Heating device for plastic blanks

a heating device and blank technology, applied in the direction of electric heating, microwave heating, electric/magnetic/electromagnetic heating, etc., can solve the problem of not being desirable in the upper part of the preform, and achieve the effect of precise temperature profiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

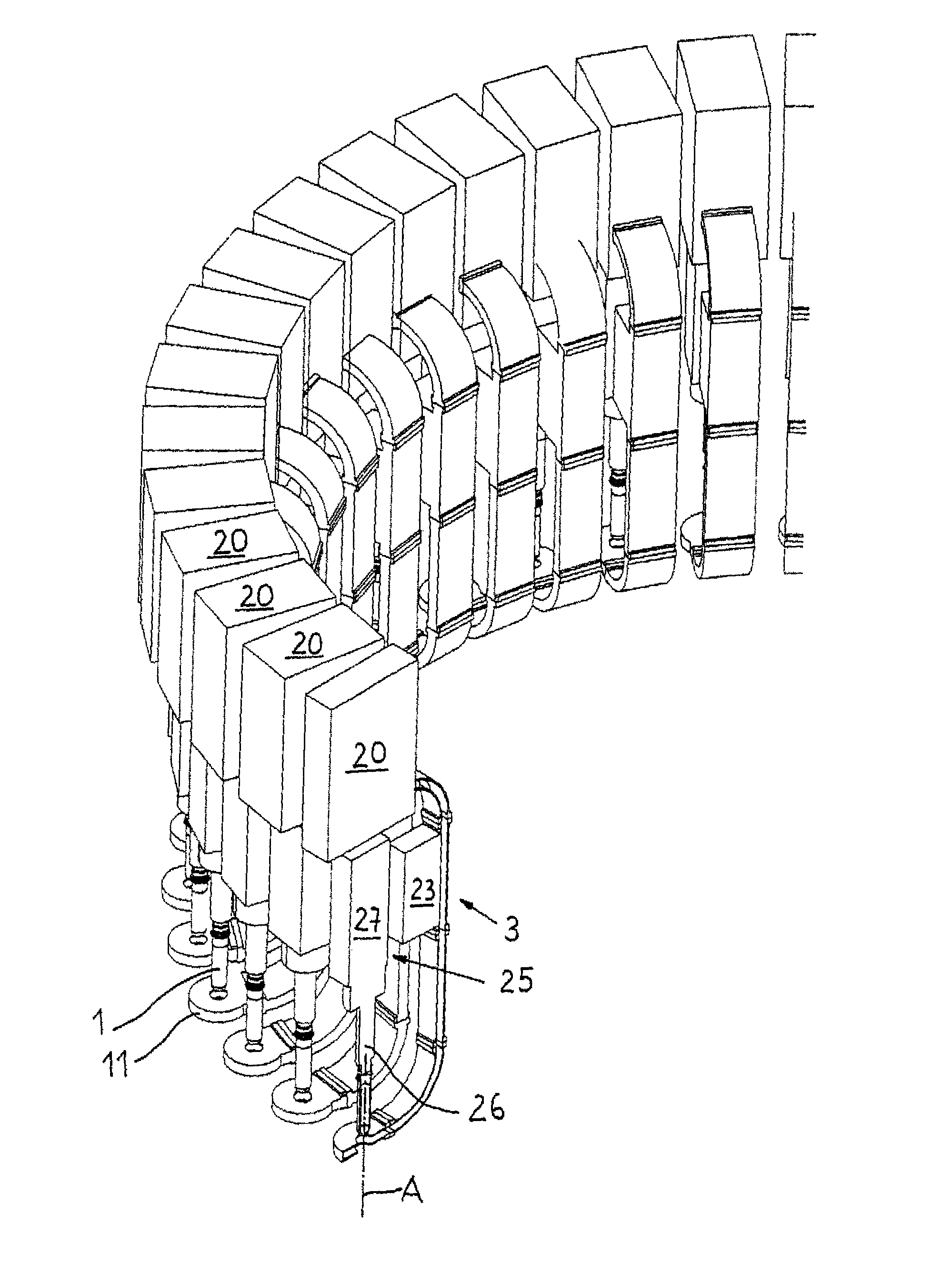

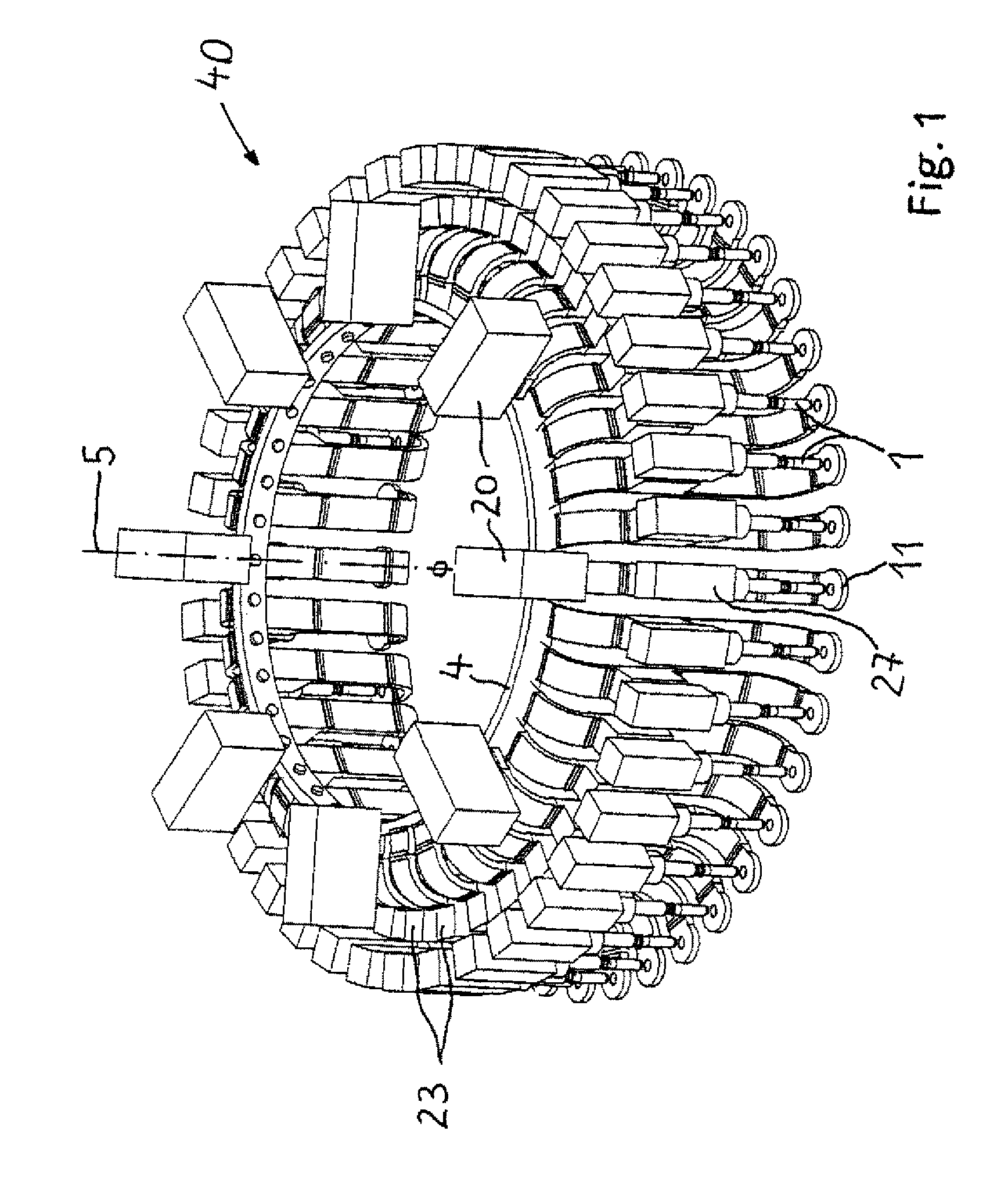

[0059]FIG. 1 shows a circular heating device for preforms 1, the latter being moved on a circular path, according to the circumference of the heating device, in the course of the heating operation. The heating device has a carrier 4, which, in this case, simultaneously constitutes a rectangular hollow conductor. Fastened to this carrier 4 are various structural units, for instance eight microwave compact heads 20 and forty microwave heating units 3. These units, fastened to the carrier 4, revolve jointly about the machine axis 5. The transfer from an upstream unit to the oven 40 is effected by means of a star, such as, for example, a sawtooth star or a clip star.

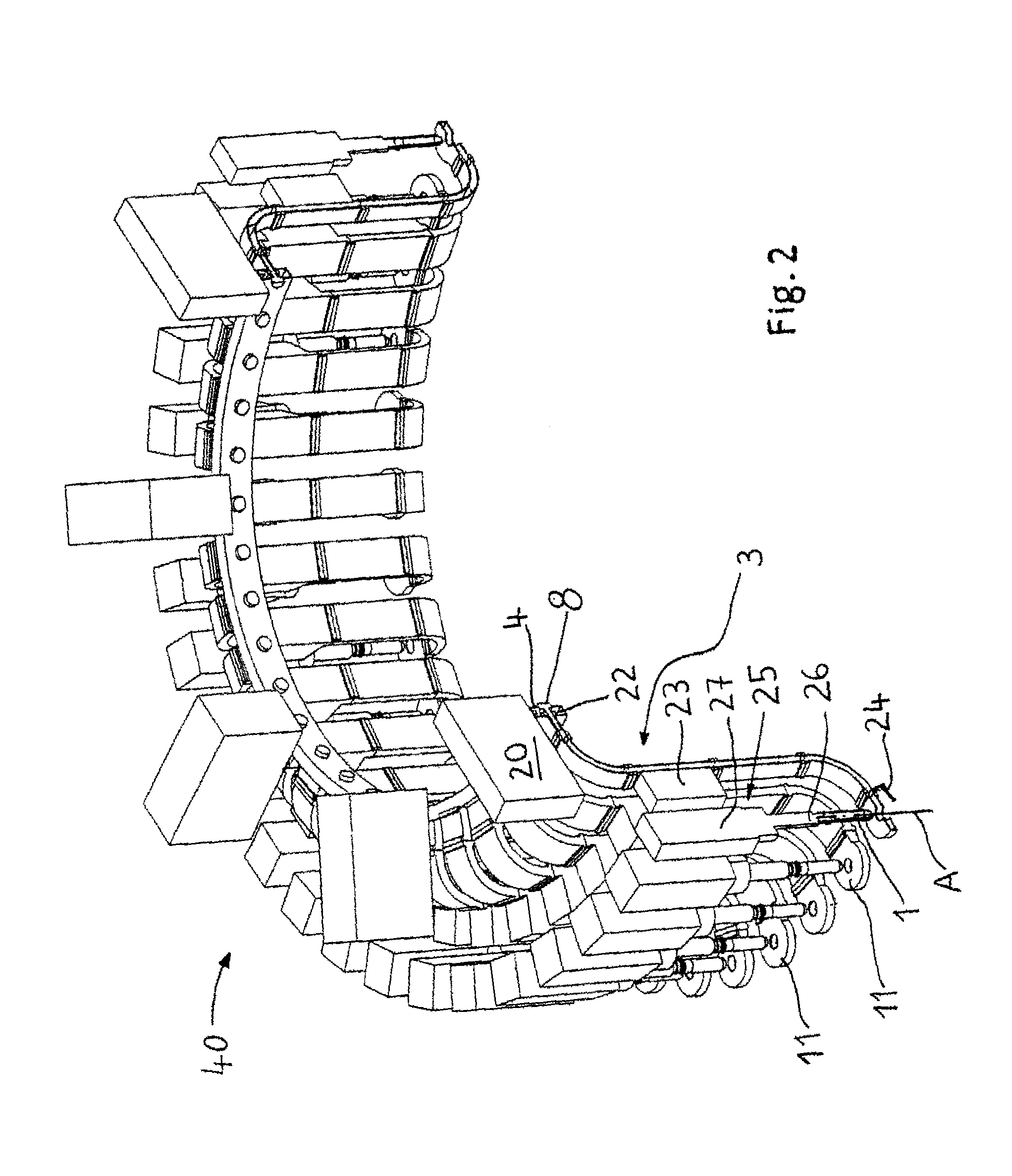

[0060]FIG. 2 shows a portion of the oven 40 according to FIG. 1, the microwave heating unit 3 being better explained here. Seen here, likewise, are the microwave compact heads 20, which generate the microwaves and which are directly connected to the carrier 4, which, in this case, constitutes a hollow conductor 22. Mounted i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com