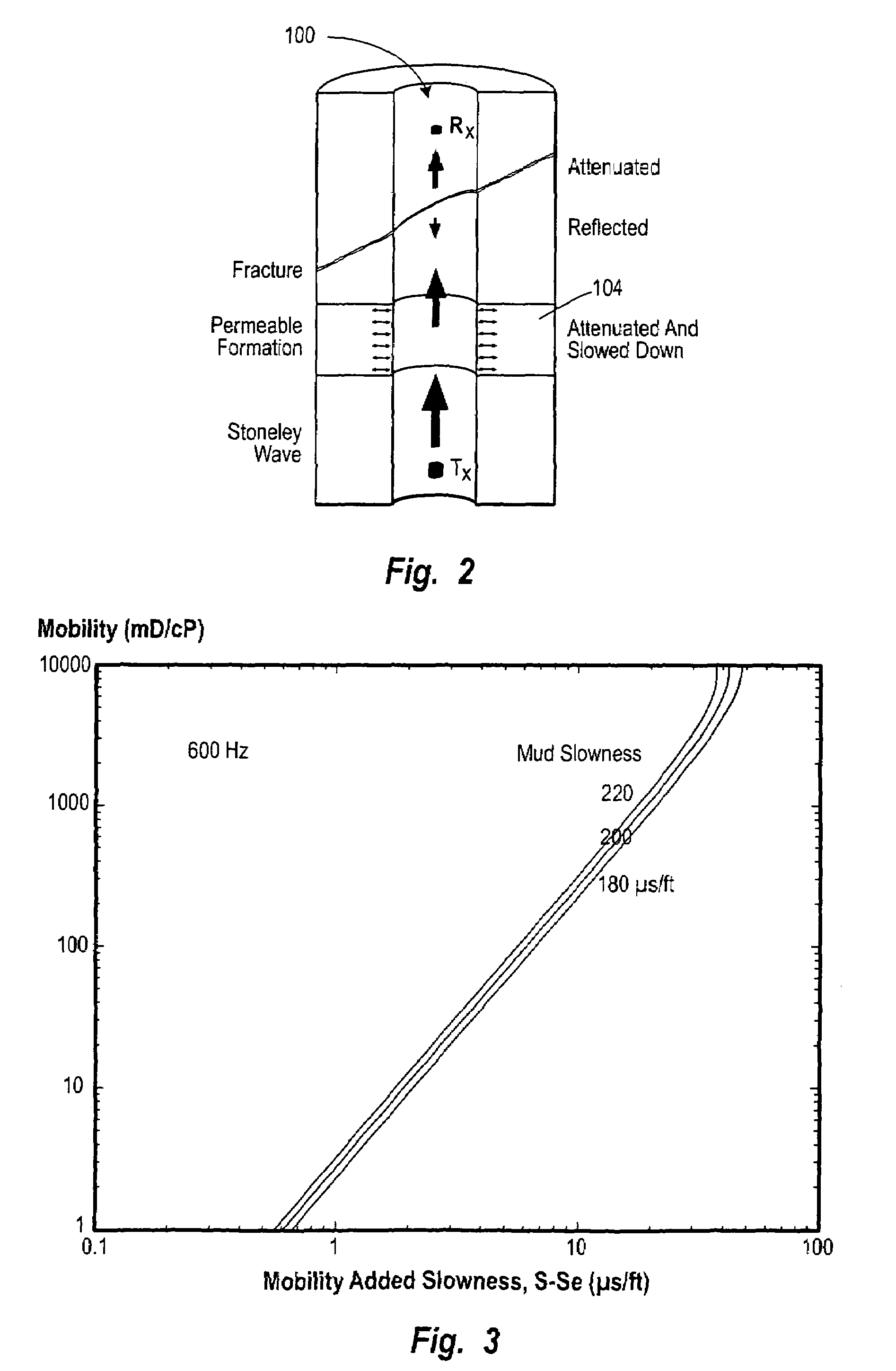

Radial profiling of formation mobility using horizontal and vertical shear slowness profiles

ActiveUS20060285437A1Accurate radial profileAccurate profileSeismology for water-loggingVertical shearAids walking

Methods and apparatus facilitating radial profiling of formation mobility are disclosed. Radial profiling of formation mobility aids in an optimal completion of a well for enhanced production. Some aspects of the present invention provide a technique for radial profiling of formation mobility based on inverting differences between a Stoneley radial profile of horizontal shear slowness and a dipole radial profile of vertical shear slowness for a reservoir interval.

Owner:SCHLUMBERGER TECH CORP

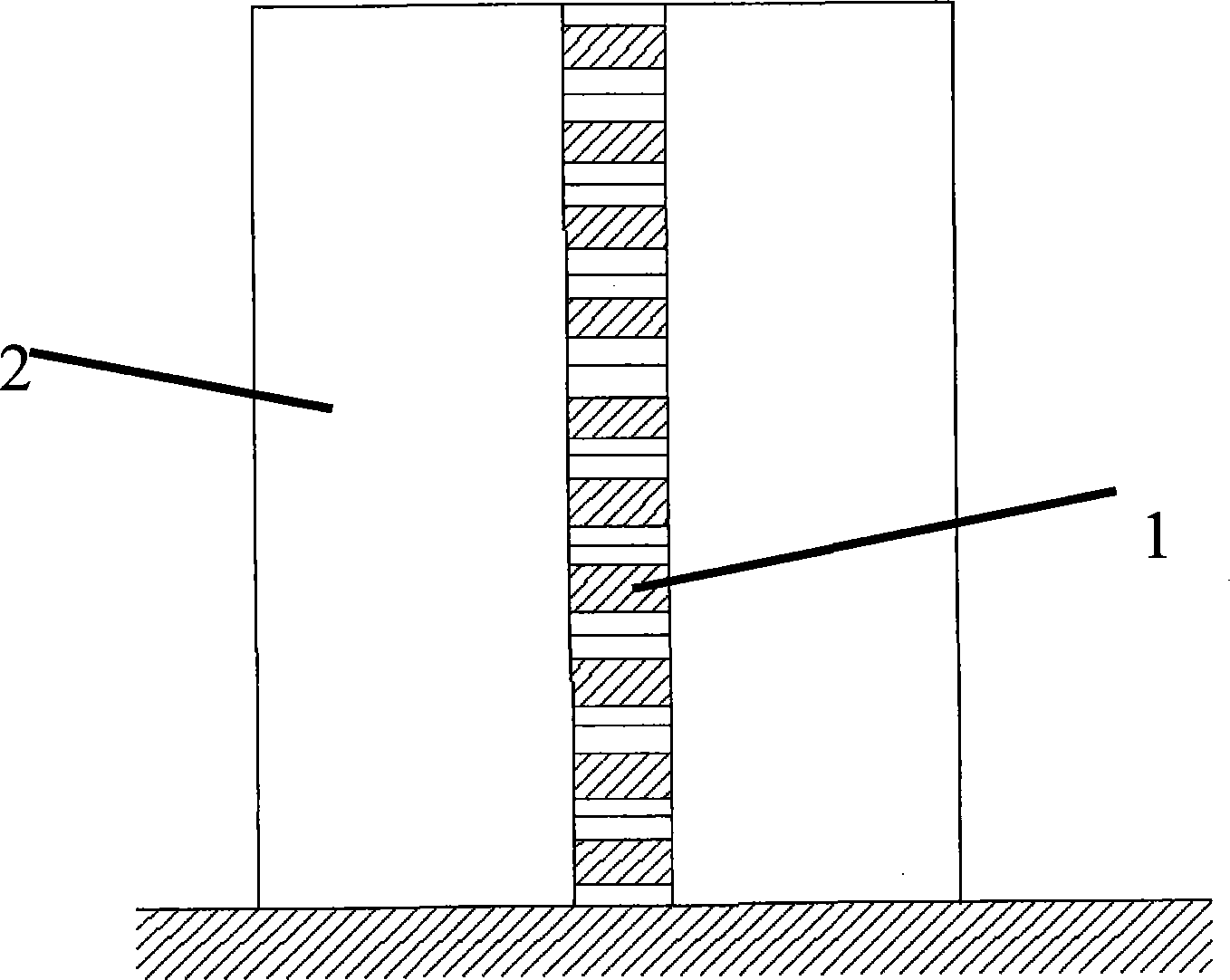

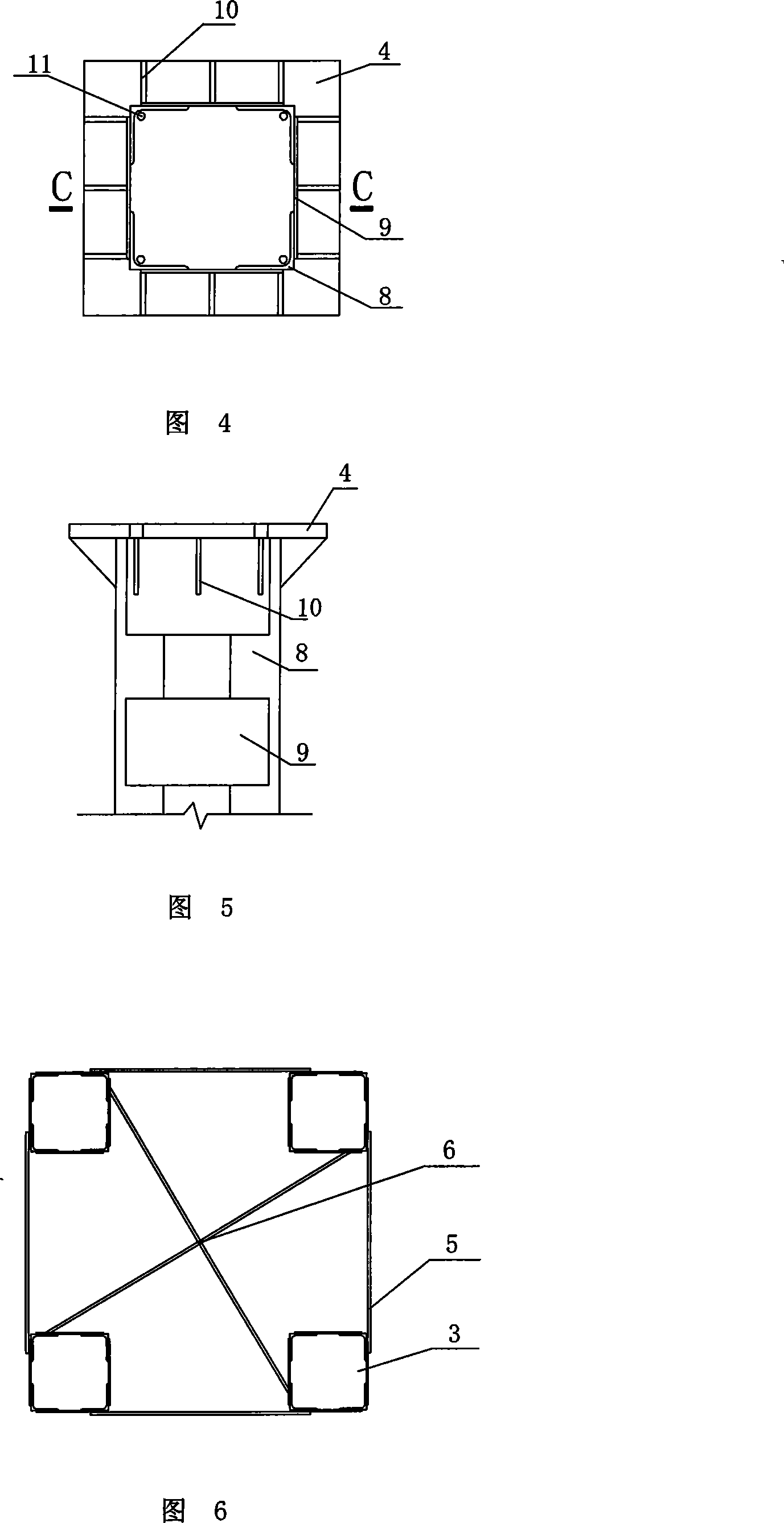

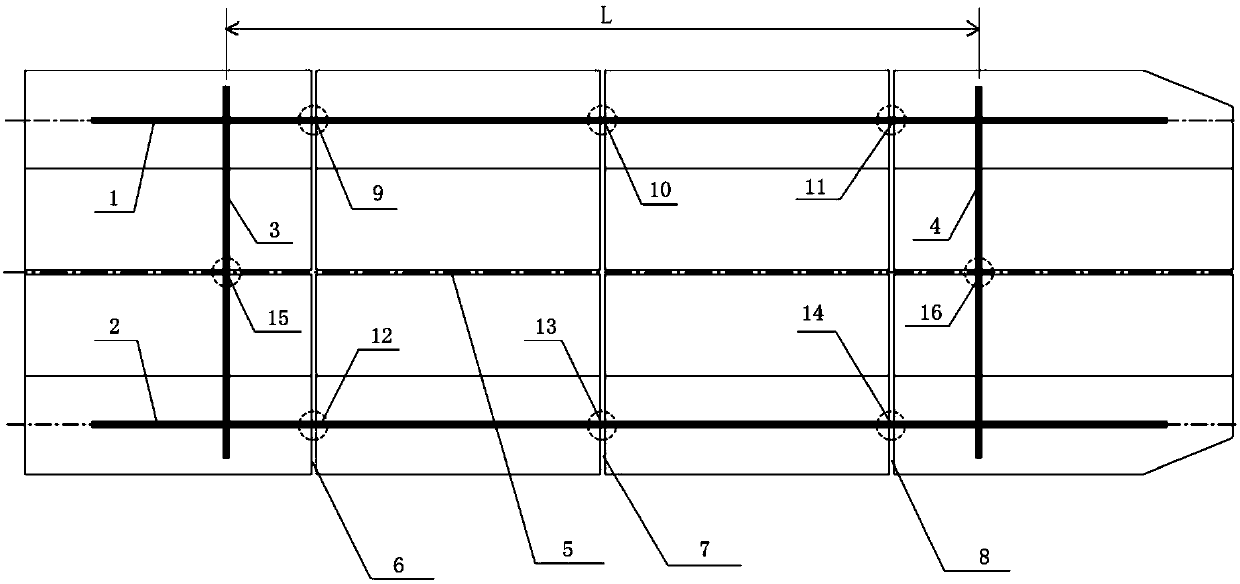

High-rise vertical shearing energy-consuming steel plate wall structure system

The invention belongs to the structural engineering technical field, and more particularly relates to a structural system which cuts an energy-consumption steel plate wall in high level and vertically. The structural system consists of a wall, the two sides of which are connected with thin steel plates, which is taken as an energy-consumption component and other optional structural components; the system is provided with a steel plate wall which is connected with the two sides of a column in a run-through way in a certain intermediate span, and the steel plate wall is used in vertical cutting energy-consumption when the structure suffers from dynamic action such as earthquake or oscillating wind, etc. The horizontal anti-lateral force system of the structure can be the system of frame support, a frame steel plate wall, a frame combined wall, a concrete shear wall and a concrete shear cylinder, etc. The wall, the two sides of which are connected with thin steel plates, refers to the steel plate wall, the two sides of which are connected with the column or the wall; the structural system which cuts an energy-consumption steal plate wall in high level and vertically which is provided by the invention is a multiple high-level structural system which is suitable for an earthquake region; has the advantages of definite failure mode, high bearing capacity, large anti-lateral stiffness, concentrated damage and being convenient for reparation, etc.; has good earthquake-resistance performance and good capacities of tensibility and hysteresis energy-consumption; therefore, the structural system which cuts the energy-consumption steel plate wall in high level and vertically is a superior anti-earthquake and energy-consumption component.

Owner:TONGJI UNIV

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS7849649B2Maximization of building volumeEffective volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Sea wind resource evaluation method based on WRF mode

InactiveCN103778572ADensity is accurateThe result is accurateData processing applicationsDensity of airEngineering

The invention discloses a sea wind resource evaluation method based on a WRF mode. The sea wind resource evaluation method based on the WRF mode mainly comprises the steps of obtaining WRF numerical value weather forecast data and anemometer tower data, building a vertical shear model of wind, building a wind speed probability model, evaluating air density and evaluating wind power density and annual energy output. The sea wind resource evaluation method based on the WRF mode evaluates sea wind resources through the WRF numerical value weather forecast data, and effectively overcomes the defect that a traditional wind resource evaluation technology is low in accuracy.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

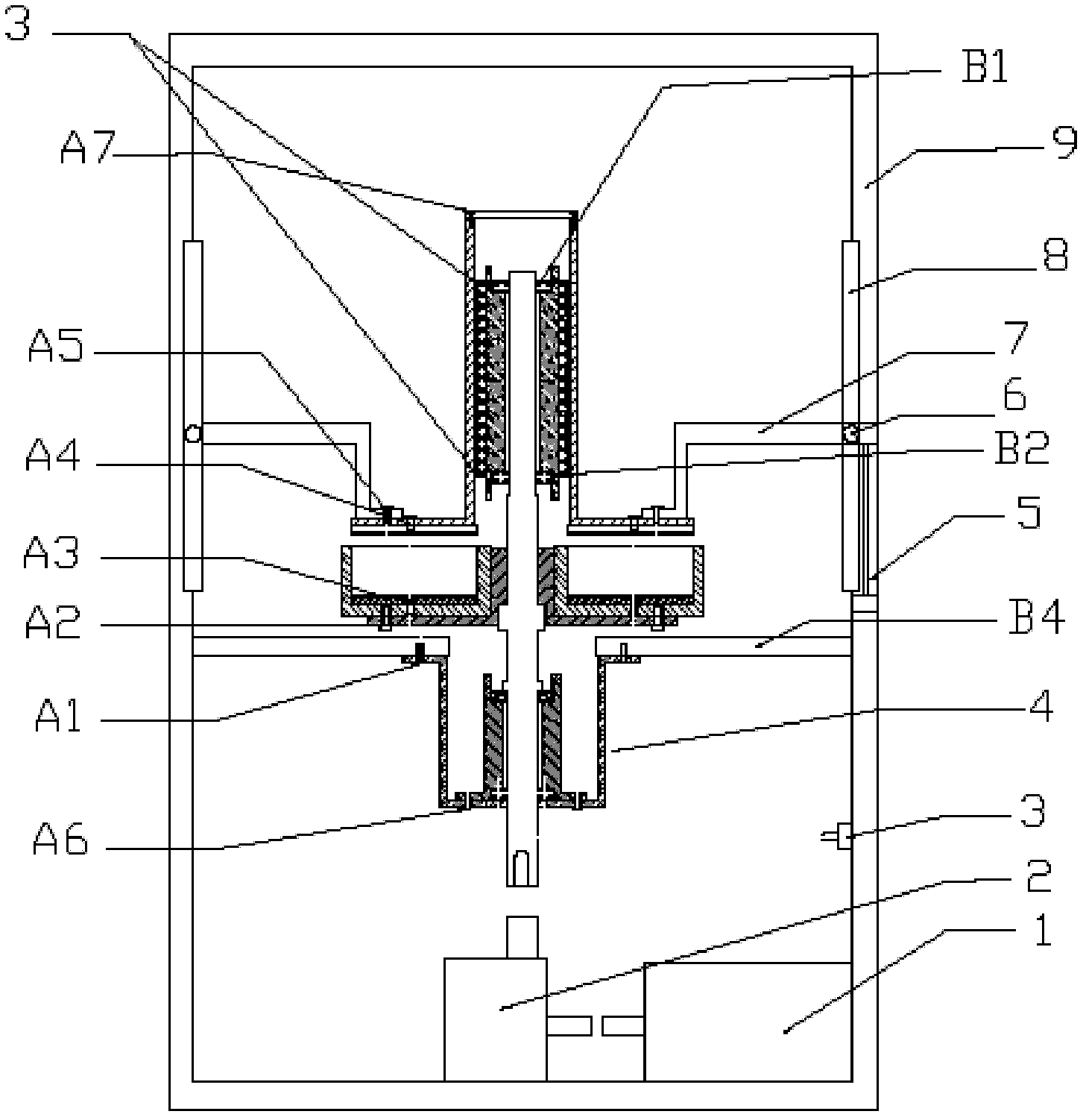

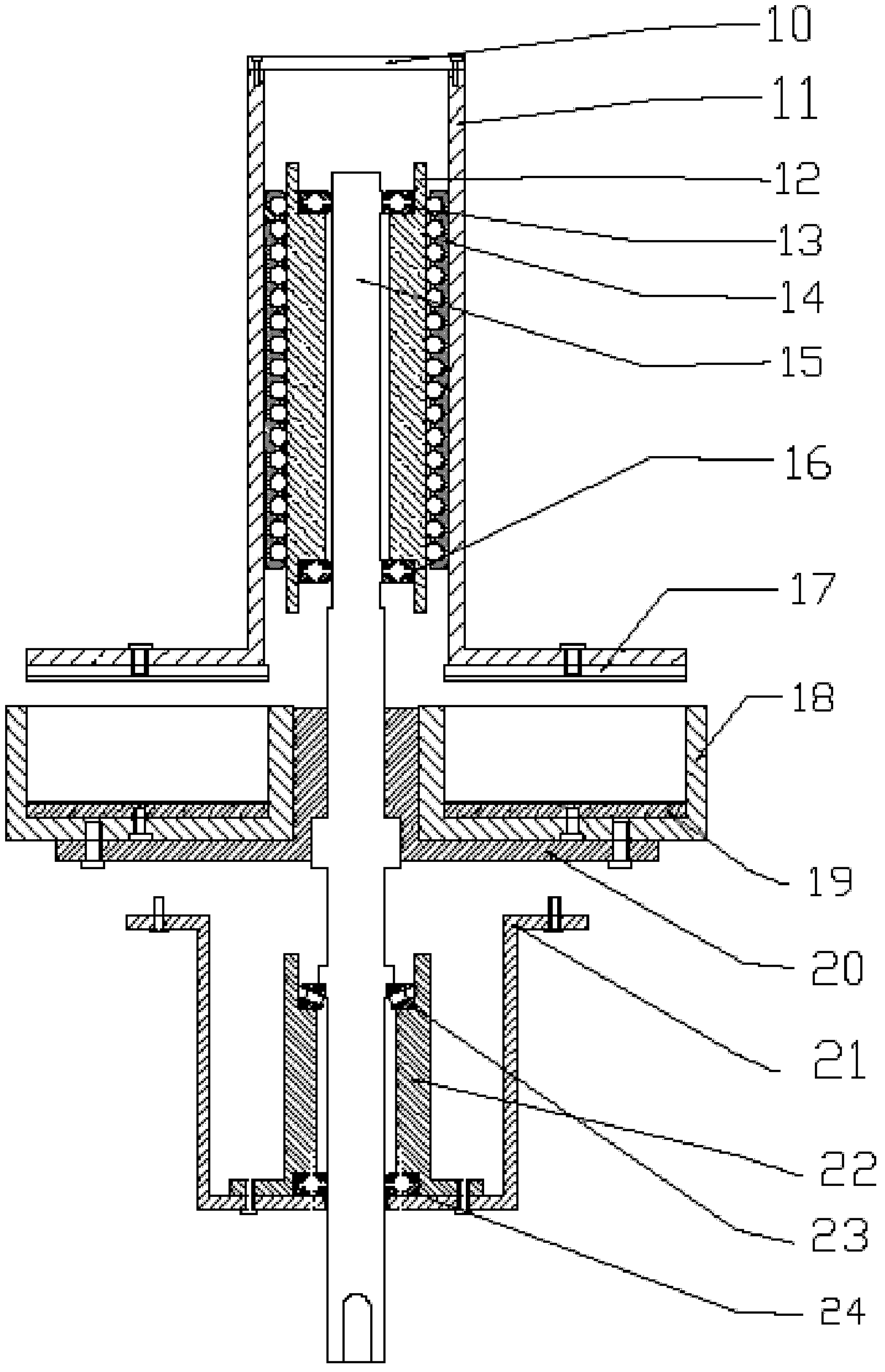

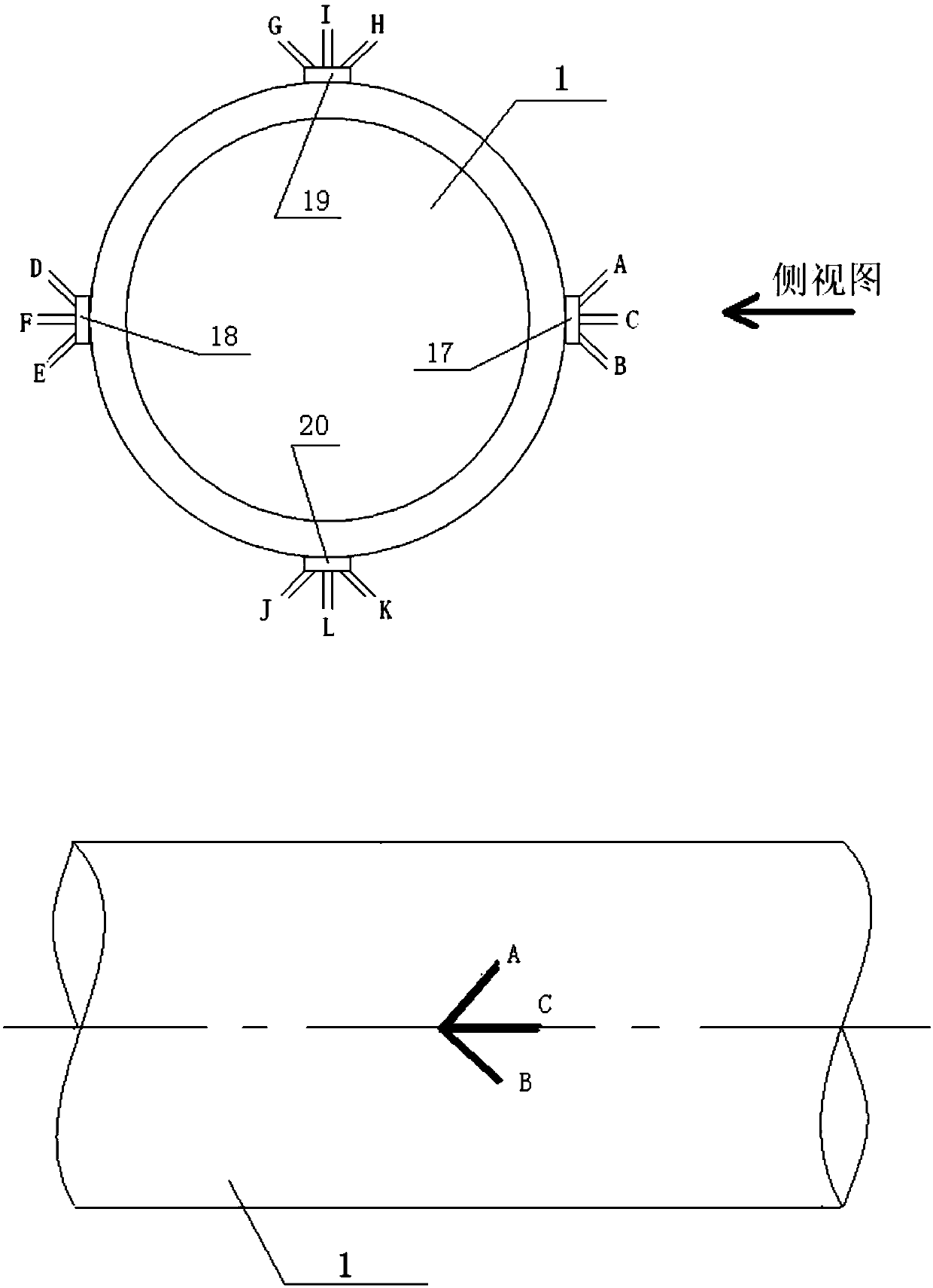

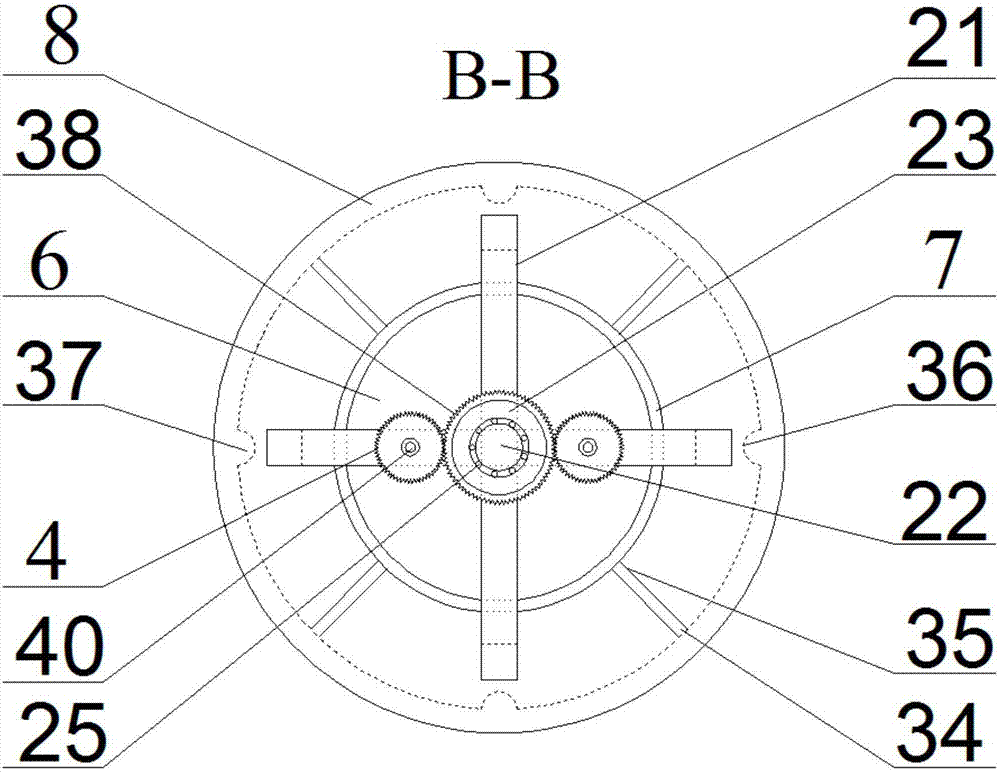

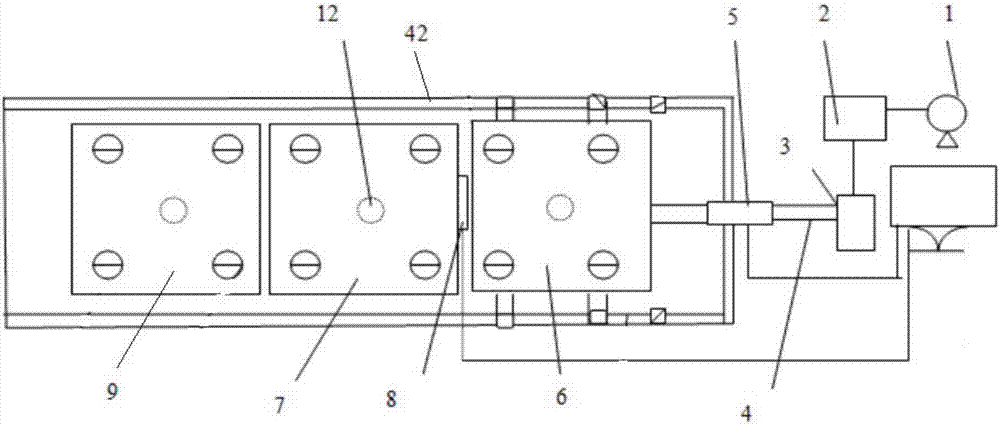

Multifunctional ring shear apparatus

InactiveCN102621044AThe upper limit of exercise distance is unlimitedDifferent shear ratesMaterial strength using steady shearing forcesEngineeringVertical shear

The invention relates to a multifunctional ring shear apparatus, which is applicable to measuring shear resistance of granular materials such as soil, stones and the like and volume change of the granular materials during shear. The multifunctional ring shear apparatus mainly comprises a main unit, a hydraulic lifting system, a rotary power system, a measuring system, a frame and the like, wherein the main unit, the rotary power system, the hydraulic lifting system and the measuring system are respectively fixed onto the frame, and the main unit comprises a shaft, an upper shear box, a lower shear box, a bearing flange and the like. A ring shear box provides a horizontal shear mode, a vertical shear mode and different roughness conditions, bulk granular materials such as the soil, the stones and the like flow in the ring shear box, the shear force of sheared surfaces of the granular materials is measured during flowing, and the ring shear box can be replaced in use. The multifunctional ring shear apparatus can be used for accurately measuring volume control, vertical pressure control, shear rate control, the shear force, shear rate, the volume change, pressure and the like of action objects.

Owner:DALIAN UNIV OF TECH

Radial profiling of formation mobility using horizontal and vertical shear slowness profiles

ActiveUS7652950B2Accurate profileIncrease productionSeismic signal processingSeismology for water-loggingVertical shearAids walking

Methods and apparatus facilitating radial profiling of formation mobility are disclosed. Radial profiling of formation mobility aids in an optimal completion of a well for enhanced production. Some aspects of the present invention provide a technique for radial profiling of formation mobility based on inverting differences between a Stoneley radial profile of horizontal shear slowness and a dipole radial profile of vertical shear slowness for a reservoir interval.

Owner:SCHLUMBERGER TECH CORP

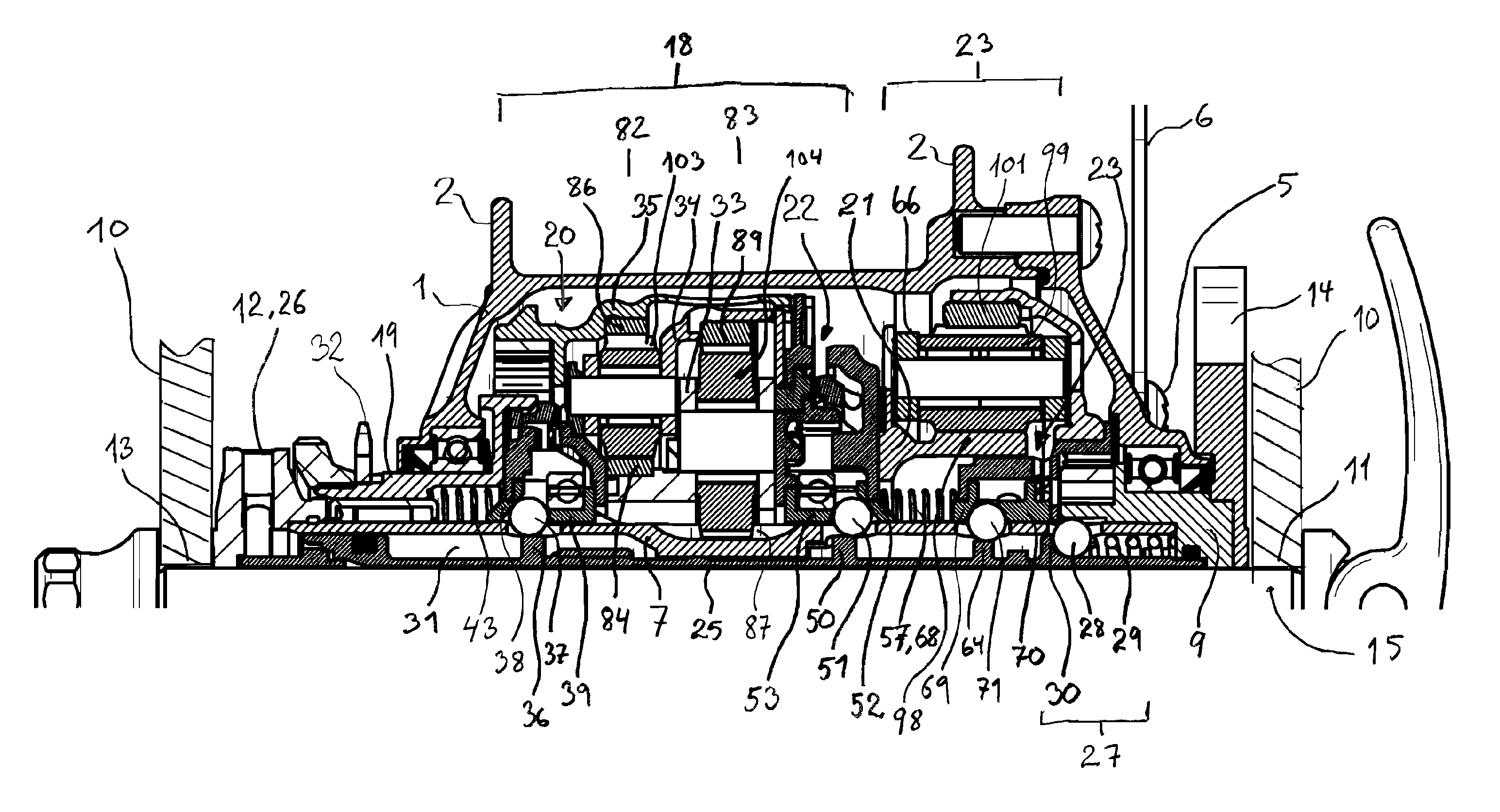

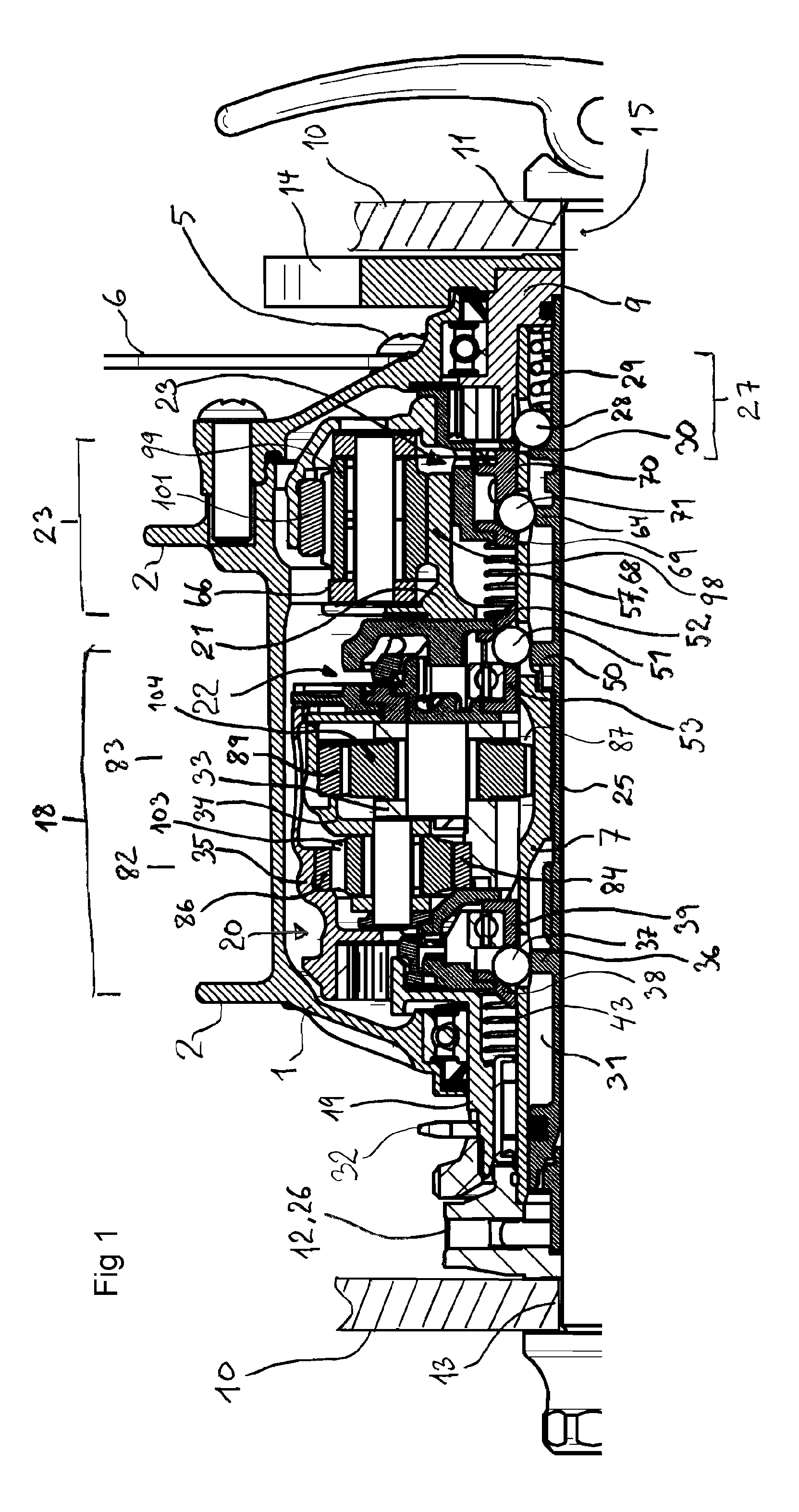

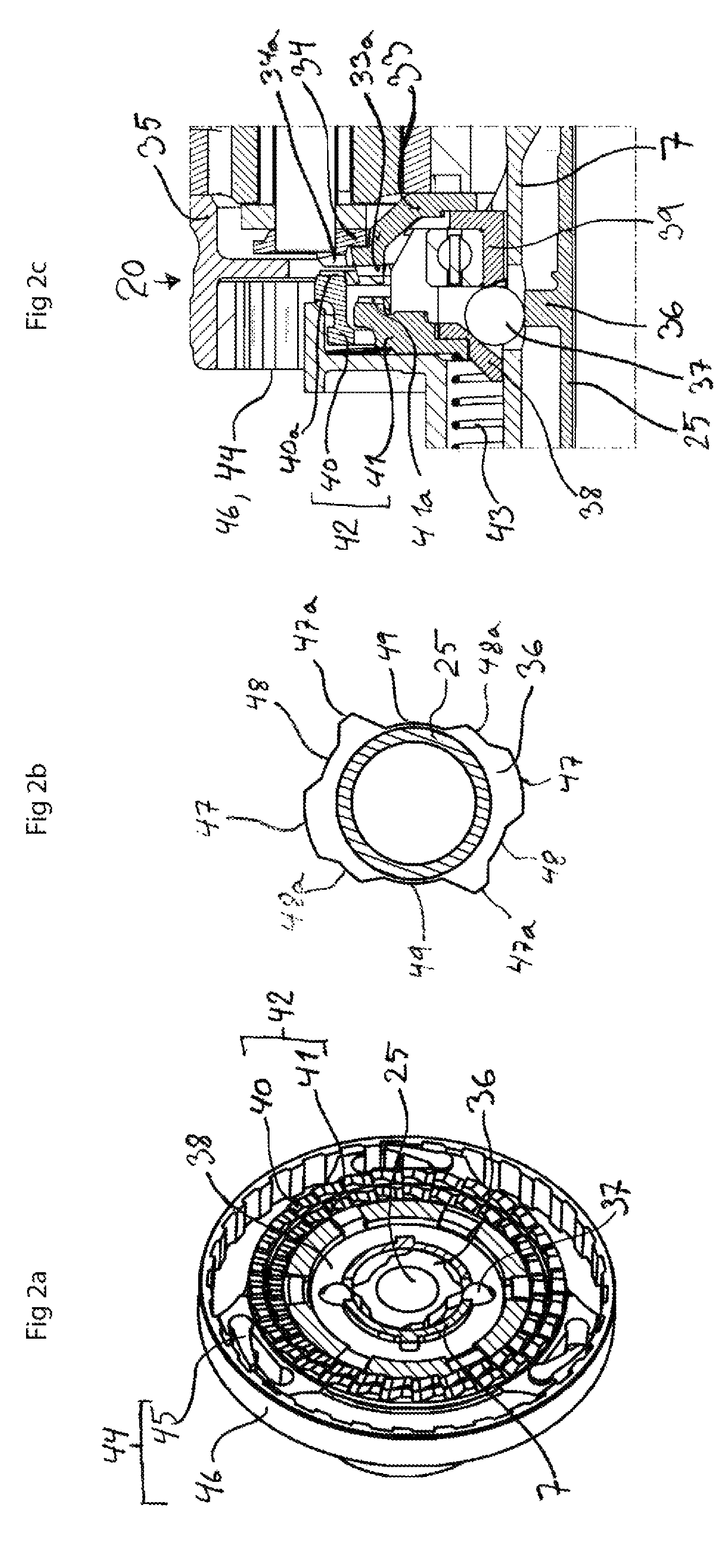

Multi-speed gear system

ActiveUS9279480B2Adequate level of strength and rigidityRigid enoughWheel based transmissionToothed gearingsVehicle frameGear system

Owner:CA TECH SYST

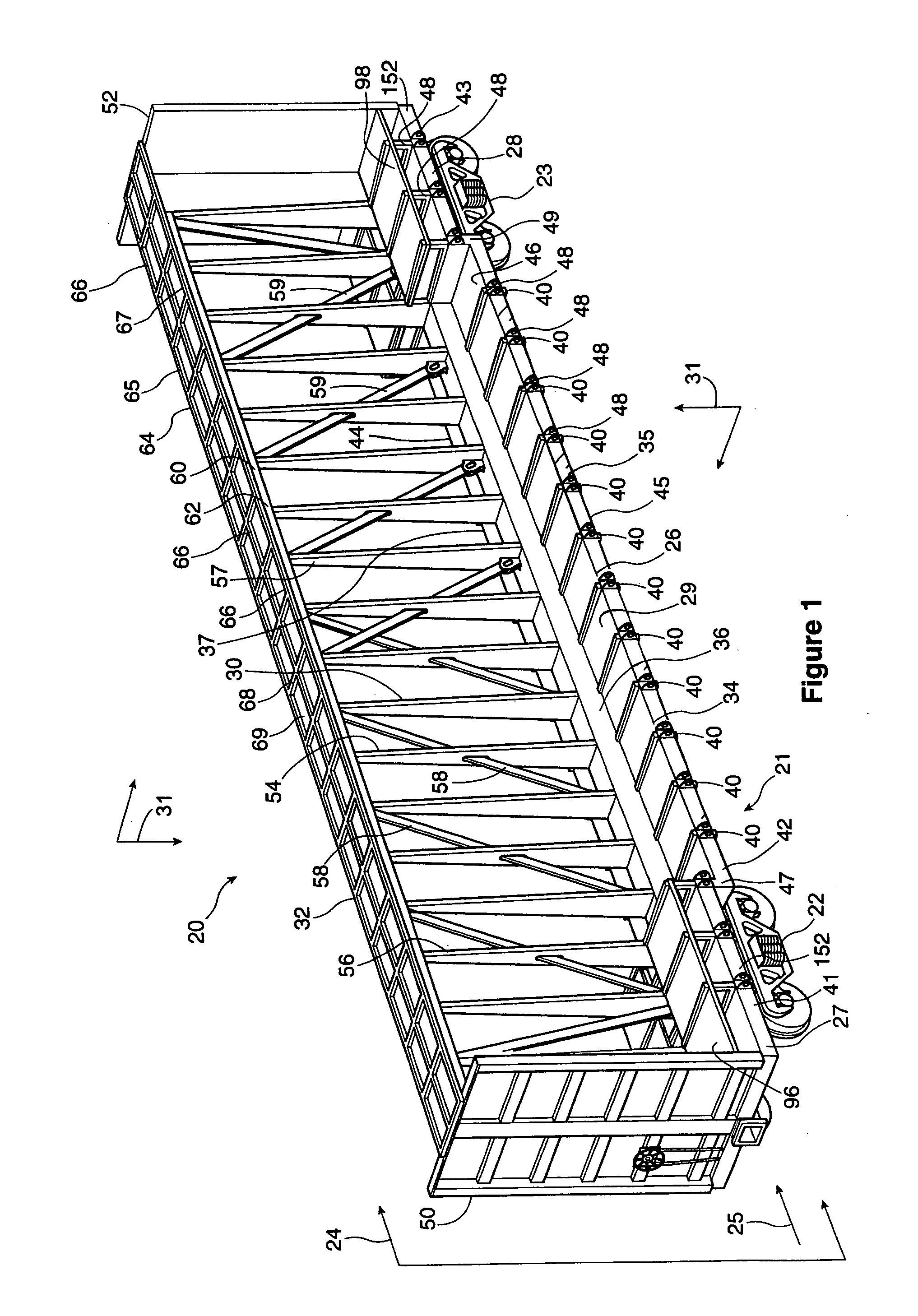

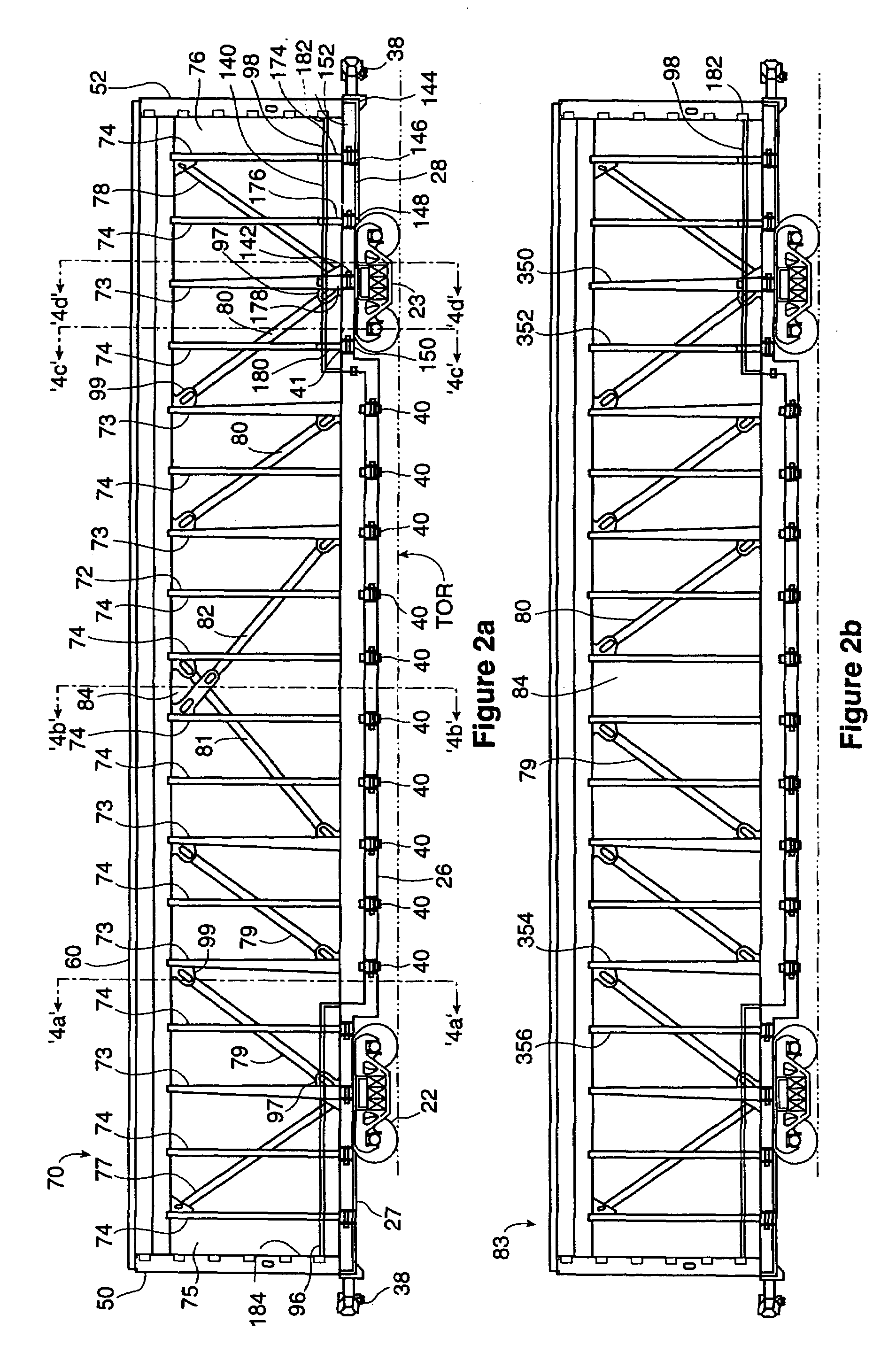

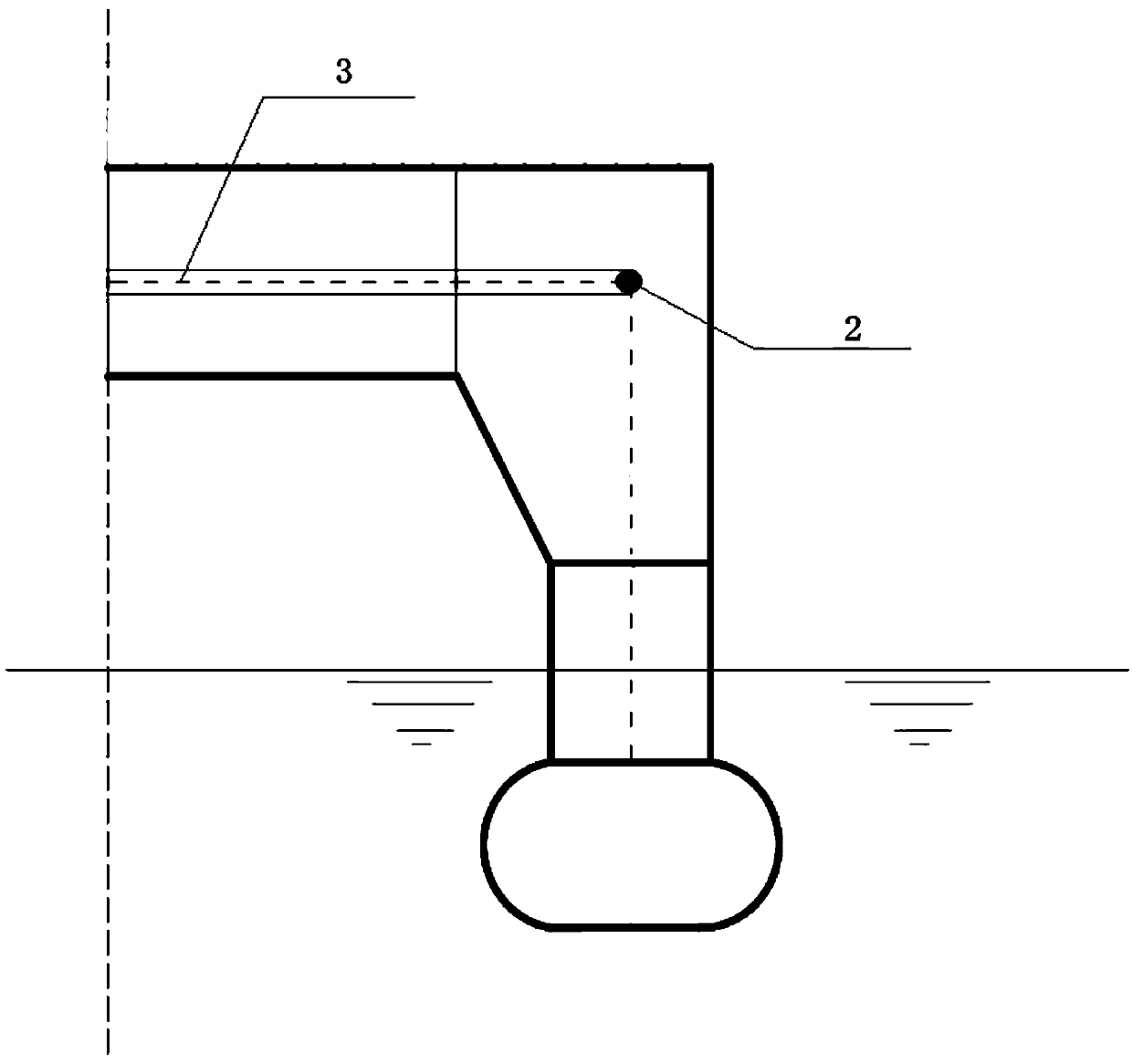

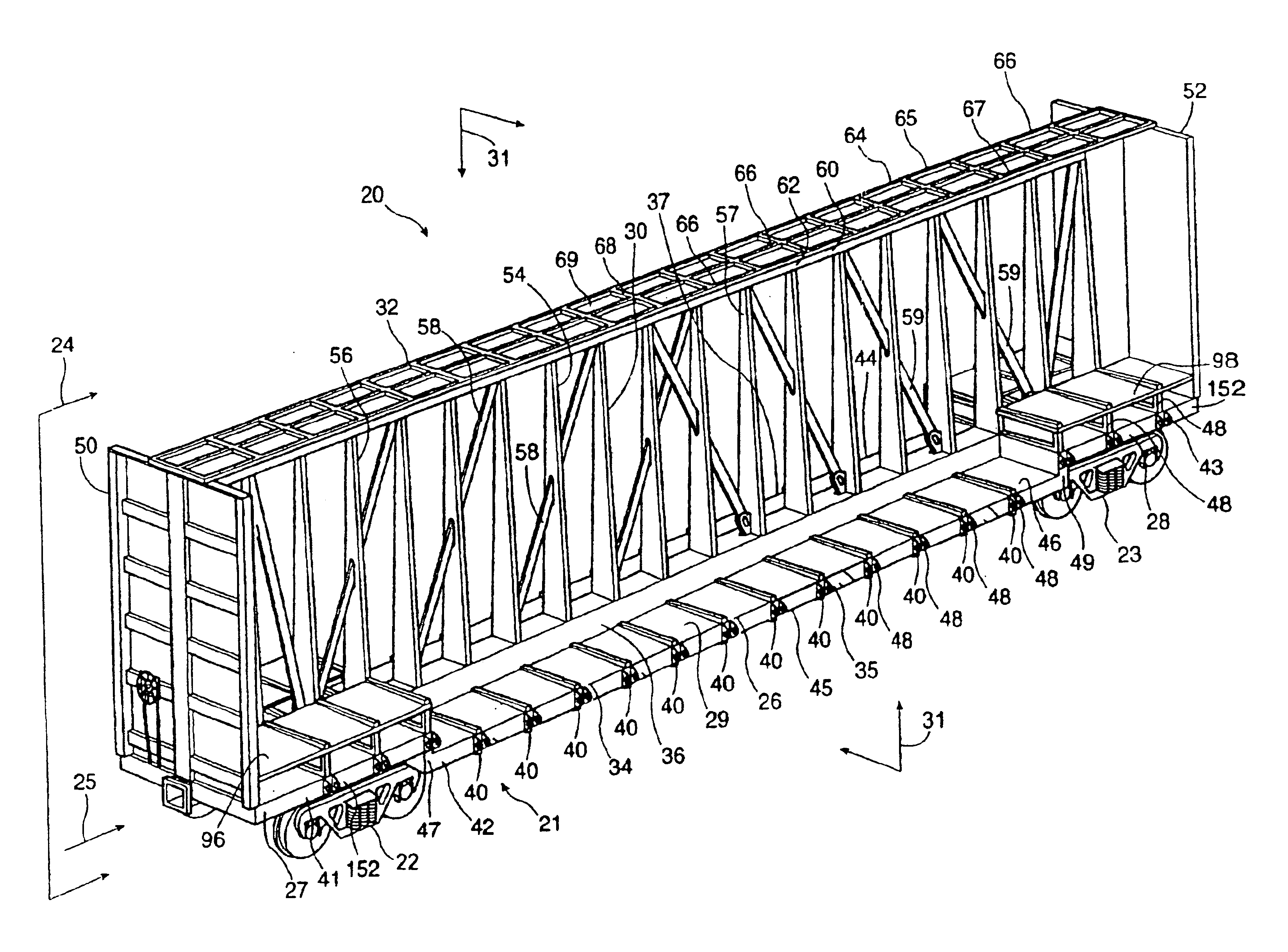

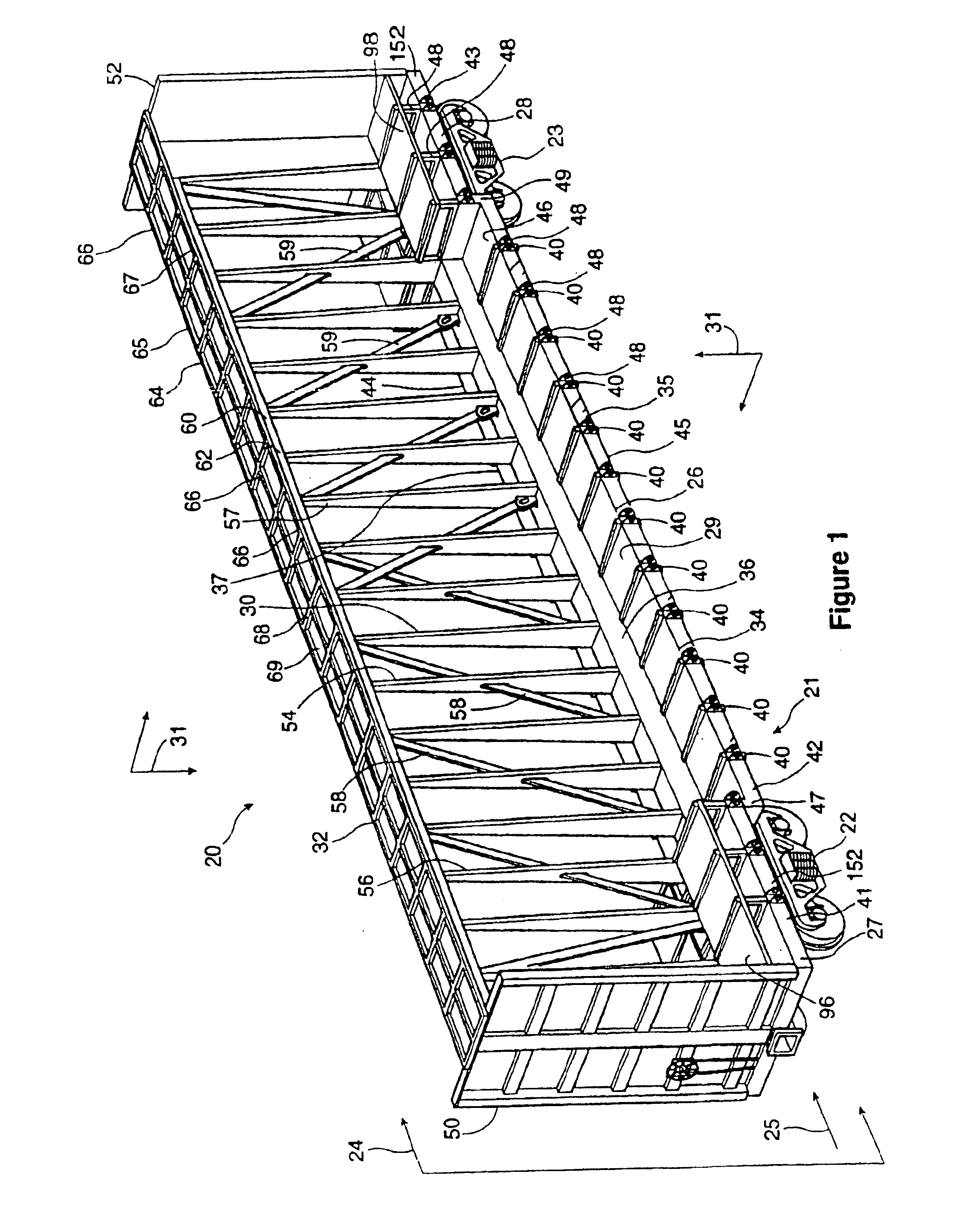

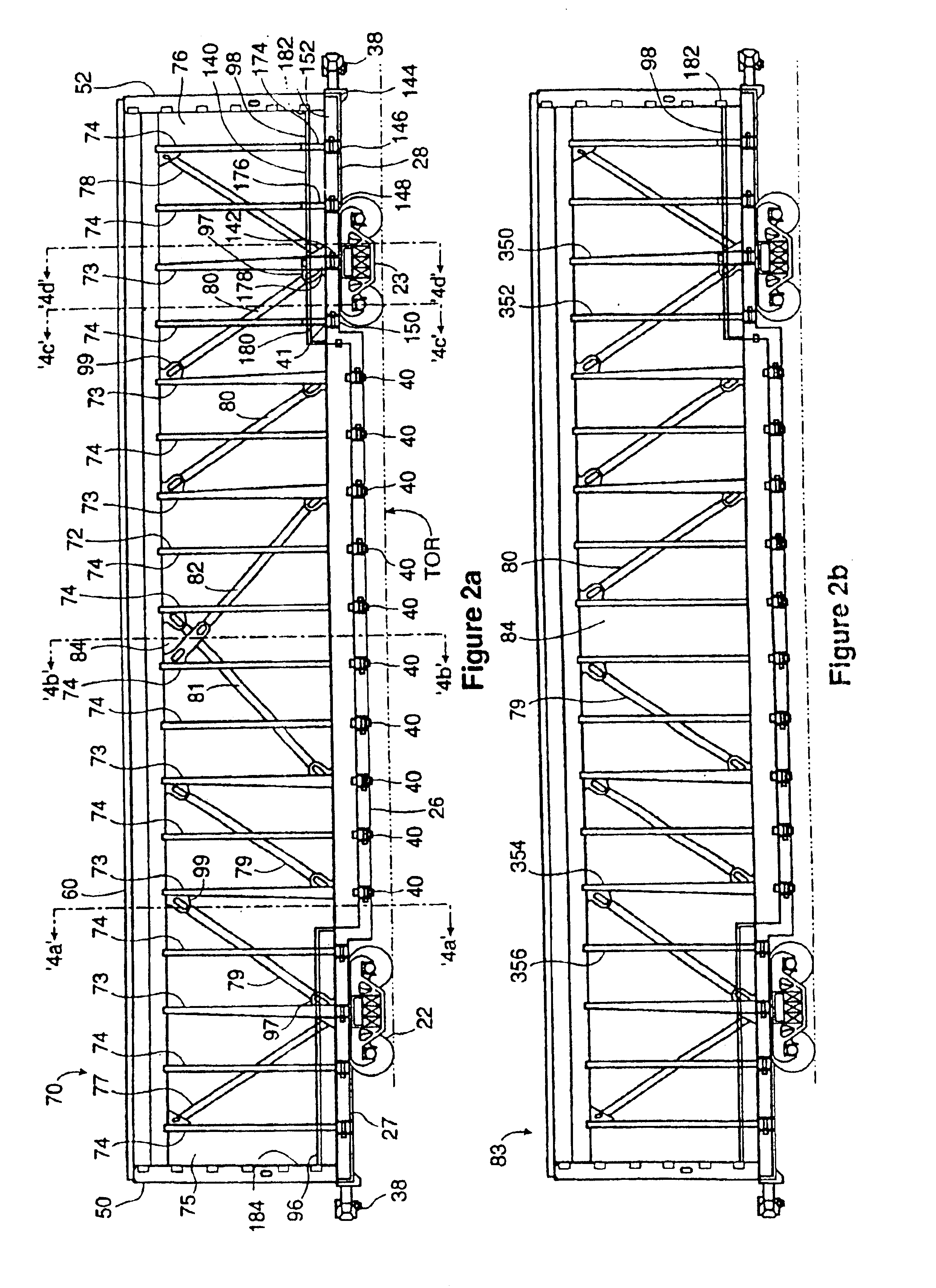

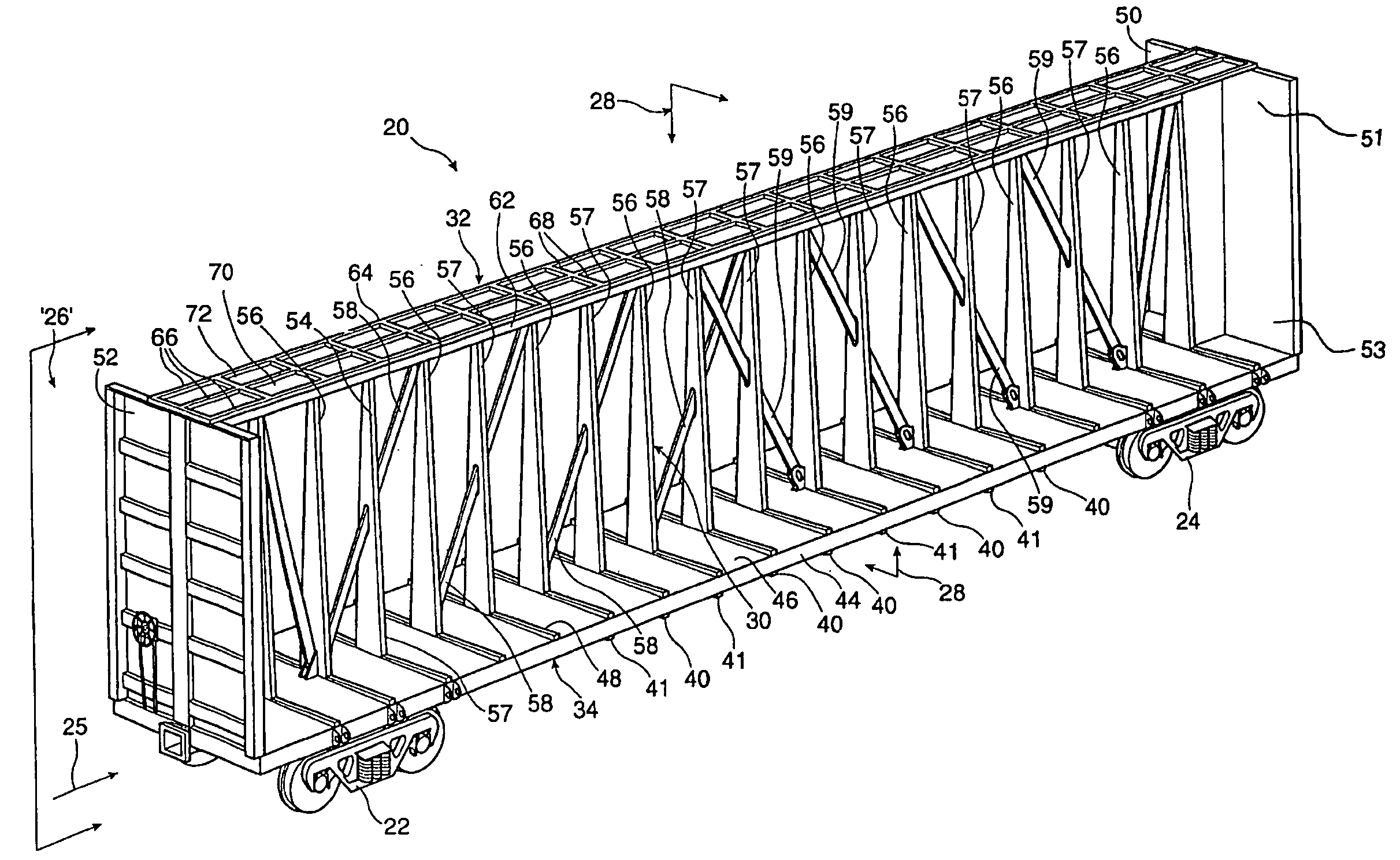

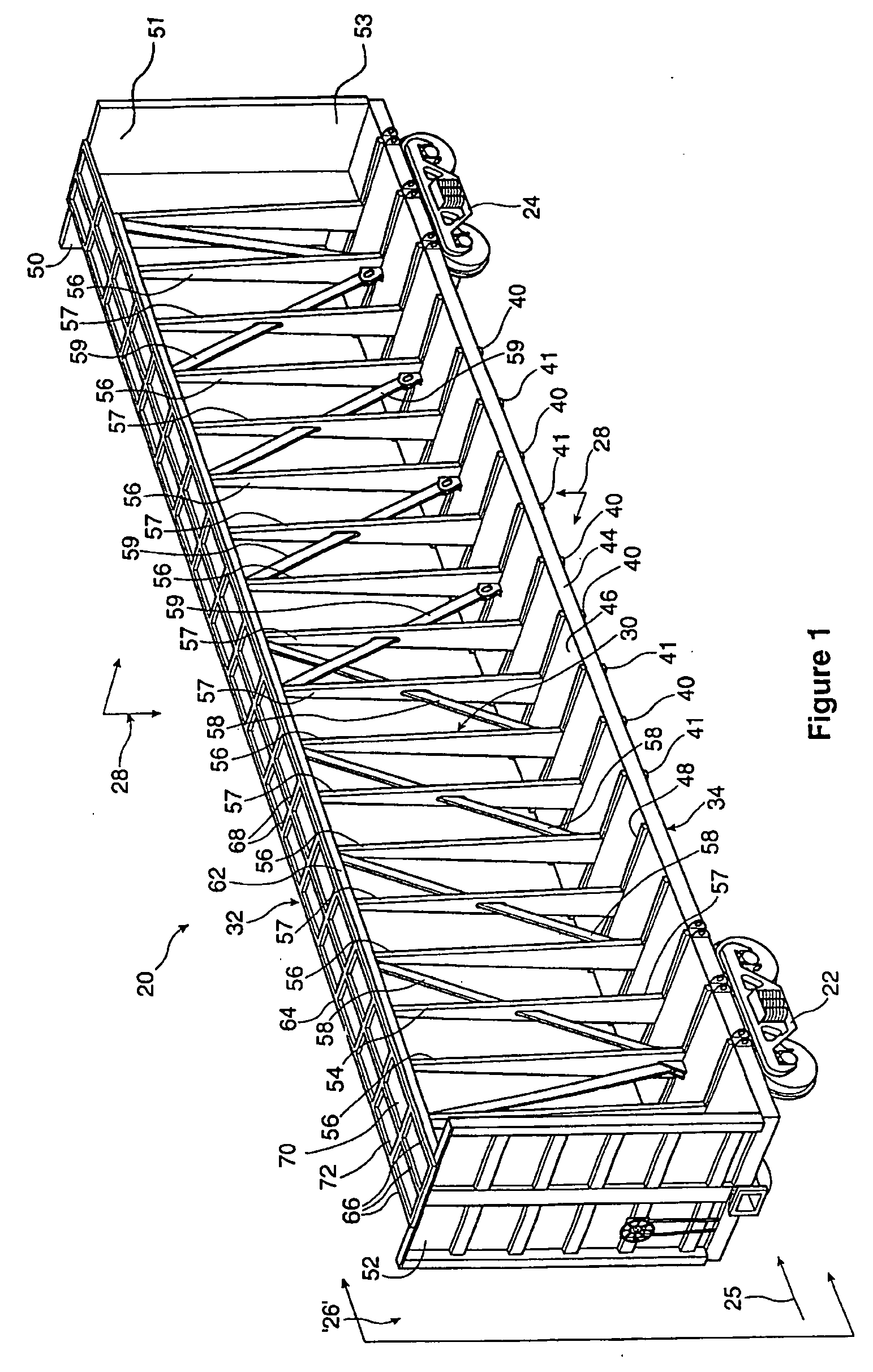

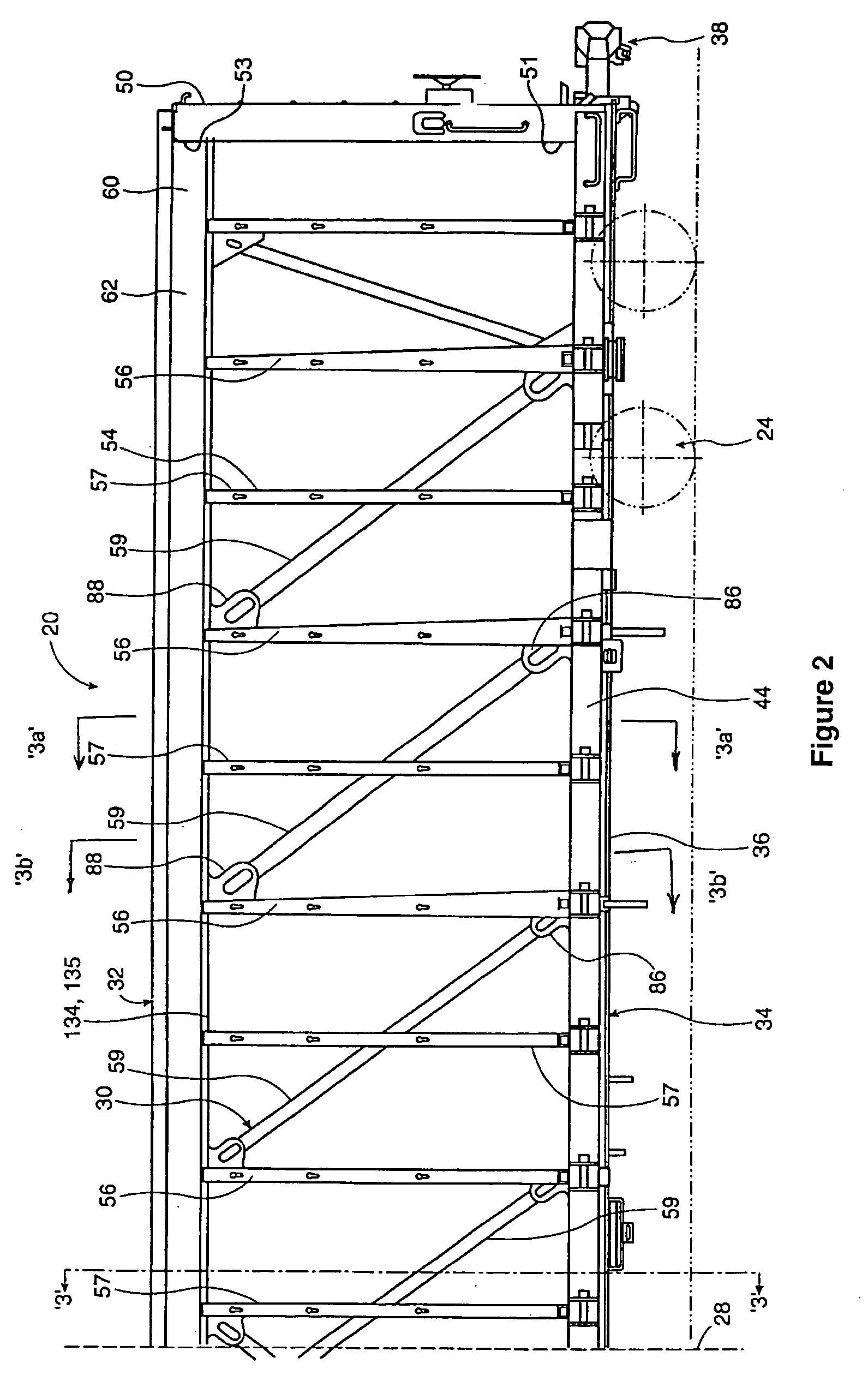

Dropped deck center beam rail road car

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented web work structure for carrying vertical shear loads between the top truss and the center sill and decking. The center beam so formed defines bunks upon in which to carry cargo. The upper region of the web-work structure includes a deep upper beam structure that has downwardly extending skirts. The skirts provide an extended bearing area upon against which bundled loads can be secured. The skirts are inwardly reinforced to discourage deflection between adjacent upright members of the deep upper beam structure.

Owner:GREYPOINT CAPITAL INC

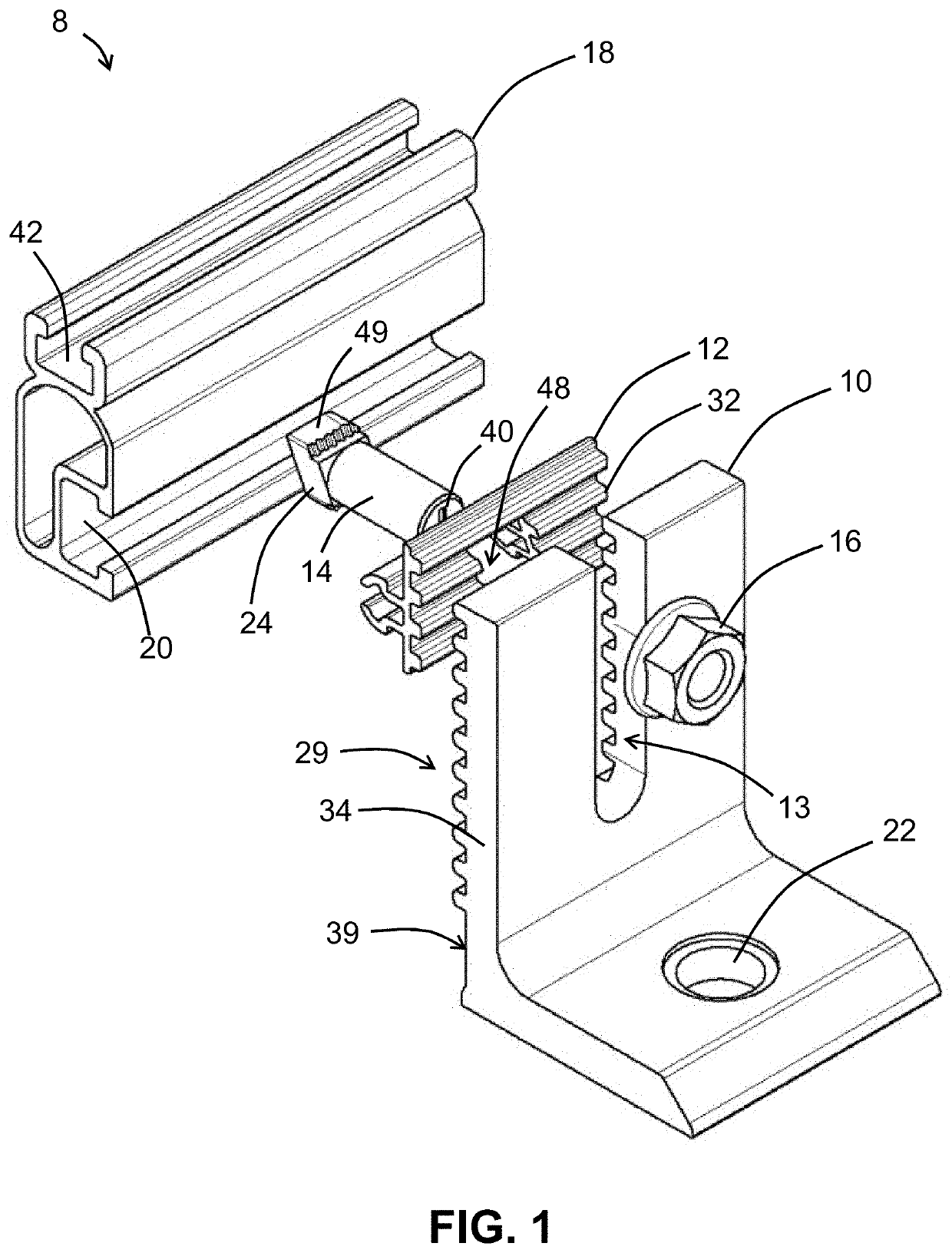

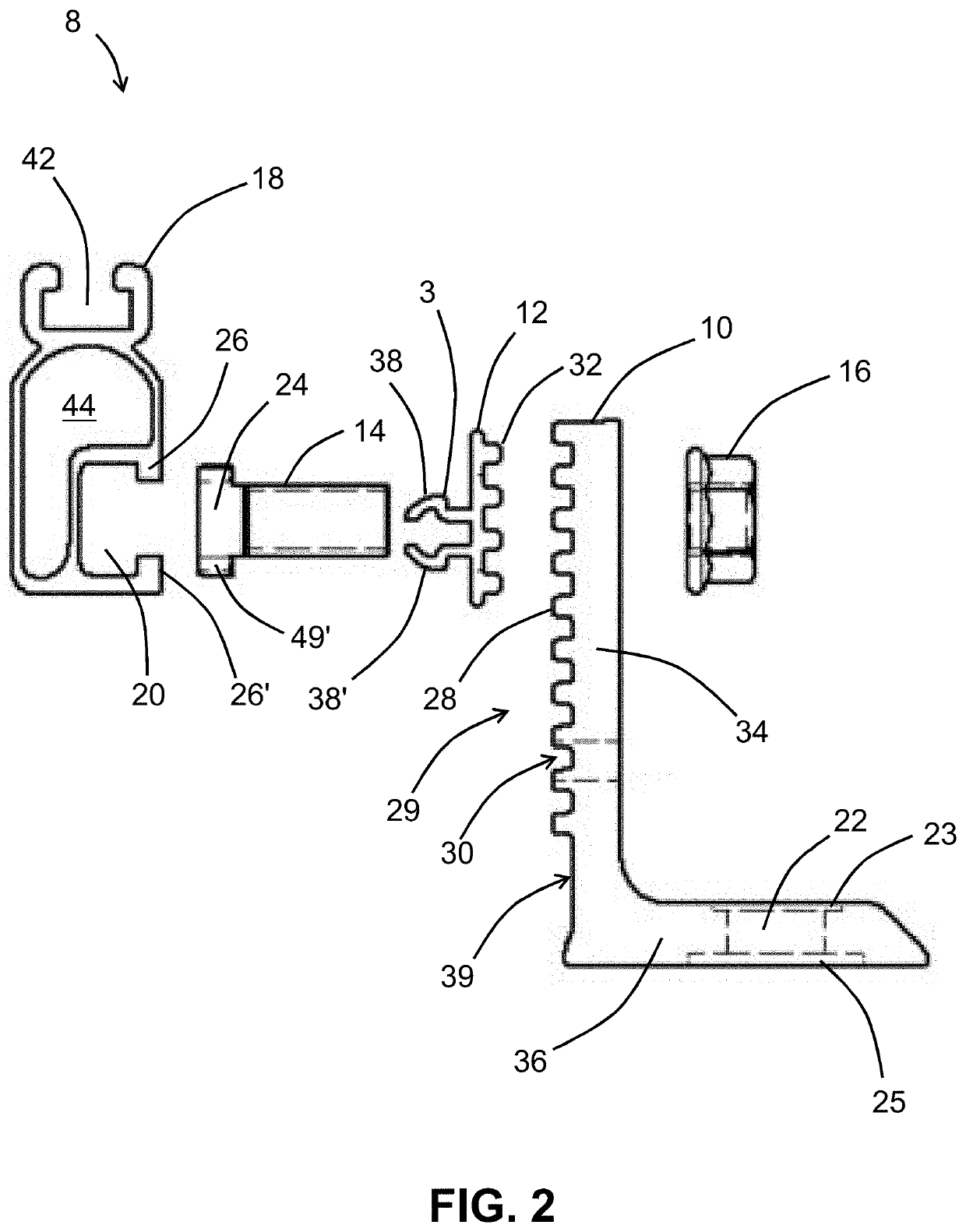

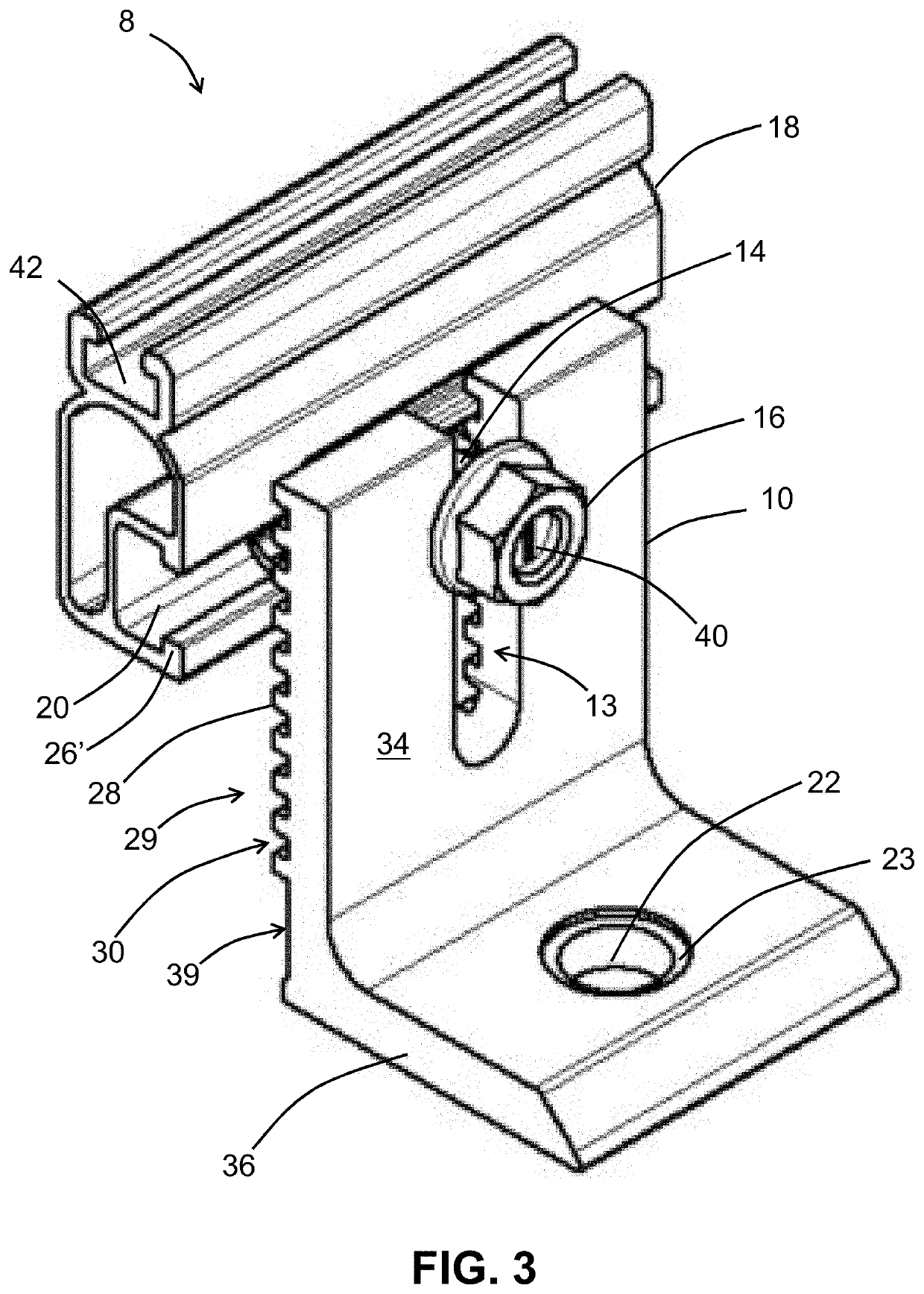

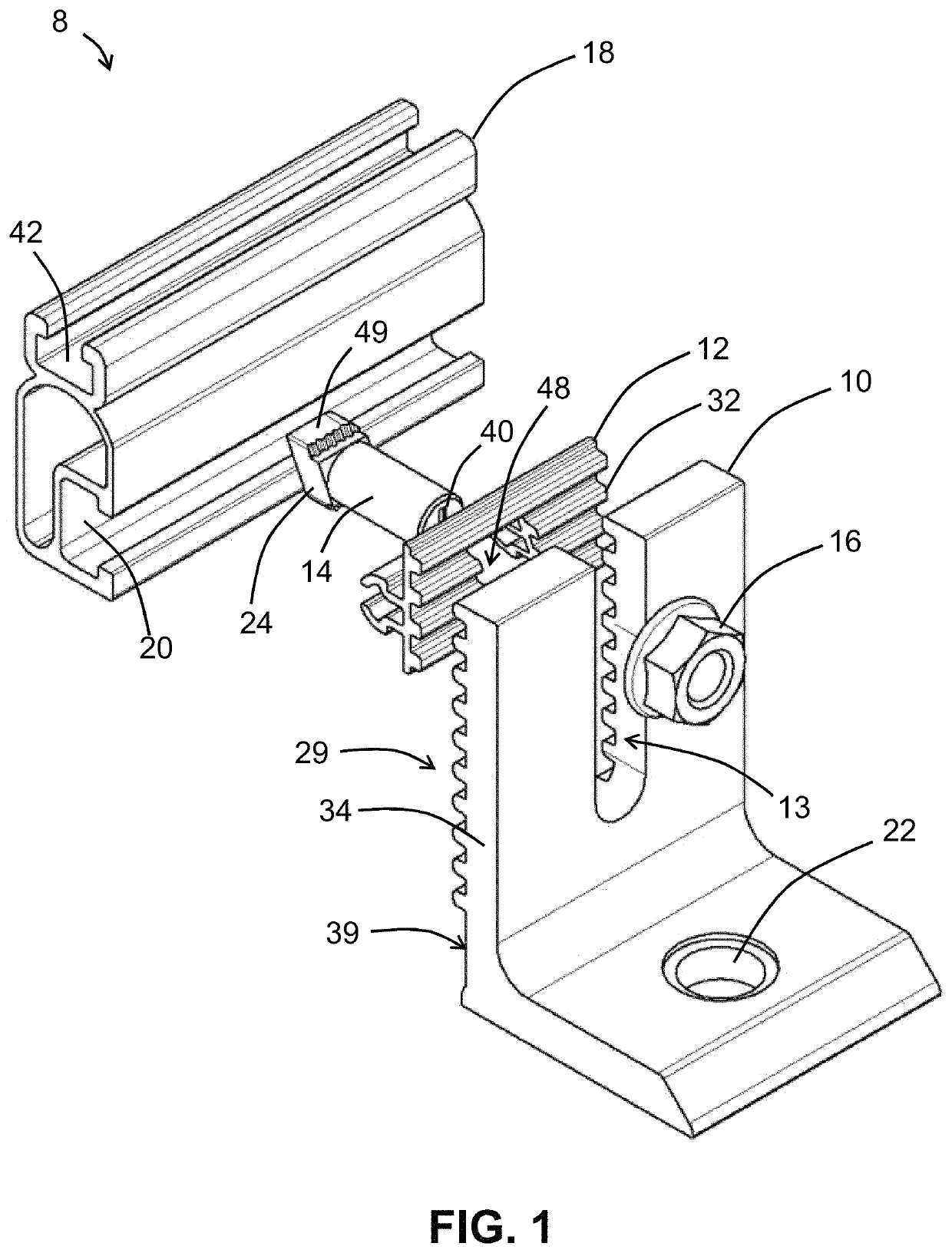

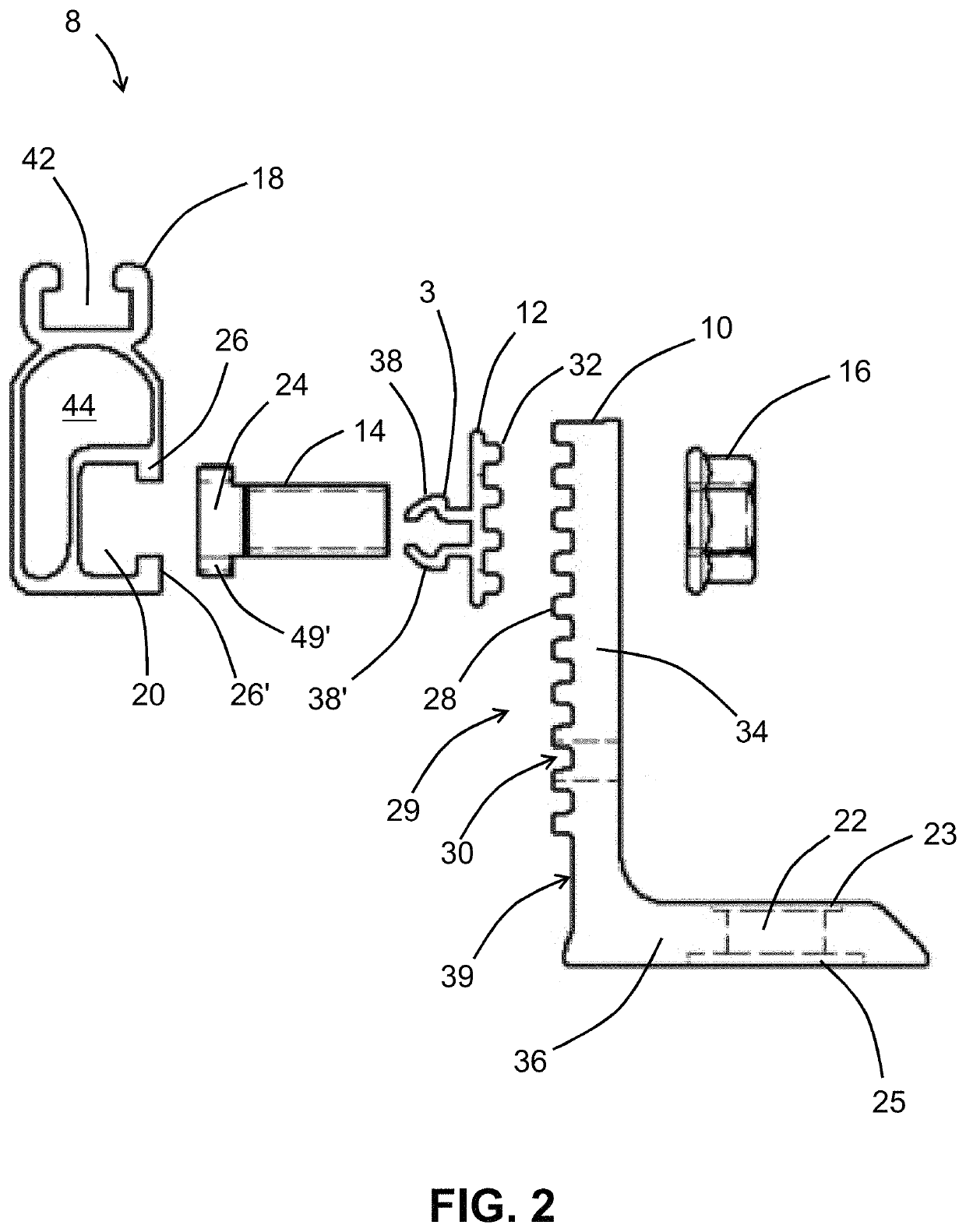

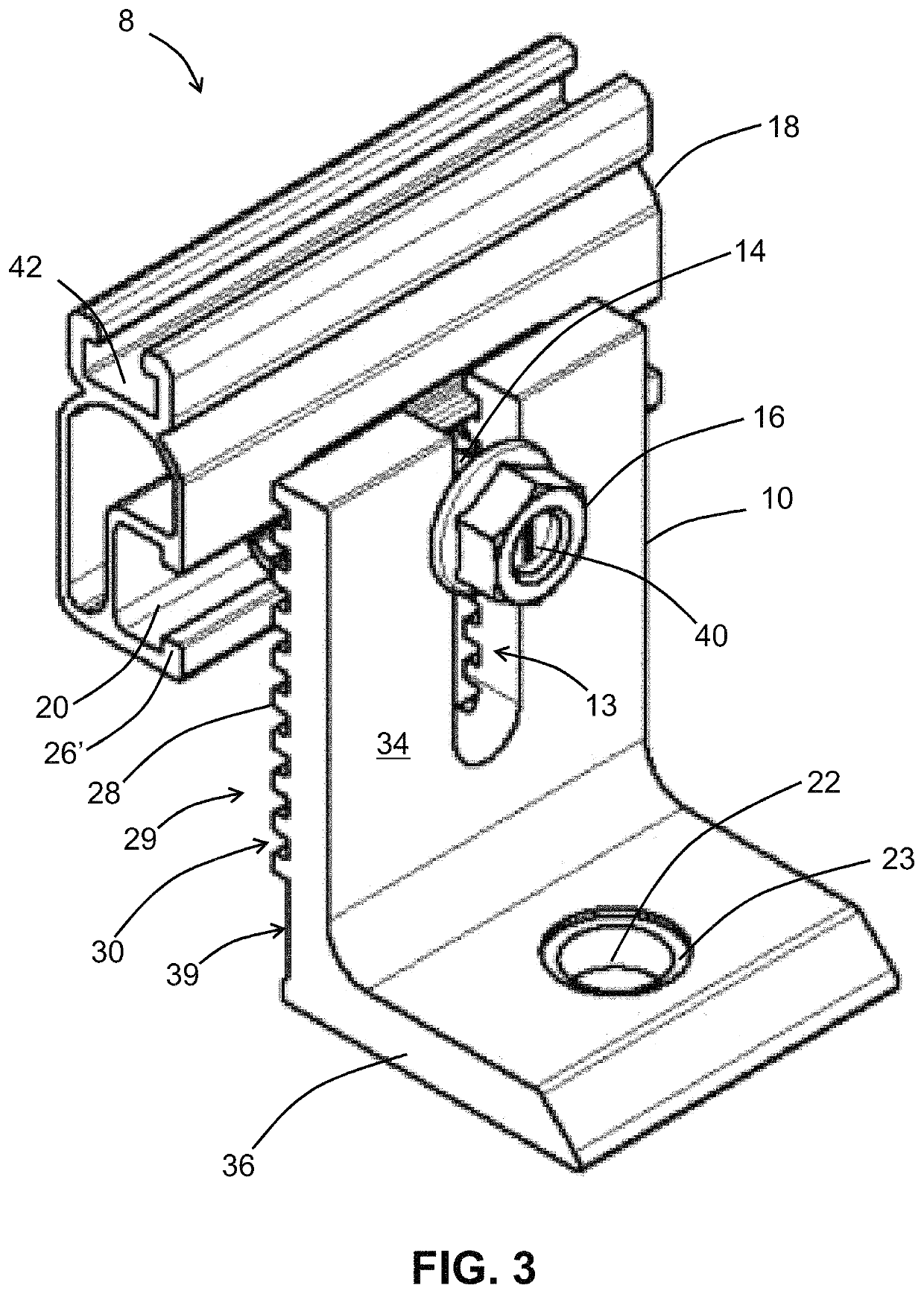

Corrugated Washer for Use with a Corrugated L-Foot Mounting Bracket for Mounting Solar Panels to a Roof

ActiveUS20200116191A1Preventing vertical shearPhotovoltaic supportsSolar heating energyClassical mechanicsEngineering

A corrugated washer for use with a corrugated L-foot mounting bracket and a structural mounting rail prevents vertical shear at the joint between the rail and the corrugated L-foot bracket when mounting photovoltaic modules (i.e., solar panels) to a roof of a building or other structure. The design locks the T-bolt from falling off the rail slot, and always aligns the T-bolt in the correct orientation and prevents back-rotation. The corrugations on the washer and L-foot help for making height adjustments, too.

Owner:UNIRAC INC

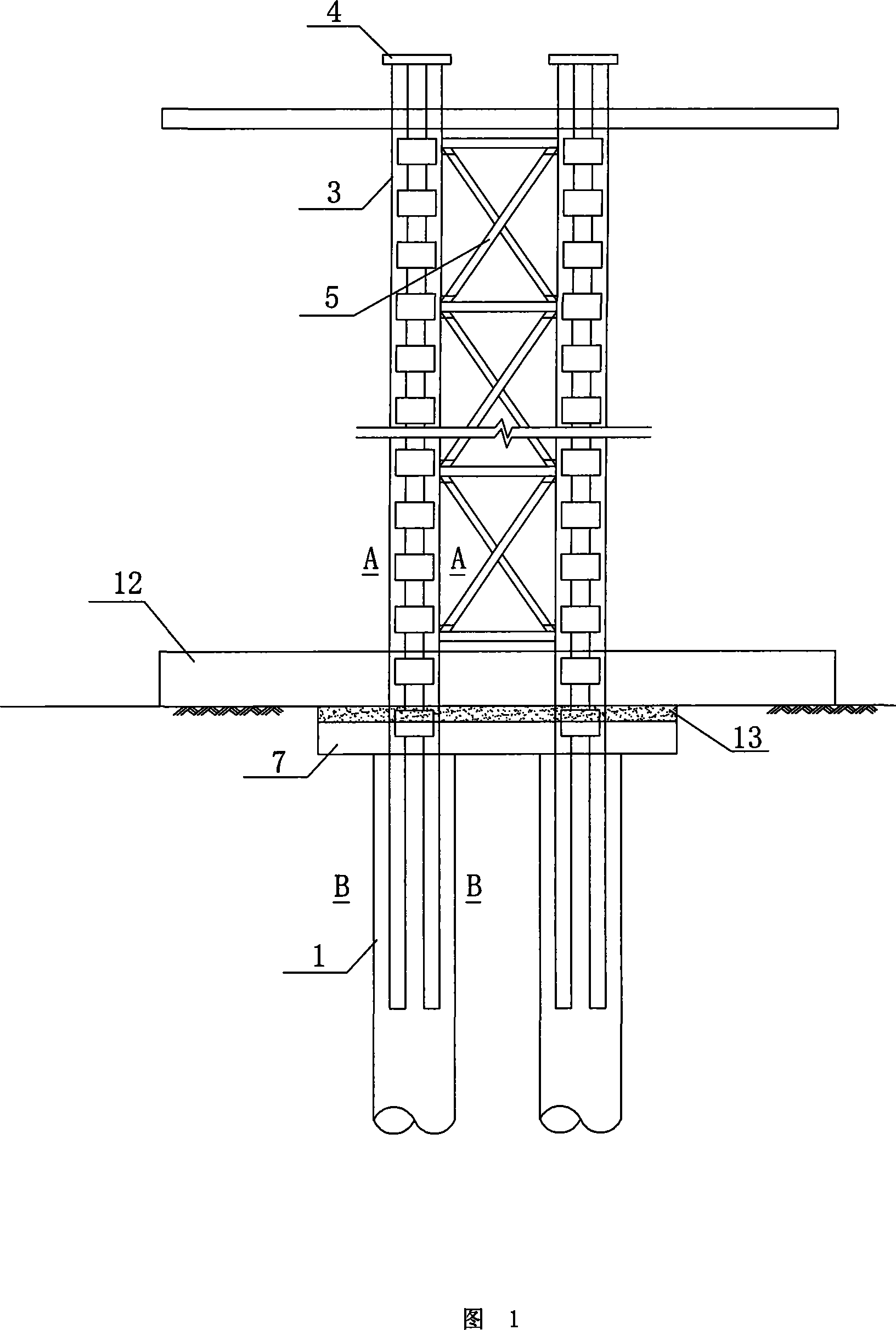

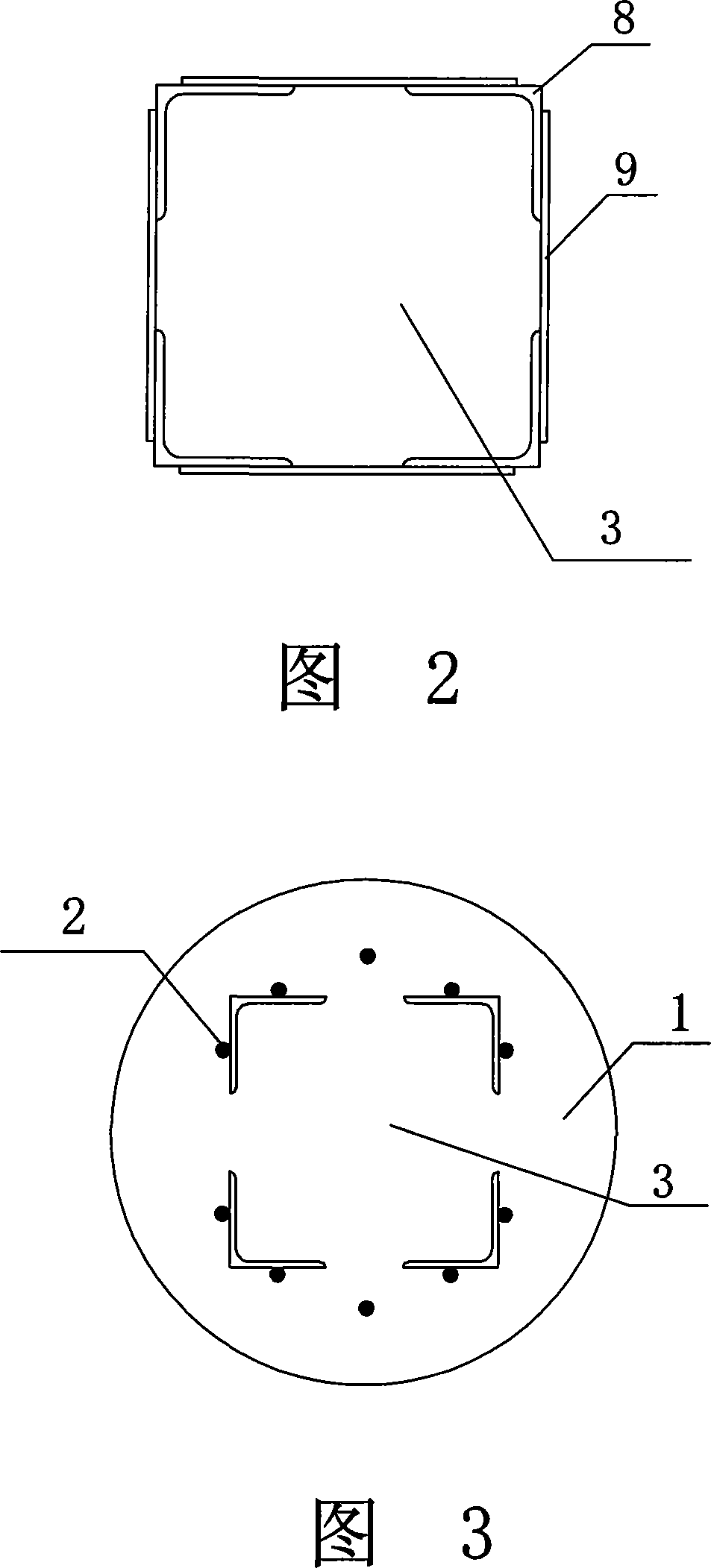

Construction method for lattice type steel column tower crane pedestal

A construction method for a lattice steel column tower crane base seat comprises: disposing four bored piles at the cutting position before cutting earth underground, pouring pile steel bar cage welded with a lattice steel column composed of a angle steel and a batten plate into the bored piles, disposing a conversion bearing steel plate on the top of a lattice steel column, disposing a tower body base section on the conversion bearing steel plate, disposing a tower body on the tower body base section, cutting earth among and around the four lattice steel piles, welding a horizontal shears supporting rack and a vertical shears supporting rack among the lattice steel piles when earth of each 1-3 meter depth is cut, and connecting four lattice steel columns by using a connection platform under the foundation pit bottom plate after the foundation pit is cut. The construction method has strong applicability, and is especially adapted to conditions that a hanging tower can not be disposed in a cut foundation pit by the restriction of ground or the hanging tower must be disposed and used at the foundation pit position before starting to cut the foundation pit. The lattice hanging tower constructed according to the invented method has a stable and sage base seat structure.

Owner:浙江省三建建设集团有限公司

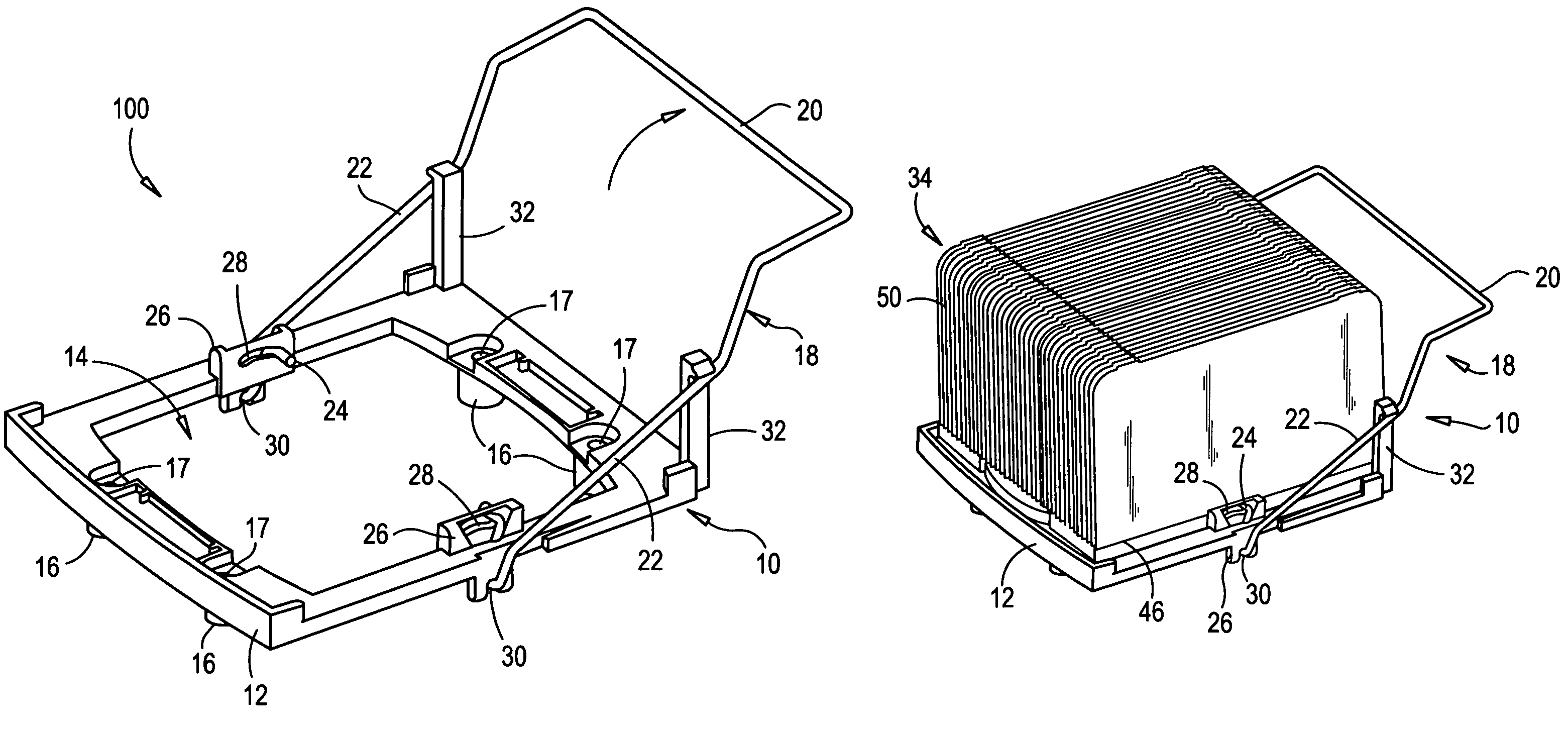

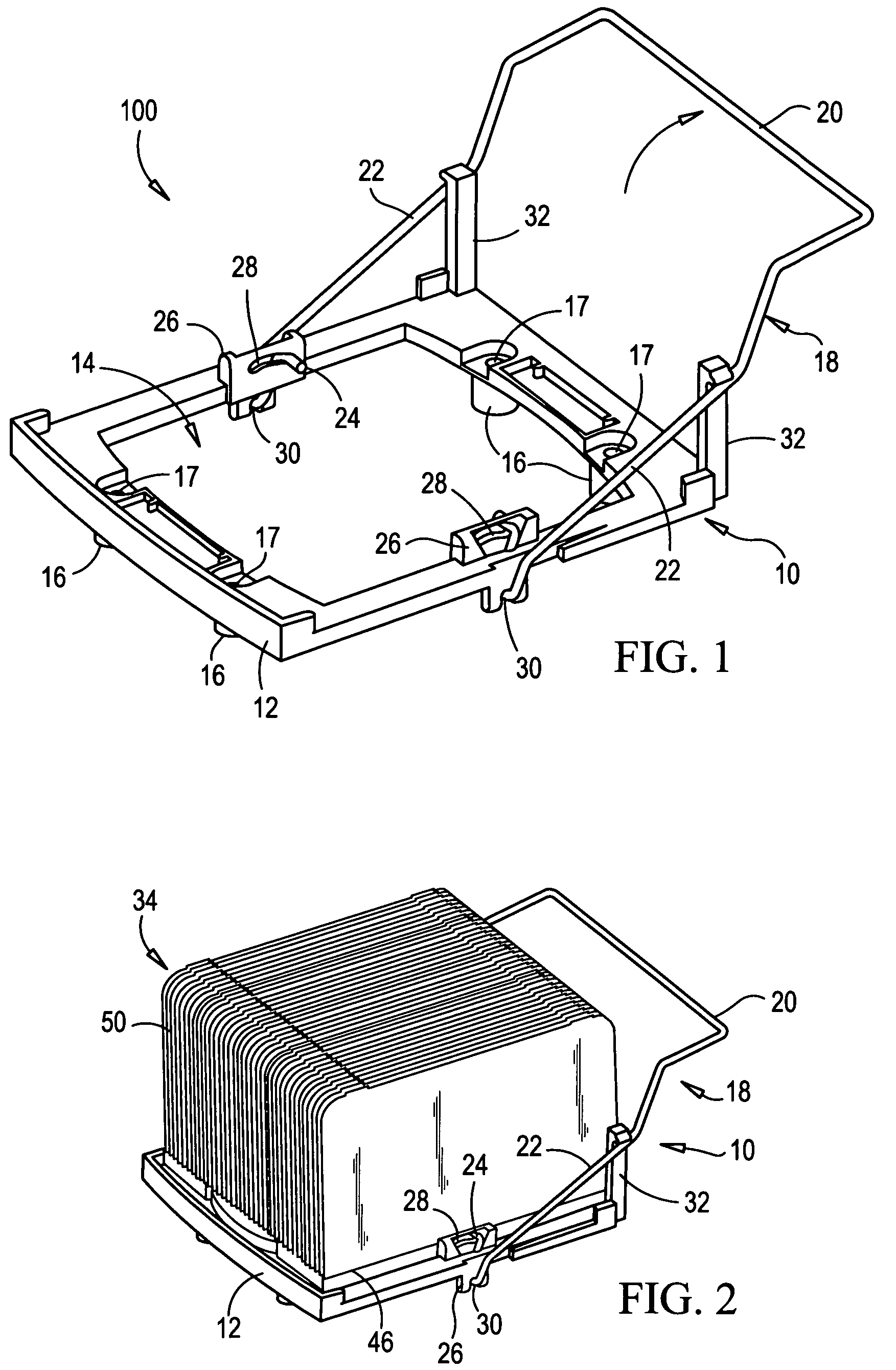

Torsion spring force and vertical shear pin retention of heat sink to CPU

InactiveUS7236369B2Make up for deficienciesAvoid separationSnap fastenersSemiconductor/solid-state device detailsThermal contactVertical shear

A heat sink retention assembly for retaining a heat sink in thermal contact with a CPU while transmitting load away from the CPU. The heat sink retention assembly includes a frame sized to receive the heat sink, the frame including opposing pin capture channels and a wire module. The wire module includes an upper handle section and a lower pivoting section. The wire module is pivotably coupled to the frame at the lower pivoting section. The wire module further includes opposing end pins, wherein each pin is moveably retained within and extends through a corresponding pin capture channel such that when the wire module is rotated with respect to the frame, the pins travel within their respective channels in order to engage the heat sink.

Owner:IBM CORP

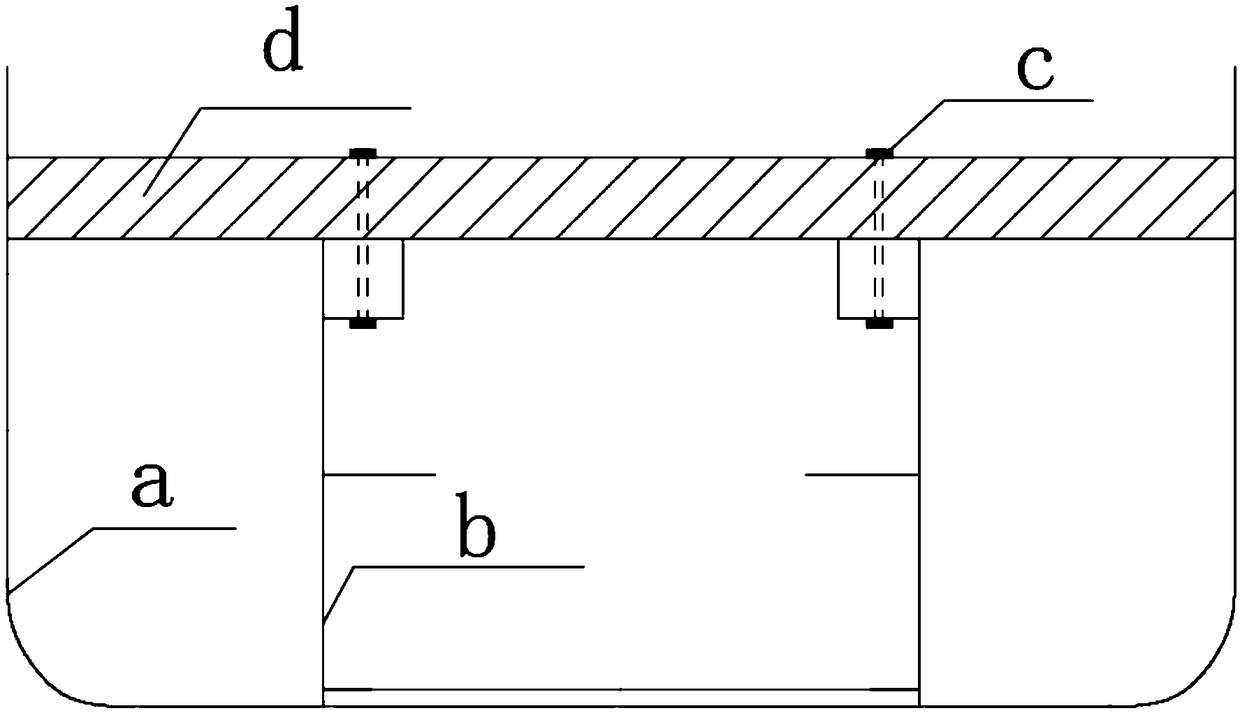

Superimposed pouring procedure of high-rise building transfer floor beam plate

The invention relates to construction of high-rise buildings and a superimposed pouring procedure of a high-rise building transfer floor beam plate, which comprises the following steps: pouring column concrete and wall concrete at the lower part of the transfer floor to a beam bottom; setting up a beam plate bottom die of the transfer floor and installing the bottom die; binding bottom-layer horizontal steel mesh reinforcement of the first layer of concrete of a transfer floor plate and surface course hogging moment steel mesh reinforcement of the first layer of concrete; installing a side form of the first layer of concrete; installing a shear-resisting key groove die plate; bonding additionally arranged vertical shear reinforcement between every two layers of transfer floor beam plates; carrying out pouring, hydrating, heat preservation, maintenance and surface treatment on the first layer of concrete; bonding constructional steel bar of the second layer of concrete of the transfer floor beam plates; installing the side form of the second layer of concrete; bonding shear wall joint bars at the upper structure of the transfer floor; disassembling the bottom die and the support when strength of the first layer of concrete reaches the design strength; carrying out pouring, hydrating, heat preservation and maintenance on the second layer of concrete. With the method of the invention adopted, construction cost can be reduced, construction quality can be improved and construction period can be shortened.

Owner:CHINA MCC20 GRP CORP

Corrugated washer for use with a corrugated L-foot mounting bracket for mounting solar panels to a roof

ActiveUS10989247B2Preventing vertical shearPhotovoltaic supportsSolar heating energyEngineeringSolar cell

A corrugated washer for use with a corrugated L-foot mounting bracket and a structural mounting rail prevents vertical shear at the joint between the rail and the corrugated L-foot bracket when mounting photovoltaic modules (i.e., solar panels) to a roof of a building or other structure. The design locks the T-bolt from falling off the rail slot, and always aligns the T-bolt in the correct orientation and prevents back-rotation. The corrugations on the washer and L-foot help for making height adjustments, too.

Owner:UNIRAC INC

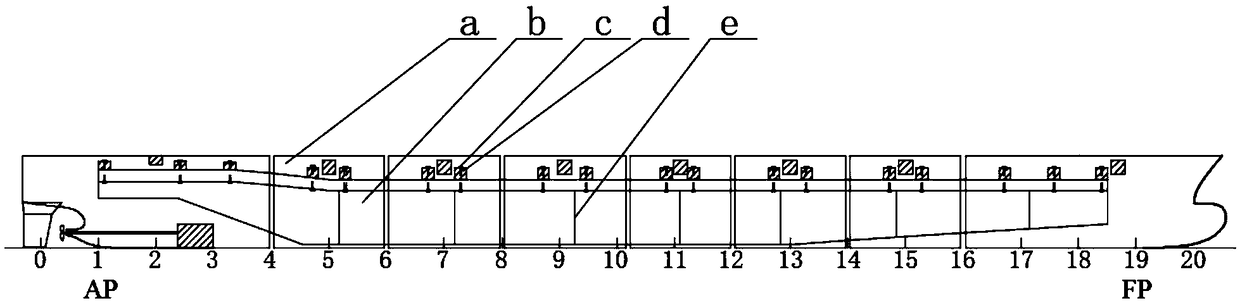

Small waterplane double-hull wave load test model design and test method

InactiveCN109655229AReasonable structural design loadGuaranteed validityHydrodynamic testingState parameterTransverse plane

The invention relates to a small waterplane double-hull wave load test model design and test method. Models which are consistent with the weight distribution, geometric similarity and motion similarity of all sections of a real ship are manufactured, the models are subjected to segmentation processing, a measuring beam frame is arranged, and through load collection and analysis calculation of strain gauges on the measuring beam frame, ship motion state parameters and main loads borne by the ship body are accurately obtained. The method can be used for measuring data of six-degree-of-freedom motion and acceleration of a small waterplane catamaran model in waves and for measuring seven key wave load values such as vertical wave bending moment and shearing force, vertical shearing force of amiddle longitudinal section, transverse opposite opening force and transverse wave bending moment, horizontal torque and overall asynchronous pitching torque. The method has very important significance in mastering wave load characteristics of the type of ship and determining reasonable structural design loads.

Owner:708TH RES INST OF CSSC

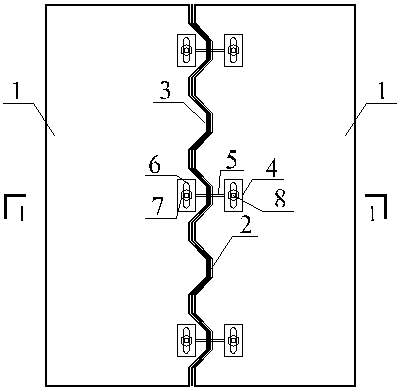

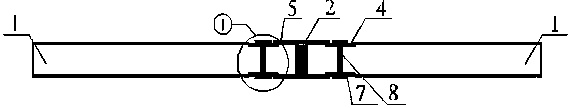

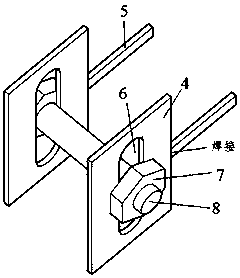

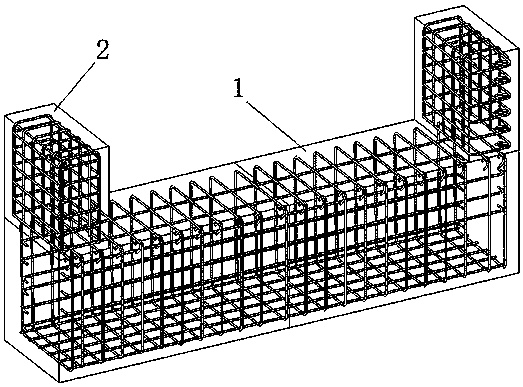

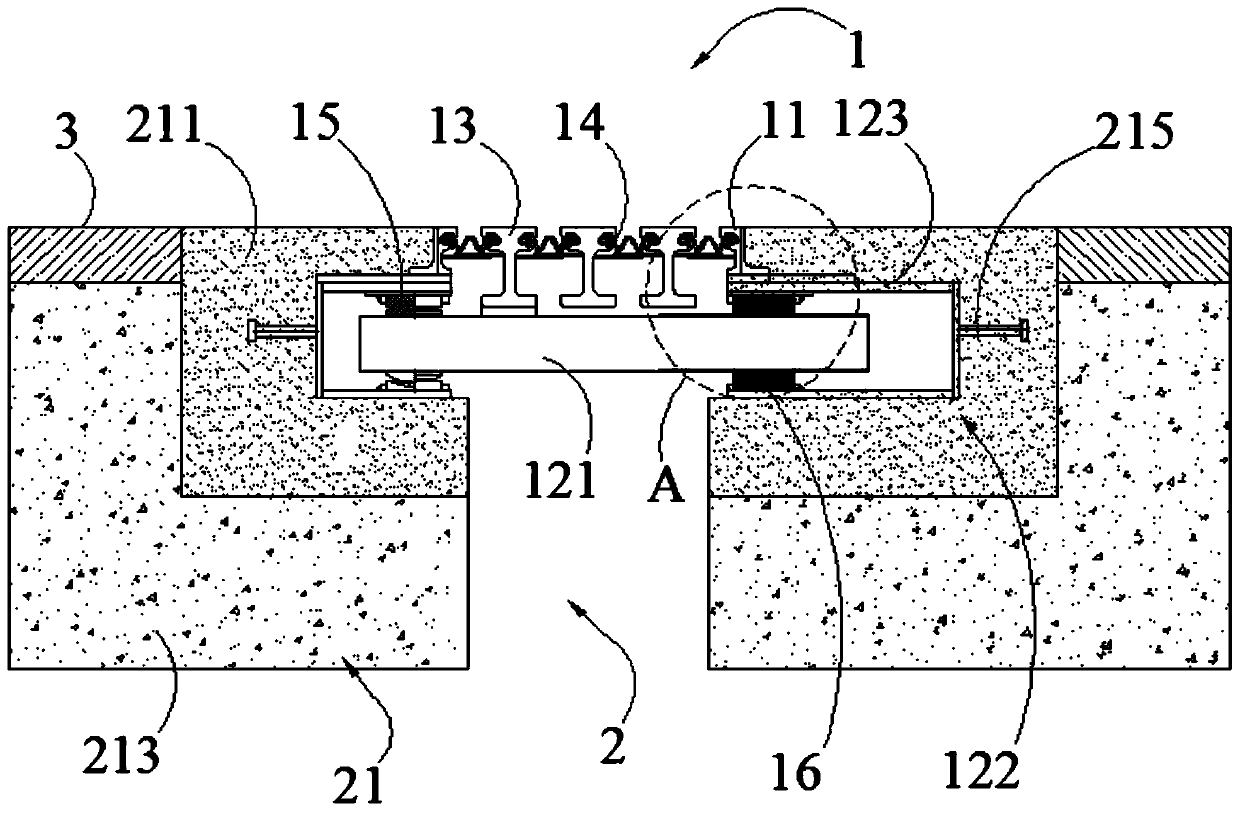

Fabricated shear-wall vertical-joint tooth-space-type energy-consuming connecting device

ActiveCN107190880AImprove structural performanceEffective performance of energy consumptionWallsProtective buildings/sheltersVertical shearMechanical engineering

The invention provides a fabricated shear-wall vertical-joint tooth-space-type energy-consuming connecting device. The joint edge of a prefabricated shear wall piece is prefabricated to be a tooth-space-type edge, viscous-elastic materials are pre-pasted or site filled in a joint, and the prefabricated shear wall piece is pulled and tied in the horizontal direction by using pull rods on the two sides of the shear wall surface at the vertical joint to keep the integrality of the shear wall in the horizontal direction; anchor bearing plates are welded at the ends of the pull rods, vertical long round bolt holes are reserved in the anchor bearing plates, so that the pull rods only transmit the internal force in the horizontal direction but release the vertical shear force, and thus the energy dissipation capacity of the viscous-elastic materials can be more effectively developed. According to the fabricated shear-wall vertical-joint tooth-space-type energy-consuming connecting device, the performance of a traditional cast-in-place belt rigid connection is improved, the energy-dissipating capacity of the prefabricated concrete shear wall structure is enhanced, and wet construction of a construction site is cast off; and an energy-dissipation device and the prefabricated shear wall are combined, industrialized production is facilitated, and the fabricated shear-wall vertical-joint tooth-space-type energy-consuming connecting device can be widely applied to the prefabricated concrete shear wall structure.

Owner:SOUTHEAST UNIV

Single station wind profile radar-based wind shear identification and tracking method

ActiveCN102565771ASimple methodImprove recognition accuracyElectromagnetic wave reradiationRadio wave reradiation/reflectionStart timeData acquisition

The invention discloses a single station wind profile radar-based wind shear identification and tracking method. The method comprises establishing a wind profile radar wind shear tracking system including a data acquisition module, a data preprocessing module, a wind shear identification module and a wind shear tracking module; allowing the data acquisition module to acquire wind profile radar detection data; allowing the data preprocessing module to perform quality control on the wind profile radar detection data; allowing the wind shear identification module to perform wind shear automatic detection and identification; and allowing the wind shear tracking module to realize wind shear automatic tracking and warning. The inventive method has simple and easy implementation, high identification accuracy and full automatic operation, can obtain horizontal wind vertical shear information and vertical wind vertical shear information, and effectively detects and tracks wind shear start time, height and strength in the air above the station.

Owner:航天新气象科技有限公司

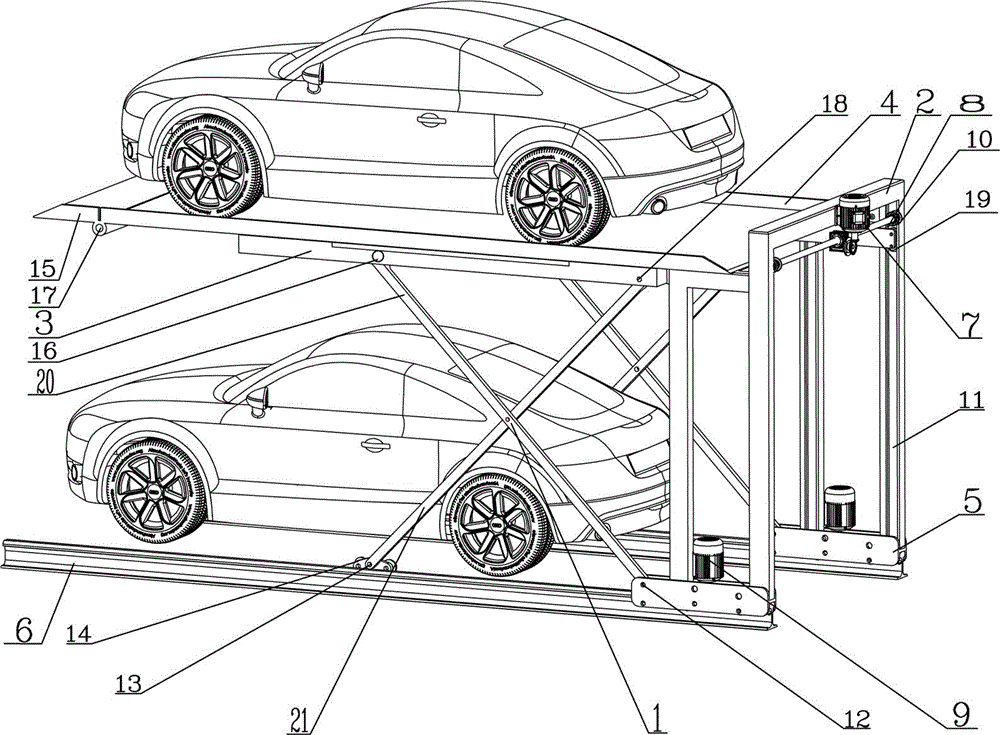

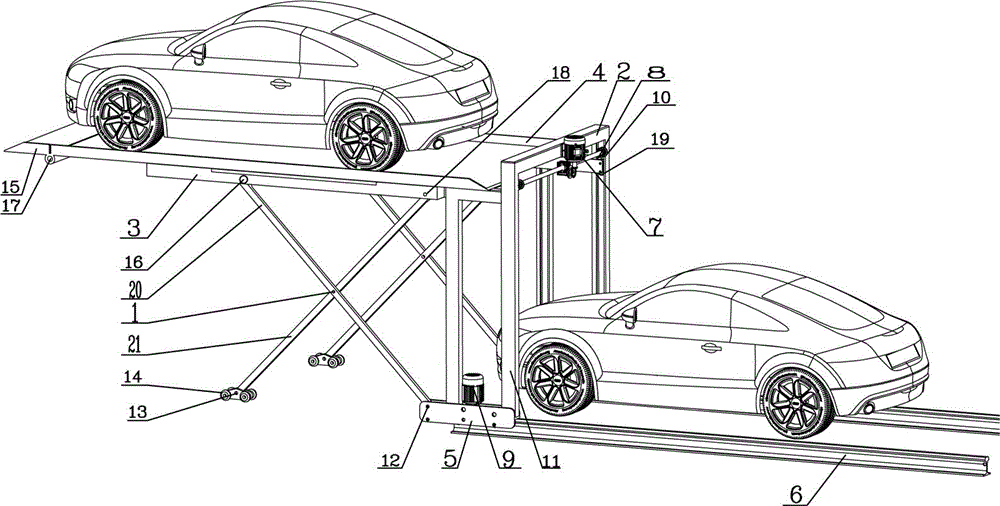

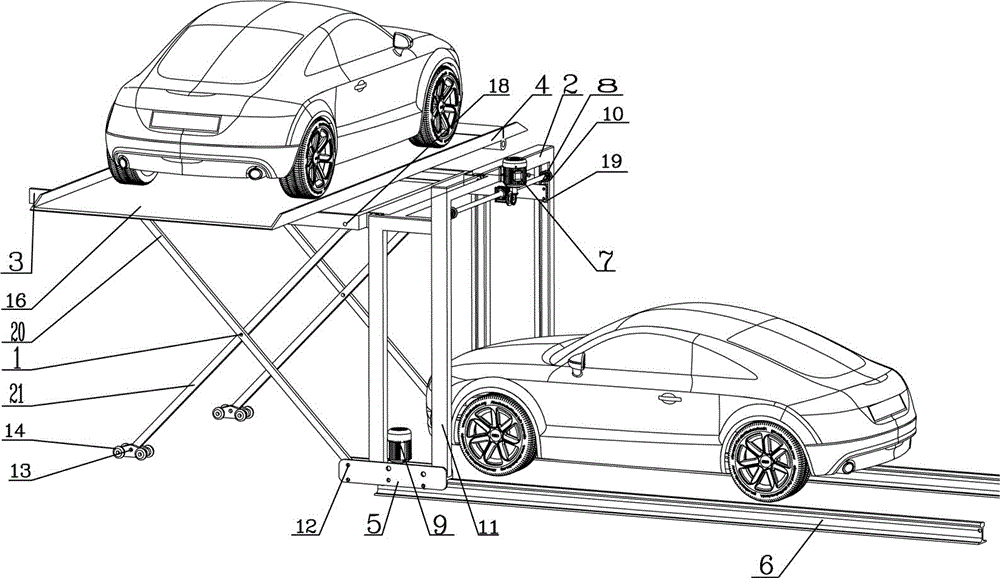

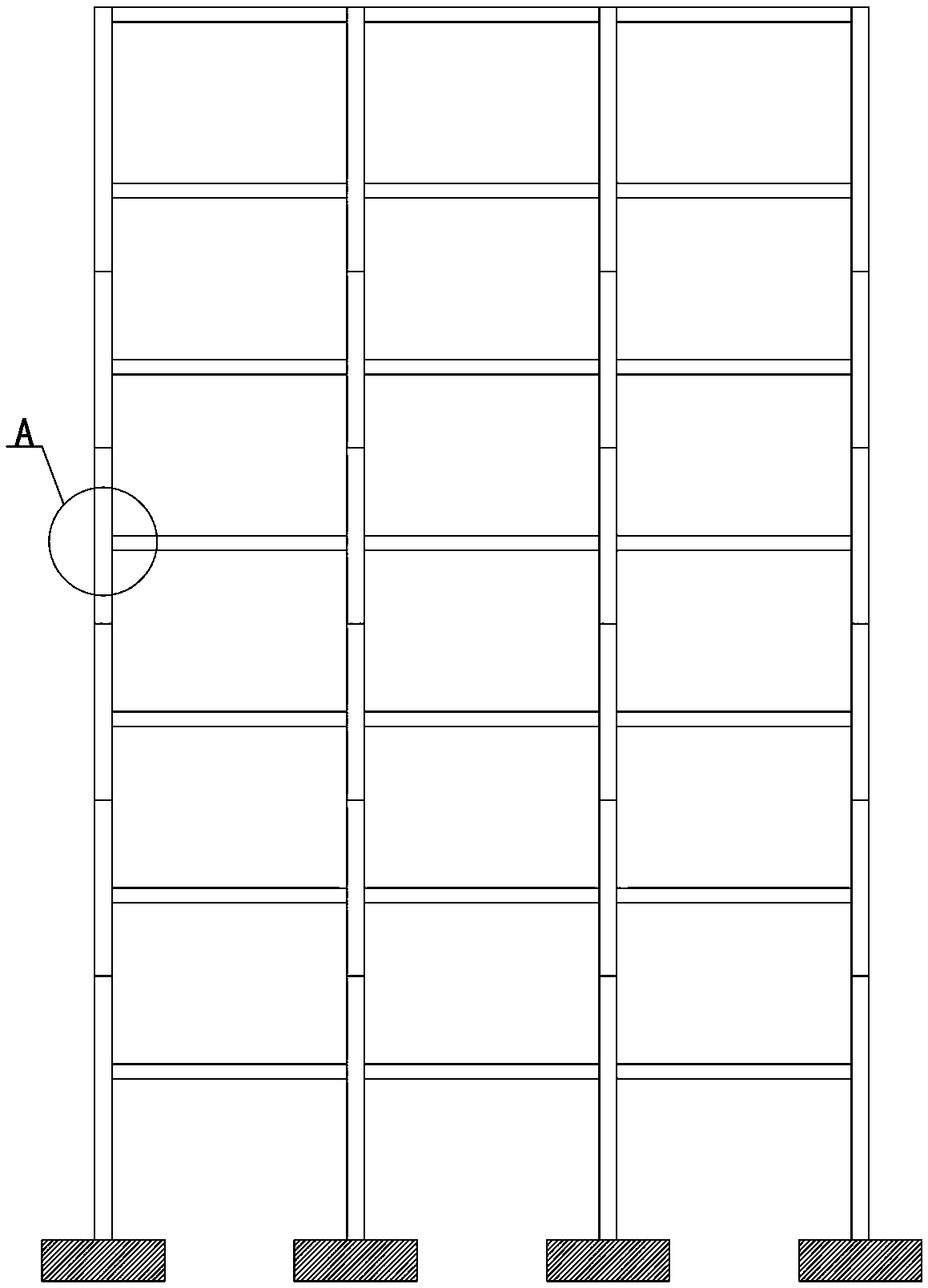

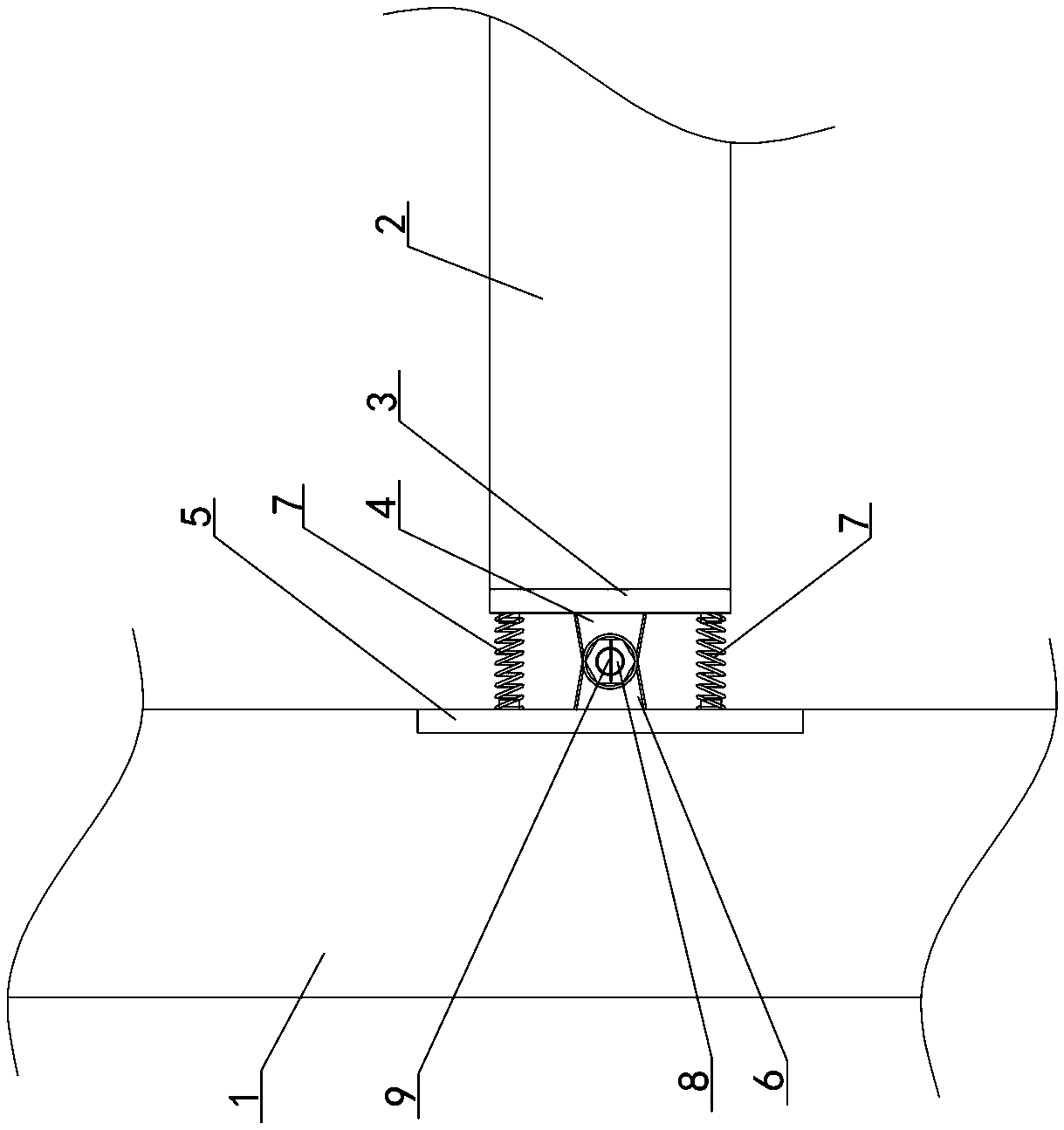

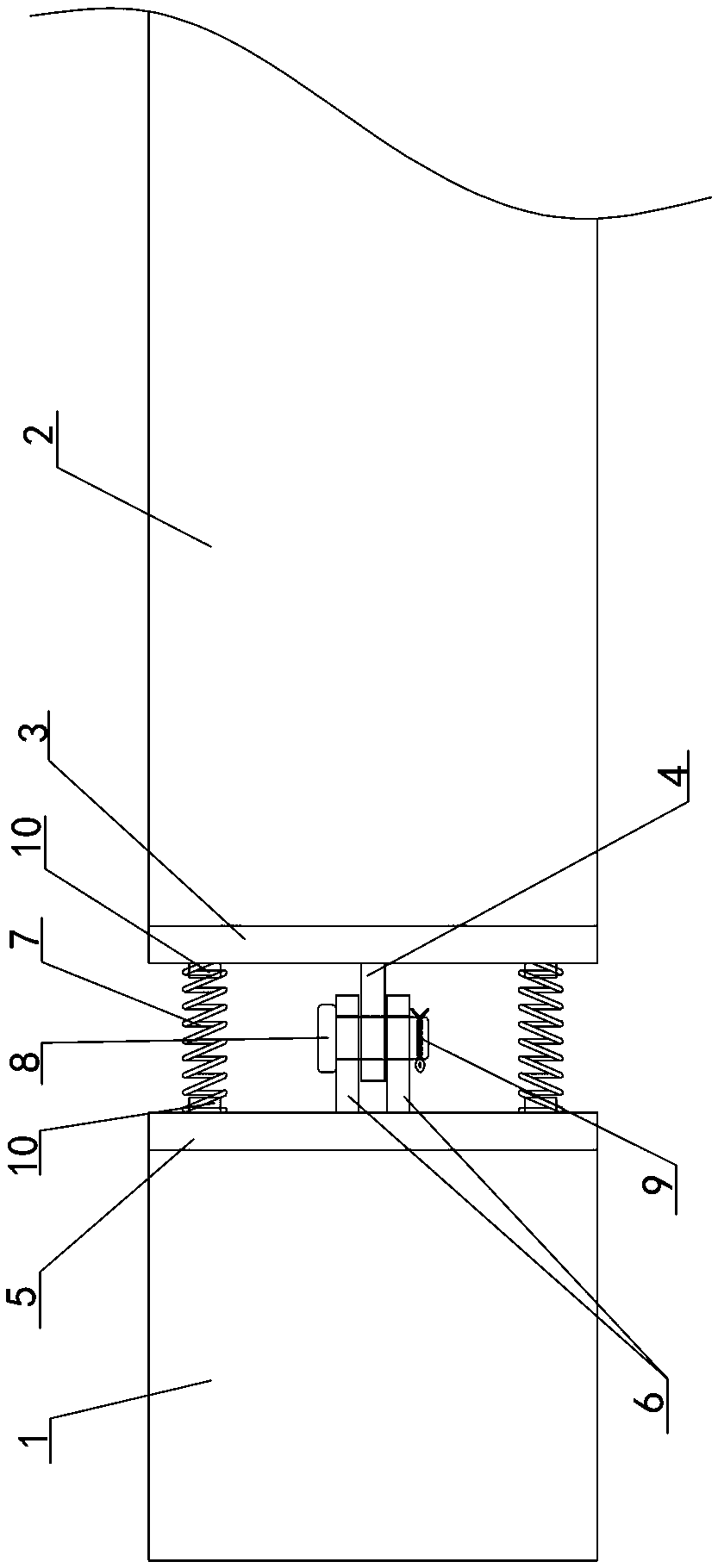

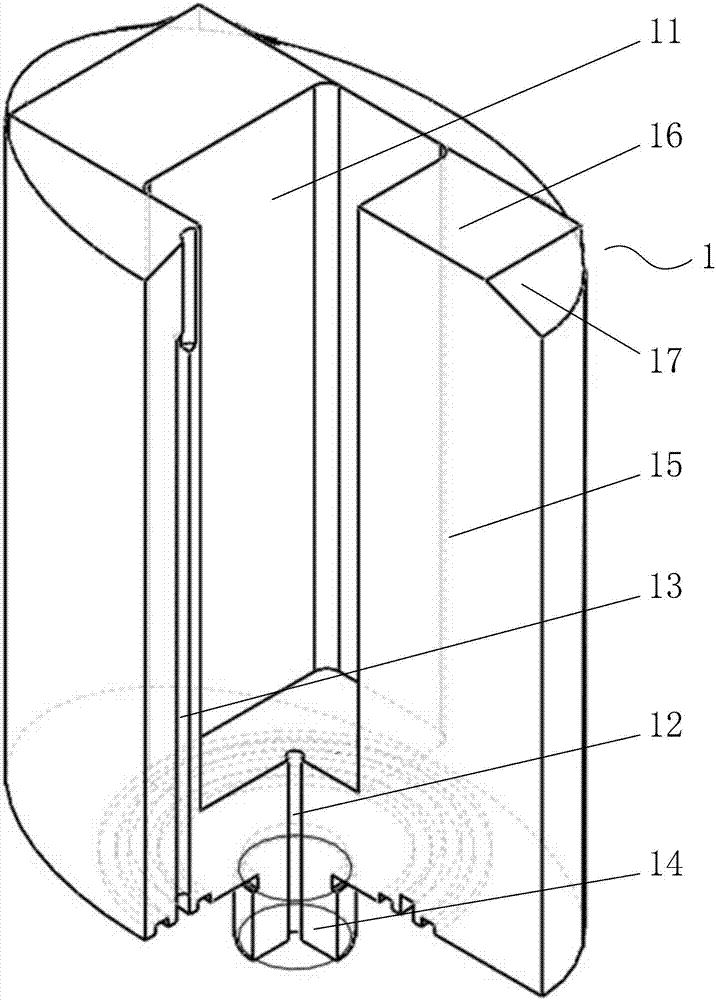

Vertical shears-fork type yielding-free stereo garage

InactiveCN104947982ASolve the problem of excessive starting forceResolve in and outParkingsMotor driveParking space

The invention relates to a vertical shears-fork type yielding-free stereo garage which comprises shears-fork mechanisms on the two sides of a parking space. The rear end of the parking space is provided with a four-stand-column portal frame. A winding plant on the four-stand-column portal frame pulls and lifts a rotary disk bracket through a steel rope, and therefore an automobile tray can ascend and descend. A small rail car is arranged below the four-stand-column portal frame. A small rail car motor driving mechanism horizontally moves on a rail. The shears-fork mechanisms are provided with ground pulleys. The rotary disk bracket is arranged on the upper portion. The automobile tray is attached to the upper portion of the rotary disk bracket. The rotary disk bracket and the portal frame achieve locked protection through an electromagnetic pin. By means of the vertical shears-fork type yielding-free stereo garage, stereoscopic parking can be achieved in two layers of stereo garages in the mode that the bottom layer of stereo garage can be free of yielding, structure stress is relatively reasonable, a hoist rope chain system or a hydraulic system can be used as a driving source, various power sources can be provided, interference is not likely to be formed, and vertical shears-fork type yielding-free stereo garage is safe and reliable.

Owner:宜昌车云台立体车库科技有限公司

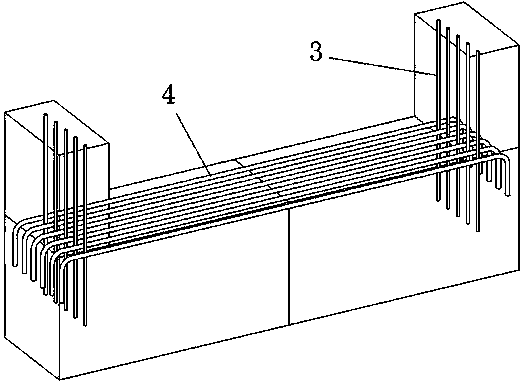

Non-damage stiffness-adjustable prefabricated frame beam and column connection structure and construction method thereof

InactiveCN108487460AGuaranteed flexural elasticityGuaranteed not to be brokenBuilding constructionsReinforced concrete columnSteel bar

The invention discloses a non-damage stiffness-adjustable prefabricated frame beam and column connection structure and a construction method thereof. The non-damage stiffness-adjustable prefabricatedframe beam and column connection structure comprises a prefabricated reinforced concrete column and a prefabricated beam which are connected; a pin joint device which enables the beam end of the prefabricated beam to vertically and freely rotate relative to the prefabricated column is fixed between the center of the beam end face of the prefabricated beam and the prefabricated column; the pin joint device is a vertical shear-resisting connecting lug plate set, and a pin joint shaft is arranged on the shear-resisting connecting lug plate set in a penetrating mode; and the pin joint shaft is located in the middle of a reserved gap between the reinforced concrete column and the prefabricated beam. Compared with the ideas of bending and shearing separation, strong shearing and weak bending, and bending shearing elasticity, a pre-embedded piece capable of being accurately positioned is prefabricated in a factory through a fabricated structure, processing is convenient, on-site mounting of the structure is easy and convenient, the mounting efficiency is improved, the economic feasibility is achieved, and the performance cost ratio is high; and structural steel bars are completely disconnected, the steel bar overlapping problem is avoided, and the advantage of convenient construction is achieved in the real sense.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

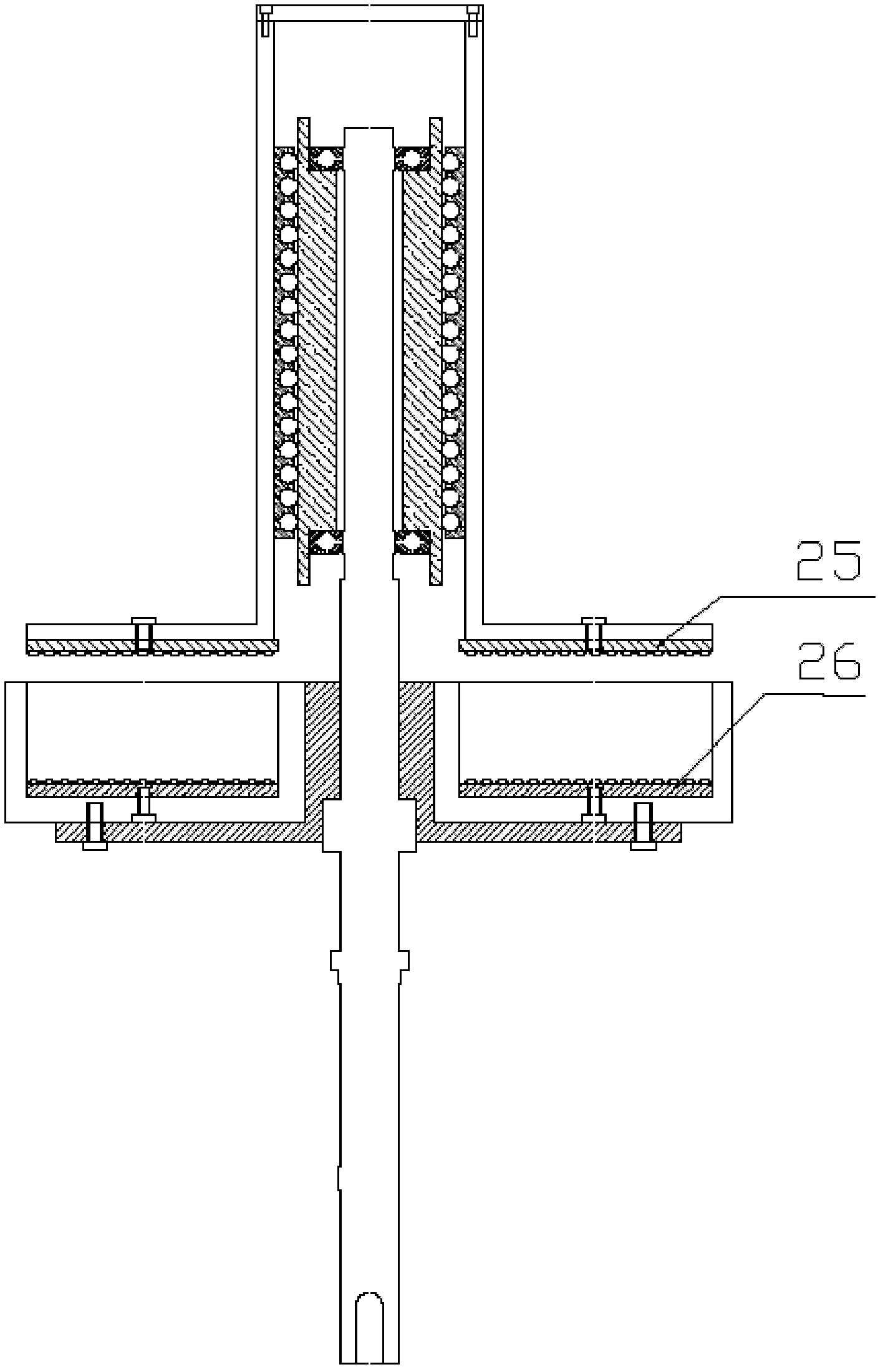

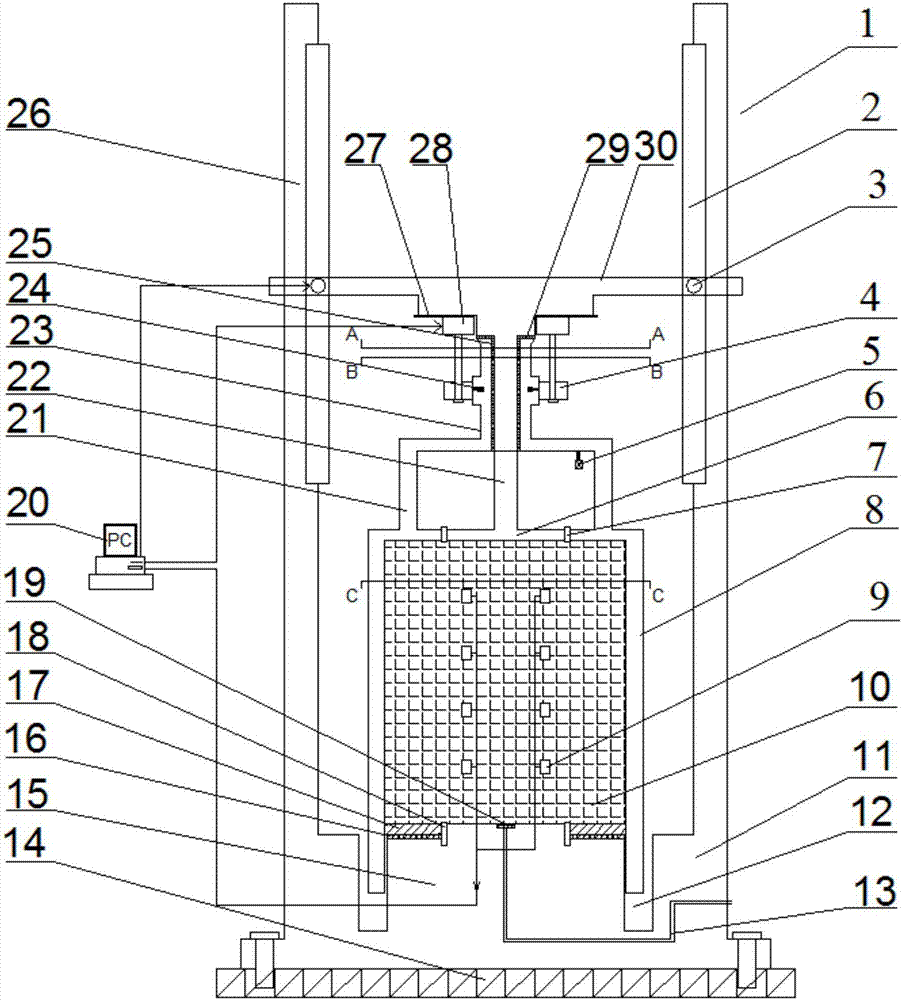

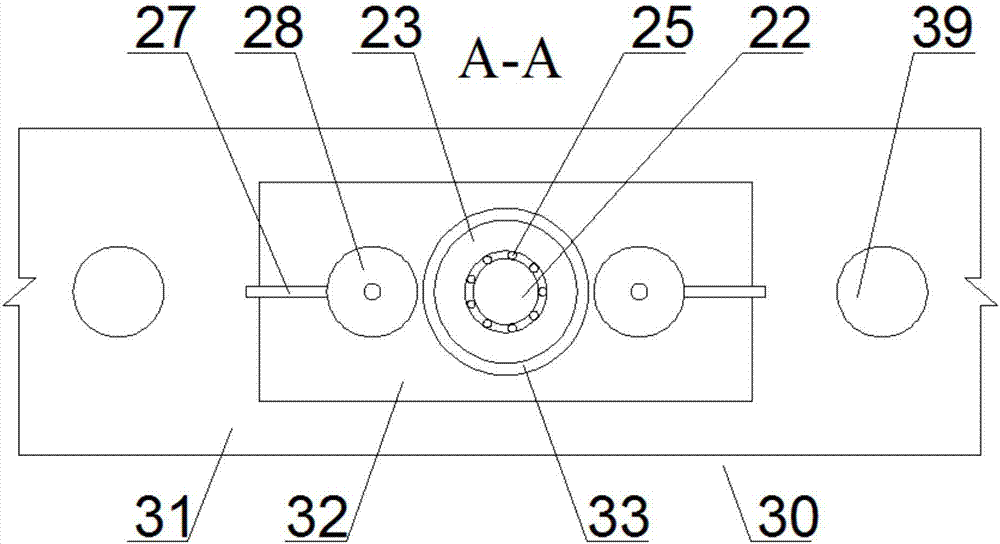

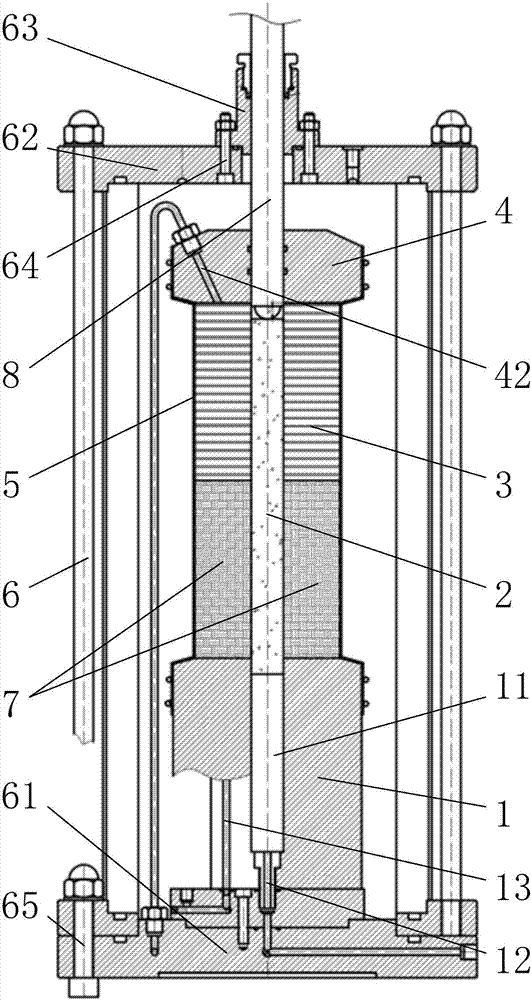

Ring shear test instrument suitable for vertical shear surface

ActiveCN107036909AAct as supportEnough room to descendMaterial strength using steady shearing forcesParticulatesShear stress

The invention relates to a ring shear test instrument suitable for a vertical shear surface. The ring shear test instrument comprises a shear box, a lifting system, a power rotating system, a monitoring and controlling system and a frame. In the shear box, shear plates are evenly fixed to an annular bottom plate in the radial direction of the annular bottom plate, and a shear box outer cover is buckled to the annular bottom plate and the shear plates in a covering mode and is assembled and fixed to the annular bottom plate through guide bars and guide grooves; the shear box outer cover is connected with a rotating force arm of the power rotating system to transmit torque, a coupling shaft pressing plate is embedded in a center hole of a top plate of the shear box outer cover in a centered mode and is driven by the lifting system to conduct normal force loading, the annular bottom plate is embedded in a cylindrical supporting platform in a centered mode, and an inner cylindrical side face generated when the annular bottom plate drives the shear plates to conduct circular motion under the action of rotating torque is a vertical shear surface. The ring shear test instrument can ensure that shear displacement and shear stress on the shear surface are uniformly distributed, the thickness of the vertical shear surface is not limited, and thus a large ring shear test in the presence of large particulate matter is realized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Dropped deck center beam rail road car

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented web work structure for carrying vertical shear loads between the top truss and the center sill and decking. The center beam so formed defines bunks upon in which to carry cargo. The upper region of the web-work structure includes a deep upper beam structure that has downwardly extending skirts. The skirts provide an extended bearing area upon against which bundled loads can be secured. The skirts are inwardly reinforced to discourage deflection between adjacent upright members of the deep upper beam structure.

Owner:NATIONAL STEEL CAR

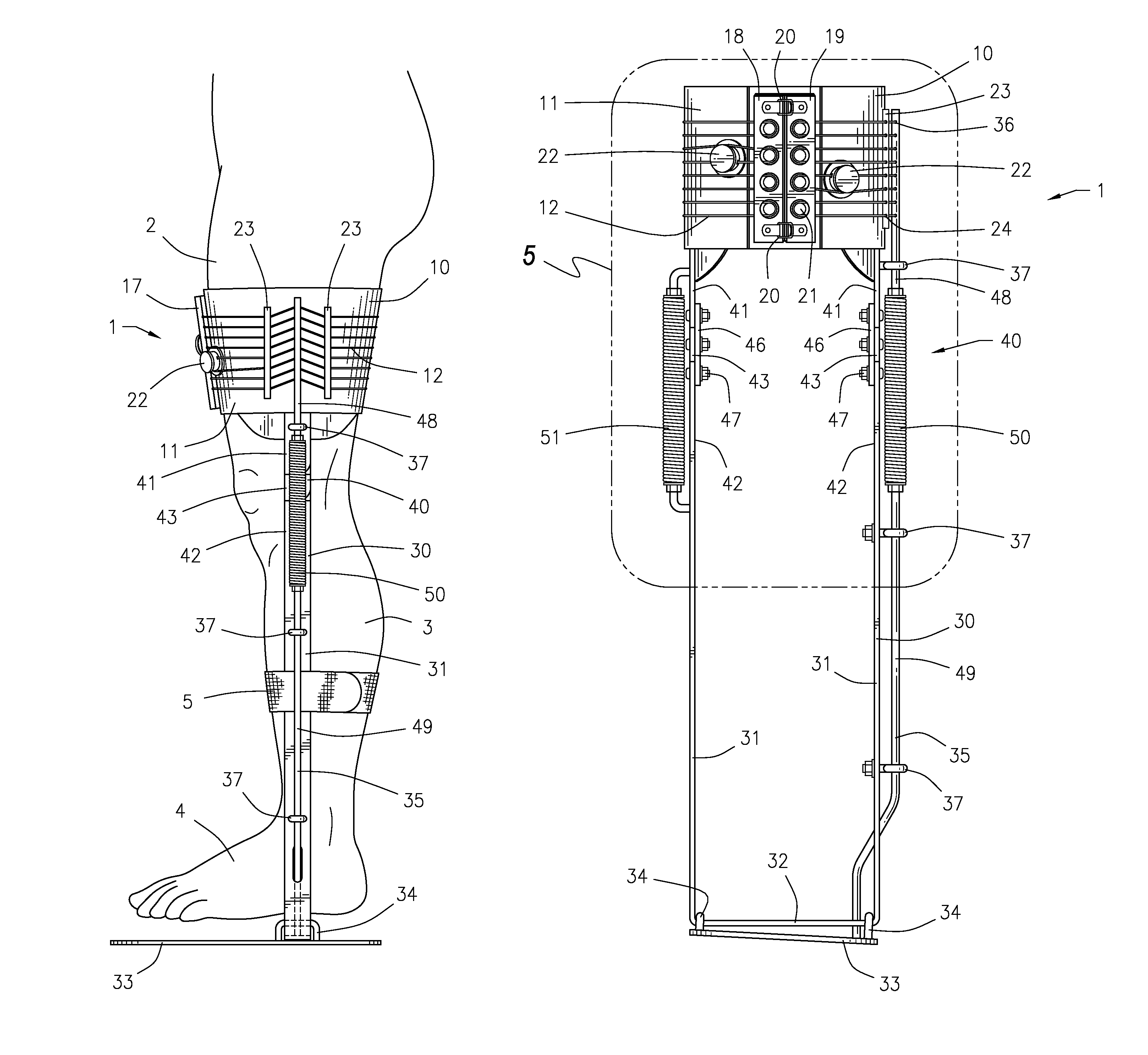

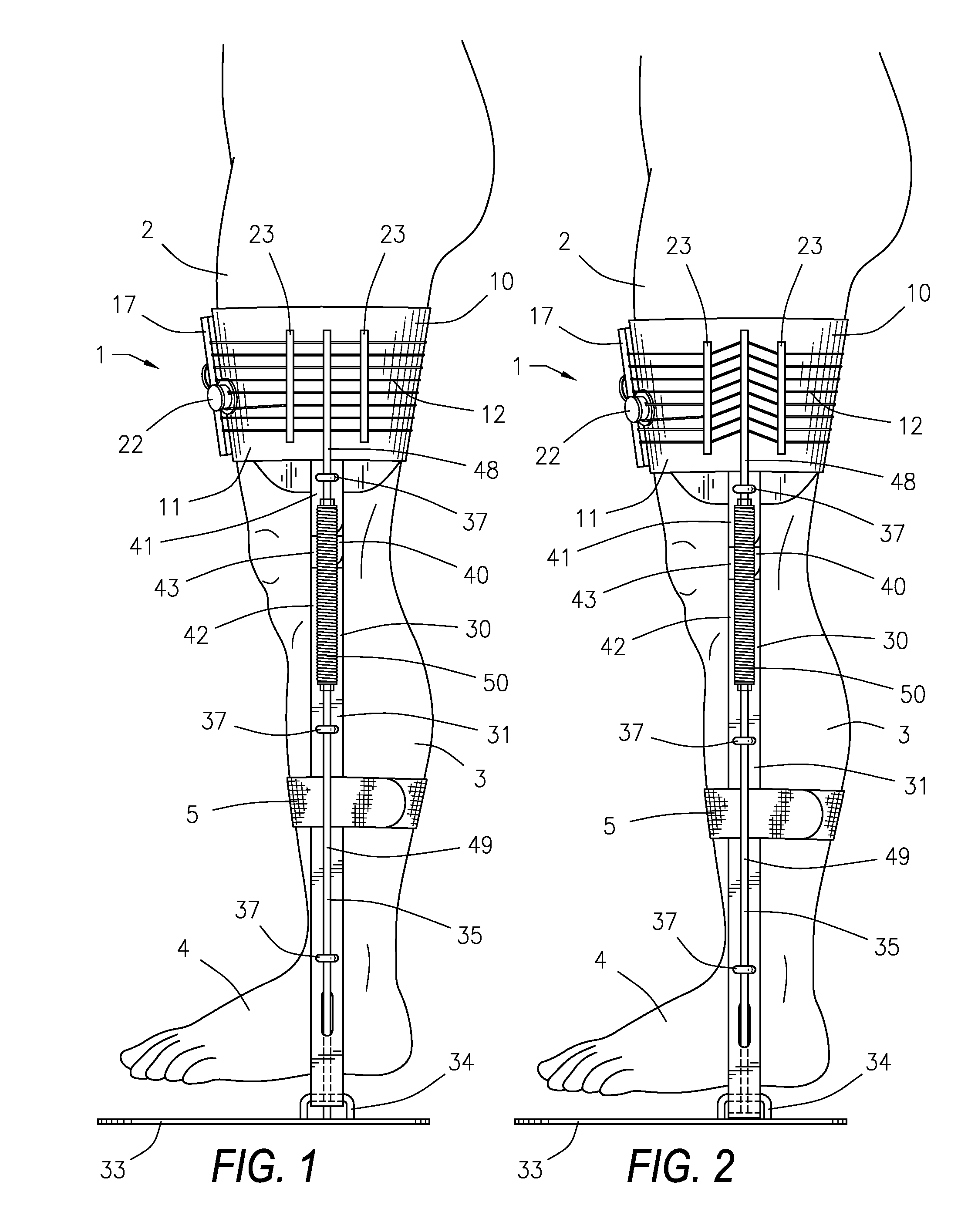

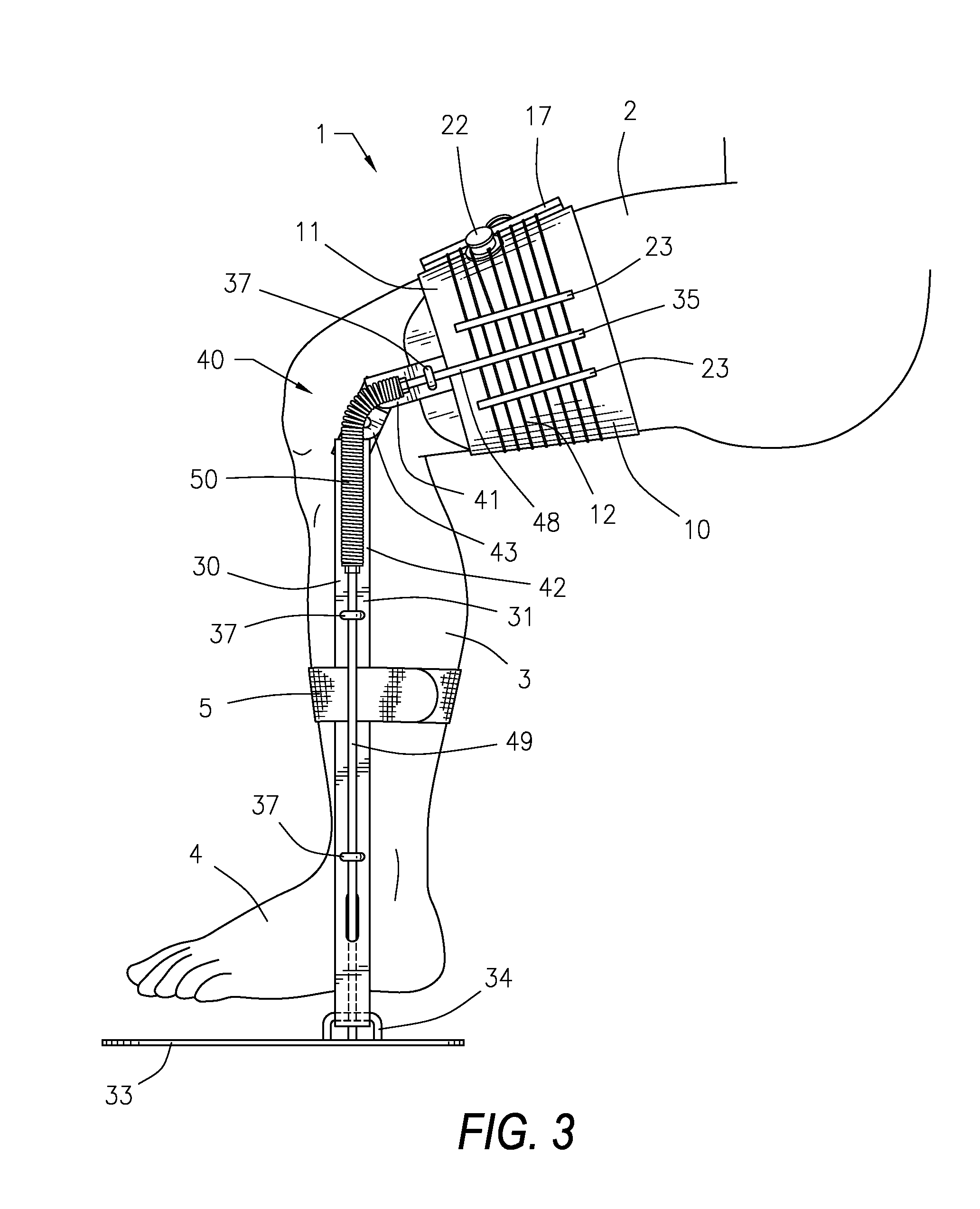

Compression leg support

A leg support that attaches to a user's upper leg and extends below the user's foot, where stepping on the portion below the user's foot causes the portion around the user's upper leg to tighten. This allows the leg support and the user's upper leg to bear the user's weight with the user's foot remaining untouched. When the user takes his or her weight off of the leg support, the portion around the user's upper leg loosens for the user's comfort. The leg support insures that there is zero pressure on the bottom of the user's foot and all of the user's weight and vertical shear pressure is converted into horizontal compression pressure around the user's thigh, while the user's center of gravity remains in a position that allows upright balance to be maintained.

Owner:FULLERTON M J

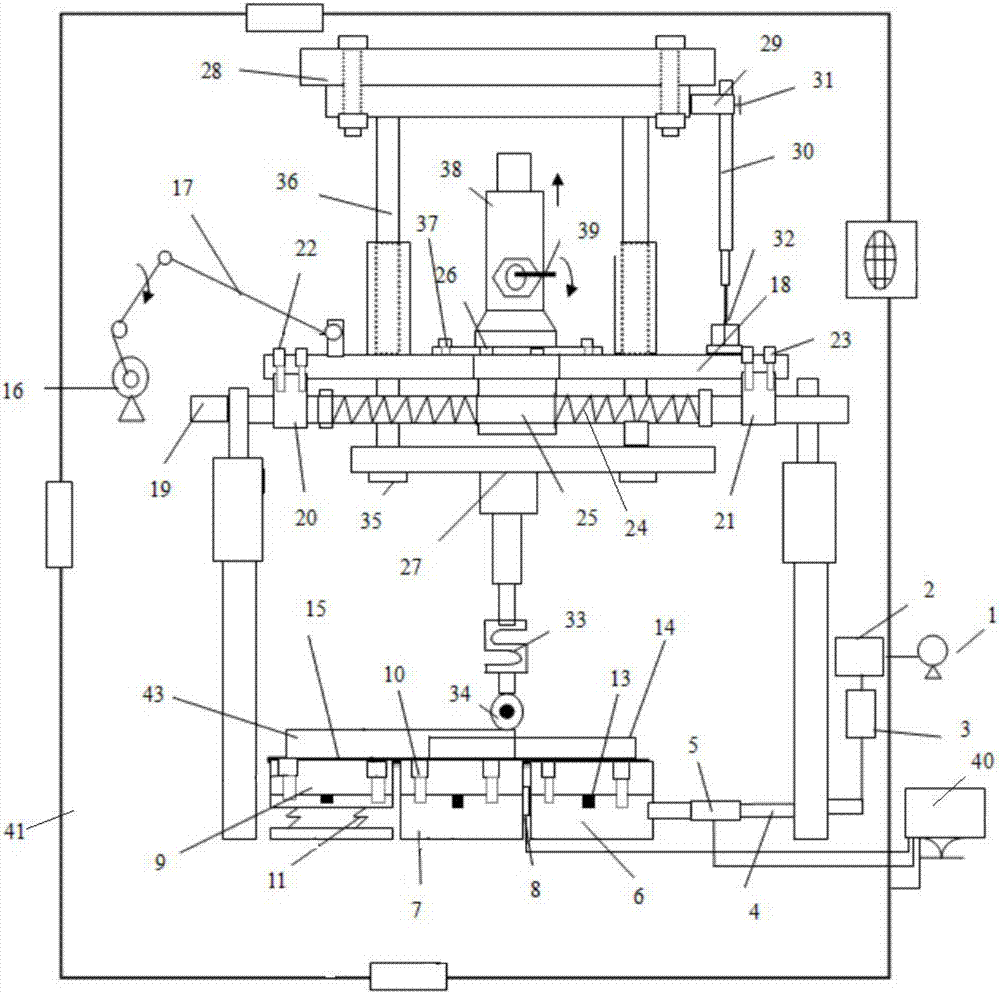

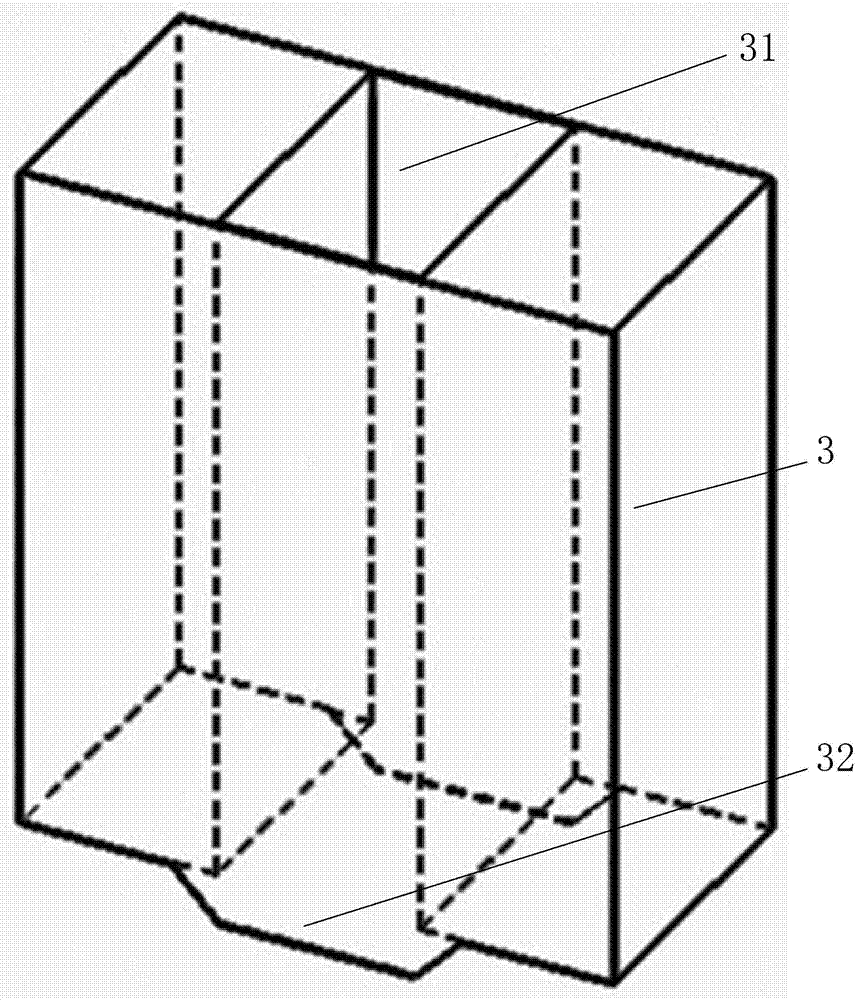

Device and method for simulating propagation of reflective cracks of semi-rigid-base asphalt pavement

PendingCN106896029ACrack Resistance EvaluationMaterial strength using steady shearing forcesMaterial strength using repeated/pulsating forcesControl systemStructural engineering

The invention discloses a device and a method for simulating propagation of reflective cracks of a semi-rigid-base asphalt pavement. The device comprises an environmental cabinet, a reflective crack simulating platform, a reflective crack testing system and an acquisition control system, wherein a pedestal is arranged at the bottom of the environmental cabinet; and the reflective crack testing system comprises a horizontal open-type reflective crack testing module and a vertical shear-type reflective crack testing module. The device not only can simulate open-type reflective cracks in the horizontal direction, but also can simulate shear-type reflective cracks in the vertical direction, and can really simulate occurrence and the propagation of the actual reflective cracks of the semi-rigid-base asphalt pavement, so that a reference basis is provided for selecting an anti-cracking material and an anti-cracking structure in pavement structure design.

Owner:青海省交通规划设计研究院有限公司 +2

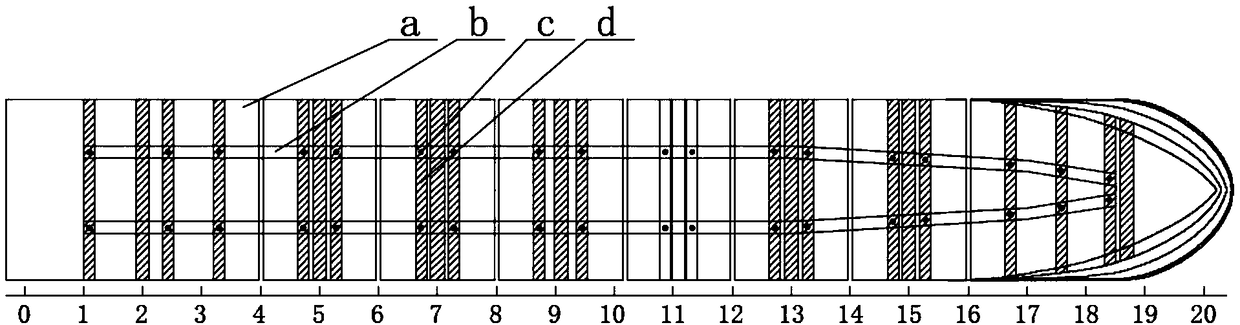

Method for measuring torque and shear force of hull model

The invention relates to a method for measuring the torque and shear force of a hull model, which comprises a ship body, wherein the ship body is internally provided with a U-shaped beam, the internalpart of the U-shaped beam is provided with transverse bulkheads installed at intervals, the upper surface of the U-shaped beam is provided with a plurality of parallel wooden cross beams which are fixed at intervals through bolts, and each board of the U-shaped beam is attached with a set of strain gauges. Data is obtained according to a calculation formula. The method does not need to take the mutual coupling among the vertical bending, the horizontal bending and the distortion of the U-shaped beam into account. No matter what kind of load the U-shaped beam bears, the torque, the vertical shear force and the horizontal shear force can be directly obtained through the shear stress at the middle position of each board distributed on the profile.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

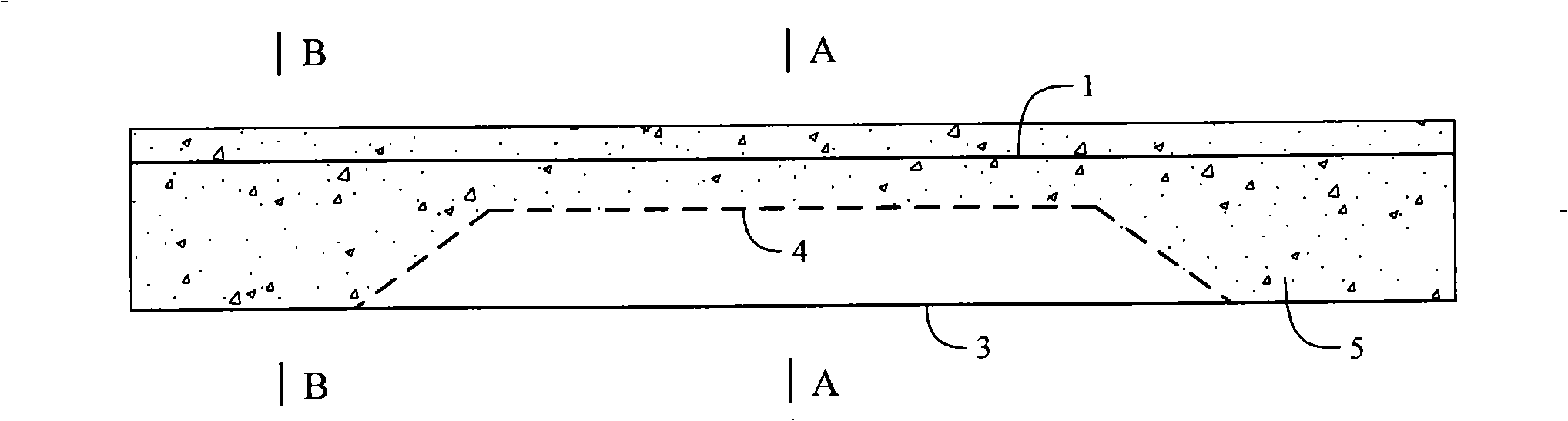

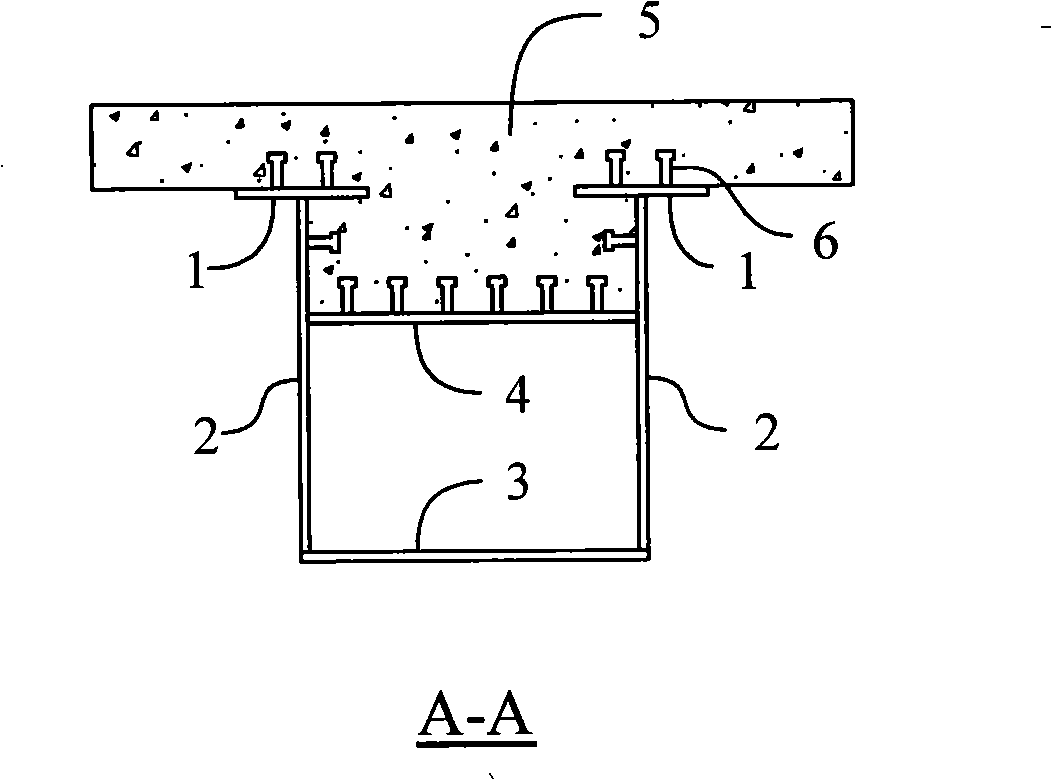

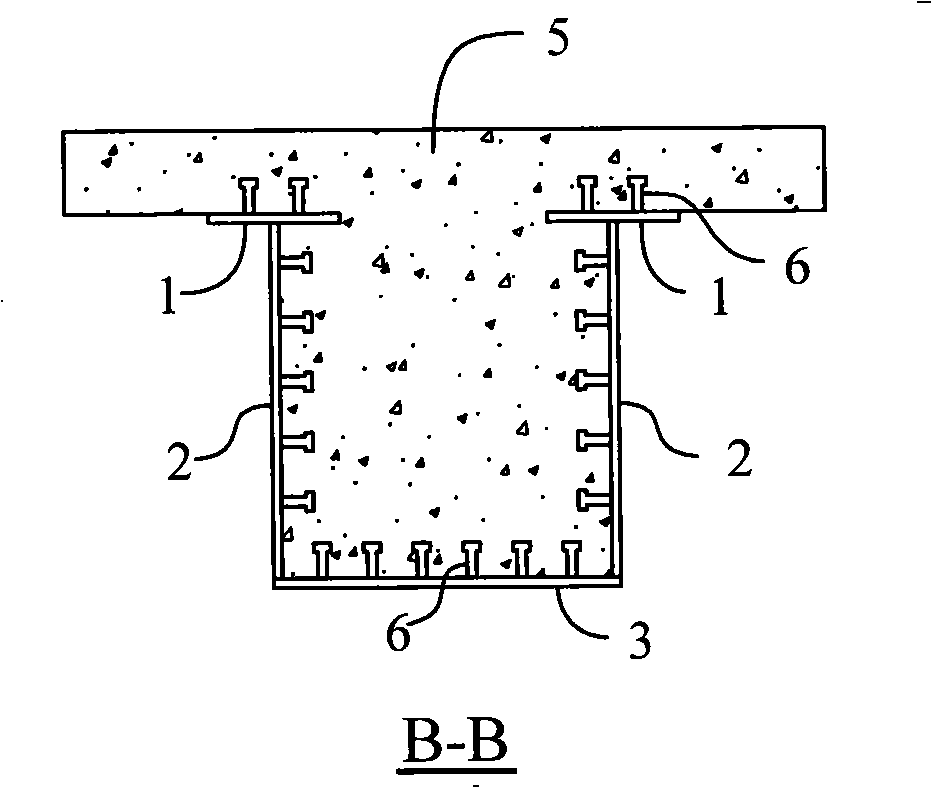

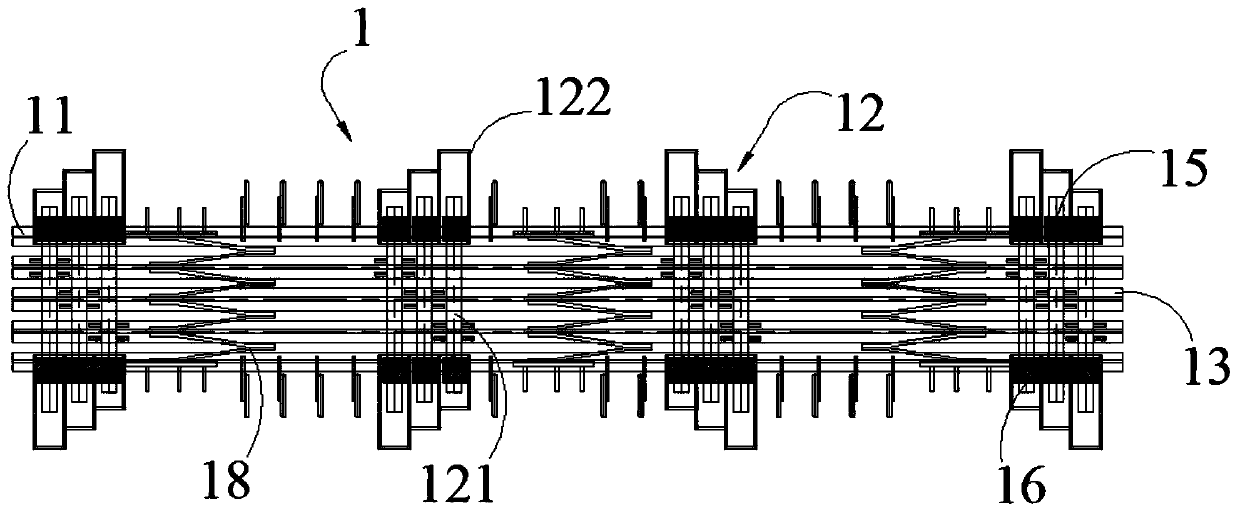

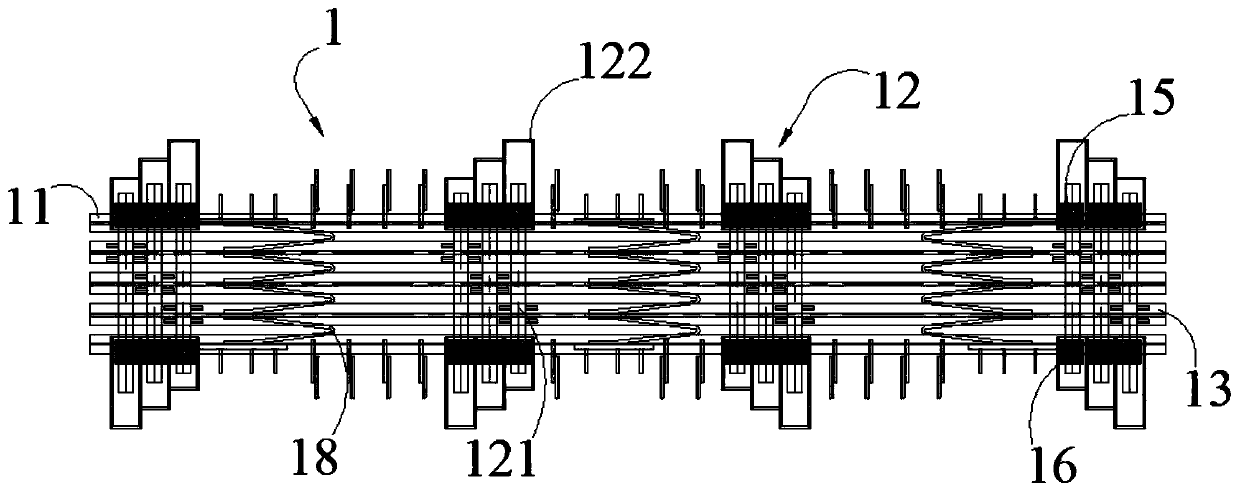

Steel-concrete combined conversion joist

InactiveCN101338608AAvoid the effects of crackingIncrease stiffnessLoad-supporting elementsFalseworkHigh stiffness

The invention discloses a steel-concrete combined conversion girder which relates to a conversion structure used in tall buildings and skyscrapers. The combined conversion beam consists of a steel box girder, concrete poured on the top of and in the steel box girder and a shearing resistant connector. Concrete is poured on the upper part inside the steel box in the span-center bending moment area to solve the problem of the insufficient pressing area of concrete on the top of the steel box girder; concrete is not poured on a lower part inside the steel box in the span-center bending moment area, which effectively reduces the self-weight of the structure. Concrete is poured in the steel box at the girder end to keep the stability of the steel girder and to increase the vertical shearing resistant capability and the stiffness of the structure. The shearing resistant connector combines the steel girder with concrete and transfers the shearing force between the steel girder and concrete and prevents the steel girder from separating from concrete. The combined conversion girder provided by the invention is light and can save moulding boards and scaffolding; the construction of the combined conversion girder is convenient and can avoid the problem of the crack of the concrete in the span center; meanwhile, the combined conversion girder has higher stiffness and loading capacity, particularly has higher shearing resistant loading capacity at the girder end. The combined conversion girder has wider application perspective in tall buildings and skyscrapers.

Owner:TSINGHUA UNIV

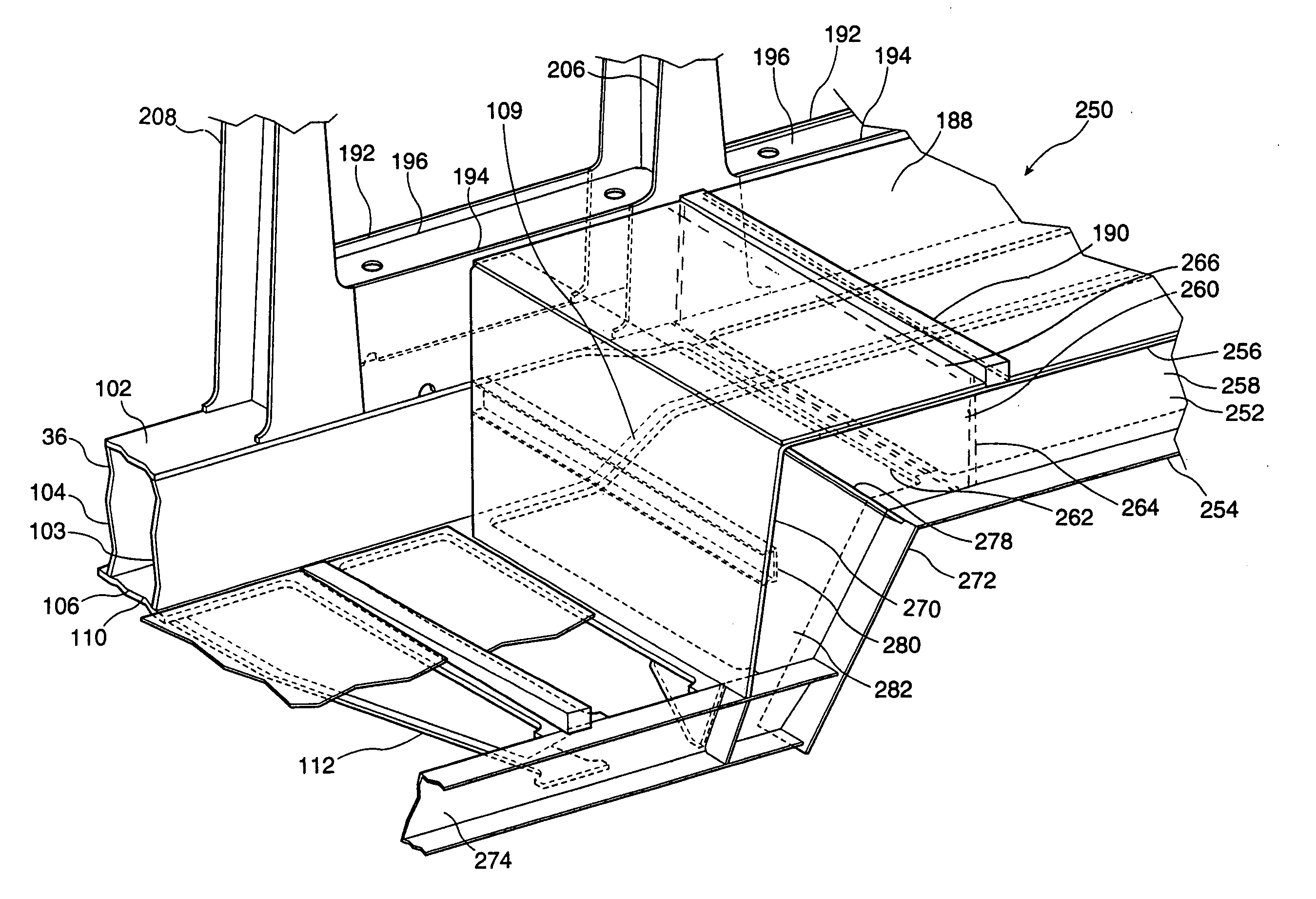

Center beam car with deep upper beam structure

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented web work structure for carrying vertical shear loads. The center beam so formed defines bunks upon in which to carry cargo. The upper region of the web-work structure includes a deep upper beam structure that has downwardly extending planar surfaces. The surfaces provide a bearing area against which bundled loads can be secured. The surfaces are inwardly reinforced to discourage deflection between adjacent upright members of the vertical web work.

Owner:NATIONAL STEEL CAR

Bridge ductility anti-earthquake structure easy to replace after earthquake and construction method

InactiveCN107829362ALarge deformationLimit lateral displacementBridge structural detailsBridge erection/assemblyEarthquake resistant structuresRebar

The invention discloses a bridge ductility anti-earthquake structure easy to replace after an earthquake. The bridge ductility anti-earthquake structure is composed of a foundation and anti-earthquakechock blocks, wherein the foundation and the anti-earthquake chock blocks are relatively independent; the anti-earthquake chock blocks are arranged on the upper side surface of the foundation; and the anti-earthquake chock blocks are connected with the foundation through a plurality of vertical shear reinforcements. Based on the above-mentioned structure, the invention also discloses a corresponding construction method. The bridge ductility anti-earthquake structure easy to replace after the earthquake and the construction method, disclosed by the invention, have the following beneficial technical effects: the deformation quantity of the bridge ductility anti-earthquake structure is larger, so that the transverse displacement of a girder can be better limited; after the anti-earthquake chock blocks are damaged, the damage to the foundation is less; and the anti-earthquake chock blocks are relatively convenient to replace, thereby being favorable for repairing in rescue and relief works after the earthquake.

Owner:CHONGQING JIAOTONG UNIVERSITY

Steel elastomer lattice beam type section steel bridge expansion device

PendingCN109778691AMeet the requirements of multi-directional displacementMeet water resistanceBridge structural detailsElastomerGusset plate

The invention provides a steel elastomer lattice beam type section steel bridge expansion device. The device comprises two side beams located at both sides of an expansion joint, at least one middle beam and at least two joist beam sets; the middle beams and the joist beam sets are fixedly connected, the two ends of each joist beam set are fixed to the two sides of the expansion joint through a sliding pressure bearing support base and a movable steel ball support base respectively, each middle beam is connected with the side beam exactly opposite to the middle beam or another middle beam through waterproof adhesive tape, gusset plates are vertically fixed below each side beam and below each middle beam, and every two adjacent gusset plates are connected through a steel plate spring elastomer. By means of the device, on the one hand, the multi-directional displacement requirement of a bridge can be met, and the stability and the binding property are very good; on the other hand, the gusset plates are connected by the steel plate spring elastomers, the service life is long, the steel plate spring elastomers jointly decompose the expansion and contraction amount of the bridge, partial horizontal force borne by the middle beams can be balanced, the vertical shear force is transmitted, and the synchronism is good.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Test device for large deformation shearing seepage of contact surface and use method thereof

PendingCN106932284AAvoid squeezingGuaranteed accuracyMaterial strength using steady shearing forcesInvestigating abrasion/wear resistanceStructural engineeringVertical shear

The invention relates to a test device for large deformation shearing seepage of a contact surface and a use method thereof. The test device comprises a base, a contact panel, a sleeve, a top cap and sealing films, wherein a deep slot is formed at the top of the base; two side faces of the middle part of the contact panel are in tight contact with soil samples; a mounting hole is formed at the center of the sleeve; the top cap is supported at the top of the sleeve; the sealing films are used for wrapping the peripheries of the base, the soil samples on the two sides of the contact panel, the sleeve and the top cap; a seepage water draining pipeline parallel to a shearing surface direction and a seepage water draining pipeline vertical to the shearing surface direction are arranged in the base; the contact panel is arranged in the deep slot through the lower part; the cross sectional dimension of the contact panel is smaller than the cross sectional dimension of the deep slot; the sleeve is sleeved on the part of the upper part of the contact panel, higher than the soil samples, through the mounting hole; the cross sectional dimension of the mounting hole is greater than the cross sectional dimension of the contact panel; a piston rod hole is formed at the center of the top cap; a piston rod penetrates through the top cap and directly acts on the contact panel; a seepage water feeding pipeline parallel to the shearing surface direction and a seepage water feeding pipeline vertical to the shearing surface direction are arranged on the top cap.

Owner:TSINGHUA UNIV

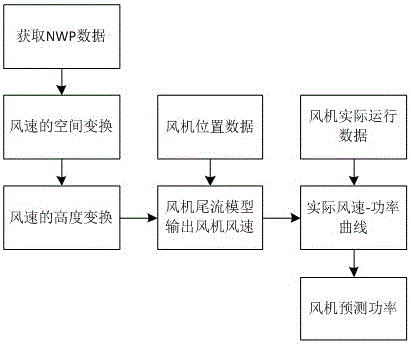

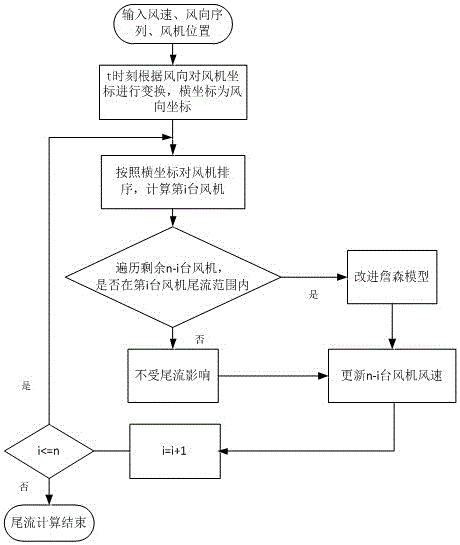

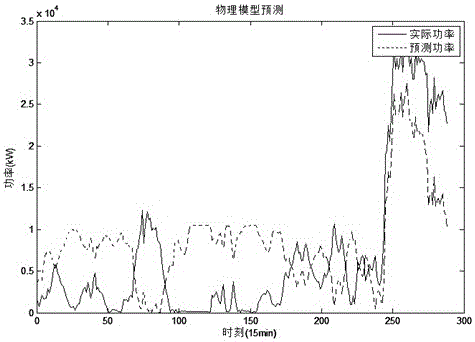

Wind power prediction method considering wake effect

The invention provides a wind power prediction method considering the wake effect. The method is characterized by comprising the following steps that (1) spatial difference is performed on NWP wind speed data by adopting an inverse distance method according to spatial distribution consistency of wind speed so that wind speed (the expression is described in the specification) of x is obtained, wherein (the expression is described in the specification) x refers to spatial coordinates, x refers to the spatial coordinates of the sampling position i, u(x) refers to the wind speed data of the sampling position i, lambda refers to the weight of the sampling position i, and l refers to Euclidean distance; (2) height difference of wind speed is realize by using the law of wind vertical shear power so that wind speed v<2>=v<1>(h<2> / h<2>)<alpha> of height h<2> is obtained, wherein alpha is a vertical wind shear index, v(2) is wind speed of height h<2>, and v<1> is wind speed of height h<1>; (3) wind speed of an actual operation blower is obtained according to a wake model and blower position data; and (4) corresponding power of the blower is obtained according to the wind speed-power curve of the actual operation blower. The wake effect and the wind speed-power curve of the actual operation blower are fully considered so that accurate prediction of wind power can be realized.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com