Full-automatic high-pressure die-casting machine for aluminum material forming

A fully automatic, die-casting machine technology, applied in the field of aluminum processing, can solve problems such as inability to replace molds and affect production efficiency, and achieve the effect of improving production efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

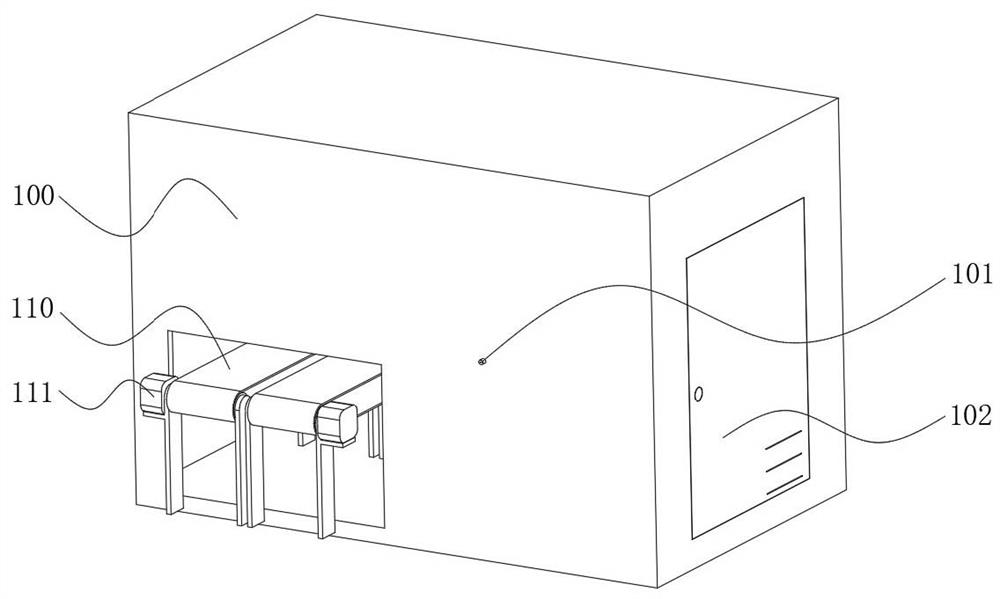

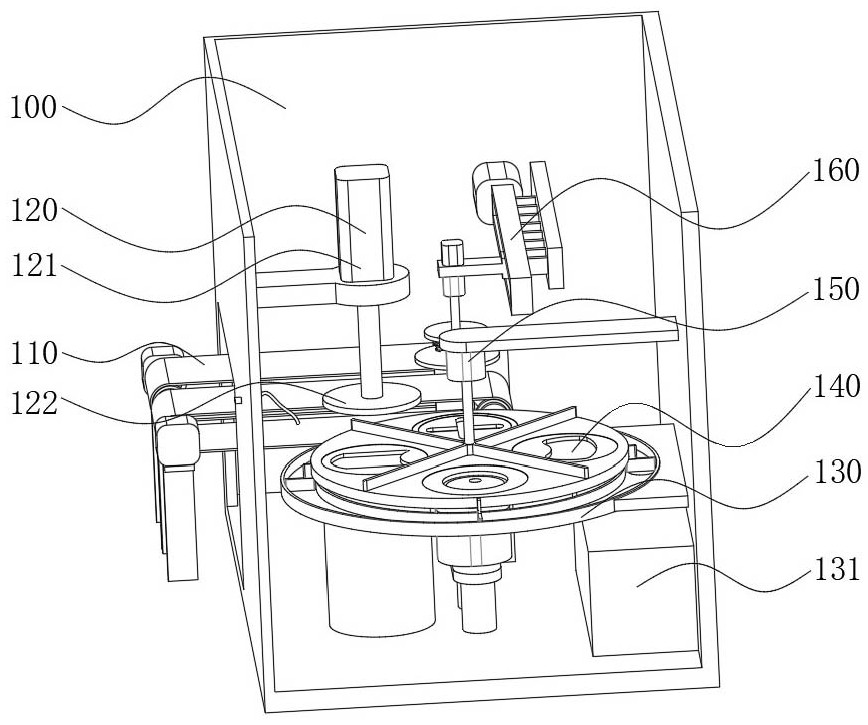

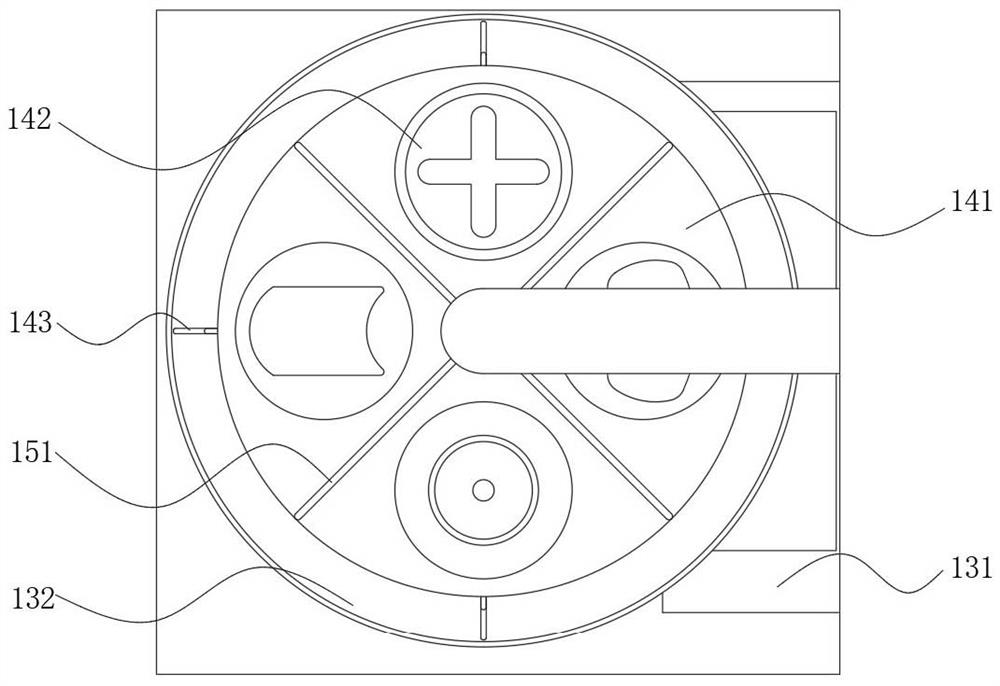

[0036] A fully automatic high-pressure die-casting machine for aluminum forming, such as Figure 1-4 As shown, it includes a device main body 100, a transmission mechanism 110, a hydraulic mechanism 120, a waste collection mechanism 130, a mold mechanism 140, a cleaning mechanism 150 and a handling mechanism 160, and the hydraulic mechanism 120, the waste collection mechanism 130, the cleaning mechanism 150 and the handling mechanism 160 are respectively installed on the three inner walls of the equipment main body 100 through the support frame, and the transmission mechanism 110 and the mold mechanism 140 are respectively fixed on the bottom inner wall of the equipment main body 100 by bolts; The plate 122 is fixed to the output end of the hydraulic press 121 by screws; the mold mechanism 140 includes a mold turntable 141, more than four mold units 142, a push plate 143 and a turntable motor 144; the turntable motor 144 is fixed to the main body of the equipment through a moto...

Embodiment 2

[0048] A fully automatic high-pressure die-casting machine for aluminum molding, in order to reduce the cost of equipment structure, such as Figure 8 As shown, the present embodiment makes the following improvements on the basis of Embodiment 1: the transport mechanism 160 includes a transport motor 161, a suction cup base 162, a first telescopic rod 169, a fixed frame 164, a sliding frame 165, a suction cup 167 and a threaded rod 168, the outer wall on one side of the transport motor 161 is fixed to the inner wall on one side of the equipment main body 100 by screws, the output end of the transport motor 161 is connected to one end of the threaded rod 168 through a synchronous wheel rotation, and the other end of the threaded rod 168 is slidably connected to one end of the fixed frame 164 The side inner wall, the outer wall on one side of the sliding frame 165 is slidably connected to the inner wall of the fixed frame 164, preferably in this embodiment, the sliding frame 165 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com