Multipoint sensor for determining the existing temperature profile of a medium and method for its production

A temperature sensor and temperature distribution technology, applied in the field of multi-point sensors, can solve the problem of difficulty in local accurate sensing of measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

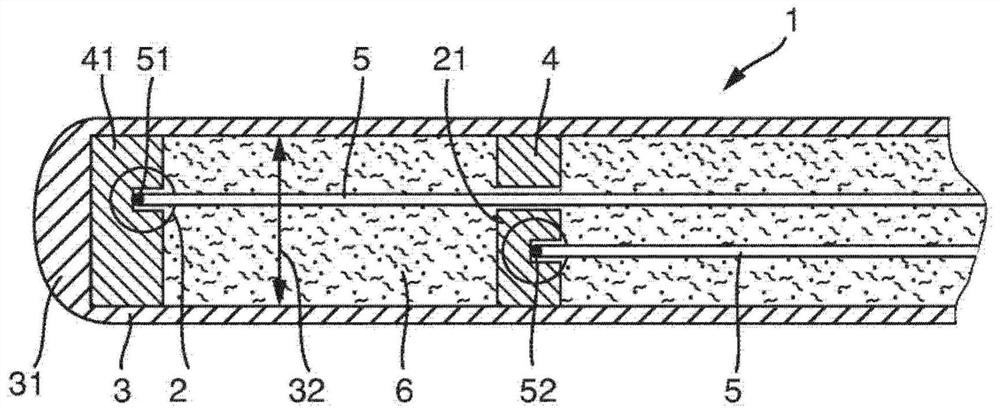

[0045] figure 1 An exemplary embodiment of a multipoint sensor 1 according to the invention is shown. The multipoint sensor 1 consists of a tubular sheath 3 , which is preferably produced from a metallic material and has a closed end region 31 . In the initial state, the end region opposite the closed end region 31 is open.

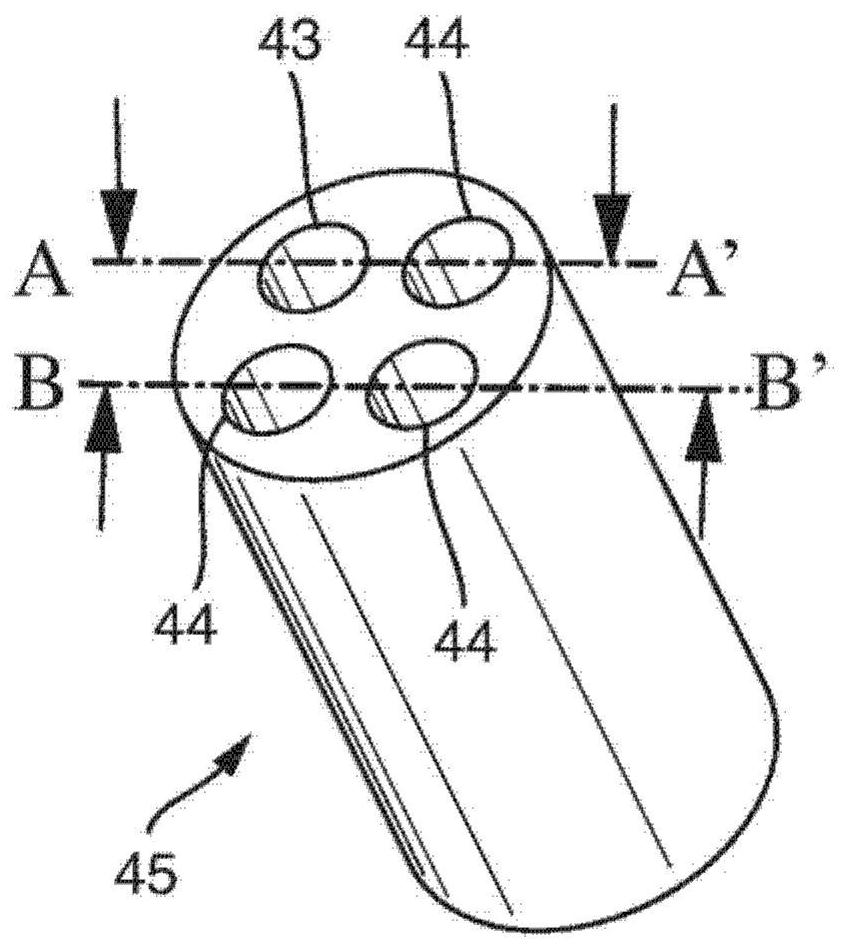

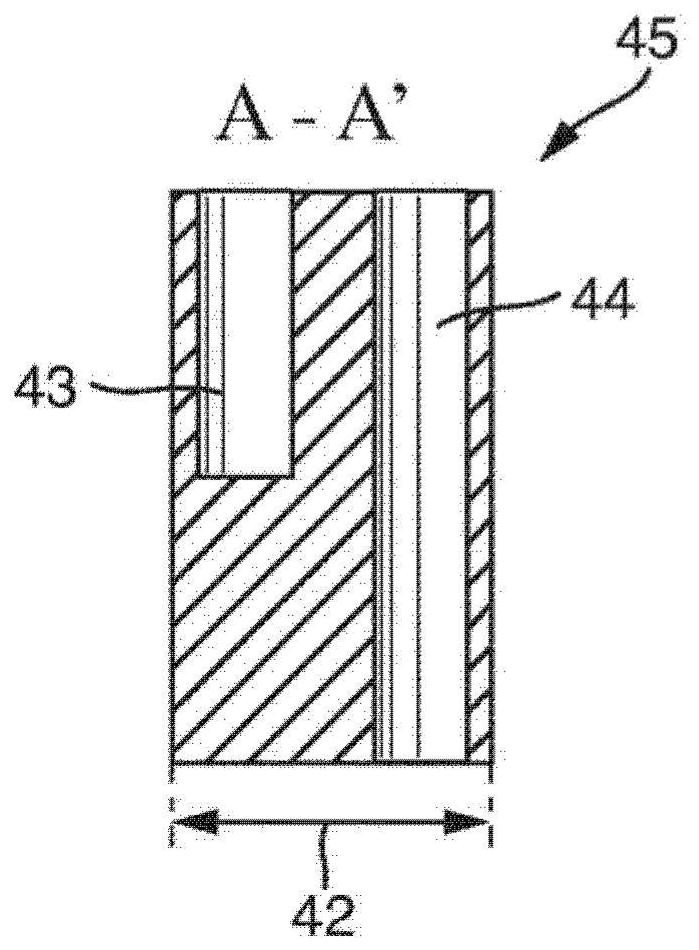

[0046] Furthermore, the multipoint sensor 1 has at least two cylindrical spacers 41 , 4 . exist figure 1 In the exemplary embodiment shown, exactly two spacers 41, 4 are used. The spacers 4 , 41 each have a recess 43 in which respectively fastened temperature sensitive members 51 , 52 of the elongated temperature sensors 5 sense one measurement point 2 of the medium temperature profile respectively. The temperature-sensitive components 51 , 52 can be, for example, resistance thermometers or thermal elements.

[0047] The spacers 4, 41 are produced from a material with high thermal conductivity, preferably from a ceramic material such as boron nitride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com