Test device for large deformation shearing seepage of contact surface and use method thereof

A test device and contact surface technology, applied in the direction of applying stable shear force to test material strength, measurement device, test wear resistance, etc., can solve the problem of limiting shear dislocation deformation, sealing film and soil samples are prone to occur Extrusion, test cannot be carried out and other problems, to achieve the effect of ensuring accuracy, reasonable loading method, and avoiding extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

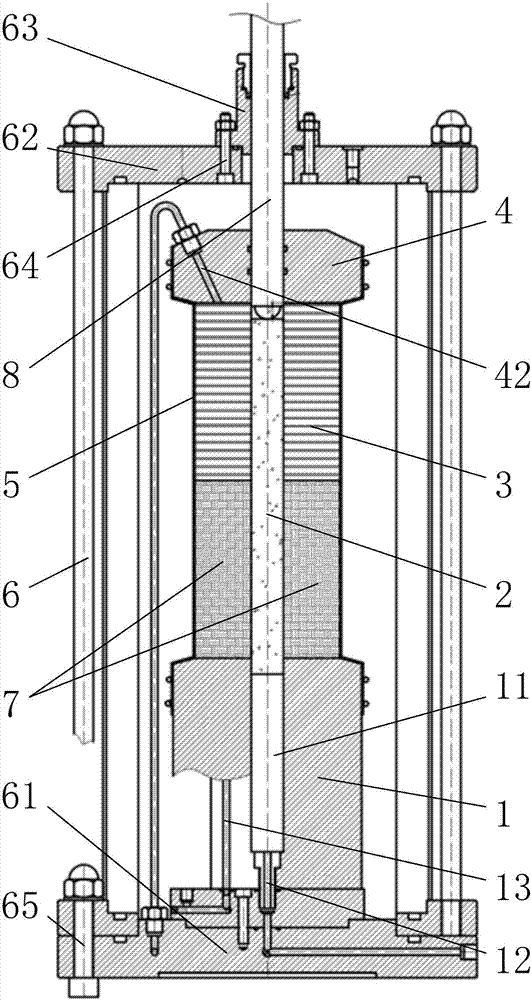

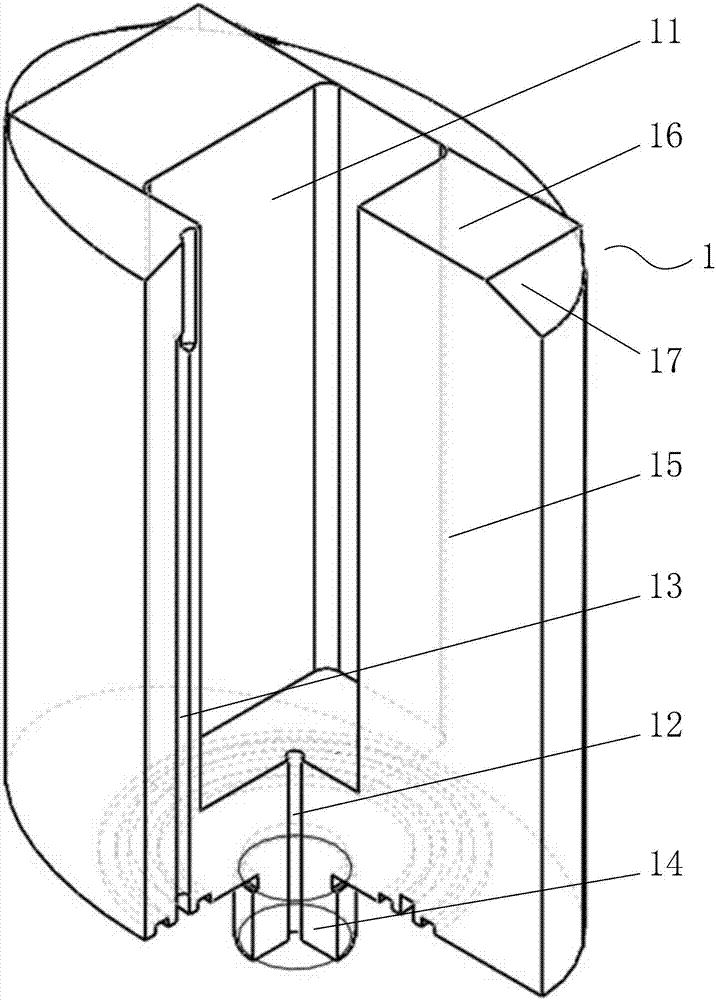

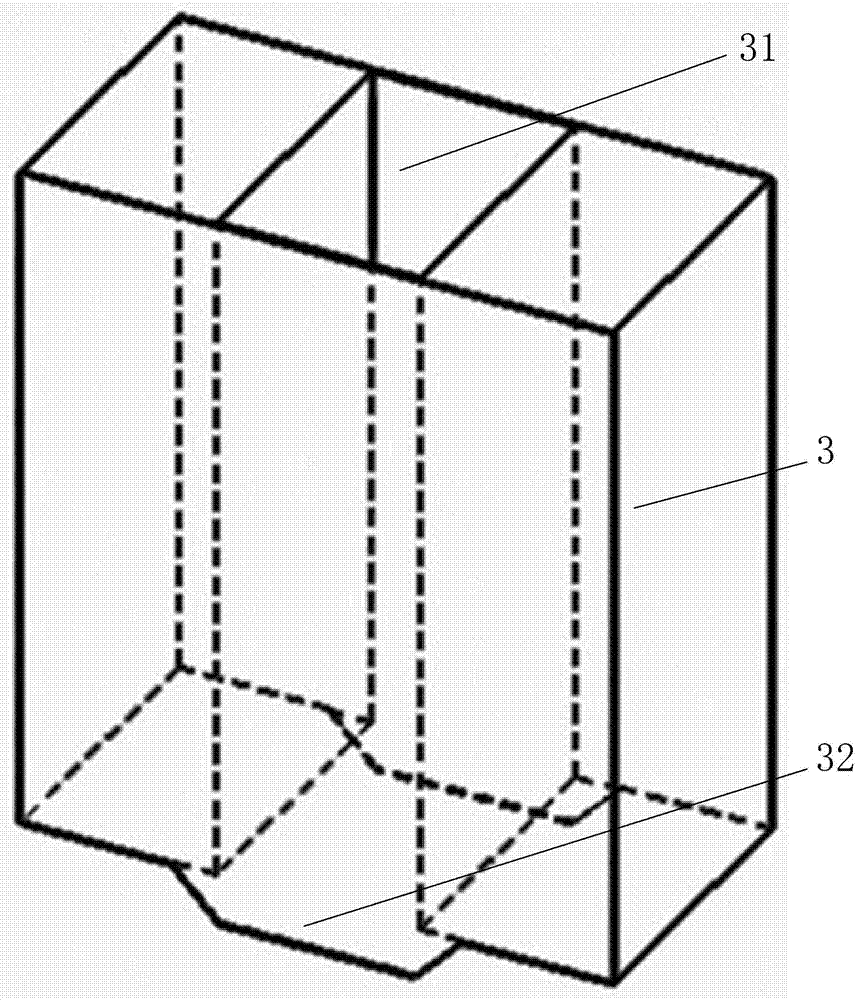

[0023] Such as Figure 1 to Figure 4 As shown, the present invention provides a contact surface large deformation shear seepage test device, which includes a base 1 , a contact panel 2 , a sleeve 3 , a top cap 4 and a sealing film 5 . Among them, the base 1 is used to be fixedly installed on the pressure chamber base 61 of the pressure chamber 6 of the triaxial shearing instrument. The top of the base 1 is provided with a deep groove 11, and the bottom of the deep groove 11 is provided with a direction parallel to the shear plane. The seepage outlet pipeline 12 is also provided inside the base 1 with a seepage outlet pipeline 13 in a direction perpendicular to the shear plane. The contact panel 2 can be installed in the deep groove 11 through the lower part, and the two sides of the middle part of the contact panel 2 are used for close contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com