Ring shear test instrument suitable for vertical shear surface

A shear plane and tester technology, applied in the field of ring shear tester, can solve the problems of limited shear plane thickness, different shear displacements, and uneven shear stress distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

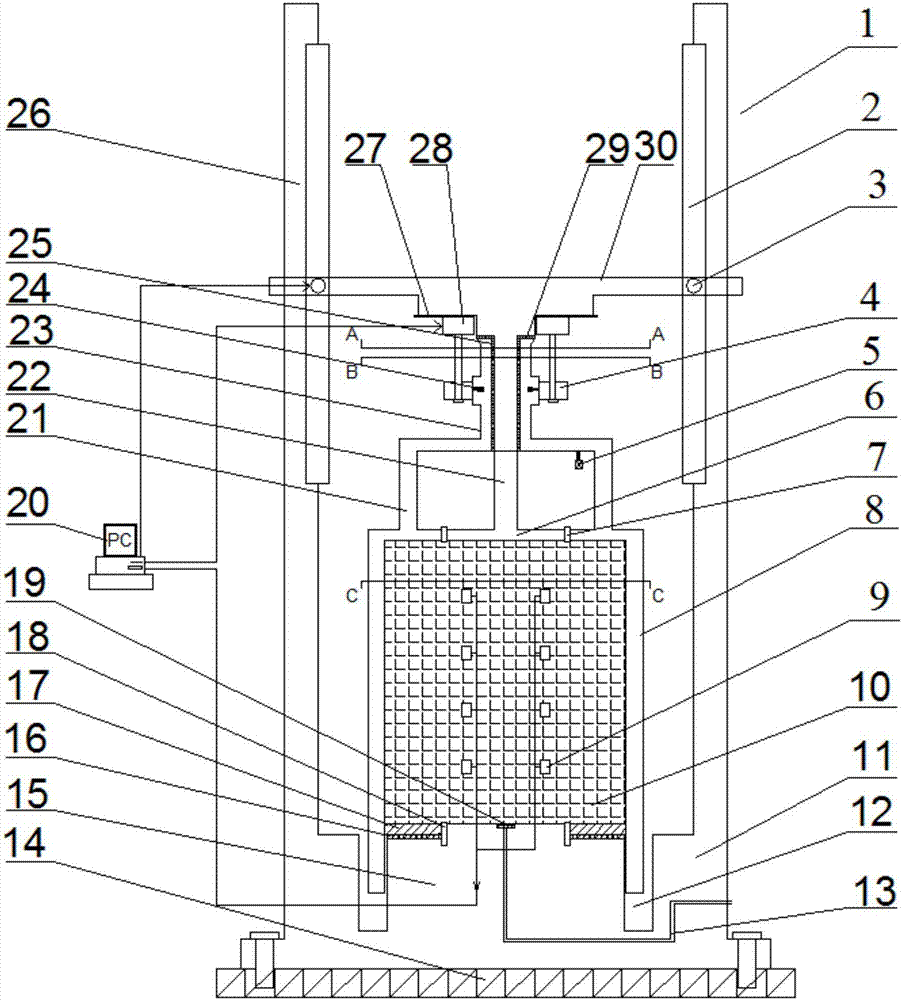

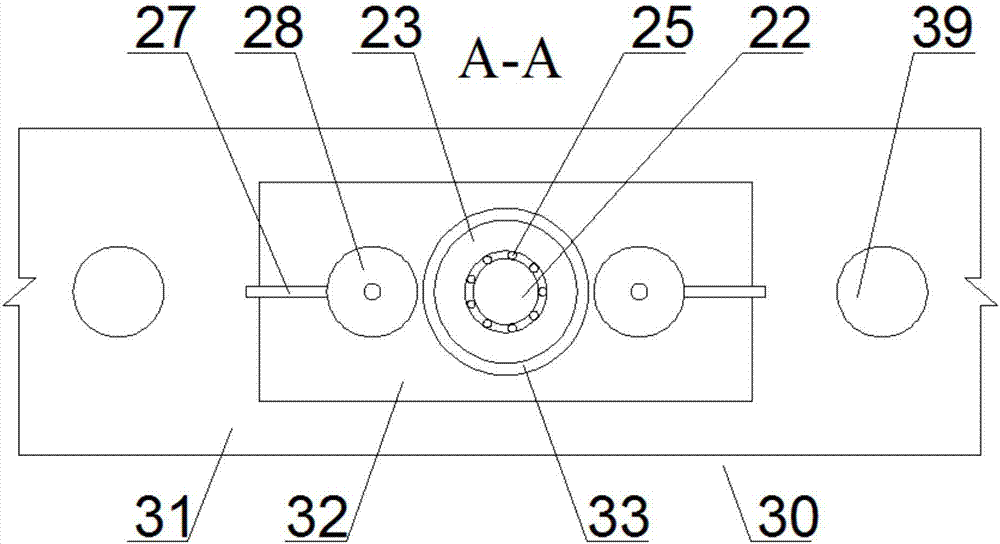

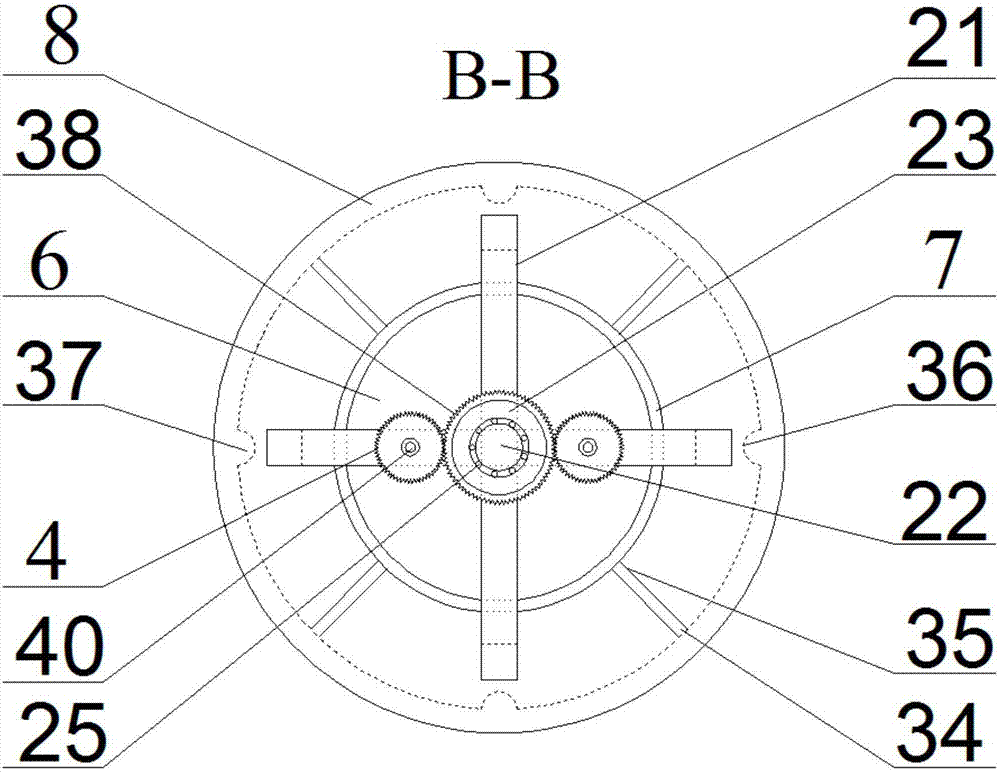

[0037] The ring shear tester suitable for vertical shear plane provided by the present invention has a structure such as figure 1 Shown, including shear box, lifting system, power rotation system, monitoring and control system and frame 1;

[0038] The frame 1 supports the entire test structure, including a base 11 and two uprights 26 fixed on both sides of the base 11. A drainage groove 19 is opened in the middle of the base 11, and the groove surface of the drainage groove 19 is covered with a layer of wool cloth 41. Lay a water filter board, the bottom of the groove is connected with the drain pipe 13 to control the drainage during the test; an annular groove 12 is opened on the edge of the base 11 of the frame 1 for the lower end of the shear box cover 8 to be embedded; large-size bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com