Non-damage stiffness-adjustable prefabricated frame beam and column connection structure and construction method thereof

A beam-column connection without damage technology, which is applied in building construction and construction, can solve problems such as difficult quality assurance, inability to effectively realize strong columns and weak beams, and difficult construction of steel bar lapping, achieving convenient processing and high cost performance , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

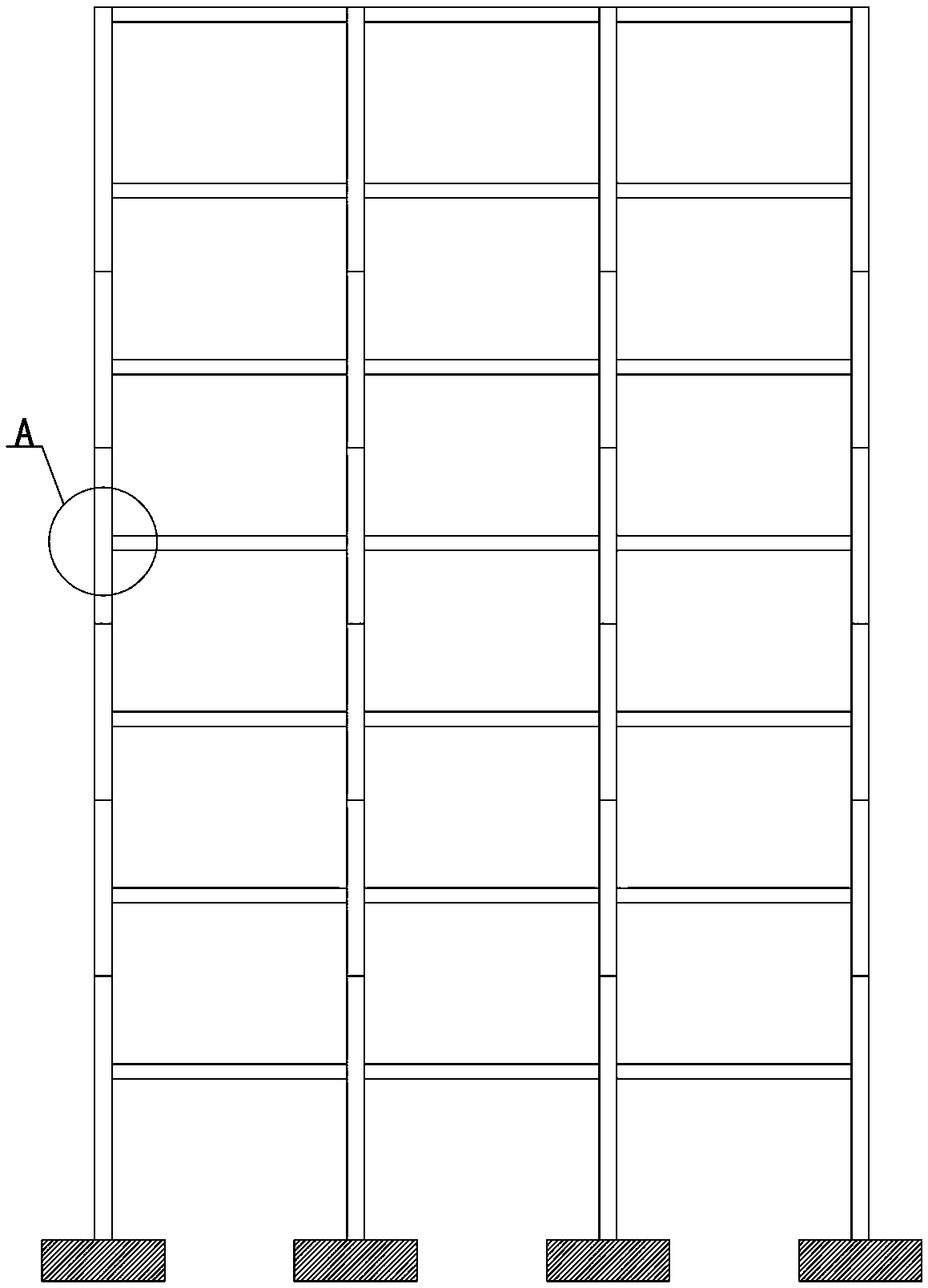

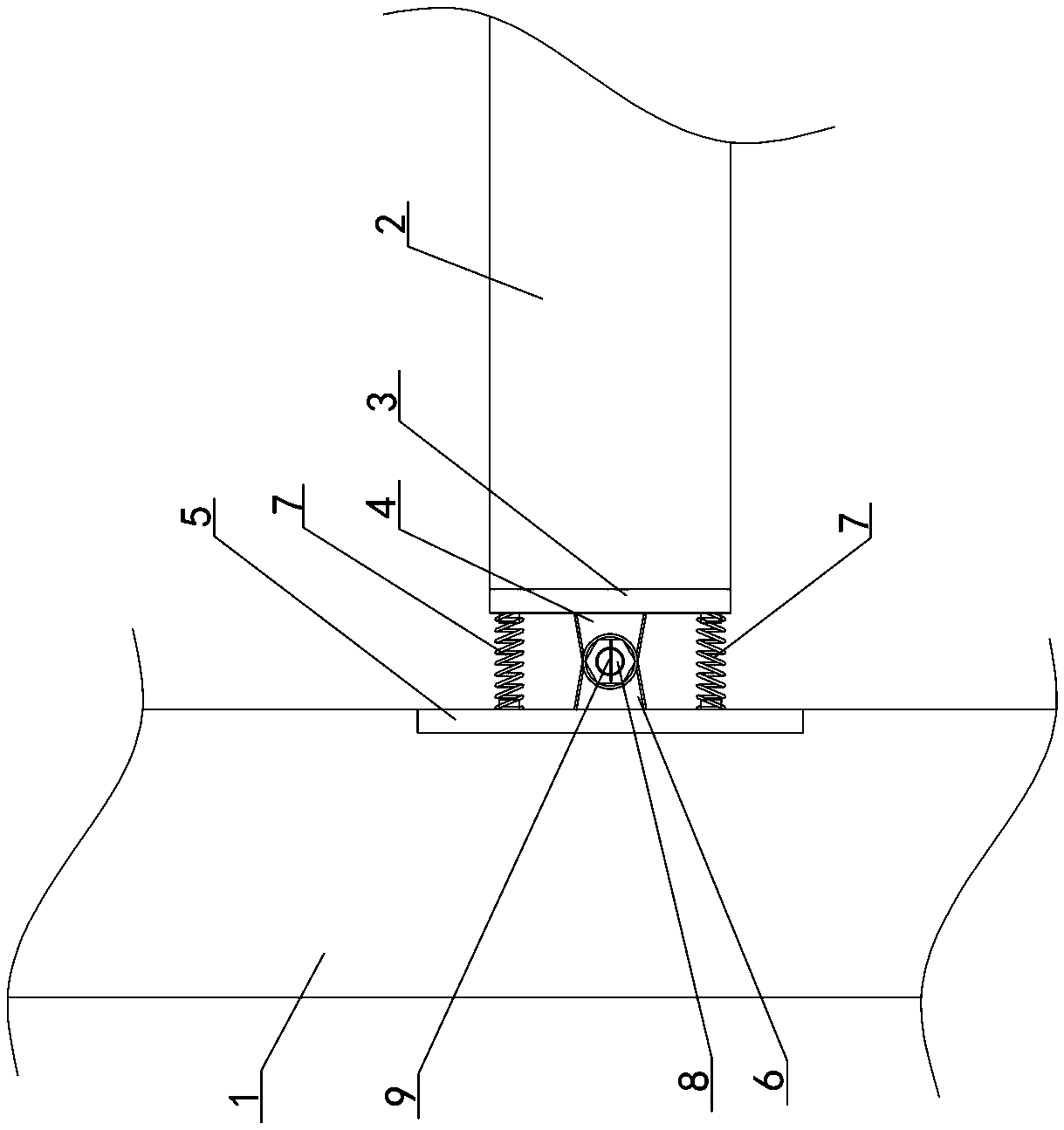

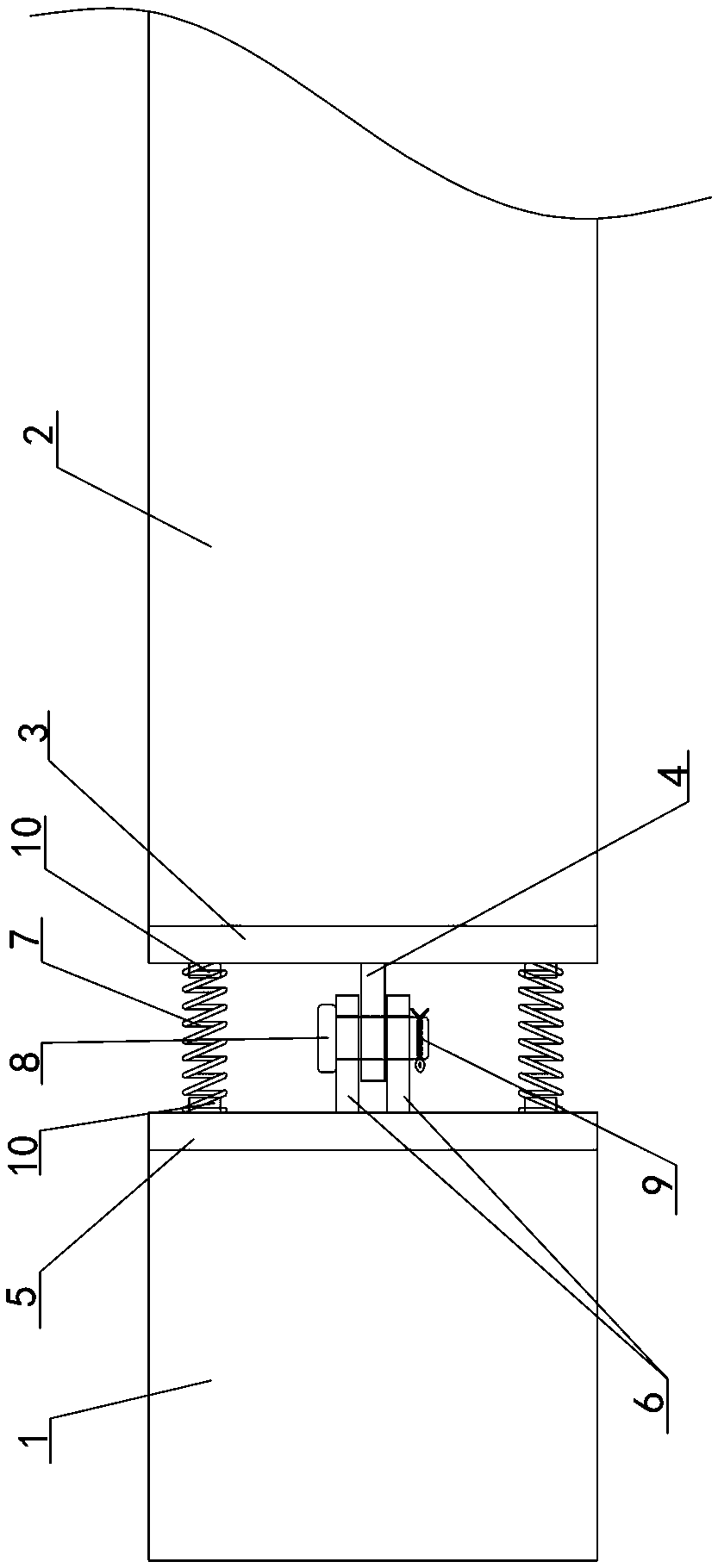

[0038] Embodiment Referring to the figure, a prefabricated beam-column connection structure with adjustable stiffness without damage includes prefabricated columns 1 and prefabricated beams 2 connected. In this embodiment, both the prefabricated column 1 and the prefabricated beam 2 are reinforced concrete prefabricated components.

[0039] Between the beam end center of the prefabricated beam 2 and the prefabricated column 1, a pin connection device is fixed so that the beam end of the prefabricated beam 2 can freely rotate up and down relative to the prefabricated column 1, and the pin connection device is a vertical shear connection ear The plate group, the shear connection ear plate group is penetrated with a pin joint shaft 8, and the pin joint shaft is located in the middle of the reserved space between the reinforced concrete column 1 and the prefabricated beam 2.

[0040] A vertical beam end plate 3 is pre-embedded on the beam end surface of the prefabricated beam 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com