Patents

Literature

64results about How to "Accurate profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

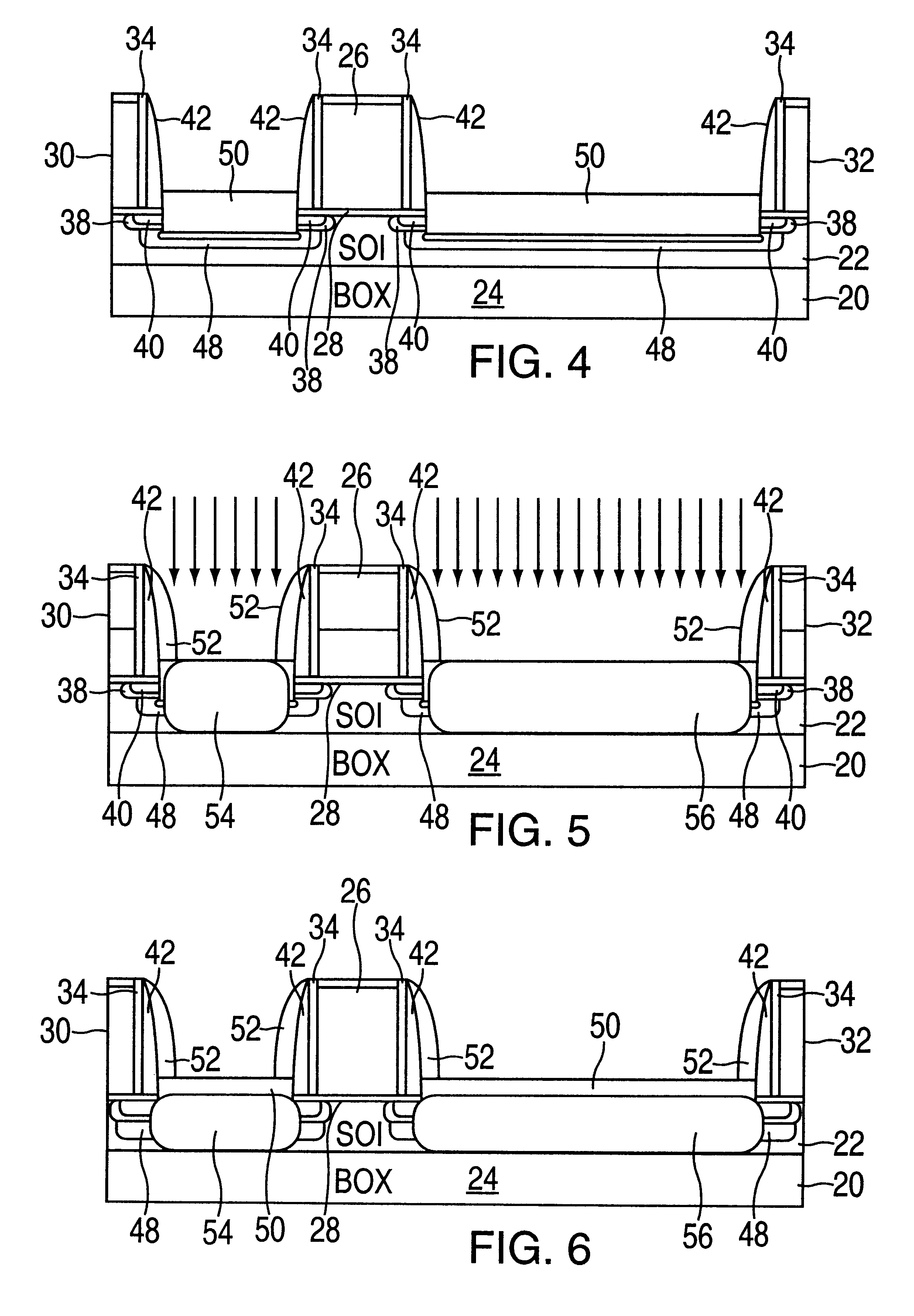

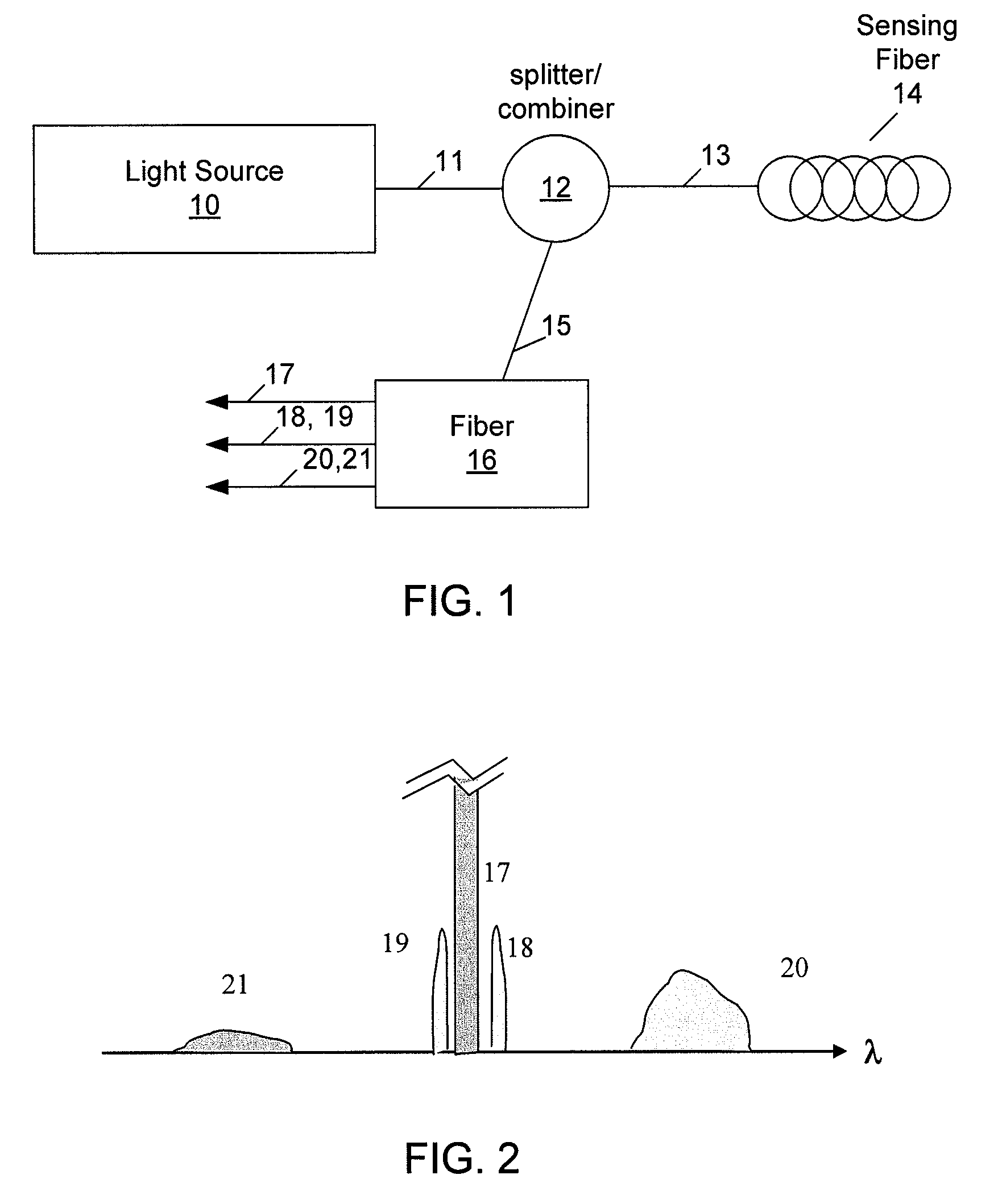

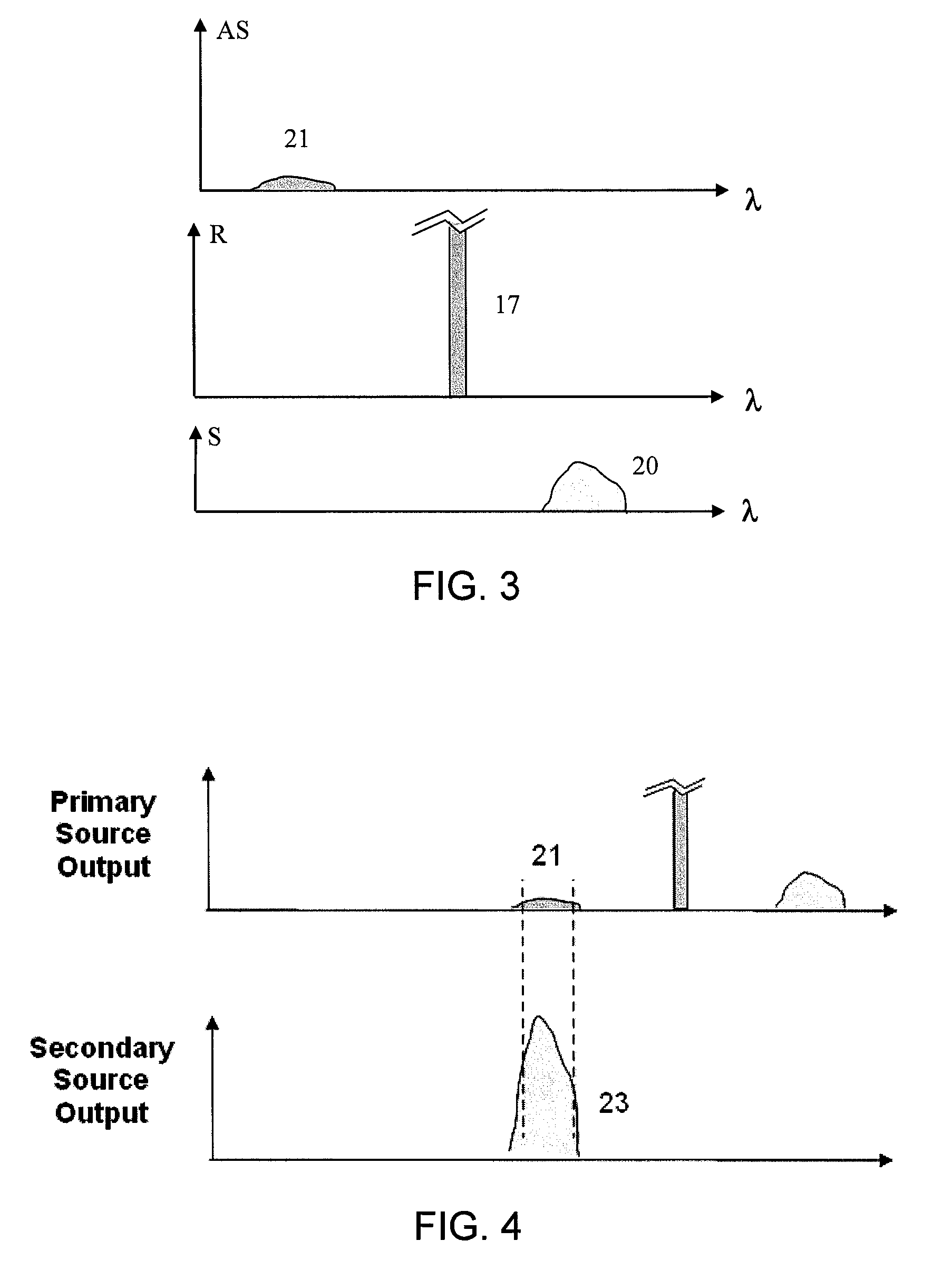

Methods and apparatus for dual source calibration for distributed temperature systems

InactiveUS20070223556A1Accurate temperature profileAccurate profileRadiation pyrometryWeather/light/corrosion resistanceFiberWave band

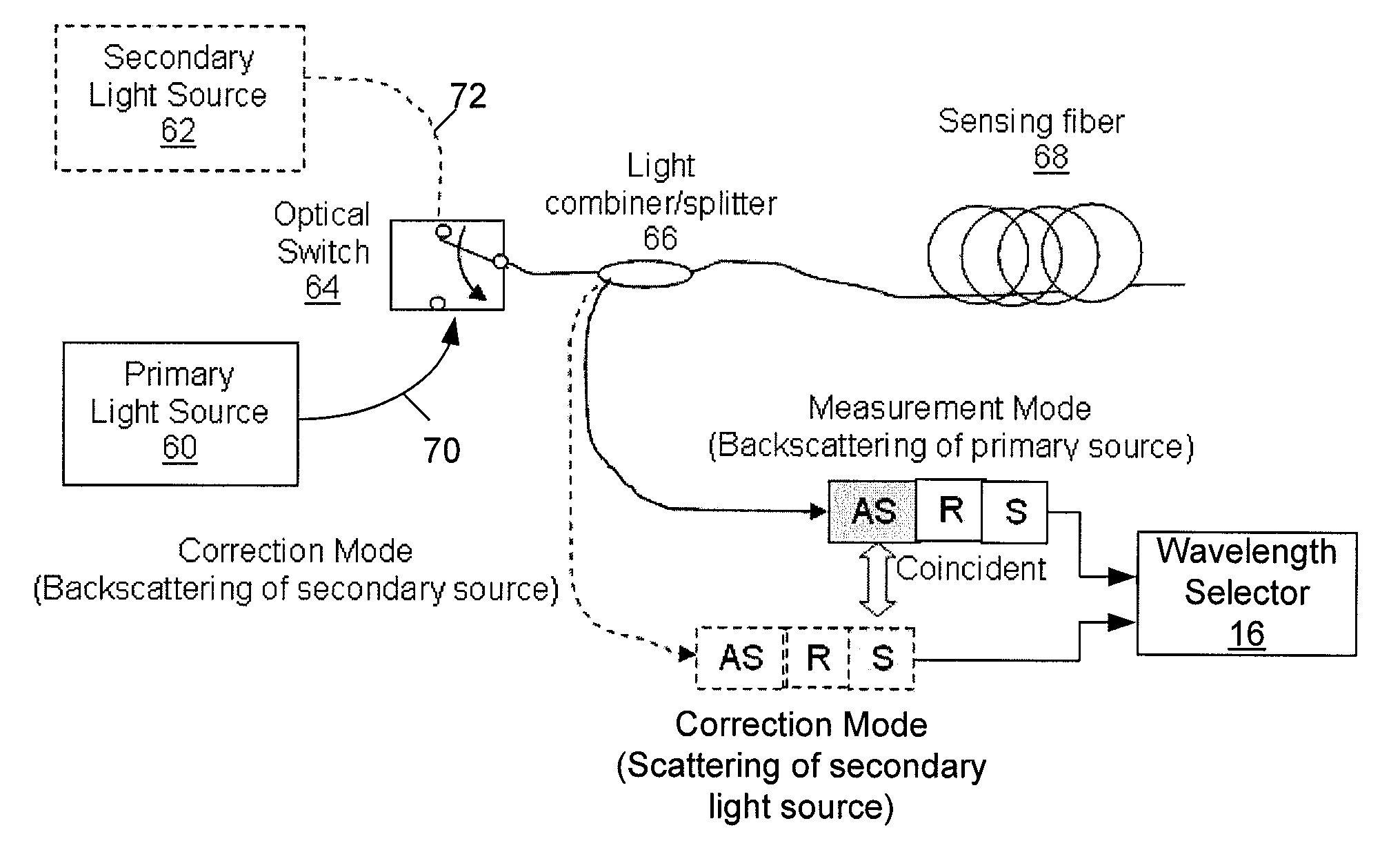

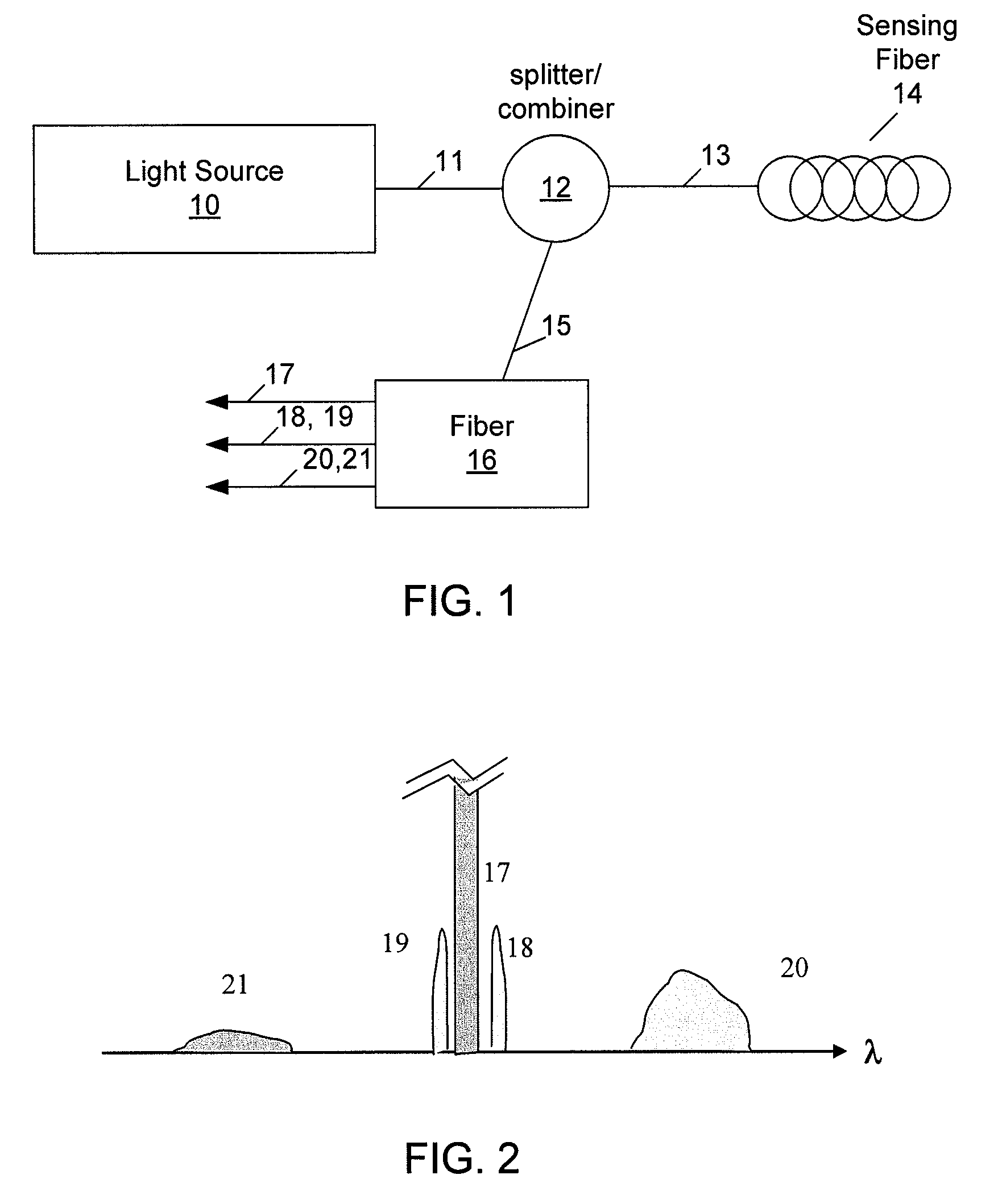

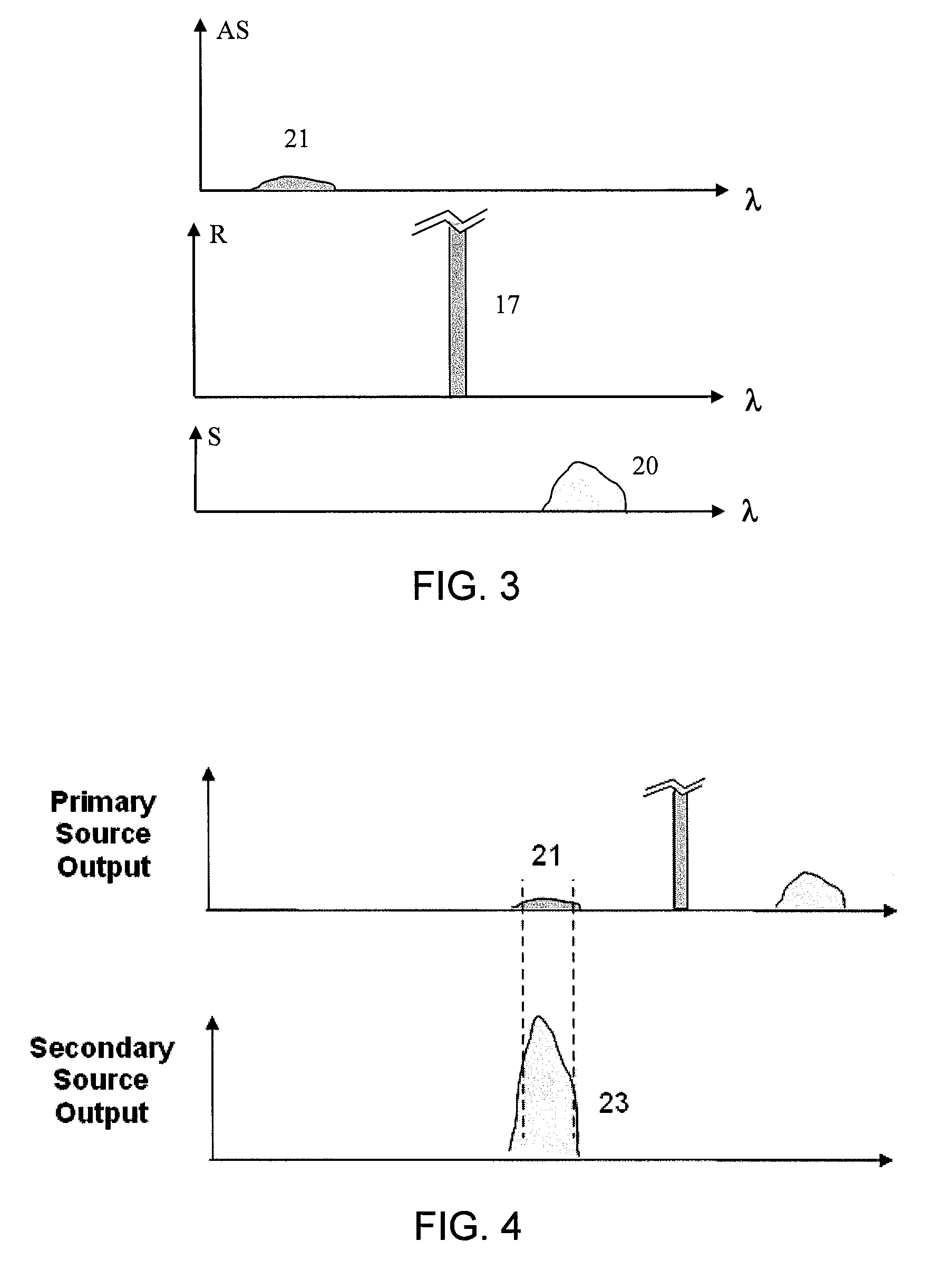

Systems and methods for calibrating a temperature sensing system are disclosed. In one respect, a dual light source configuration may be provided. A first light source may illuminate a sensing fiber and an anti-Stokes band may be detected. A second light source may illuminate a sensing fiber and a Stokes band may be detected, where the Stokes band is substantially similar to the anti-Stokes band of the first light source. A ratio between the anti-Stokes and Stokes band may be used to calibrate a temperature sensing system.

Owner:SENSORTRAN

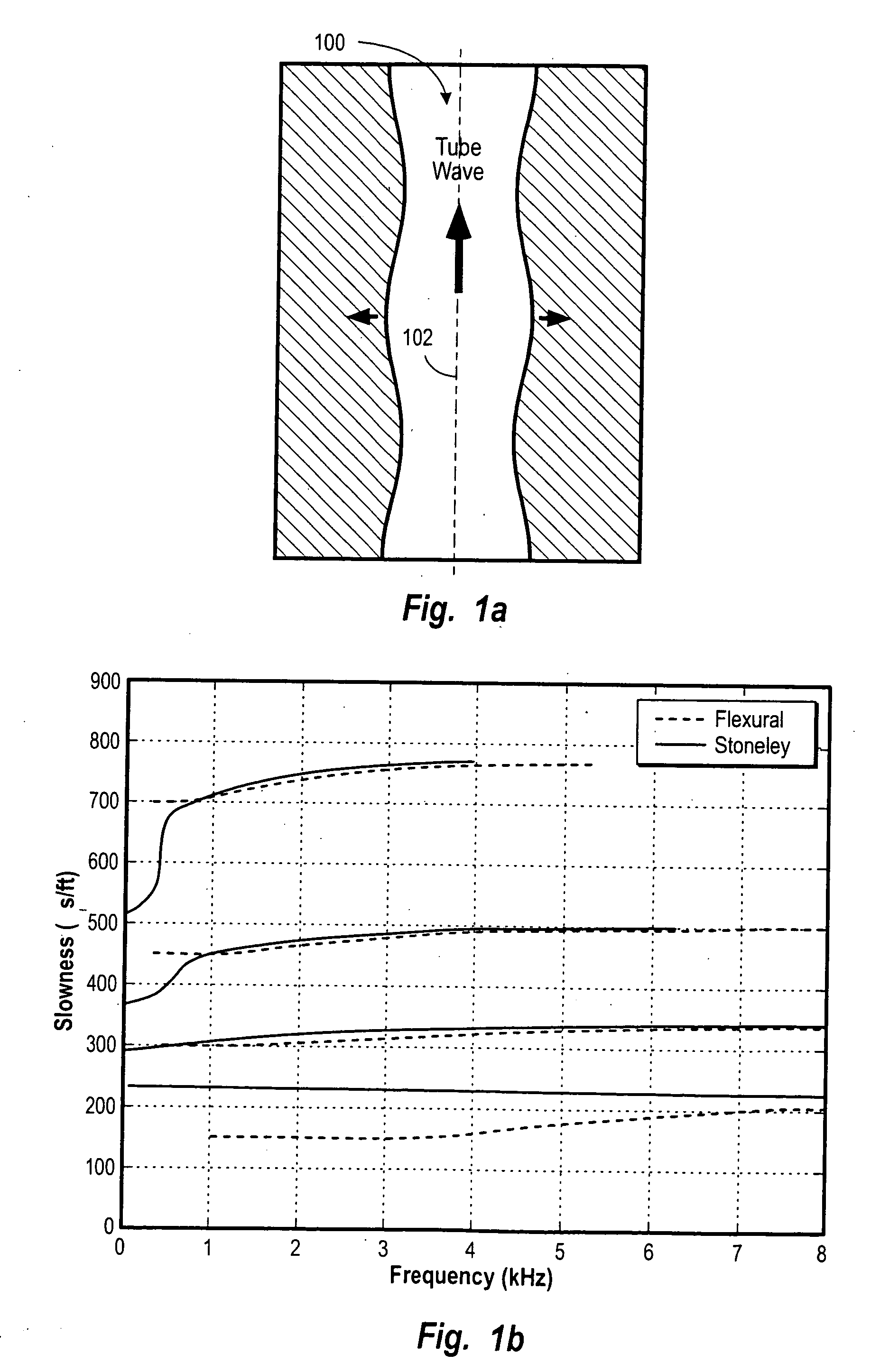

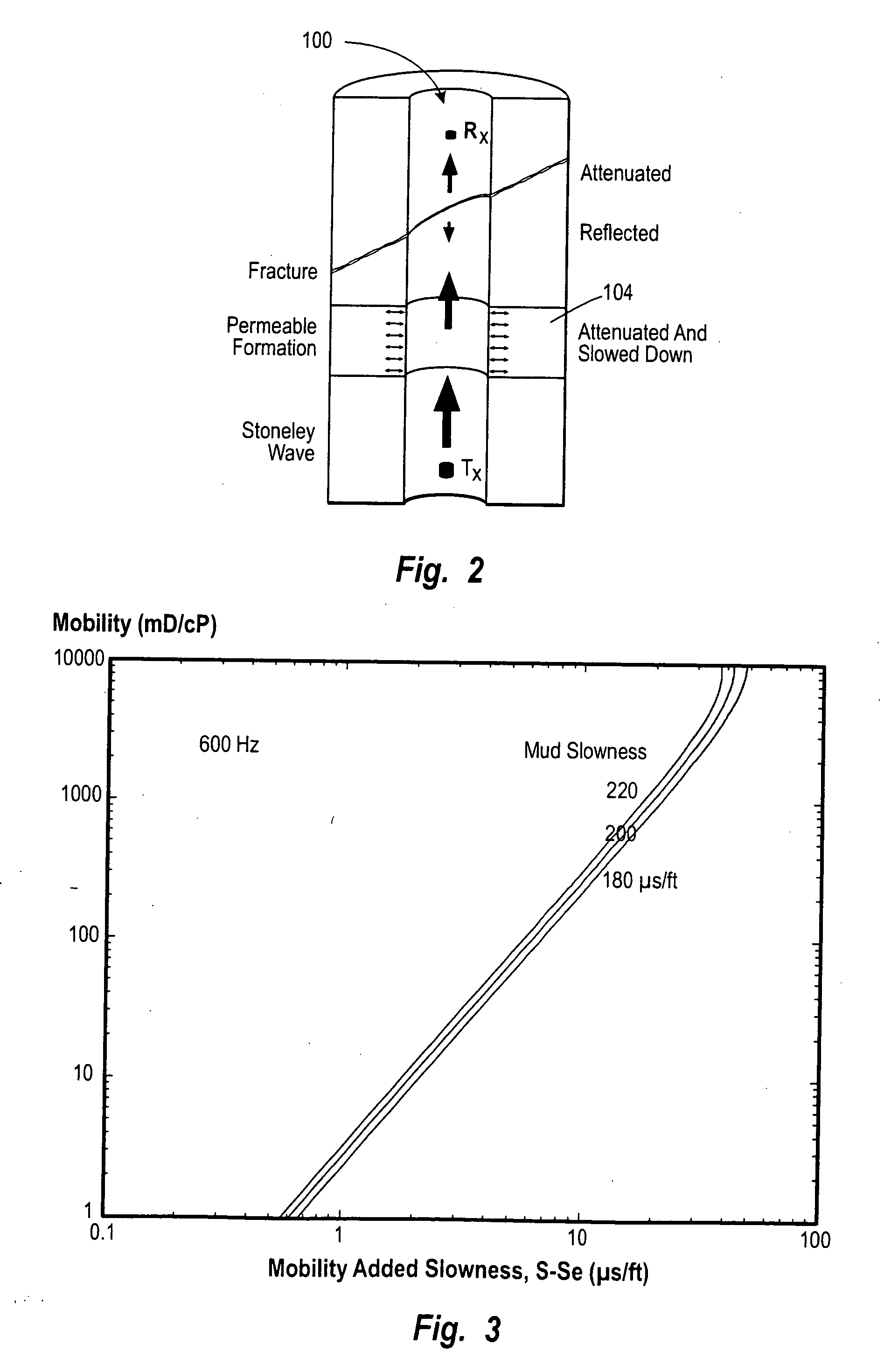

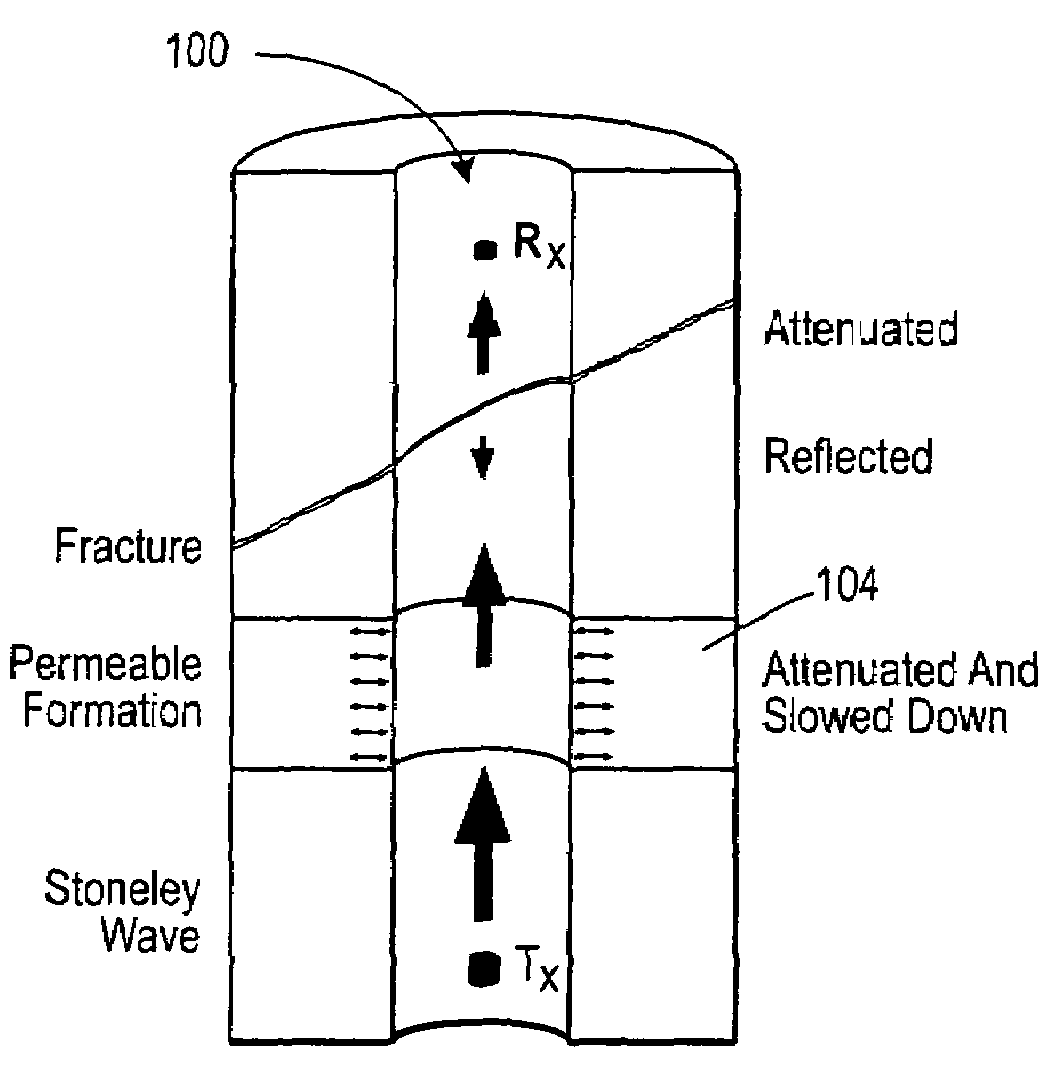

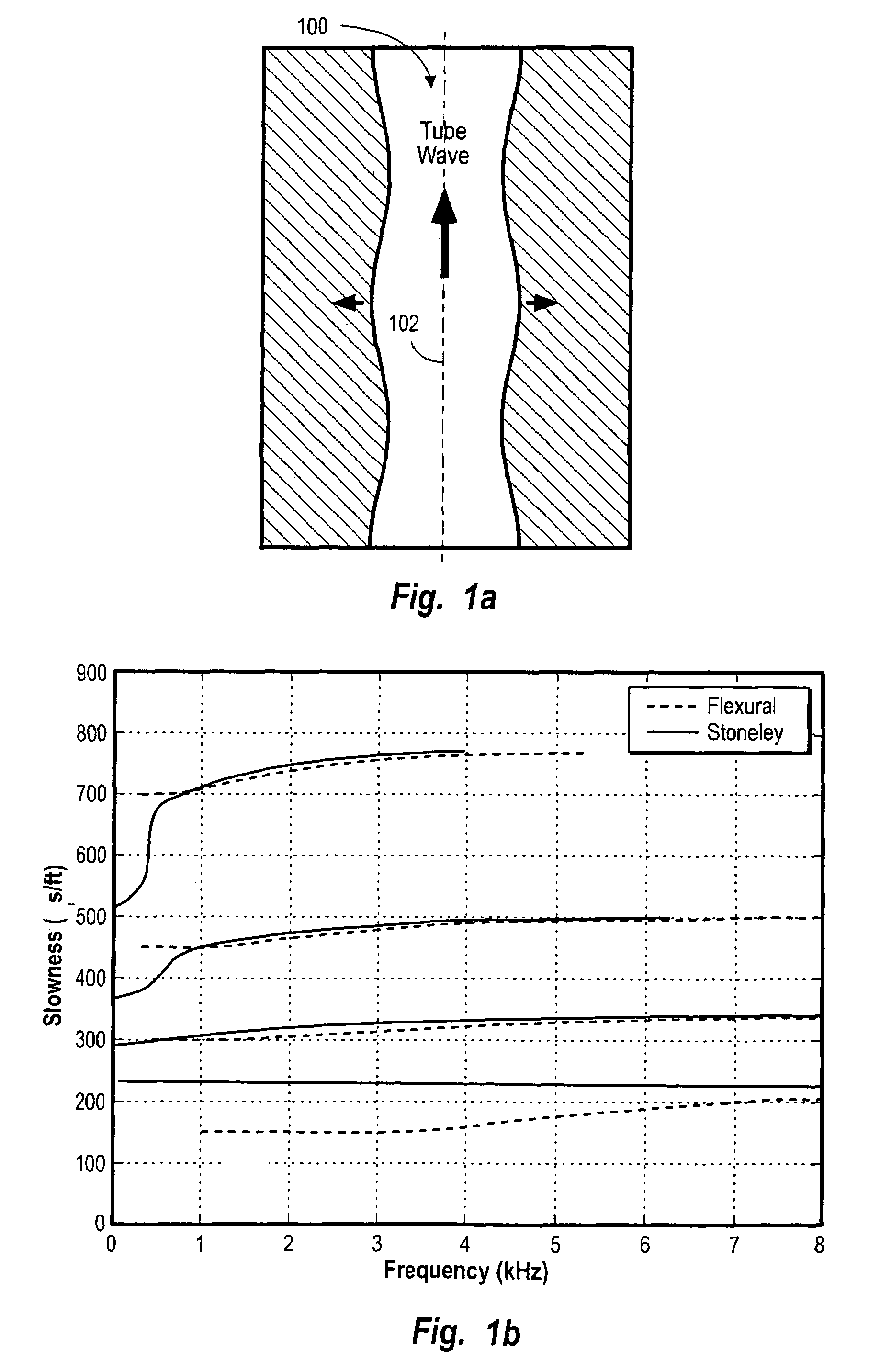

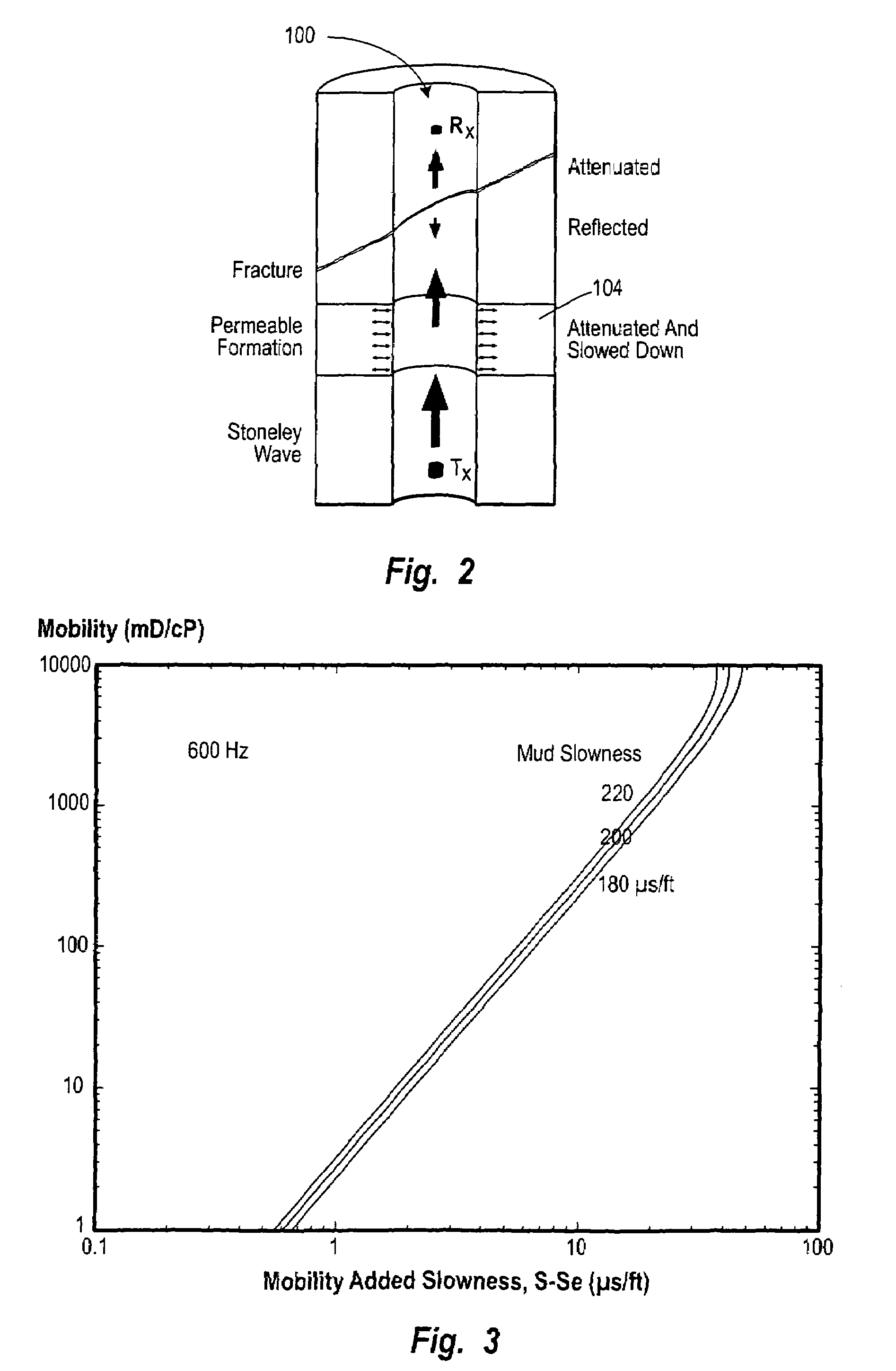

Radial profiling of formation mobility using horizontal and vertical shear slowness profiles

ActiveUS20060285437A1Accurate radial profileAccurate profileSeismology for water-loggingVertical shearAids walking

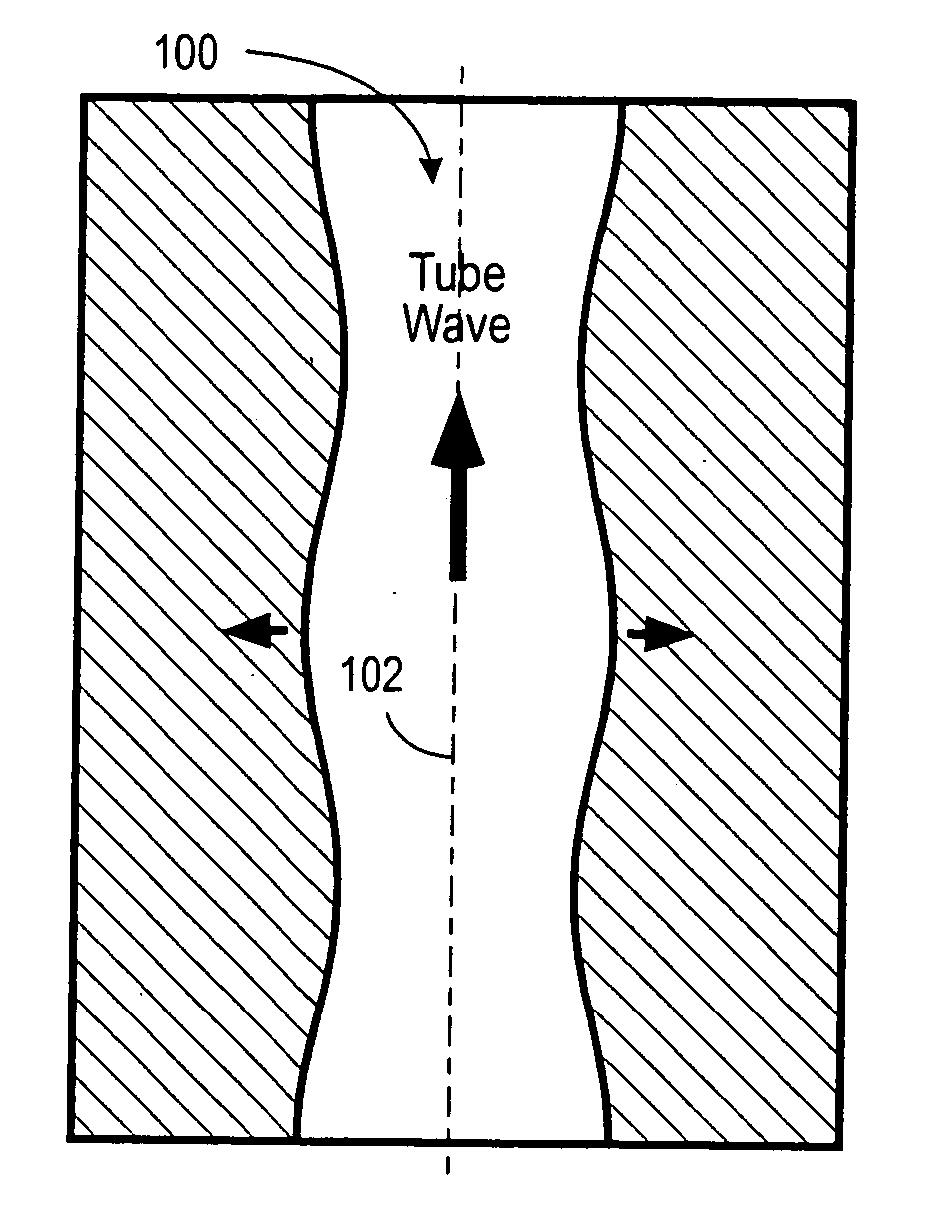

Methods and apparatus facilitating radial profiling of formation mobility are disclosed. Radial profiling of formation mobility aids in an optimal completion of a well for enhanced production. Some aspects of the present invention provide a technique for radial profiling of formation mobility based on inverting differences between a Stoneley radial profile of horizontal shear slowness and a dipole radial profile of vertical shear slowness for a reservoir interval.

Owner:SCHLUMBERGER TECH CORP

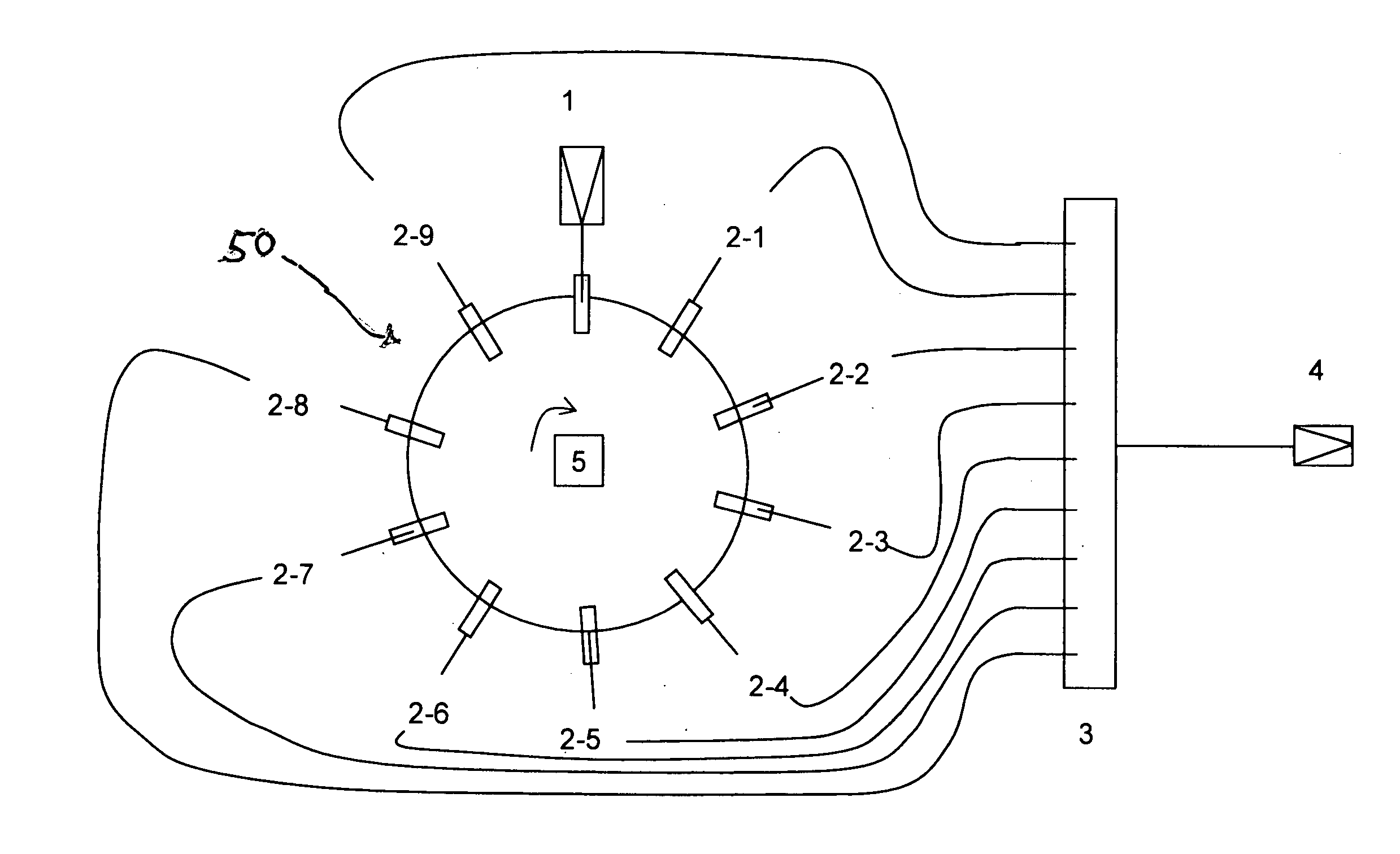

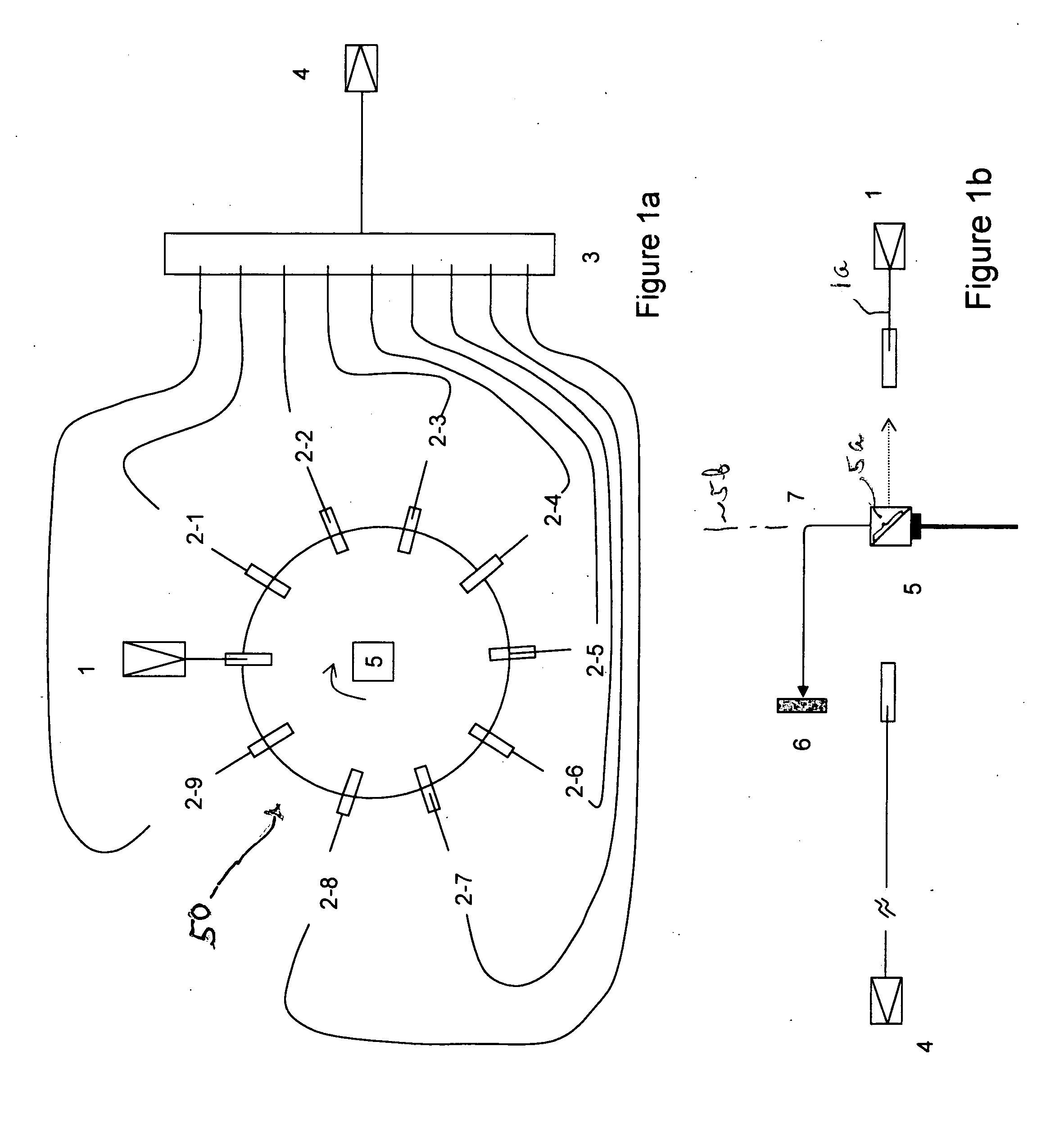

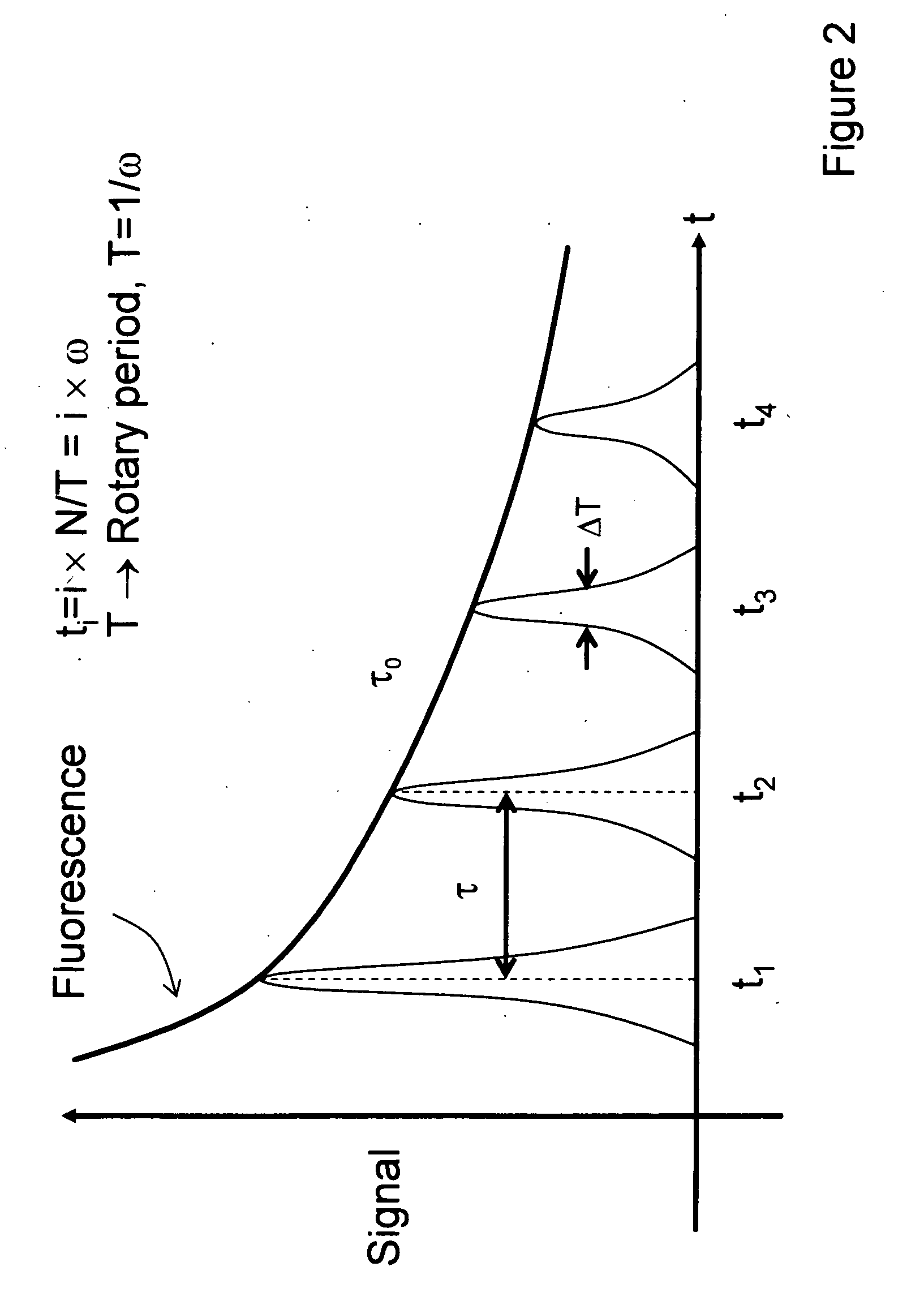

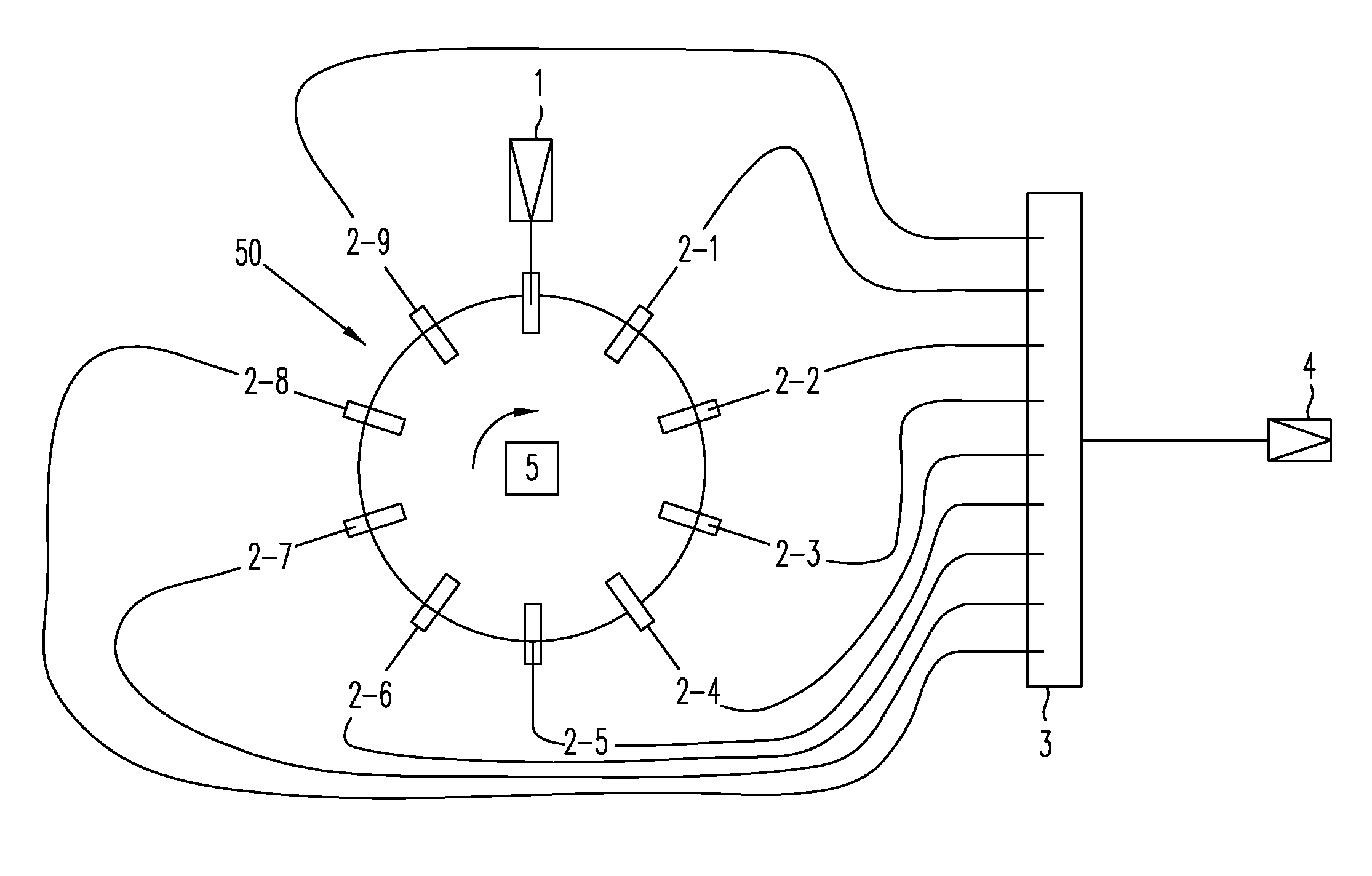

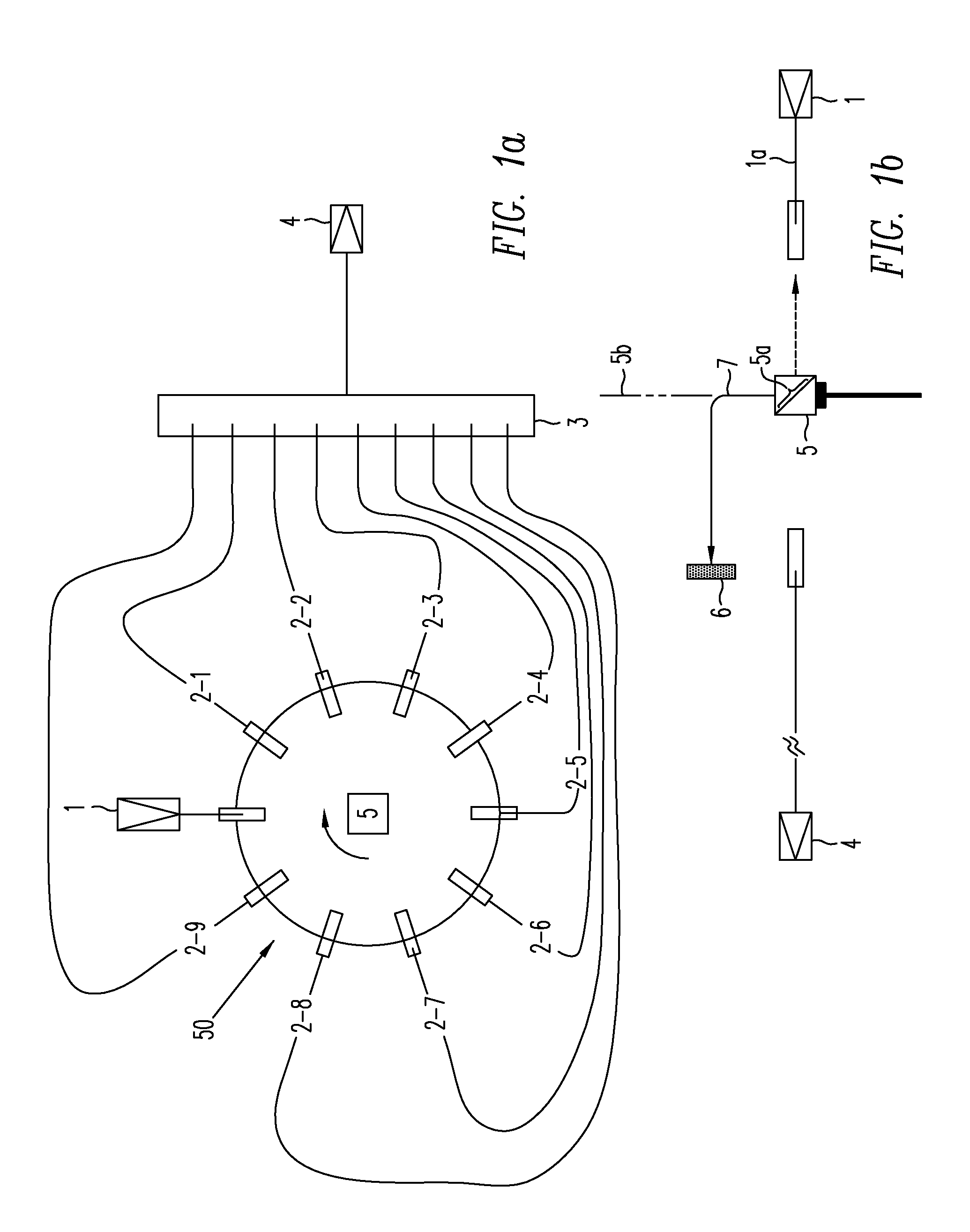

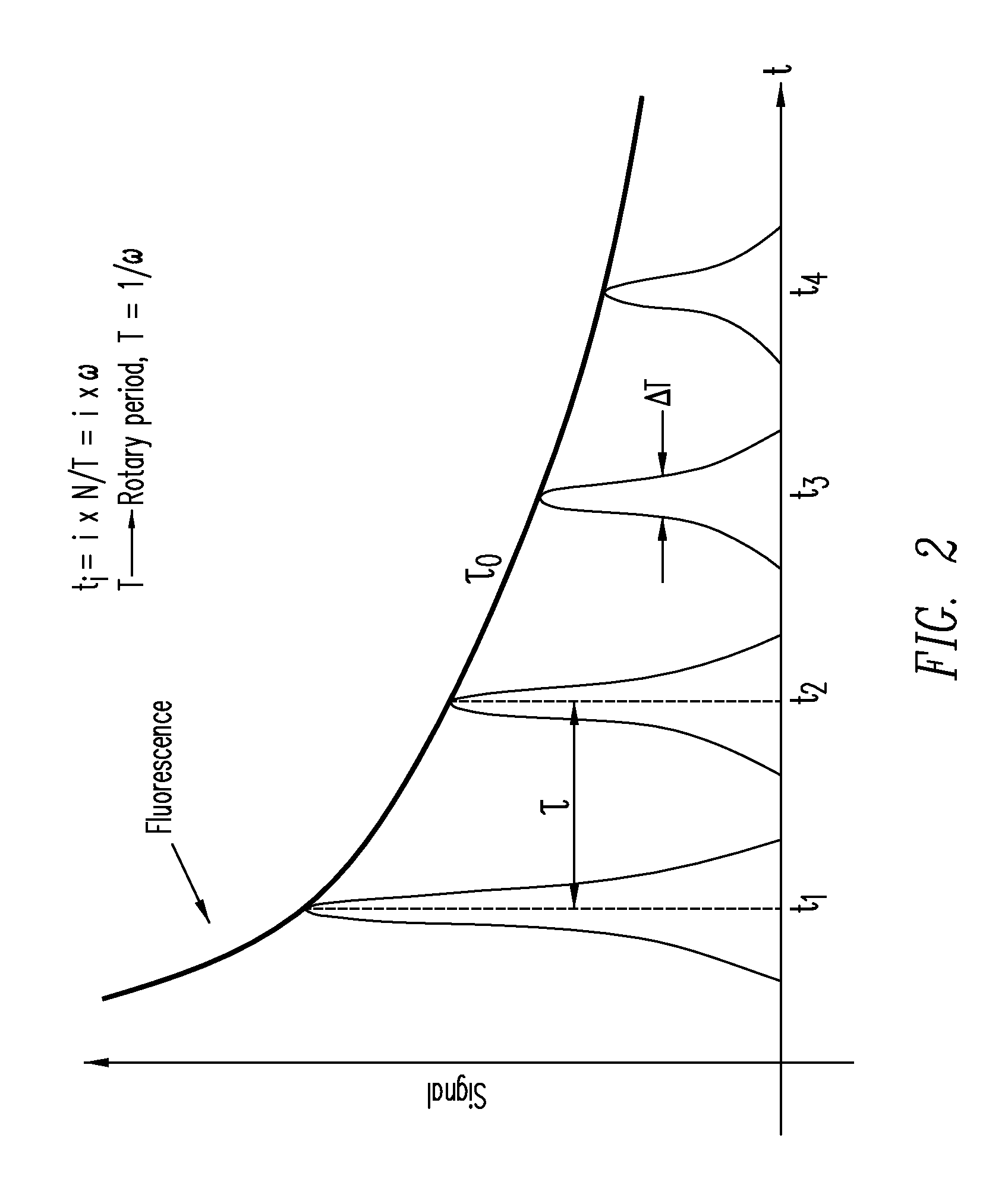

Time-resolved fluorescence spectrometer for multiple-species analysis

InactiveUS20080117418A1Accurate profileLong excited state lifetimesRadiation pyrometryRaman/scattering spectroscopyGratingOpto electronic

A time-resolved, fluorescence spectrometer makes use of a RadiaLight® optical switch and no dispersive optical elements (DOE) like gratings. The structure is unique in its compactness and simplicity of operation. In one embodiment, the spectrometer makes use of only one photo-detector and an efficient linear regression algorithm. The structure offers a time resolution, for multiple species measurements, of less than 1 s. The structure can also be used to perform fluorescence correlation spectroscopy and fluorescence cross-correlation spectroscopy.

Owner:OPTICAL ONCOLOGY

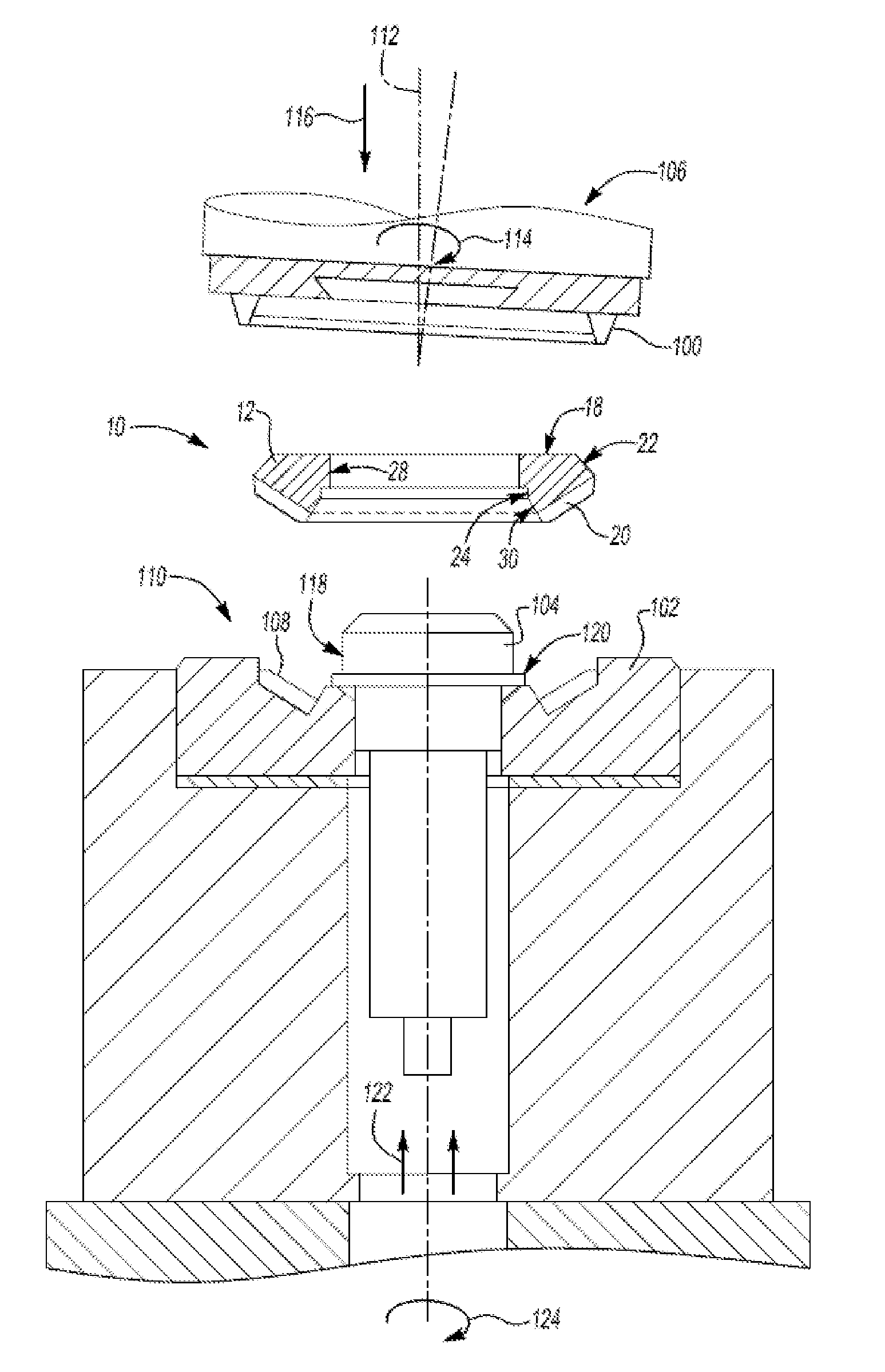

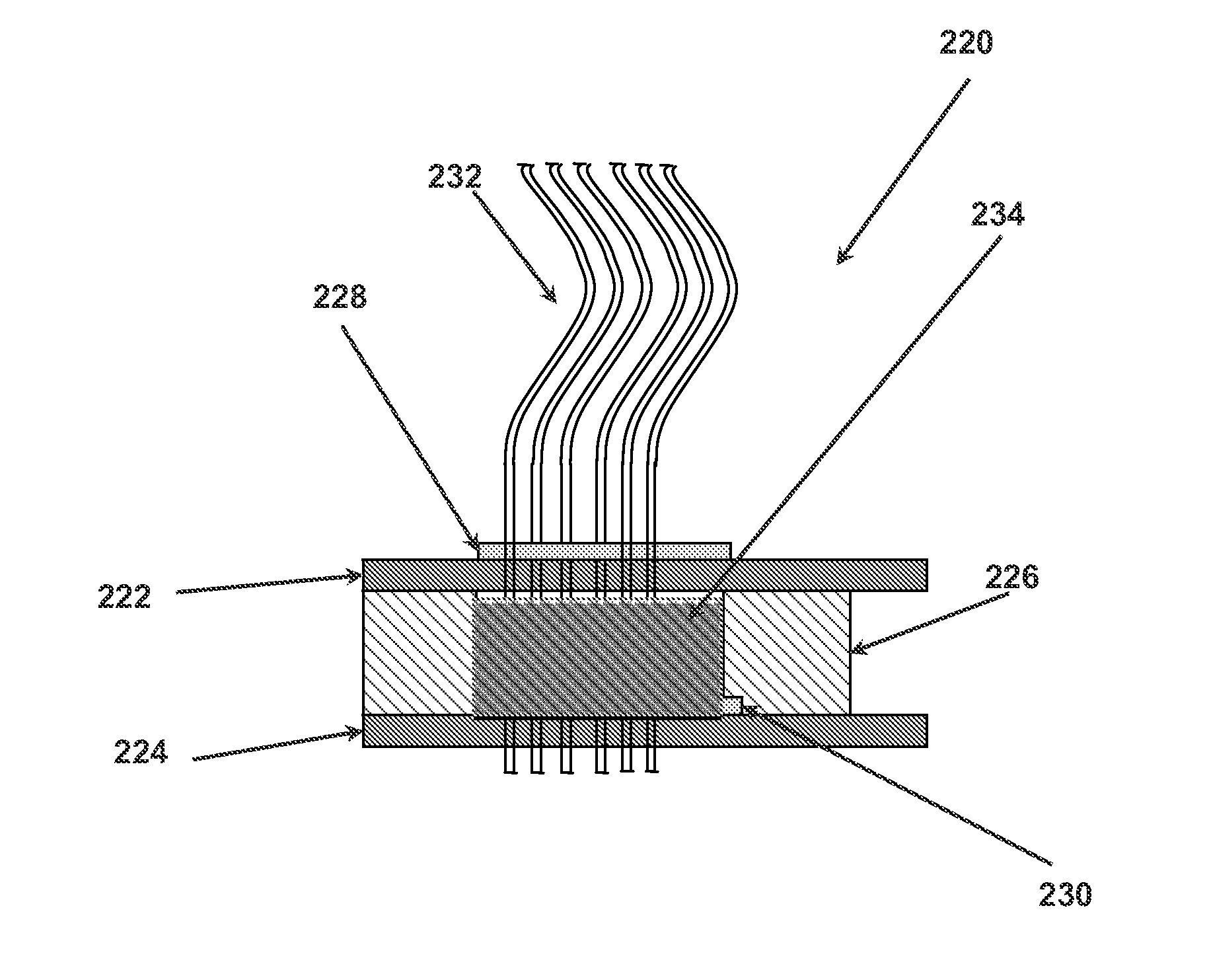

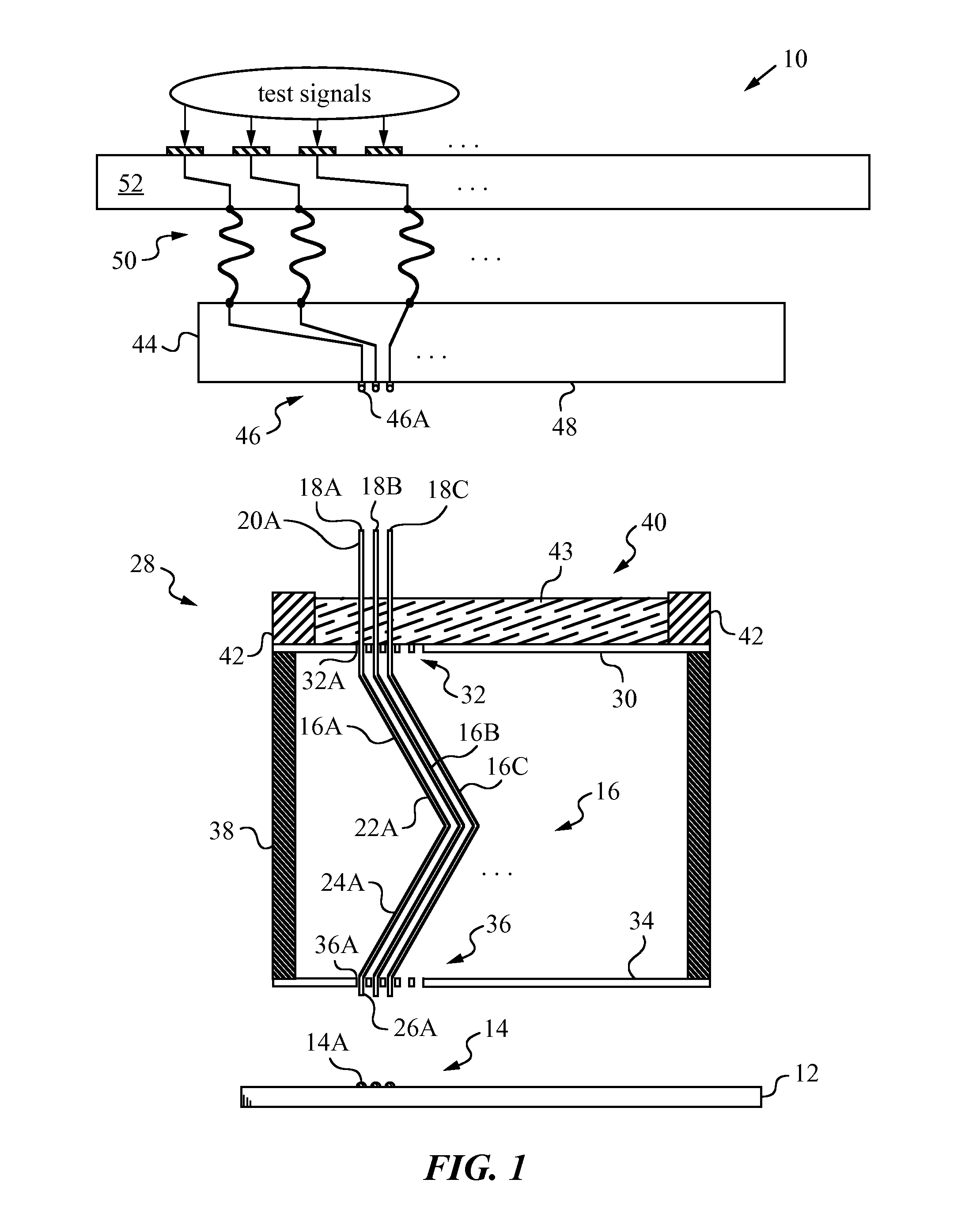

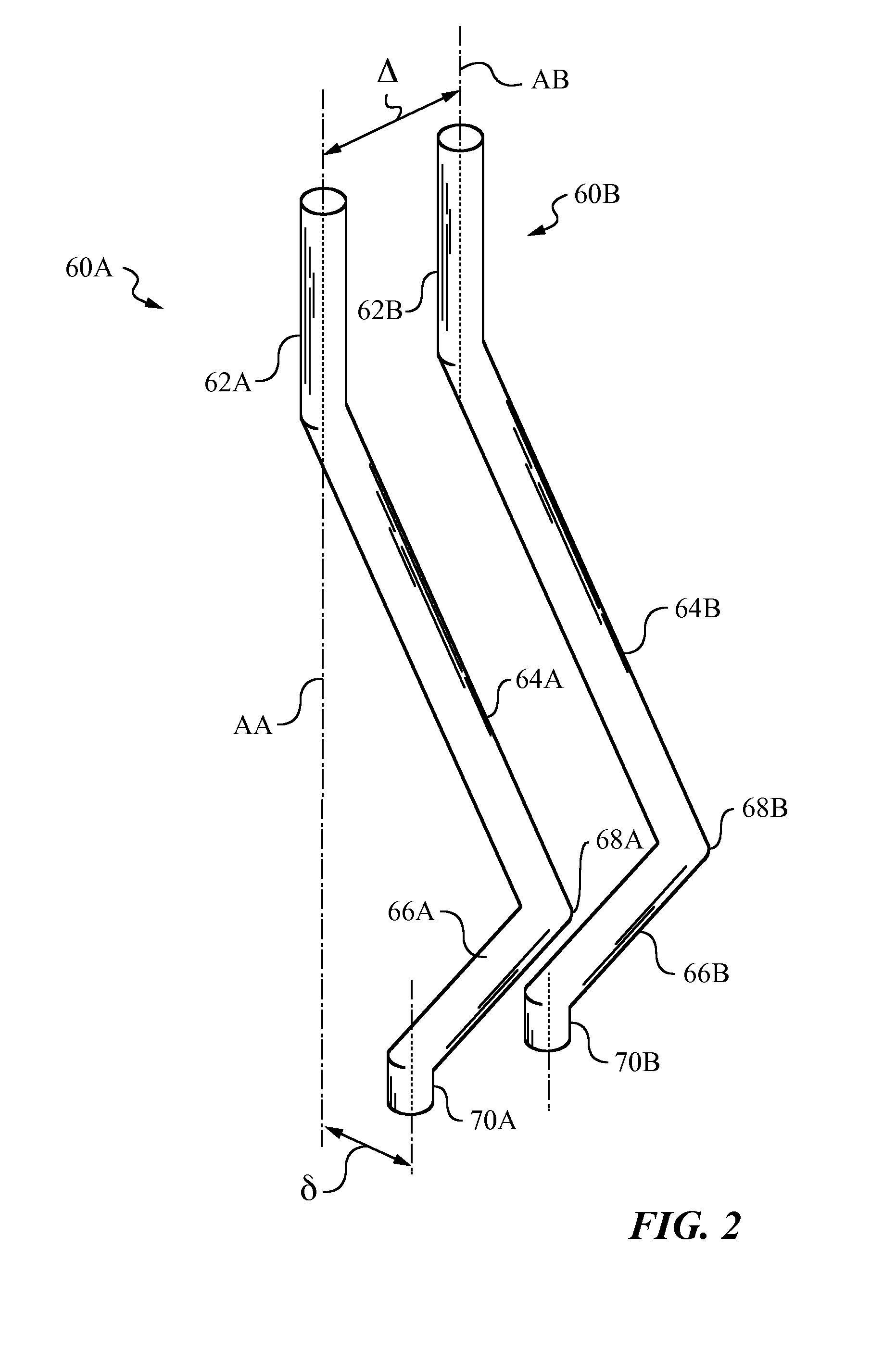

Probe retention arrangement

InactiveUS20110006796A1Precise opening profileAccurate profileElectrical measurement instrument detailsElectrical testingEngineeringDevice under test

A retention arrangement that includes one or more templates for securing and aligning probes for testing a device under test.

Owner:MICRO PROBE

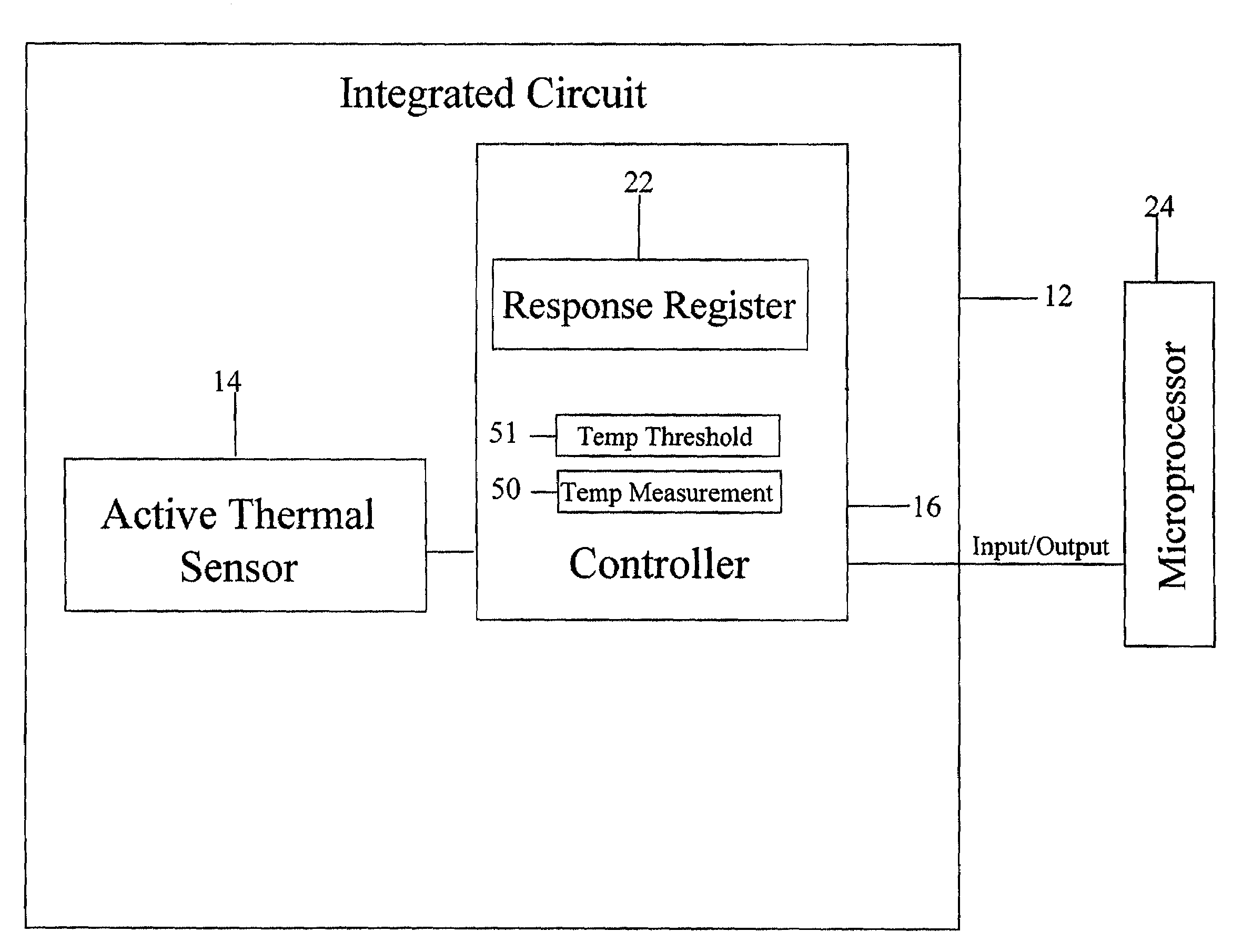

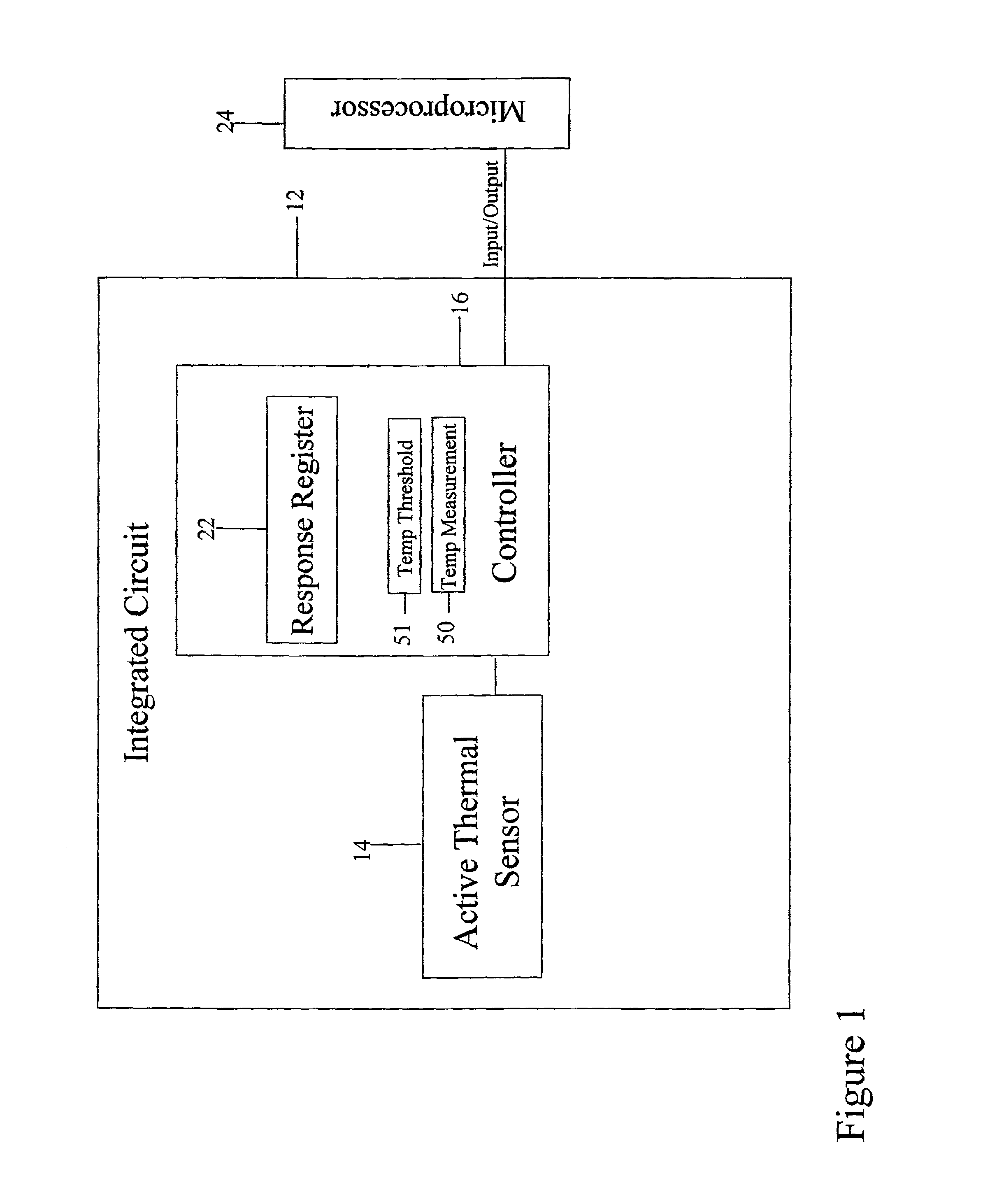

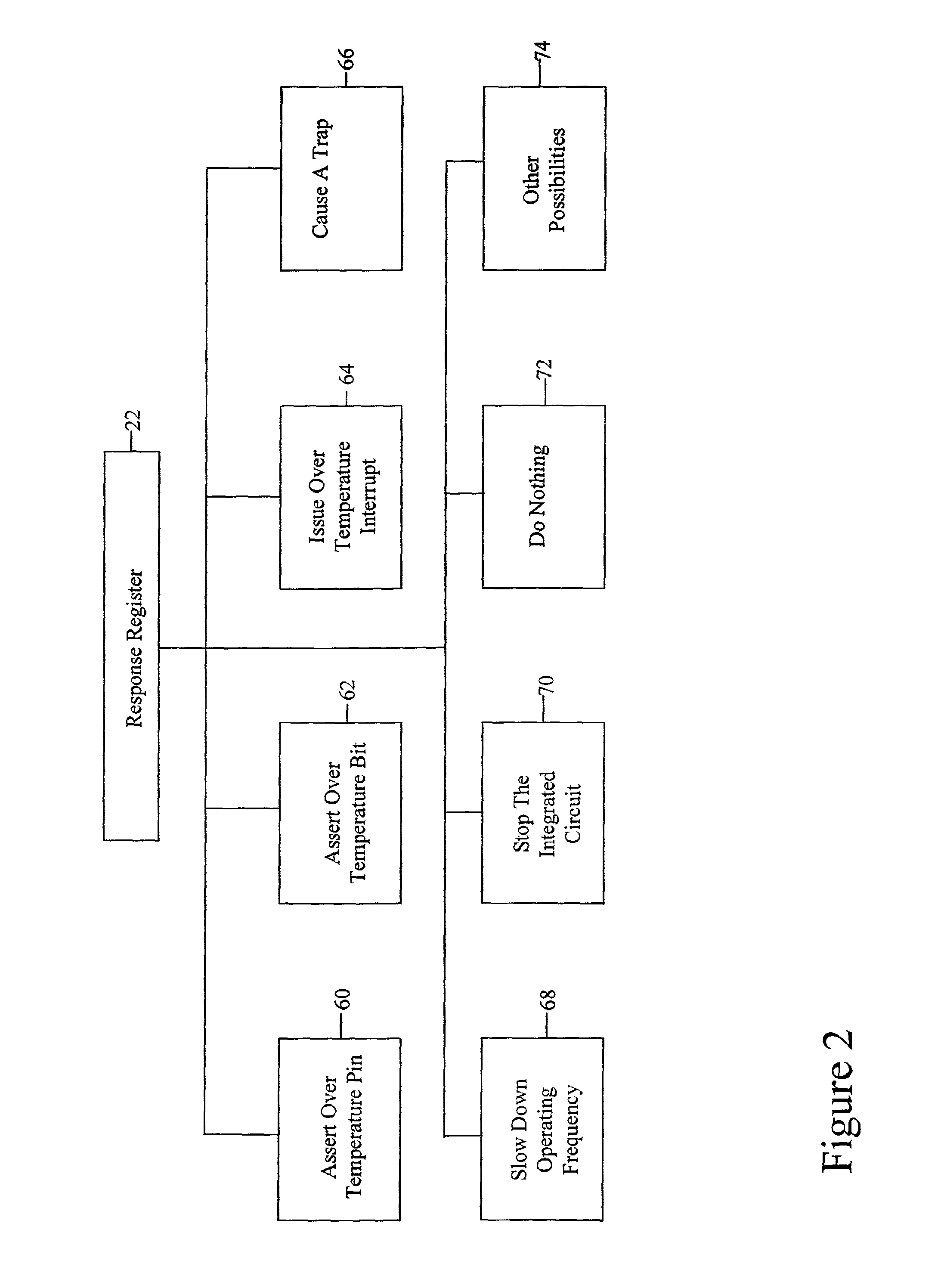

Method and system for monitoring and profiling an integrated circuit die temperature

InactiveUS6996491B2Avoid unnecessary responseAccurate temperature profileThermometer detailsDigital data processing detailsIntegrated circuitThermal sensors

A system and method are provided for sensing a physical stimulus of an integrated circuit. The system and method operate with one or more active thermal sensors embedded in the die of an integrated circuit to provide highly accurate die temperature measurements. The system and method are able to monitor and control the die temperature of the integrated circuit to avoid an integrated circuit malfunction due to an undesirable temperature condition.

Owner:ORACLE INT CORP

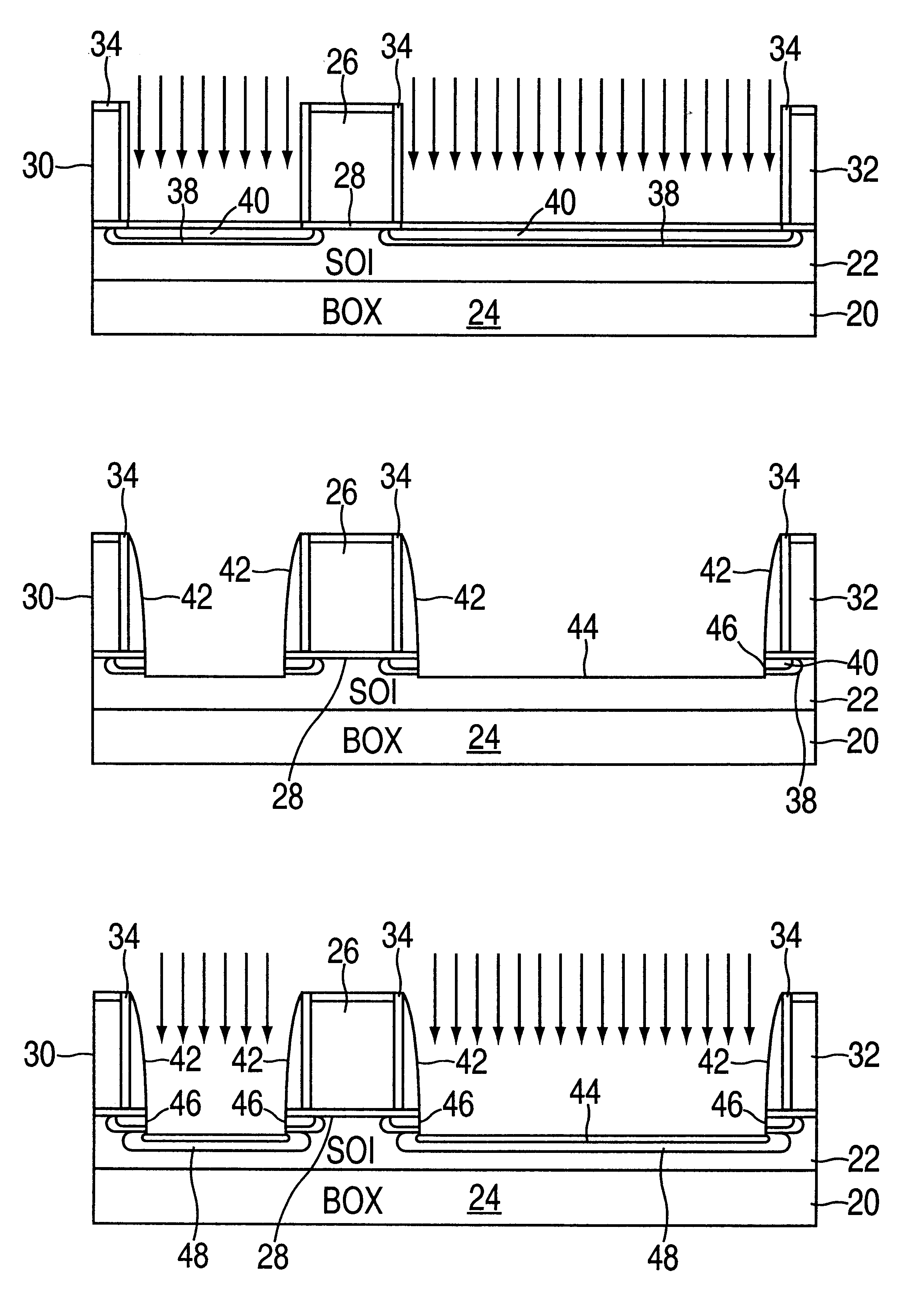

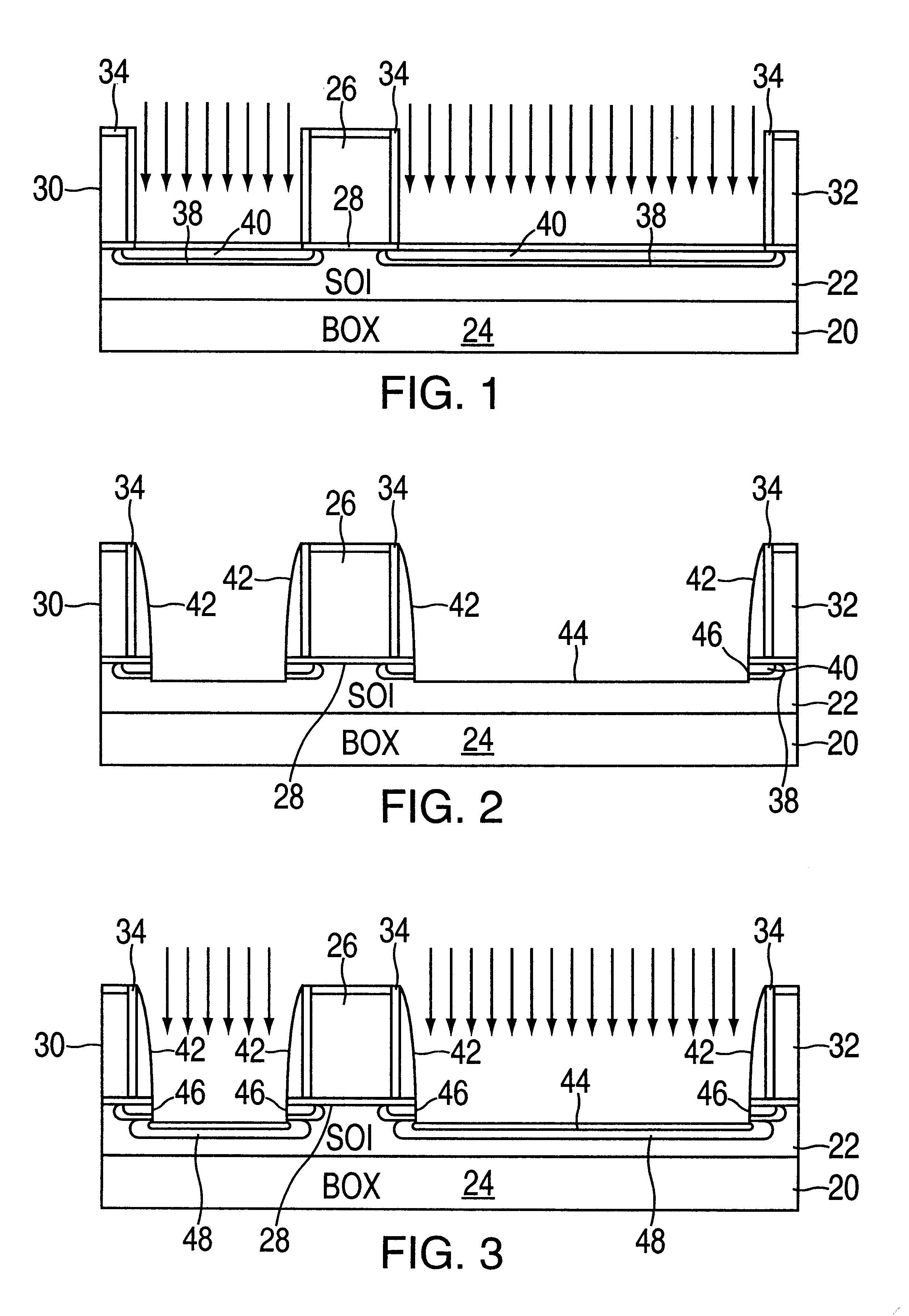

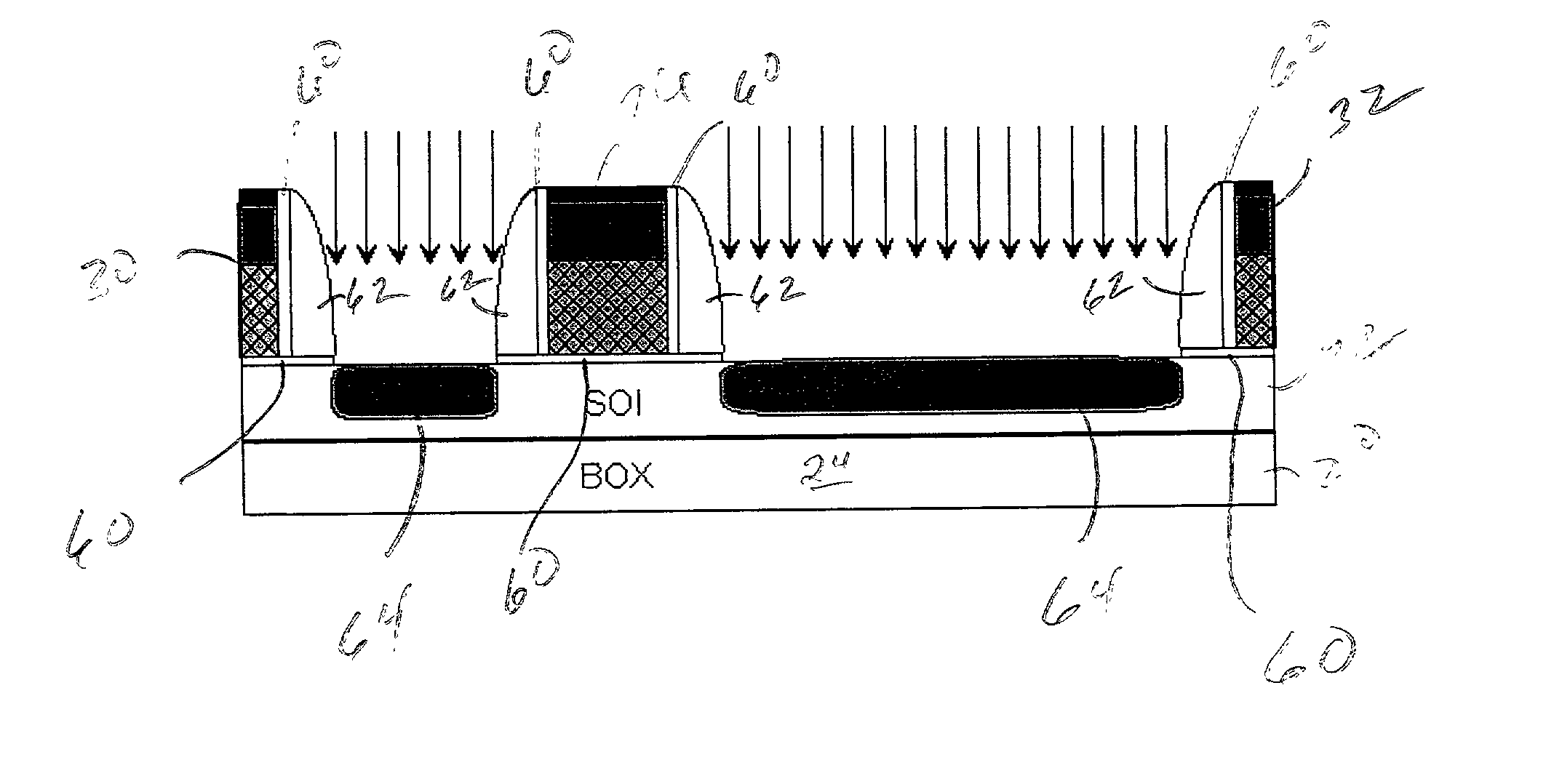

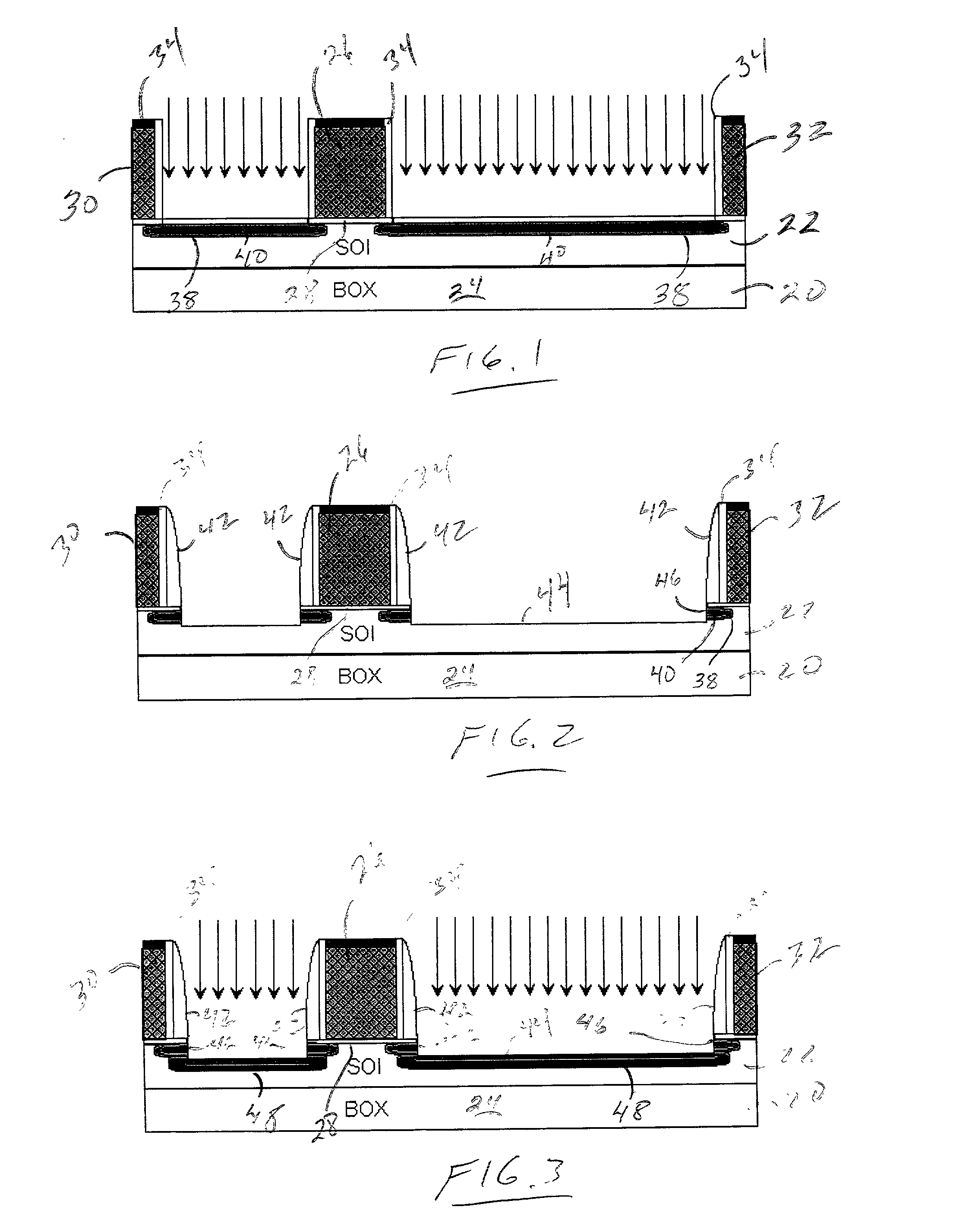

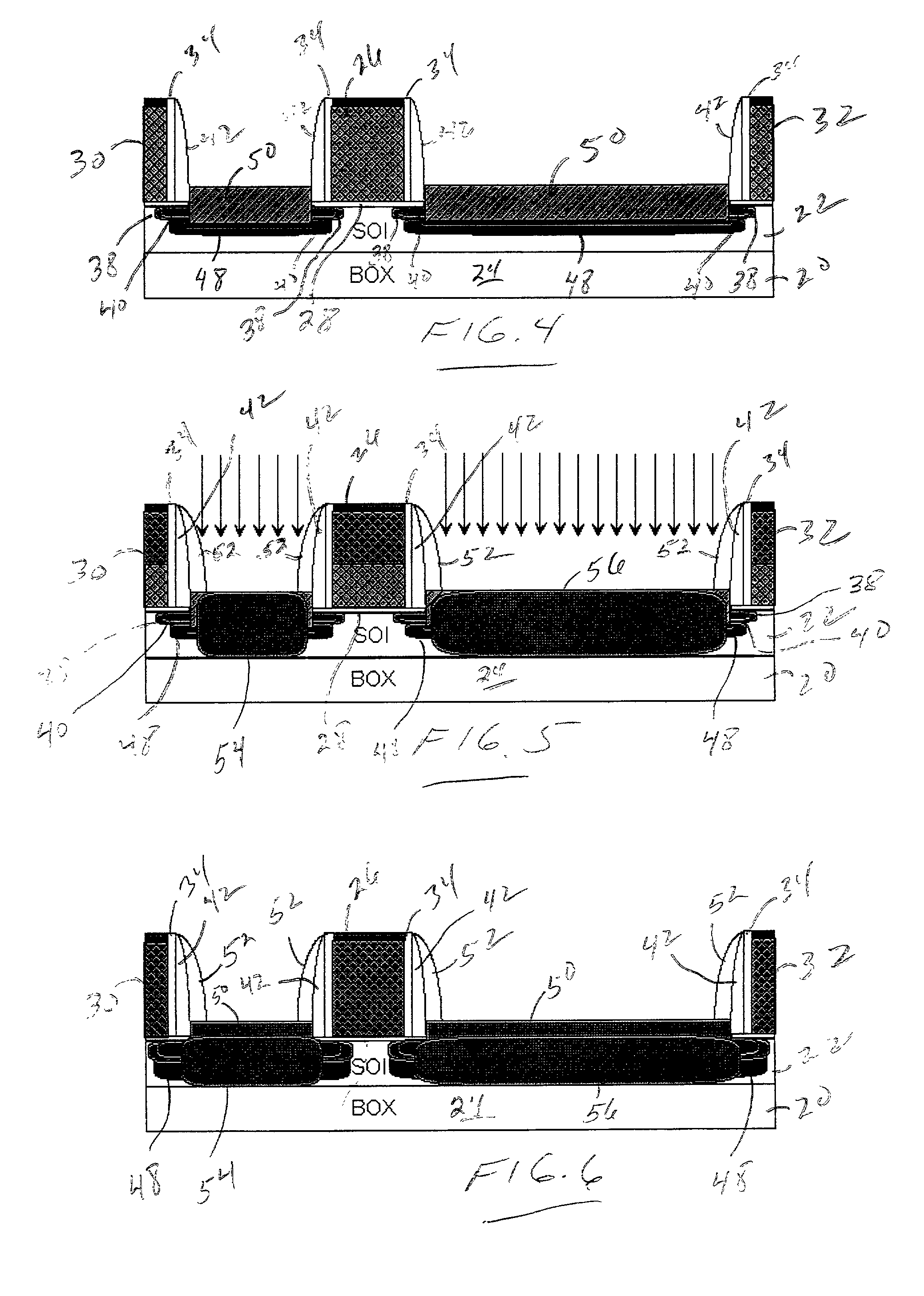

Process for fabricating an MOS device having highly-localized halo regions

Owner:INT BUSINESS MASCH CORP

Methods and apparatus for dual source calibration for distributed temperature systems

InactiveUS7628531B2Accurate profileRadiation pyrometryWeather/light/corrosion resistanceFiberWave band

Systems and methods for calibrating a temperature sensing system are disclosed. In one respect, a dual light source configuration may be provided. A first light source may illuminate a sensing fiber and an anti-Stokes band may be detected. A second light source may illuminate a sensing fiber and a Stokes band may be detected, where the Stokes band is substantially similar to the anti-Stokes band of the first light source. A ratio between the anti-Stokes and Stokes band may be used to calibrate a temperature sensing system.

Owner:SENSORTRAN

Process for fabricating an MOS device having highly-localized halo regions

InactiveUS20020072176A1Large diffusionEasy to makeTransistorSolid-state devicesBoronIon implantation

A process for fabricating an MOS device having a highly-localized halo region includes the formation of a first halo region at a first surface of a silicon substrate, and a second halo region at a second surface of the silicon substrate. The second surface of the silicon substrate is formed by anisotropically etching the first surface of the silicon substrate to remove a portion of the material from the substrate. Both the first and second halo regions are formed by low-energy ion implantation. For the fabrication of an n-channel device, boron is implanted at an energy of no more than about 1 keV. Upon implantation and a subsequent annealing process, the first and second halo regions form a continuous halo region within the semiconductor substrate.

Owner:IBM CORP

Time-resolved fluorescence spectrometer for multiple-species analysis

InactiveUS7679745B2Accurate profileLong excited state lifetimesRadiation pyrometryRaman/scattering spectroscopyGratingPhotovoltaic detectors

A time-resolved, fluorescence spectrometer makes use of a RadiaLight® optical switch and no dispersive optical elements (DOE) like gratings. The structure is unique in its compactness and simplicity of operation. In one embodiment, the spectrometer makes use of only one photo-detector and an efficient linear regression algorithm. The structure offers a time resolution, for multiple species measurements, of less than 1 s. The structure can also be used to perform fluorescence correlation spectroscopy and fluorescence cross-correlation spectroscopy.

Owner:OPTICAL ONCOLOGY INC

Heating device for plastic blanks

ActiveUS8231823B2Accurate temperature profileEasy to produceDielectric heatingMicrowave heatingMicrowaveEngineering

The invention relates to a method and a device for heating preforms of a thermoplastic material, the preforms, after having been heated, being subjected to a reshaping operation, and microwaves being applied to the preforms, at least during a portion of the period of heating, in a resonator.

Owner:KRONES AG

Method and apparatus for measuring and removing rotational variability from a nip pressure profile of a covered roll of a nip press

ActiveUS20140257719A1Accurate detectionAccurate measurementForce measurementWork measurementMultiple sensorEngineering

Owner:INT PAPER CO

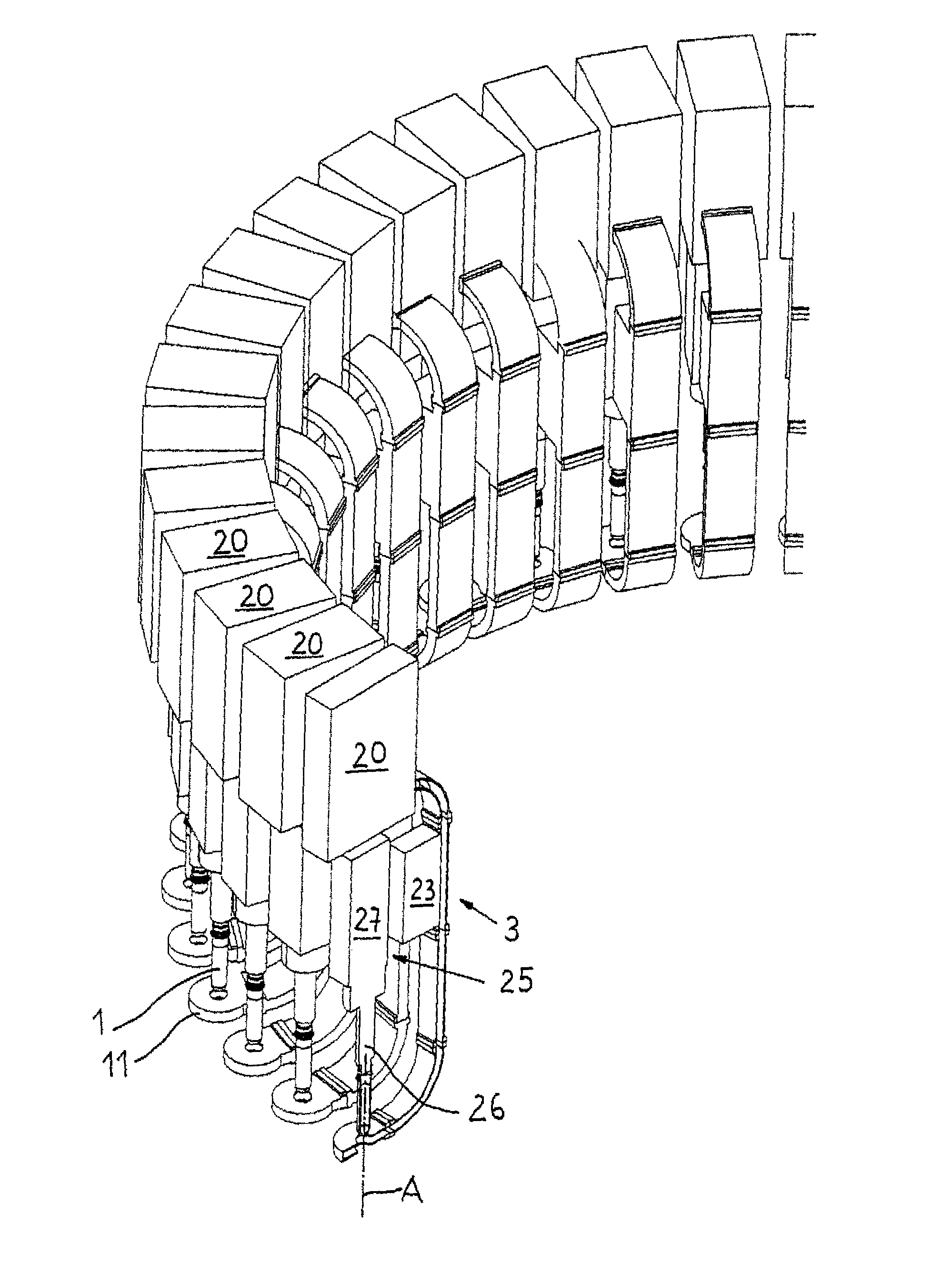

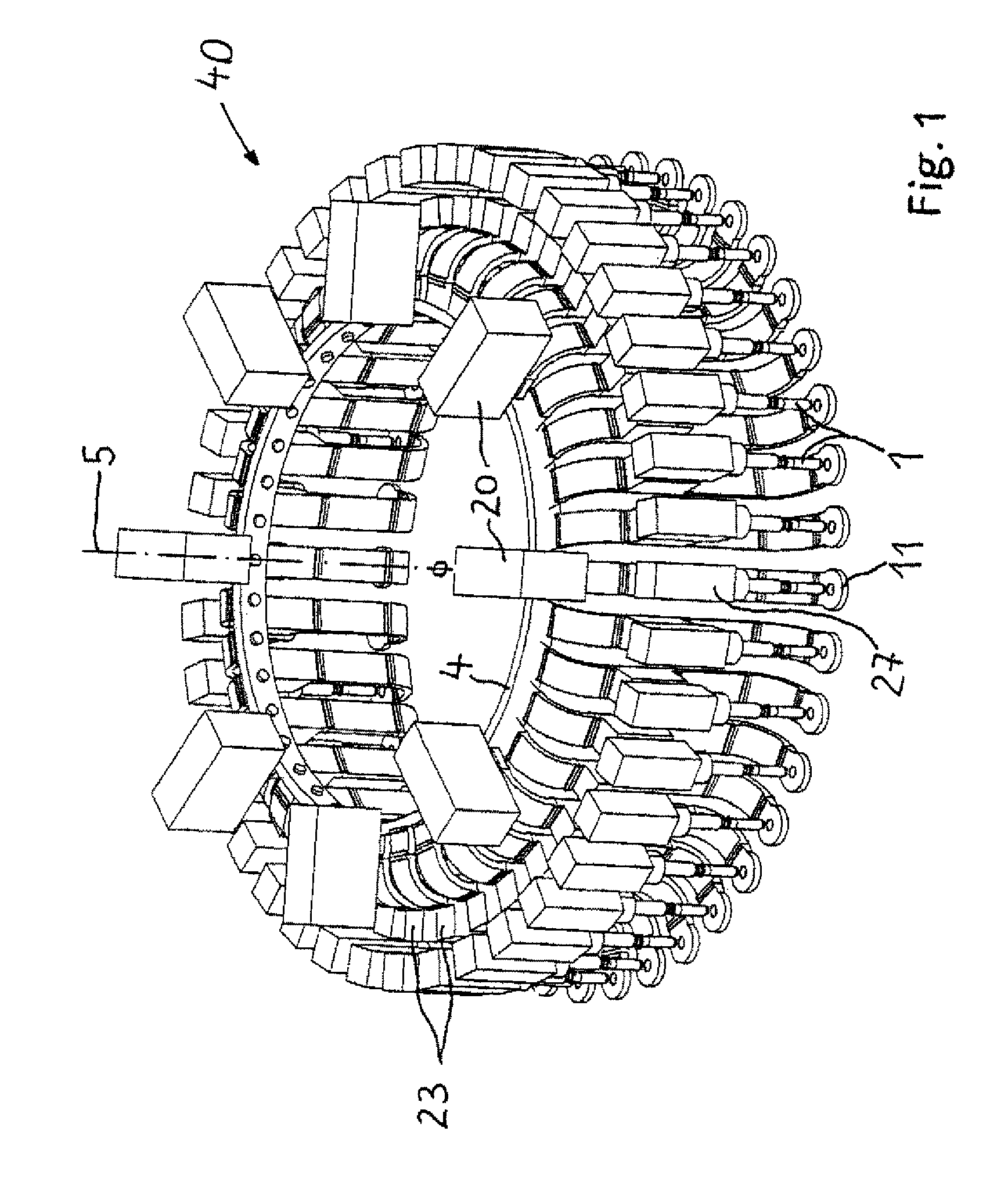

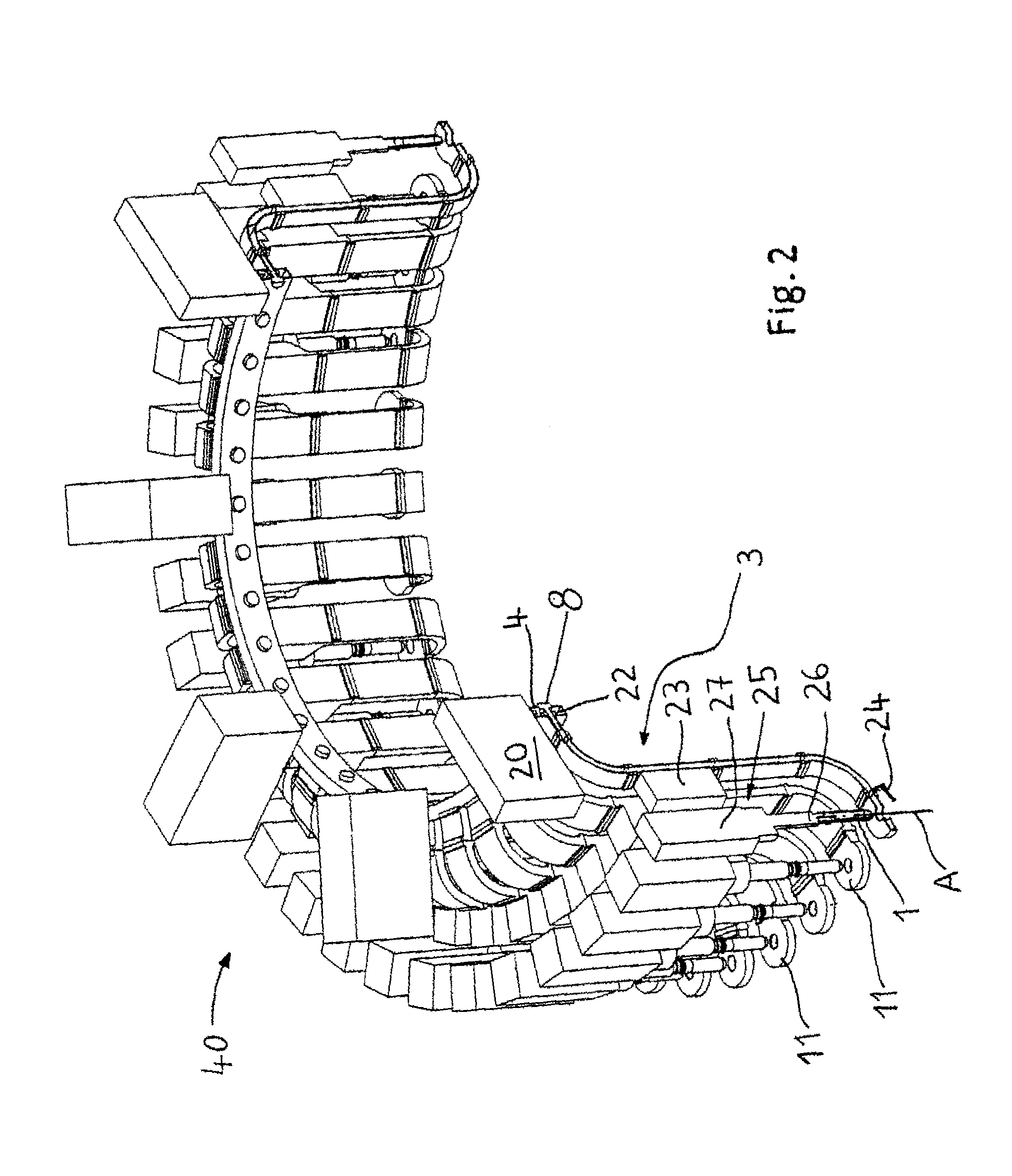

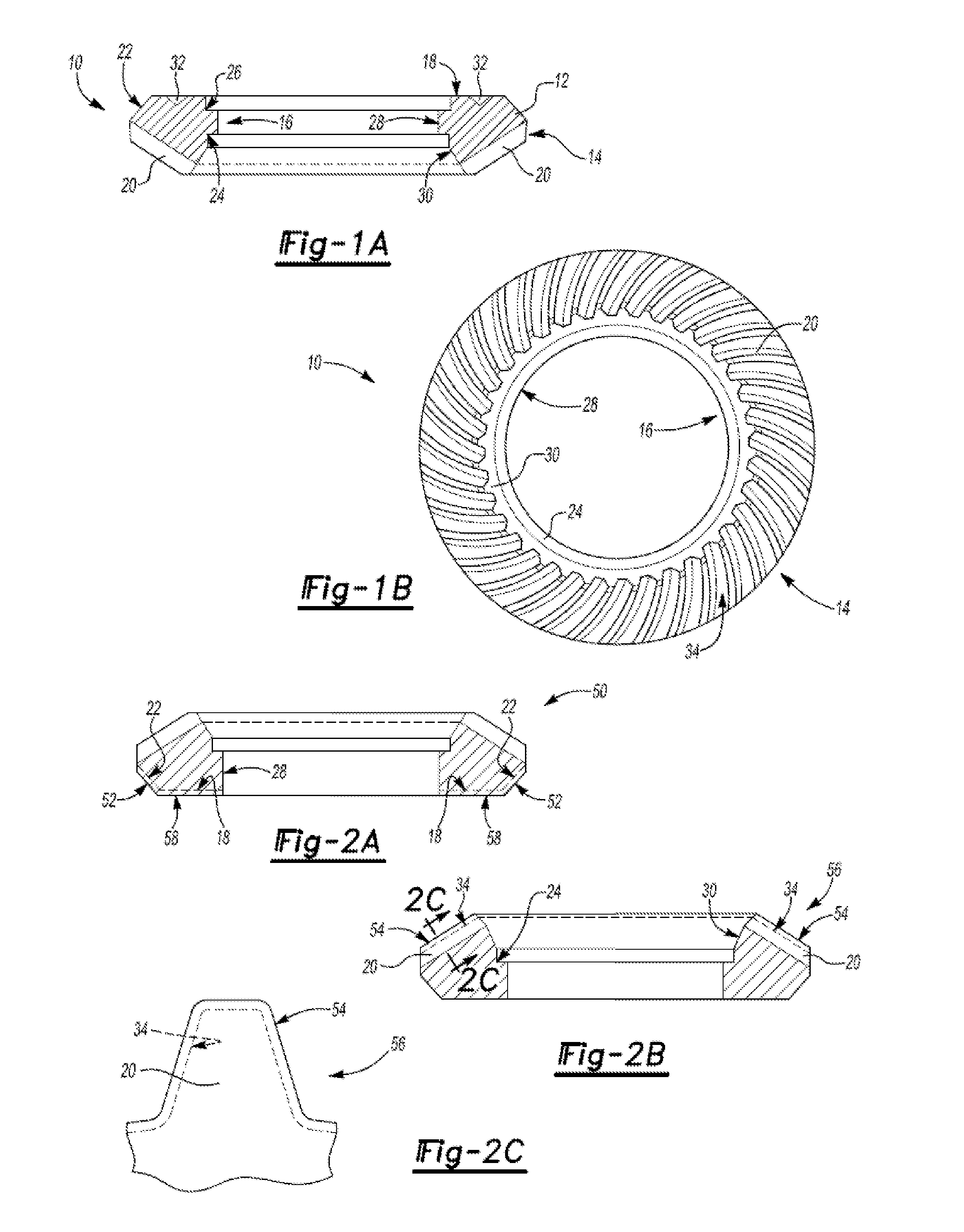

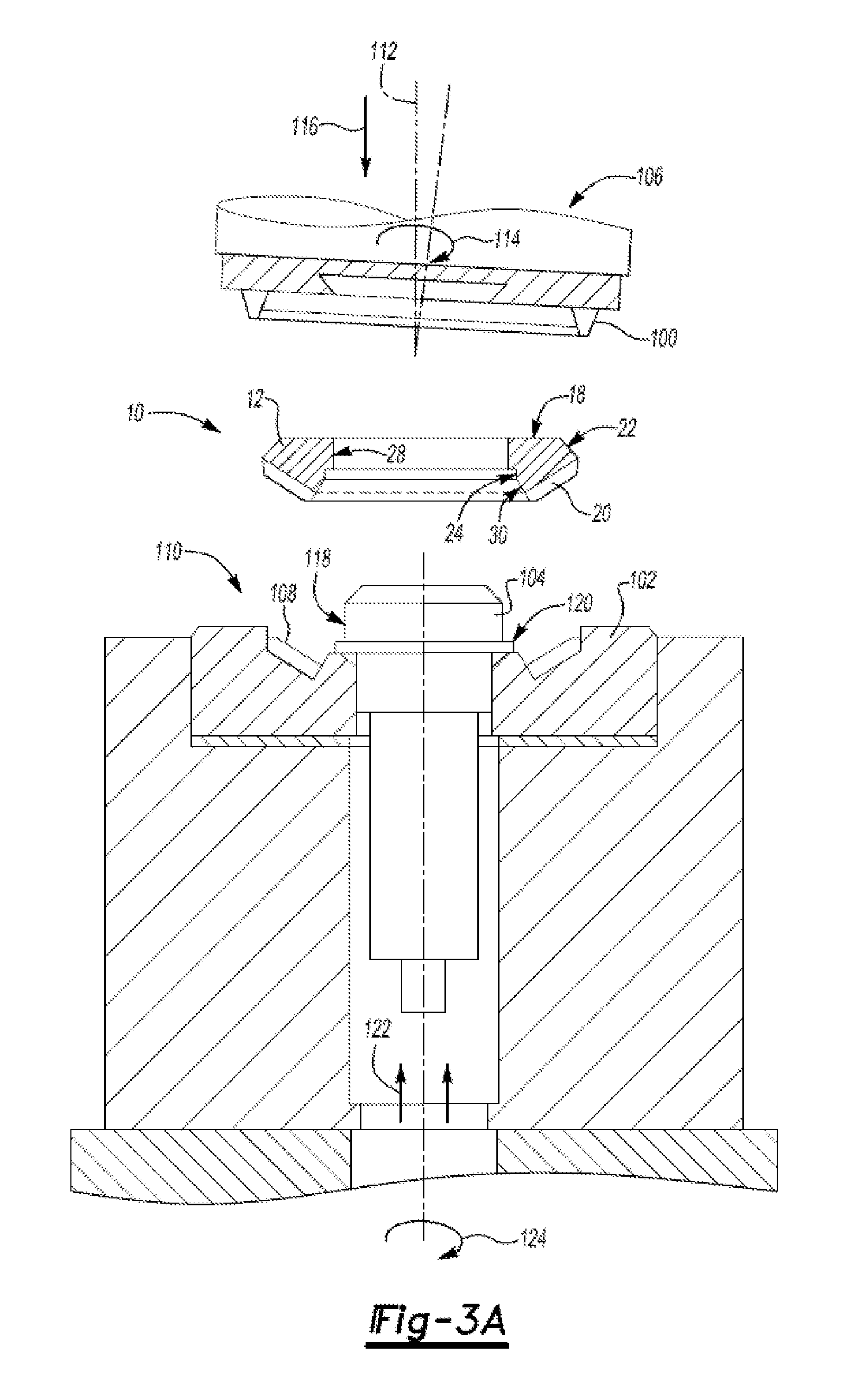

Bevel and hypoid gear and method of manufacture

InactiveUS20110126654A1Improve surface propertiesReduce molding processMetal-working apparatusPortable liftingRoll formingEngineering

Bevel and hypoid gears are used in power transmissions including automotive applications. Provided is a net shaped bevel or hypoid gear having a generally annular gear body including a plurality of radially outwardly extending gear teeth formed from a generally annular blank made of powdered metal. Also provided is a method for manufacturing a net shaped bevel or hypoid gear including the steps of providing and optionally heat treating a generally ring-shaped or annular blank made of metal powder, then incrementally deforming the blank by orbitally forming or roll forming to produce a net shaped gear member with a plurality of outwardly extending gear teeth, which may be of a bevel or hypoid type.

Owner:GM GLOBAL TECH OPERATIONS LLC

Radial profiling of formation mobility using horizontal and vertical shear slowness profiles

ActiveUS7652950B2Accurate profileIncrease productionSeismic signal processingSeismology for water-loggingVertical shearAids walking

Methods and apparatus facilitating radial profiling of formation mobility are disclosed. Radial profiling of formation mobility aids in an optimal completion of a well for enhanced production. Some aspects of the present invention provide a technique for radial profiling of formation mobility based on inverting differences between a Stoneley radial profile of horizontal shear slowness and a dipole radial profile of vertical shear slowness for a reservoir interval.

Owner:SCHLUMBERGER TECH CORP

Infrared detection unit using a semiconductor optical lens

InactiveUS20090266988A1Eliminate effectiveAccurate detectionRadiation pyrometrySolid-state devicesSemiconductorFlange

An infrared detection unit includes a base carrying an infrared sensor element, and a cap configured to be fitted on the base to surround the infrared sensor element. The cap has a top wall with a window in which a semiconductor lens is fitted to collect an infrared radiation onto the infrared sensor element. The semiconductor optical lens is formed from a semiconductor substrate to have a convex lens and a flange which surround said convex lens. An infrared barrier is formed on the semiconductor lens to block the infrared radiation from passing through the boundary between the circumference of the convex lens and the window. Accordingly, the infrared sensor element can receive only the infrared radiation originating from a detection area intended by the convex lens.

Owner:MATSUSHITA ELECTRIC WORKS LTD

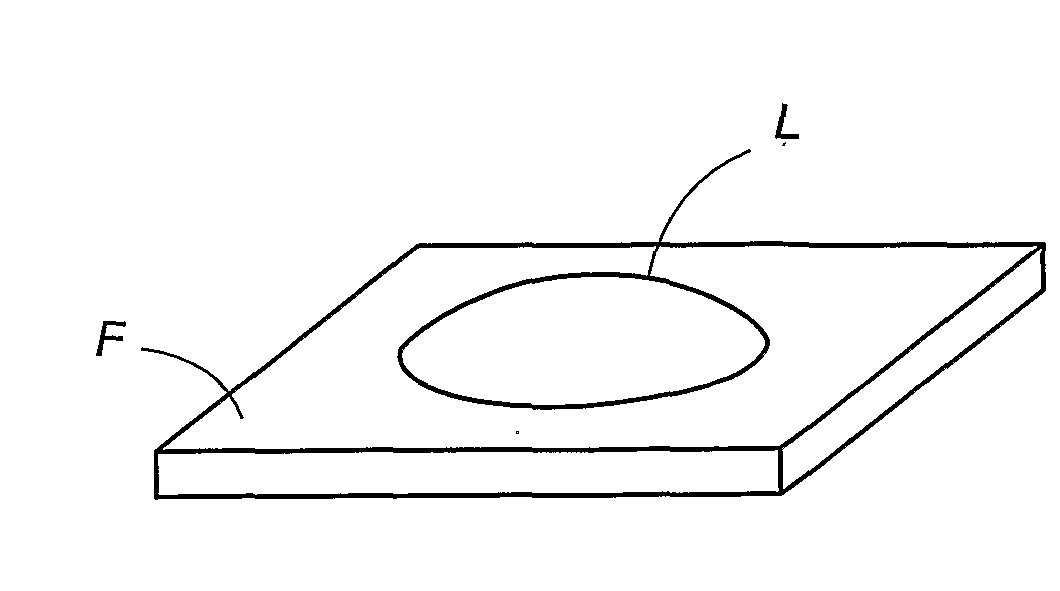

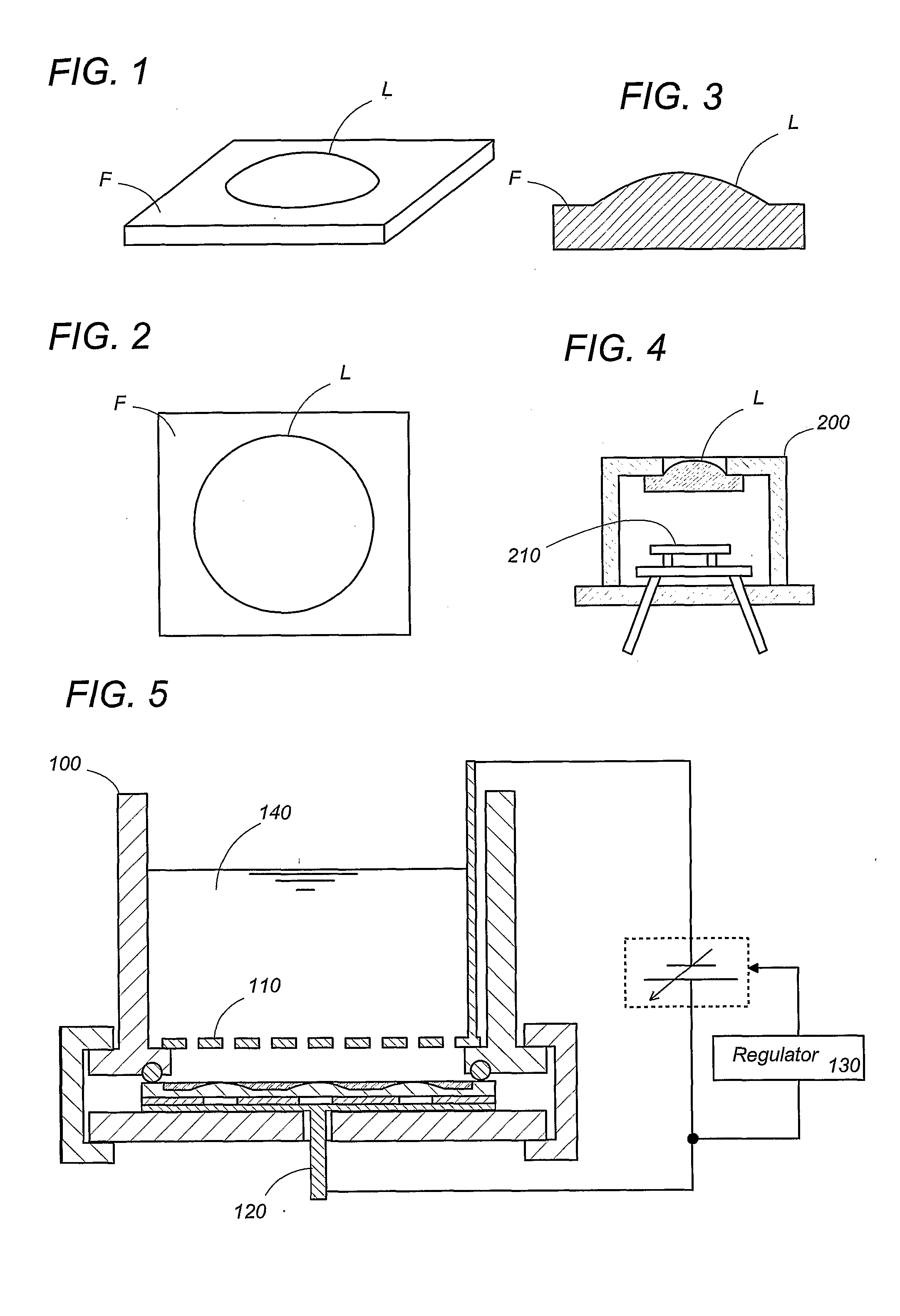

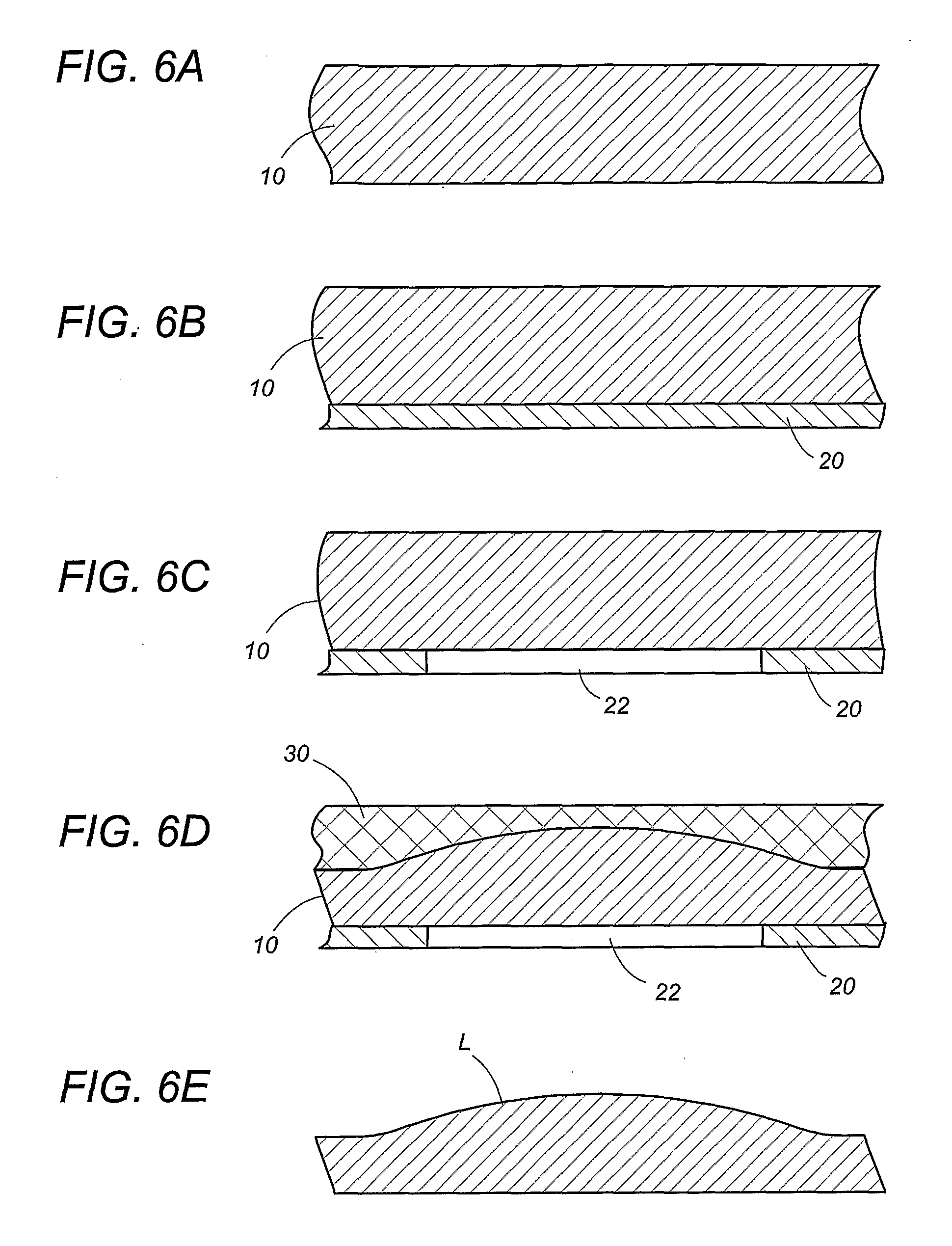

Process of forming a curved profile on a semiconductor substrate

InactiveUS7749868B2Allocation is accurateSpeed up the processSemiconductor/solid-state device manufacturingLensIn planePorous layer

A semiconductor substrate shaped to have a curved surface profile by anodization. Prior to being anodized, the substrate is finished with an anode pattern on its bottom surface so as to be consolidated into a unitary structure in which the anode pattern is precisely reproduced on the substrate. The anodization utilizes an electrolytic solution which etches out an oxidized portion as soon as it is formed as a result of the anodization, to thereby develop a porous layer in a pattern in match with the anode pattern. The anode pattern brings about an in-plane distribution of varying electric field intensity by which the porous layer develops into a shape complementary to a desired surface profile. Upon completion of the anodization, the curves surface is revealed on the surface of the substrate by etching out the porous layer and the anode pattern from the substrate.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Profile correction apparatus and profile correction program storage medium

InactiveUS7006691B2Reduce the differenceImprove versatilityImage enhancementDigitally marking record carriersComputer science

Owner:FUJIFILM CORP +1

Method and apparatus for manufacturing semiconductor devices

InactiveUS20050028837A1Precise lateral profileLarge deviation rangeSemiconductor/solid-state device manufacturingCleaning using liquidsRoom temperatureEngineering

A method and an apparatus for cleaning (e.g., removing etch by-products from) an etched target are disclosed. The method comprises providing a cleaning solution at a predetermined temperature lower than room temperature and cleaning the etched target with the cleaning solution. The apparatus for cleaning semiconductor devices comprises a chuck on which a semiconductor substrate is mounted; a solution storage part for storing a cleaning solution; a solution supply part for supplying the semiconductor substrate with the cleaning solution; a heat exchange part for maintaining the cleaning solution at a temperature lower than room temperature; and a control part for controlling the chuck rotation for a predetermined time and the cleaning solution delivery from the heat exchange part to the semiconductor substrate via the solution supply part. Accordingly, the present invention provides a more precise lateral profile of an etched pattern from the etch by-product cleaning process.

Owner:DONGBU ELECTRONICS CO LTD

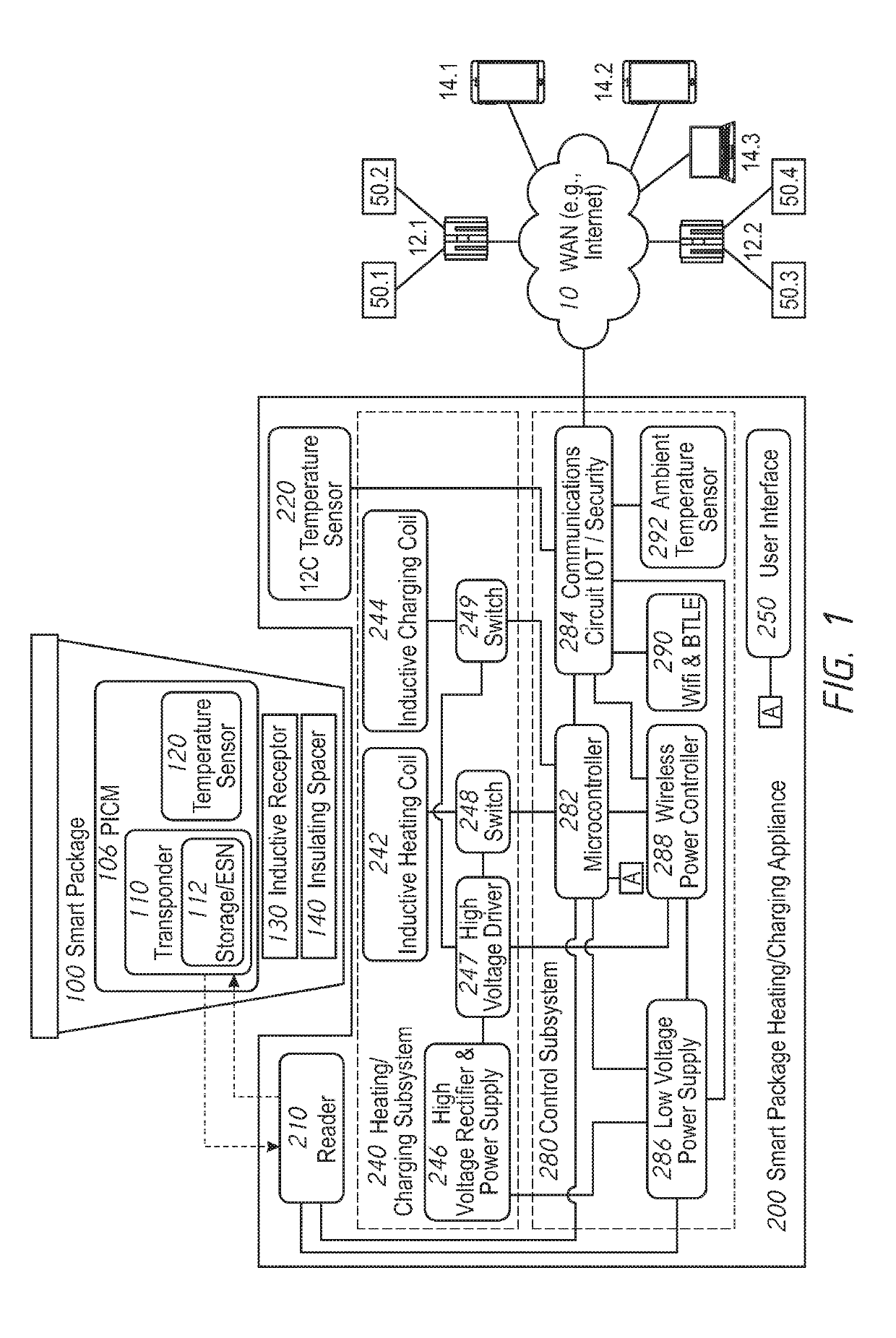

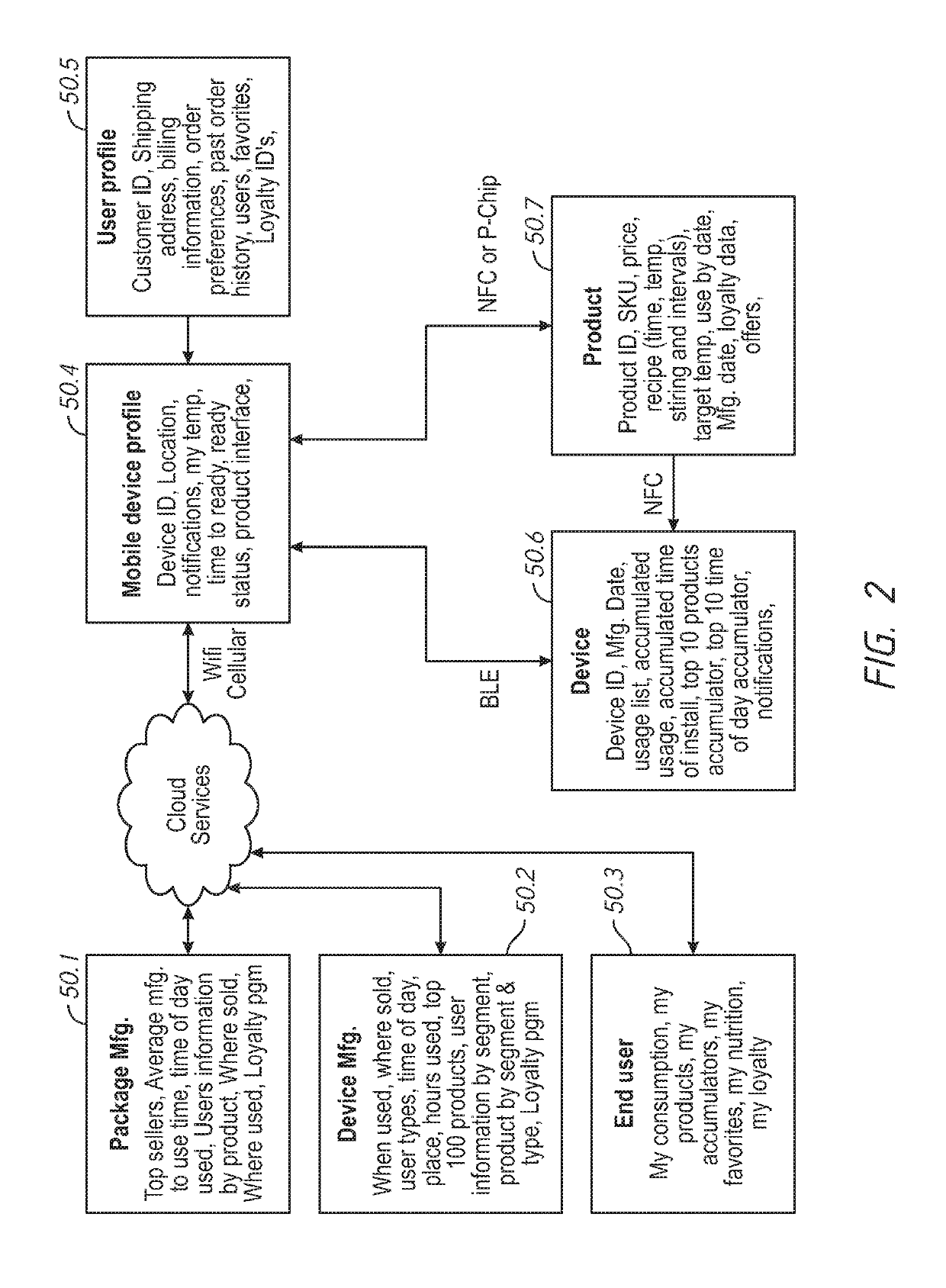

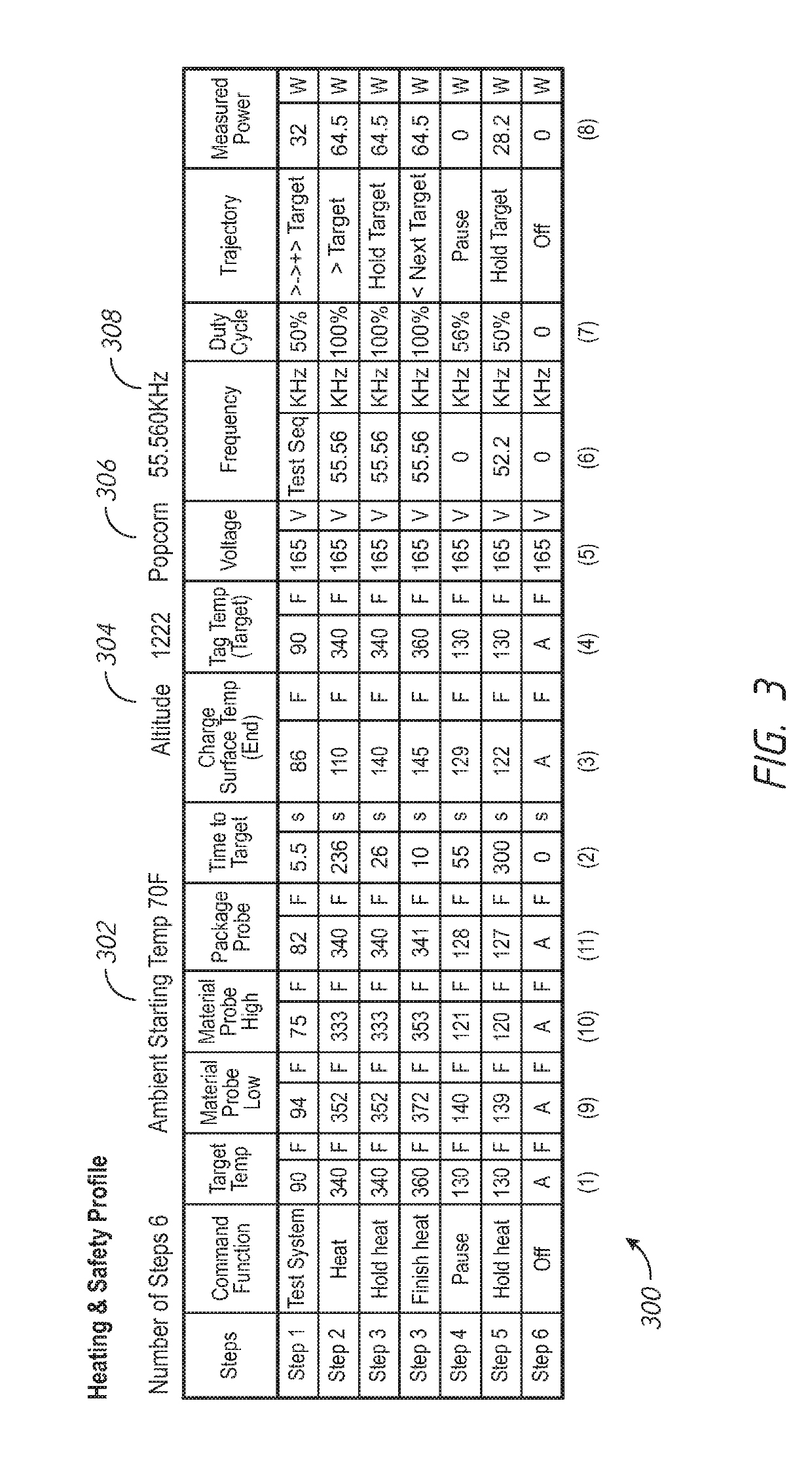

Smart appliances, systems and methods

ActiveUS20190104571A1Increase productionImprove heating safetyCooking vesselsBeverage vesselsPackage testingData set

A smart inductive heating appliance includes an interface for interacting with a package intelligence and communication module on a smart package. The smart heating appliance may also detect and charge chargeable devices inductively. A number of data sets may be utilized to enhance control of heating / cooking and to enhance safety. A thermodynamic load profile of the package may include detailed data correlations established in a package testing step and utilized to control heating of the package as well as to validate and authenticate the package.

Owner:HOLLYMATIC

Device, program and method for generating a profile

InactiveUS20060062441A1Improve matching accuracyAccurate contourCharacter and pattern recognitionPictoral communicationComputer graphics (images)Position dependent

A profile generation device obtains image data including information on pixel locations each indicating a location of a pixel, and extracts a location as an extraction point from the image data, the location being correlated with a predetermined color value to be used for generating a profile. The profile generation device performs a color measurement on an output image, and detects a location in the output image and a colorimetric value of the location, then generates data to be used for generating the profile from a pair of the color value correlated with the extraction point and the colorimetric value correlated with the location in the output image, wherein the location corresponds to the extraction point. Consequently, the profile generation device generates the profile by using the generated data.

Owner:DAINIPPON SCREEN MTG CO LTD

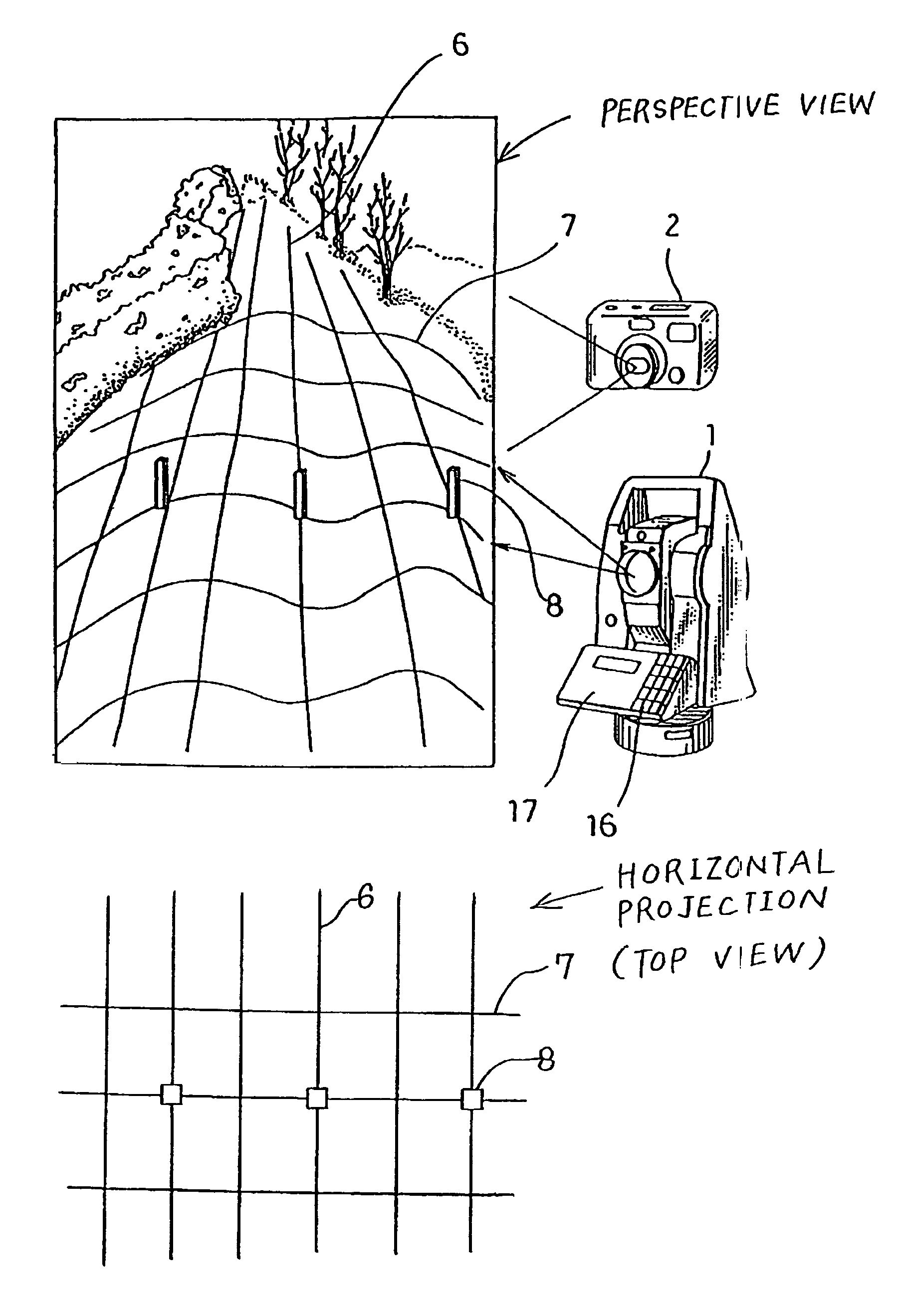

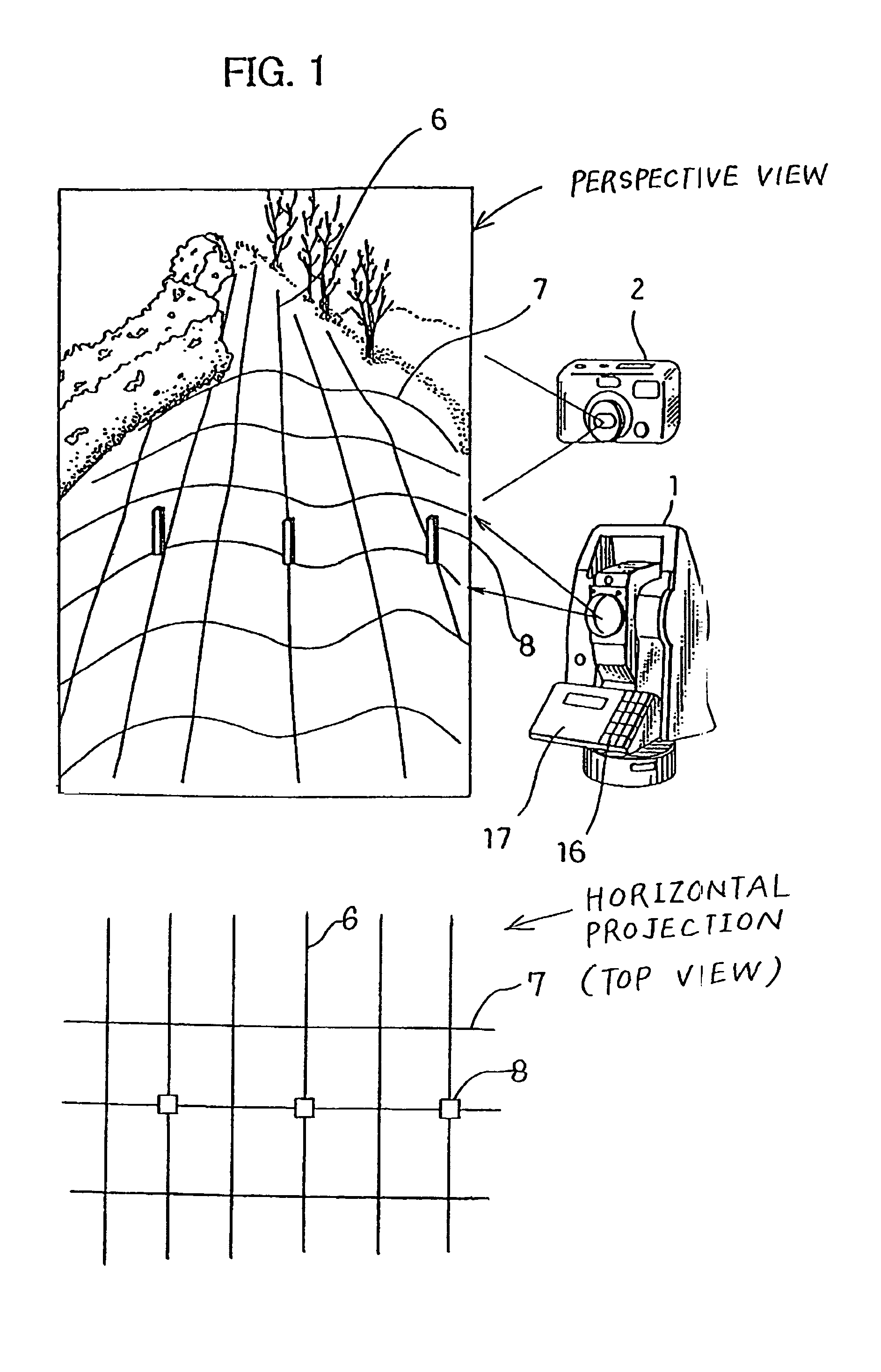

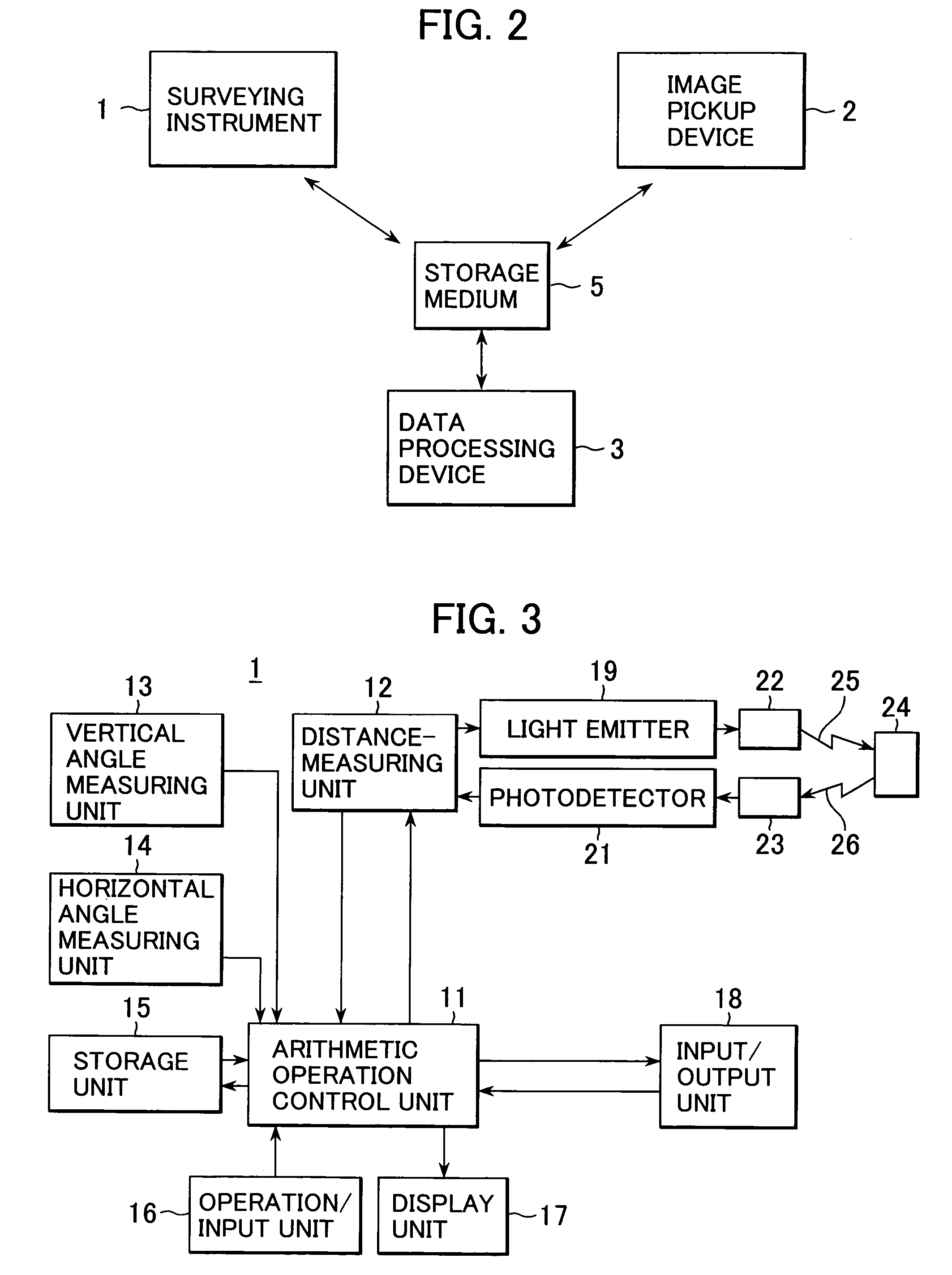

Measuring method and measuring system

ActiveUS20050243329A1Reduce workloadReduce the burden onOptical rangefindersGeometric image transformationComputer scienceImaging data

Owner:KK TOPCON

Method of forming a semiconductor device using a sacrificial uniform vertical thickness spacer structure

ActiveUS20100233873A1Uniform vertical thicknessUniform thicknessTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Disclosed is a method of forming planar and non-planar semiconductor devices using a sacrificial gate sidewall spacer with a uniform vertical thickness. The method forms such spacers by selectively growing an epitaxial film on the vertical sidewalls of a gate structure. The use of an epitaxial growth process, as opposed to a deposition and etch process, ensures that the resulting spacers will have a uniform vertical thickness. Then, any process steps (e.g., implant and / or etch process steps) requiring the use of the gate sidewall spacers (e.g., as a mask or shield) are performed. Precise implant and / or etch profiles can be achieved, during these process steps, as a function of the uniformity of the gate sidewall spacers. Once such process steps are completed, the sidewall spacers are selectively removed. Optionally, before removing the sidewall spacers, they can be oxidized in order to enhance the selective removal process.

Owner:TAIWAN SEMICON MFG CO LTD

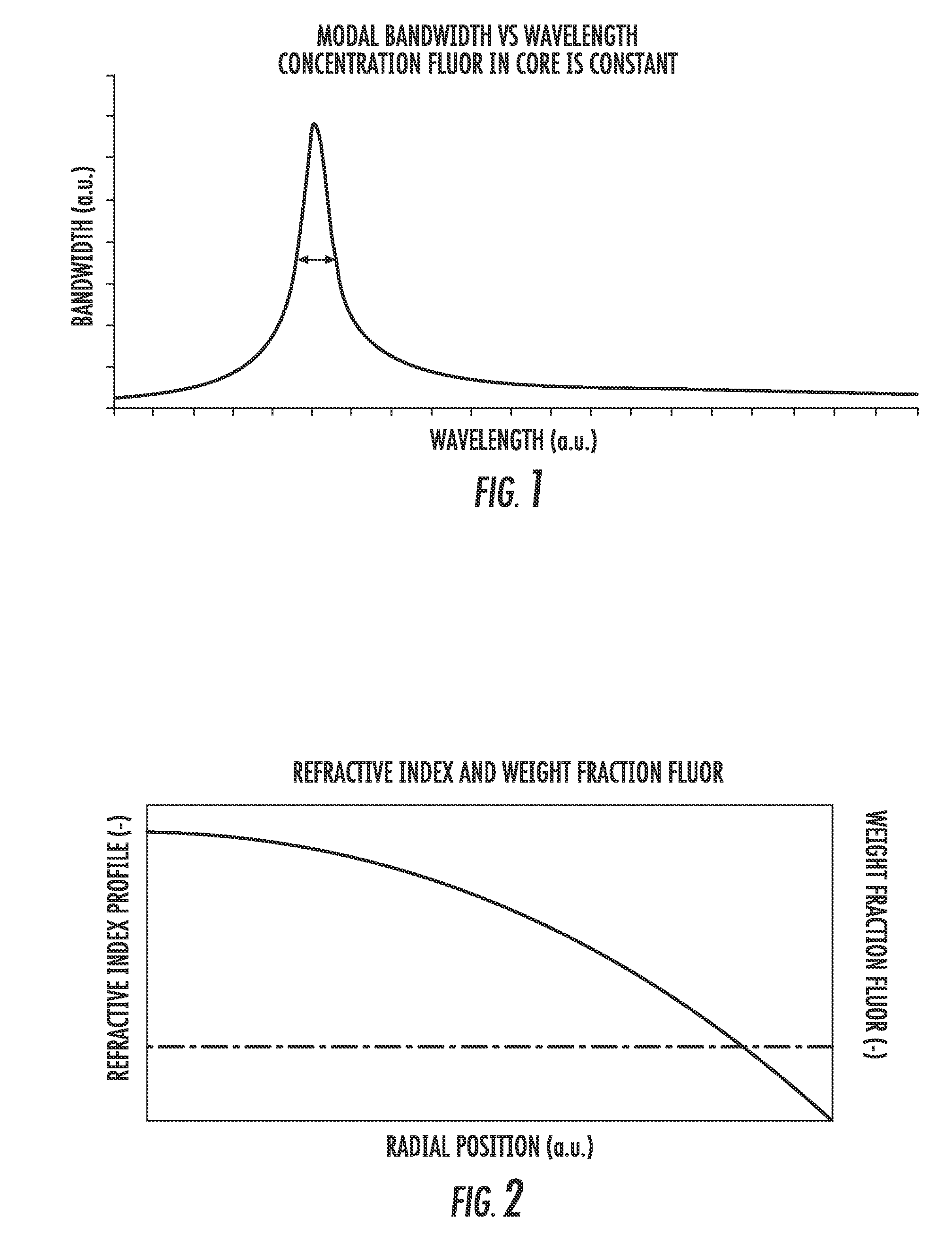

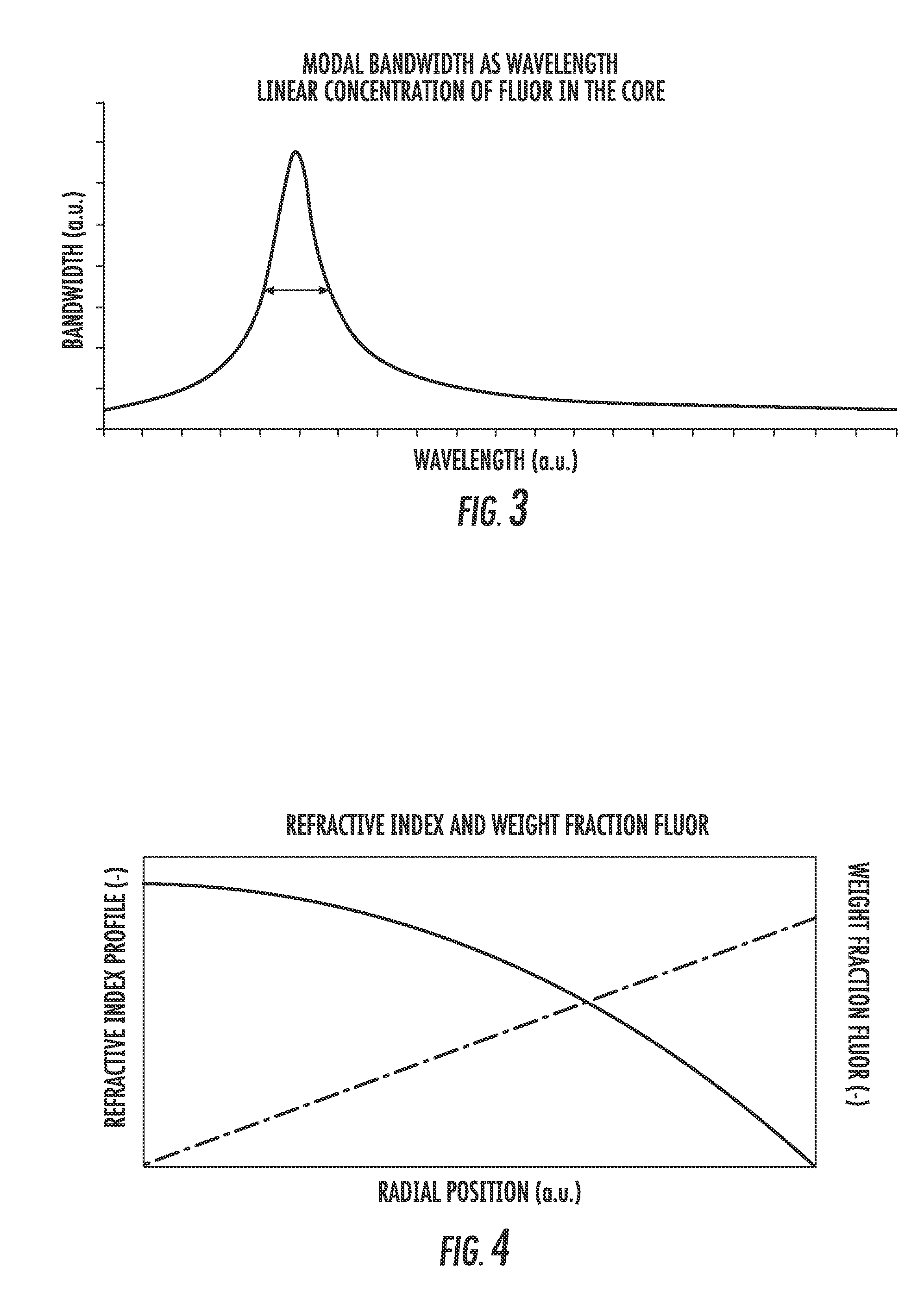

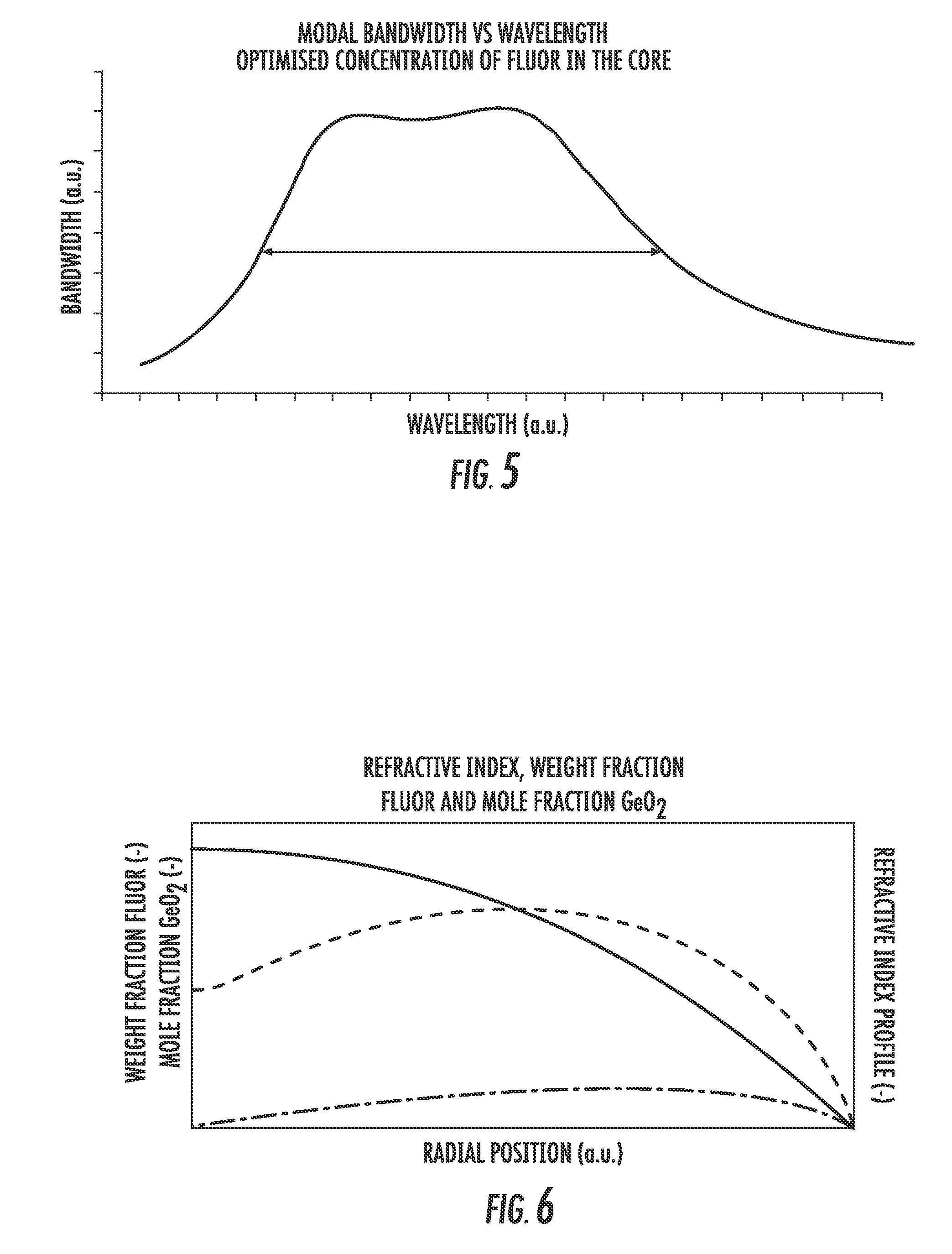

Method for Manufacturing a Multimode Optical Fibre

ActiveUS20090019894A1Less wavelength-dependentHigh bandwidthGlass making apparatusOptical fibre with graded refractive index core/claddingCommunications systemLight guide

The invention relates to a multimode optical fibre having a refractive index profile, comprising a light-guiding core surrounded by one or more cladding layers. The present invention furthermore relates to an optical communication system comprising a transmitter, a receiver and a multimode optical fibre.

Owner:DRAKA COMTEQ BV

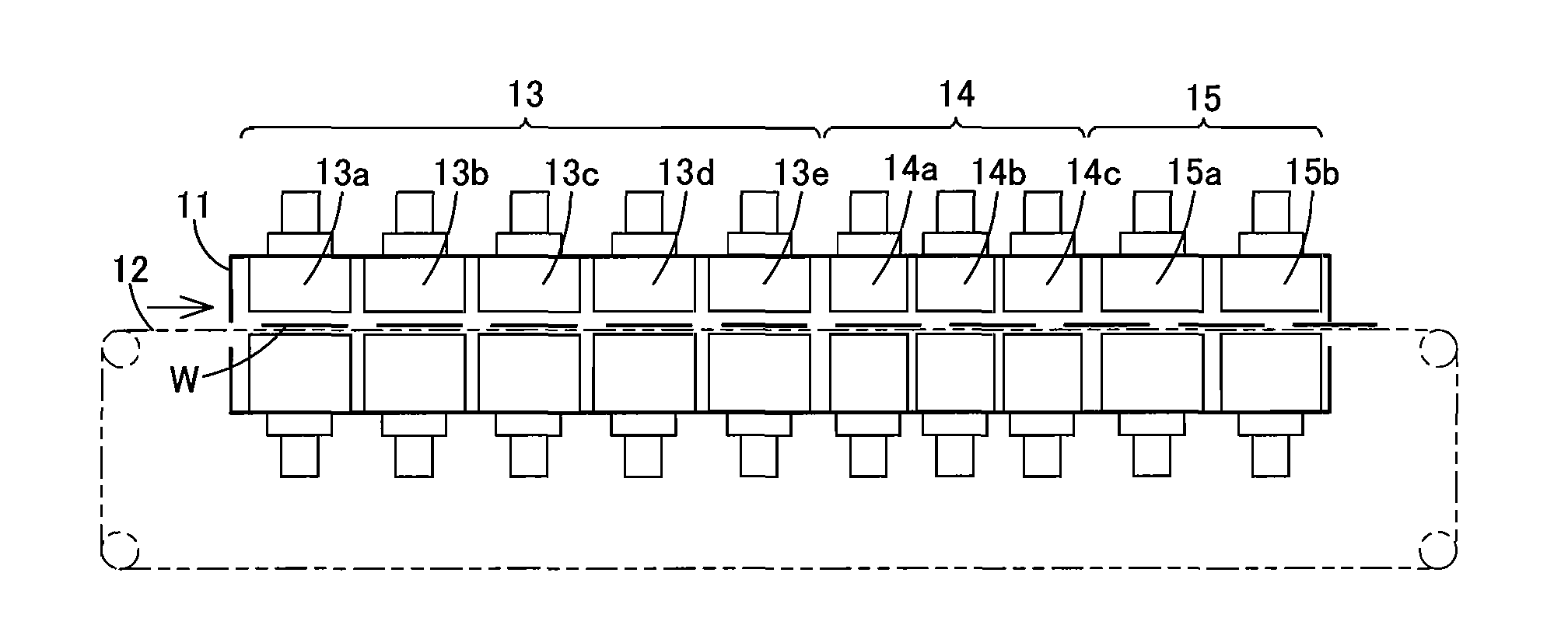

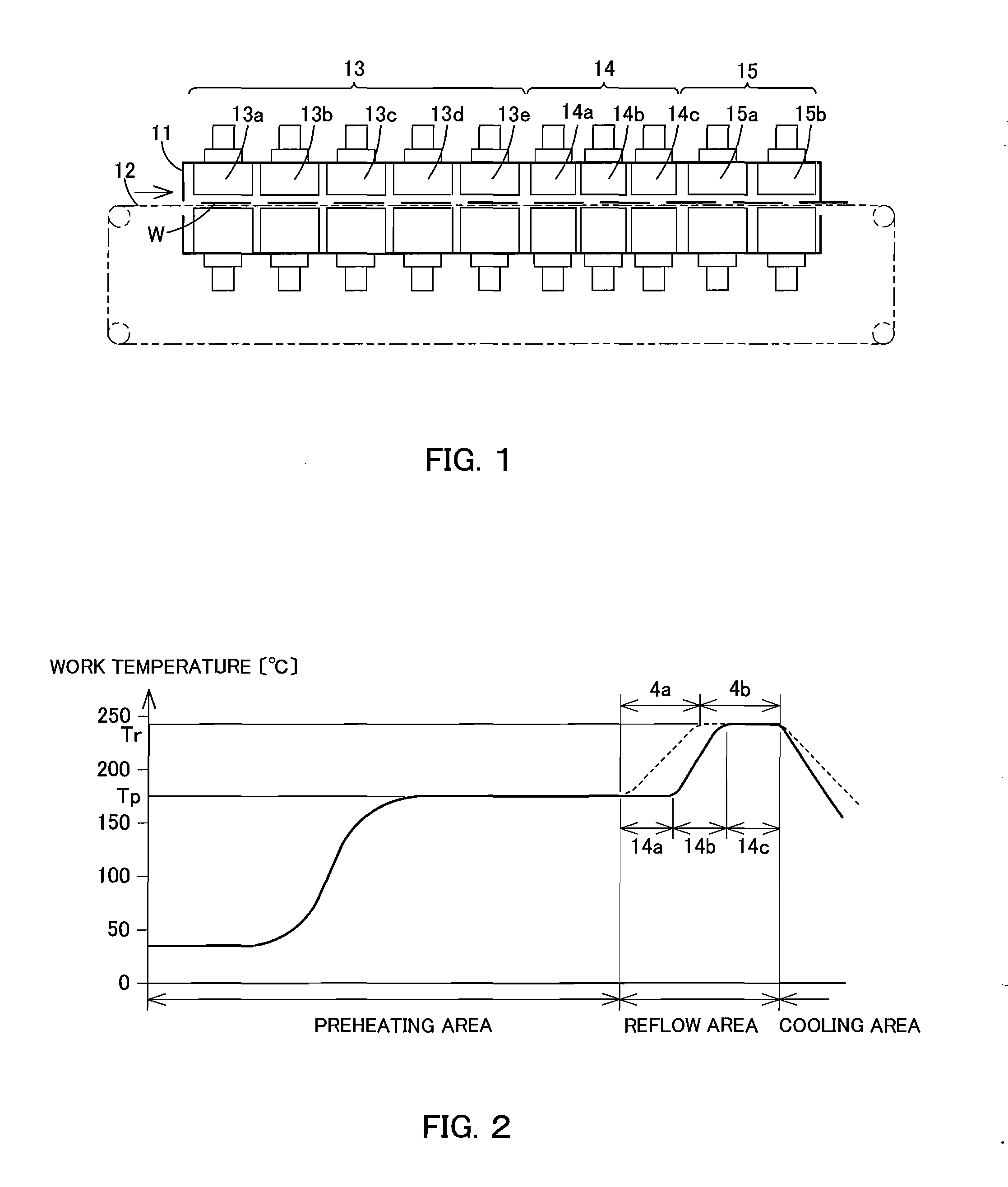

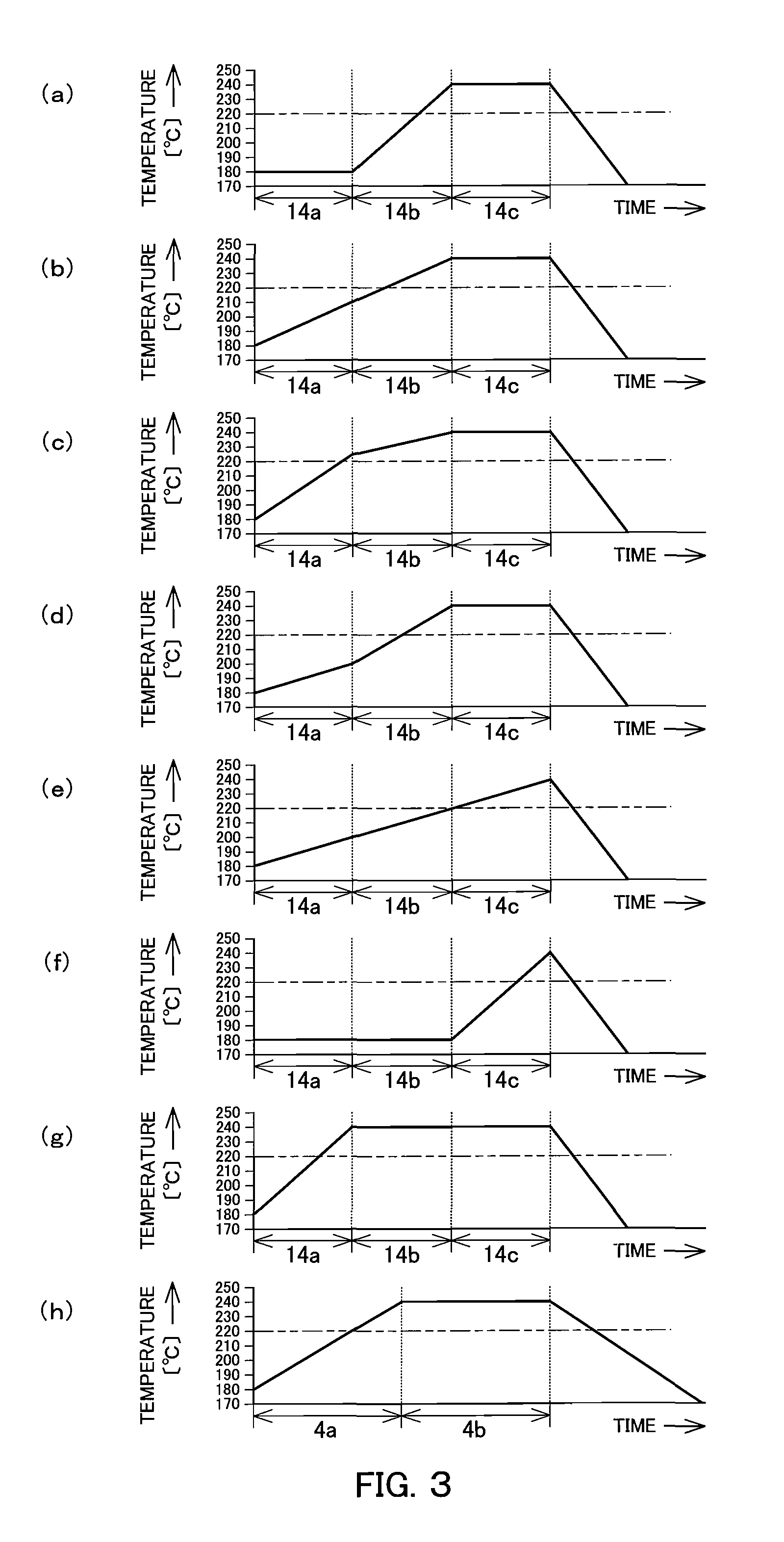

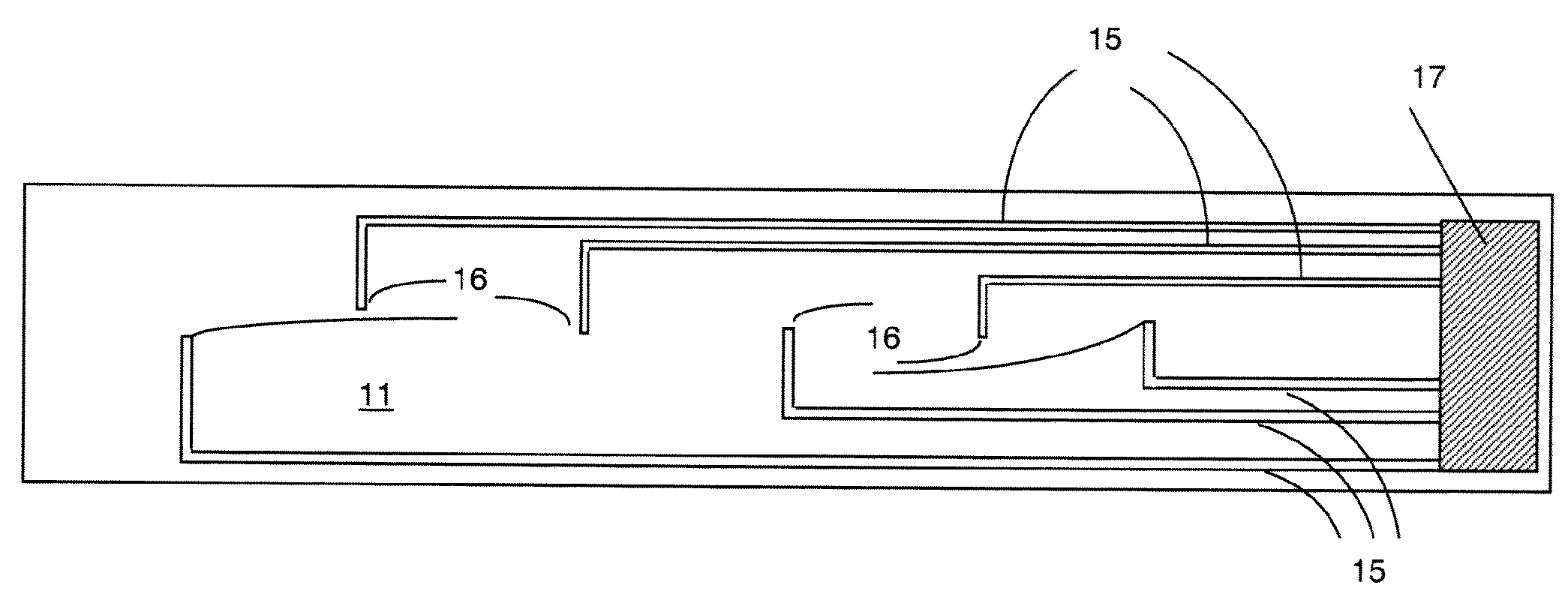

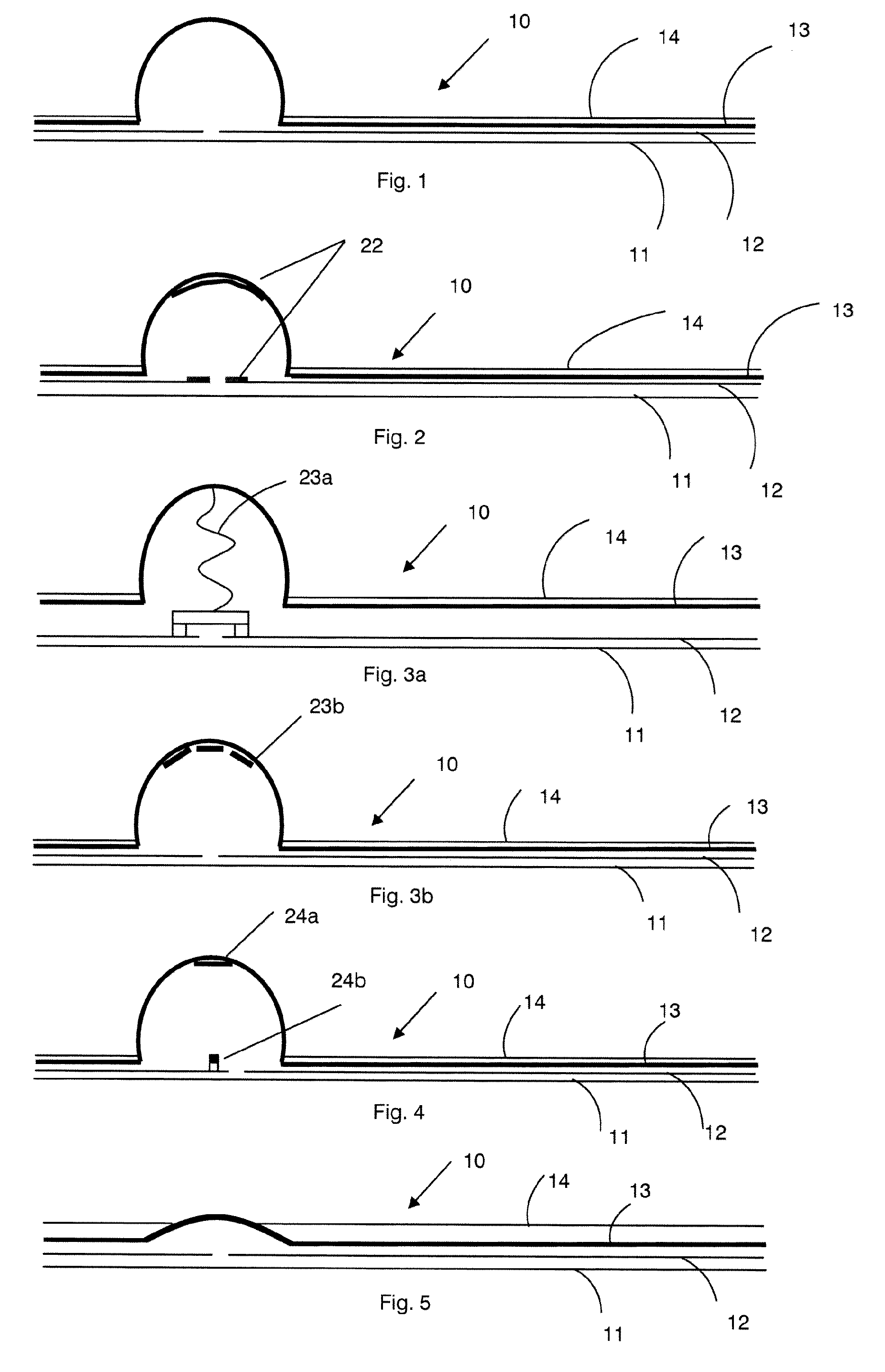

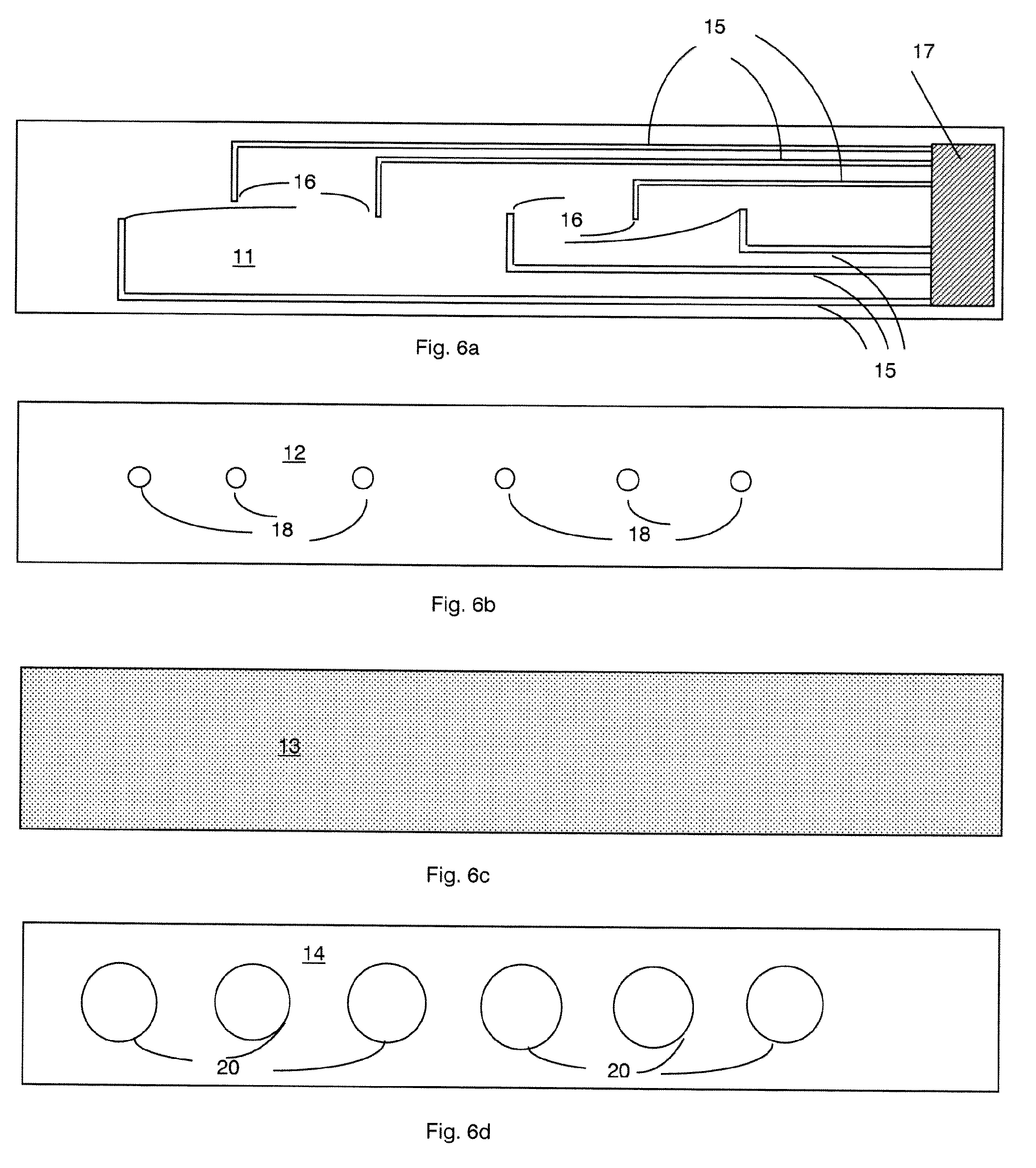

Reflow apparatus

InactiveUS20100219228A1Easy to adjustImprove variationFinal product manufacturePrinted circuit aspectsHeating timeEngineering

The present invention provides a reflow apparatus capable of precisely adjusting the heating temperature and heating time when heating a work for reflow. A work transfer conveyor for transferring a work into a furnace body is disposed, wherein a plurality of preheating zones through for preheating the work, a plurality of reflow zones for heating the work for reflow, and a plurality of cooling zones for cooling the work are successively arranged along the work transfer conveyor in the furnace body. The individual reflow zones are formed shorter than the individual preheating zones in the work transfer direction. It is preferable that the sizes of the individual reflow zones in the transfer direction are shortened to approximately 65% to 85% with respect to the individual preheating zones or the conventional individual reflow zones.

Owner:TAMURA KK +1

Information handling system cable seal

ActiveUS10231034B1Reduce disadvantagesReduce problemsServersDigital processing power distributionEngineeringHandling system

An information handling system routes cables from a chassis interior to a chassis exterior through a cable channel defined in the housing and having airflow managed by a blocking element biased to a closed position. As cable configurations change, the blocking element adapts to fit cables through the cable channel in a compact manner that minimizes cooling airflow escape through the cable channel. Automated adjustments to a cooling fan profile based upon a predicted cable configuration and associated airflow help to ensure adequate cooling as airflow characteristics change due to the presence of cables and an expected position of the blocking element.

Owner:DELL PROD LP

Pressure sensor

ActiveUS9204799B2The implementation process is simpleEasy to useDiagnostics using pressurePerson identificationEngineeringBandage

A sensor suitable for measuring the pressure applied by a bandage, the sensor being in the form of an elongate strip having a plurality of pads arranged along its length, wherein the sensor includes a connection to each pad, whereby the pressure applied to each pad can be determined independently, wherein each pad is inflatable to form an expanded pad protruding above the surface of the strip, and deflatable so that it does not impede removal of the sensor from the bandage. Such a sensor is primarily intended for single use, i.e. is disposable.

Owner:SFH OXFORD

Surface configuration measuring method and surface configuration measuring system

ActiveUS7671998B2Reduce the burden onAccurate profileOptical rangefindersGeometric image transformationComputer scienceImaging data

Owner:KK TOPCON

Probe retention arrangement

InactiveUS8907689B2Accurate profileElectrical measurement instrument detailsManufacture of electrical instrumentsEngineeringDevice under test

Owner:MICRO PROBE

Process Of Making An Optical Lens

InactiveUS20090101509A1Easy to makeEasy to controlElectrolysis componentsSemiconductor/solid-state device manufacturingIn planeCamera lens

A semiconductor substrate is anodized to be shaped into an optical lens. Prior to being anodized, the substrate is finished with an anode pattern on its bottom surface so as to be consolidated into a unitary structure in which the anode pattern is precisely reproduced on the substrate. The anodization utilizes an electrolytic solution which etches out oxidized portion as soon as it is formed as a result of the anodization, to thereby develop a porous layer in a pattern in match with the anode pattern. The anode pattern brings about an in-plane distribution of varying electric field intensity by which the porous layer develops into a shape complementary to a desired lens profile. Upon completion of the anodization, the semiconductor substrate is shaped into the lens by etching out the porous layer and the anode pattern from the substrate.

Owner:PANASONIC CORP

Method and apparatus for measuring and removing rotational variability from a nip pressure profile of a covered roll of a nip press

ActiveUS20170114499A1Accurate detectionAccurate measurementPress sectionApparatus for force/torque/work measurementMultiple sensorEngineering

Owner:INT PAPER CO

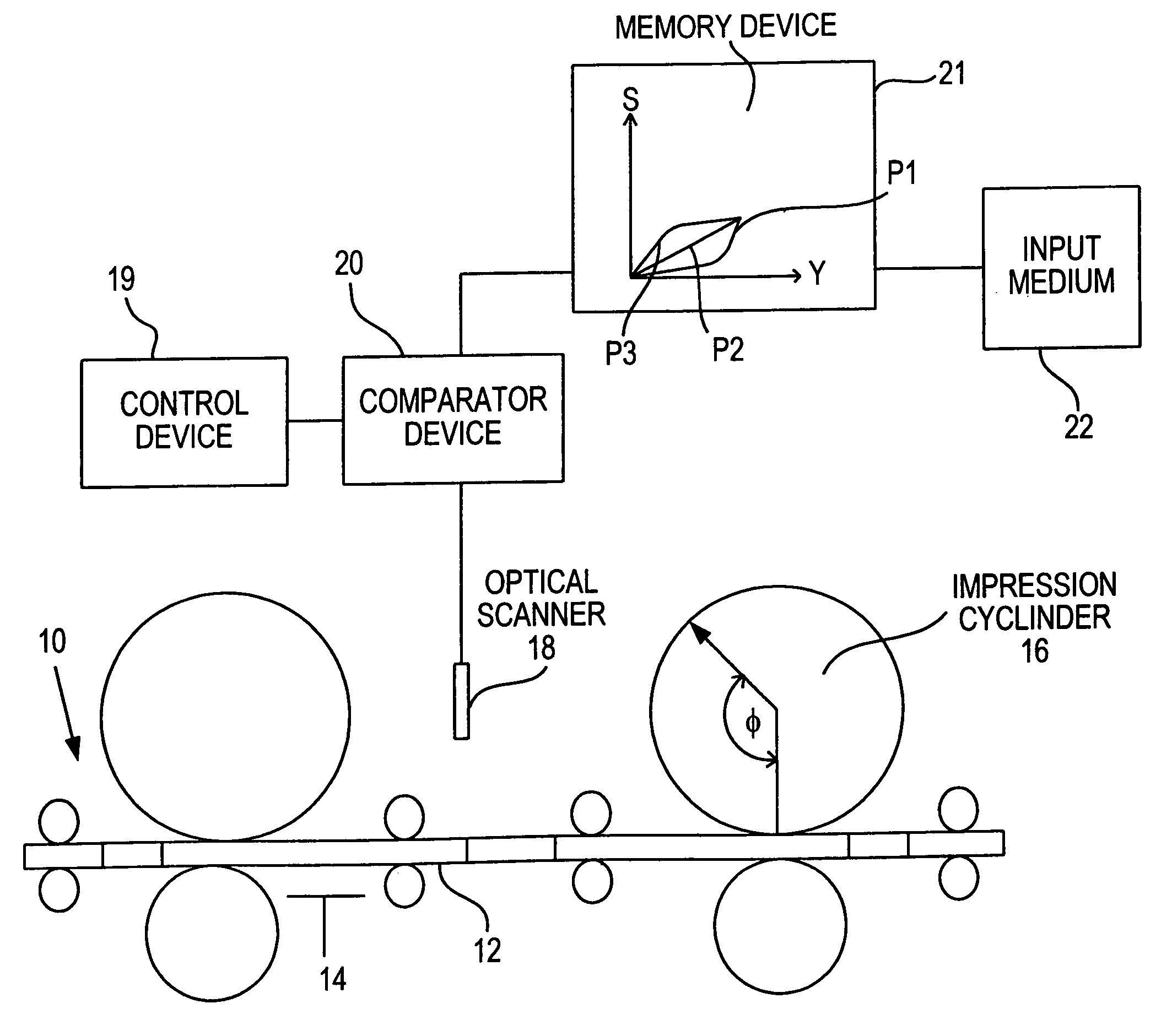

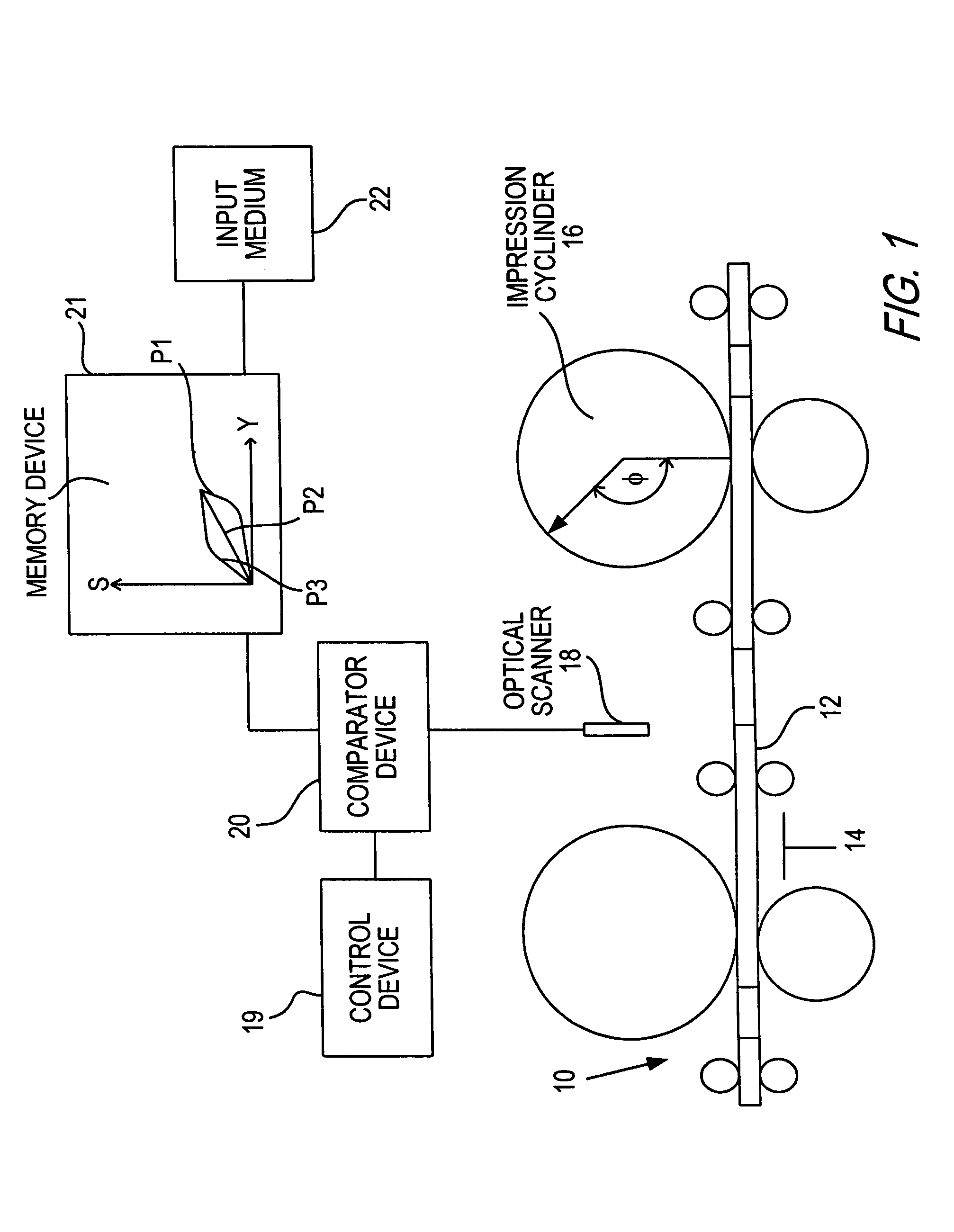

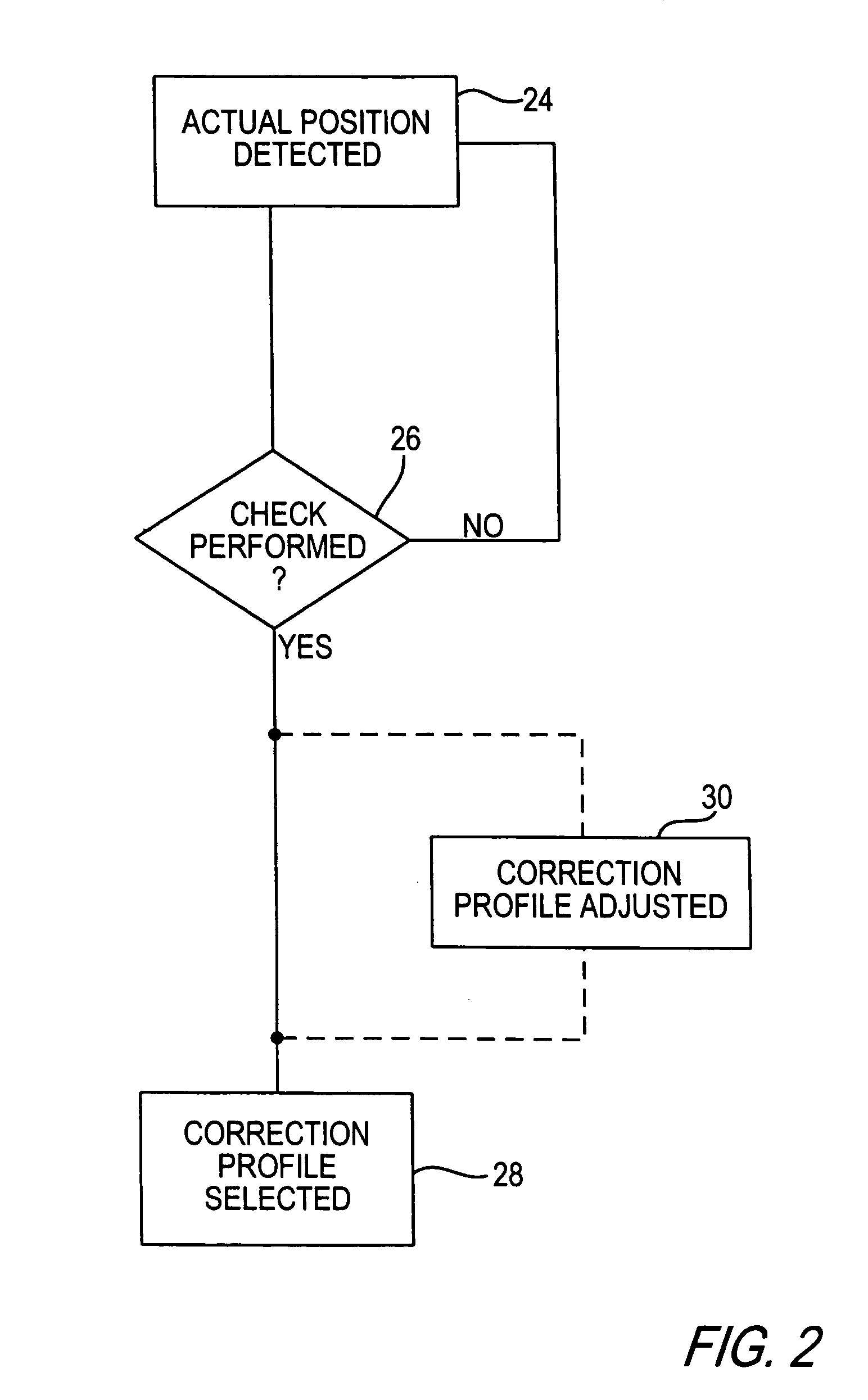

Method and device for correcting the positional deviation of a conveyed item by adjusting the cylinder's angle rotation relative to the conveyed item

InactiveUS7117795B2Easy to processAccurate profilePlaten pressesRotary pressesComputer scienceDelivery system

To correct the position of a conveyed item (12) in a conveyance system (10), the deviation of the conveyed item (12) from its target position is detected. If this deviation reveals that a correction is necessary, a suitable correction profile Pi is selected from a plurality of available correction profiles (P1, P2, P3), and the correction is carried out.

Owner:REXROTH INDRAMAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com