A non-damage adjustable rigidity prefabricated frame column foot connection structure and its construction method

A technology for connecting structures and frame columns, applied in building components, building structures, building types, etc., can solve the problems of cumbersome cast-in-place connection construction, easy damage to prefabricated columns, and inability to restore, achieving high cost performance, excellent seismic performance, The effect of repair-free construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

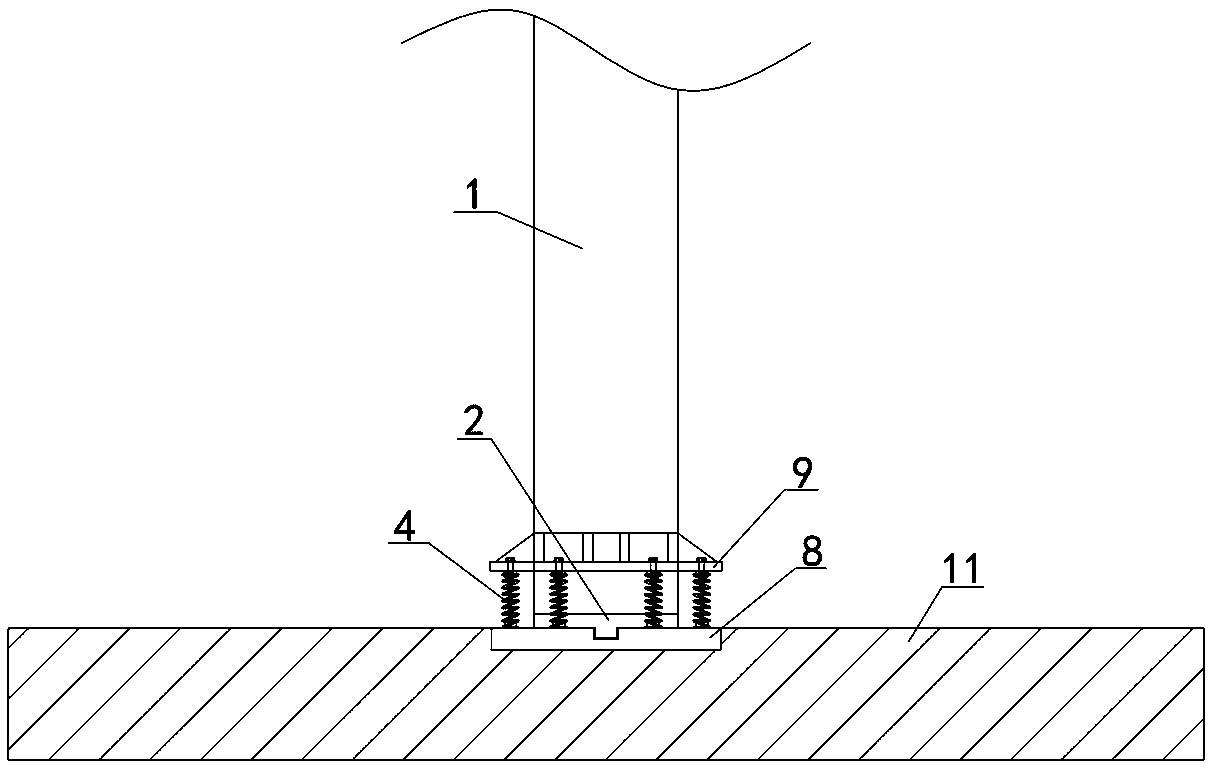

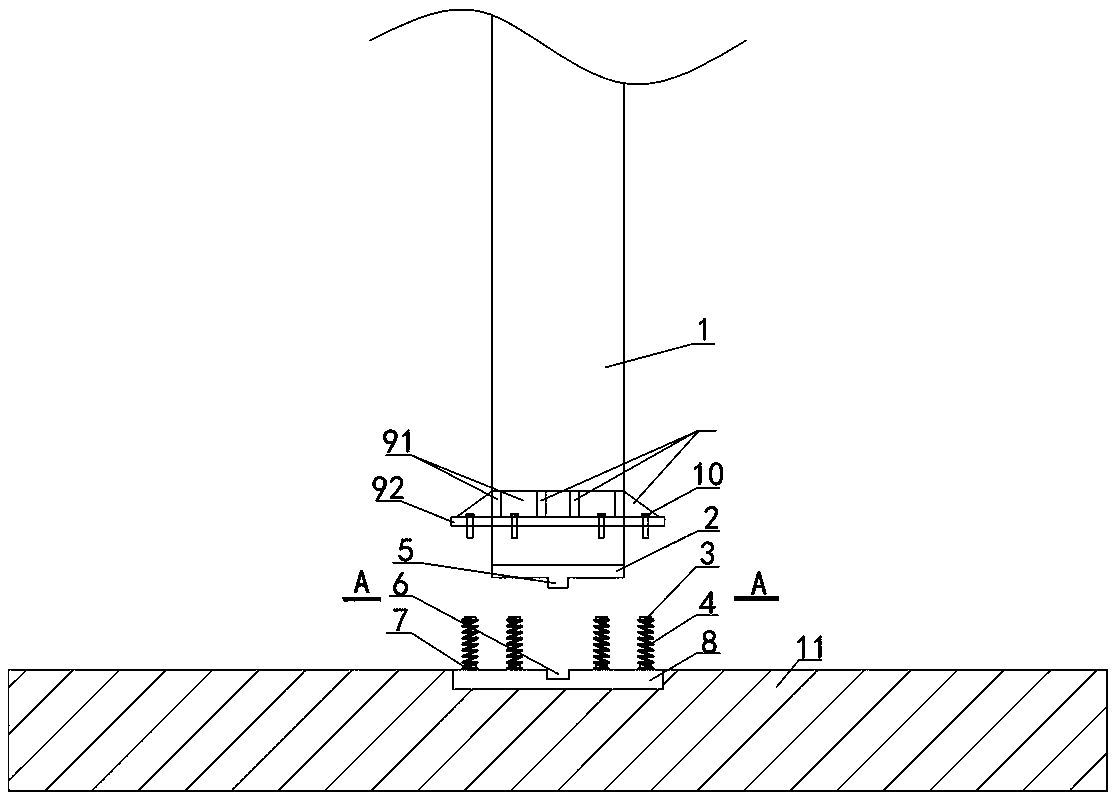

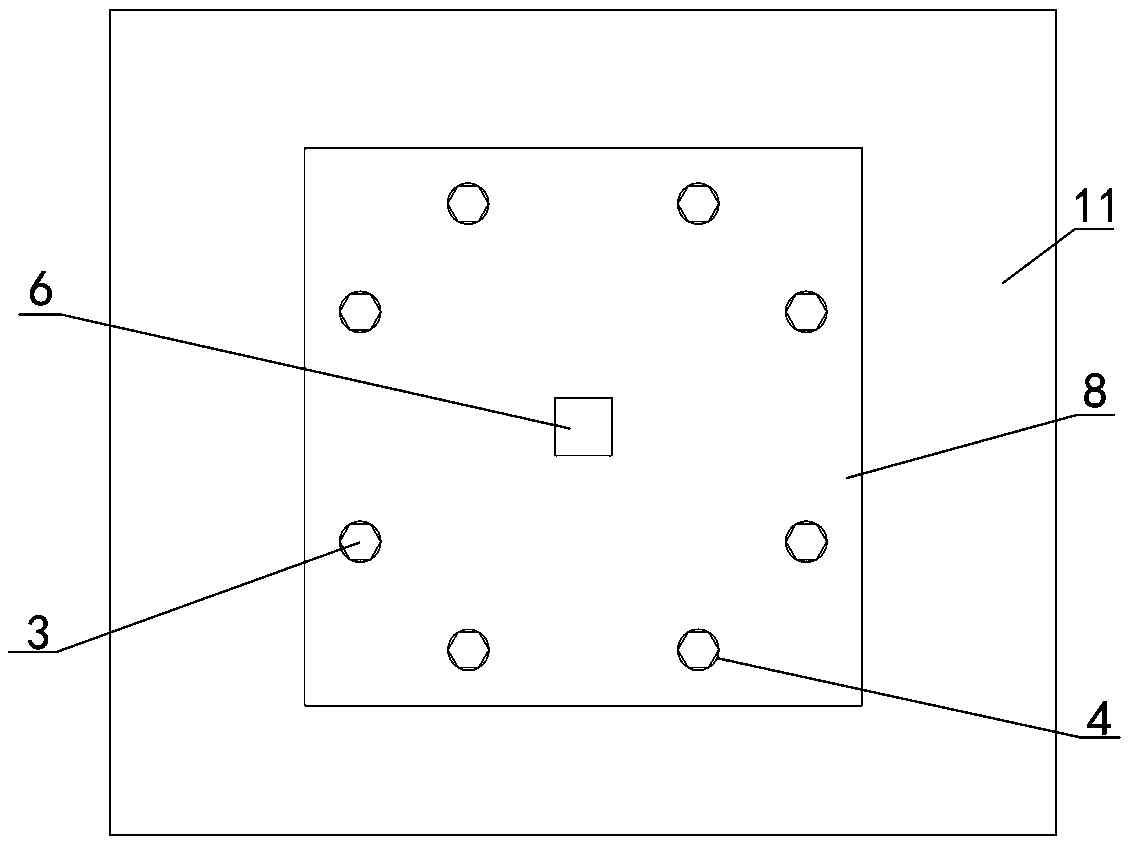

[0038] Examples see Figure 1-5 As shown, a prefabricated frame column foot connection structure with adjustable stiffness without damage includes a foundation 11 and a prefabricated concrete column 1 connected to the foundation.

[0039] The bottom end surface of the precast concrete column is pre-embedded with a horizontal end steel plate 2, the center of the end steel plate 2 coincides with the center of the cross section of the precast concrete column, and the lower surface of the end steel plate 2 is provided with a downward convex anti- The shear key 5, the outer surface of the end steel plate 2 is flush with the outer surface of the prefabricated concrete column. The shear key 5 and the end steel plate 2 are integrally machined and formed, both of which are made of steel. The shear key 5 is arranged symmetrically on the center of the end steel plate 2, and is a bump, a convex line or a combination of the two located in the center of the bottom steel sealing plate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com